3.1. True Stress–True Strain Curves

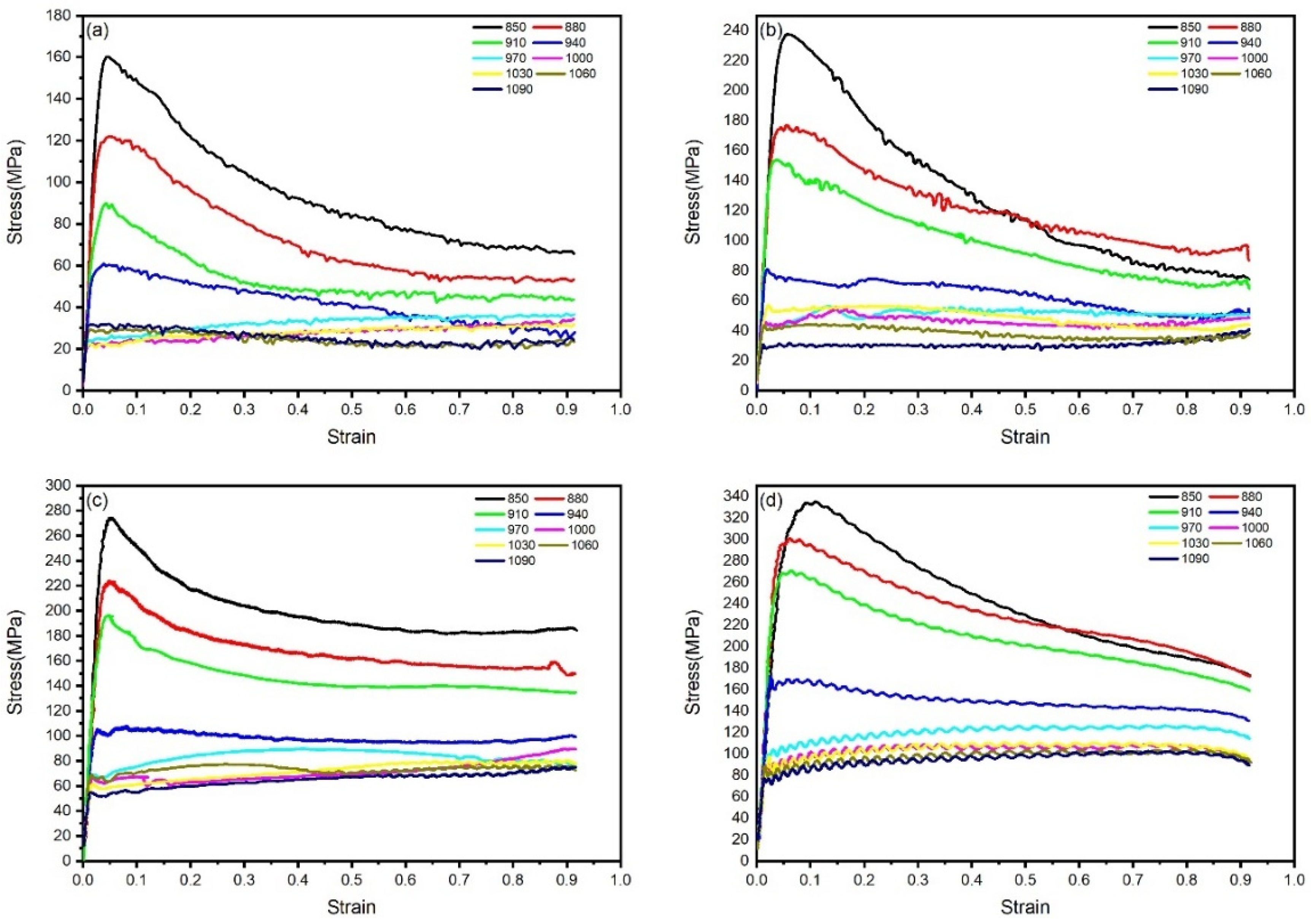

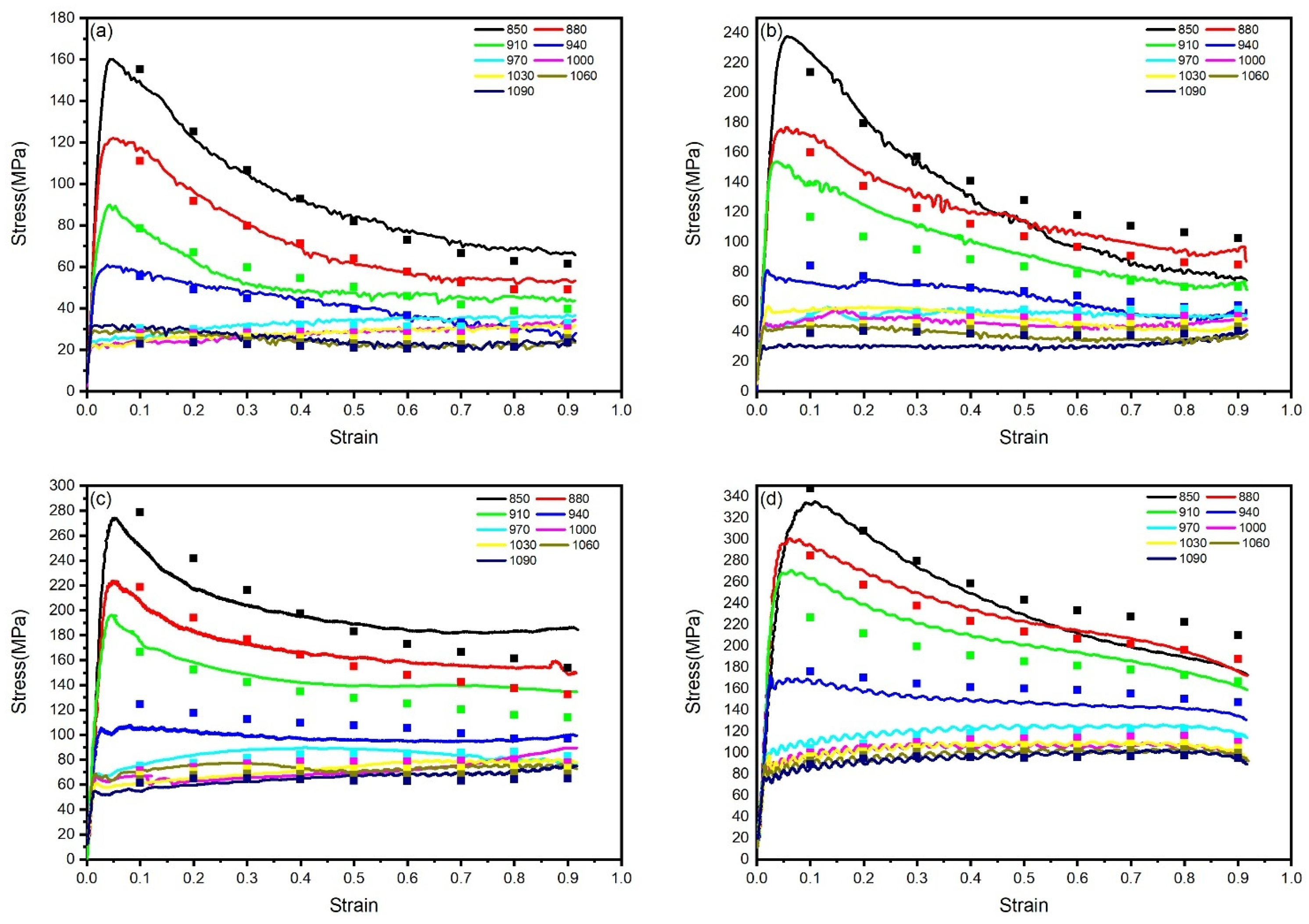

Based on the thermal compression simulation experimental data of TA15N titanium alloy, the true stress–strain curves under different strain rates and deformation temperatures are plotted in

Figure 2. It can be observed that, after the start of compression, the stress of TA15N titanium alloy rapidly reaches a peak with the increase in strain, which is a manifestation of work hardening. As the compression continues, the stress begins to slowly decrease and gradually reaches a stable value at the end. In this stage, flow softening gradually increases and reaches a balance with work hardening.

During hot working, DRV and DRX are two crucial flow-softening mechanisms. The manifestation of DRV on the true stress–strain curve is characterized by a gradual increase in flow stress after deformation initiation, followed by a decelerating rate of increase until reaching a steady state. In contrast, DRX typically presents as flow stress first reaching a peak value and then declining to a stable state after deformation commences [

18]. As shown in the figure, significant dynamic softening is observed in the alloy when deformed within the temperature range of 850–910 °C, where the flow curves exhibit typical DRX-dominated characteristics. With increasing deformation temperature, the DRX features in the true stress–strain curves gradually diminish. During deformation in the 940–1090 °C range, after reaching the peak stress, no pronounced softening occurs. Instead, a balance between work hardening and dynamic softening is maintained throughout the process, transforming the flow curves into DRV-dominated patterns.

Under the deformation conditions of 880 °C and 0.1 s

−1, the true stress–strain curve exhibits periodic serrated fluctuations, manifesting discontinuous yielding behavior [

19]. Currently, there remains controversy regarding the underlying causes of discontinuous yielding in titanium alloys. Possible deformation mechanisms include: dislocation multiplication theory caused by activation of numerous dislocation sources at high temperatures, the pinning mechanism of Cottrell atmospheres, and high-temperature softening theory of metallic materials [

20,

21,

22,

23,

24].

By observing the flow curves of materials under different strain rates, it can be seen that the peak stress and steady-state stress of TA15N titanium alloy during hot deformation become higher with the increase in strain rate. As the strain rate increases, the internal dislocation pile-up of the material accelerates, and the material does not have enough time for DRV and DRX. Work hardening becomes dominant and increases the stress value.

3.2. Constitutive Modeling

Due to the significant difference in the constitutive relationship between the α phase and β phase of titanium alloy, it is necessary to construct constitutive equations in the two-phase region (α + β) and the single-phase region (β) separately. Currently, the widely used model to characterize the relationship between flow stress and thermodynamic parameters is described by the three forms of Arrhenius functions proposed by Zener et al. [

25], which are used to describe the constitutive relationship of alloys. The equations are as follows:

In the formula, represents the strain rate (s−1), σ denotes the peak stress (MPa), T signifies the deformation temperature (K), Q indicates the deformation activation energy (J·mol−1), and R stands for the gas constant (8.314 J·mol−1·K−1). α, A1, A2, A3, n1, n, and β are material constants independent of temperature, where α = β/n1. The constitutive equation presented in this article adopts the form of the hyperbolic sine function.

Taking the logarithm of both sides of the constitutive equation, we obtain:

From the above formula, we can obtain the relevant constants by performing partial differentiation on the stress term:

For a certain strain rate, the deformation activation energy can be expressed as follows:

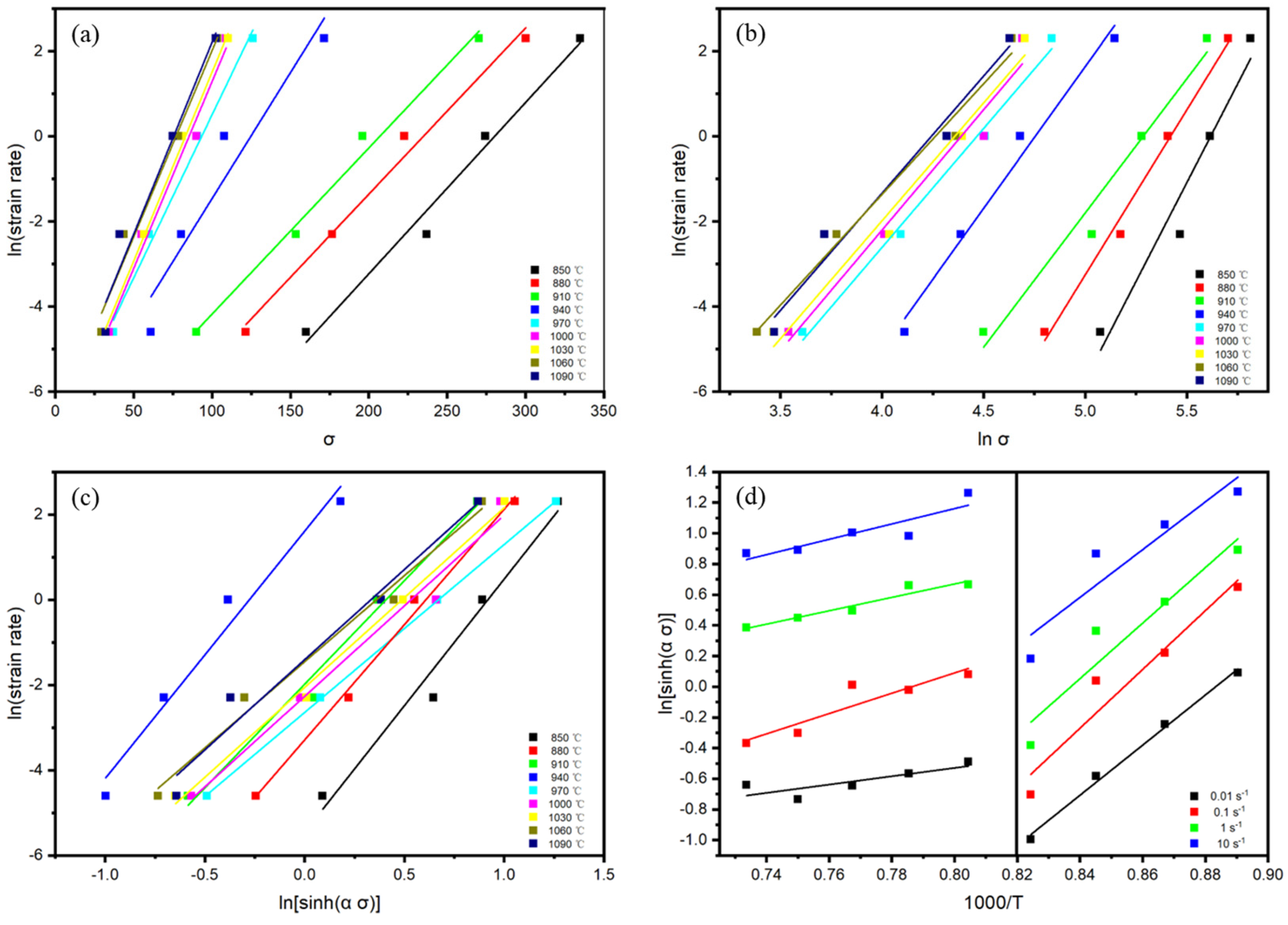

As shown in

Figure 3a,b, linear fitting was performed on

− lnσ and

− σ at different deformation temperatures. The slopes of the straight lines were calculated and averaged, resulting in n

1 = 7.5025625 and β = 0.0443825 in the two-phase region and n

1 = 5.499172 and β = 0.086182 in the single-phase region. From α = β/n

1, α = 0.005915 in the two-phase region and α = 0.015672 in the single-phase region can be obtained.

Substituting the value of α into ln[sinh(ασ)], linear fitting was performed for ln

–ln[sinh(ασ)] under different deformation temperatures, as shown in

Figure 3c. The slopes of the lines were determined and averaged, yielding n = 5.504483 for the two-phase region and n = 4.135173 for the single-phase region. Similarly, linear fitting of ln[sinh(ασ)]–1000/T under different strain rates was conducted, as illustrated in

Figure 3d. By calculating and averaging the slopes of the lines and substituting them into the equation, the deformation activation energy was determined as Q = 791.4046 kJ·mol

−1 for the two-phase region and Q = 160.7561 kJ·mol

−1 for the single-phase region.

The reported deformation activation energy for the TA15 titanium alloy in the two-phase region ranges from 600–700 kJ/mol [

18,

26], reflecting its relatively poor deformability in this phase regime. The deformation activation energy observed in this study slightly exceeds this range, which may be attributed to the addition of Ni element. Research indicates that Ni tends to segregate at grain boundaries and phase interfaces, exerting a pinning effect that influences deformation behavior [

14,

15].

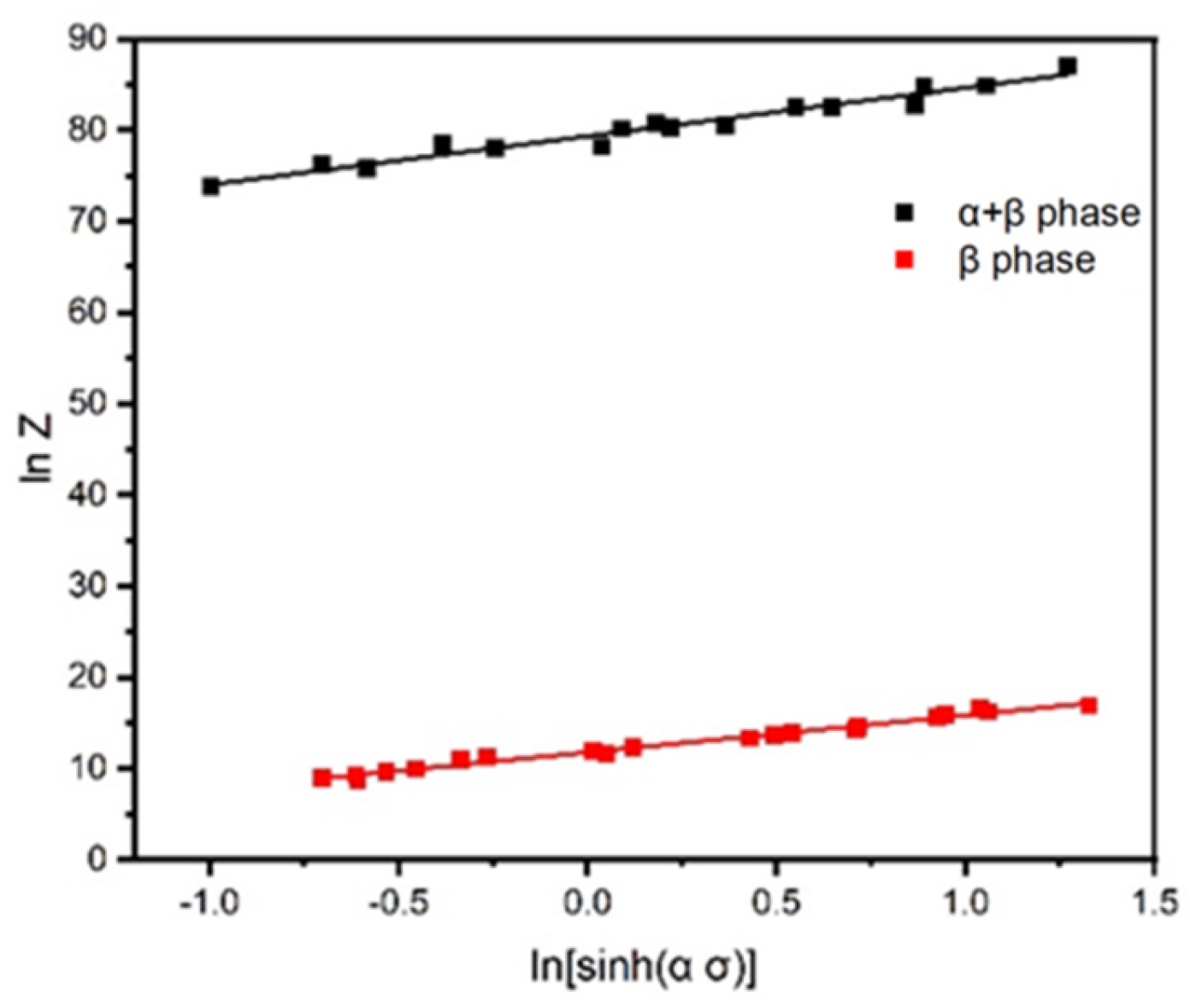

The obtained Q value is substituted into

+ Q/RT, and linear fitting is performed on lnZ − ln[sinh(α σ)] for different phase regions. The intercept of the straight line is lnA, as shown in

Figure 4. In the two-phase region, lnA = 79.31994, and in the single-phase region, lnA = 11.78349.

Thus, all the parameters involved in the constitutive equation of TA15N titanium alloy were obtained. By substituting these parameters into Equation (1), the constitutive equations of TA15N titanium alloy in both the two-phase region and the single-phase region can be obtained:

Only peak stress is involved in the calculation of the constitutive equation. However, the influence of strain on material parameters is significant [

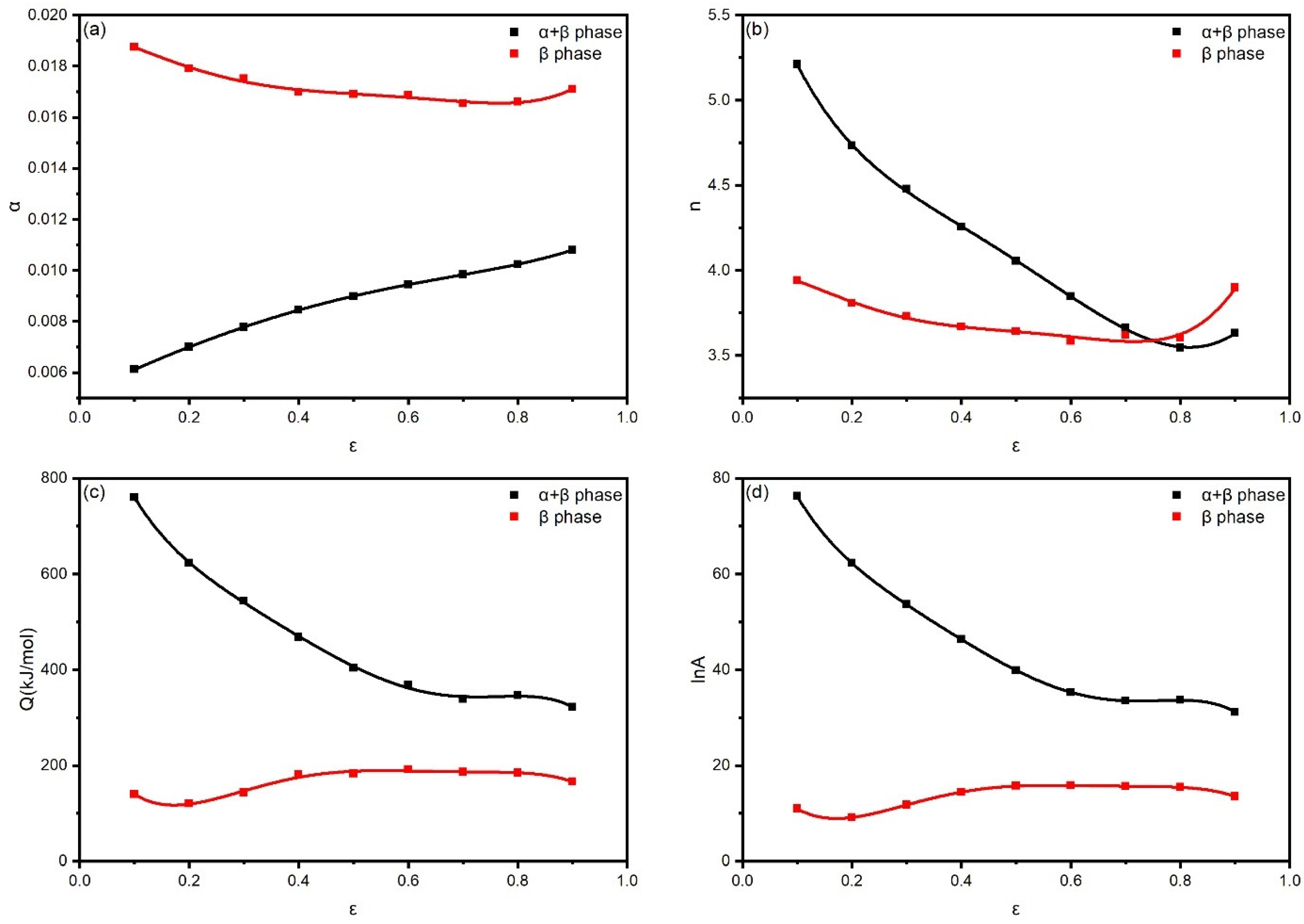

27]. To comprehensively consider the influence of various factors on the flow stress during hot deformation, the impact of the strain needs further discussion. By calculating, material parameter values of TA15N titanium alloy at true strains ranging from 0.1 to 0.9 were obtained, as shown in

Figure 5. It can be seen that the influence of the strain on material parameters cannot be ignored. Research has shown [

28] that polynomial fitting can be used to obtain a function of material and strain. By substituting the fitted values into the following formula, the calculated stress values for various strains can be obtained.

In this article, the material parameters are fitted using a fifth-degree polynomial function, with the following form:

In the formula, P represents the material parameter and k denotes the polynomial coefficient. The polynomial coefficients corresponding to different material parameters are shown in

Table 1 and

Table 2.

Figure 6 shows a good match between calculated stress and experimental stress, indicating that the Arrhenius model effectively describes the stress of the TA15N titanium alloy. To further verify the accuracy of the constitutive equation, the correlation coefficients (R) and the mean absolute errors (Δ) were used to assess the accuracy of the predictions:

where σ

E is the experimental stress; σ

P is the predicted stress;

and

are the average values, and N is the number of data.

As shown in

Figure 7, the calculated stress is in good agreement with the actual stress, and the calculated R = 0.988, Δ = 8.04%, indicating that the constitutive equation established has good calculation accuracy

3.3. Hot Processing Map

The established constitutive equation of TA15N titanium alloy can determine the relationship between true stress and true strain, but it is not intuitive enough for selecting appropriate thermal processing parameters. Therefore, it is necessary to establish a corresponding hot processing map. Hot processing maps are often used to comprehensively evaluate the processing performance of materials and optimize processing parameters. Based on the dynamic material model, the hot processing map is generated by superimposing the power dissipation efficiency map on the plastic flow instability map. According to the laws of thermodynamics, the total input power P of the system during hot compression can be expressed as:

In the formula, σ represents the peak stress (MPa), G represents the power consumption caused by plastic deformation, while J denotes the power consumption resulting from microstructural evolution. The power dissipation efficiency η is calculated using the following formula:

In the formula, m represents the strain rate sensitivity index, which is an important constant for analyzing the deformation behavior and microstructural evolution of titanium alloys. The strain rate sensitivity index m can be calculated using the following formula:

The instability parameter in the instability map is calculated based on different instability criteria. Among them, Prasad [

29] proposed the instability criterion based on the principle of large plastic flow irreversible thermodynamics. The calculation formula is as follows:

In the formula, ξ() represents the instability factor. When the instability factor is less than 0, flow instability will occur in the alloy.

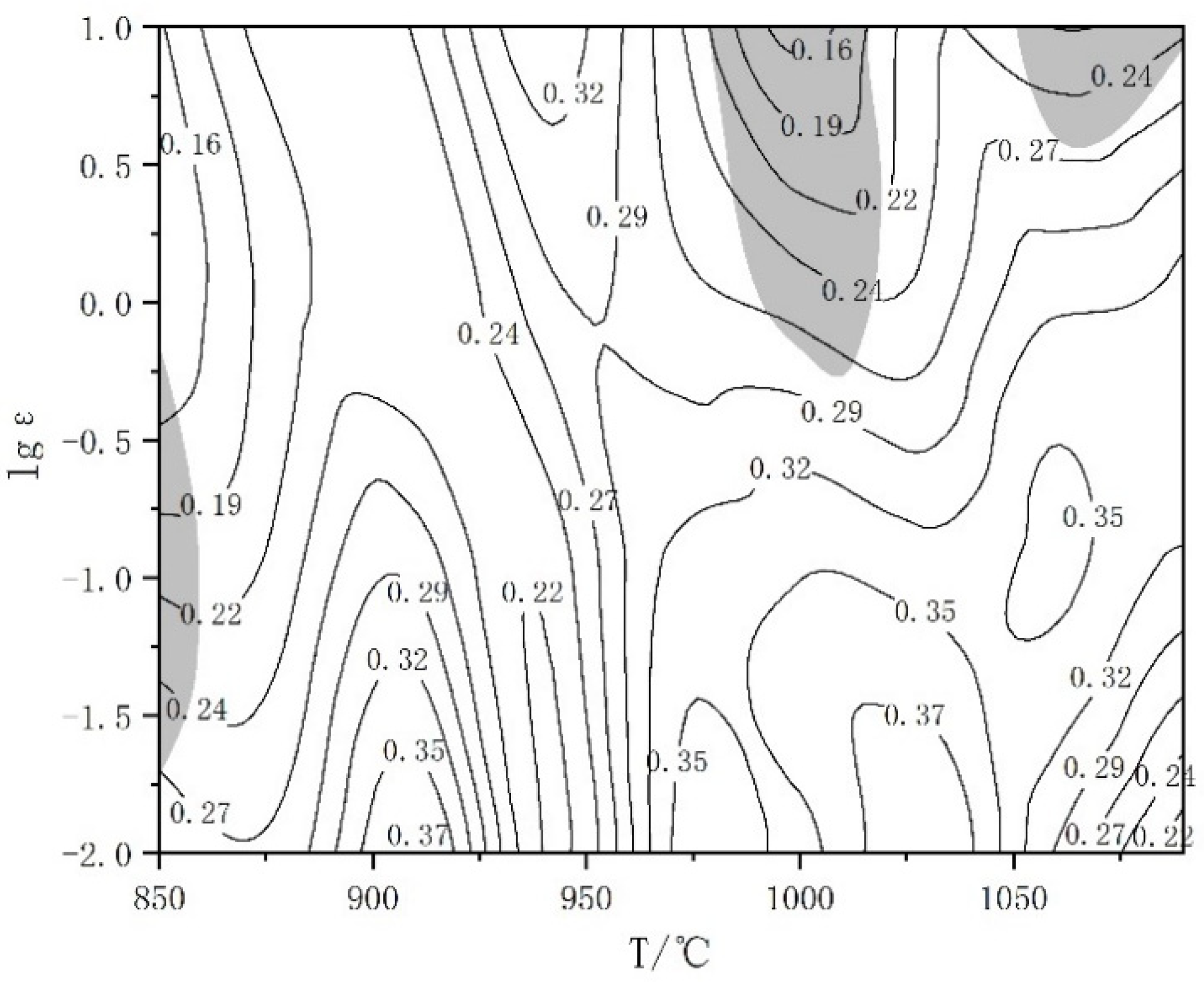

The hot processing map of TA15N titanium alloy is obtained by superimposing the power dissipation efficiency map and plastic flow instability map, as shown in

Figure 8. The contour lines represent the magnitude of the η value, where higher values indicate better hot workability. The material hot processing map is divided into two parts: the instability zone and the safe zone, represented by the gray shaded areas and other areas, respectively. In the instability zone, the energy of material plastic deformation accounts for the majority of the external force input during processing, resulting in low power dissipation efficiency. Therefore, materials in the instability zone are prone to local deformation, forming defects such as adiabatic shear bands and cracks. In the safe zone, the higher the power dissipation efficiency η is, the easier it is for the material to undergo DRX during the hot processing, leading to flow softening and gradually forming stable rheology.

There are three instability zones in

Figure 8, where the temperatures and strain rates are 850–860 °C and 0.02–0.75 s

−1, 980–1020 °C and 0.65–10 s

−1, 1060–1090 °C and 4.35–10 s

−1. In these three zones, hot processing of TA15N titanium alloy is prone to cause material deformation instability. Therefore, hot processing in these zones should be avoided in practical production. Near the deformation temperature range of 880–920 °C and 0.01 s

−1 and 970–1050 °C and 0.01–0.1 s

−1, the η value is relatively high, indicating that TA15N titanium alloy exhibits good hot processing performance under these deformation conditions.

3.3.1. Metallographic Analysis

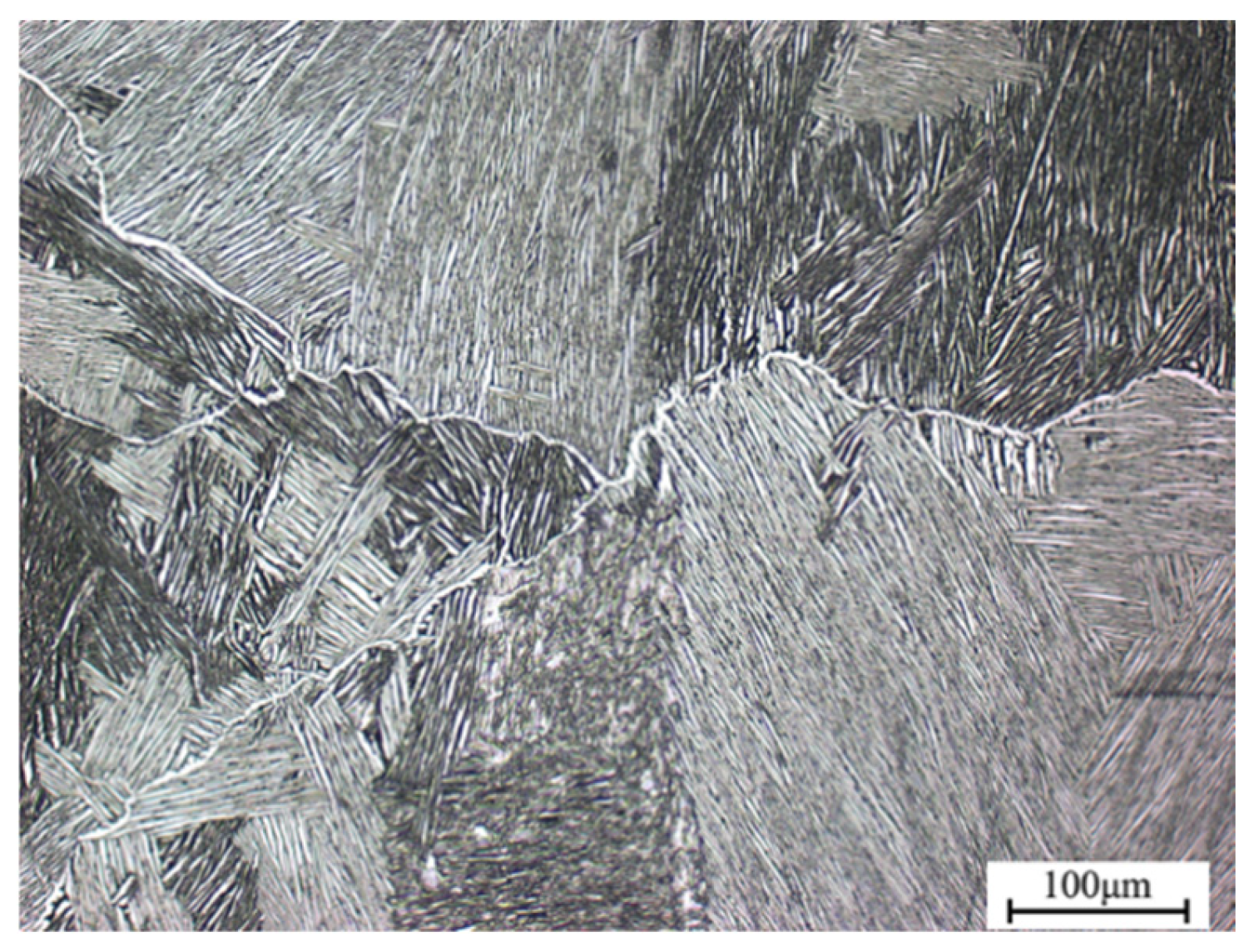

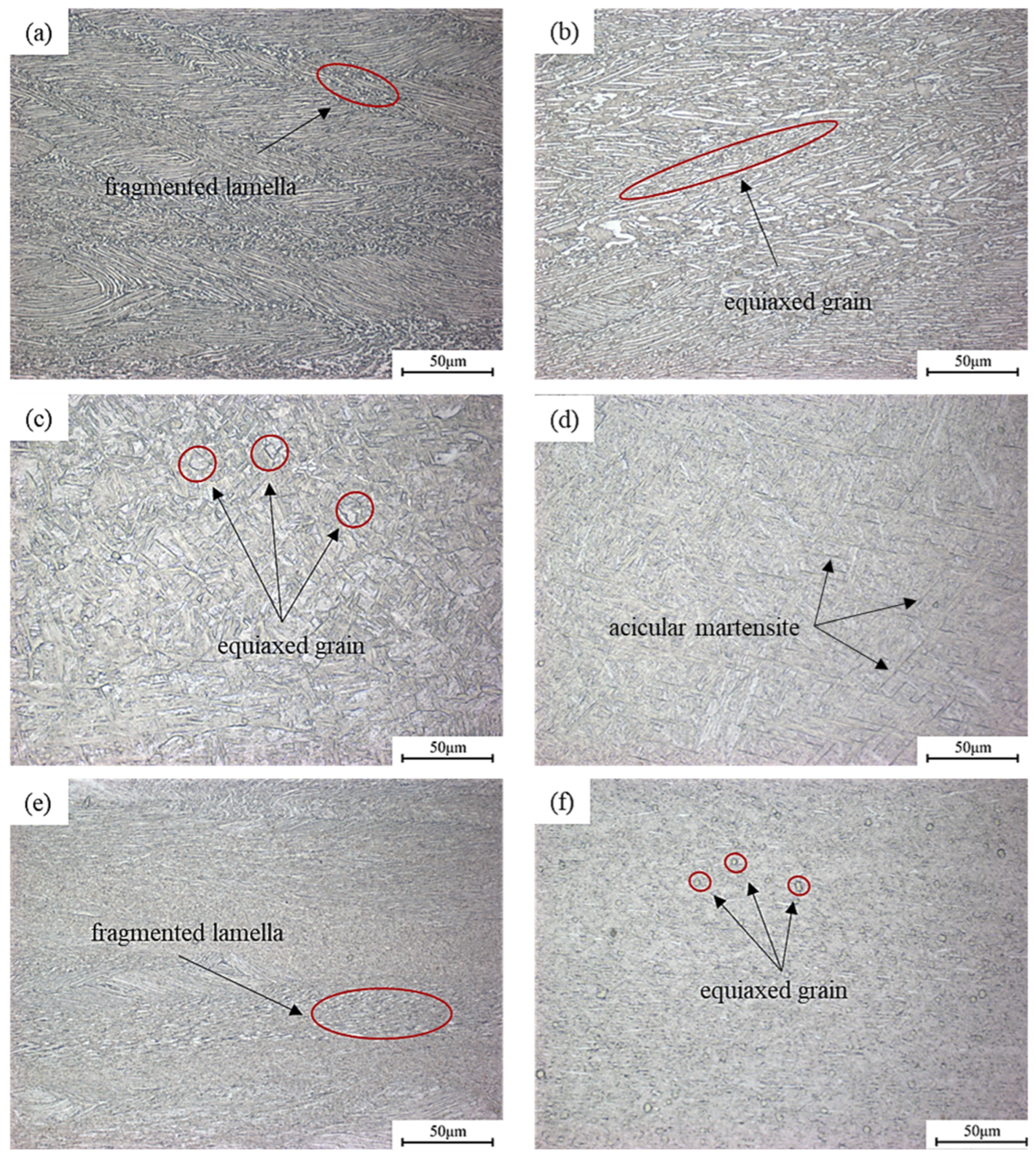

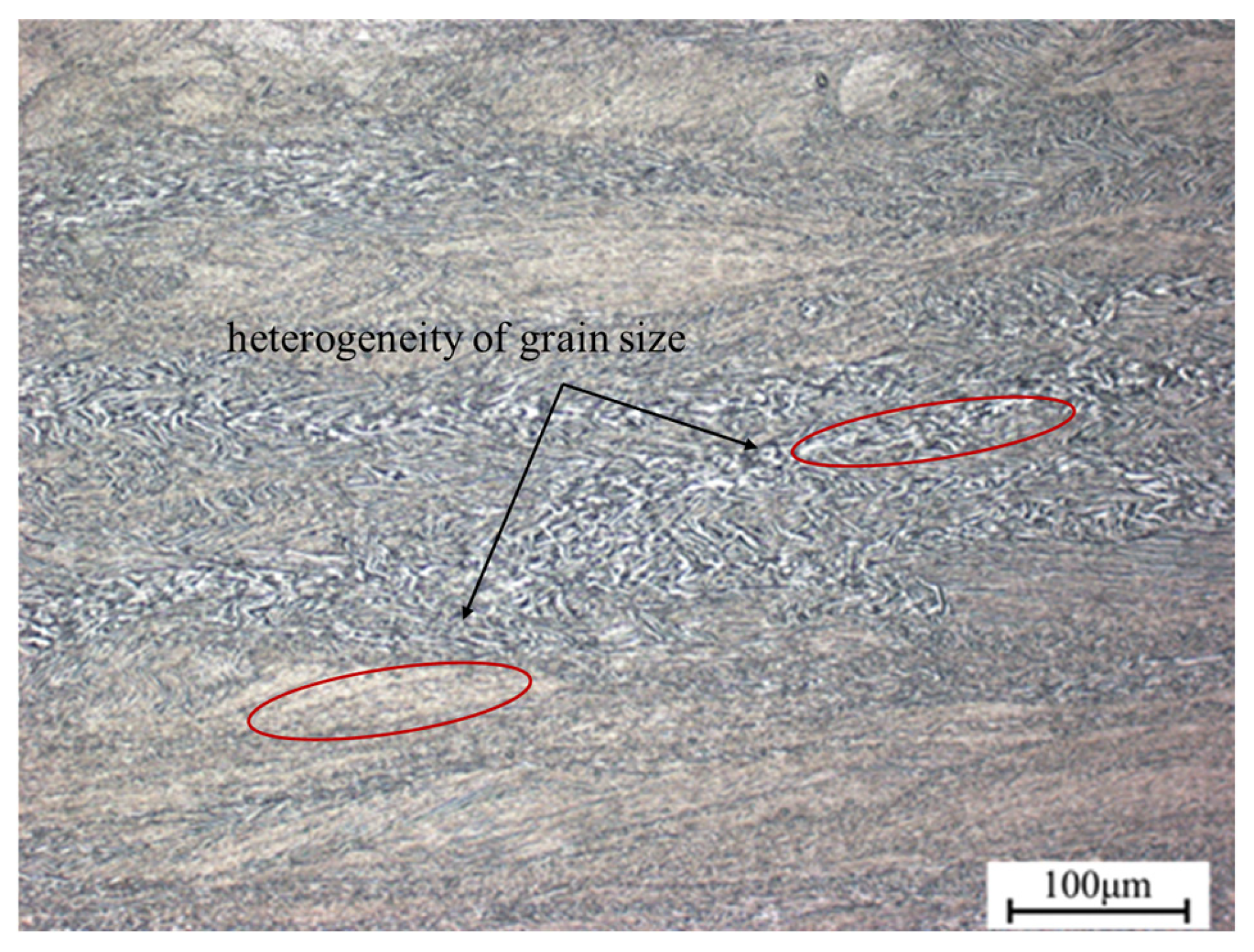

Figure 9 depicts the microstructure of TA15N titanium alloy under different deformation parameters in the steady-state region, with compression direction being vertical. Under the conditions of strain rate of 0.01 s

−1 and a deformation temperature of 850 °C, most α lamellar grains elongate, while a small portion of them fragment into fine grains distributed among the lamellae. Due to the low deformation temperature and high deformation resistance, the α lamellar grains tend to be perpendicular to the compression direction but not unified. When the deformation temperature increases to 910 °C, the deformation resistance decreases. A large number of fine equiaxed α grains can be observed, while some α lamellar grains still exist in shorter lengths compared to the lower temperature. It can be seen that, within the range of 850–910 °C, at the same stain rate, the number of equiaxed grains increases with temperature, which also results in an increase in η.

When the temperature rises to 940 °C, the size of equiaxed α grains increases compared to that at 910 °C, indicating that the equiaxed α phase begins to grow at this point, which has a relatively adverse effect on the deformation performance of the alloy. The η value also begins to decrease around this temperature. When the temperature rises to 970 °C, due to the heat generated during deformation, the highest temperature of the alloy during deformation is about 1030 °C and it can be considered to be deformed in the single-phase region. Therefore, the microstructure after water cooling consists of acicular martensite. Since the titanium slip system of the β phase is more than that of the α phase, the deformation capacity of the alloy increases significantly after entering the single-phase region, which is the reason why the η value increases after the temperature exceeds 970 °C.

Compared to a lower strain rate (0.01 s−1), the α lamellar grains have no time to elongate and twist at higher strain rate (10 s−1), resulting in most of them fragmenting and generating fine grains. The remaining unfragmented α lamellar grains tend towards the vertical compression direction but are not unified. When the deformation temperature was increased to 940 °C, in addition to the fragmented α lamellae, there were also some equiaxed α grains in the microstructure. And at this moment, the value of η is the highest.

Figure 10 depicts the microstructure of TA15N titanium alloy in the instability zone. It is evident that the microstructural changes are uneven. TA15N titanium alloy may exhibit uneven deformation under these conditions. Therefore, processing within the instability zone should be avoided.

3.3.2. EBSD Analysis

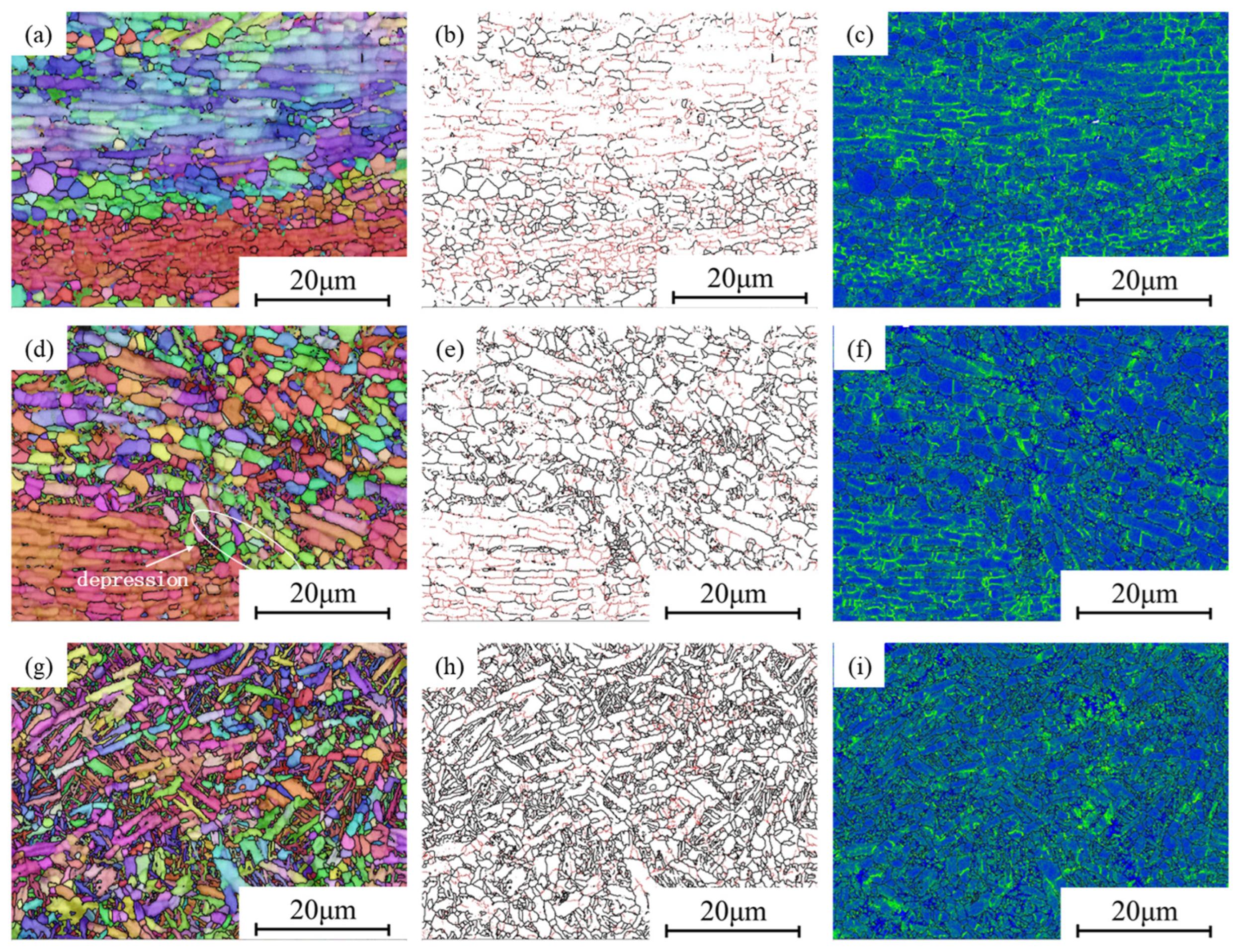

In

Figure 11, EBSD images of stability zones with higher η values (η > 0.25) in the hot processing map, with the compression direction being vertical, are shown. In

Figure 11a, it can be seen that most α lamellar grains form deformation bands perpendicular to the compression direction. At the boundaries of different deformation bands, there are equiaxed grains, some of which are relatively coarse. In

Figure 11b, HAGBs are represented in black and LAGBs are represented in red, with the contents of the two being 44.7% and 55.3%. Research has shown that DRX can transform LAGBs into HAGBs under appropriate conditions. It can be seen that LAGBs are mainly concentrated within the deformation bands, while they rarely appear in the equiaxed grains. In addition, DRX is related to the dislocation density during hot processing. Dislocation density analysis is usually performed using KAM maps, as shown in

Figure 11c. The blue areas have lower KAM values, while the green areas have higher KAM values. It can be seen that the green parts are mainly concentrated near the LAGBs, while the blue parts mainly appear in the DRX grains, and the KAM peak values are lower than those in other areas, indicating that DRX can significantly reduce dislocation density and deformation energy.

As can be seen in

Figure 11d, the raised temperature gradually replaces deformed grains with equiaxed grains, and the boundaries of the deformation bands begin to exhibit depressions. This indicates that the degree of DRX at 910 °C is significantly higher compared to that at 880 °C. In

Figure 11e, the content of HAGBs is as high as 70.3%, indicating that DRX has been relatively sufficient under this condition, which is also consistent with the conclusions of metallographic analysis. In

Figure 11f, not only are there higher KAM values near LAGBs but also higher KAM values near the regions of fine equiaxed grains.

In

Figure 11g, the deformation band is basically replaced by equiaxed grains, with only some shorter lamellar grains remaining. In

Figure 11h, the HAGB content reaches 85%, which is the highest value within the selected experimental range. Compared with the deformation conditions of 910 °C and 0.01 s

−1, increasing the deformation rate to 0.1 s

−1 can provide energy for DRX nucleation, which is beneficial for the refinement of lamellar grains. In

Figure 11i, it can be seen that the overall KAM value is relatively low, with only some high KAM values near some LAGBs, indicating that DRX is basically complete at this time.

Clearly, all regions with high η values exhibit varying degrees of DRX. DRX provides uniform and fine grains by eliminating dislocations, thereby resulting in good processability. The deformation should be controlled cautiously to obtain a high-η region.

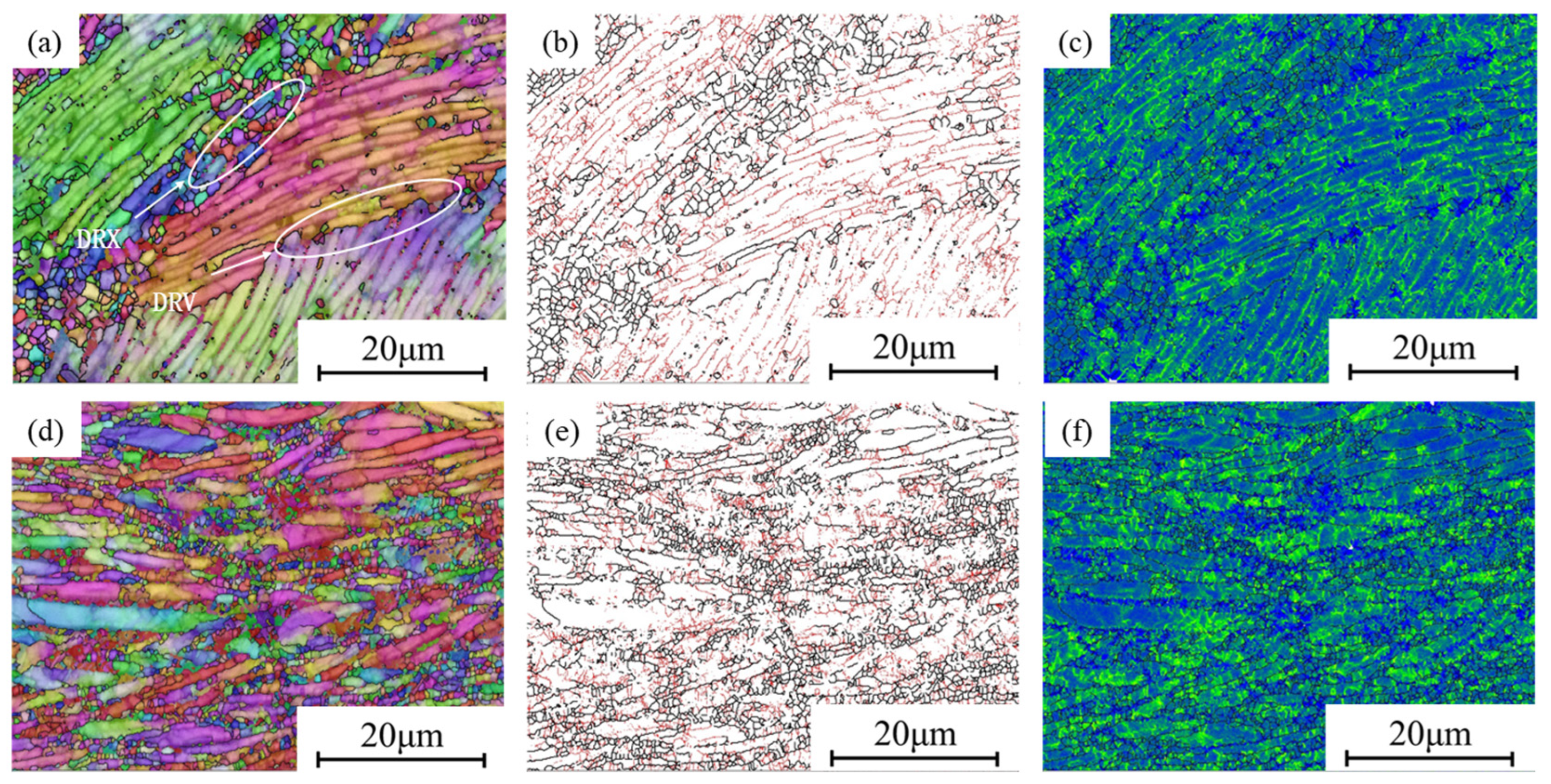

Figure 12 shows the EBSD image of the region with a medium η value (0.2 < η < 0.25). As can be seen in

Figure 12a, α lamellar grains with similar orientations form deformation bands, but these deformation bands are not perpendicular to the compression direction. Some of the deformation bands contain equiaxed grains. On deformation bands without equiaxed grains, their boundaries are straight without depressions. In

Figure 12b, LAGBs dominate in this region. These are all characteristics of DRV. In

Figure 12c, it can be seen that the KAM value in the DRV region is higher than that in the DRX region.

As shown in

Figure 12d, the α lamellar grains are almost entirely perpendicular to the compression direction. However, no deformation bands are formed, and some lamellae are relatively coarse. Distributed among some lamellae unevenly, the α equiaxed grains are relatively fine, indicating that the softening effect of DRX is suppressed. Meanwhile, a higher strain rate also promotes the diffusion of dislocations, resulting in a higher KAM, as shown in

Figure 12f.

It can be observed that the softening mechanism of DRX still plays a role in the medium η value region, but DRV gradually replaces DRX as the dominant softening mechanism, resulting in smaller and fewer DRX grains. Compared to the high η value region, the decrease in η value leads to the generation of more dislocations within the material. Furthermore, the microstructure in this region is uneven, which is not conducive to engineering applications.

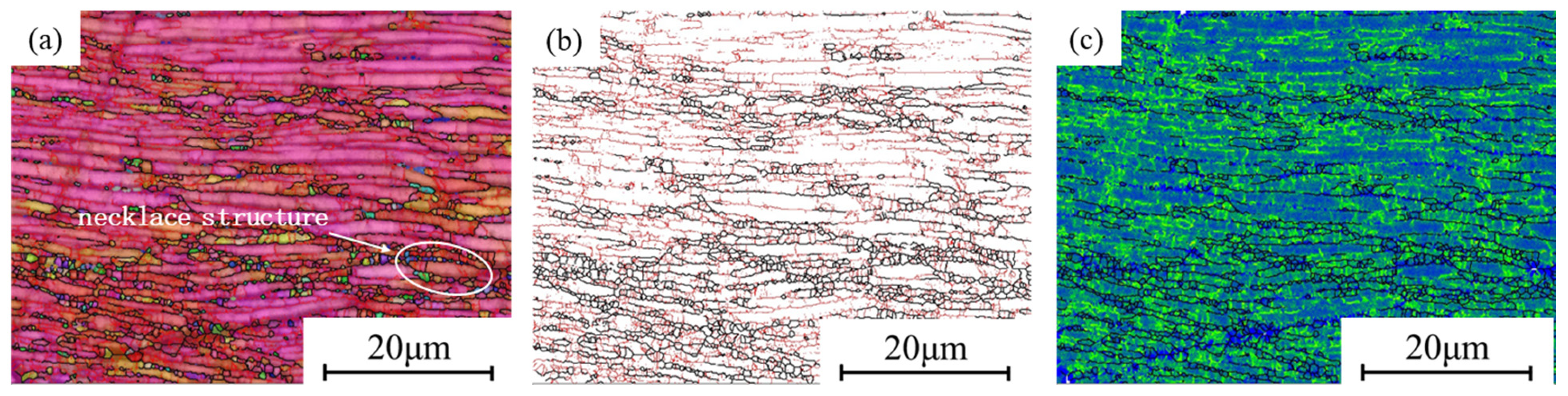

Figure 13 shows the EBSD image of the low η value region (η < 0.2). It can be observed that most α lamellae are perpendicular to the compression direction and have nearly consistent orientation. Some α lamellae are surrounded by fine equiaxed α grains, forming a necklace structure. This structure is caused by uneven DRX and has adverse effects on the deformation properties. In

Figure 13b, it can be seen that there is a high content of LAGBs, accounting for 54.1%. At the same time, due to the high deformation rate, the KAM value in this region is relatively high, as shown in

Figure 13c. As the region with the lowest stability in the hot processing map, low η values can lead to unstable plastic flow, resulting in fewer DRX grains and uneven microstructure. Therefore, this region should be avoided during hot processing.

In summary, the deformation mechanism is influenced by the deformation conditions. Within a certain range, increasing temperature is conducive to promoting the occurrence of DRX in TA15N titanium alloy, while increasing the deformation rate will inhibit the occurrence of DRV. Uniform DRX can enable TA15N titanium alloy to achieve a higher power dissipation efficiency η value, which is beneficial to improving processing performance.