Ultra-Low Core Loss and High-Frequency Permeability Stability in Hot-Press Sintered FeSi Soft Magnetic Composites by Fe2O3 Nanoparticles Air Gap Filling

Abstract

1. Introduction

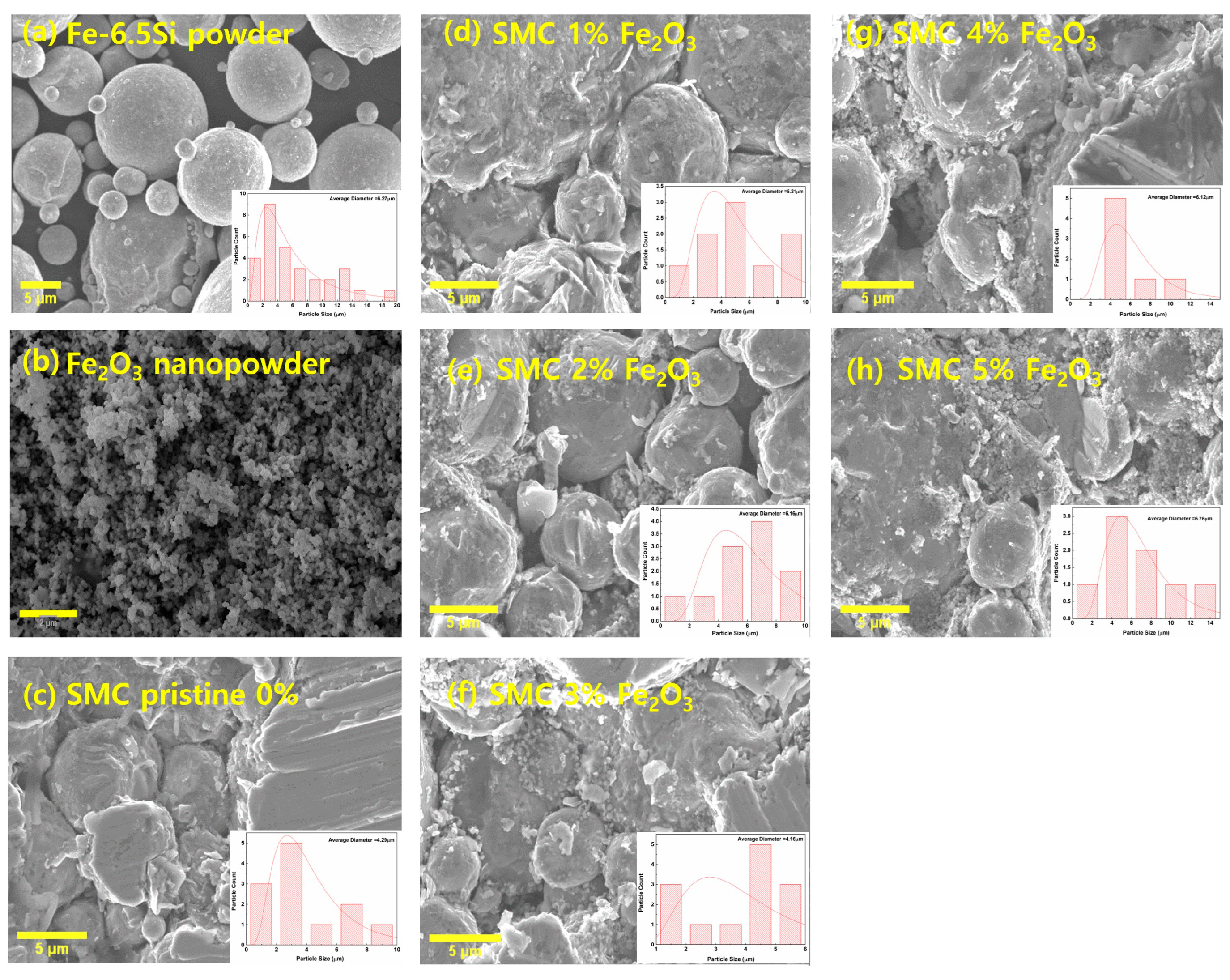

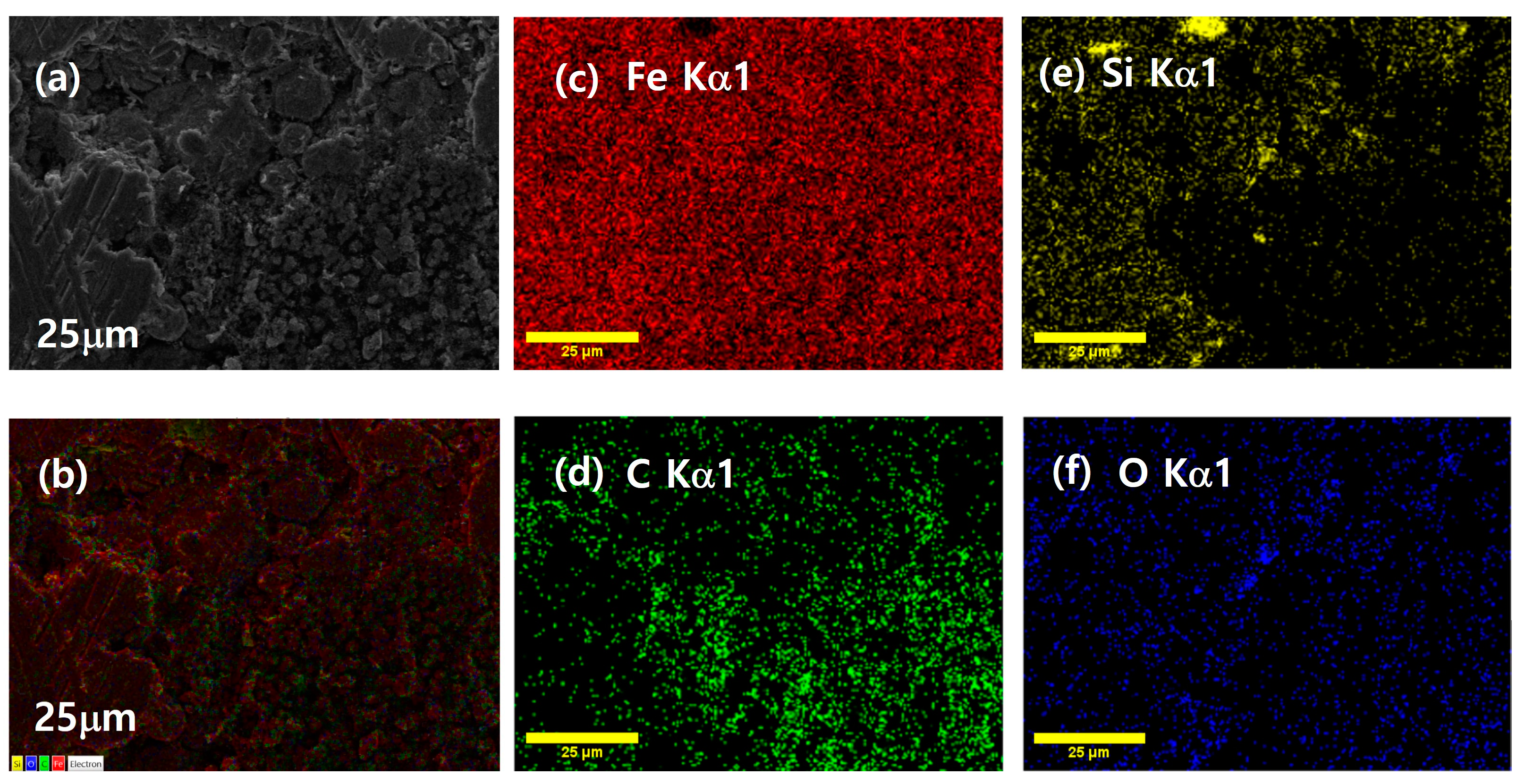

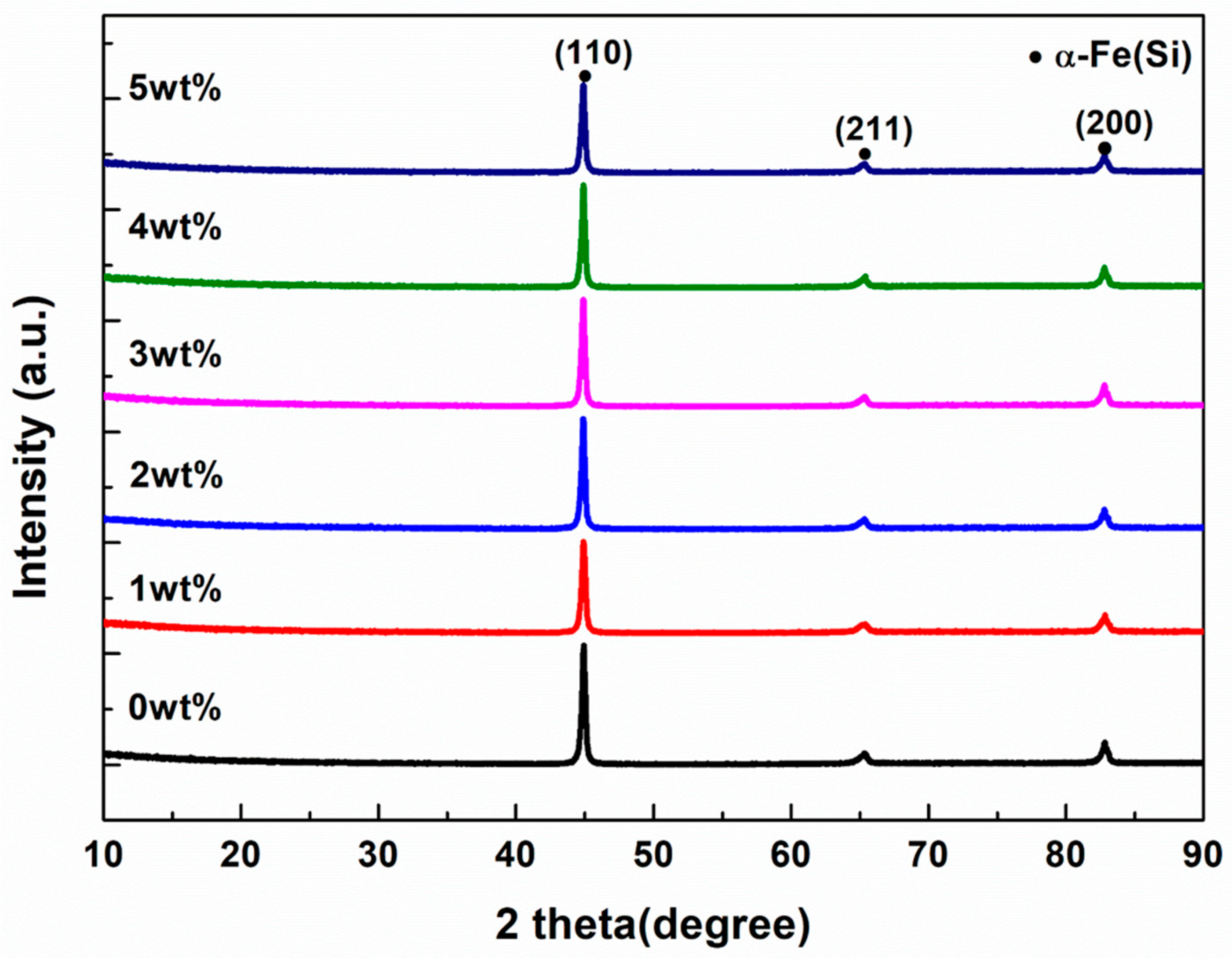

2. Materials and Methods

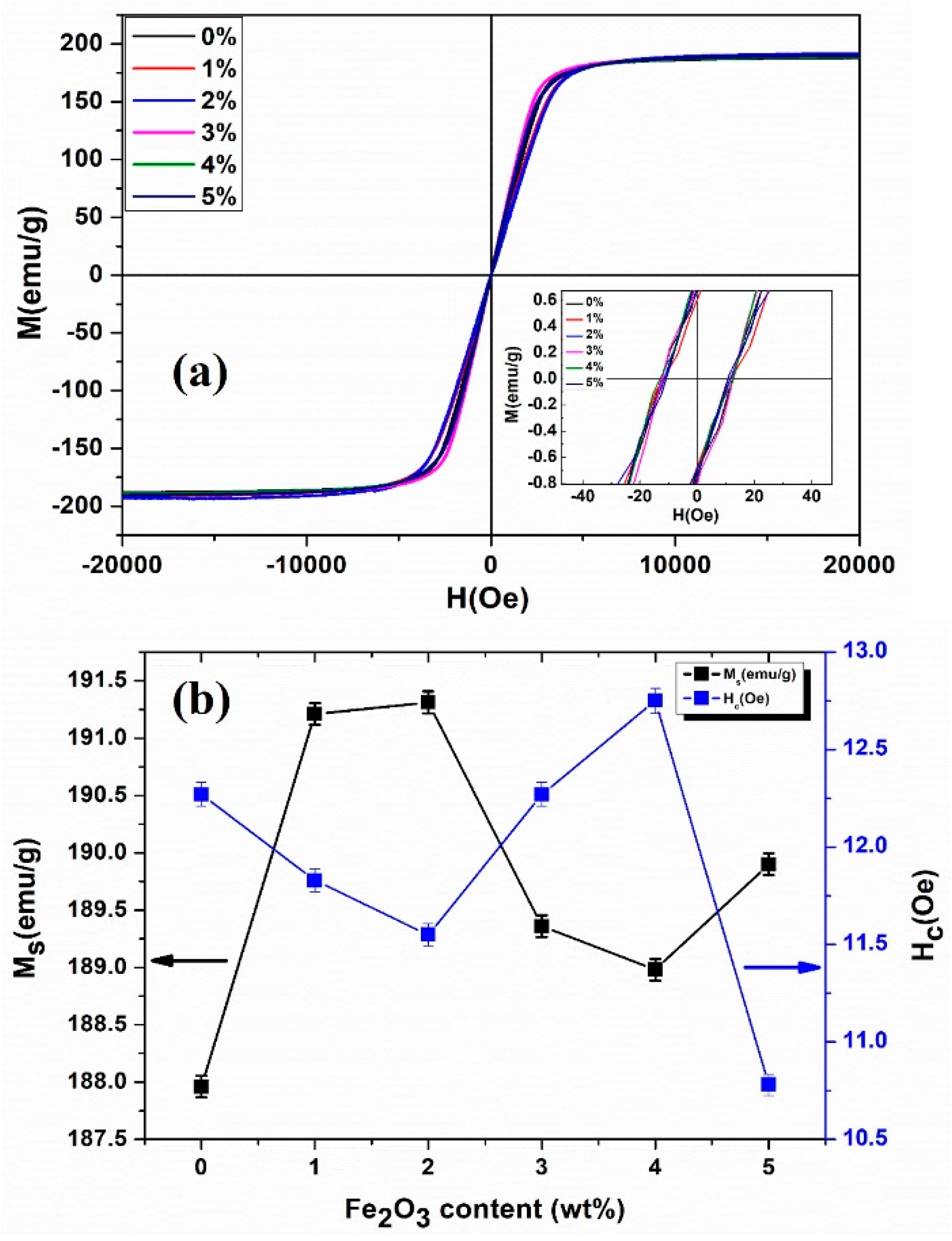

3. Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, D.; Liu, X.; Wang, J.; Mao, X.; Xu, X. The influence of Fe nanoparticles on microstructure and magnetic properties of Fe-6.5 wt% Si soft magnetic composites. J. Alloys Compd. 2020, 835, 155215. [Google Scholar] [CrossRef]

- Perigo, E.A.; Weidenfeller, B.; Kollár, P.; Füzer, J. Past, present, and future of soft magnetic composites. Appl. Phys. Rev. 2018, 5, 031301. [Google Scholar] [CrossRef]

- Peng, Y.; Nie, J.; Zhang, W.; Ma, J.; Bao, C.; Cao, Y. Effect of the addition of Al2O3 nanoparticles on the magnetic properties of Fe soft magnetic composites. J. Magn. Magn. Mater. 2016, 399, 88–93. [Google Scholar] [CrossRef]

- Wu, S.; Sun, A.; Zhai, F.; Wang, J.; Zhang, Q.; Xu, W.; Logan, P.; Volinsky, A.A. Annealing effects on magnetic properties of silicone-coated iron-based soft magnetic composites. J. Magn. Magn. Mater. 2012, 324, 818–822. [Google Scholar] [CrossRef]

- He, W.; Li, H.; Han, X.; Wang, X.; Wang, G.; Zhang, X.; Shcheretskyi, O. High-temperature dry sliding friction and wear behavior of in-situ (Al3Zr + ZrB2)/AA6016 aluminum matrix composites. Mater. Today Commun. 2024, 39, 108951. [Google Scholar] [CrossRef]

- Wang, G.; Li, H.; Jiao, L.; Zhang, X.; Wang, X.; Shen, W.; Zhang, C. Effect of rotational speed on friction stir welding microstructure and properties of cast and rolled (ZrB2 + Al3Zr) particle-reinforced aluminum matrix composites. J. Mater. Sci. 2024, 59, 18734–18755. [Google Scholar] [CrossRef]

- Wu, Y.; Bitoh, T.; Hono, K.; Makino, A.; Inoue, A. Microstructure and properties of nanocrystalline Fe–Zr–Nb–B soft magnetic alloys with low magnetostriction. Acta Mater. 2001, 49, 4069–4077. [Google Scholar] [CrossRef]

- Kim, Y.B.; Jang, D.; Seok, H.; Kim, K. Fabrication of Fe–Si–B based amorphous powder cores by cold pressing and their magnetic properties. Mater. Sci. Eng. A 2007, 449, 389–393. [Google Scholar] [CrossRef]

- Schoppa, A.; Delarbre, P. Soft magnetic powder composites and potential applications in modern electric machines and devices. IEEE Trans. Magn. 2014, 50, 2004304. [Google Scholar] [CrossRef]

- Gilbert, I.; Moorthy, V.; Bull, S.; Evans, J.; Jack, A. Development of soft magnetic composites for low-loss applications. J. Magn. Magn. Mater. 2002, 242, 232–234. [Google Scholar] [CrossRef]

- Sundar, R.; Deevi, S. Soft magnetic FeCo alloys: Alloy development, processing, and properties. Int. Mater. Rev. 2005, 50, 157–192. [Google Scholar] [CrossRef]

- Streckova, M.; Medvecky, L.; Füzer, J.; Kollár, P.; Bures, R.; Faberova, M. Design of novel soft magnetic composites based on Fe/resin modified with silica. Mater. Lett. 2013, 101, 37–40. [Google Scholar] [CrossRef]

- Schäfter, T.; Burghaus, J.; Pieper, W.; Petzoldt, F.; Busse, M. New concept of Si–Fe based sintered soft magnetic composite. Powder Metall. 2015, 58, 106–111. [Google Scholar] [CrossRef]

- Krings, A.; Boglietti, A.; Cavagnino, A.; Sprague, S. Soft magnetic material status and trends in electric machines. IEEE Trans. Ind. Electron. 2016, 64, 2405–2414. [Google Scholar] [CrossRef]

- Zheng, Z.; Li, S.; Peng, K. Magnetic properties regulation and loss contribution analysis of FeSi soft magnetic composites doped by carbonyl iron powders. J. Magn. Magn. Mater. 2023, 568, 170423. [Google Scholar] [CrossRef]

- Luo, Z.; Hu, W.; Luo, F.; Li, Y.; Wang, J.; Liu, X. Enhanced magnetic properties and reduced core loss of intergranular insulating Fe-Si soft magnetic composites with three-shell SiO2-Fe2SiO4-SiO2 insulating layer. J. Solid State Chem. 2019, 270, 311–316. [Google Scholar] [CrossRef]

- Fan, X.; Wu, Z.; Li, G.; Wang, J.; Xiang, Z.; Gan, Z. High resistivity and low core loss of intergranular insulated Fe–6.5 wt.% Si/SiO2 composite compacts. Mater. Des. 2016, 89, 1251–1258. [Google Scholar] [CrossRef]

- Zhao, Y.W.; Zhang, X.; Xiao, J.Q. Submicrometer Laminated Fe/SiO2 Soft Magnetic Composites—An Effective Route to Materials for High-Frequency Applications. Adv. Mater. 2005, 17, 915–918. [Google Scholar] [CrossRef]

- Frayman, L.; Quinn, S.; Quinn, R.; Green, D.; Hanejko, F. Advanced soft magnetic composite materials for AC applications with reduced iron losses. Powder Metall. 2015, 58, 335–338. [Google Scholar] [CrossRef]

- Wang, M.; Zan, Z.; Deng, N.; Zhao, Z. Preparation of pure iron/Ni–Zn ferrite high strength soft magnetic composite by spark plasma sintering. J. Magn. Magn. Mater. 2014, 361, 166–169. [Google Scholar] [CrossRef]

- Páez-Pavón, A.; Jiménez-Morales, A.; Santos, T.; Quintino, L.; Torralba, J. Influence of thermal debinding on the final properties of Fe–Si soft magnetic alloys for metal injection molding (MIM). J. Magn. Magn. Mater. 2016, 416, 342–347. [Google Scholar] [CrossRef]

- Zhou, T.; Liu, Y.; Cao, P.; Du, J.; Lin, Z.; Wang, R.; Jin, L.; Lian, L.; Harris, V.G. Cold Sintered Metal–Ceramic Nanocomposites for High-Frequency Inductors. Adv. Electron. Mater. 2020, 6, 2000868. [Google Scholar] [CrossRef]

- Fu, H.; Mo, Y.; Zhang, Z.; Xie, J. Ultra-low deformation rate sensitivity of columnar-grained Fe-6.5 wt% Si alloy with <100> orientation. Mater. Sci. Eng. A 2016, 656, 90–93. [Google Scholar]

- Fu, H.; Zhang, Z.; Jiang, Y.; Xie, J. Applying the grain orientation dependence of deformation twinning to improve the deformation properties of an Fe-6.5 wt% Si alloy. J. Alloys Compd. 2016, 689, 307–312. [Google Scholar] [CrossRef]

- Li, W.; Xiao, S.; Li, W.; Ying, Y.; Yu, J.; Zheng, J.; Qiao, L.; Li, J.; Naoki, W.; Wu, J. Hybrid amorphous soft magnetic composites with ultrafine FeSiBCr and submicron FeBP particles for MHz frequency power applications. J. Magn. Magn. Mater. 2022, 555, 169365. [Google Scholar] [CrossRef]

- Liu, M.; Huang, K.; Liu, L.; Li, T.; Cai, P.; Dong, Y.; Wang, X.-M. Fabrication and magnetic properties of novel Fe-based amorphous powder and corresponding powder cores. J. Mater. Sci. Mater. Electron. 2018, 29, 6092–6097. [Google Scholar] [CrossRef]

- Yu, H.; Li, J.; Li, J.; Chen, X.; Han, G.; Yang, J.; Chen, R. Enhancing the properties of FeSiBCr amorphous soft magnetic composites by annealing treatments. Metals 2022, 12, 828. [Google Scholar] [CrossRef]

- Haibo, S.; Ce, W.; Changbao, Z.; Jinghui, W. High-frequency loss analysis and related magnetic properties of Fe-based amorphous soft magnetic composites with different granularity matches. J. Appl. Phys. 2022, 131, 193903. [Google Scholar] [CrossRef]

- Li, Z.; Dong, Y.; Pauly, S.; Chang, C.; Wei, R.; Li, F.; Wang, X.-M. Enhanced soft magnetic properties of Fe-based amorphous powder cores by longitude magnetic field annealing. J. Alloys Compd. 2017, 706, 1–6. [Google Scholar] [CrossRef]

- Wang, J.; Guo, Z.; Zeng, Q.; Hang, G.; Xue, Z.; Chen, D.; Liang, Z.; Sun, H. Magnetic properties regulation and loss contribution analysis for Fe-based amorphous powder cores doped with micron-sized FeSi powders. J. Magn. Magn. Mater. 2020, 510, 166931. [Google Scholar] [CrossRef]

- Shi, G.; Li, M.; Wang, H.; Yin, G.; Wang, M.; Wang, L. Effect of the shape and content for added iron powder on properties of nanocrystalline soft magnetic composites. Mater. Today Commun. 2024, 39, 108888. [Google Scholar] [CrossRef]

- Zhao, R.; Huang, J.; Yang, Y.; Jiao, L.; Dong, Y.; Liu, X.; Liu, Z.; Wu, S.; Li, X.; He, A. The influence of FeNi nanoparticles on the microstructures and soft magnetic properties of FeSi soft magnetic composites. Adv. Powder Technol. 2022, 33, 103663. [Google Scholar] [CrossRef]

- Wang, J.; Liu, X.; Lei, C.; Mao, X.; Liu, D.; Luo, Z.; Luo, F. Core loss reduction for Fe-6.5 wt% Si soft magnetic composites doped with Co element. J. Magn. Magn. Mater. 2020, 502, 166553. [Google Scholar] [CrossRef]

- Luo, F.; Luo, Z.; Hu, W.; Wang, J.; Wu, Z.; Li, G.; Li, Y.; Liu, X. Influences of Fe2O3 content on structure and magnetic performances of FeSiAl soft magnetic composites. Mater. Res. Express 2019, 6, 116106. [Google Scholar] [CrossRef]

- Liu, J.; Dong, Y.; Zhu, Z.; Zhao, H.; Pang, J.; Wang, P.; Zhang, J. Fe-based amorphous magnetic powder cores with low core loss fabricated by novel gas–water combined atomization powders. Materials 2022, 15, 6296. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Zhang, W.; Yuan, W.; Peng, K. Preparation and magnetic properties of core–shell structured Fe-Si/Fe3O4 composites via in-situ reaction method. J. Magn. Magn. Mater. 2021, 531, 167955. [Google Scholar] [CrossRef]

- Liu, X.; Zhang, Z.; Guo, W.; Zhang, R.; Xu, F. Ultra-low core loss and high permeability Fe-based amorphous soft magnetic composites with ultra-fine FeNi additives. J. Mater. Sci. Mater. Electron. 2024, 35, 1655. [Google Scholar] [CrossRef]

- Anhalt, M.; Weidenfeller, B. Theoretical and experimental approach to characteristic magnetic measurement data of polymer bonded soft magnetic composites. J. Appl. Phys. 2009, 105, 113903. [Google Scholar] [CrossRef]

- Liu, Z.; Dong, Y.; Liu, X.; Lu, H.; Wu, Y.; Zhang, H.; He, A.; Li, J.; Wang, X. Microstructure and soft magnetic properties of Fe85−xSi9.6Al5.4Tix composite magnetic powder cores. J. Alloys Compd. 2021, 885, 160924. [Google Scholar] [CrossRef]

- Abdel-Aal, S.K.; Abdel-Rahman, A.S. Fascinating physical properties of 2D hybrid perovskite [(NH3)(CH2)7(NH3)]CuClxBr4−x, x = 0, 2 and 4. J. Electron. Mater. 2019, 48, 1686–1693. [Google Scholar] [CrossRef]

- Wu, T.; Ju, D.; Wang, C.; Huang, H.; Li, C.; Wu, C.; Wang, C.; Liu, H.; Jiang, X.; Ye, K. Ferrite materials with high saturation magnetic induction intensity and high permeability for magnetic field energy harvesting: Magnetization mechanism and Brillouin function temperature characteristics. J. Alloys Compd. 2023, 933, 167654. [Google Scholar] [CrossRef]

- Qiu, Y.; Wang, R.; He, Y.; Kong, H.; Li, S.; Wu, Z. Effects of axial pressure on the evolution of core–shell heterogeneous structures and magnetic properties of Fe–Si soft magnetic powder cores during hot-press sintering. RSC Adv. 2022, 12, 19875–19884. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; He, Y.; Kong, H.; Wang, J.; Wu, Z.; Wang, H. Influence of sintering temperature on heterogeneous-interface structural evolution and magnetic properties of Fe–Si soft magnetic powder cores. Ceram. Int. 2022, 48, 29854–29861. [Google Scholar] [CrossRef]

- Wang, R.; Huang, H.; Li, K.; Yang, J.; Wu, Z.; Kong, H. Design and evolution of Fe–Si–Al soft magnetic composites doped with carbonyl iron powders: Overcoming the restrictive relation between permeability and core loss. Ceram. Int. 2024, 50, 17861–17872. [Google Scholar] [CrossRef]

- Bertotti, G. General properties of power losses in soft ferromagnetic materials. IEEE Trans. Magn. 1988, 24, 621–630. [Google Scholar] [CrossRef]

- Zhang, Y.; Huijuan, J.; Ying, S. General properties of low-frequency power losses in Fe-based nanocrystalline soft magnetic alloys. J. Mater. Sci. Technol. 2000, 16, 37. [Google Scholar]

- Füzerová, J.; Füzer, J.; Kollár, P.; Bureš, R.; Fáberová, M. Complex permeability and core loss of soft magnetic Fe-based nanocrystalline powder cores. J. Magn. Magn. Mater. 2013, 345, 77–81. [Google Scholar] [CrossRef]

- Peng, X.; Zhang, A.; Li, J.; Yu, S.; Chang, J.; Ge, M.; Yang, Y.; Xu, J.; Hong, B.; Jin, D. Design and fabrication of Fe–Si–Al soft magnetic composites by controlling orientation of particles in a magnetic field: Anisotropy of structures, electrical and magnetic properties. J. Mater. Sci. 2019, 54, 8719–8726. [Google Scholar] [CrossRef]

- Choi, Y.J.; Ahn, J.H.; Kim, D.H.; Kim, Y.R.; Lee, B.W. Core-loss reduction of Fe–Si–Cr crystalline alloy according to particle size in the high frequency band. Curr. Appl. Phys. 2022, 39, 324–330. [Google Scholar] [CrossRef]

- Wu, S.; Dong, Y.; Li, X.; Gong, M.; Zhao, R.; Gao, W.; Wu, H.; He, A.; Li, J.; Wang, X. Microstructure and magnetic properties of FeSiCr soft magnetic powder cores with a MgO insulating layer prepared by the sol-gel method. Ceram. Int. 2022, 48, 22237–22245. [Google Scholar] [CrossRef]

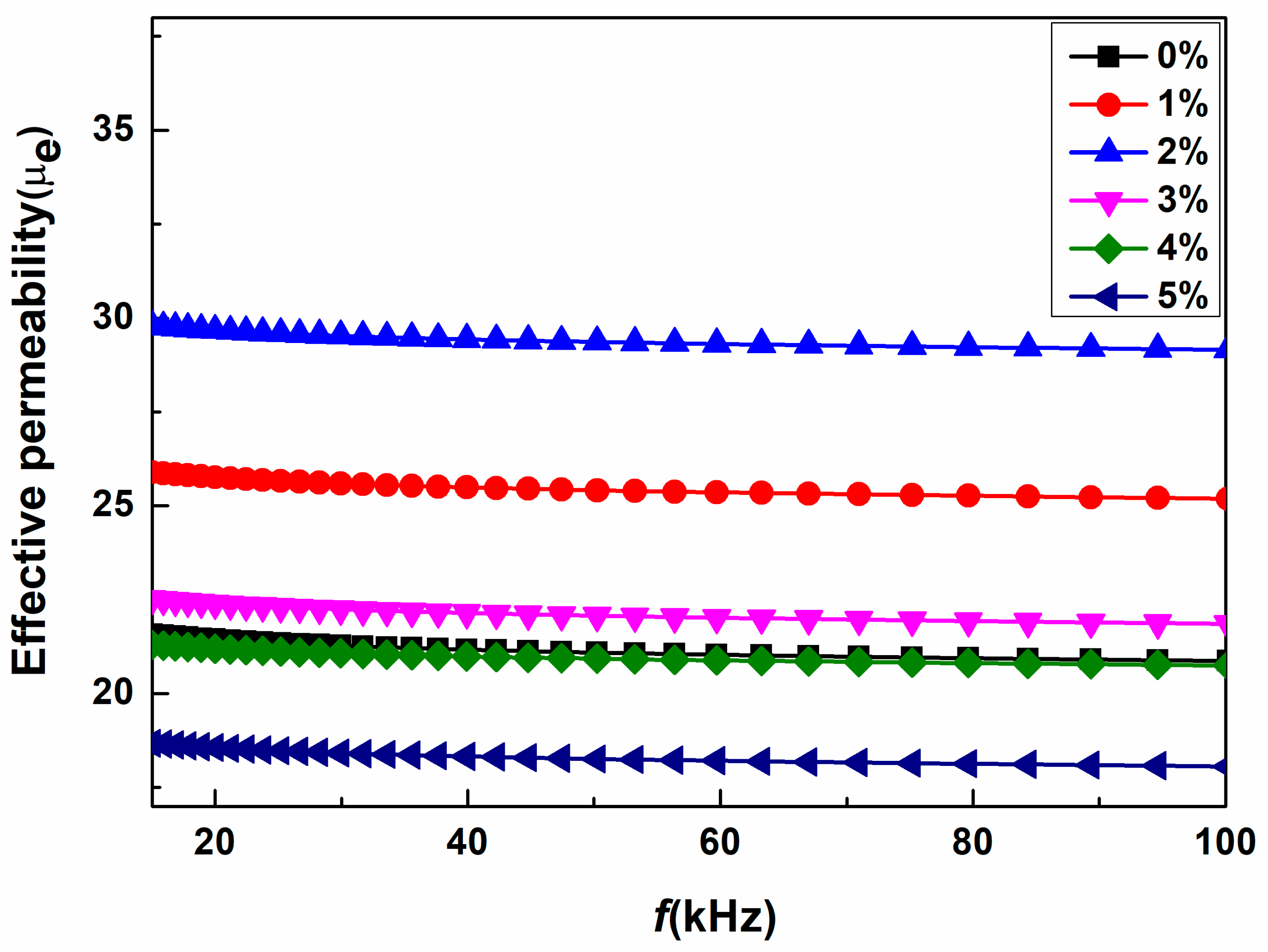

| Contents wt% | 0 wt% | 1 wt% | 2 wt% | 3 wt% | 4 wt% | 5 wt% |

|---|---|---|---|---|---|---|

| Ms | 187.6 | 191.21 | 191.31 | 189.36 | 188.98 | 189.9 |

| Hc | 12.27 | 11.83 | 11.55 | 12.27 | 12.75 | 10.78 |

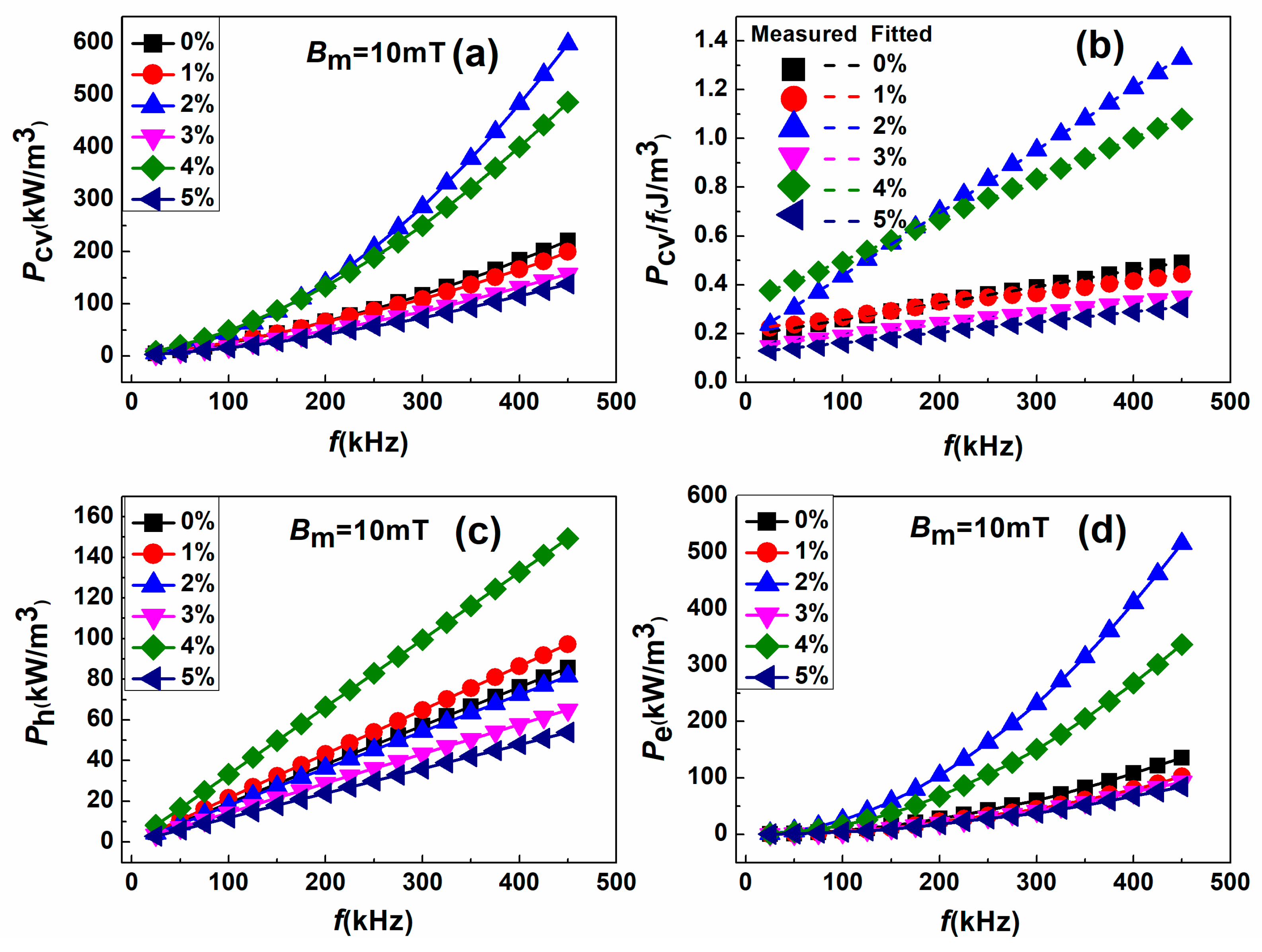

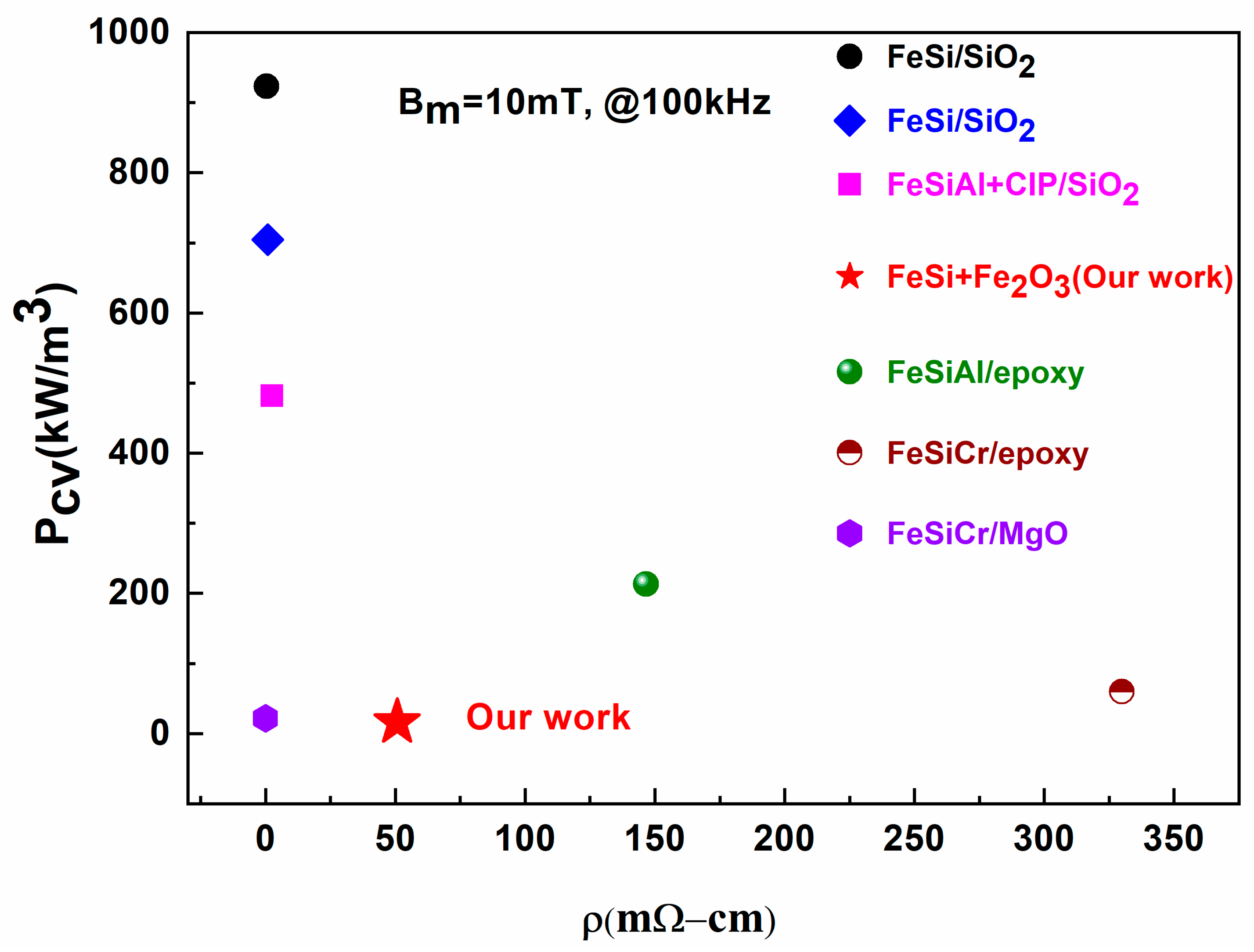

| Contents wt% | Pcv(kW/m3) f = 100 kHz, Bm = 10 mT | Ph(kW/m3) f = 100 kHz, Bm = 10 mT | Pe(kW/m3) f = 100 kHz, Bm = 10 mT | μe | ρ (g/cm3) | ρ (mΩ-cm) |

|---|---|---|---|---|---|---|

| 0 | 25.63 | 19.02 | 6.61 | 21.57 | 6.56 | 29.55 |

| 1 | 26.68 | 21.61 | 5.07 | 25.89 | 6.88 | 30.23 |

| 2 | 43.45 | 18.11 | 25.33 | 30.05 | 7.12 | 34.18 |

| 3 | 18.05 | 14.43 | 4.38 | 22.51 | 6.94 | 36.34 |

| 4 | 49.26 | 33.19 | 16.07 | 21.29 | 6.79 | 40.96 |

| 5 | 16.13 | 11.97 | 4.153 | 18.67 | 6.71 | 50.70 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Arif, M.; Han, D.; Shin, W.; Cha, S.; Pak, C.; Kim, Y.; Kim, S.; Lee, B.; Rhyee, J. Ultra-Low Core Loss and High-Frequency Permeability Stability in Hot-Press Sintered FeSi Soft Magnetic Composites by Fe2O3 Nanoparticles Air Gap Filling. Materials 2025, 18, 2013. https://doi.org/10.3390/ma18092013

Arif M, Han D, Shin W, Cha S, Pak C, Kim Y, Kim S, Lee B, Rhyee J. Ultra-Low Core Loss and High-Frequency Permeability Stability in Hot-Press Sintered FeSi Soft Magnetic Composites by Fe2O3 Nanoparticles Air Gap Filling. Materials. 2025; 18(9):2013. https://doi.org/10.3390/ma18092013

Chicago/Turabian StyleArif, Muhammad, Donghun Han, Wonchan Shin, Seunghun Cha, Changsun Pak, Youngkwang Kim, Sangwoo Kim, Bowha Lee, and Jongsoo Rhyee. 2025. "Ultra-Low Core Loss and High-Frequency Permeability Stability in Hot-Press Sintered FeSi Soft Magnetic Composites by Fe2O3 Nanoparticles Air Gap Filling" Materials 18, no. 9: 2013. https://doi.org/10.3390/ma18092013

APA StyleArif, M., Han, D., Shin, W., Cha, S., Pak, C., Kim, Y., Kim, S., Lee, B., & Rhyee, J. (2025). Ultra-Low Core Loss and High-Frequency Permeability Stability in Hot-Press Sintered FeSi Soft Magnetic Composites by Fe2O3 Nanoparticles Air Gap Filling. Materials, 18(9), 2013. https://doi.org/10.3390/ma18092013