1. Introduction

The World Report on Vision by the World Health Organization (WHO), published in 2019, reveals alarming data: it is estimated that at least 2.2 billion individuals globally experience some degree of visual impairment or loss of sight. Among these, at least 1 billion have a problem that could have been prevented or has not yet been treated [

1]. Myopia, commonly known as “short-sightedness”, has shown a significant increase, particularly among the younger population. This growing prevalence is directly related to the excessive time children and young people spend in front of digital devices. Conversely, the aging population drives the demand for single-vision lenses to correct presbyopia, an age-related eye condition. Factors such as lifestyle and fashion also influence the choice and consumption of ophthalmic lenses, highlighting the need for personalized solutions that meet the specific needs of everyone [

2].

Keeping pace with the accelerated demand, the ophthalmic lens market is expected to show a compound annual growth rate (CAGR) of 4.85% from 2022 to 2027. In monetary terms, this translates to a USD 14.3 billion increase in the lens market size [

3]. In addressing this growth, it is crucial to consider the environmental implications of increased production. The rising demand for lenses will lead to a proportional increase in generated waste, which can cause negative environmental impacts if not properly managed. Materials used in ophthalmic lens production, such as glass, plastic, and acrylic, have a long decomposition time and can pollute landfills and oceans [

4]. Although precise global data on the amount of ophthalmic lens waste (OLW) generated annually is not available, it is evident that the industry recognizes its environmental impact and has adopted various strategies to mitigate it.

To minimize these impacts, it is essential to adopt measures that promote the reduction, reuse, and recycling of waste generated from ophthalmic lenses. Studies conducted by Perez et al. [

5] highlight that plastics are the primary material used in the manufacturing of lenses and eyewear in the ophthalmic industry. However, during the production of prescription lenses, up to 90% of the thermoset material is wasted, making it unsuitable for recycling. To improve the overall energy balance and minimize environmental impact, several strategies have been proposed. These include reducing the total manufacturing time, enhancing the efficiency of scratch-resistant treatments, improving vacuum coating systems, and utilizing data generated throughout the production process. Furthermore, the recycling of waste generated from processing materials emerges as a viable alternative. It is argued that the implementation of these measures can significantly contribute to reducing energy consumption, carbon footprint, waste generation, and operational costs in the manufacturing of ophthalmic lenses and eyewear.

The approach proposed by Encarnação et al. [

6] involves integrating solid waste materials from ophthalmic lenses into polymer and cement matrices, alongside using effluent for cultivating microalgae. This pioneering approach concentrates on biomass production and the economic enhancement of waste. By implementing a circular economy framework, the objective is to transform ecological contaminants found in the effluent into valuable organic products. Batista et al. [

7] investigated the feasibility of creating composites using bamboo powder and OLW combined with polyester resin. These materials are often discarded in large quantities and have the potential to be reused in an environmentally sustainable manner. Tests were conducted to determine the optimal proportions of each material in the composite composition, aiming to ensure good processability and suitable mechanical properties. The results indicated that the produced composites exhibited a reduction in mechanical resistance relative to the resin matrix but demonstrated a substantial enhancement in impact resistance. For practical implementation, tables and benches were fabricated using the most cost-effective and environmentally sustainable composite composed of 40% OLW.

Considering the above, it is evident that studies are directed toward environmental awareness and reducing water consumption, electricity, and the volume of waste produced. Nevertheless, limited focus has been given to the management of solid waste produced during the fabrication of ophthalmic lenses. To address this gap, this study aims to explore the potential of OLW to enhance the properties of vulcanized rubber composite, especially styrene–butadiene rubber (SBR). The effects of incorporating OLW on rheometric, structural, and morphological properties were analyzed. SBR/OLW composites were subjected to various analytical conditions, evaluating mechanical and thermal responses, as well as the reinforcement degree between the filler and elastomeric matrix.

4. Comparative Study of Fillers in Vulcanized SBR Rubber Composites

Styrene–butadiene rubber (SBR) is a widely used synthetic elastomer in the industry due to its excellent processability, abrasion resistance, and low production cost. It is commonly employed in the manufacture of tires, footwear, automotive components, and coatings [

38]. To enhance its performance, the incorporation of particulate materials—referred to as fillers—is a common strategy. These fillers may function as reinforcing or non-reinforcing (extender) agents, depending on their nature and the degree of interaction with the polymer matrix. Reinforcing fillers, such as carbon black and silica, significantly improve the mechanical and dynamic properties of the composite through efficient dispersion and strong interfacial adhesion with the rubber matrix. In contrast, non-reinforcing fillers, such as talc and calcium carbonate, are primarily added to reduce formulation costs and increase volume, offering limited or no structural reinforcement. The appropriate selection of filler type and its compatibility with SBR are essential in determining the final performance of the material, particularly in applications that demand high strength, flexibility, or damping capacity [

39]. The following section presents scientific studies from the literature that explore the incorporation of fillers into the SBR rubber matrix, emphasizing their influence on the resulting properties of the composites.

Yang et al. [

40] employed waste derived from synthetic running tracks (WSTP) as a reinforcing agent in styrene–butadiene rubber (SBR) composites. The researchers analyzed the composition of the waste and found it to be a mixture containing, by mass fraction, approximately 10.24% ethylene–propylene–diene rubber (EPDM), 6.47% paraffinic oil, and 75.77% calcium carbonate (CaCO

3). In the composite formulations, 1.2 phr of bis(1-(tert-butylperoxy)-1-methylethyl)-benzene (BIBP) was incorporated—a bifunctional coupling agent capable of promoting chemical bonding between the organic phase of the SBR matrix and the inorganic phase of the waste material. This approach allowed for the incorporation of up to 90 phr of WSTP into the polymer matrix, resulting in significant improvements in mechanical properties. The unfilled composite exhibited a tensile strength of only 0.78 MPa and an elongation at break of 180%, attributed to the low molecular weight and reduced entanglement of the polymer chains. In contrast, the formulation containing 90 phr of WSTP demonstrated a tensile strength of 1.35 MPa and an impressive elongation at break of 1270%, which was attributed to the interaction between the rubber and the waste, indicating the formation of a type of physical crosslinking. This newly formed network contributed to better energy dissipation and, consequently, enhanced mechanical performance. The interfacial adhesion between the waste and the matrix was confirmed by scanning electron microscopy (SEM) images, which revealed a homogeneous distribution of WSTP particles within the SBR matrix. The authors emphasized that good filler dispersion favors improved mechanical performance. Furthermore, numerous particles were observed on the fracture surface of the composites; although some protruded from the surface, their contours with the matrix appeared blurred, indicating good compatibility. Larger particles were also embedded in the matrix, further suggesting satisfactory interfacial adhesion. This compatibility was attributed to the hydrophobic nature of WSTP, which favors interaction with the similarly nonpolar SBR matrix. Since the main component of WSTP is calcium carbonate, an inorganic material with a high modulus, this waste acted as a self-reinforcing filler in the composites. Consequently, increasing the WSTP content led to a gradual enhancement in the tensile strength of the composites. However, the strong interfacial adhesion also restricted the mobility of the SBR chains, which may result in decreased elongation at break with higher filler content. Swelling experiments were conducted by immersing the SBR/WSTP composites in toluene at room temperature for 24 h. It was observed that the degree of swelling increased with the WSTP content. Given that WSTP does not swell in toluene, this increase was attributed exclusively to the SBR matrix, indicating a reduction in its chemical crosslinking density. Thus, while mechanical strength benefited from the high modulus of the filler and the strong interfacial adhesion, the increased molecular mobility contributed to the enhanced elongation at break observed in the composites.

Abd El Aziz et al. [

41] investigated the reinforcing effect provided by carbon black derived from agricultural waste biochar, used as a partial substitute for commercial carbon black in SBR rubber composites. As expected, the results were significant, given the inherently reinforcing nature of carbon black. The composite containing 100% commercial carbon black exhibited a tensile strength of 14.9 MPa and an elongation at break of 633%. In contrast, the composite formulated with 100% biochar-derived carbon black showed a tensile strength of 7 MPa and an elongation at break of 750%. Finally, the composite produced with an equal (50%) mixture of commercial and biochar-derived carbon black achieved a tensile strength of 11.2 MPa and an elongation at break of 700%. Scanning electron microscopy (SEM) analysis revealed that the progressive substitution of commercial carbon black with biochar promoted the formation of aggregates within the matrix. Crosslink density analyses, determined by swelling experiments in toluene, indicated that increasing the proportion of biochar led to a reduction in the rubber’s crosslink density. This behavior was attributed to the constant amount of curing agents used across all formulations.

Lopes et al. [

42] evaluated the use of EVA (ethylene-vinyl acetate) waste incorporated into styrene–butadiene rubber (SBR) composites, aiming to propose a sustainable application for this residue within the footwear industry. The formulations were prepared with 10 and 20 parts per hundred rubbers (phr) of EVA waste, both at laboratory and industrial scales, and subjected to various tests to characterize their physical, mechanical, and rheological properties. Rheometric analyses indicated that the addition of EVA slightly affected the vulcanization parameters of the SBR matrix. A small increase in the scorch time (t

s) was observed compared to the virgin material, along with a reduction in maximum torque (M

H), suggesting a slight decrease in the crosslink density. Despite these variations, the changes were not deemed significant enough to require adjustments to the original formulation. In the laboratory-scale samples, the incorporation of EVA waste did not compromise properties such as flexural performance, density, or hardness, all remaining within the limits established by the Portuguese Footwear Technology Centre (CTCP). The density values ranged from 1.13 to 1.17 g cm

−3, while hardness values varied between 57 and 62 Shore A—both suitable for outsole applications. Regarding abrasion behavior, an increase in material loss was recorded with higher EVA content, a result attributed to the presence of larger, less-integrated particles that detached more easily from the matrix. Nevertheless, all values remained below the CTCP’s upper limit of 250 mm

3. With respect to tear resistance, SBR composites containing 10 phr of EVA exhibited values at the lower limit permitted by the standard, while those with 20 phr showed a slight decrease, particularly after thermal aging. Tensile strength followed a similar trend: a slight increase was observed at 10 phr, whereas a mild reduction occurred at 20 phr. Still, all measurements exceeded the required threshold of 8 MPa, indicating that the mechanical performance remained acceptable despite partial substitution by waste material. In industrial trials aimed at outsole production, the results were consistent with those obtained in the laboratory. Hardness and density remained stable, and flexural resistance was unaffected. Interestingly, the tear resistance of the outsoles incorporating EVA waste improved compared to laboratory-prepared sheets. This difference was attributed to the anisotropy induced by the multidirectional flow of material during molding, which may have promoted greater polymer chain entanglement. Tensile strength, although adequate, approached the minimum acceptable threshold, particularly in the composite containing 20 phr of EVA. Overall, the study demonstrated that incorporating up to 20 phr of EVA waste into SBR composites is technically feasible and compatible with the mechanical and physical requirements of the footwear industry. The waste acted as a non-reinforcing filler, providing moderate reinforcement in certain properties while contributing to slight reductions in others, such as tensile and tear strength. Nevertheless, the composites met all technical specifications, confirming the viability of sustainably reusing thermoset residues like EVA in higher value-added products.

Shanmugharaj et al. [

43] compared the effects of pure silica (SiO

2) and a functionalized hybrid silica–graphite (SiG) filler on the rheological, mechanical, and abrasion resistance performance of vulcanized SBR composites. The results demonstrated that the silica–graphite filler, synthesized via chemical grafting of silica onto expanded graphite, provided significantly superior reinforcement compared to pure silica. Specifically, the incorporation of 20 parts per hundred rubber (phr) of SiG led to an approximate 160% increase in the 100% modulus relative to unfilled SBR, whereas the same loading of pure silica resulted in only a 50% increase. This substantial difference indicates a considerable enhancement in material stiffness when using the hybrid filler, which is attributed to the stronger interaction between the polymer matrix and the filler, as well as to the lamellar morphology of graphite that promotes mechanical interlocking and more effective stress transfer. Tensile strength was also positively influenced. With 20 phr of pure silica, a 33% increase in tensile strength was observed, while the same amount of SiG produced a 45.5% improvement. Although elongation at break showed a decreasing trend with higher filler content—an expected outcome due to the presence of rigid domains that facilitate crack propagation—all values remained suitable for elastomeric applications. Complementary bound rubber tests revealed a higher amount of physically entrapped rubber at the filler–elastomer interface in composites containing SiG compared to those with pure silica. The bound rubber content increased by approximately 20% in the SiG systems, indicating a more cohesive and effective interface for mechanical load transfer. Additionally, composites filled with SiG exhibited lower swelling indices in toluene, suggesting a denser network structure consistent with a higher degree of physical and/or chemical entanglement between the filler and the matrix. These findings were corroborated by scanning electron microscopy (SEM) micrographs, which revealed better dispersion of SiG particles within the SBR matrix, with average sizes below 5 μm, whereas pure silica formed agglomerates up to 10 μm in size. Furthermore, abrasion performance was markedly improved in the SiG-containing composites. For the formulation with 40 phr, abrasion loss was reduced by 59% compared to neat SBR and was significantly lower than the 32% reduction observed with conventional silica. Overall, the results indicate that silica–graphite acts as a highly efficient reinforcing filler for SBR, delivering substantial enhancements in mechanical properties and wear resistance. The synergistic effect between the lamellar structure of graphite and the functional groups of silica not only promotes better interfacial coupling but also introduces a geometric reinforcement effect not observed with traditional fillers such as pure silica or carbon black. These findings are promising for the development of high-performance and more sustainable elastomeric composites, with potential applications in tires, footwear, and other sectors requiring elevated mechanical strength combined with enhanced durability.

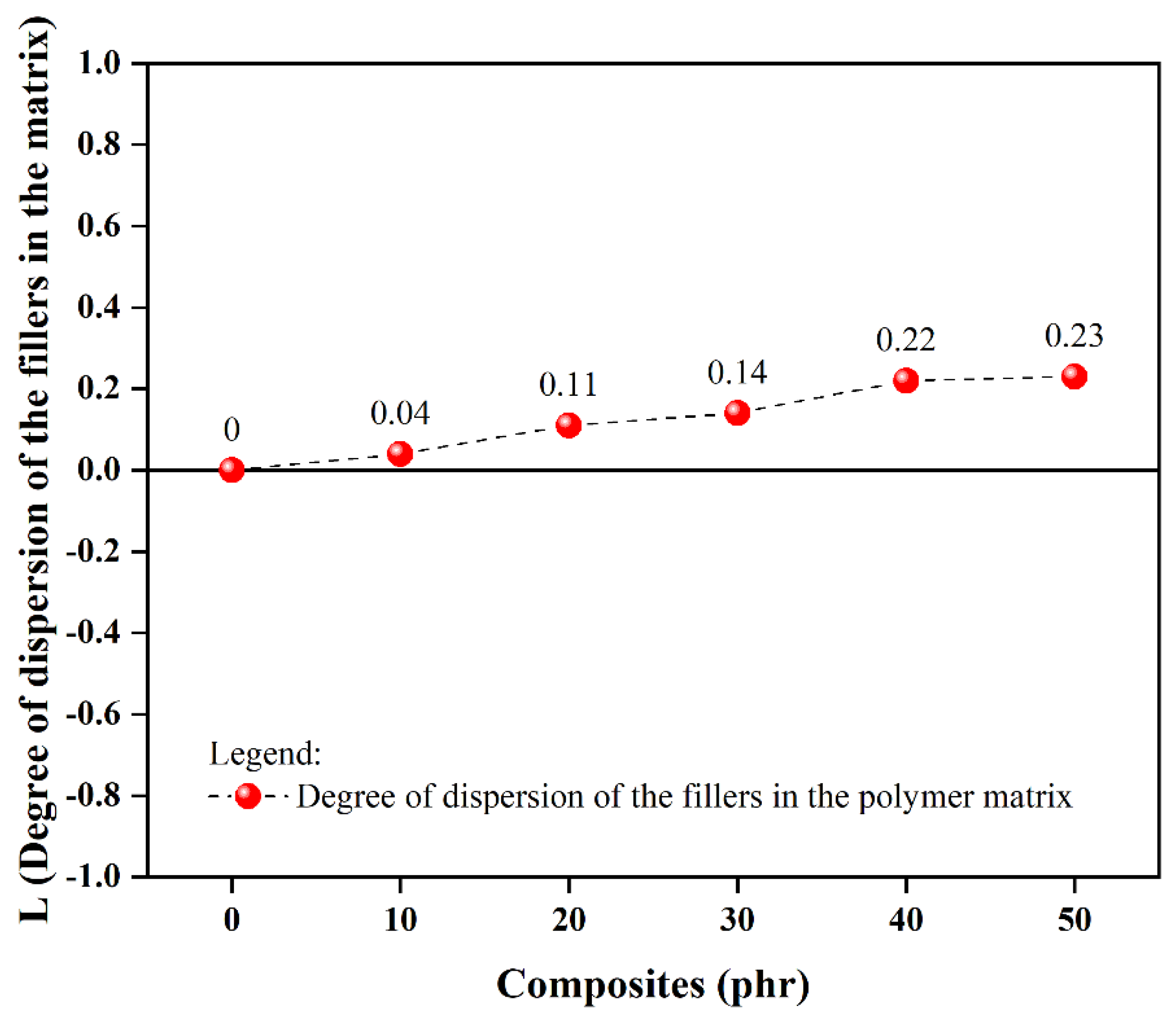

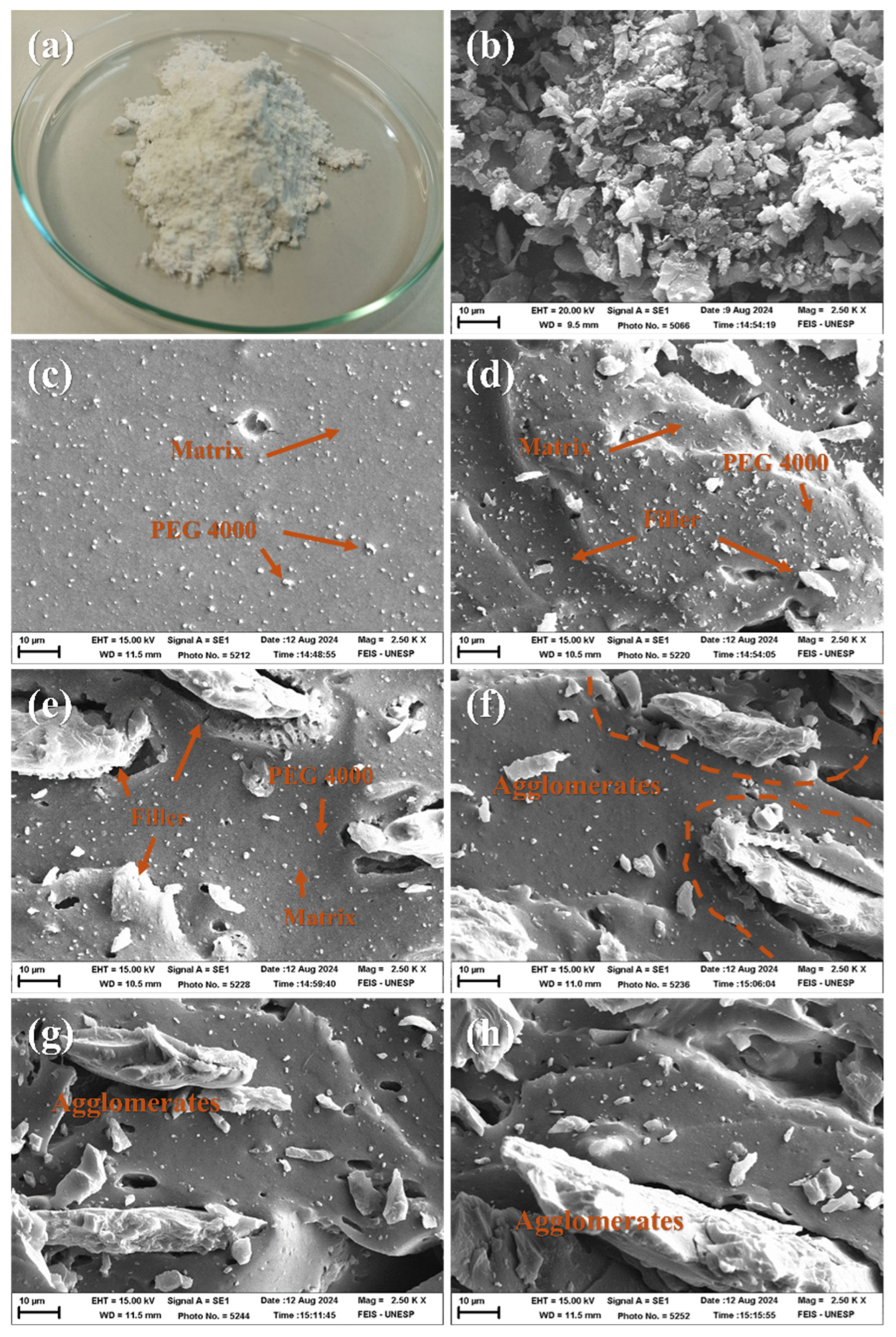

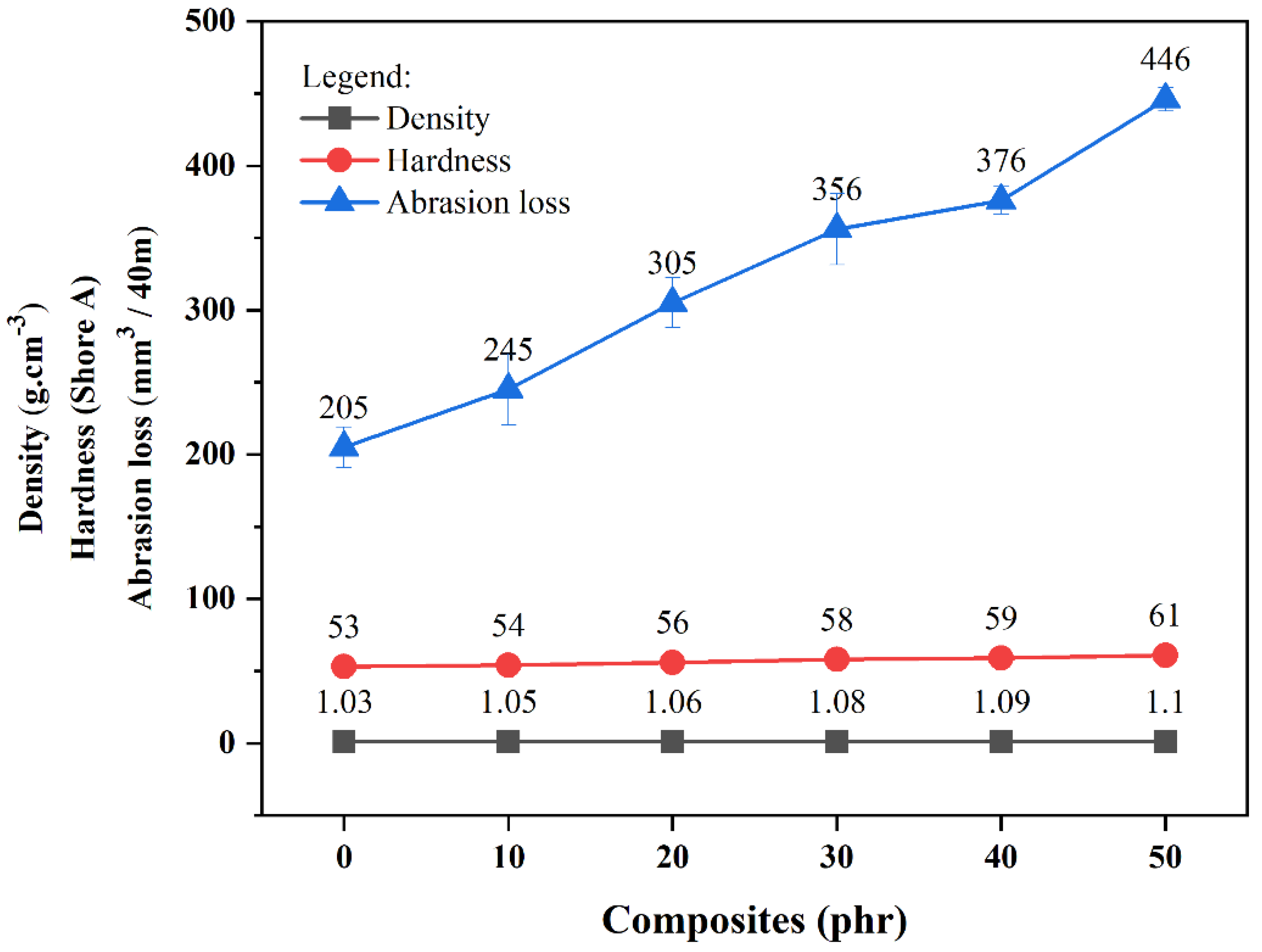

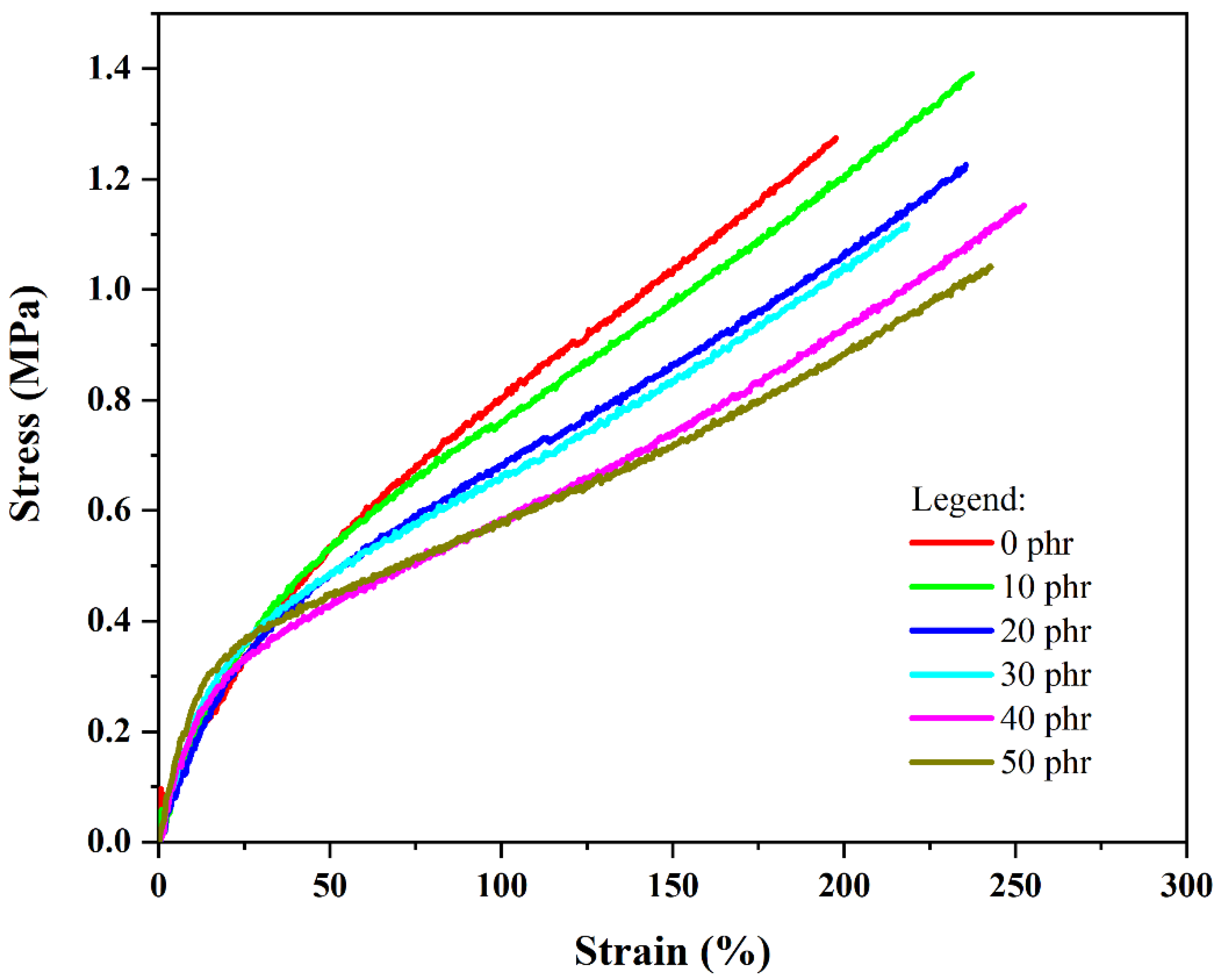

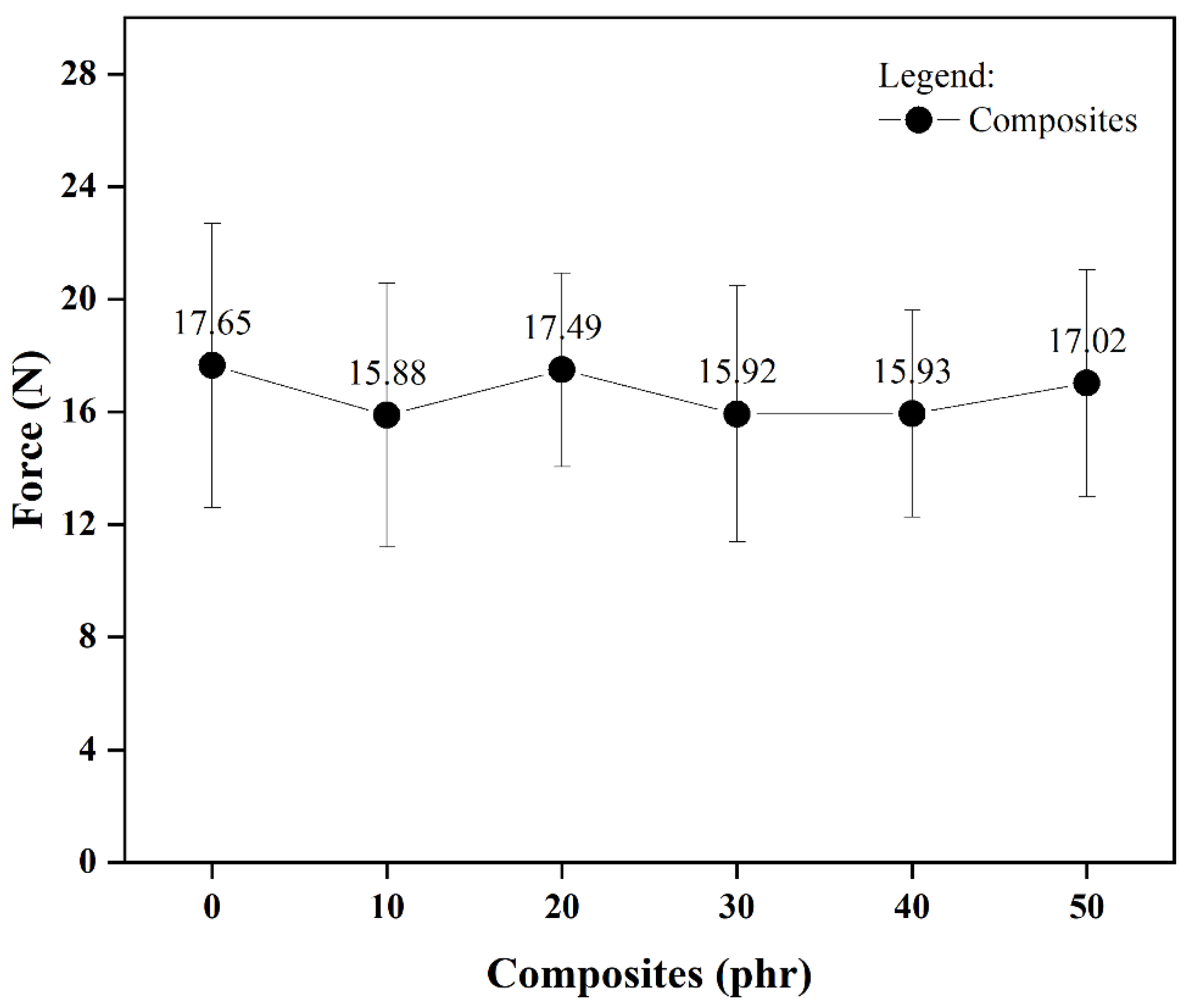

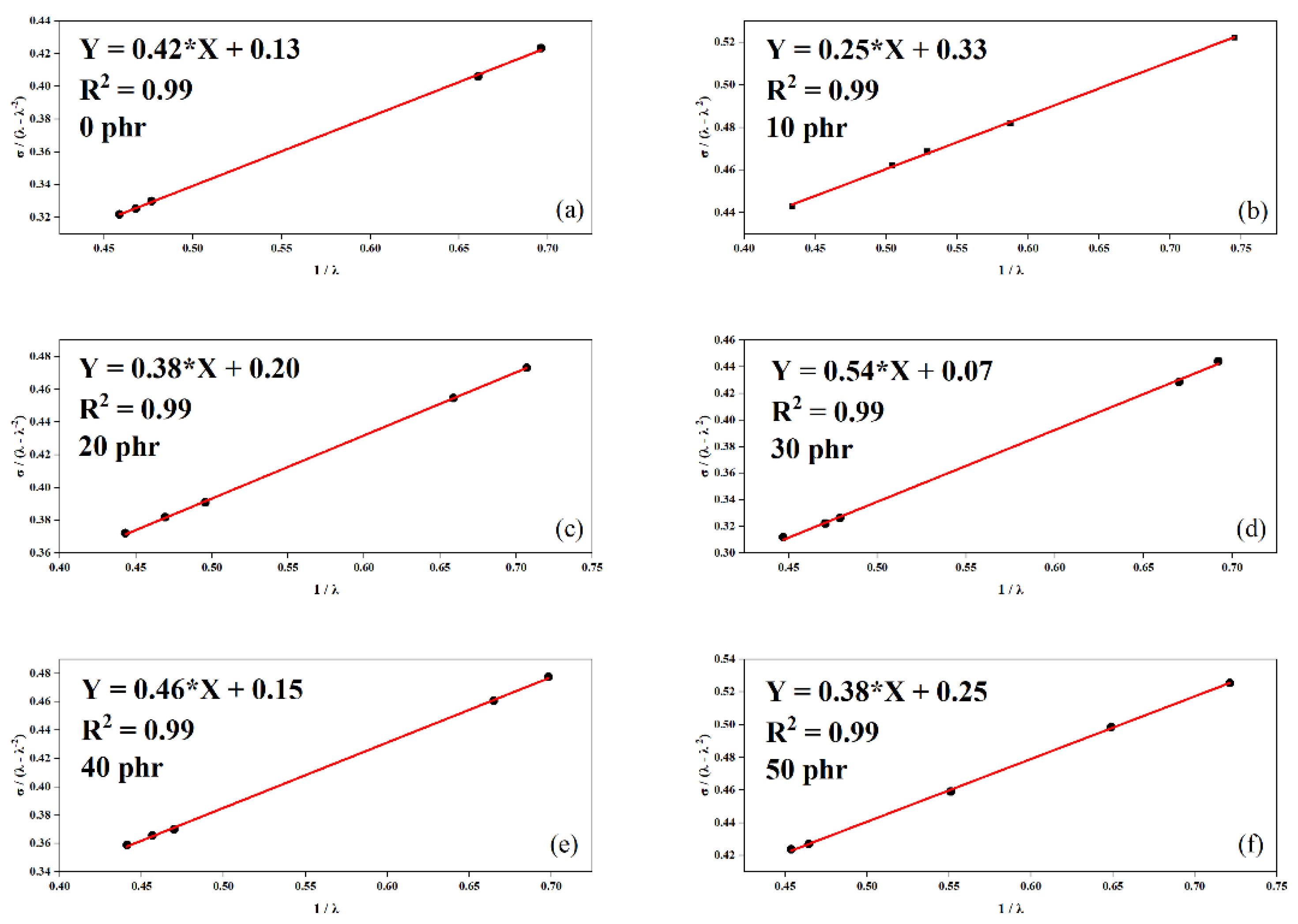

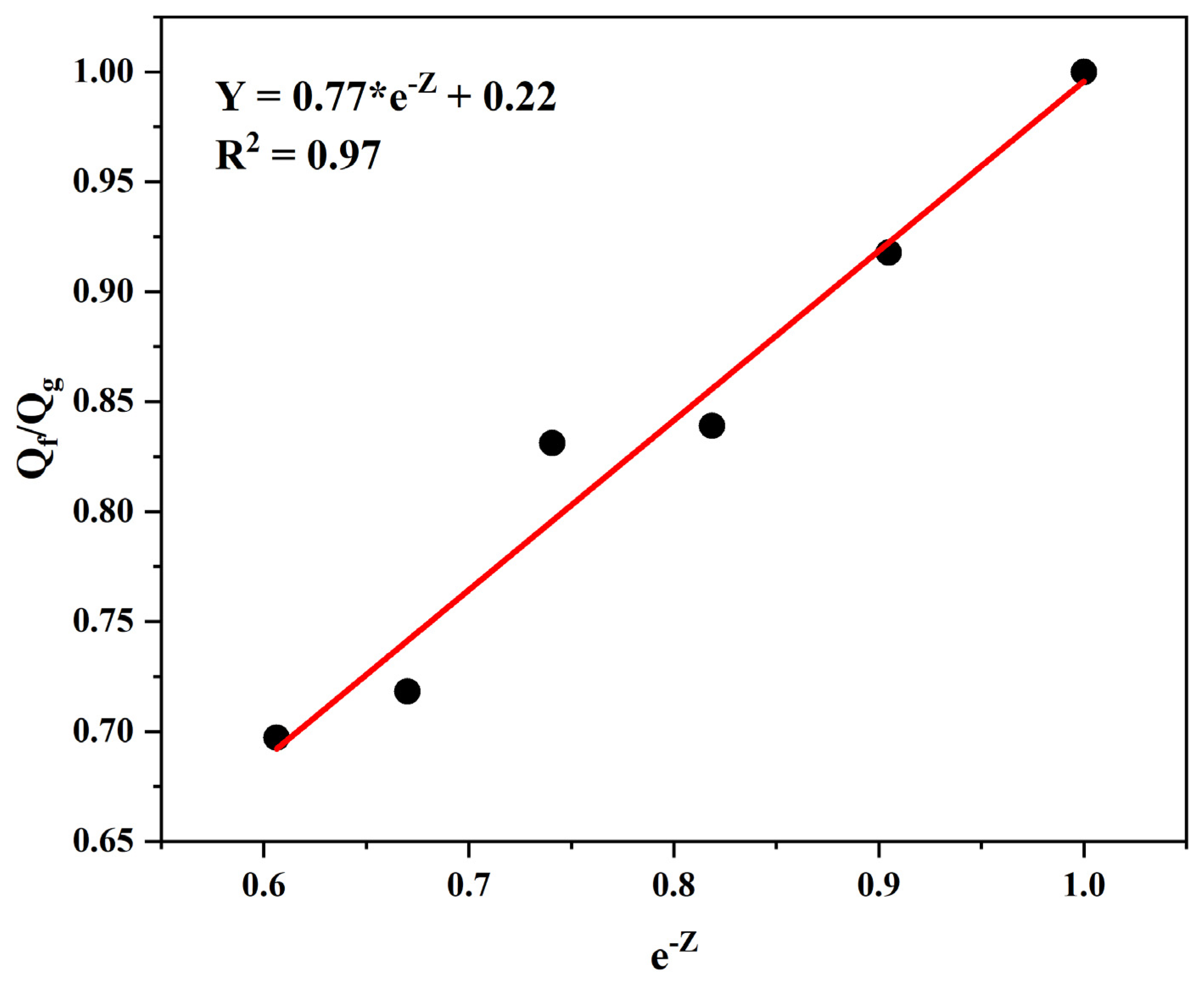

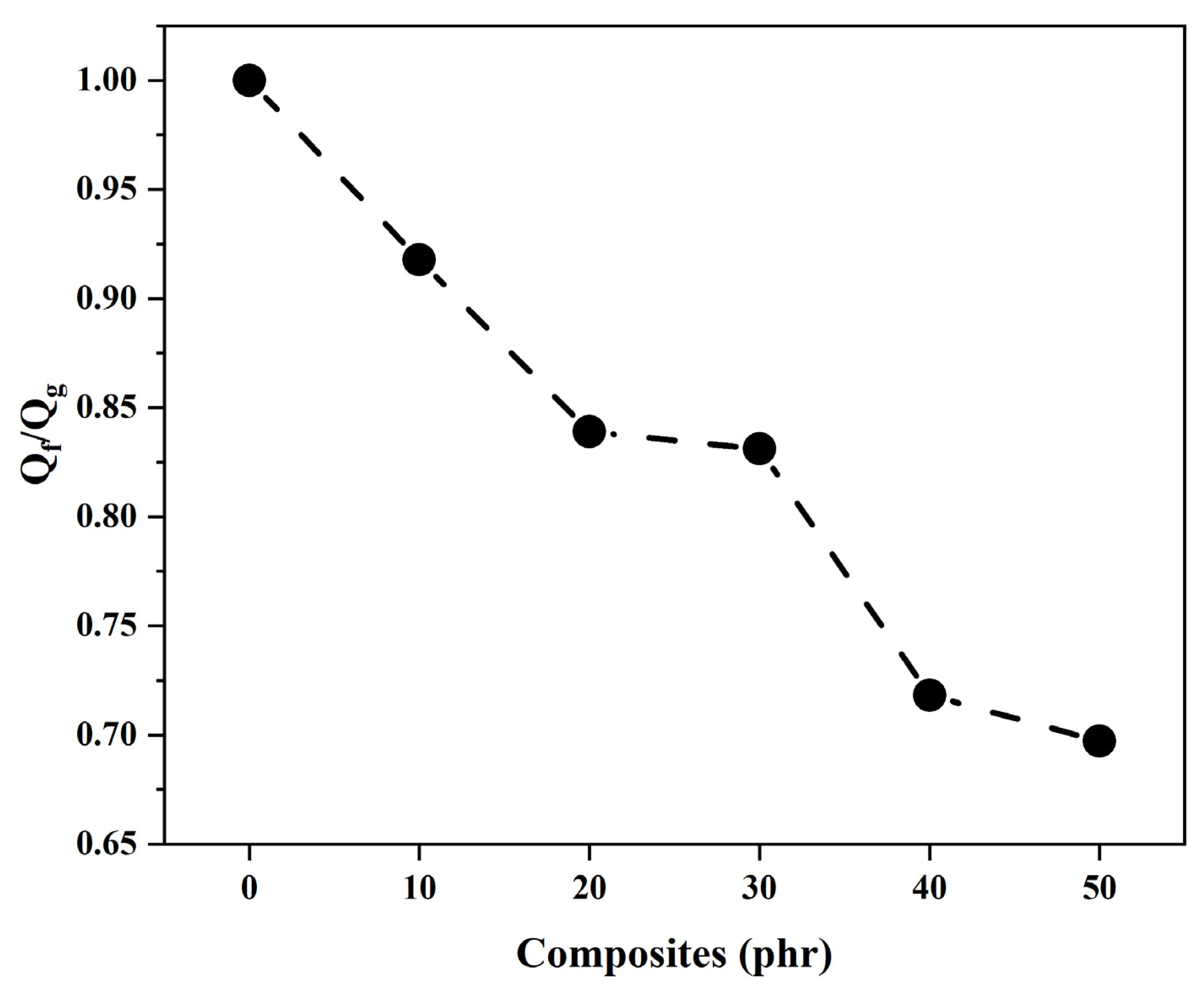

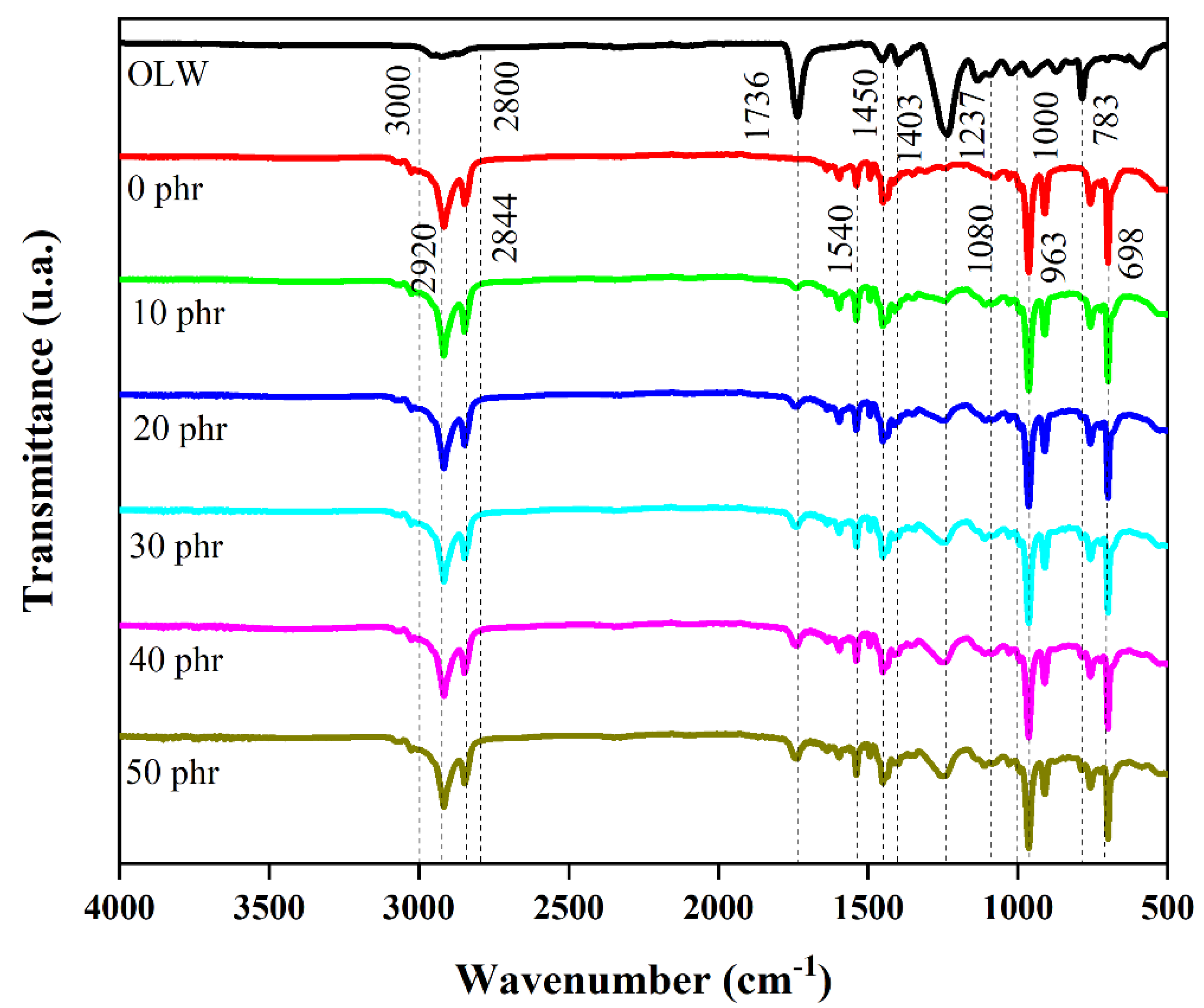

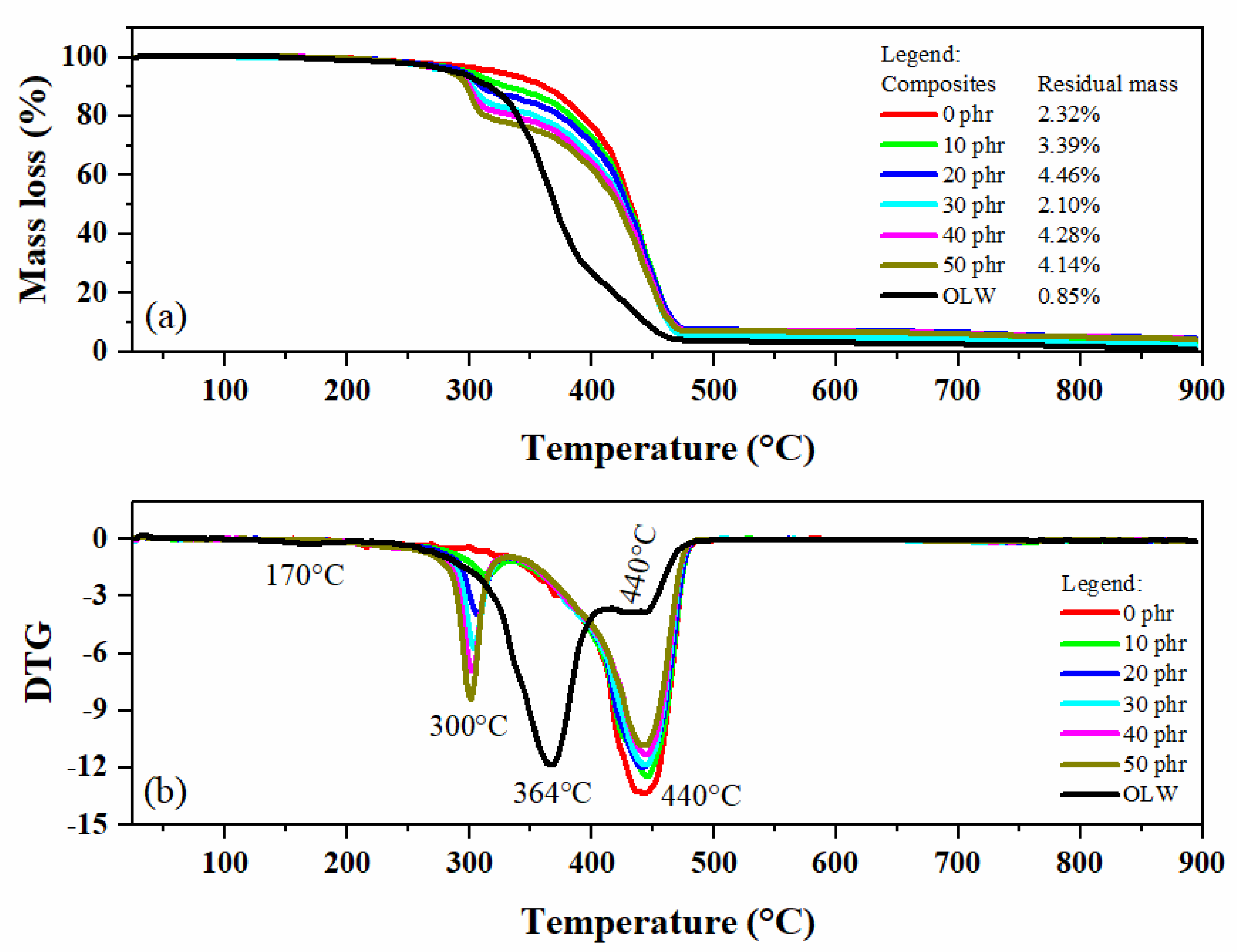

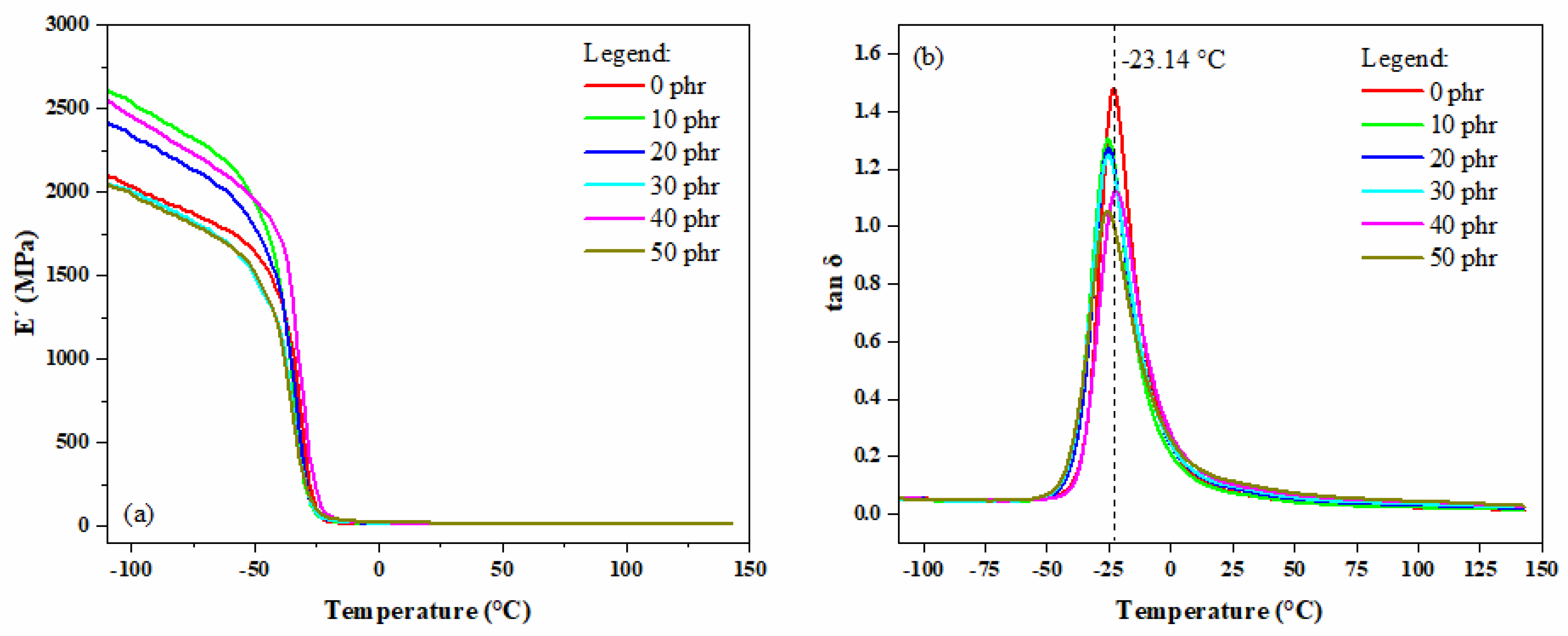

In our study, 2 phr of the coupling agent Chartwell® was employed. The results demonstrated that the incorporation of ophthalmic lens waste (OLW) into styrene–butadiene rubber (SBR) composites led to significant improvements in several physico-mechanical and thermal properties, particularly in formulations containing between 10 and 20 phr of OLW. These compositions proved to be the most balanced in terms of mechanical performance and stability and were identified as the most suitable for practical applications such as the production of footwear soles and rubberized flooring. Regarding mechanical properties, the addition of 10 phr OLW resulted in the highest elongation at break (236.74 ± 27.76%), surpassing even the control composite (without OLW), which exhibited 184.02 ± 23.78%. Moreover, this formulation also showed the highest tensile strength among the evaluated composites (1.34 ± 0.16 MPa), indicating that, at low concentrations, OLW can positively contribute to the mechanical strength of the material. Shore A hardness analysis revealed a progressive increase in the OLW content, indicating a rise in the surface stiffness of the composites. This behavior was accompanied by an increase in density, which rose from approximately 1.0 to 1.1 g·cm−3 with the incorporation of up to 50 phr OLW. These characteristics are desirable in applications that demand higher resistance to surface wear, such as footwear and industrial coatings. Morphological analysis via scanning electron microscopy (SEM) revealed good dispersion of OLW particles within the SBR matrix up to 30 phr, with homogeneous distribution and a well-defined interface. Above this concentration, agglomerations and the formation of stress concentration points were observed, which may compromise mechanical performance. With respect to crosslink density, both the swelling method (Flory–Rehner) and mechanical analysis (Mooney–Rivlin) indicated a systematic increase in the polymer network connectivity upon OLW addition. The crosslink density ranged from 1.31 × 10−4 mol·cm−3 (0 phr) to 1.47 × 10−4 mol·cm−3 (50 phr), suggesting that OLW acts as a restricting agent on polymer chain mobility. However, FTIR spectroscopic analysis did not detect the formation of chemical bonds between OLW and the polymer matrix, indicating that the interaction occurs predominantly through physical effects and surface adhesion. Thermal analysis by thermogravimetry (TG) showed that the incorporation of OLW did not compromise the thermal stability of the composites. The samples exhibited two degradation stages associated with the decomposition of OLW and the SBR matrix, maintaining degradation temperatures above 300 °C—an acceptable behavior for various industrial applications. Finally, dynamic mechanical analysis (DMA) revealed that OLW-containing composites exhibited an increase in storage modulus (E’), confirming greater stiffness. However, there was a reduction in damping capacity, evidenced by the decrease in the tan δ peak. Despite this, the glass transition temperature (Tg) remained virtually unchanged (~−23.14 °C), indicating that the addition of OLW did not significantly affect the thermal performance of the material. Therefore, the formulation containing 10 to 20 phr of OLW represents the best combination of properties, being both technically feasible and environmentally advantageous for the production of vulcanized SBR composites intended for applications such as soles, coatings, and general-purpose materials.

5. Conclusions

The research in question investigated the feasibility of incorporating OLW into polymeric composites, aiming to develop more sustainable and economically viable solutions. One of the main aspects analyzed was the impact of OLW addition on the vulcanization parameters of SBR. The findings revealed that the OLW additive minimally affected the curing kinetics, offering potential energy efficiency benefits during production. Moreover, the waste material incorporation elevated the network density within the elastomeric matrix, as quantified through both swelling equilibrium and stress–strain analysis. These observations imply interfacial bonding between the particulate filler and styrene–butadiene elastomer, though insufficient to substantially improve the material’s load-bearing capacity, primarily functioning as a space-filling component. The analysis of matrix–filler interaction using the Lorenz–Parks model supported the observation of interaction between OLW and SBR rubber. However, such molecular interactions did not translate into meaningful improvement of the composite’s structural performance.

In the thermogravimetric tests, the composites containing OLW demonstrated good thermal stability, which is a desirable characteristic for various applications. In contrast, dynamic mechanical analysis shows that the addition of OLW to the SBR composite increases the material’s rigidity, as evidenced by the rise in the storage modulus (E’). However, this addition slightly reduces the composite’s damping capacity, as indicated by the decrease in the tan δ peak. The polymer’s viscoelastic transition point shows minimal variation, demonstrating that the heat-related characteristics of the formulated material are largely unaltered by the incorporated optical waste, while the structural and energy dissipation capabilities are modified.

Additionally, infrared spectroscopy did not detect significant chemical interactions between the polymer matrix and the filler. Based on the results obtained, it was possible to identify that the optimal compositions of OLW are in the range of 10 to 20 phr. This information enabled the production of a new vulcanized composite, demonstrating the feasibility of its application.

In summary, incorporating ophthalmic lens residues as reinforcing particulates in crosslinked styrene–butadiene elastomer formulations offers a viable approach toward developing eco-friendly and cost-effective material solutions. This study contributes to advancing knowledge on the reuse of industrial waste in the polymer industry, promoting more efficient and environmentally responsible practices.