A Comprehensive Study on the Physicochemical Characterisation of Plant-Based By-Products

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Chemicals

2.2. Pre-Treatment and Storage of Residues

2.3. Physicochemical and Morphological Characterisation

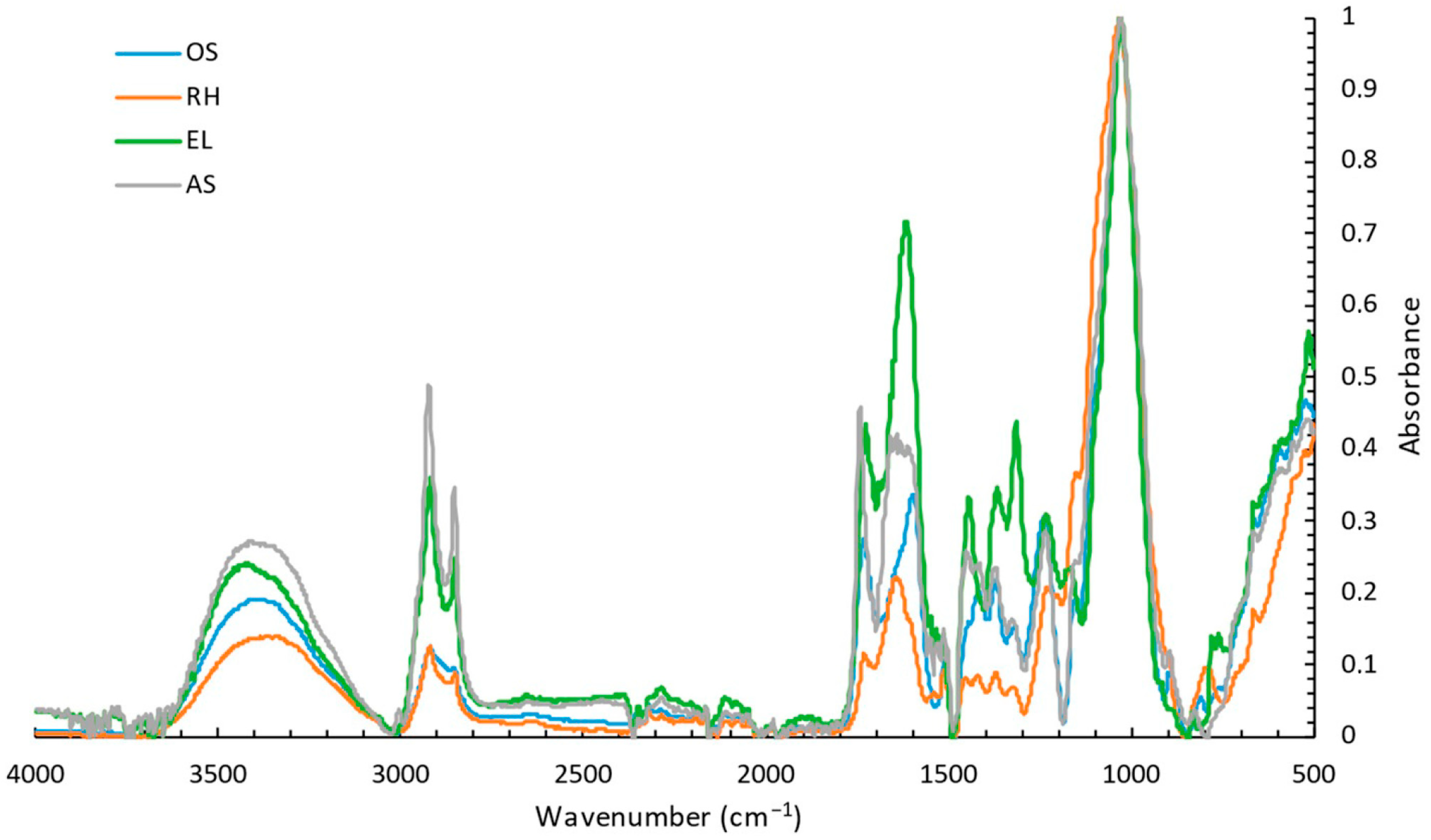

2.3.1. Fourier Transform Infrared Spectroscopy (FTIR)

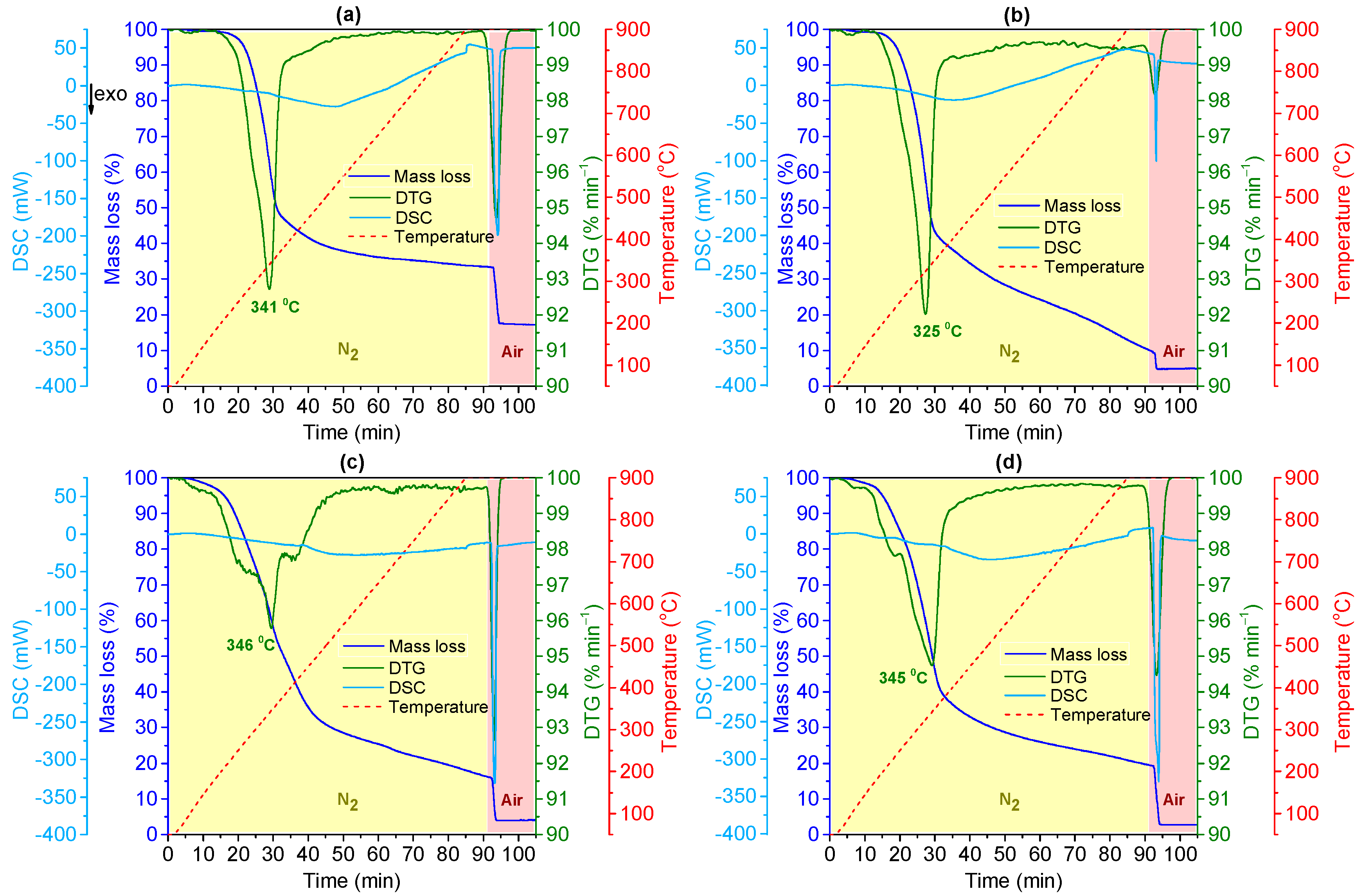

2.3.2. Thermogravimetric and Differential Scanning Calorimetry Analysis (TGA-DSC)

2.3.3. Elemental Analysis (EA)

2.3.4. Chlorine Content Determination by Ionic Chromatography (IC)

2.3.5. Inductively Coupled Plasma-Optical Emission Spectroscopy (ICP-OES)

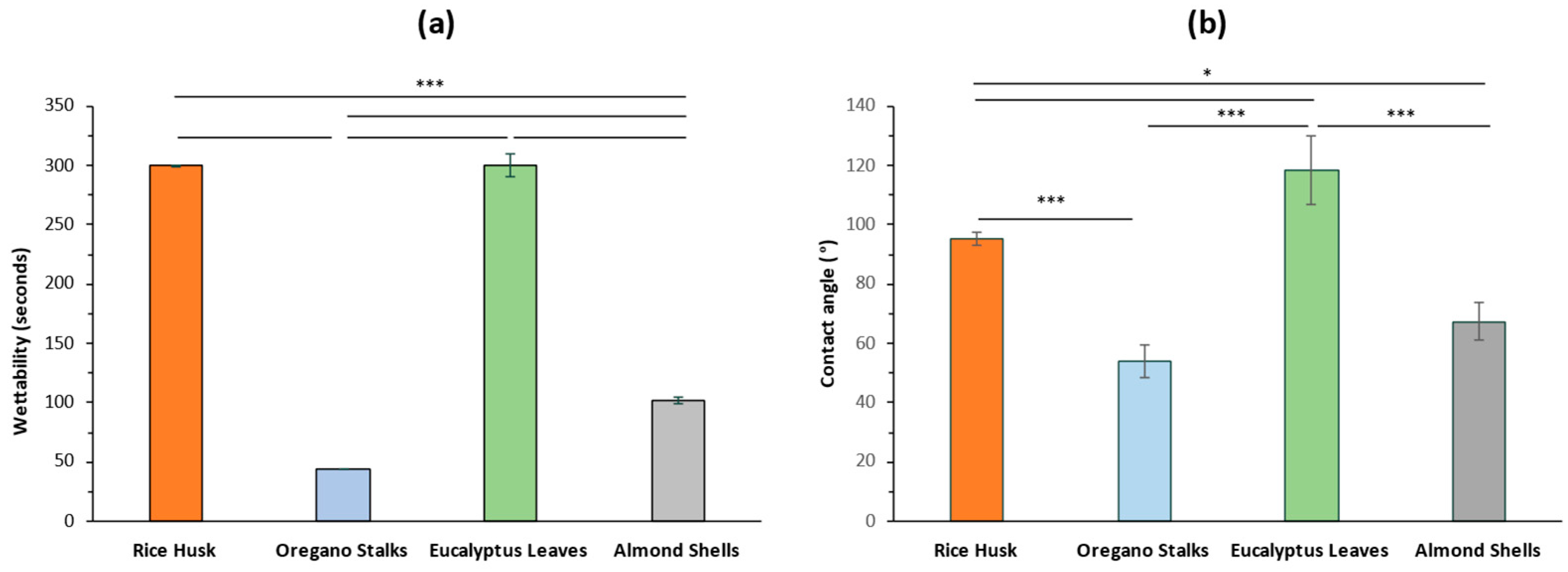

2.3.6. Wettability

2.3.7. Contact Angle

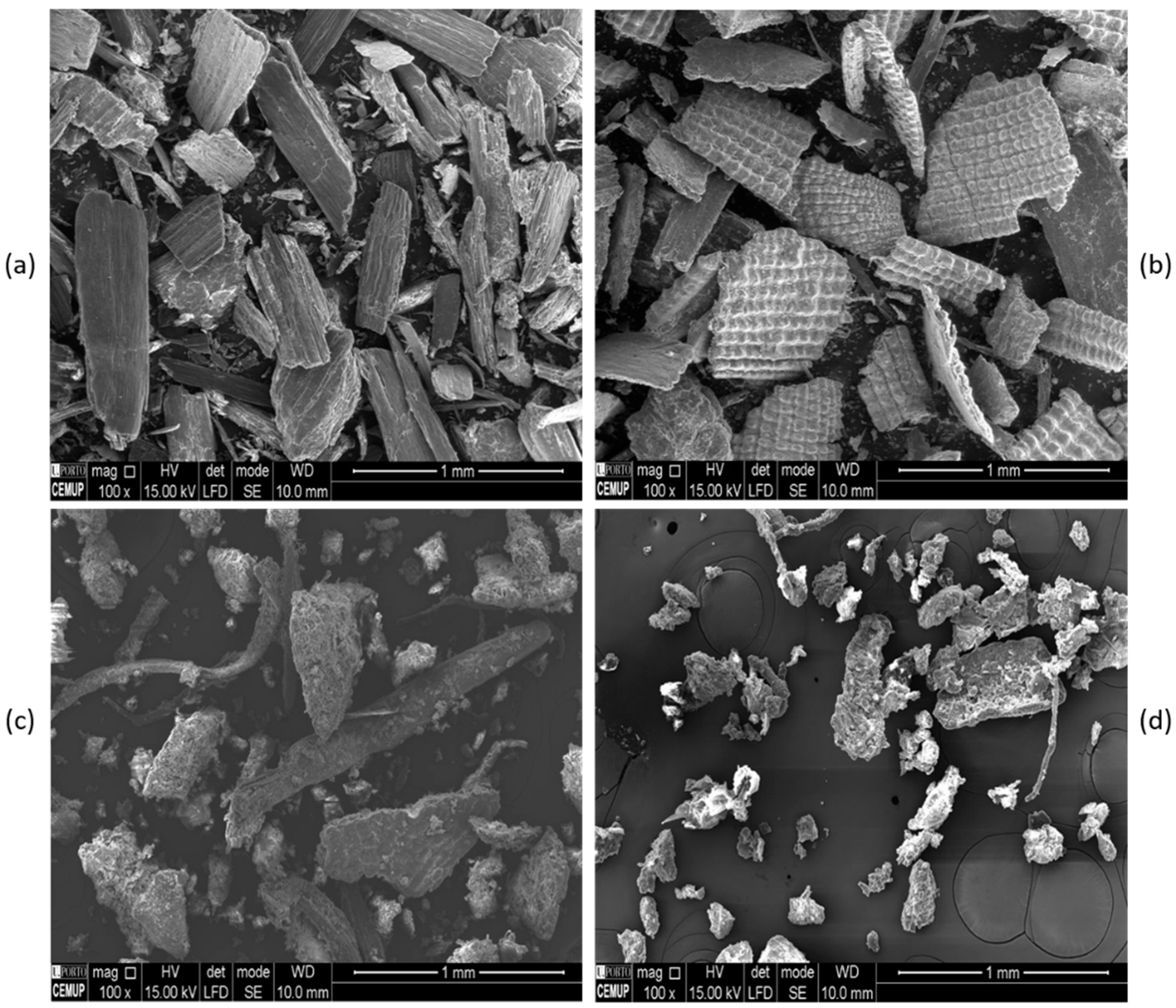

2.3.8. Scanning Electron Microscopy (SEM)

2.4. Antioxidant Activity

2.5. Statistical Analyses

3. Results and Discussion

3.1. Physicochemical Characterisation of the Plant-Based By-Products

3.1.1. Chemical Composition and Thermal Stability of the Materials

3.1.2. Chlorine Content

3.1.3. Metals Assessment

3.1.4. Wetting Behaviour and Hydrophobicity

3.1.5. Morphological Analysis of the Plant-Based By-Products

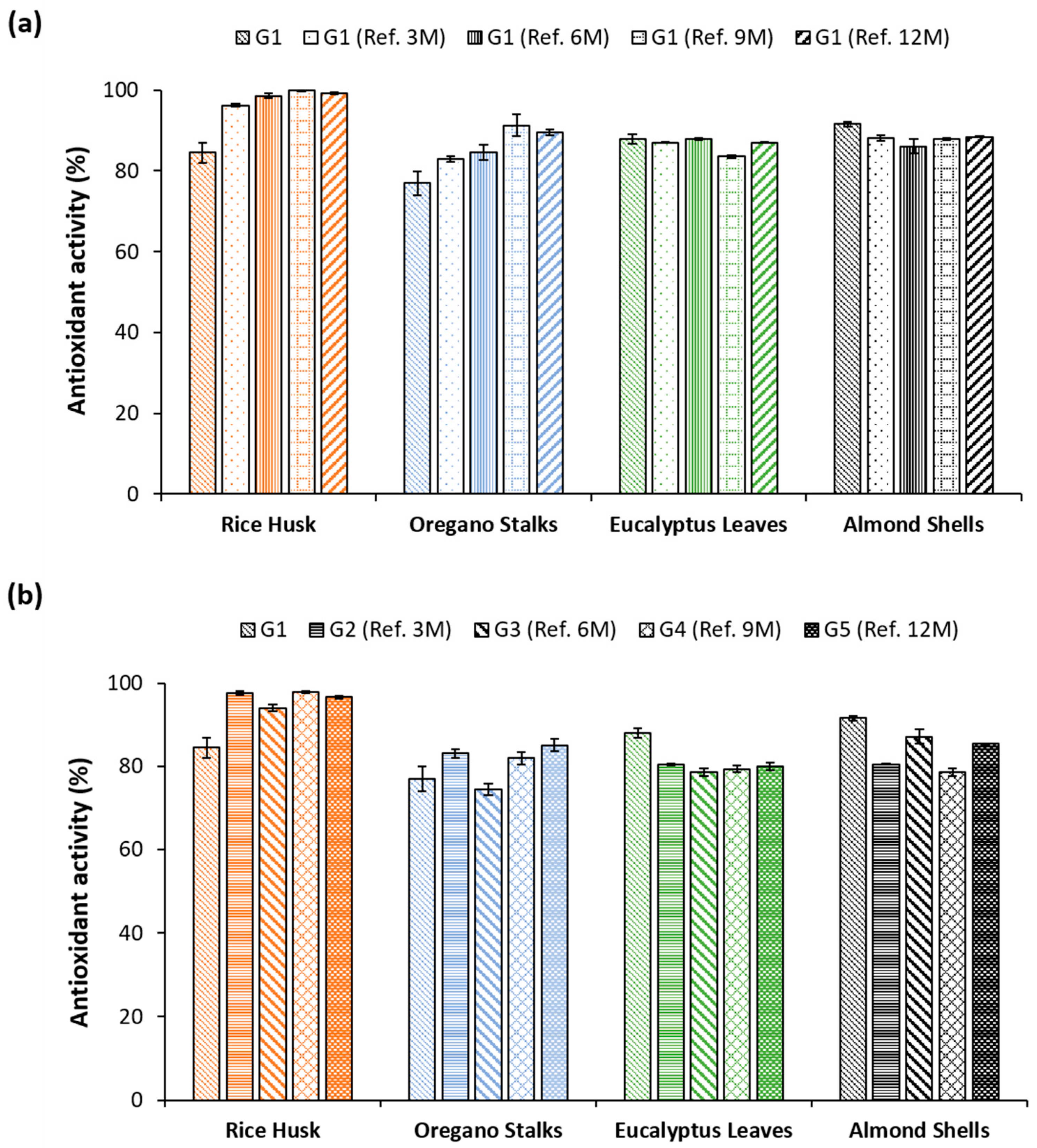

3.2. Antioxidant Activity and Assessment of Stability over Time

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Velenturf, A.P.M.; Purnell, P. Principles for a Sustainable Circular Economy. Sustain. Prod Consum. 2021, 27, 1437–1457. [Google Scholar] [CrossRef]

- Salvia, G.; Zimmermann, N.; Willan, C.; Hale, J.; Gitau, H.; Muindi, K.; Gichana, E.; Davies, M. The Wicked Problem of Waste Management: An Attention-Based Analysis of Stakeholder Behaviours. J. Clean. Prod. 2021, 326, 129200. [Google Scholar] [CrossRef] [PubMed]

- Arruda, E.H.; Melatto, R.A.P.B.; Levy, W.; de Melo Conti, D. Circular Economy: A Brief Literature Review (2015–2020). Sustain. Oper. Comput. 2021, 2, 79–86. [Google Scholar] [CrossRef]

- Macarthur, E. The Nature Imperative: How the Circular Economy Tackles Biodiversity Loss; Ellen Macarthur Foundation: Cowes, UK, 2021. [Google Scholar]

- Arranz, J.I.; Sepúlveda, F.J.; Montero, I.; Romero, P.; Miranda, M.T. Feasibility Analysis of Brewers’ Spent Grain for Energy Use: Waste and Experimental Pellets. Appl. Sci. 2021, 11, 2740. [Google Scholar] [CrossRef]

- Stefanidou, M.; Kamperidou, V.; Kouroutzidou, C.; Kampragkou, P. Utilization of Lavender Waste in Traditional Mortars. In Proceedings of the Conservation and Restoration of Historic Mortars and Masonry Structures, Ljubljana, Slovenia, 21–23 September 2022; Bokan Bosiljkov, V., Padovnik, A., Turk, T., Eds.; Springer Nature: Cham, Switzerland, 2023; pp. 351–358. [Google Scholar]

- Yu, S.; Zhang, W.; Dong, X.; Wang, F.; Yang, W.; Liu, C.; Chen, D. A Review on Recent Advances of Biochar from Agricultural and Forestry Wastes: Preparation, Modification and Applications in Wastewater Treatment. J. Environ. Chem. Eng. 2023, 12, 111638. [Google Scholar] [CrossRef]

- Gupta, J.; Kumari, M.; Mishra, A.; Akram, M.; Thakur, I.S. Agro-Forestry Waste Management-A Review. Chemosphere 2022, 287, 132321. [Google Scholar] [CrossRef]

- Gregg, J.S.; Jürgens, J.; Happel, M.K.; Strøm-Andersen, N.; Tanner, A.N.; Bolwig, S.; Klitkou, A. Valorization of Bio-Residuals in the Food and Forestry Sectors in Support of a Circular Bioeconomy: A Review. J. Clean. Prod. 2020, 267, 122093. [Google Scholar] [CrossRef]

- Aït-Kaddour, A.; Hassoun, A.; Tarchi, I.; Loudiyi, M.; Boukria, O.; Cahyana, Y.; Ozogul, F.; Khwaldia, K. Transforming Plant-Based Waste and by-Products into Valuable Products Using Various “Food Industry 4.0” Enabling Technologies: A Literature Review. Sci. Total Environ. 2024, 955, 176872. [Google Scholar] [CrossRef] [PubMed]

- Sembiring, N.; Napitupulu, H.L.; Sembiring, M.T.; Ishak, A.; Gunawan, H.A. Fulfilling Eucalyptus Raw Materials for Pulp and Paper Production Plants. In Proceedings of the IOP Conference Series: Earth and Environmental Science; IOP Publishing: Bristol, UK, 2021; Volume 912, p. 012008. [Google Scholar]

- Surbhi; Kumar, A.; Singh, S.; Kumari, P.; Rasane, P. Eucalyptus: Phytochemical Composition, Extraction Methods and Food and Medicinal Applications. Adv. Tradit. Med. 2023, 23, 369–380. [Google Scholar] [CrossRef]

- Kordi, M.; Farrokhi, N.; Pech-Canul, M.I.; Ahmadikhah, A. Rice Husk at a Glance: From Agro-Industrial to Modern Applications. Rice Sci. 2024, 31, 14–32. [Google Scholar] [CrossRef]

- Nzereogu, P.U.; Omah, A.D.; Ezema, F.I.; Iwuoha, E.I.; Nwanya, A.C. Silica Extraction from Rice Husk: Comprehensive Review and Applications. Hybrid Adv. 2023, 4, 100111. [Google Scholar] [CrossRef]

- Li, X.; Liu, Y.; Hao, J.; Wang, W. Study of Almond Shell Characteristics. Materials 2018, 11, 1782. [Google Scholar] [CrossRef]

- Ibáñez García, A.; Martínez García, A.; Ferrándiz Bou, S. Study of the Influence of the Almond Shell Variety on the Mechanical Properties of Starch-Based Polymer Biocomposites. Polymers 2020, 12, 2049. [Google Scholar] [CrossRef]

- Ollani, S.; Peano, C.; Sottile, F. Recent Innovations on the Reuse of Almond and Hazelnut By-Products: A Review. Sustainability 2024, 16, 2577. [Google Scholar] [CrossRef]

- Saha, A.; Basak, B.B. Scope of Value Addition and Utilization of Residual Biomass from Medicinal and Aromatic Plants. Ind. Crops Prod. 2020, 145, 111979. [Google Scholar] [CrossRef]

- Dina, E.; Vontzalidou, A.; Cheilari, A.; Bagatzounis, P.; Agapidou, E.; Giannenas, I.; Grigoriadou, K.; Aligiannis, N. Sustainable Use of Greek Herbs By-Products, as an Alternative Source of Biologically Active Ingredients for Innovative Products. Front. Nutr. 2022, 9, 867666. [Google Scholar] [CrossRef]

- ISO 16948:2015; UNE-EN ISO 16948 Solid Biofuels—Determination of Total Content of Carbon, Hydrogen and Nitrogen (ISO 16948:2015). AENOR: Madrid, Spain, 2015.

- Bajcar, M.; Zardzewiały, M.; Saletnik, B.; Zaguła, G.; Puchalski, C.; Gorzelany, J. Torrefaction as a Way to Remove Chlorine and Improve the Energy Properties of Plant Biomass. Energies 2023, 16, 7365. [Google Scholar] [CrossRef]

- Nielsen, H.P.; Frandsen, F.J.; Dam-Johansen, K.; Baxter, L.L. The Implications of Chlorine-Associated Corrosion on the Operation of Biomass-Fired Boilers. Prog. Energy Combust. Sci. 2000, 26, 283–298. [Google Scholar] [CrossRef]

- Piva, D.H.; Barbosa, J.R.M.; Oliveira, I.; Sousa, J.; Restivo, J.; Orge, C.A.; Pereira, M.F.R.; Soares, O.S.G.P. Catalytic Performance of PdCu Supported on Mesoporous MCM− 41 with Different Morphologies for Reduction of Aqueous Oxyanion Pollutants. J. Environ. Chem. Eng. 2024, 12, 114816. [Google Scholar] [CrossRef]

- Zemljič, L.F.; Volmajer, J.; Ristić, T.; Bracic, M.; Sauperl, O.; Kreže, T. Antimicrobial and Antioxidant Functionalization of Viscose Fabric Using Chitosan–Curcumin Formulations. Text. Res. J. 2014, 84, 819–830. [Google Scholar] [CrossRef]

- Feriancová, A.; Pajtášová, M.; Moricová, K.; Pecušová, B. Using of Wood Ash as the Alternative Filler for Preparation of Rubber Mixtures. In Proceedings of the IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2020; Volume 776, p. 012087. [Google Scholar]

- Santos, J.; Escobar-Avello, D.; Magalhães, P.; Magalhães, F.D.; Martins, J.M.; González-Álvarez, J.; de Carvalho, L.H. High-Value Compounds Obtained from Grape Canes (Vitis vinifera L.) by Steam Pressure Alkali Extraction. Food Bioprod. Process. 2022, 133, 153–167. [Google Scholar] [CrossRef]

- Babu, R.; Jackowski, M.; Capannelli, G.; Comite, A.; Trusek, A. Acid and Alkali Pre-Treatment Studies on Brewer’s Spent Grains (Bsg). Chem. Eng. Trans. 2022, 92, 451–456. [Google Scholar]

- Chen, H.; Rubenthaler, G.L.; Schanus, E.G. Effect of Apple Fiber and Cellulose on the Physical Properties of Wheat Flour. J. Food Sci. 1988, 53, 304–305. [Google Scholar] [CrossRef]

- Kaloustian, J.; El-Moselhy, T.F.; Portugal, H. Chemical and Thermal Analysis of the Biopolymers in Thyme (Thymus Vulgaris). Thermochim. Acta 2003, 401, 77–86. [Google Scholar] [CrossRef]

- Singh, A.P.; Kumar, S. Applications of Tannins in Industry. In Tannins: Structural Properties, Biological Properties and Current Knowledge; IntechOpen: London, UK, 2020; pp. 1–13. [Google Scholar]

- Fraga-Corral, M.; García-Oliveira, P.; Pereira, A.G.; Lourenço-Lopes, C.; Jimenez-Lopez, C.; Prieto, M.A.; Simal-Gandara, J. Technological Application of Tannin-Based Extracts. Molecules 2020, 25, 614. [Google Scholar] [CrossRef] [PubMed]

- Stenseng, M.; Jensen, A.; Dam-Johansen, K. Investigation of Biomass Pyrolysis by Thermogravimetric Analysis and Differential Scanning Calorimetry. J. Anal. Appl. Pyrolysis 2001, 58–59, 765–780. [Google Scholar] [CrossRef]

- Zhao, J.; Xiuwen, W.; Hu, J.; Liu, Q.; Shen, D.; Xiao, R. Thermal Degradation of Softwood Lignin and Hardwood Lignin by TG-FTIR and Py-GC/MS. Polym. Degrad. Stab. 2014, 108, 133–138. [Google Scholar] [CrossRef]

- Lu, Q.; Yang, X.; Zhu, X. Analysis on Chemical and Physical Properties of Bio-Oil Pyrolyzed from Rice Husk. J. Anal. Appl. Pyrolysis 2008, 82, 191–198. [Google Scholar] [CrossRef]

- Rammal, M.; Kataya, G.; Badran, A.; Yazbeck, L.; Haidar, C.; Hassan, K.H.; Hijazi, A.; Meouche, W.; Bechelany, M.; El-Dakdouki, M.H. Biochar Derived from Citronella and Oregano Waste Residues for Removal of Organic Dyes and Soil Amendment. Curr. Res. Green Sustain. Chem. 2024, 9, 100433. [Google Scholar] [CrossRef]

- Garzón, E.; Arce, C.; Callejón-Ferre, A.J.; Pérez-Falcón, J.M.; Sánchez-Soto, P.J. Thermal Behaviour of the Different Parts of Almond Shells as Waste Biomass. J. Therm. Anal. Calorim. 2022, 147, 5023–5035. [Google Scholar] [CrossRef]

- Patel, A.; Agrawal, B.; Rawal, B.R. Elemental Composition of Biodiesel Produced by Fast Pyrolysis of Eucalyptus Leaves. J. Eng. Res. 2021, 9, 1–14. [Google Scholar] [CrossRef]

- Yitayew, T.; Moges, D.; Satheesh, N. Effect of Brewery Spent Grain Level and Fermentation Time on the Quality of Bread. Int. J. Food Sci. 2022, 2022, 8704684. [Google Scholar] [CrossRef] [PubMed]

- Iftikhar, Z.A.; Shahid, U.; Farooq, M.; Kamila, H.; Ali, N.; Mastoor, M.; Almutairi, S.M.; Ahmed Rasheed, R.; Chen, T.-W. Investigating the Nutraceutical Potential of Apple Peel Extract Supplementation for Regulating the Glucose Metabolism in Hyperlipidemic Female Human Subjects. Pak. J. Pharm. Sci. 2023, 36, 625–629. [Google Scholar]

- El Midaoui, A.; Khallouki, F.; Couture, R.; Moldovan, F.; Ismael, M.A.; Ongali, B.; Akoume, M.Y.; Alem, C.; Ait Boughrous, A.; Zennouhi, W.; et al. Thymus Atlanticus: A Source of Nutrients with Numerous Health Benefits and Important Therapeutic Potential for Age-Related Diseases. Nutrients 2023, 15, 4077. [Google Scholar] [CrossRef] [PubMed]

- Asri, F.Ö. The Effects of Organic and Conventional Fertilization on Oregano (Origanum Onites L.) Yield and Quality Factors. Folia Hortic. 2023, 35, 209–219. [Google Scholar] [CrossRef]

| Sample | Cellulose (%) | Lignin (%) | Extractable Tannins (%) | Oils (%) |

|---|---|---|---|---|

| OS | 38 | 15 | 10 | 3 |

| RH | 52 | 14 | 7 | 3 |

| EL | 33 | 26 | 14 | 6 |

| AS | 34 | 18 | 11 | 8 |

| Sample | Humidity (wt.%) | Volatiles (wt.%) | Fixed Carbon (wt.%) | Ash (wt.%) |

|---|---|---|---|---|

| RH | 0.24 | 66.7 | 16.3 | 17.0 |

| OS | 0.40 | 90.6 | 4.84 | 4.53 |

| EL | 0.29 | 84.2 | 12.0 | 3.78 |

| AS | 0.45 | 81.0 | 16.7 | 2.28 |

| Sample | C (wt.%) | H (wt.%) | N (wt.%) | S (wt.%) | O (wt.%) | O (wt.%) ISO |

|---|---|---|---|---|---|---|

| RH | 45.5 | 6.11 | 0.72 | 0.01 | 47.9 | 39.6 |

| OS | 43.8 | 5.81 | 0.50 | 0.01 | 46.7 | 47.6 |

| EL | 52.6 | 6.70 | 1.12 | 0.00 | 38.3 | 38.1 |

| AS | 48.0 | 6.43 | 1.08 | 0.01 | 42.4 | 43.4 |

| Metal (wt.%) | RH | OS | EL | AS |

|---|---|---|---|---|

| B | 0.40 | 0.00 | 0.00 | 0.51 |

| Ca | 6.36 | 0.91 | 1.07 | 4.16 |

| Fe | 0.46 | 0.00 | 0.02 | 0.00 |

| K | 2.87 | 1.49 | 0.49 | 1.97 |

| Mg | 0.98 | 0.05 | 0.22 | 0.06 |

| Na | 0.39 | 0.04 | 0.19 | 0.04 |

| P | 0.57 | 0.20 | 0.42 | 0.57 |

| Zn | 0.67 | 0.00 | 0.00 | 0.04 |

| Sample | Average Particle Size (µm) | Standard Deviation (µm) |

|---|---|---|

| RH | 420.5 | 263.9 |

| OS | 637.5 | 550.0 |

| EL | 244.2 | 230.5 |

| AS | 82.0 | 73.2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Costa, F.; Mendanha, D.; Gomes, J.M.; Oliveira, J.A.S.A.; Ribeiro, C.; Miranda, A.F.; Barbosa, J.R.M.; Soares, O.S.G.P.; Pereira, M.F.R.; Santos, J.; et al. A Comprehensive Study on the Physicochemical Characterisation of Plant-Based By-Products. Materials 2025, 18, 2054. https://doi.org/10.3390/ma18092054

Costa F, Mendanha D, Gomes JM, Oliveira JASA, Ribeiro C, Miranda AF, Barbosa JRM, Soares OSGP, Pereira MFR, Santos J, et al. A Comprehensive Study on the Physicochemical Characterisation of Plant-Based By-Products. Materials. 2025; 18(9):2054. https://doi.org/10.3390/ma18092054

Chicago/Turabian StyleCosta, Filipa, Daniel Mendanha, Joana M. Gomes, Juliana A. S. A. Oliveira, Cecília Ribeiro, Ana Francisca Miranda, José R. M. Barbosa, Olívia Salomé G. P. Soares, Manuel Fernando R. Pereira, Jorge Santos, and et al. 2025. "A Comprehensive Study on the Physicochemical Characterisation of Plant-Based By-Products" Materials 18, no. 9: 2054. https://doi.org/10.3390/ma18092054

APA StyleCosta, F., Mendanha, D., Gomes, J. M., Oliveira, J. A. S. A., Ribeiro, C., Miranda, A. F., Barbosa, J. R. M., Soares, O. S. G. P., Pereira, M. F. R., Santos, J., Freitas, B., & Silva, C. J. (2025). A Comprehensive Study on the Physicochemical Characterisation of Plant-Based By-Products. Materials, 18(9), 2054. https://doi.org/10.3390/ma18092054