Performance Evolution and Damage Evaluation of CRTS I Track Slab in Service Status

Abstract

1. Introduction

2. Track Slab Damage State Quantification

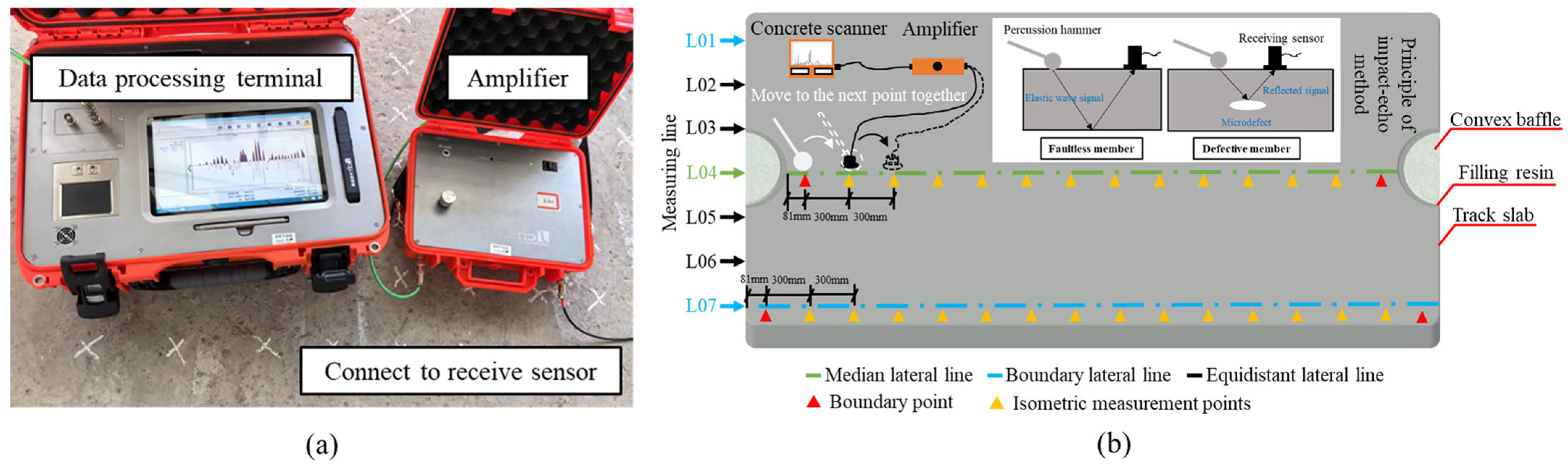

2.1. Method for Determining the Emptying Coefficient of the Track Slab

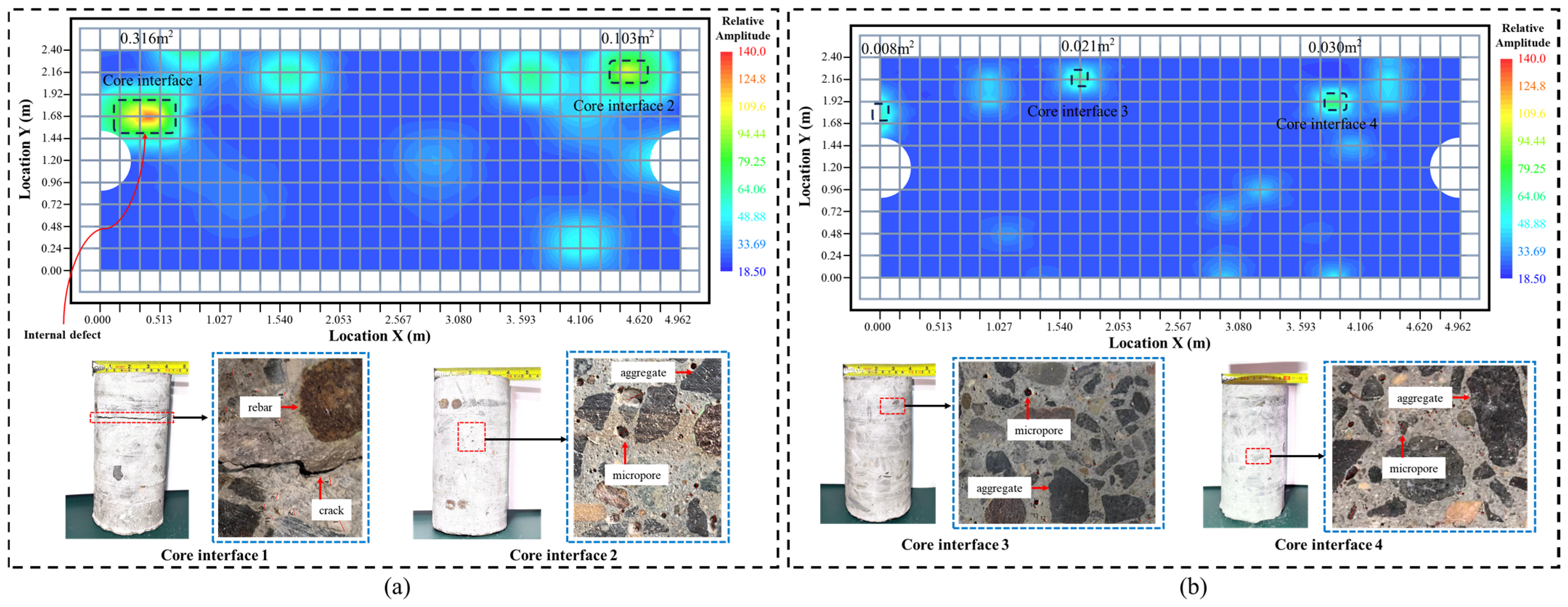

2.2. Core Sampling to Measure the Remaining Bearing Capacity of the Track Slab

2.3. The Correspondence Between the Unloading Coefficient of Track Slab and the Remaining Bearing Capacity

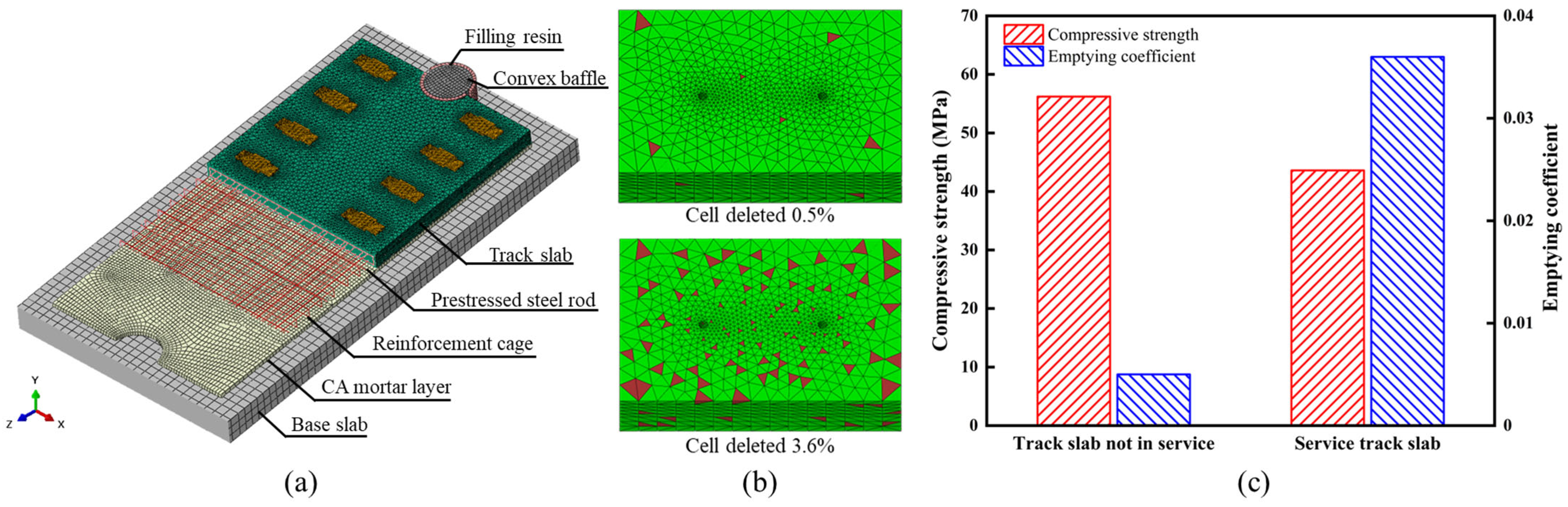

3. Modeling of Plastic Damage of Track Slab

3.1. Modeling Based on Concrete Plastic-Damage Coupling Theory

3.2. Site Monitoring and Load Setting

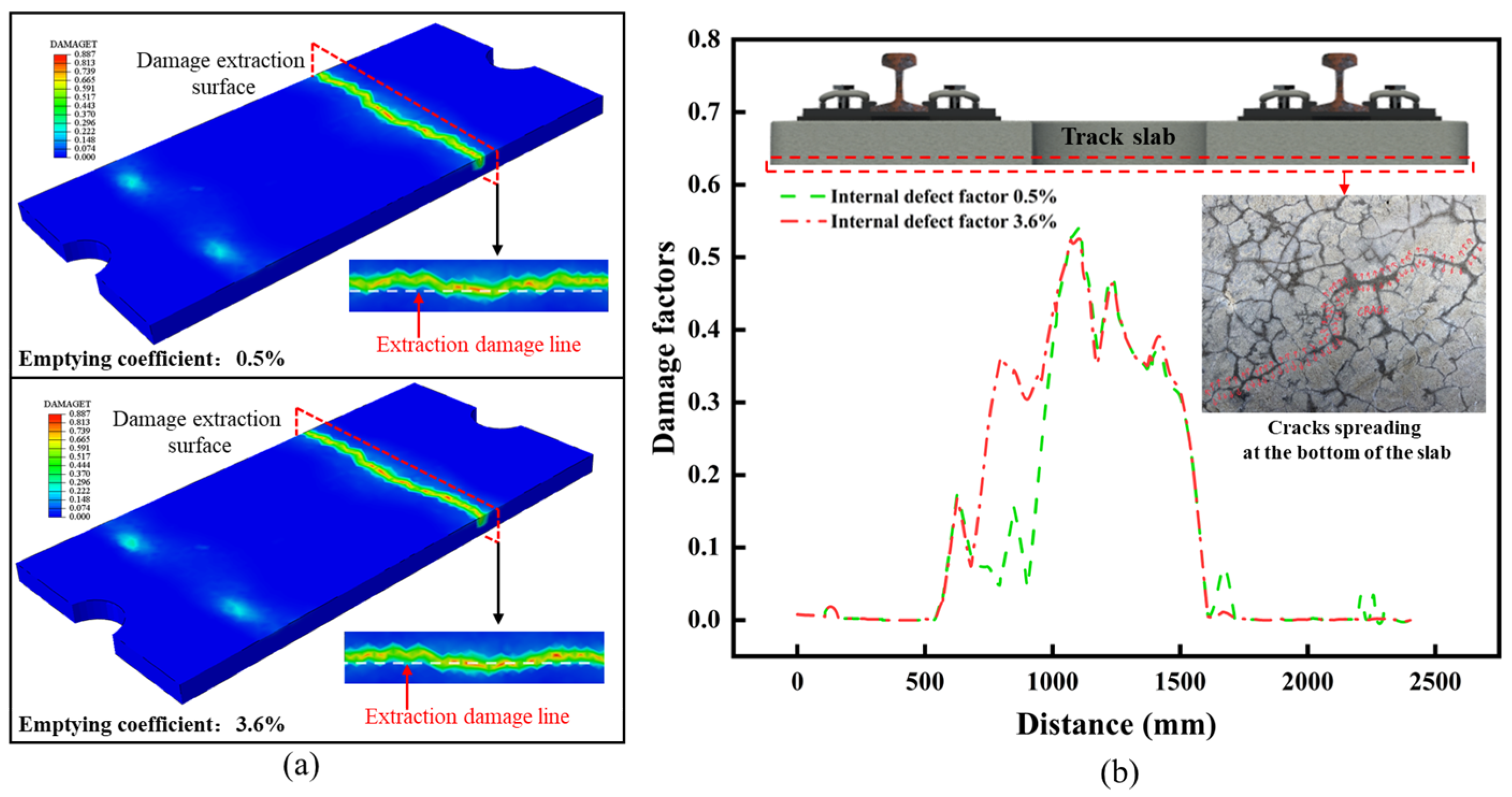

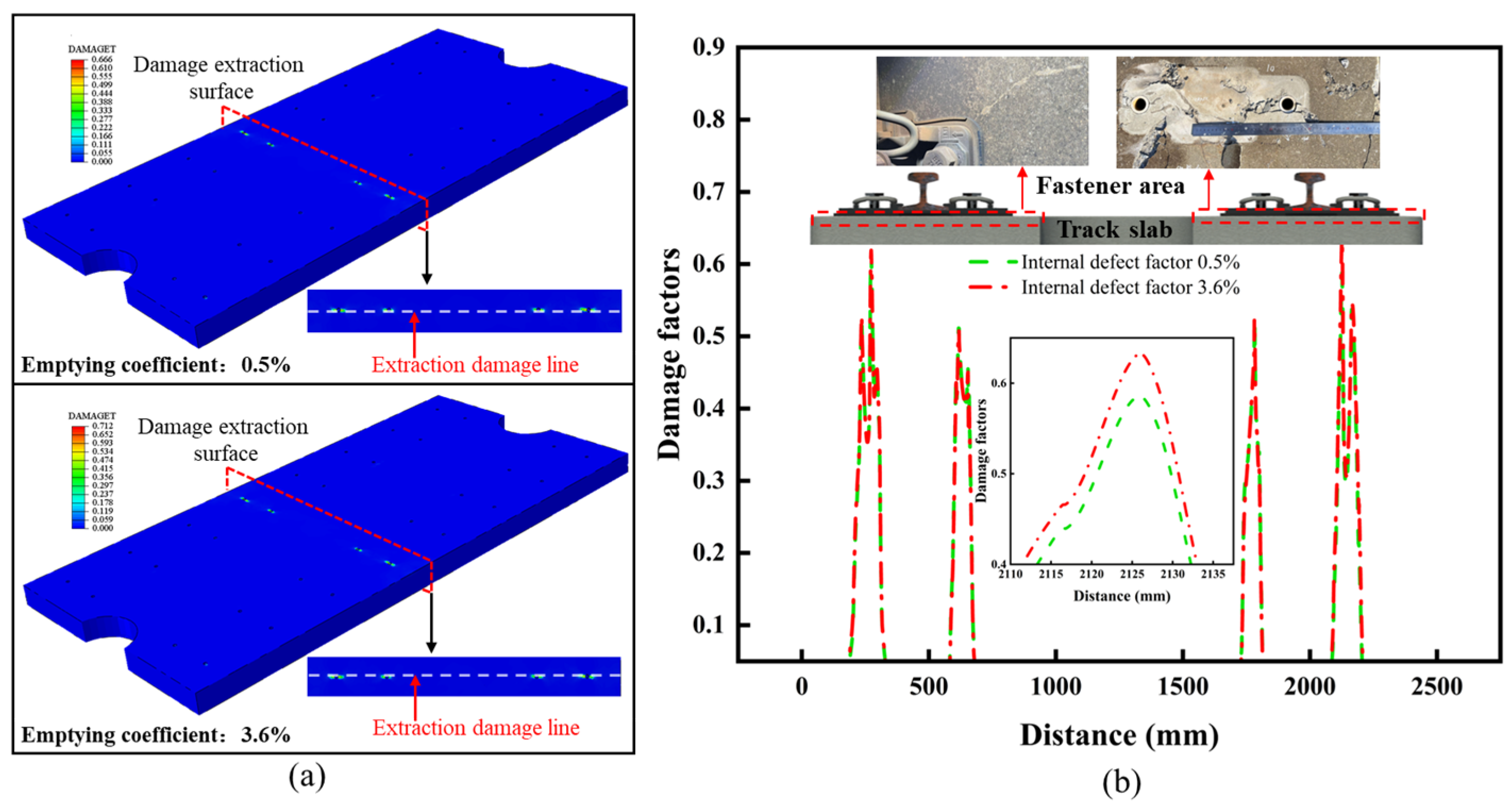

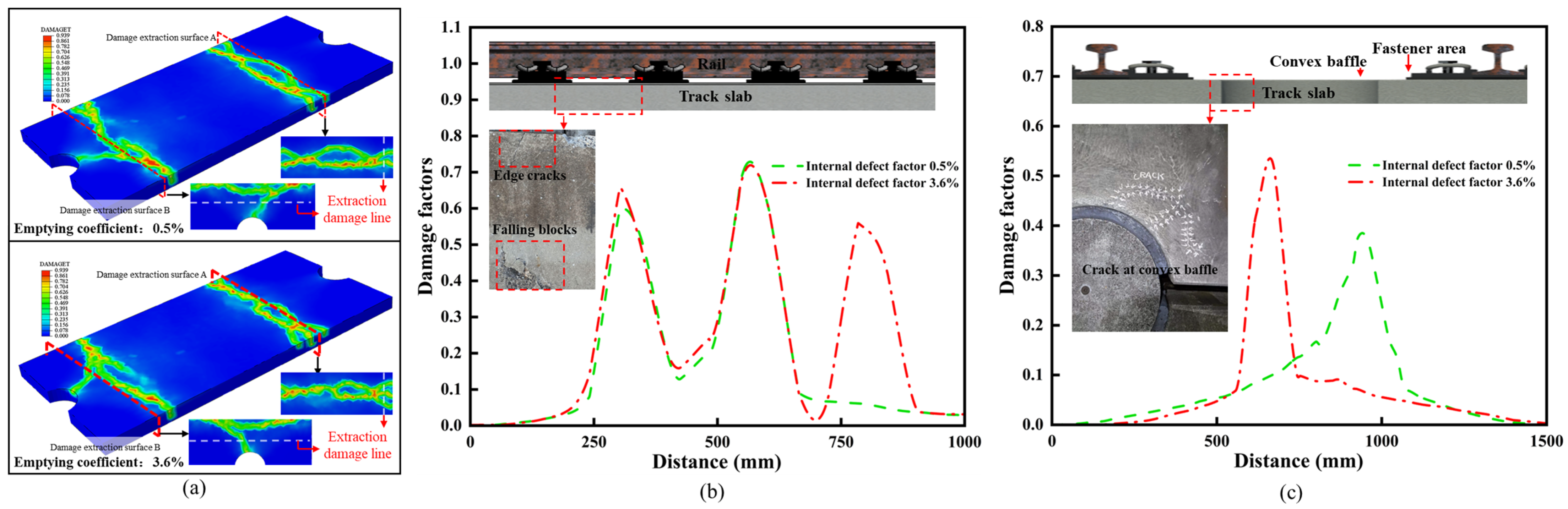

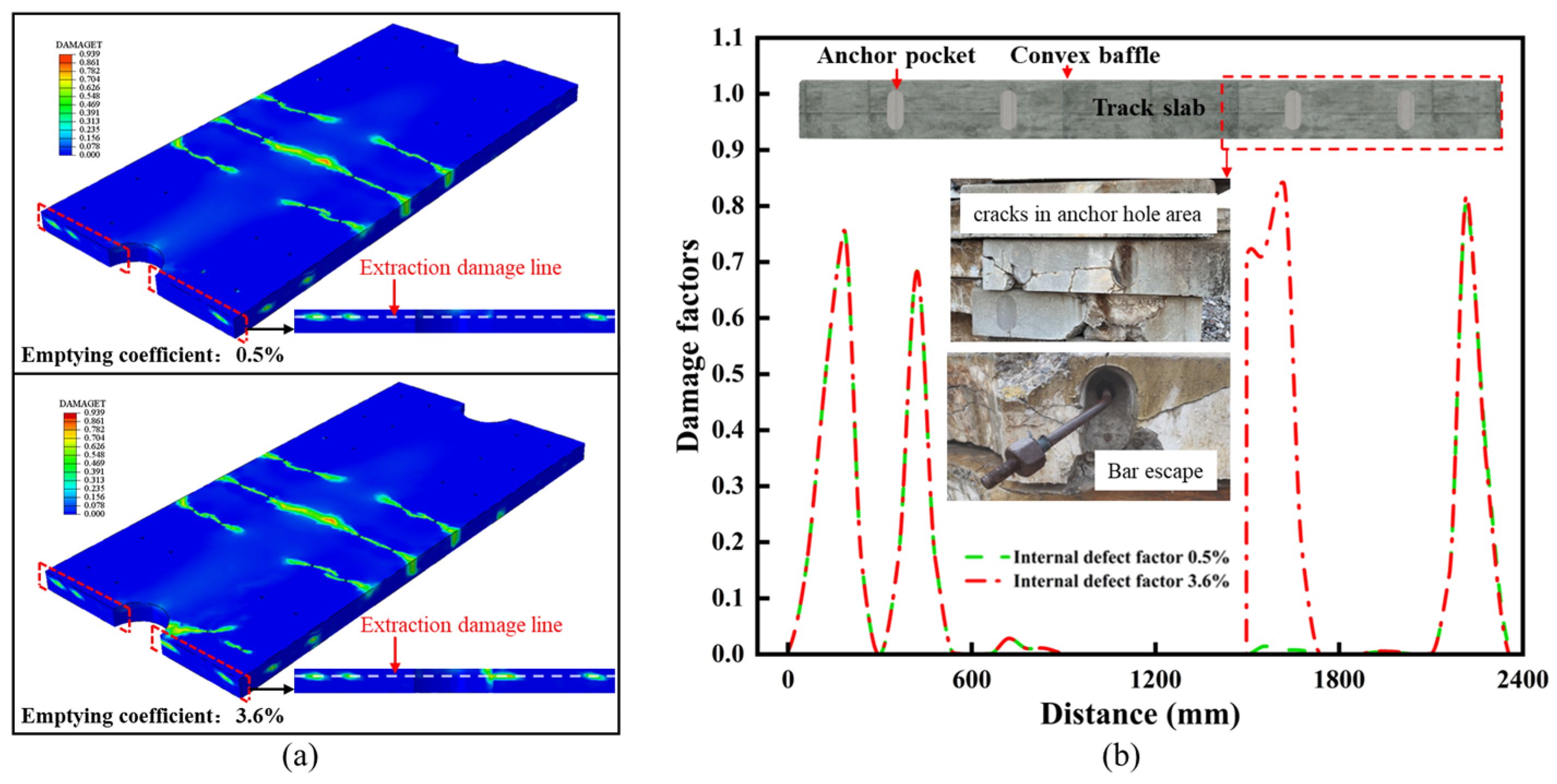

3.3. Analysis of Surface Damage Evolution Law of Track Slab

4. Conclusions

- The void coefficient inside the old track slab increased from 0.5% to 3.6%, and the expansion of internal void disease led to a decrease in the actual bearing strength of the track slab. The uniaxial compression test results of the core specimens showed that the average compressive strength of the track slab decreased from 56.2 MPa to 43.6 MPa after service, with a decrease of 22.4% in compressive strength.

- Combining long-term monitoring and detection data of actual lines could provide data support for simulation analysis. The average wheel–rail force acting on the track slab was 84.0 kN. The temperature changes on the surface and bottom of the track slab reached 60.9 °C and 39.8 °C, respectively, and the temperature gradient range varied from −50.4 °C/m to 100.0 °C/m, exceeding the allowable value of the design specifications, which can easily lead to initial damage at critical stress locations.

- Under different load combinations, there were significant differences in the damage distribution of track slabs after performance degradation. The damage distribution areas were mainly located near key stress positions such as fasteners, convex abutments, and anchor holes of prestressed steel bars. In addition to focusing on the extreme damage values and locations of track slabs under different load conditions, it is still necessary to accurately grasp the evolution of the damage propagation path of track slabs after overall performance degradation, in order to achieve the scientific maintenance and repair of track structures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cai, C.; Huang, S.; He, X.; Zhou, T.; Zou, Y. Investigation of Concrete Box Girder Positive Temperature Gradient Patterns Considering Different Climatic Regions. Structures 2022, 35, 591–607. [Google Scholar] [CrossRef]

- Zhao, L.; Zhou, L.-Y.; Zhang, G.-C.; Wei, T.-Y.; Mahunon, A.D.; Jiang, L.-Q.; Zhang, Y.-Y. Experimental Study of the Temperature Distribution in CRTS-II Ballastless Tracks on a High-Speed Railway Bridge. Appl. Sci. 2020, 10, 1980. [Google Scholar] [CrossRef]

- Lan, C.; Yang, Z.; Liang, X.; Yang, R.; Li, P.; Liu, Z.; Li, Q.; Luo, W. Experimental Study on Wayside Monitoring Method of Train Dynamic Load Based on Strain of Ballastless Track Slab. Constr. Build. Mater. 2023, 394, 132084. [Google Scholar] [CrossRef]

- You, R.; Kaewunruen, S. Evaluation of Remaining Fatigue Life of Concrete Sleeper Based on Field Loading Conditions. Eng. Fail. Anal. 2019, 105, 70–86. [Google Scholar] [CrossRef]

- Zhou, L.-Y.; Zhao, L.; Mahunon, A.D.; Zhang, Y.-Y.; Li, H.-Y.; Zou, L.-F.; Yuan, Y.-H. Experimental Study on Stiffness Degradation of Crts II Ballastless Track-Bridge Structural System under Fatigue Train Load. Constr. Build. Mater. 2021, 283, 122794. [Google Scholar] [CrossRef]

- Liu, X.; Yu, Z.; Xiang, P.; Jin, C. Composite Action of the Track Slab and the Self-Compacting Concrete Filling Layer Subjected to Train-Induced Fatigue Load: An Experimental Investigation. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 580–592. [Google Scholar] [CrossRef]

- Liu, R.; Yang, Y. Research on Fatigue Performance of Steel-Plate-Concrete Composite Slab. Thin-Walled Struct. 2021, 160, 107339. [Google Scholar] [CrossRef]

- Yang, J.; Zhu, S.; Zhai, W. A Novel Dynamics Model for Railway Ballastless Track with Medium-Thick Slabs. Appl. Math. Model. 2020, 78, 907–931. [Google Scholar] [CrossRef]

- Cui, X.; Zhou, R.; Guo, G.; Du, B.; Liu, H. Effects of Train Load and Water on Stress Intensity Factors of the Crack in Slab Track. Constr. Build. Mater. 2021, 299, 124247. [Google Scholar] [CrossRef]

- Li, Z.-W.; Liu, X.-Z.; He, Y.-L. Identification of Temperature-Induced Deformation for HSR Slab Track Using Track Geometry Measurement Data. Sensors 2019, 19, 5446. [Google Scholar] [CrossRef]

- Yan, D.; Xu, Y.; Zhu, W. Effects of Debonding Repairment on Interfacial Damage and Thermal Deformation of CRTS II Slab Ballastless Track. Constr. Build. Mater. 2023, 389, 131793. [Google Scholar] [CrossRef]

- Zhang, Q.; Cai, X.; Zhong, Y.; Chen, Z.; Wang, C. Temperature Field and Thermal Effects of the Longitudinal Connected Slab Track Based on the Measurement Data and Thermal-Fluid-Structure Coupling Analysis. Constr. Build. Mater. 2022, 343, 128121. [Google Scholar] [CrossRef]

- Chen, W.; Li, S.; Wang, W.; Pan, Z.; Lou, P.; Li, D. Analysis on Crack Propagation of CRTS III Slab Ballastless Track under Temperature Loads and Freeze–Thaw Deterioration. Theor. Appl. Fract. Mech. 2024, 129, 104206. [Google Scholar] [CrossRef]

- He, Y.-L.; Shen, J.-K.; Li, Z.-W.; Lu, H.-Y. Fractal Characteristics of Transverse Crack Propagation on CRTSII Type Track Slab. Math. Probl. Eng. 2019, 2019, 6587343. [Google Scholar] [CrossRef]

- Zhang, K.; Yuan, Q.; Huang, T.; Zuo, S.; Chen, R.; Wang, M. Predicting the Cracking Behavior of Early-Age Concrete in CRTS III Track. Constr. Build. Mater. 2022, 353, 129105. [Google Scholar] [CrossRef]

- Li, Z.-W.; Liu, X.-Z.; Lu, H.-Y.; He, Y.-L.; Zhou, Y. Surface Crack Detection in Precasted Slab Track in High-Speed Rail via Infrared Thermography. Materials 2020, 13, 4837. [Google Scholar] [CrossRef]

- Ospitia, N.; Korda, E.; Kalteremidou, K.-A.; Lefever, G.; Tsangouri, E.; Aggelis, D.G. Recent Developments in Acoustic Emission for Better Performance of Structural Materials. Dev. Built Environ. 2023, 13, 100106. [Google Scholar] [CrossRef]

- Chen, W.; Zhang, Y.; Li, D.; Pan, Z.; Lou, P. Research on Crack Propagation of CRTS III Track Slabs under Train Load. Eng. Fail. Anal. 2024, 157, 107896. [Google Scholar] [CrossRef]

- Liu, X.-Z.; Li, Z.-W.; Lu, H.-Y.; He, Y.-L. Structural Deformation Monitoring and Service Reliability Analysis for Slab Track in Plateau Areas. J. Mech. Sci. Technol. 2023, 37, 4413–4424. [Google Scholar] [CrossRef]

- Sapidis, G.M.; Naoum, M.C.; Papadopoulos, N.A.; Golias, E.; Karayannis, C.G.; Chalioris, C.E. A Novel Approach to Monitoring the Performance of Carbon-Fiber-Reinforced Polymer Retrofitting in Reinforced Concrete Beam–Column Joints. Appl. Sci. 2024, 14, 9173. [Google Scholar] [CrossRef]

- Hu, M.; Xu, Y.; Li, S.; Lu, H. Detection of Defect in Ballastless Track Based on Impact Echo Method Combined with Improved SAFT Algorithm. Eng. Struct. 2022, 269, 114779. [Google Scholar] [CrossRef]

- Hu, M.; Xu, Y.; Xue, Z.; Wang, S. An Inversion Method for Evaluating Ballastless Track Degradation Based on Multi-Channel Analysis of Surface Wave. Mech. Syst. Signal Process. 2023, 200, 110572. [Google Scholar] [CrossRef]

- Jiang, W.; Xie, Y.; Wu, J.; Guo, J.; Long, G. Identifying Bonding Interface Flaws in CRTS III Type Ballastless Track Structure Using the Impact-Echo Method. Eng. Struct. 2021, 227, 111429. [Google Scholar] [CrossRef]

- Barbosa, R.A.; Hansen, S.G.; Hansen, K.K.; Hoang, L.C.; Grelk, B. Influence of Alkali-Silica Reaction and Crack Orientation on the Uniaxial Compressive Strength of Concrete Cores from Slab Bridges. Constr. Build. Mater. 2018, 176, 440–451. [Google Scholar] [CrossRef]

- Taman, M.; Abd Elaty, M.; Behiry, R.N. Codes Applicability of Estimating the FRC Compressive Strength by the Core-Drilling Method. Constr. Build. Mater. 2022, 330, 127227. [Google Scholar] [CrossRef]

- Ambroziak, A.; Haustein, E.; Kondrat, J. Chemical and Mechanical Properties of 70-Year-Old Concrete. J. Mater. Civ. Eng. 2019, 31, 04019159. [Google Scholar] [CrossRef]

- Dok, G.; Caglar, N.; Ilki, A.; Yilmaz, C. Residual Load Bearing Capacity and Failure Mechanism of Impacted High-Strength Reinforced Concrete Shear Beams. Eng. Fail. Anal. 2021, 121, 105185. [Google Scholar] [CrossRef]

- Deng, S.; Ren, J.; Wei, K.; Ye, W.; Du, W.; Zhang, K. Fatigue Damage Evolution Analysis of the CA Mortar of Ballastless Tracks via Damage Mechanics-Finite Element Full-Couple Method. Constr. Build. Mater. 2021, 295, 123679. [Google Scholar] [CrossRef]

- Li, Z.G.; Wu, T.X. Modelling and Analysis of Force Transmission in Floating-Slab Track for Railways. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2008, 222, 45–57. [Google Scholar] [CrossRef]

- Liu, L.; Jiang, L.; Zhou, W.; Yu, J.; Peng, K.; Zuo, Y. Study on the Restoring Force Model for the High-Speed Railway CRTS III Slab Ballastless Track. Arch. Civ. Mech. Eng. 2022, 22, 148. [Google Scholar] [CrossRef]

- Wang, J.; Gao, L.; Wang, L.; Zhao, W.; Qin, Y.; Hua, C.; Li, Y. Evolution Mechanism of Interlayer Properties of CRTS III Slab Track during Construction. Appl. Sci. 2024, 14, 704. [Google Scholar] [CrossRef]

- Yan, B.; Li, Z.; Liu, S.; Xie, H.-R. Seismic Response of CRTS II Ballastless Track-Bridge System Considering the Damage of Track Structure. Sci. Prog. 2021, 104, 00368504211035207. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Lu, Z.-H.; Zhang, X.-Y.; Zhao, Y.-G. Interface Behaviour Analysis of China Railway Track System II Slab Ballastless Track under Temperature Action and Initial Gap Damage. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2024, 238, 102–117. [Google Scholar] [CrossRef]

- JGJ/T 384-2016; Technical Specification for Testing Concrete Strength with Drilled Core Method. China Architecture & Building Press: Beijing, China, 2016.

- TB/T 2489-2016; Track Side Test Methods of Vertical and Lateral Wheel–Rail Forces. China Railway Publishing House: Beijing, China, 2016.

| Components | Modulus of Elasticity/MPa | Poisson Ratio | Mass Density/kg m−3 | Coefficient of Linear Expansion/°C−1 |

|---|---|---|---|---|

| Slab | 3.6 × 104 | 0.2 | 2500 | 1.0 × 10−5 |

| CA mortar layer | 300 | 0.2 | 2000 | 1.8 × 10−5 |

| Filling resin | - | 0.1 | 1200 | 2.0 × 10−5 |

| Convex baffle | 3.3 × 104 | 0.2 | 1200 | 1.0 × 10−5 |

| Rebar | 2.1 × 105 | 0.3 | 7856 | 1.18 × 10−5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lu, H.; Wu, W.; He, Y. Performance Evolution and Damage Evaluation of CRTS I Track Slab in Service Status. Materials 2025, 18, 2041. https://doi.org/10.3390/ma18092041

Lu H, Wu W, He Y. Performance Evolution and Damage Evaluation of CRTS I Track Slab in Service Status. Materials. 2025; 18(9):2041. https://doi.org/10.3390/ma18092041

Chicago/Turabian StyleLu, Hongyao, Wentao Wu, and Yuelei He. 2025. "Performance Evolution and Damage Evaluation of CRTS I Track Slab in Service Status" Materials 18, no. 9: 2041. https://doi.org/10.3390/ma18092041

APA StyleLu, H., Wu, W., & He, Y. (2025). Performance Evolution and Damage Evaluation of CRTS I Track Slab in Service Status. Materials, 18(9), 2041. https://doi.org/10.3390/ma18092041