Application of Voronoi Tessellation to the Additive Manufacturing of Thermal Barriers of Irregular Porous Materials—Experimental Determination of Thermal Properties

Abstract

1. Introduction

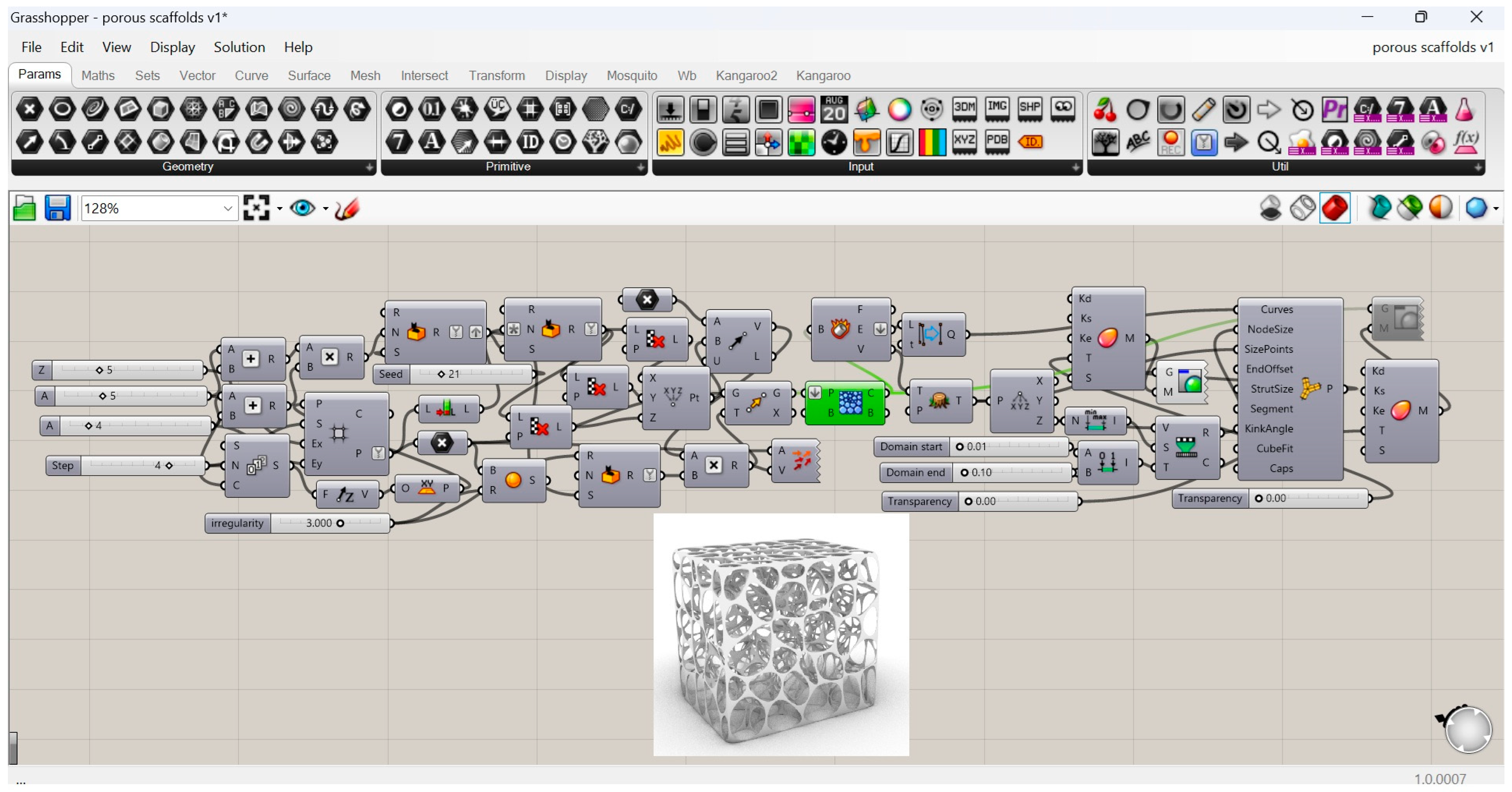

1.1. Parametric Design

1.2. Design of Cellular Composites That Have a Complex Core Geometry–Voronoi Diagram

2. Materials and Methods

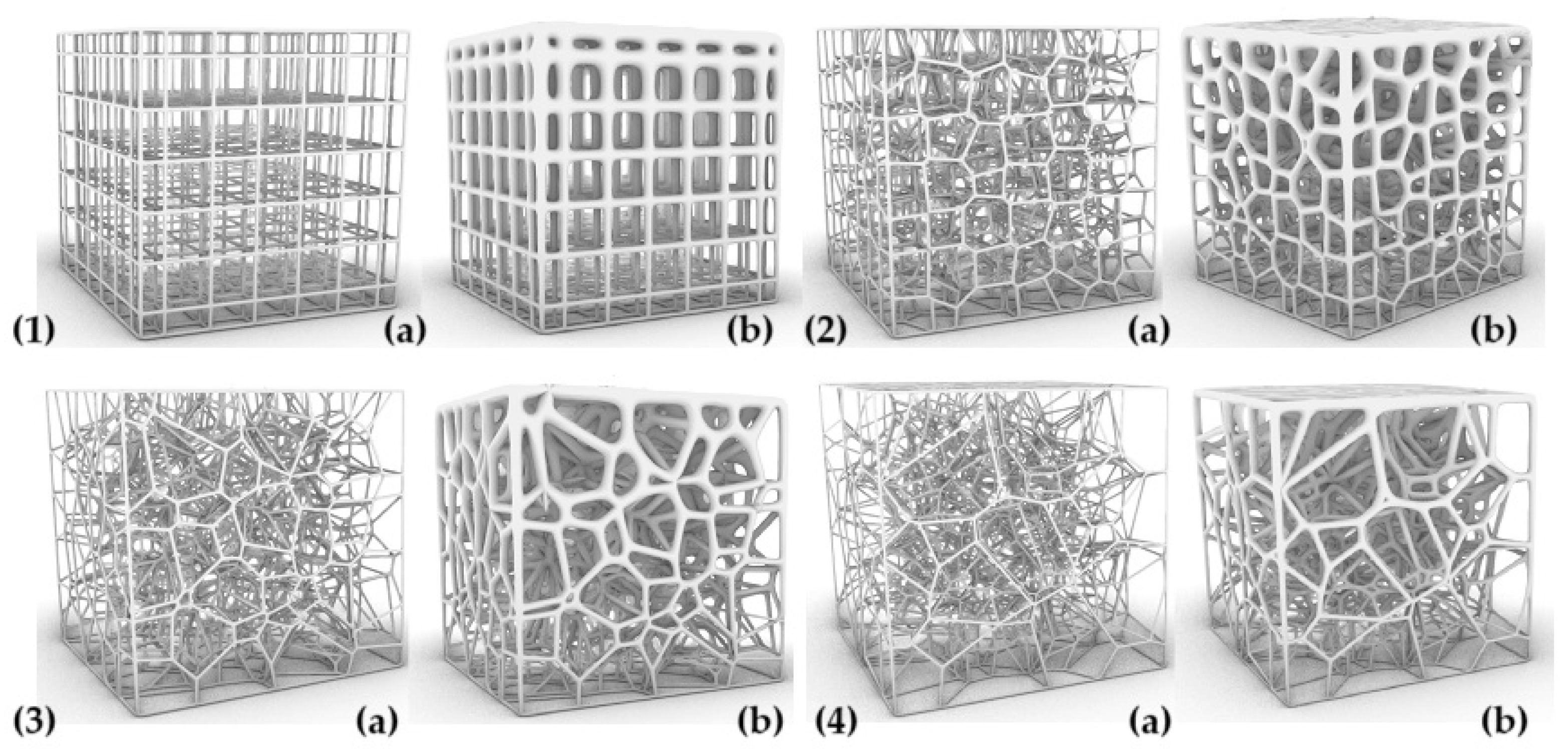

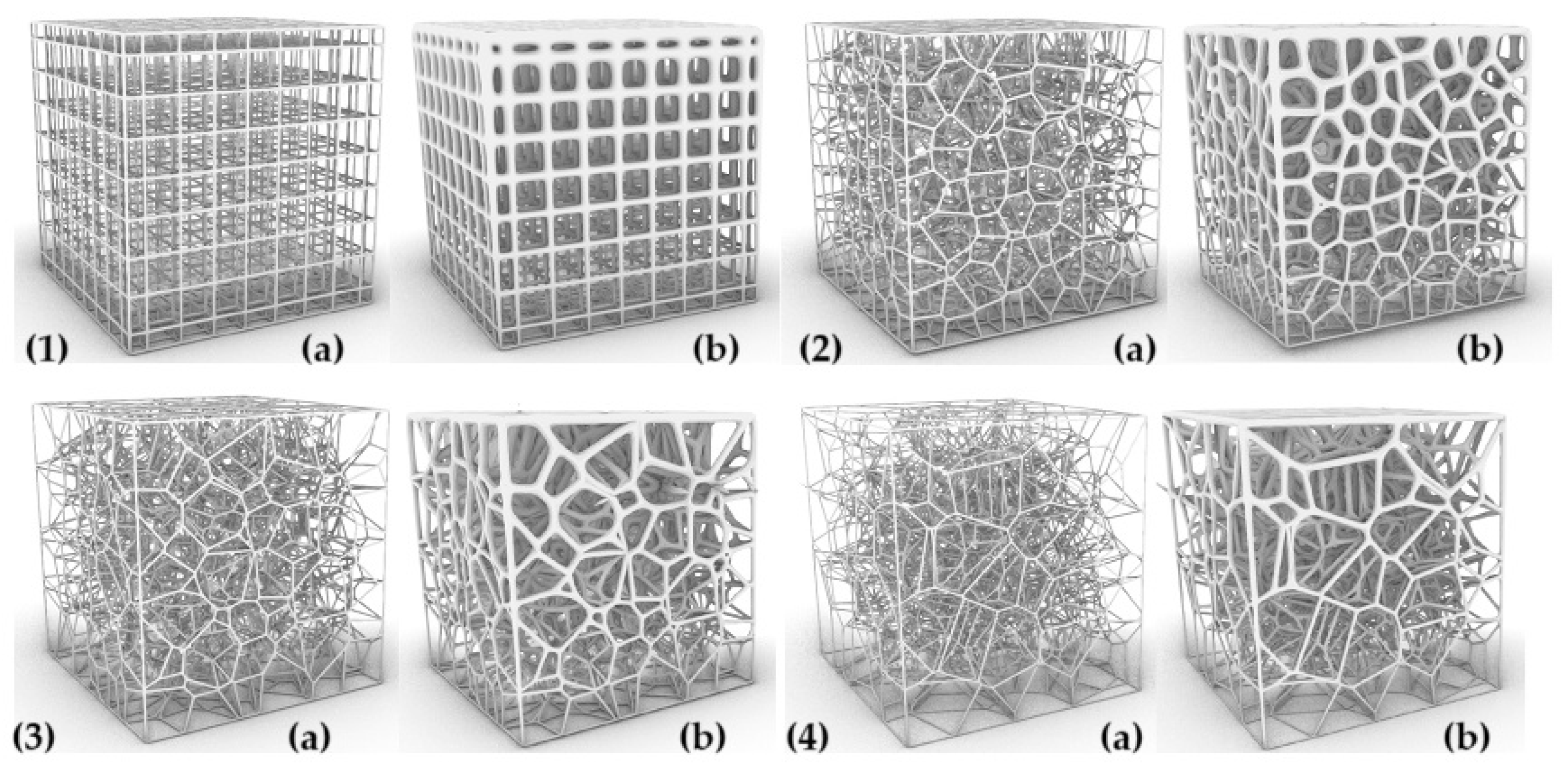

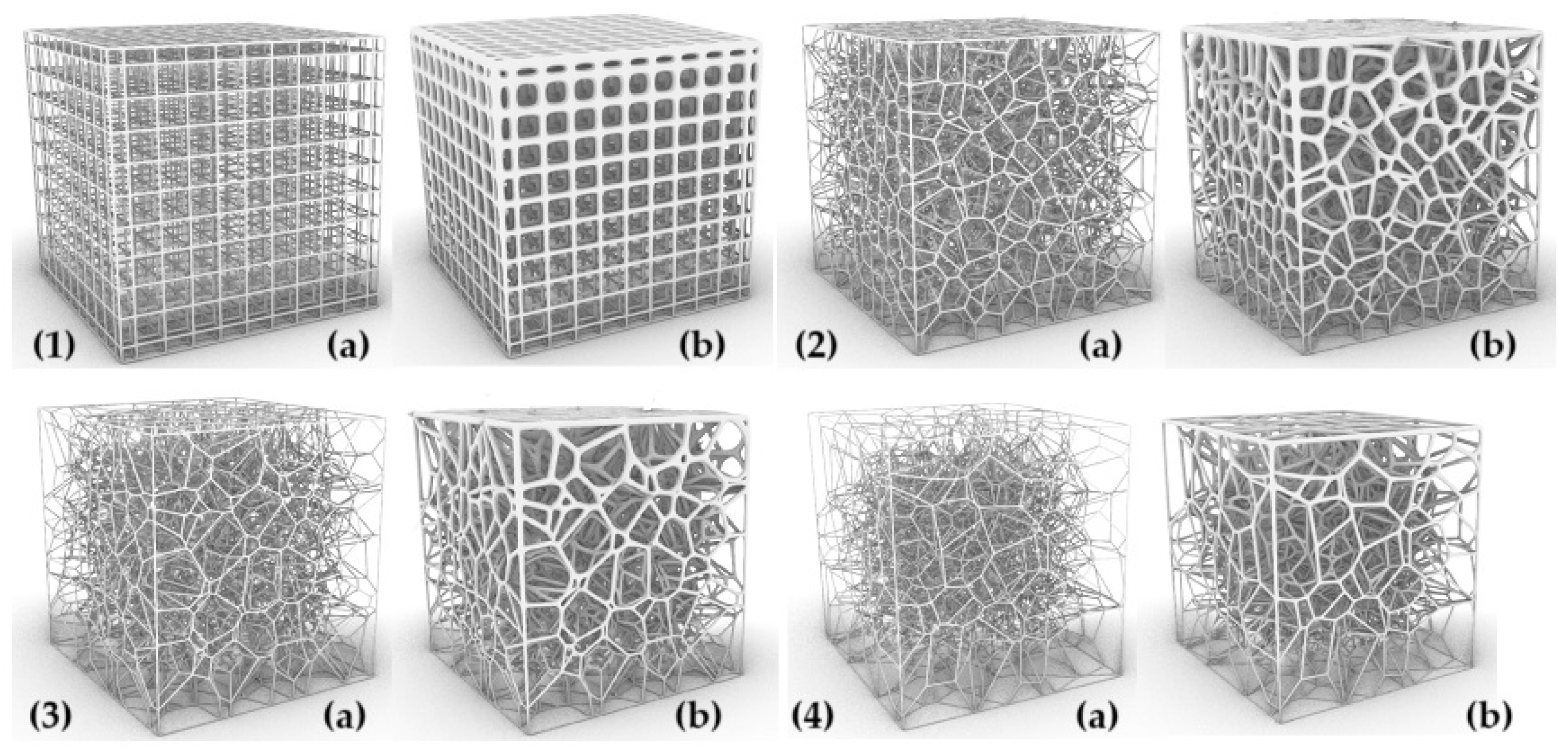

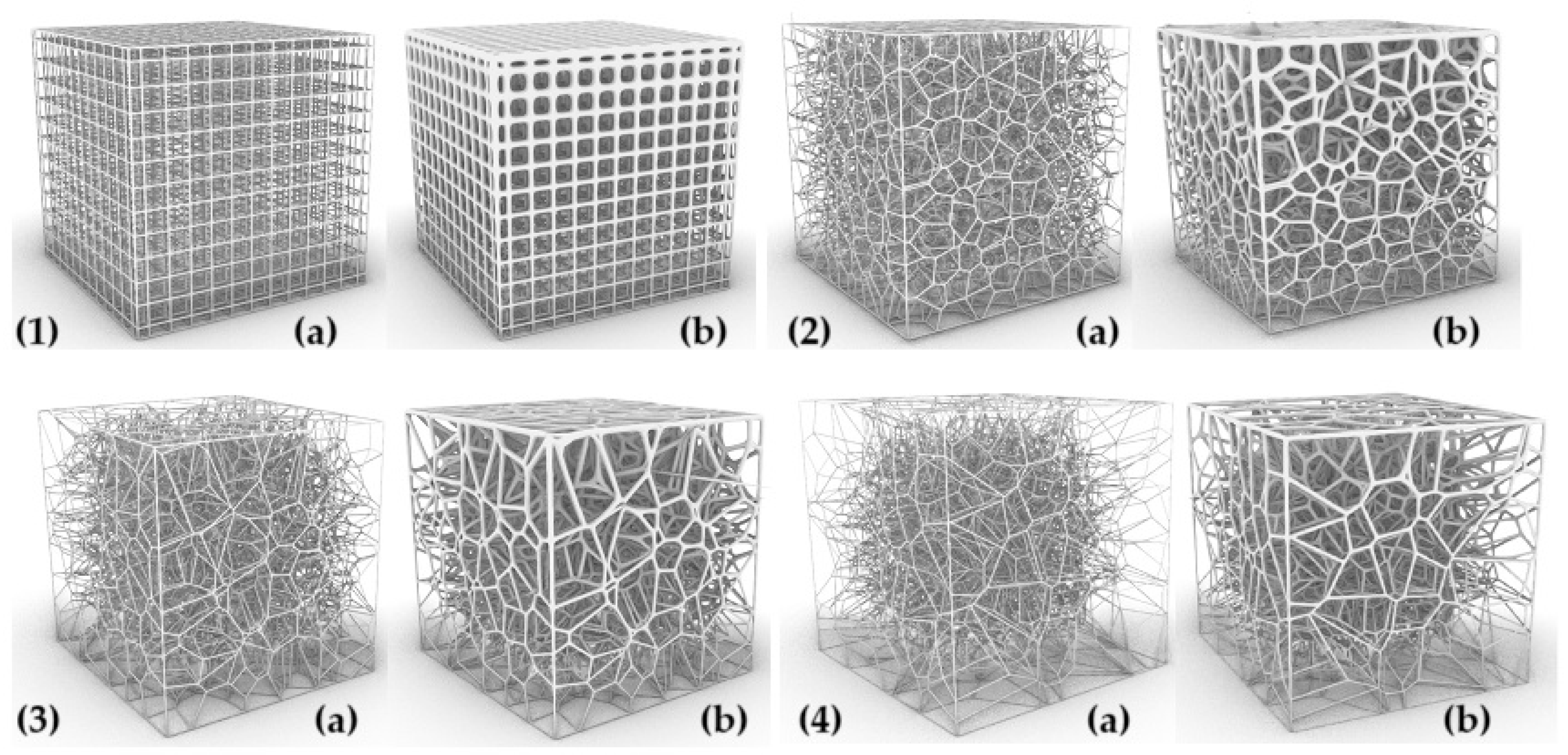

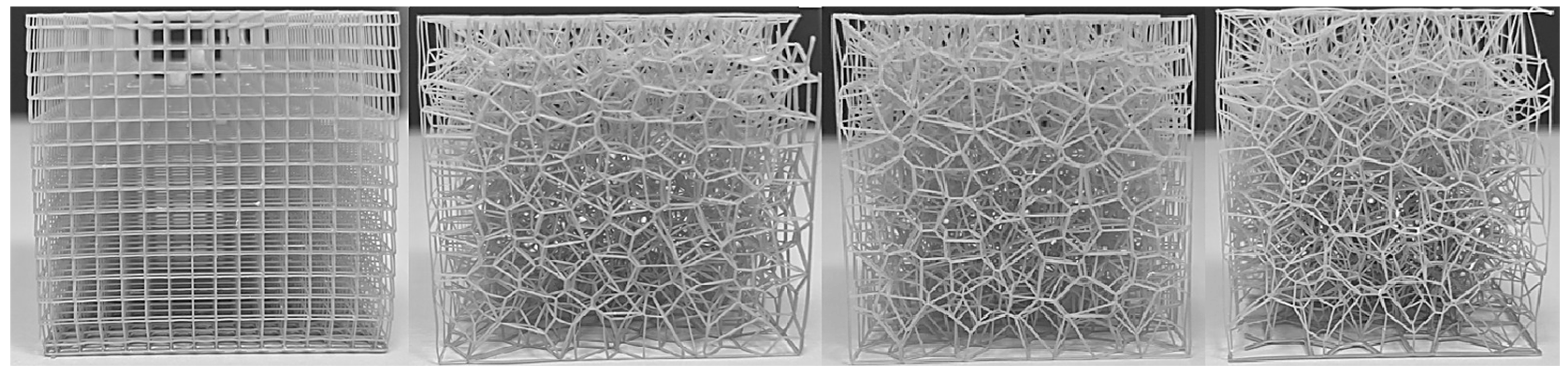

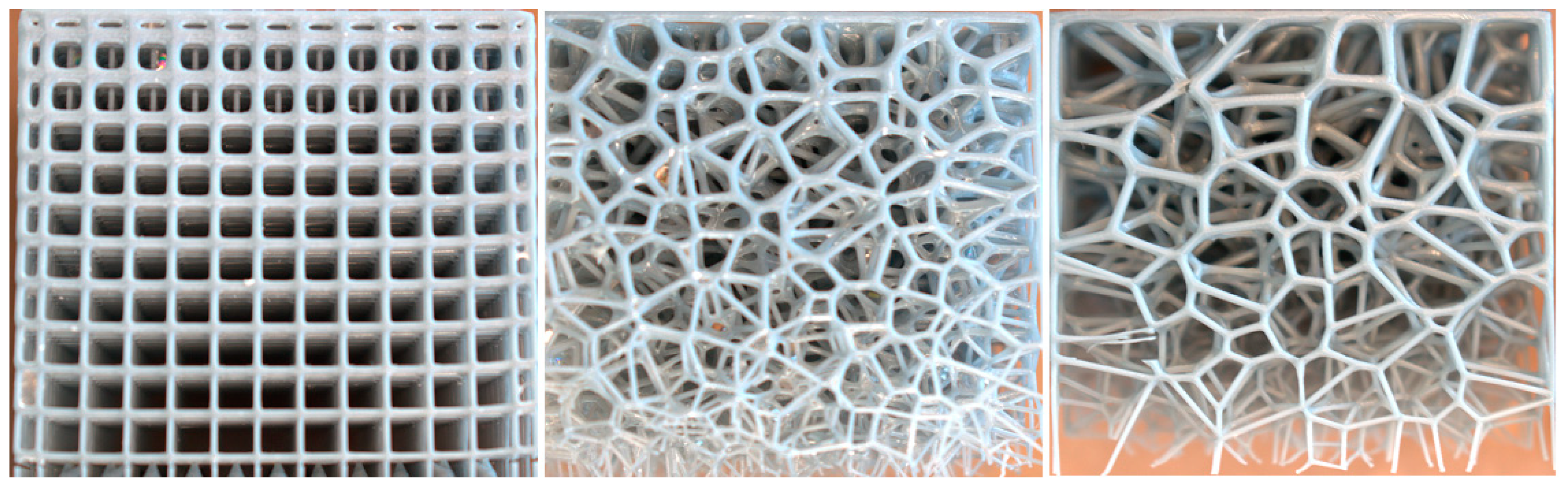

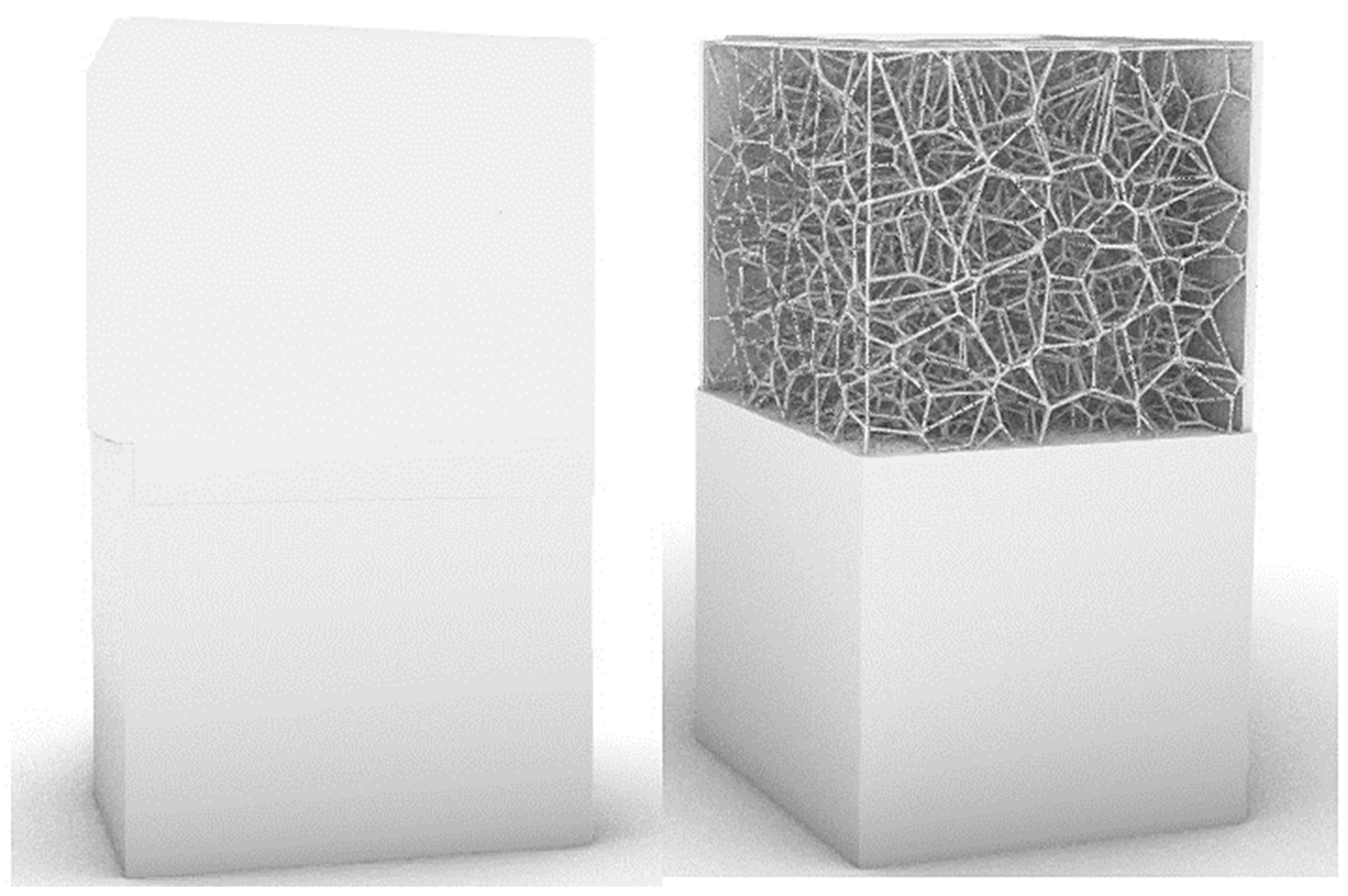

2.1. Materials: Irregular Porous Structure Design

2.2. Experimental Section

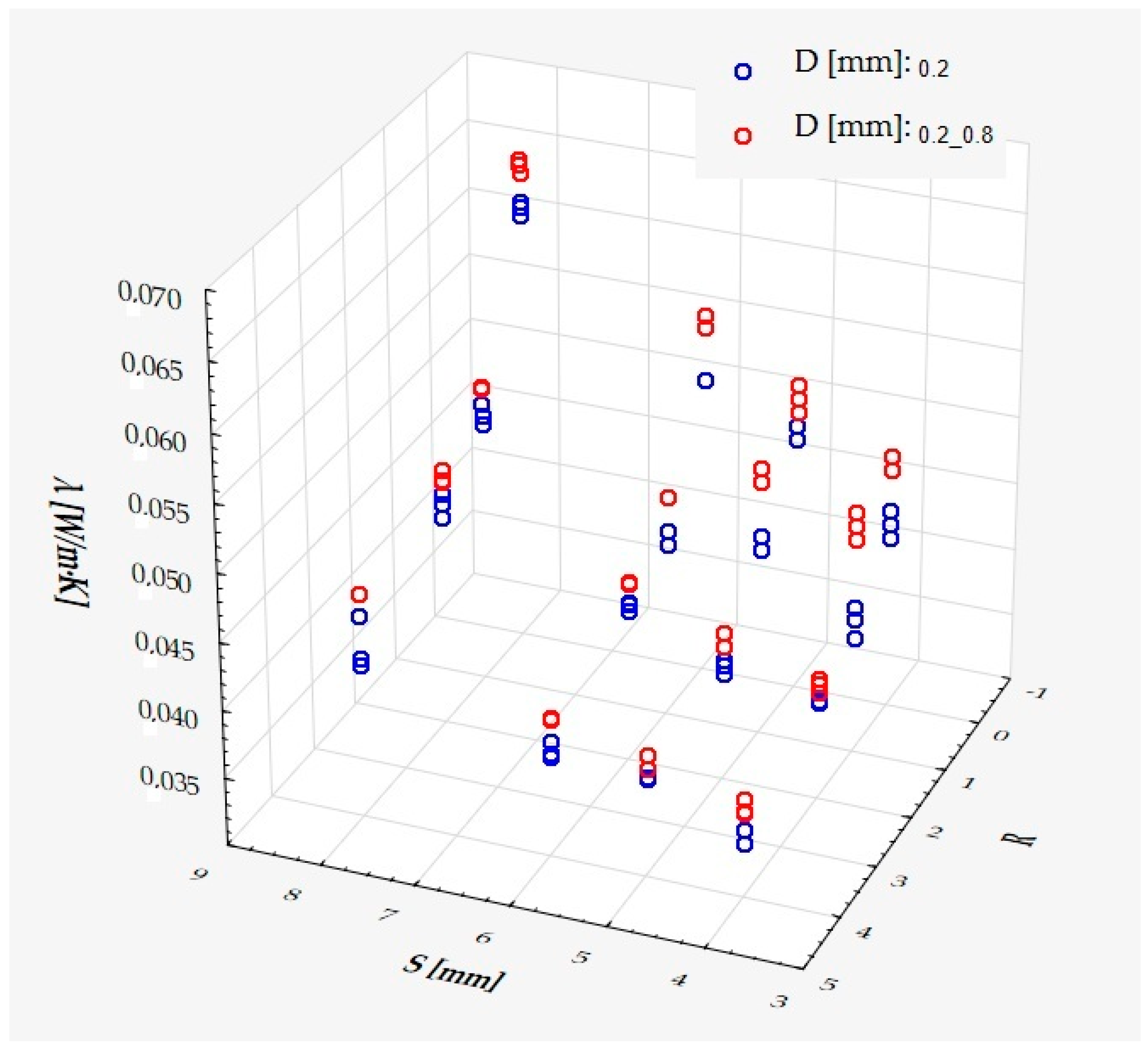

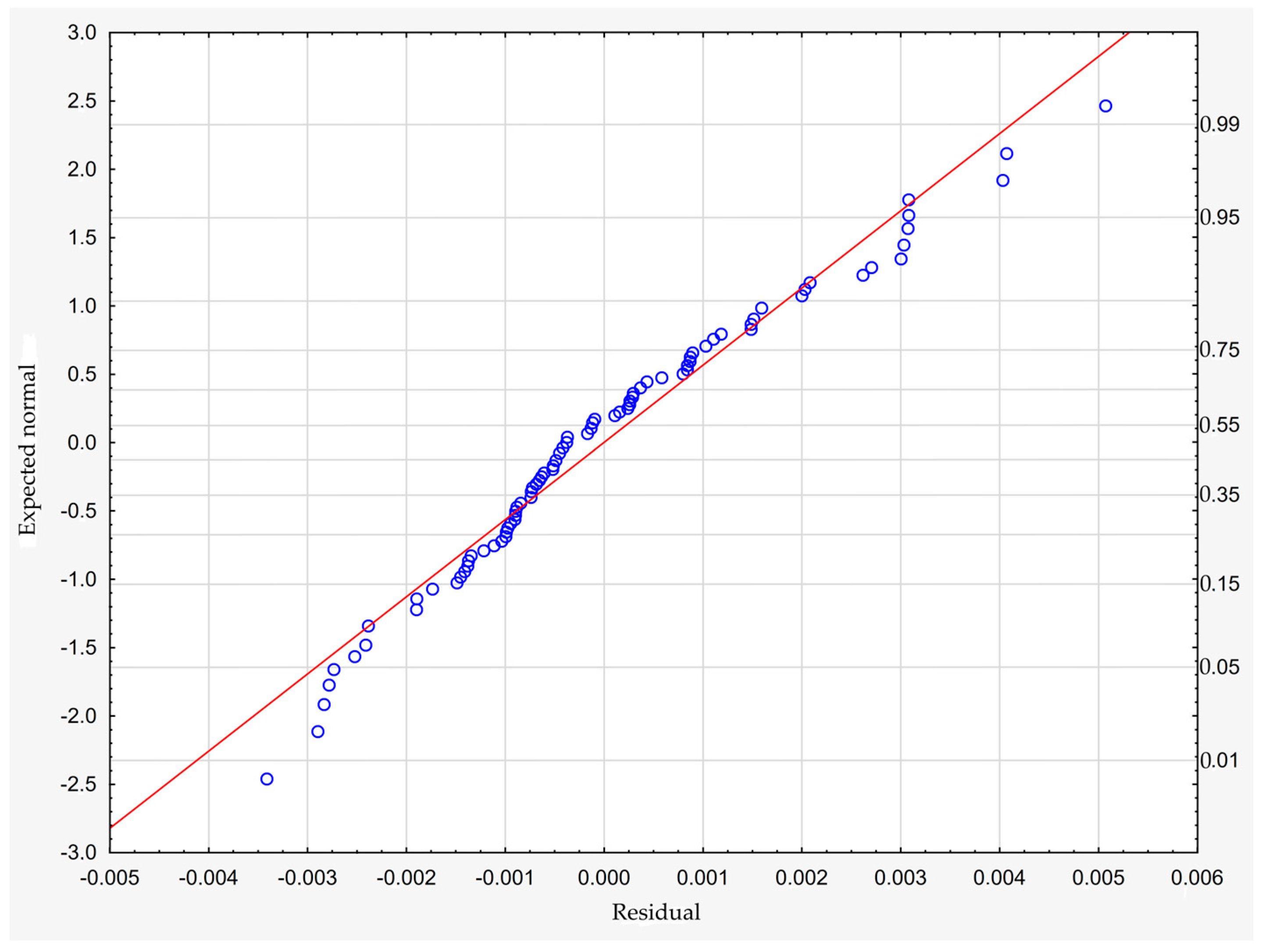

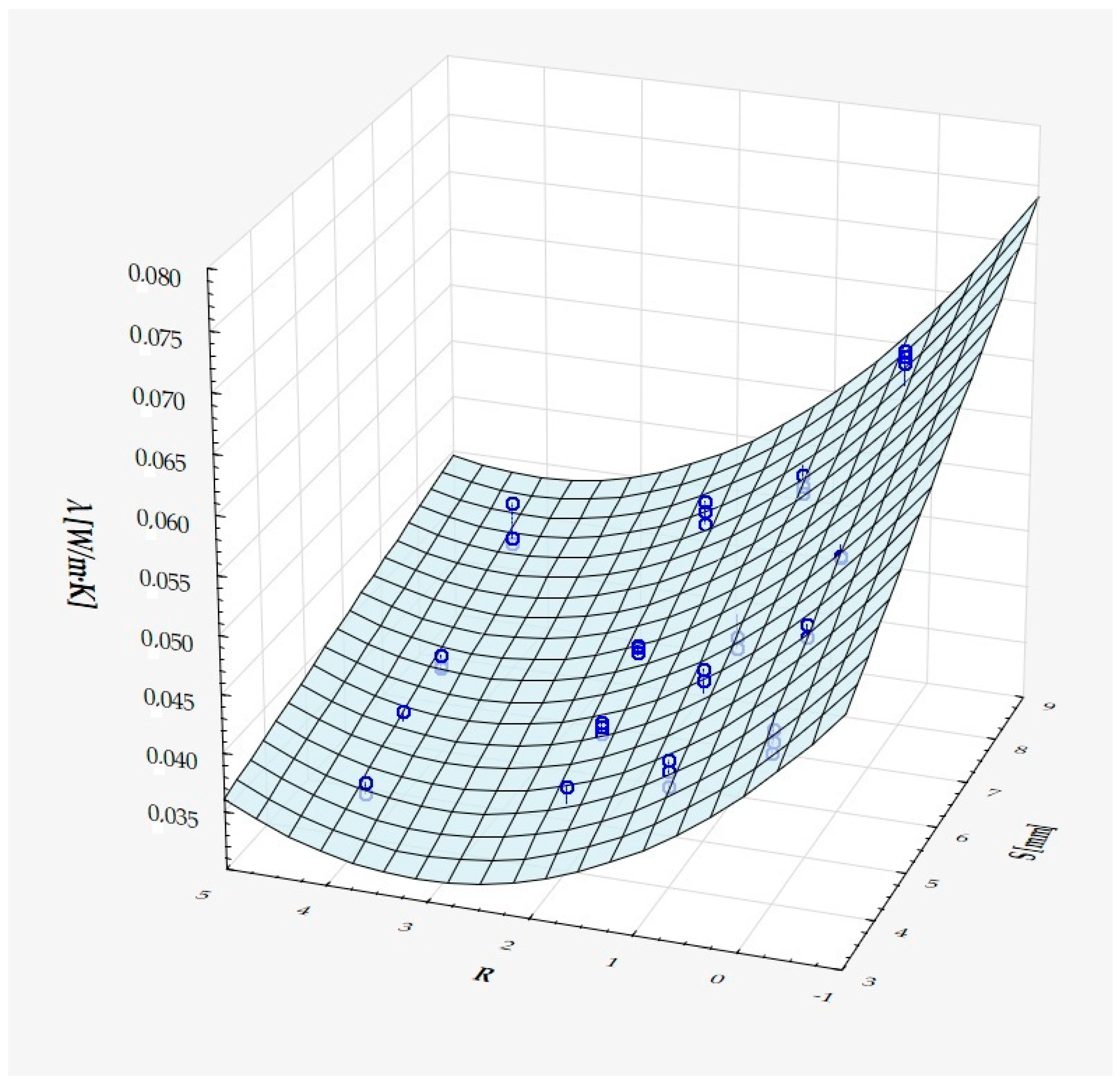

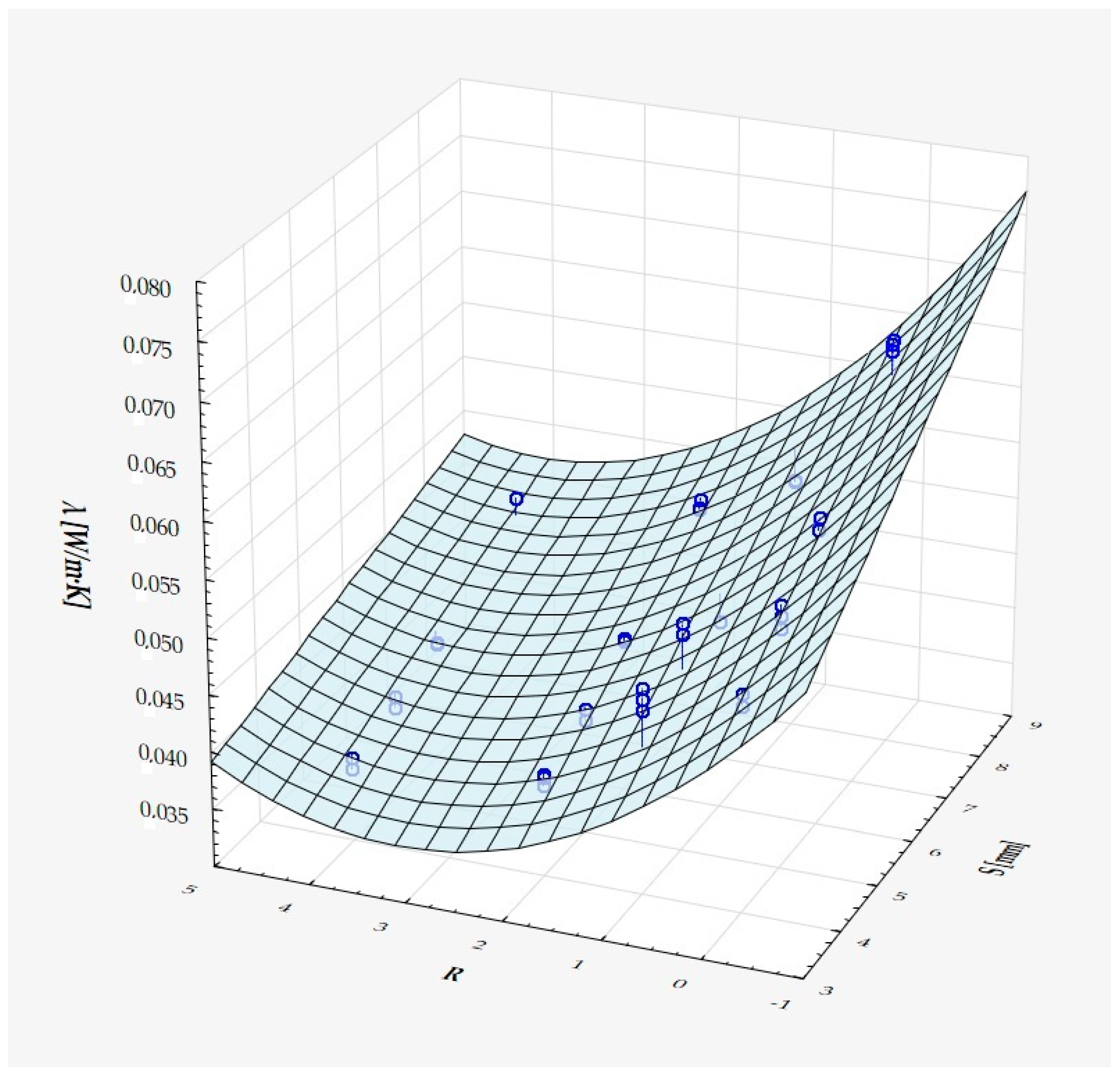

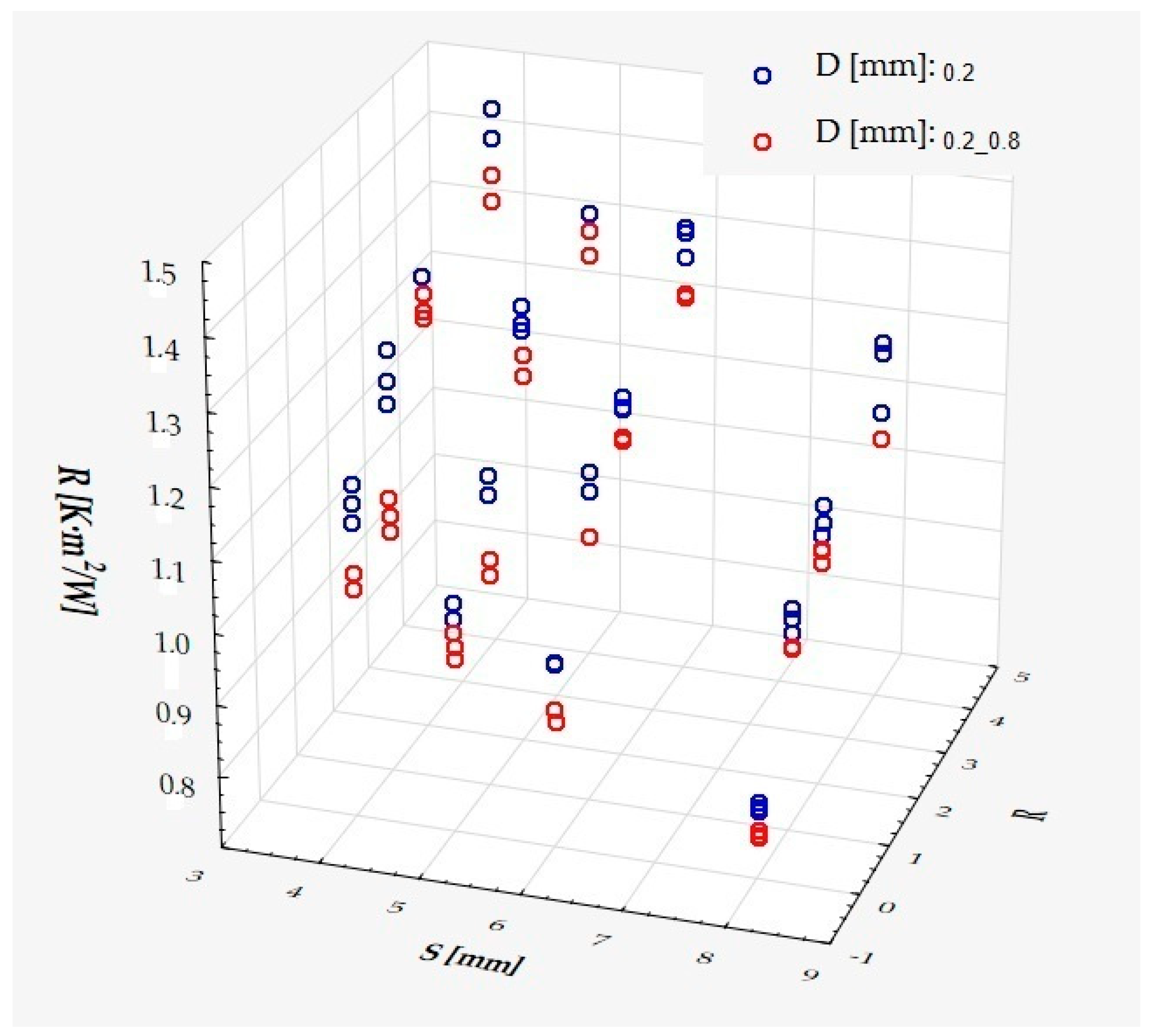

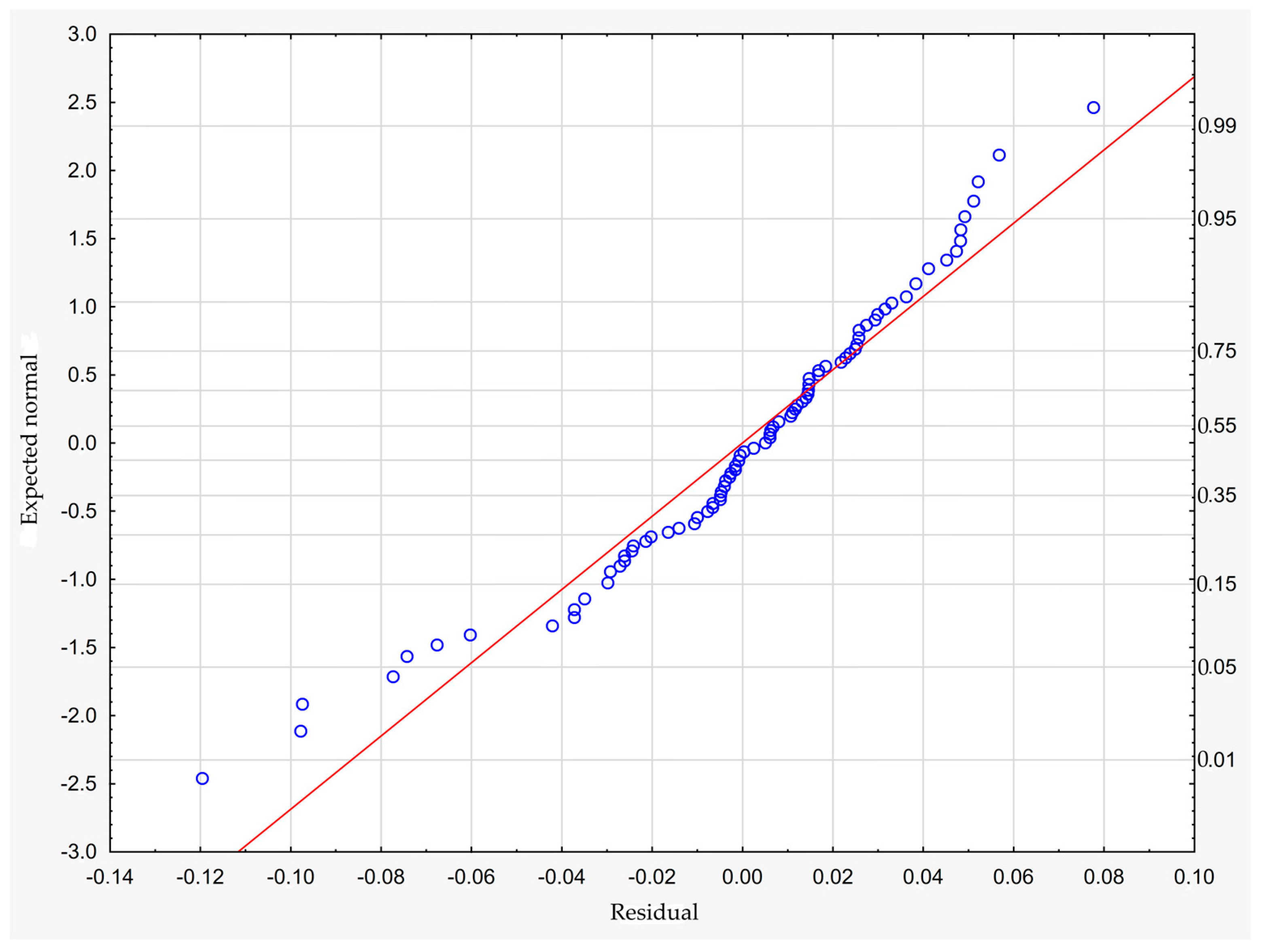

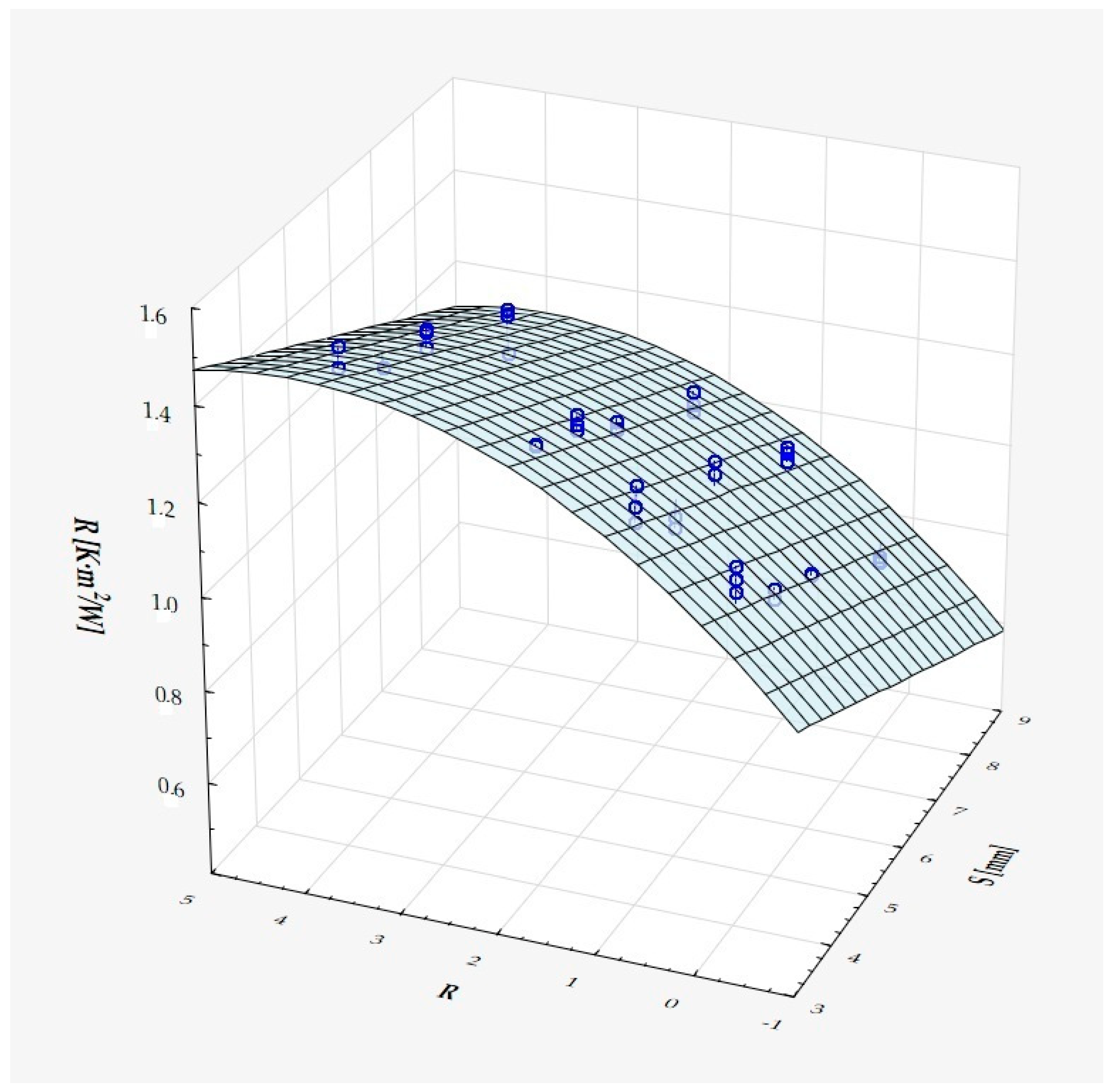

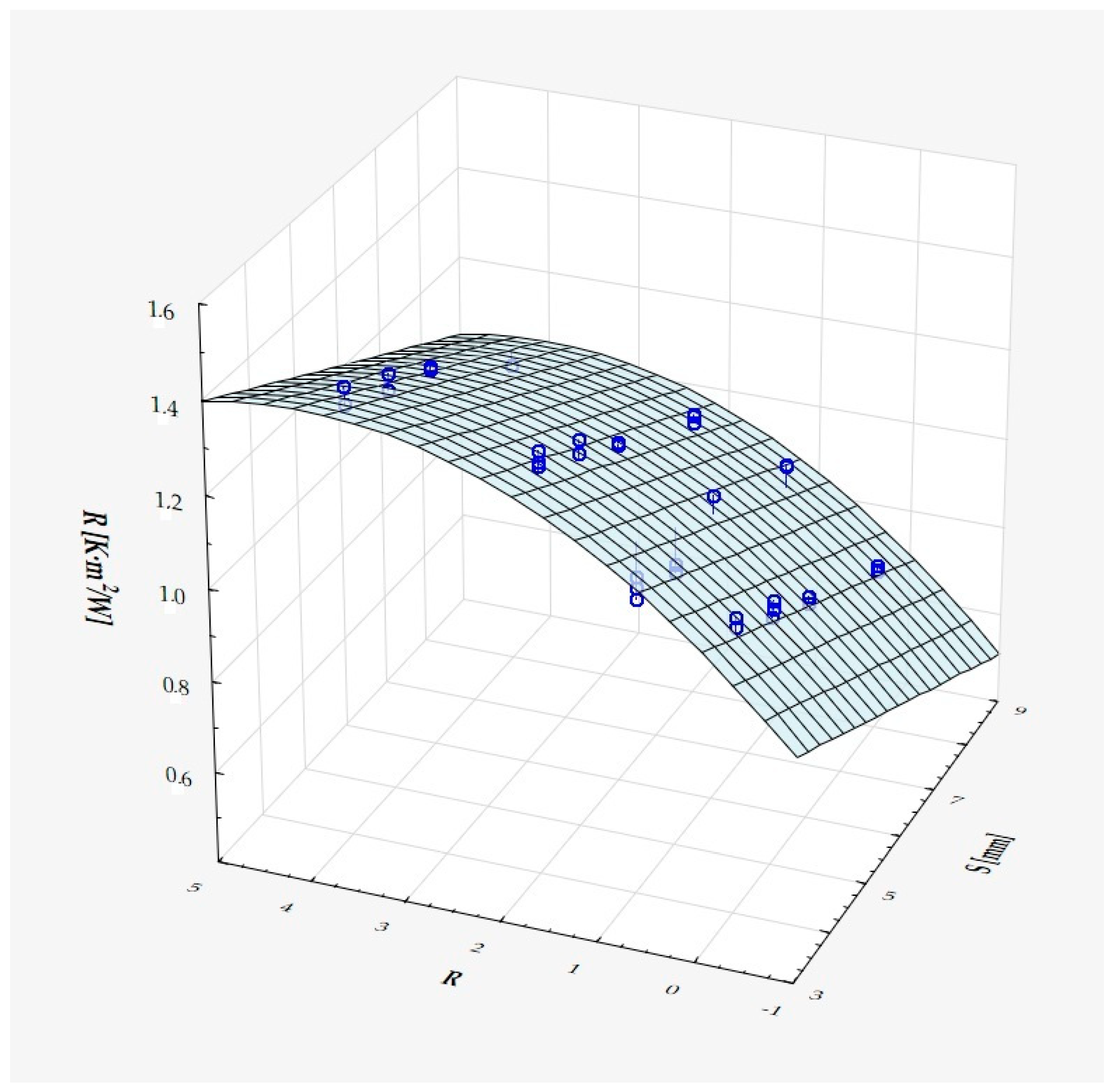

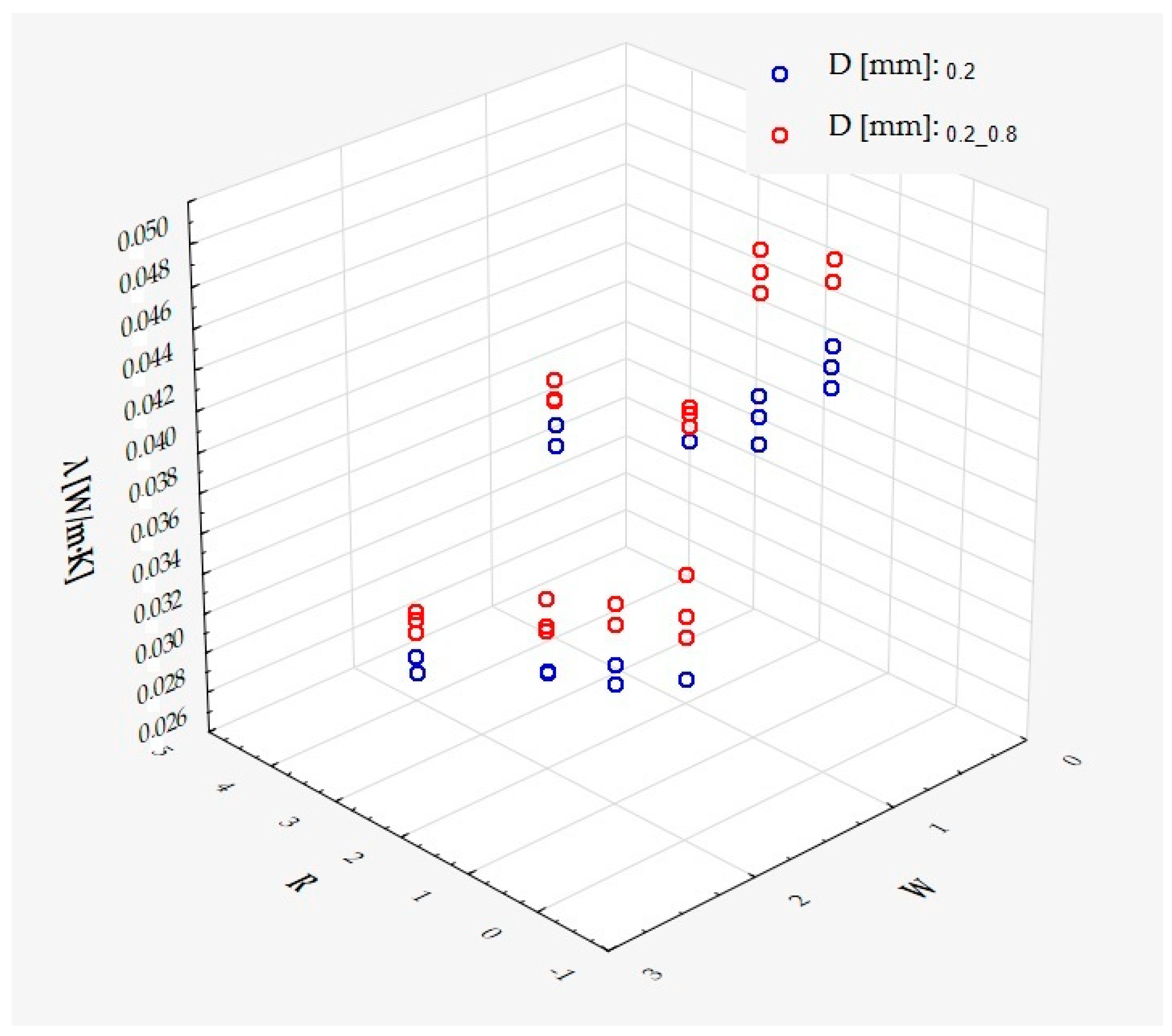

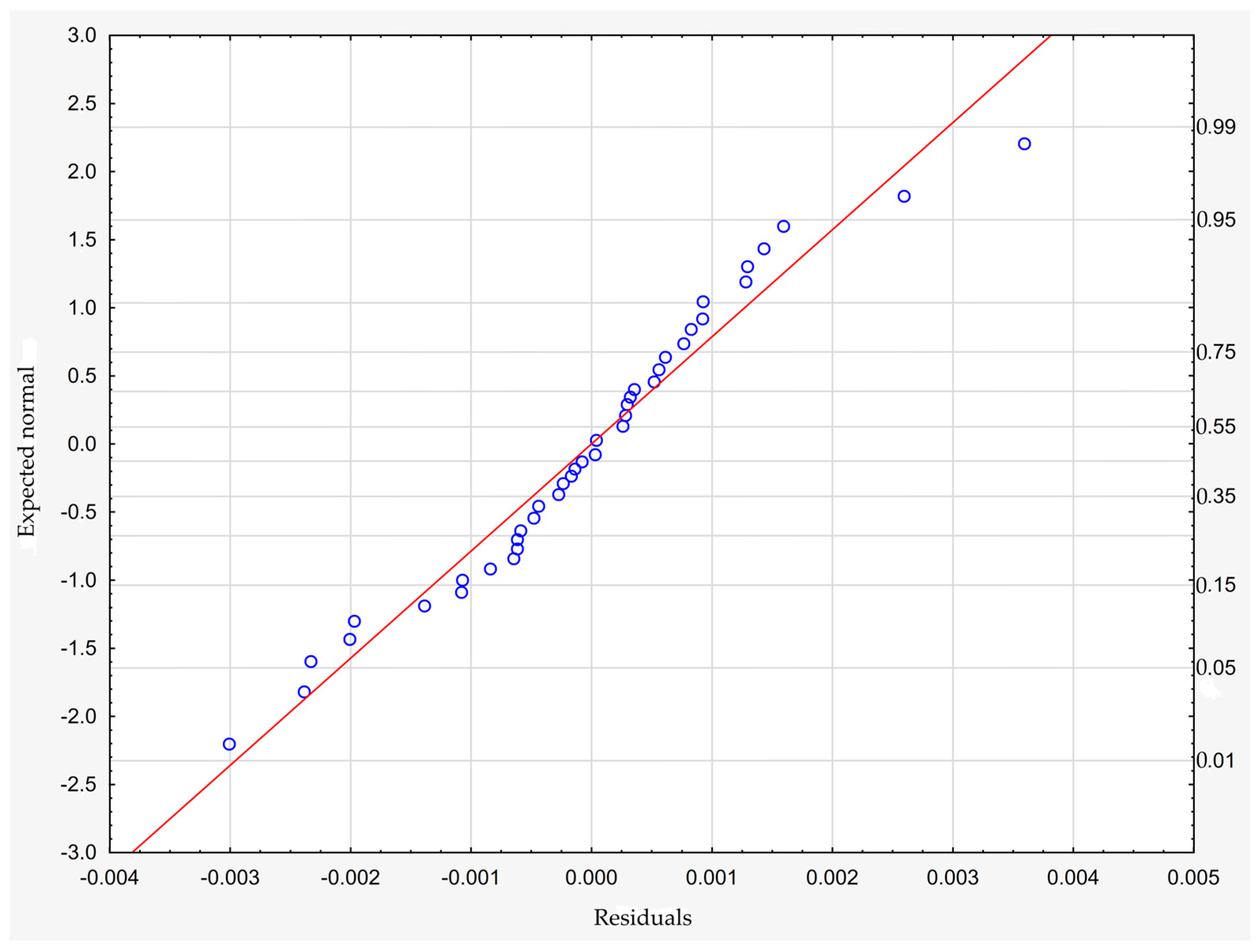

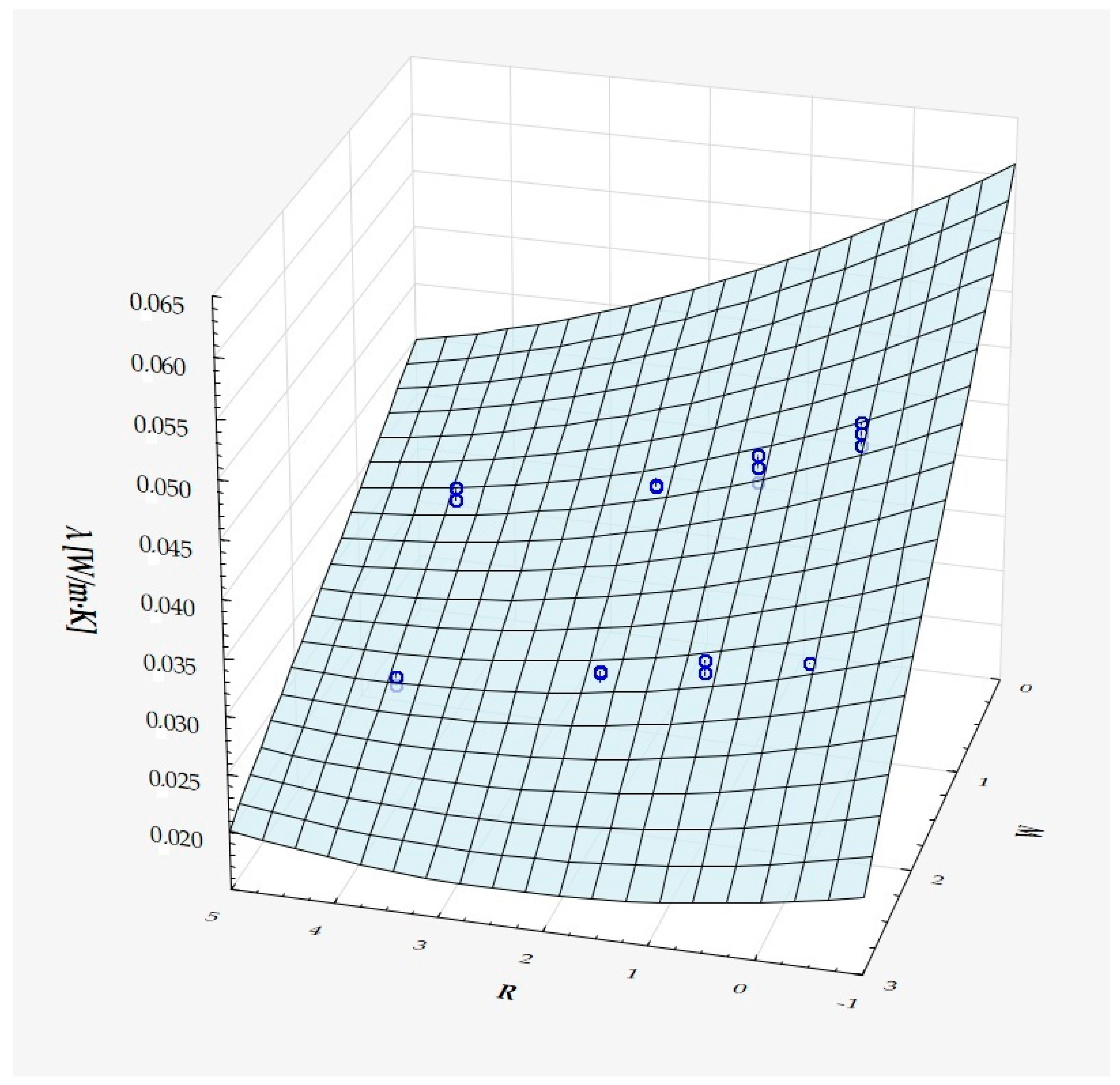

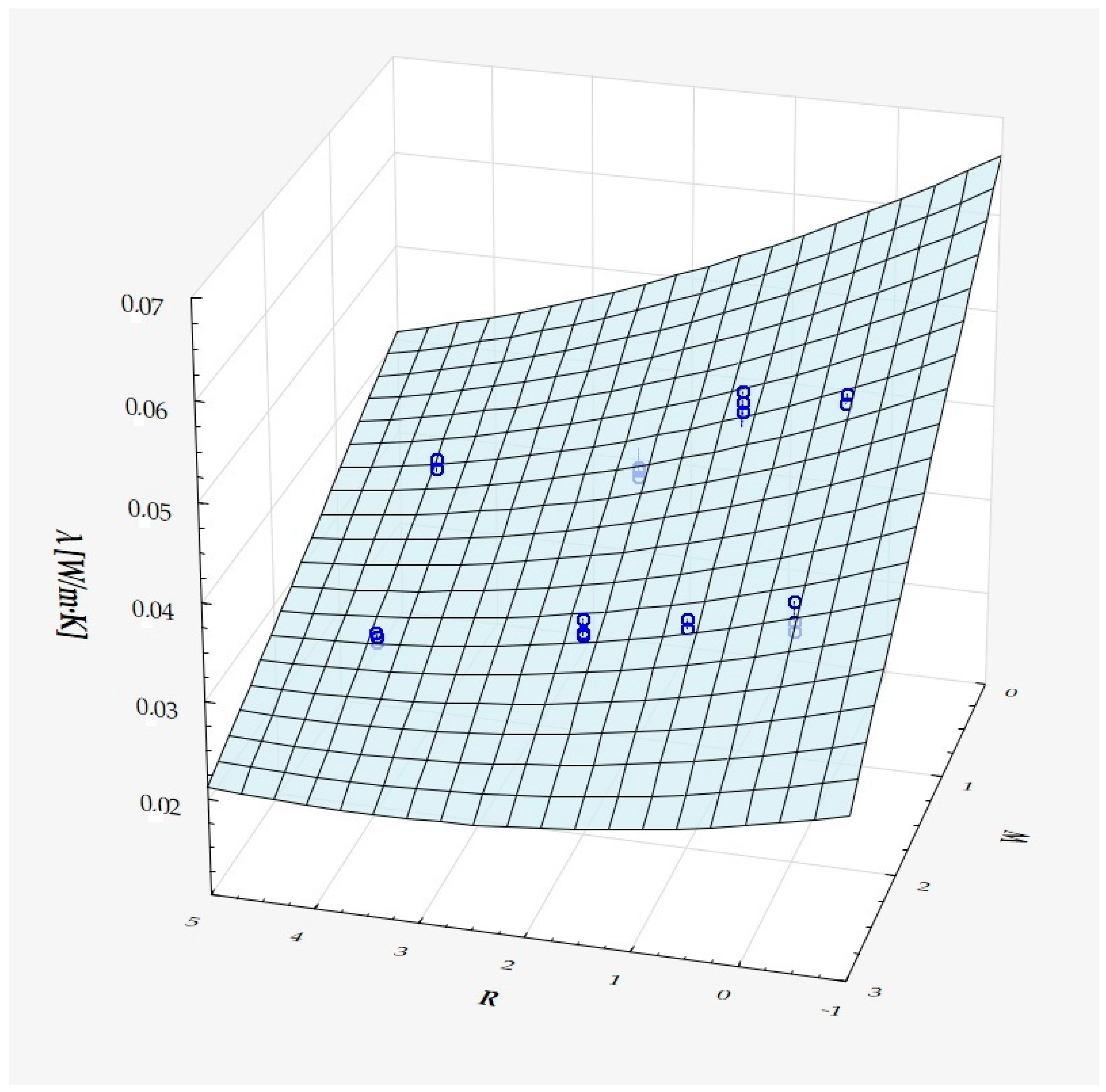

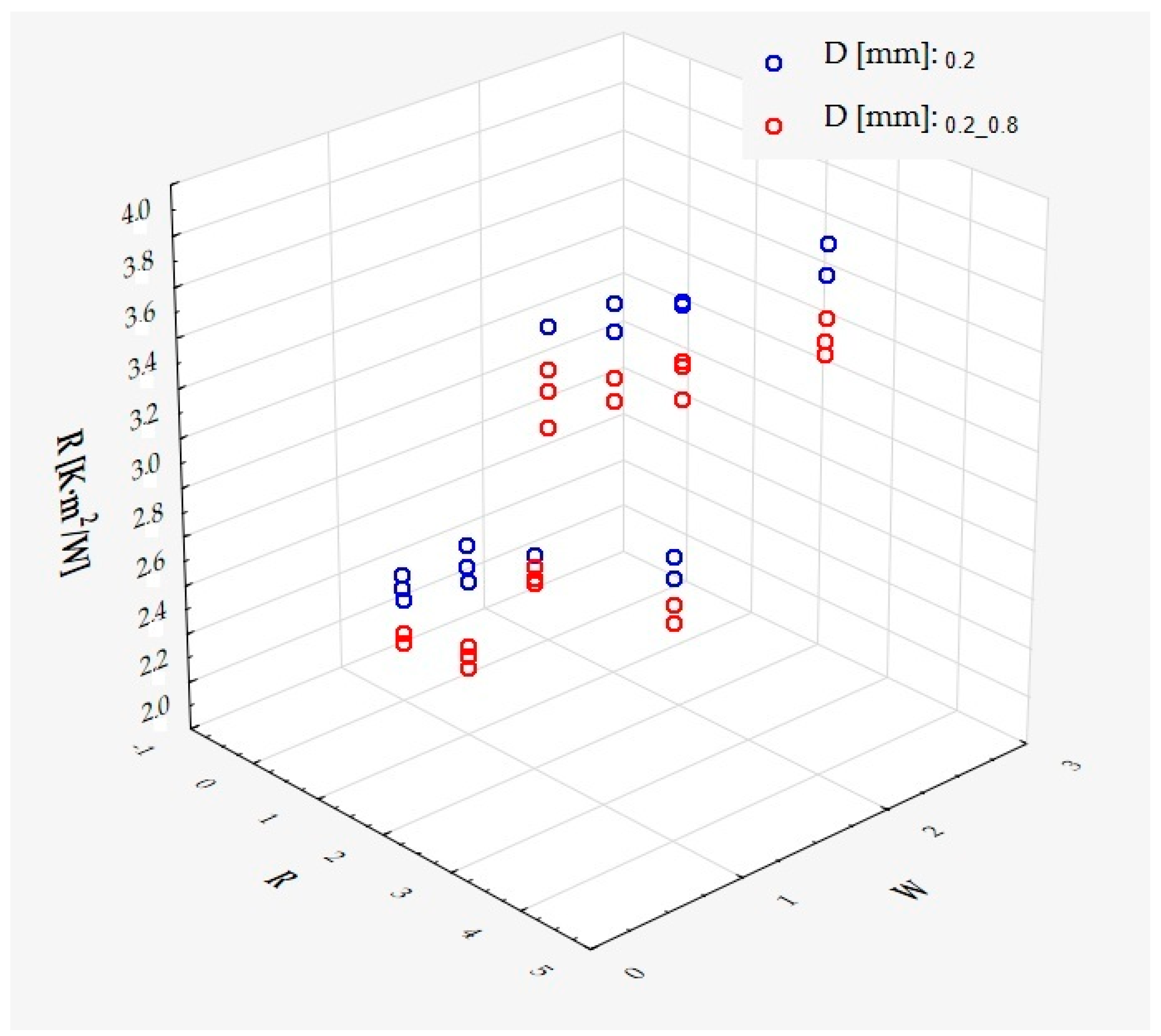

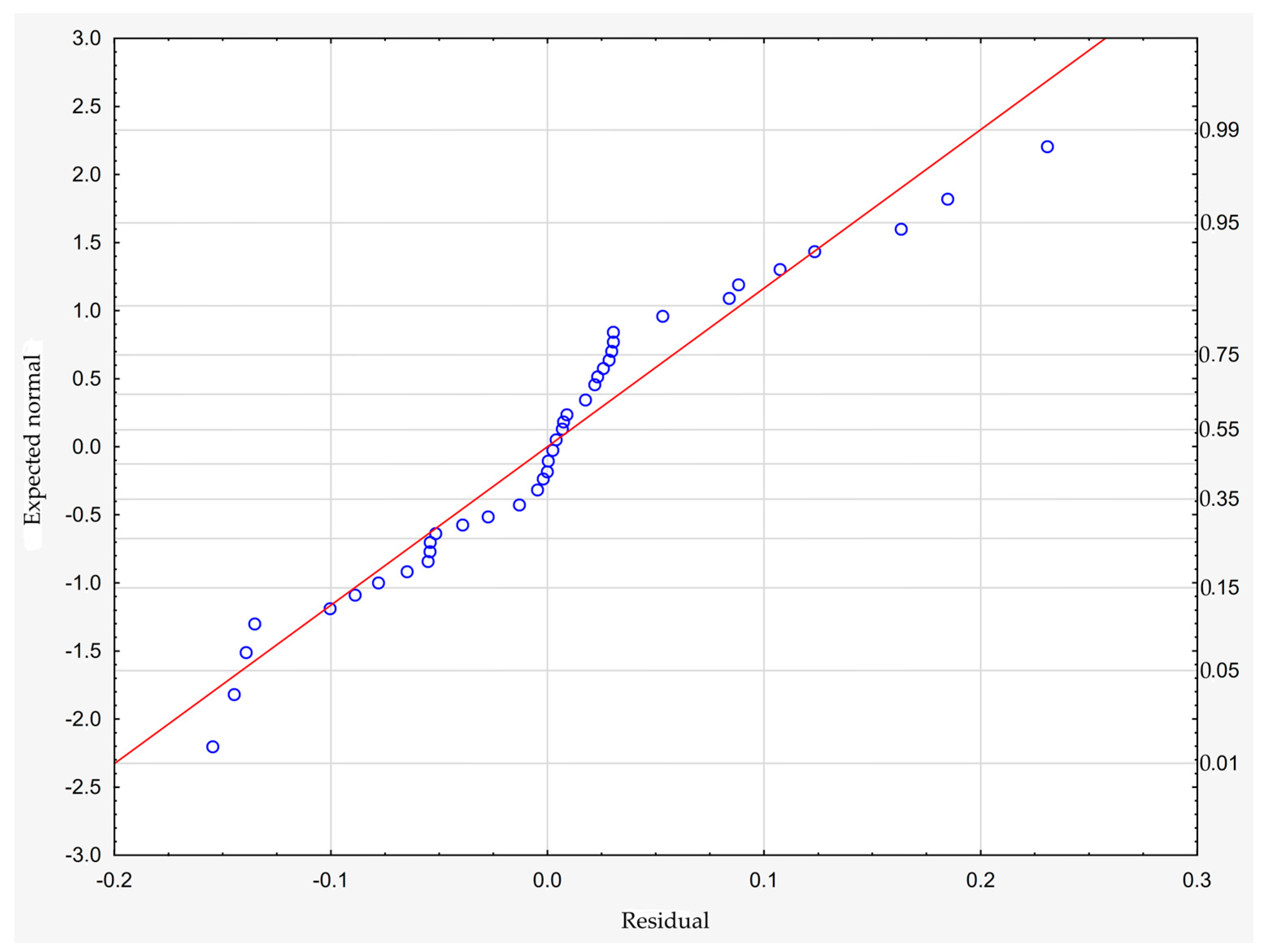

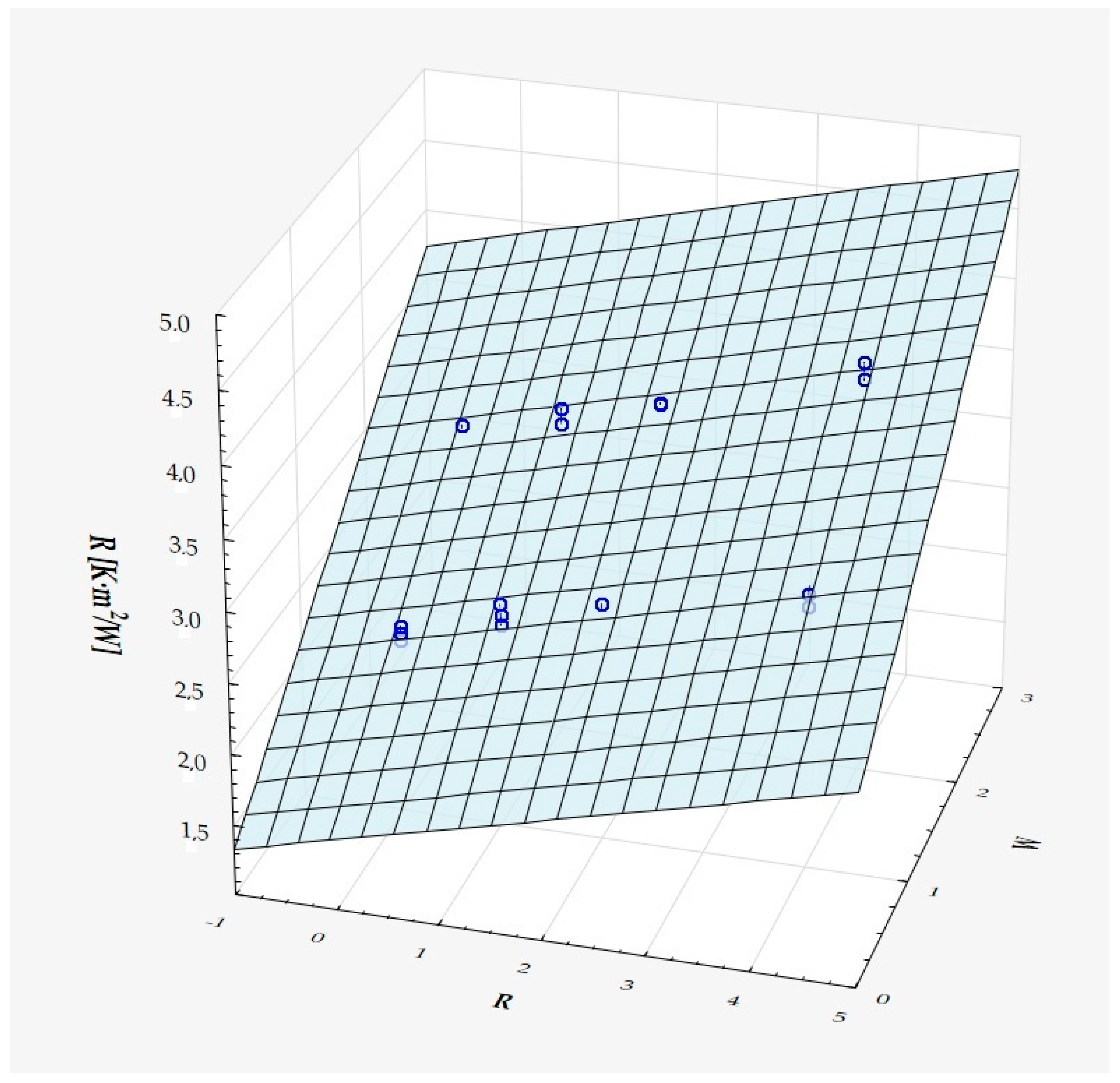

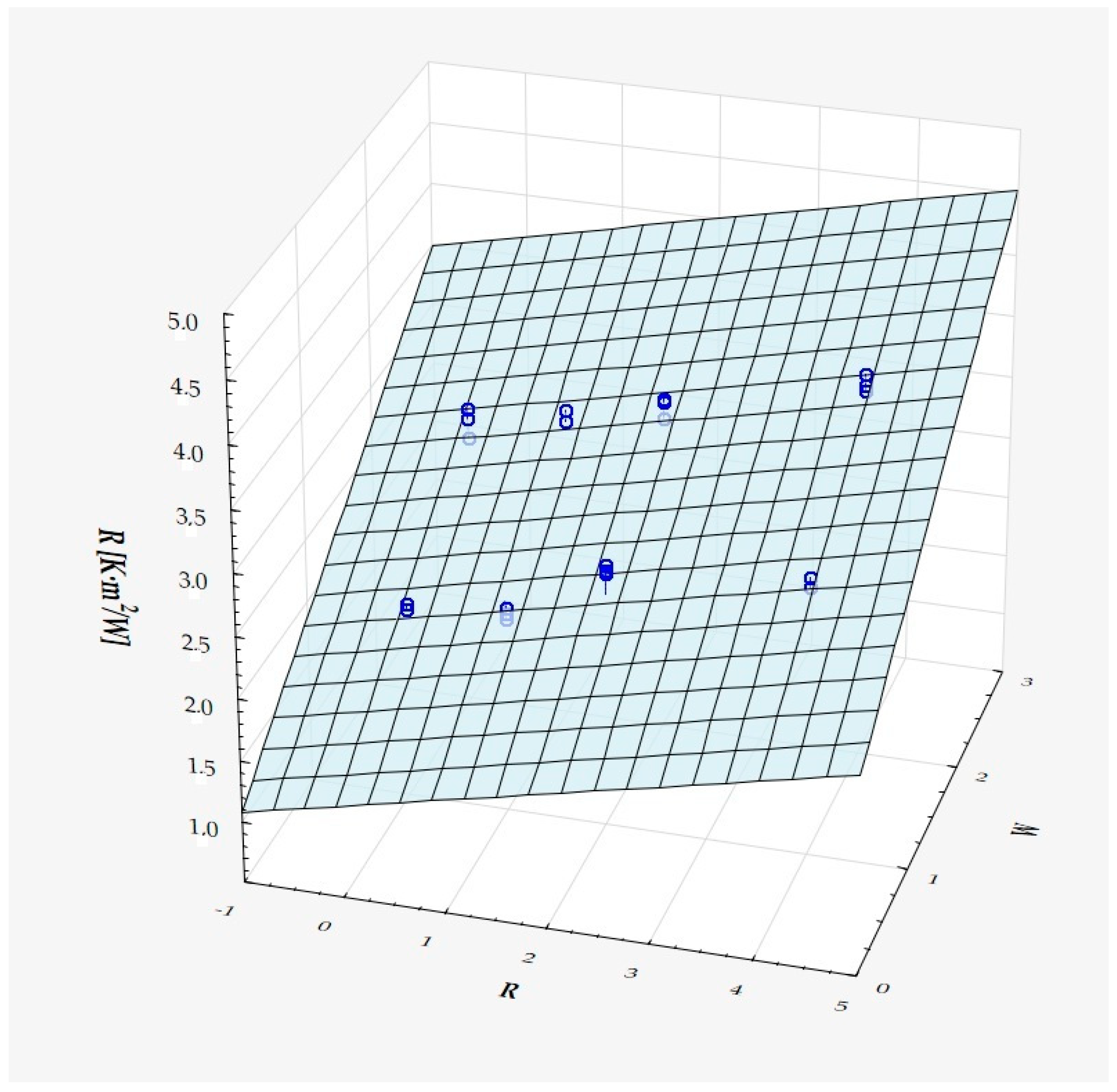

3. Results and Discussion

4. Conclusions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Hu, F.; Wu, S.; Sun, Y. Hollow-Structured Materials for Thermal Insulation. Adv. Mater. 2019, 31, 1801001. [Google Scholar] [CrossRef]

- Santoni, A.; Bonfiglio, P.; Fausti, P.; Marescotti, C.; Mazzanti, V.; Mollica, F.; Pompoli, F. Improving the Sound Absorption Performance of Sustainable Thermal Insulation Materials: Natural Hemp Fibres. Appl. Acoust. 2019, 150, 279–289. [Google Scholar] [CrossRef]

- Javaid, M.; Haleem, A.; Singh, R.P.; Suman, R.; Rab, S. Role of Additive Manufacturing Applications towards Environmental Sustainability. Adv. Ind. Eng. Polym. Res. 2021, 4, 312–322. [Google Scholar] [CrossRef]

- Kafle, A.; Luis, E.; Silwal, R.; Pan, H.M.; Shrestha, P.L.; Bastola, A.K. 3D/4D Printing of Polymers: Fused Deposition Modelling (FDM), Selective Laser Sintering (SLS), and Stereolithography (SLA). Polymers 2021, 13, 3101. [Google Scholar] [CrossRef]

- Gide, K.M.; Islam, S.; Bagheri, Z.S. Polymer-Based Materials Built with Additive Manufacturing Methods for Orthopedic Applications: A Review. J. Compos. Sci. 2022, 6, 262. [Google Scholar] [CrossRef]

- Sharma, V.; Bhandari, K.; Barua, R. Sustainable Cooling, Layer by Layer, Shaping Magnetic Regenerators via Additive Manufacturing. J. Compos. Sci. 2025, 9, 114. [Google Scholar] [CrossRef]

- Sudamrao Getme, A.; Patel, B. A Review: Bio-Fiber’s as Reinforcement in Composites of Polylactic Acid (PLA). Mater. Today Proc. 2020, 26, 2116–2122. [Google Scholar] [CrossRef]

- Jafferson, J.M.; Sabareesh, M.C.; Sidharth, B.S. 3D Printed Fabrics Using Generative and Material Driven Design. Mater. Today Proc. 2021, 46, 1319–1327. [Google Scholar] [CrossRef]

- Sabbatini, B.; Cambriani, A.; Cespi, M.; Palmieri, G.F.; Perinelli, D.R.; Bonacucina, G. An Overview of Natural Polymers as Reinforcing Agents for 3D Printing. ChemEngineering 2021, 5, 78. [Google Scholar] [CrossRef]

- Ahmad, M.N.; Ishak, M.R.; Mohammad Taha, M.; Mustapha, F.; Leman, Z. A Review of Natural Fiber-Based Filaments for 3D Printing: Filament Fabrication and Characterization. Materials 2023, 16, 4052. [Google Scholar] [CrossRef]

- Delgado Camacho, D.; Clayton, P.; O’Brien, W.J.; Seepersad, C.; Juenger, M.; Ferron, R.; Salamone, S. Applications of Additive Manufacturing in the Construction Industry—A Forward-Looking Review. Autom. Constr. 2018, 89, 110–119. [Google Scholar] [CrossRef]

- Parandoush, P.; Lin, D. A Review on Additive Manufacturing of Polymer-Fiber Composites. Compos. Struct. 2017, 182, 36–53. [Google Scholar] [CrossRef]

- Zakari, A.; Khan, I.; Tan, D.; Alvarado, R.; Dagar, V. Energy Efficiency and Sustainable Development Goals (SDGs). Energy 2022, 239, 122365. [Google Scholar] [CrossRef]

- Islam, S.; Bhat, G.; Sikdar, P. Thermal and Acoustic Performance Evaluation of 3D-Printable PLA Materials. J. Build. Eng. 2023, 67, 105979. [Google Scholar] [CrossRef]

- de Rubeis, T. 3D-Printed Blocks: Thermal Performance Analysis and Opportunities for Insulating Materials. Sustainability 2022, 14, 1077. [Google Scholar] [CrossRef]

- de Rubeis, T.; Ciccozzi, A.; Paoletti, D.; Ambrosini, D. 3D Printing for Energy Optimization of Building Envelope—Experimental Results. Heliyon 2024, 10, e31107. [Google Scholar] [CrossRef]

- de Rubeis, T.; Ciccozzi, A.; Giusti, L.; Ambrosini, D. The 3D Printing Potential for Heat Flow Optimization: Influence of Block Geometries on Heat Transfer Processes. Sustainability 2022, 14, 15830. [Google Scholar] [CrossRef]

- Grabowska, B.; Kasperski, J. The Thermal Conductivity of 3D Printed Plastic Insulation Materials—The Effect of Optimizing the Regular Structure of Closures. Materials 2020, 13, 4400. [Google Scholar] [CrossRef]

- Du, Y.; Liang, H.; Xie, D.; Mao, N.; Zhao, J.; Tian, Z.; Wang, C.; Shen, L. Design and Statistical Analysis of Irregular Porous Scaffolds for Orthopedic Reconstruction Based on Voronoi Tessellation and Fabricated via Selective Laser Melting (SLM). Mater. Chem. Phys. 2020, 239, 121968. [Google Scholar] [CrossRef]

- Sawei, Q.; Xinna, Z.; Qingxian, H.; Renjun, D.; Yan, J.; Yuebo, H. Research Progress on Simulation Modeling of Metal Foams. Rare Met. Mater. Eng. 2015, 44, 2670–2676. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, J.; Jia, P. Performance of Forced Convection Heat Transfer in Porous Media Based on Gibson–Ashby Constitutive Model. Heat Transf. Eng. 2011, 32, 1093–1098. [Google Scholar] [CrossRef]

- Chiappini, D. Numerical Simulation of Natural Convection in Open-Cells Metal Foams. Int. J. Heat Mass Transf. 2018, 117, 527–537. [Google Scholar] [CrossRef]

- Zafari, M.; Panjepour, M.; Meratian, M.; Emami, M.D. CFD simulation of forced convective heat transfer by tetrakaidecahedron model in metal foams. J. Porous Media 2016, 19, 1–11. [Google Scholar] [CrossRef]

- Li, Z.; Xia, X.; Li, X.; Sun, C. Discrete vs. Continuum-Scale Simulation of Coupled Radiation and Convection inside Rectangular Channel Filled with Metal Foam. Int. J. Therm. Sci. 2018, 132, 219–233. [Google Scholar] [CrossRef]

- Suleiman, A.S.; Dukhan, N. Forced Convection inside Metal Foam: Simulation over a Long Domain and Analytical Validation. Int. J. Therm. Sci. 2014, 86, 104–114. [Google Scholar] [CrossRef]

- Cunsolo, S.; Iasiello, M.; Oliviero, M.; Bianco, N.; Chiu, W.K.S.; Naso, V. Lord Kelvin and Weaire–Phelan Foam Models: Heat Transfer and Pressure Drop. J. Heat Transf. 2016, 138, 022601. [Google Scholar] [CrossRef]

- Huang, X.; Zhao, Y.; Wang, H.; Qin, H.; Wen, D.; Zhou, W. Investigation of Transport Property of Fibrous Media: 3D Virtual Modeling and Permeability Calculation. Eng. Comput. 2017, 33, 997–1005. [Google Scholar] [CrossRef]

- Huang, X.; Zhou, Q.; Liu, J.; Zhao, Y.; Zhou, W.; Deng, D. 3D Stochastic Modeling, Simulation and Analysis of Effective Thermal Conductivity in Fibrous Media. Powder Technol. 2017, 320, 397–404. [Google Scholar] [CrossRef]

- Sadeghi, E.; Bahrami, M.; Djilali, N. Analytic Determination of the Effective Thermal Conductivity of PEM Fuel Cell Gas Diffusion Layers. J. Power Sources 2008, 179, 200–208. [Google Scholar] [CrossRef]

- Zamel, N.; Li, X.; Shen, J.; Becker, J.; Wiegmann, A. Estimating Effective Thermal Conductivity in Carbon Paper Diffusion Media. Chem. Eng. Sci. 2010, 65, 3994–4006. [Google Scholar] [CrossRef]

- Qiu, Q. Effect of Internal Defects on the Thermal Conductivity of Fiber-Reinforced Polymer (FRP): A Numerical Study Based on Micro-CT Based Computational Modeling. Mater. Today Commun. 2023, 36, 106446. [Google Scholar] [CrossRef]

- Suntharalingam, T.; Gatheeshgar, P.; Upasiri, I.; Poologanathan, K.; Nagaratnam, B.; Rajanayagam, H.; Navaratnam, S. Numerical Study of Fire and Energy Performance of Innovative Light-Weight 3D Printed Concrete Wall Configurations in Modular Building System. Sustainability 2021, 13, 2314. [Google Scholar] [CrossRef]

- Giubilini, A.; Colucci, G.; De Trane, G.; Lupone, F.; Badini, C.; Minetola, P.; Bondioli, F.; Messori, M. Novel 3D Printable Bio-Based and Biodegradable Poly(3-Hydroxybutyrate-Co-3-Hydroxyhexanoate) Microspheres for Selective Laser Sintering Applications. Mater. Today Sustain. 2023, 22, 100379. [Google Scholar] [CrossRef]

- Casini, M. Advanced Digital Design Tools and Methods. In Construction 4.0; Elsevier: Amsterdam, The Netherlands, 2022; pp. 263–334. [Google Scholar]

- Ghanavati, R.; Naffakh-Moosavy, H. Additive Manufacturing of Functionally Graded Metallic Materials: A Review of Experimental and Numerical Studies. J. Mater. Res. Technol. 2021, 13, 1628–1664. [Google Scholar] [CrossRef]

- Bandyopadhyay, A.; Mitra, I.; Goodman, S.B.; Kumar, M.; Bose, S. Improving Biocompatibility for next Generation of Metallic Implants. Prog. Mater. Sci. 2023, 133, 101053. [Google Scholar] [CrossRef] [PubMed]

- Zhu, L.; Li, N.; Childs, P.R.N. Light-Weighting in Aerospace Component and System Design. Propuls. Power Res. 2018, 7, 103–119. [Google Scholar] [CrossRef]

- Hao, C.; Sui, Y.; Yuan, Y.; Li, P.; Jin, H.; Jiang, A. Composition Optimization Design and High Temperature Mechanical Properties of Cast Heat-Resistant Aluminum Alloy via Machine Learning. Mater. Des. 2025, 250, 113587. [Google Scholar] [CrossRef]

- Sun, B.; Yan, X.; Liu, P.; Xia, Y.; Lu, L. Parametric Plate Lattices: Modeling and Optimization of Plate Lattices with Superior Mechanical Properties. Addit. Manuf. 2023, 72, 103626. [Google Scholar] [CrossRef]

- Souza Almeida, L.; Rios, P.R. Insights on the Use of Genetic Algorithm to Tessellate Voronoi Structures in Materials Science. J. Mater. Res. Technol. 2025, 34, 449–462. [Google Scholar] [CrossRef]

- Caetano, I.; Santos, L.; Leitão, A. Computational Design in Architecture: Defining Parametric, Generative, and Algorithmic Design. Front. Archit. Res. 2020, 9, 287–300. [Google Scholar] [CrossRef]

- Drezner, T.; Drezner, Z. Voronoi Diagrams with Overlapping Regions. OR Spectr. 2013, 35, 543–561. [Google Scholar] [CrossRef]

- Arvizu Alonso, A.K.; Armendáriz Mireles, E.N.; Calles Arriaga, C.A.; Rocha Rangel, E. Control of the Properties of the Voronoi Tessellation Technique and Biomimetic Patterns: A Review. Designs 2024, 8, 93. [Google Scholar] [CrossRef]

- Xu, T.; Li, M. Topological and Statistical Properties of a Constrained Voronoi Tessellation. Philos. Mag. 2009, 89, 349–374. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, B.; Wei, G.; Liu, G.; Liu, J. Parametric design, mechanical properties and permeability of biomedical porous scaffolds based on typical structure units. J. Mech. Med. Biol. 2022, 22, 2240063. [Google Scholar] [CrossRef]

- González, S.G.; Vlad, M.D.; López, J.L.; Aguado, E.F. Novel Bio-Inspired 3D Porous Scaffold Intended for Bone-Tissue Engineering: Design and in Silico Characterisation of Histomorphometric, Mechanical and Mass-Transport Properties. Mater. Des. 2023, 225, 111467. [Google Scholar] [CrossRef]

- Herath, B.; Suresh, S.; Downing, D.; Cometta, S.; Tino, R.; Castro, N.J.; Leary, M.; Schmutz, B.; Wille, M.-L.; Hutmacher, D.W. Mechanical and Geometrical Study of 3D Printed Voronoi Scaffold Design for Large Bone Defects. Mater. Des. 2021, 212, 110224. [Google Scholar] [CrossRef]

- Armendáriz-Mireles, E.N.; Raudi-Butrón, F.D.; Olvera-Carreño, M.A.; Rocha-Rangel, E. Design of Bio-Inspired Irregular Porous Structure Applied to Intelligent Mobility Products. Nexo Rev. Cient. 2023, 36, 110–121. [Google Scholar] [CrossRef]

- Chao, L.; Jiao, C.; Liang, H.; Xie, D.; Shen, L.; Liu, Z. Analysis of Mechanical Properties and Permeability of Trabecular-Like Porous Scaffold by Additive Manufacturing. Front. Bioeng. Biotechnol. 2021, 9, 779854. [Google Scholar] [CrossRef]

- Castro, A.P.G.; Ruben, R.B.; Gonçalves, S.B.; Pinheiro, J.; Guedes, J.M.; Fernandes, P.R. Numerical and Experimental Evaluation of TPMS Gyroid Scaffolds for Bone Tissue Engineering. Comput. Methods Biomech. Biomed. Eng. 2019, 22, 567–573. [Google Scholar] [CrossRef]

- Lei, H.-Y.; Li, J.-R.; Xu, Z.-J.; Wang, Q.-H. Parametric Design of Voronoi-Based Lattice Porous Structures. Mater. Des. 2020, 191, 108607. [Google Scholar] [CrossRef]

- EN ISO 9869-1:2014; Thermal Insulation—Building Elements—In Situ Measurement of Thermal Resistance and Thermal Transmittance. Part 1: Heat Flow Meter Method; International Organization for Standardization: Geneva, Switzerland, 2014.

- Bachman, D. Grasshopper: Visual Scripting for Rhinoceros 3D; Industrial Press, Inc.: New York, NY, USA, 2017. [Google Scholar]

- Anwajler, B. Modern Insulation Materials for Sustainability Based on Natural Fibers: Experimental Characterization of Thermal Properties. Fibers 2024, 12, 76. [Google Scholar] [CrossRef]

- Anwajler, B. The Thermal Properties of a Prototype Insulation with a Gyroid Structure—Optimization of the Structure of a Cellular Composite Made Using SLS Printing Technology. Materials 2022, 15, 1352. [Google Scholar] [CrossRef] [PubMed]

- Anwajler, B.; Szulc, P. The Impact of 3D Printing Technology on the Improvement of External Wall Thermal Efficiency—An Experimental Study. J. Compos. Sci. 2024, 8, 389. [Google Scholar] [CrossRef]

- Anwajler, B.; Szkudlarek, M. Właściwości Cieplne Materiałów o Strukturze TPMS Wykonanych w Technologii Druku Addytywnego SLS. Rynek Energii 2023, 1, 11–20. [Google Scholar]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P. Application of a Gyroid Structure for Thermal Insulation in Building Construction. Materials 2024, 17, 6301. [Google Scholar] [CrossRef]

- Anwajler, B.; Szołomicki, J.; Noszczyk, P.; Baryś, M. The Potential of 3D Printing in Thermal Insulating Composite Materials—Experimental Determination of the Impact of the Geometry on Thermal Resistance. Materials 2024, 17, 1202. [Google Scholar] [CrossRef]

- Anwajler, B.; Zielińska, S.; Witek-Krowiak, A. Innovative Cellular Insulation Barrier on the Basis of Voronoi Tessellation—Influence of Internal Structure Optimization on Thermal Performance. Materials 2024, 17, 1578. [Google Scholar] [CrossRef]

| M | Me | Min | Max | SD | Sk | K | |

|---|---|---|---|---|---|---|---|

| λ, W/(m·K) | 0.045 | 0.044 | 0.034 | 0.066 | 0.0073 | 0.901 | 0.673 |

| M | Me | Min | Max | SD | Sk | K | |

|---|---|---|---|---|---|---|---|

| R, (m2·K)/W | 1.127 | 1.125 | 0.757 | 1.471 | 0.167 | −0.178 | −0.575 |

| M | Me | Min | Max | SD | Sk | K | |

|---|---|---|---|---|---|---|---|

| λ, W/(m·K) | 0.036 | 0.035 | 0.026 | 0.049 | 0.007 | 0.542 | −0.529 |

| M | Me | Min | Max | SD | Sk | K | |

|---|---|---|---|---|---|---|---|

| R, (m2·K)/W | 2.88 | 2.86 | 2.04 | 3.92 | 0.50 | 0.10 | −0.72 |

| Symbol That Identifies the Input Factors and Their Interactions | SS | df | MS | F | p |

|---|---|---|---|---|---|

| λ, W/(m·K) | |||||

| Absolute term | 1 | 0.1979 | 0.197997 | 422,809.7 | 0.000 |

| S | 3 | 0.0016 | 0.000520 | 1111.3 | 0.000 |

| D | 1 | 0.000221 | 0.000221 | 472.1 | 0.000 |

| R | 3 | 0.002895 | 0.000965 | 2060.7 | 0.000 |

| S*D | 3 | 0.000004 | 0.000001 | 3.1 | 0.034 |

| S*R | 9 | 0.00024 | 0.000027 | 57.6 | 0.000 |

| D*R | 3 | 0.000023 | 0.000008 | 16.5 | 0.000 |

| S*D*R | 9 | 0.00003 | 0.000003 | 6.8 | 0.000 |

| Error | 64 | 0.00003 | 0.000 | ||

| General | 95 | 0.005 | |||

| R, (m2·K)/W | |||||

| Absolute term | 1 | 121.9009 | 121.90 | 371,490.6 | 0.000 |

| S | 3 | 0.8331 | 0.278 | 846.2 | 0.000 |

| D | 1 | 0.1340 | 0.134 | 408.5 | 0.000 |

| R | 3 | 1.5610 | 0.52 | 1585.7 | 0.000 |

| S*D | 3 | 0.0084 | 0.003 | 8.5 | 0.000 |

| S*R | 9 | 0.0533 | 0.006 | 18.0 | 0.000 |

| D*R | 3 | 0.0086 | 0.003 | 8.7 | 0.000 |

| S*D*R | 9 | 0.0179 | 0.002 | 6.1 | 0.000 |

| Error | 64 | 0.0210 | 0.0003 | ||

| General | 95 | 2.6373 | |||

| Symbol That Identifies the Input Factors and Their Interactions | SS | df | MS | F | p |

|---|---|---|---|---|---|

| λ, W/(m·K) | |||||

| Absolute term | 1 | 0.061408 | 0.061408 | 110,436.1 | 0.000 |

| D | 1 | 0.000128 | 0.000128 | 229.7 | 0.000 |

| R | 3 | 0.000520 | 0.000173 | 311.5 | 0.000 |

| W | 1 | 0.001227 | 0.001227 | 2206.2 | 0.000 |

| D*R | 3 | 0.000021 | 0.000007 | 12.7 | 0.000 |

| D*W | 1 | 0.000003 | 0.000003 | 5.5 | 0.025 |

| R*W | 3 | 0.000050 | 0.000017 | 30.2 | 0.000 |

| D*R*W | 3 | 0.000013 | 0.000004 | 7.5 | 0.000 |

| Error | 32 | 0.000018 | 0.000001 | ||

| General | 47 | 0.001979 | |||

| R, (m2·K)/W | |||||

| Absolute term | 1 | 399.1361 | 399.1361 | 117,304.8 | 0.000000 |

| D | 1 | 0.7508 | 0.7508 | 220.7 | 0.000000 |

| R | 3 | 3.1676 | 1.0559 | 310.3 | 0.000000 |

| W | 1 | 7.7174 | 7.7174 | 2268.1 | 0.000000 |

| D*R | 3 | 0.0386 | 0.0129 | 3.8 | 0.019845 |

| D*W | 1 | 0.0183 | 0.0183 | 5.4 | 0.026964 |

| R*W | 3 | 0.0785 | 0.0262 | 7.7 | 0.000525 |

| D*R*W | 3 | 0.0323 | 0.0108 | 3.2 | 0.037636 |

| Error | 32 | 0.1089 | 0.0034 | ||

| General | 47 | 11.9125 | |||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Anwajler, B. Application of Voronoi Tessellation to the Additive Manufacturing of Thermal Barriers of Irregular Porous Materials—Experimental Determination of Thermal Properties. Materials 2025, 18, 1873. https://doi.org/10.3390/ma18081873

Anwajler B. Application of Voronoi Tessellation to the Additive Manufacturing of Thermal Barriers of Irregular Porous Materials—Experimental Determination of Thermal Properties. Materials. 2025; 18(8):1873. https://doi.org/10.3390/ma18081873

Chicago/Turabian StyleAnwajler, Beata. 2025. "Application of Voronoi Tessellation to the Additive Manufacturing of Thermal Barriers of Irregular Porous Materials—Experimental Determination of Thermal Properties" Materials 18, no. 8: 1873. https://doi.org/10.3390/ma18081873

APA StyleAnwajler, B. (2025). Application of Voronoi Tessellation to the Additive Manufacturing of Thermal Barriers of Irregular Porous Materials—Experimental Determination of Thermal Properties. Materials, 18(8), 1873. https://doi.org/10.3390/ma18081873