The Impact of Organic Bentonite Content on the Properties of Stereolithographic 3D-Printed Silicon-Based Ceramic Core Paste

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

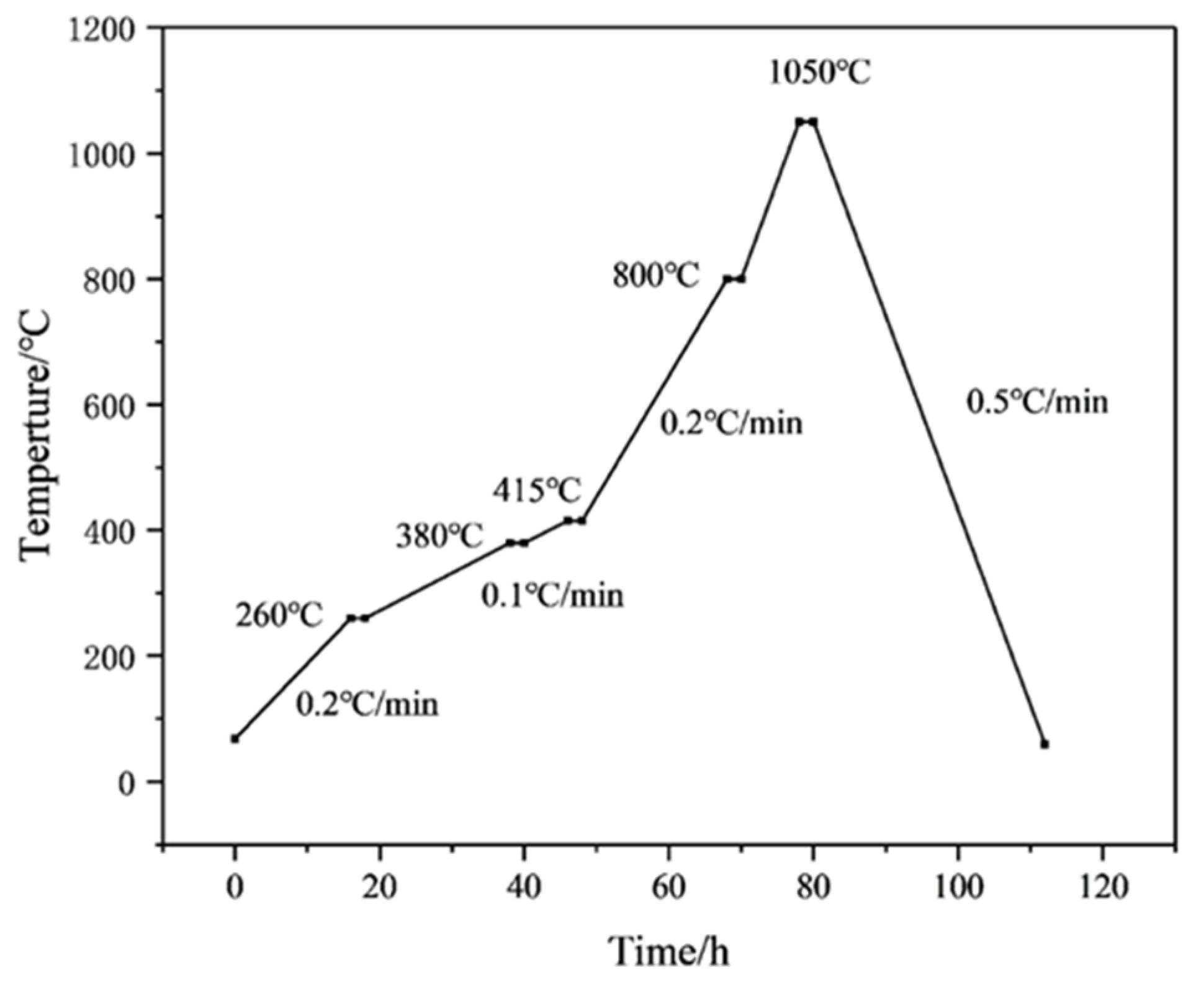

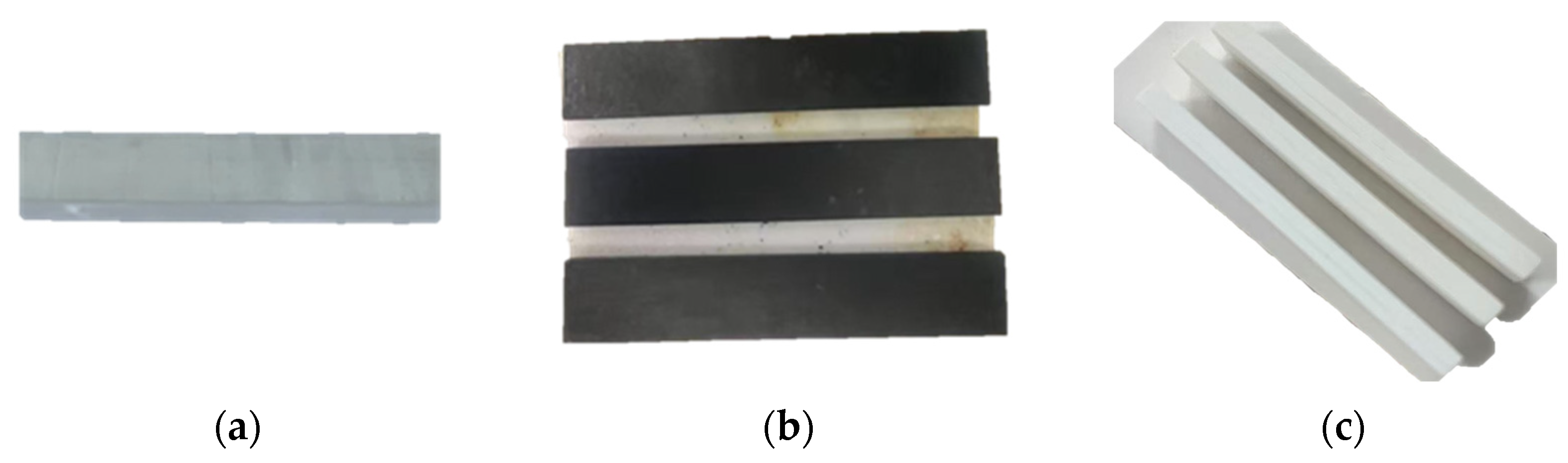

2.2. Paste Preparation and Printing

2.3. Characterization

2.3.1. Characterization of Paste Properties

2.3.2. Characterization of the Physical Properties, Mechanical Properties, and Phase Composition of Ceramic Specimens

3. Results and Discussion

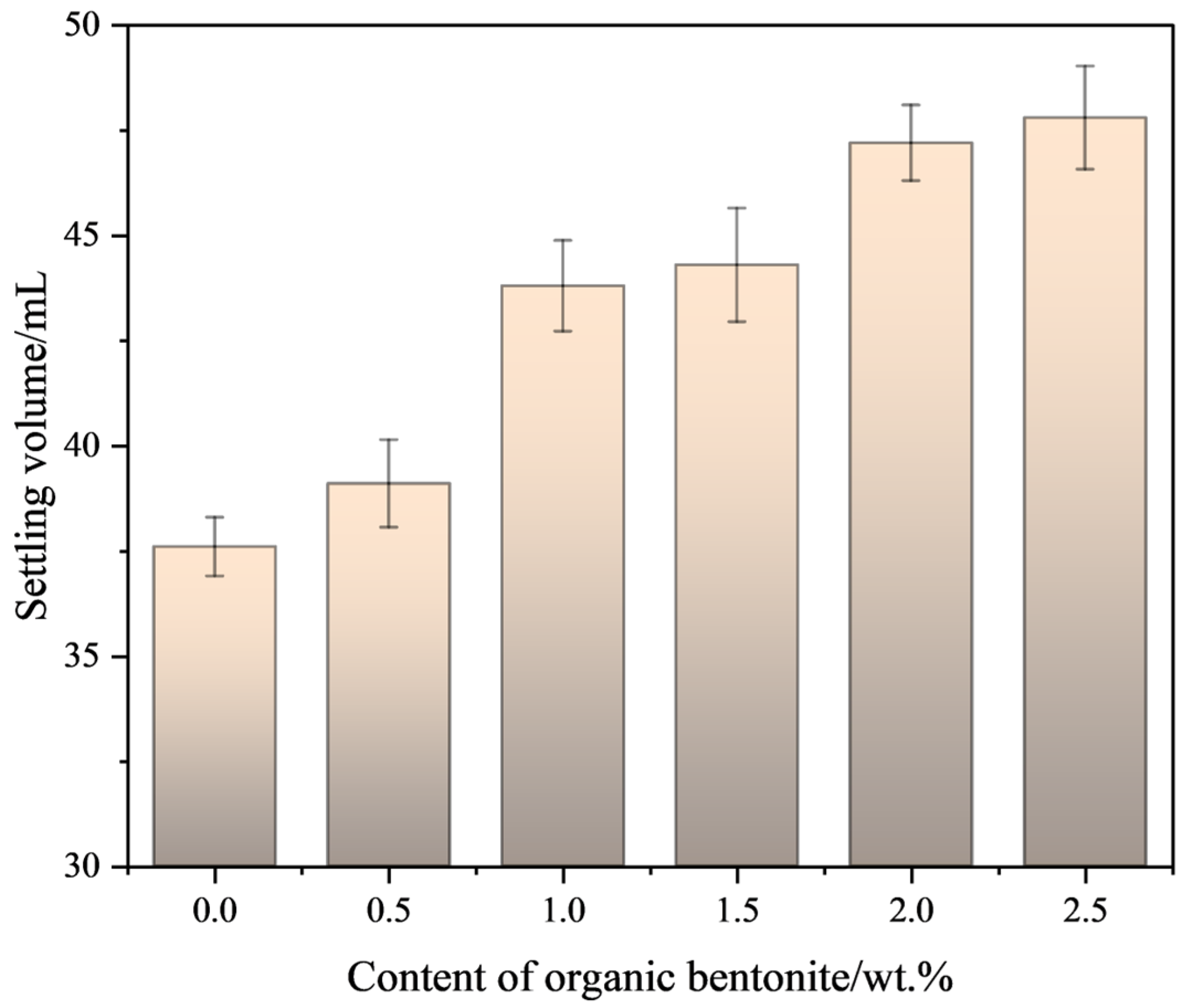

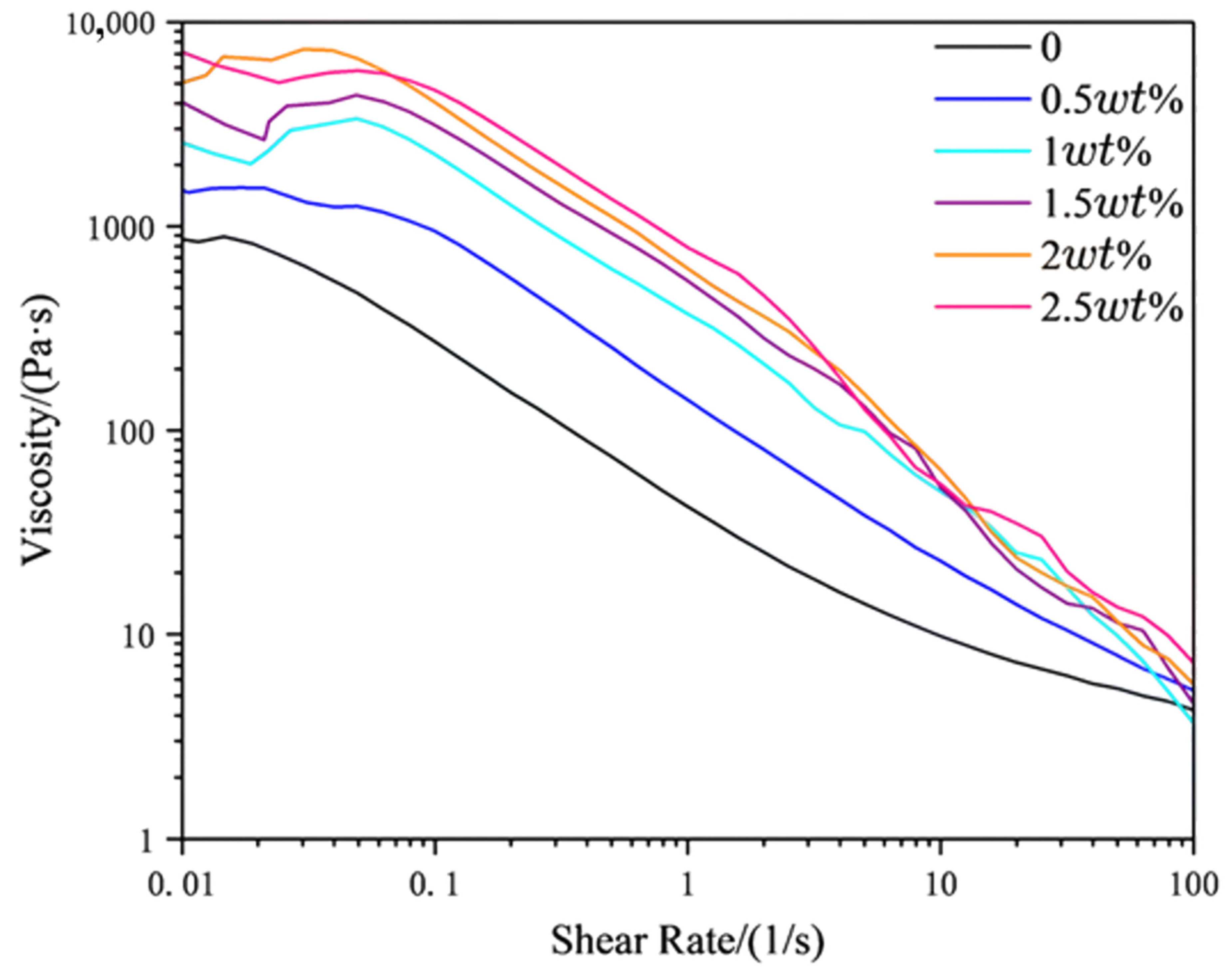

3.1. Influence of Organic Bentonite on the Rheology and Stability of Ceramic Pastes

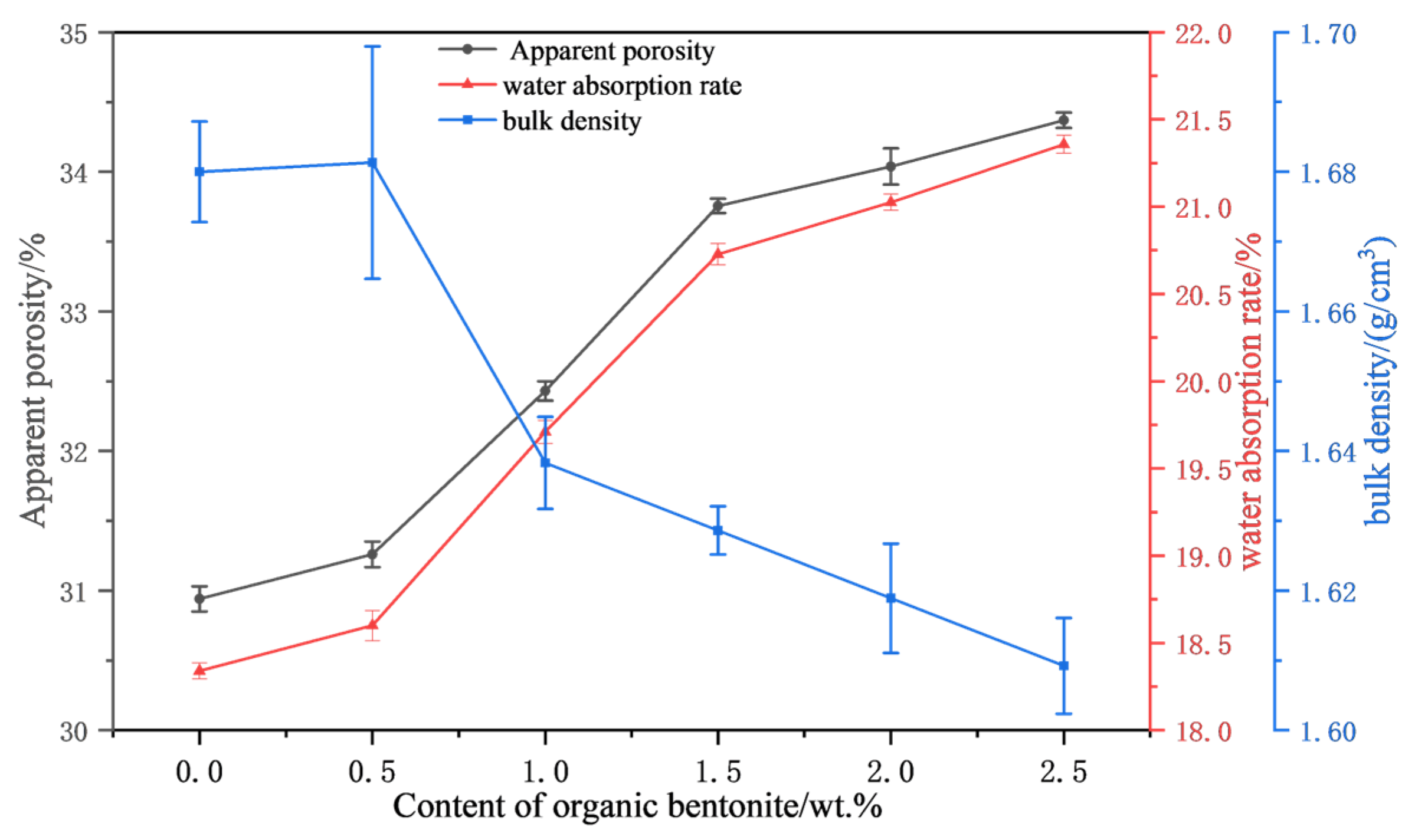

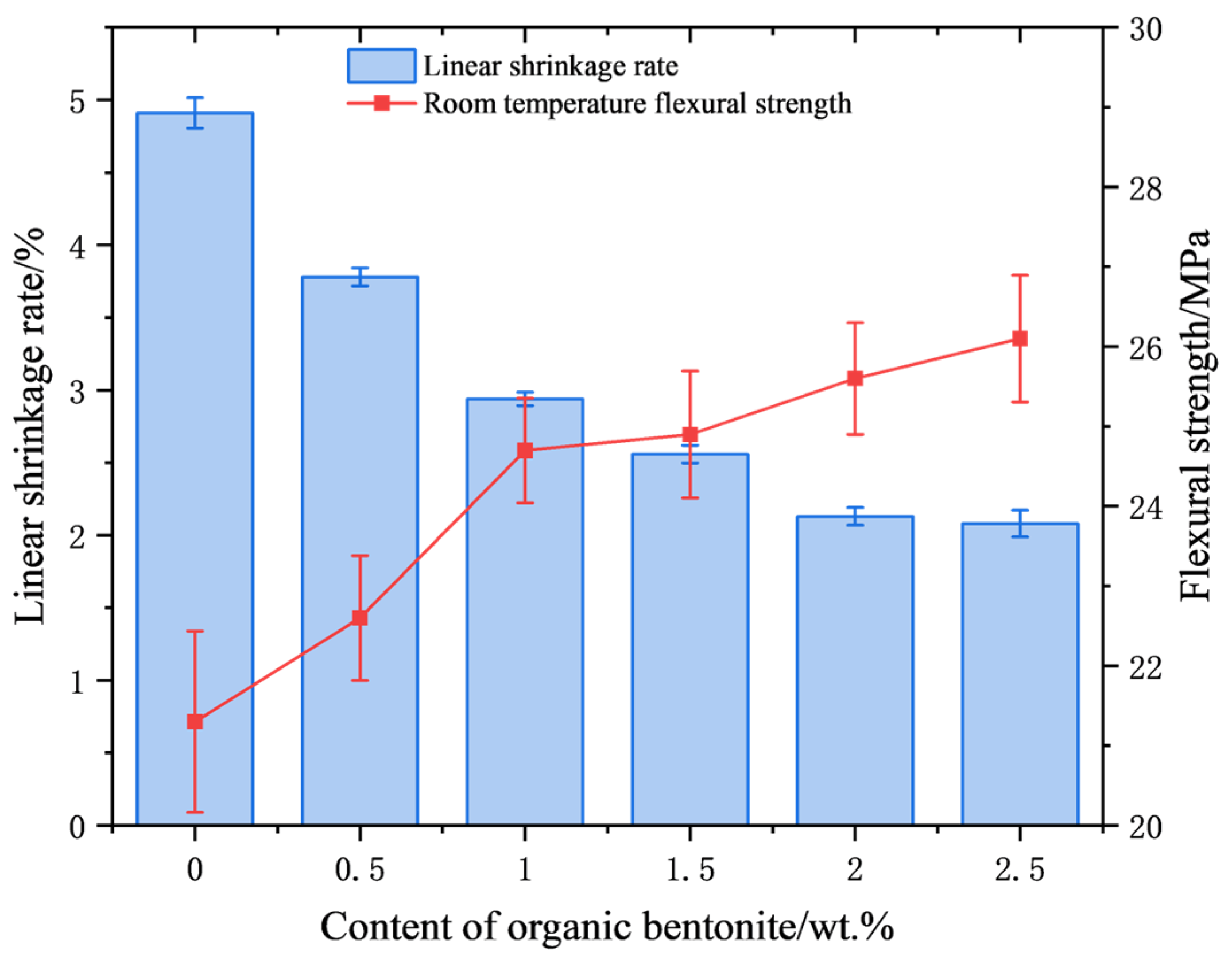

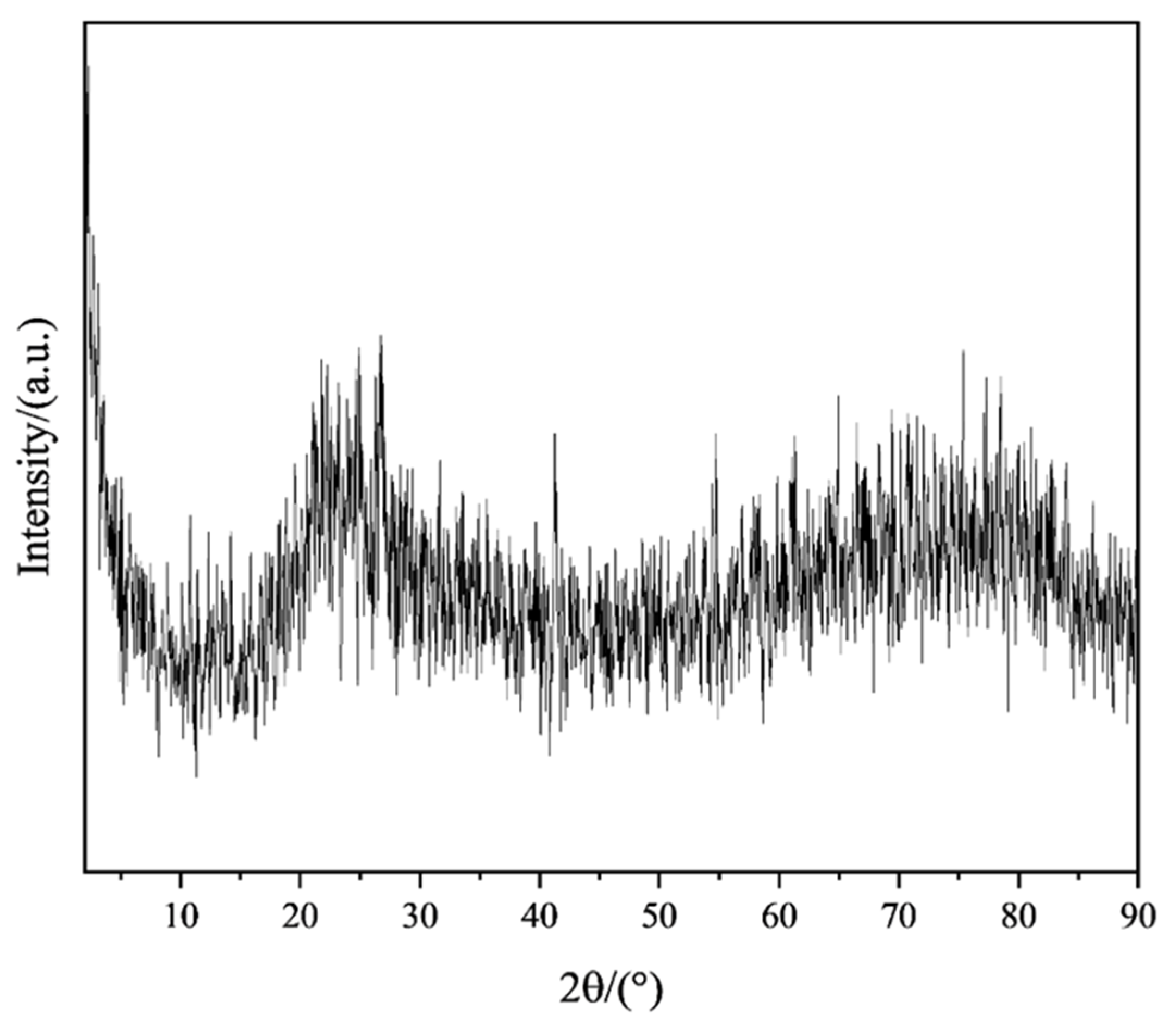

3.2. Influence of Organic Bentonite on the Room-Temperature Properties of Silicon-Based Ceramic Cores

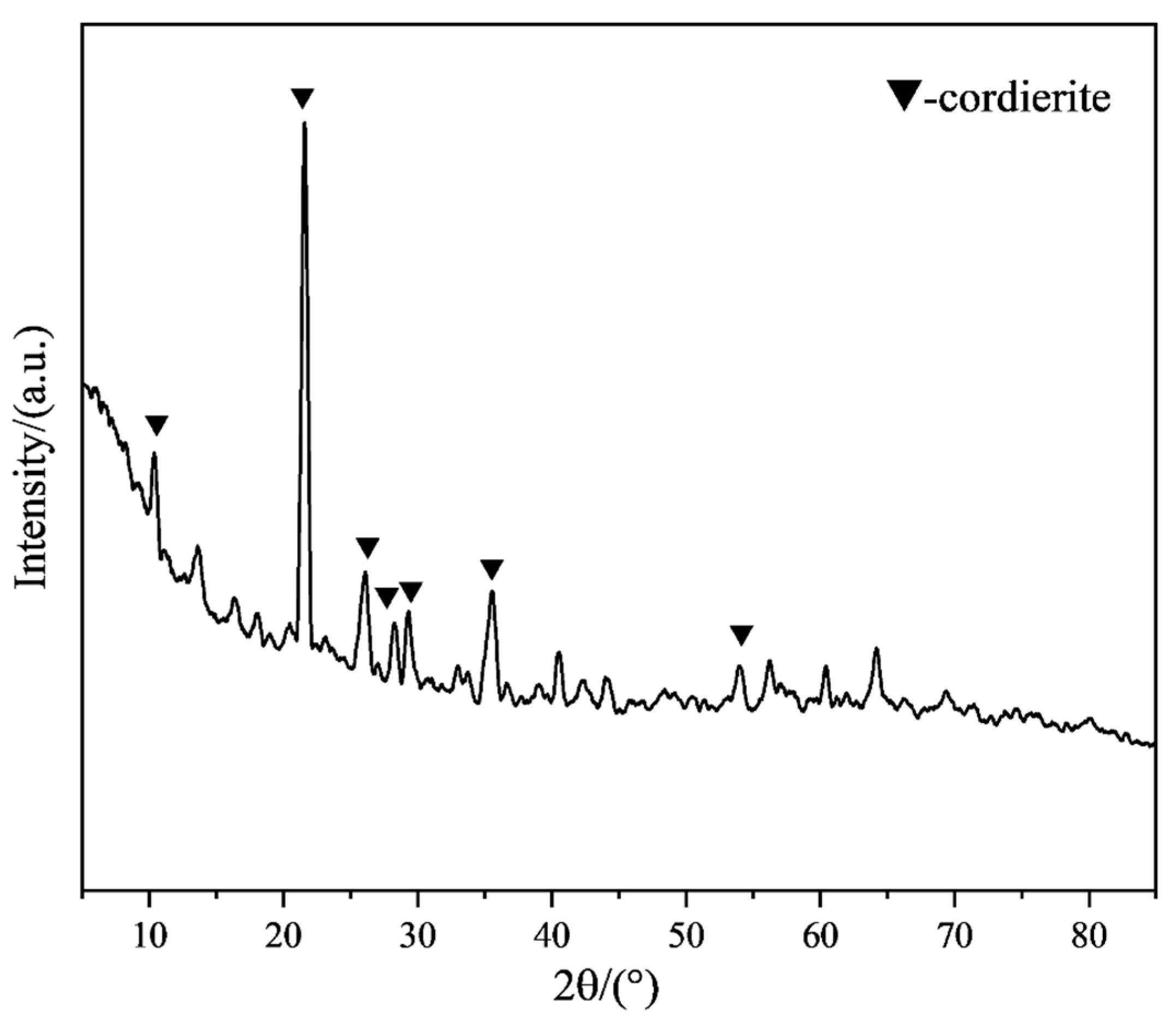

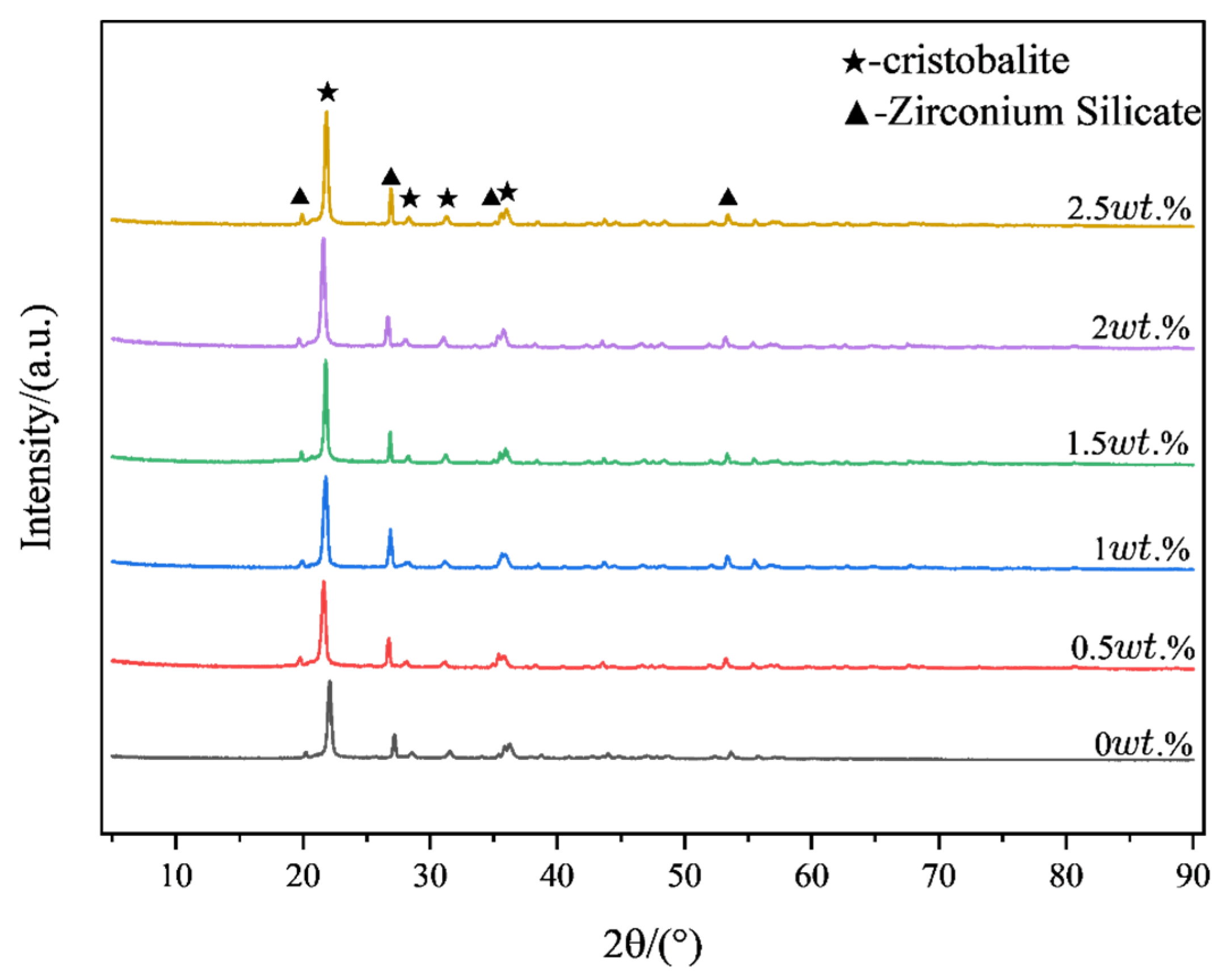

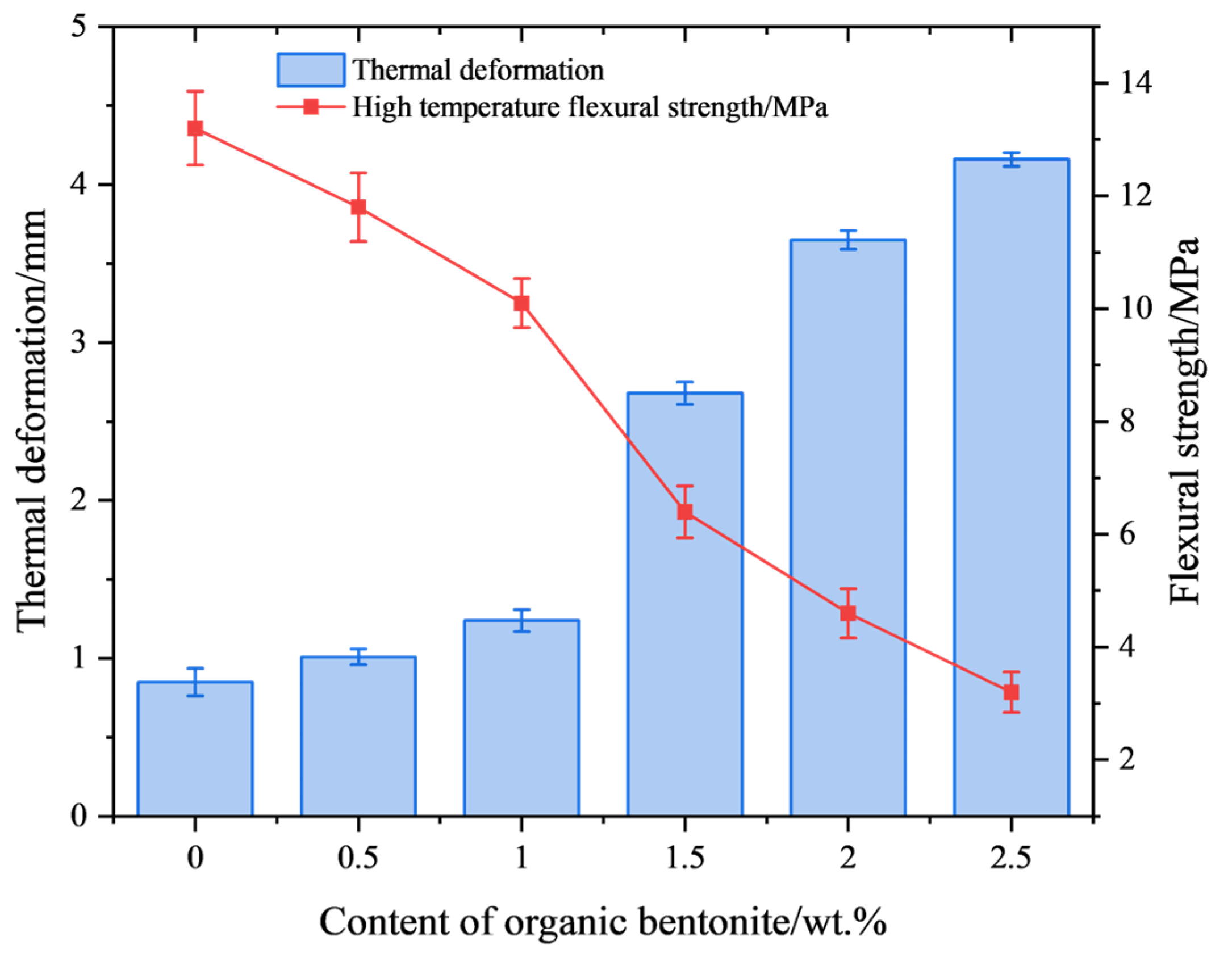

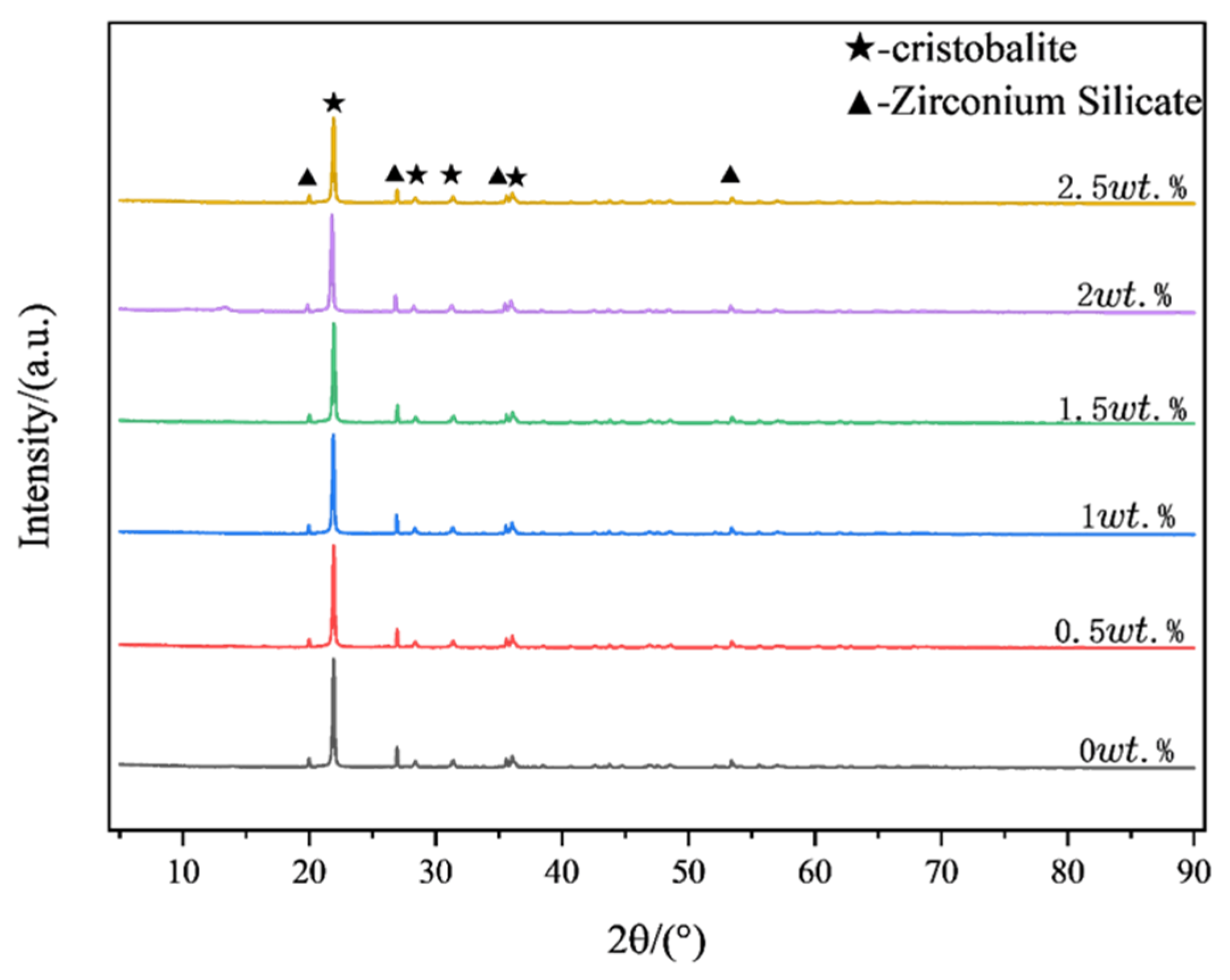

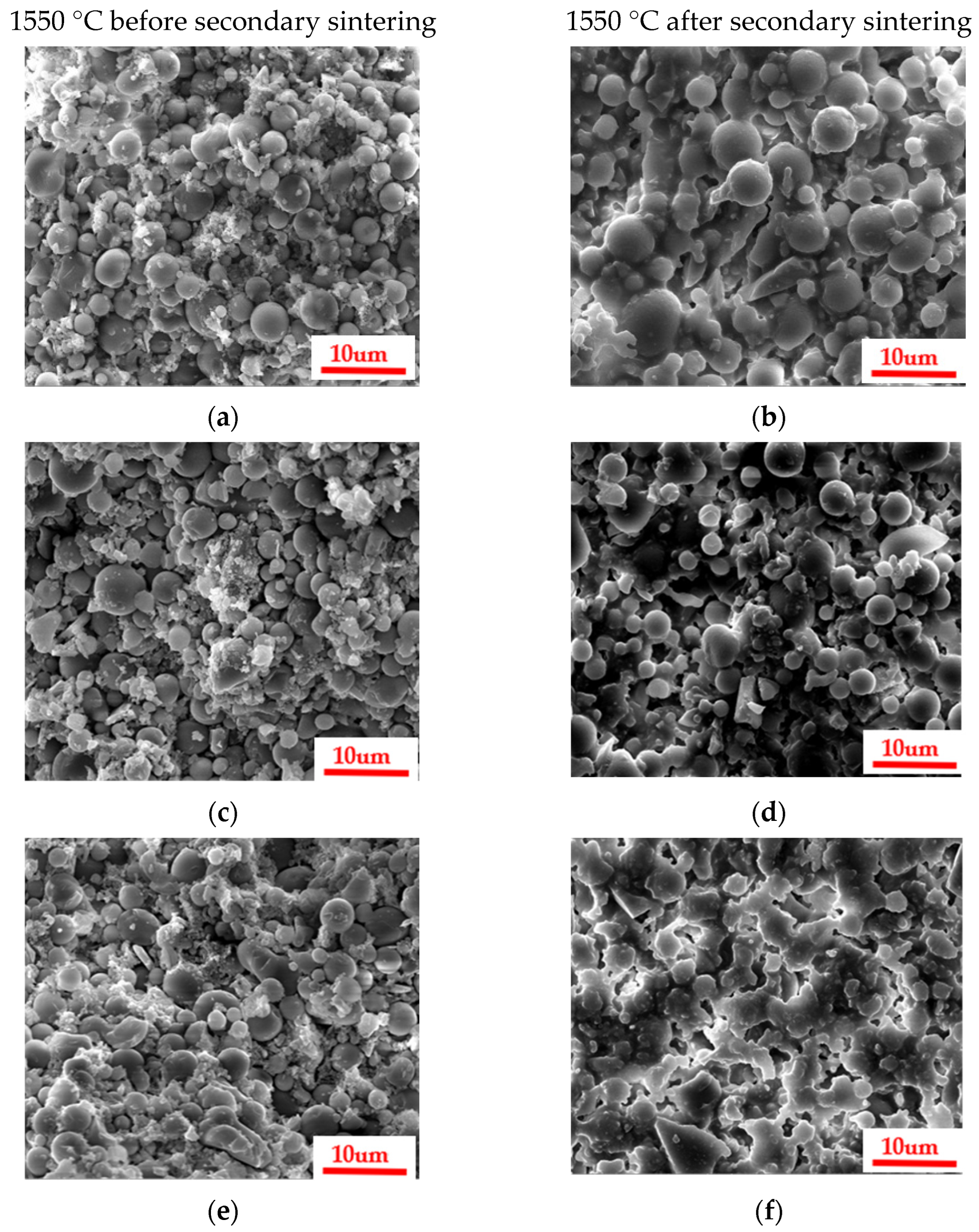

3.3. Influence of Organic Bentonite on the High-Temperature (1550 °C) Properties of Silicone-Based Ceramic Cores

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sekar, M. Gaseous fuel injection assisted with rich hydrogen content in turbojet engine for enhanced thrust and combustion efficiency. Int. J. Hydrogen Energy 2024, 78, 564–571. [Google Scholar] [CrossRef]

- Jiang, H.; Yu, S.; Wang, S.; Ding, X.; Jiang, A. Research Status and Development Trend of Cylindrical Gas Film Seals for Aeroengines. Processes 2024, 12, 69. [Google Scholar] [CrossRef]

- Zhao, T.; Jiang, Z.; Mo, G.; Wang, G.; Gao, J. Control of separation flows of turbine-blade-tip turbines by splitter blades. Proc. Inst. Mech. Eng. Part A J. Power Energy 2024, 238, 985–998. [Google Scholar] [CrossRef]

- Qian, B.; Zhang, L.; Fan, H.; Mao, J.; Li, X. The mechanical characteristics and cooling performance of a turbine blade with non-homogeneous lattice structure. Mater. Today Commun. 2024, 38, 108247. [Google Scholar] [CrossRef]

- Huo, M.; Li, Q.; Liu, J.; Zhang, X.; Yue, X.; Liang, J.; Li, J. In-situ synthesis of high-performance Al2O3-based ceramic cores reinforced with core-shell structures. Ceram. Int. 2022, 48, 33693–33703. [Google Scholar] [CrossRef]

- Liu, J.; Li, Q.; Huo, M.; Zhang, X.; Yue, X.; Liang, J.; Li, J. Microstructure and mechanical properties of 3D-printed nano-silica reinforced alumina cores. Ceram. Int. 2022, 48, 30282–30293. [Google Scholar] [CrossRef]

- Osorio, J.D.; Toro, A.; Hernandez-Ortiz, J.P. Thermal barrier coatings for gas turbine applications: Failure mechanisms and key microstructural features. Dyna 2012, 79, 149–158. [Google Scholar]

- Gao, Y.; Chen, M.C.; Shi, C.X. Study on EB-PVD zirconia thermal barrier coatings for gas turbine blade protection. Mater. Manuf. Process. 1999, 14, 691–696. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhang, Y.; Gong, H.; Guo, X.; Zhang, Y.; Wang, X.; Yu, J. Influence of Carbon Content on Ceramic Injection Molding of Reaction-Bonded Silicon Carbide. Int. J. Appl. Ceram. Technol. 2016, 13, 838–843. [Google Scholar] [CrossRef]

- Li, Q.; An, X.; Liang, J.; Liu, Y.; Hu, K.; Lu, Z.; Yue, X.; Li, J.; Zhou, Y.; Sun, X. Balancing flexural strength and porosity in DLP-3D printing Al2O3 cores for hollow turbine blades. J. Mater. Sci. Technol. 2022, 104, 19–32. [Google Scholar] [CrossRef]

- Wu, H.; Li, D.; Tang, Y.; Sun, B.; Xu, D. Rapid fabrication of alumina-based ceramic cores for gas turbine blades by stereolithography and gel casting. J. Mater. Process. Technol. 2009, 209, 5886–5891. [Google Scholar] [CrossRef]

- Deng, W.; Xie, D.; Liu, F.; Shen, L.; Tian, Z.; Yang, Y. Preparation and Properties of Functional Materials Based on Digital Light Processing 3D Printing. J. Nanomater. 2022, 2022, 4136072. [Google Scholar] [CrossRef]

- Zhang, A.P.; Qu, X.; Soman, P.; Hribar, K.C.; Lee, J.W.; Chen, S.; He, S. Rapid Fabrication of Complex 3D Extracellular Microenvironments by Dynamic Optical Projection Stereolithography. Adv. Mater. 2012, 24, 4266. [Google Scholar] [CrossRef]

- He, C.; Liu, X.; Ma, C.; Cao, Y.; Hou, F.; Yan, L.; Guo, A.; Liu, J. Digital light processing of Si-based composite ceramics and bulk silica ceramics from a high solid loading polysiloxane/SiO2 slurry. J. Eur. Ceram. Soc. 2021, 41, 7189–7198. [Google Scholar] [CrossRef]

- Li, Q.; Gu, Y.; Yu, X.; Zhang, C.; Zou, M.; Liang, J.; Li, J. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores. J. Inorg. Mater. 2022, 37, 325–332. [Google Scholar] [CrossRef]

- Zhang, K.; Dong, X.; Chen, Y.; Wu, J.; Yan, L.; Liu, J.; Guo, A. Influence of photosensitive hydroxy siloxane on the mechanical properties of silicon-based ceramic cores prepared by digital light processing. Ceram. Int. 2025, 51, 3394–3403. [Google Scholar] [CrossRef]

- Zhou, Y.; Xuan, W.; Duan, F.; Bai, X.; Ren, X.; Ren, Z. Effect of Fused Corundum on Properties of Silicon-Based Ceramic Core. Rare Met. Mater. Eng. 2023, 52, 1396–1402. [Google Scholar]

- Wang, X.; Zhou, Y.; Zhou, L.; Xu, X.; Niu, S.; Li, X.; Chen, X. Microstructure and properties evolution of silicon-based ceramic cores fabricated by 3D printing with stair-stepping effect control. J. Eur. Ceram. Soc. 2021, 41, 4650–4657. [Google Scholar] [CrossRef]

- Zeng, Y.; Pan, Y.; Zhao, C.; Yao, H.; Chen, J. Indirect forming of alumina-based ceramics by selective laser sintering combined with sol infiltration process and performance study. J. Mater. Sci. 2023, 58, 3053–3065. [Google Scholar] [CrossRef]

- Liu, X.-F.; Guo, X.-L.; Shui, G.-Y.; Li, C.-C.; Su, G.-Q.; Sun, X.; Guan, Y.; Jin, L. Properties of alumina-based ceramic cores. China Foundry 2021, 18, 593–598. [Google Scholar] [CrossRef]

- Gu, Y.; Duan, W.; Wang, T.; Liu, X.; Li, S.; Liu, B.; Wang, G. Additive manufacturing of Al2O3 ceramic core with applicable microstructure and mechanical properties via digital light processing of high solid loading slurry. Ceram. Int. 2023, 49, 25216–25224. [Google Scholar] [CrossRef]

- Zheng, W.; Wu, J.-M.; Chen, S.; Yu, K.-B.; Zhang, J.; Liu, H.; Huo, Y.-F.; Shi, Y.-S. Improved mechanical properties of SiB6 reinforced silica-based ceramic cores fabricated by 3D stereolithography printing. Ceram. Int. 2022, 48, 21110–21117. [Google Scholar] [CrossRef]

- Ding, G.; He, R.; Zhang, K.; Xia, M.; Feng, C.; Fang, D. Dispersion and stability of SiC ceramic slurry for stereolithography. Ceram. Int. 2020, 46, 4720–4729. [Google Scholar] [CrossRef]

- Zhang, F.; Li, Z.; Xu, M.; Wang, S.; Li, N.; Yang, J. A review of 3D printed porous ceramics. J. Eur. Ceram. Soc. 2022, 42, 3351–3373. [Google Scholar] [CrossRef]

- Borlaf, M.; Serra-Capdevila, A.; Colominas, C.; Graule, T. Development of UV-curable ZrO2 slurries for additive manufacturing (LCM-DLP) technology. J. Eur. Ceram. Soc. 2019, 39, 3797–3803. [Google Scholar] [CrossRef]

- Zhang, K.; Xie, C.; Wang, G.; He, R.; Ding, G.; Wang, M.; Dai, D.; Fang, D. High solid loading, low viscosity photosensitive Al2O3 slurry for stereolithography based additive manufacturing. Ceram. Int. 2019, 45, 203–208. [Google Scholar] [CrossRef]

- Dermeik, B.; Travitzky, N. Laminated Object Manufacturing of Ceramic-Based Materials. Adv. Eng. Mater. 2020, 22, 2000256. [Google Scholar] [CrossRef]

- Jin, F.; Li, Q.; Yang, K.; Qiu, Y.; Fan, J.; Liu, X.; Liang, J.; Zhou, Y.; Li, J. Optimisation and application of high solid loading stereolithography 3D printing ceramic cores slurry. Ceram. Int. 2024, 50, 3574–3583. [Google Scholar] [CrossRef]

- Sun, J.; Binner, J.; Bai, J. Effect of surface treatment on the dispersion of nano zirconia particles in non-aqueous suspensions for stereolithography. J. Eur. Ceram. Soc. 2019, 39, 1660–1667. [Google Scholar] [CrossRef]

- Yu, Y.; Zou, B.; Wang, X.; Huang, C. Rheological behavior and curing deformation of paste containing 85 wt% Al2O3 ceramic during SLA-3D printing. Ceram. Int. 2022, 48, 24560–24570. [Google Scholar] [CrossRef]

- Ye, G.; Jiao, Y.; Zhou, P.; Sun, J.; Zhu, L.; Gong, F.; Bai, J.; Liu, G.; Yan, M.; Zhang, R. Preparation of silicon carbide ceramic slurry for stereolithography-based additive manufacturing. Process. Appl. Ceram. 2023, 17, 47–54. [Google Scholar] [CrossRef]

- Wang, L.; Wang, K.; Ma, Y.; Ma, Y.; Shi, S.; Tan, H.; Jia, X.; Li, X.; Niu, L.; Lu, B. High-solid-content paste for stereolithography self-supporting printing of Luneburg lenses with a high degree of geometric-design freedom. J. Eur. Ceram. Soc. 2024, 44, 2164–2172. [Google Scholar] [CrossRef]

- Kennedy, B.M.; De Barra, E.; Hampshire, S.; Kelleher, M.C. Investigation of oleic acid as a dispersant for hydroxyapatite powders for use in ceramic filled photo-curable resins for stereolithography. J. Eur. Ceram. Soc. 2023, 43, 7146–7166. [Google Scholar] [CrossRef]

- Liu, W.; Lv, L.; Li, Y.; Wang, Y.; Wang, J.; Xue, C.; Dong, Y.; Yang, J. Effects of slurry composition on the properties of 3-1 type porous PZT ceramics prepared by ionotropic gelation. Ceram. Int. 2017, 43, 6542–6547. [Google Scholar] [CrossRef]

| Ceramic Powder Types | SiO2 (6 um)/wt.% | SiO2 (0.5 um)/wt.% | ZrSiO4/wt.% | Al2O3/wt.% |

|---|---|---|---|---|

| Contains | 72 | 8 | 15 | 5 |

| Organic Resin Types | HDDA/wt.% | TMPTA/wt.% | PUA/wt.% | TXIB/wt.% |

|---|---|---|---|---|

| Contains | 20 | 20 | 40 | 20 |

| Sample Number | Organic Resin/wt.% | Ceramic Powder/wt.% | Organic Bentonite/wt.% |

|---|---|---|---|

| No. 1 | 22 | 78 | 0 |

| No. 2 | 22 | 77.61 | 0.39 |

| No. 3 | 22 | 77.22 | 0.78 |

| No. 4 | 22 | 76.83 | 1.17 |

| No. 5 | 22 | 76.44 | 1.56 |

| No. 6 | 22 | 76.05 | 1.95 |

| Sample Number | Static Stabilization | Slip Situation | Adhesion Situation |

|---|---|---|---|

| No. 1 | Poor | Good | Moderate |

| No. 2 | Moderate | Good | Moderate |

| No. 3 | Good | Good | Good |

| No. 4 | Good | Good | Good |

| No. 5 | Good | Moderate | Good |

| No. 6 | Good | Poor | Poor |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Tang, M.; Zheng, H.; Hu, Z.; Zhong, Y.; Yang, C. The Impact of Organic Bentonite Content on the Properties of Stereolithographic 3D-Printed Silicon-Based Ceramic Core Paste. Materials 2025, 18, 1855. https://doi.org/10.3390/ma18081855

Wang Y, Tang M, Zheng H, Hu Z, Zhong Y, Yang C. The Impact of Organic Bentonite Content on the Properties of Stereolithographic 3D-Printed Silicon-Based Ceramic Core Paste. Materials. 2025; 18(8):1855. https://doi.org/10.3390/ma18081855

Chicago/Turabian StyleWang, Yu, Mingliang Tang, Hai Zheng, Zenghan Hu, Ya Zhong, and Chuanjiang Yang. 2025. "The Impact of Organic Bentonite Content on the Properties of Stereolithographic 3D-Printed Silicon-Based Ceramic Core Paste" Materials 18, no. 8: 1855. https://doi.org/10.3390/ma18081855

APA StyleWang, Y., Tang, M., Zheng, H., Hu, Z., Zhong, Y., & Yang, C. (2025). The Impact of Organic Bentonite Content on the Properties of Stereolithographic 3D-Printed Silicon-Based Ceramic Core Paste. Materials, 18(8), 1855. https://doi.org/10.3390/ma18081855