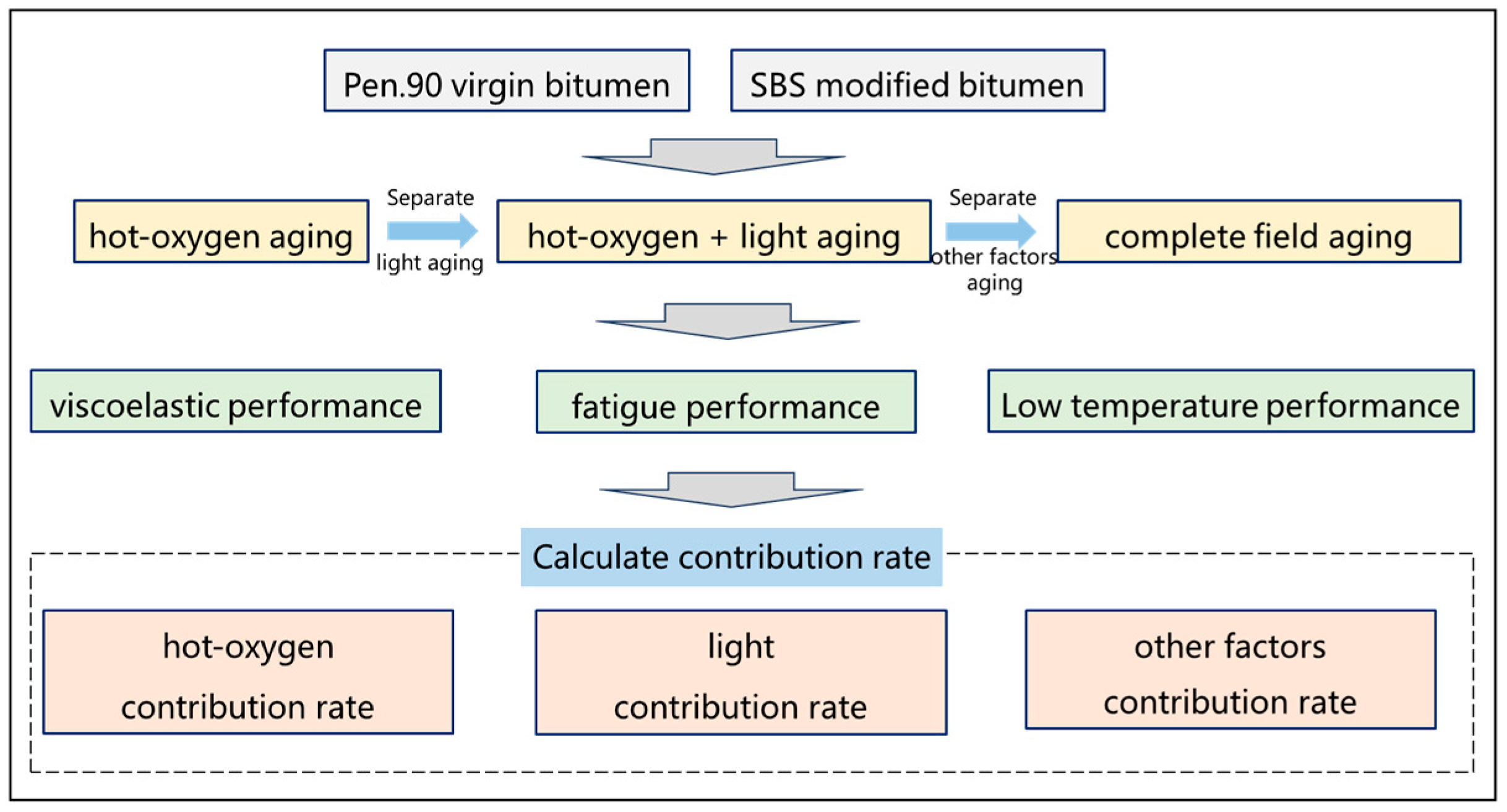

Study on the Influence and Contribution Rates of Field Aging Factors on Rheological Performance of Bitumen

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Test Methods

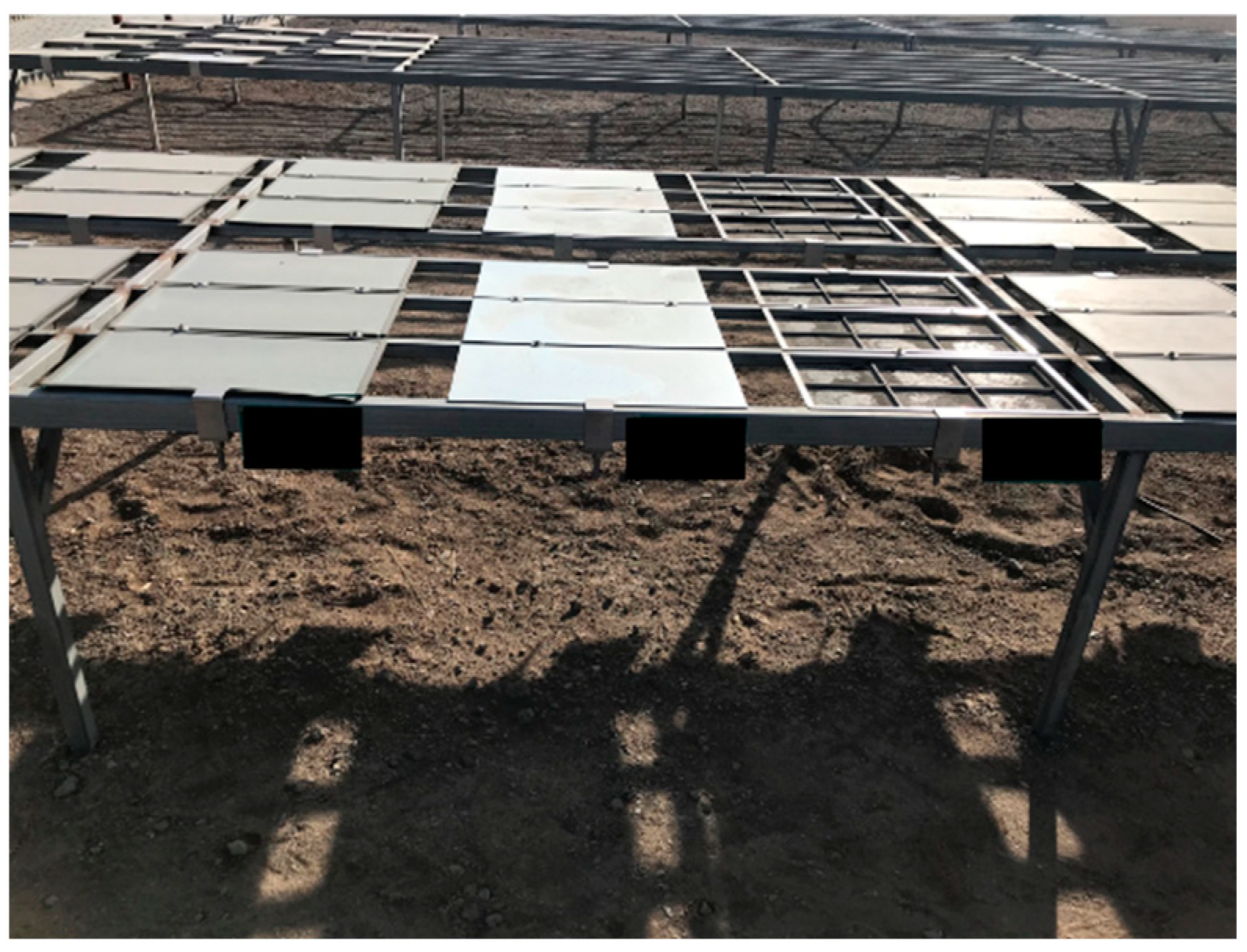

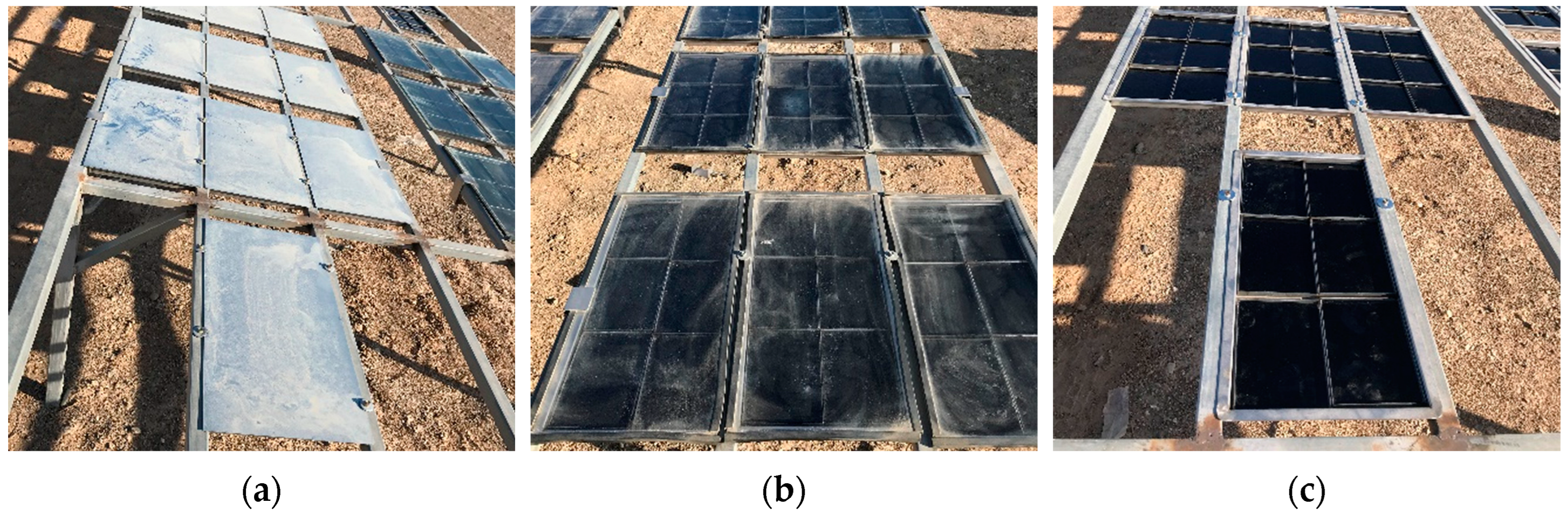

2.2.1. Field Aging Methods

2.2.2. Methods for Characterizing Rheological Performance

- Viscoelastic performance characterization of bitumen.

- 2.

- Fatigue performance characterization of bitumen.

- 3.

- Low-temperature performance characterization of bitumen.

2.3. Calculation Formula of Contribution Rates of Aging Factor

3. Results and Discussion

3.1. Influence of Various Aging Styles on Rheological Performance of Bitumen

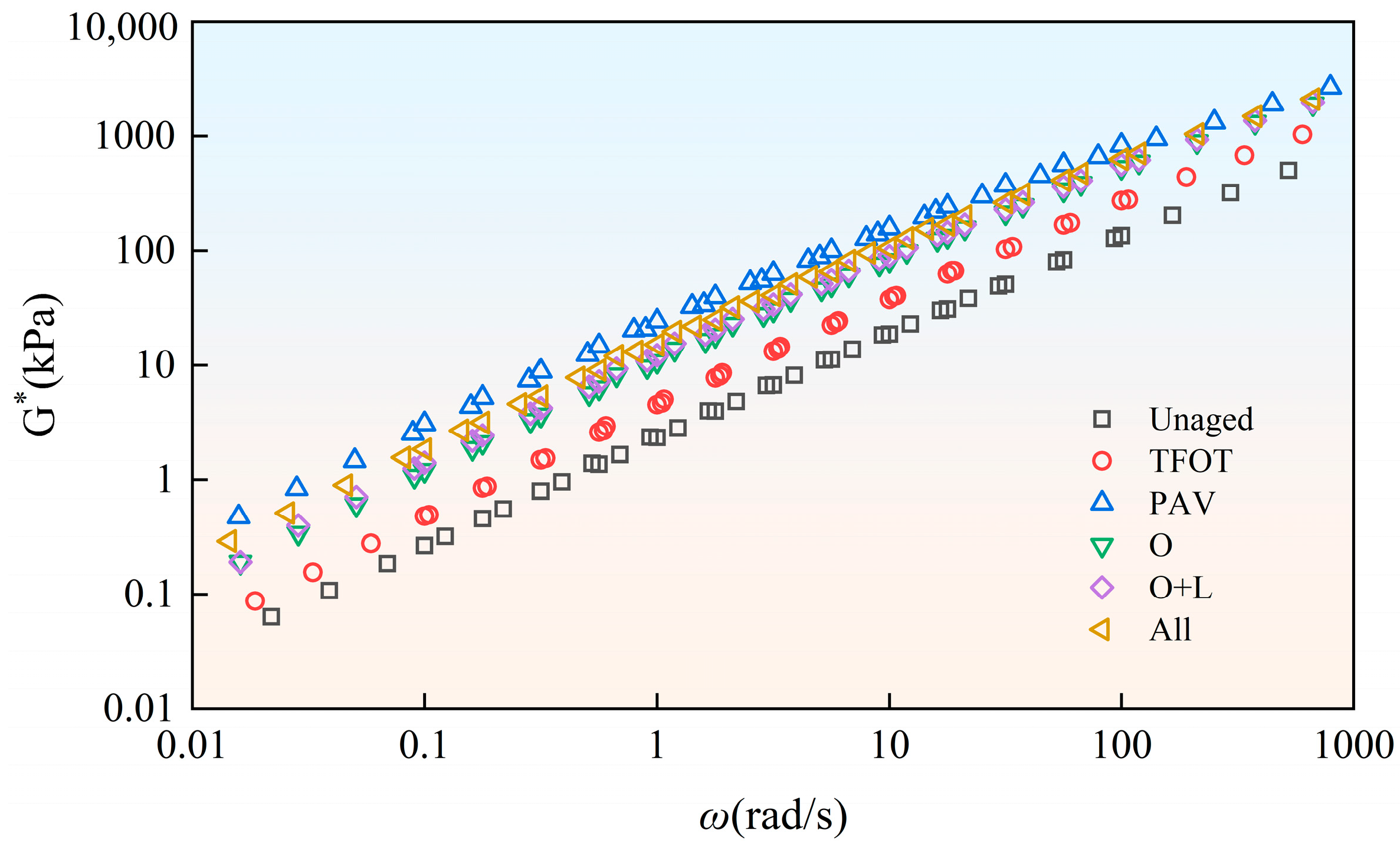

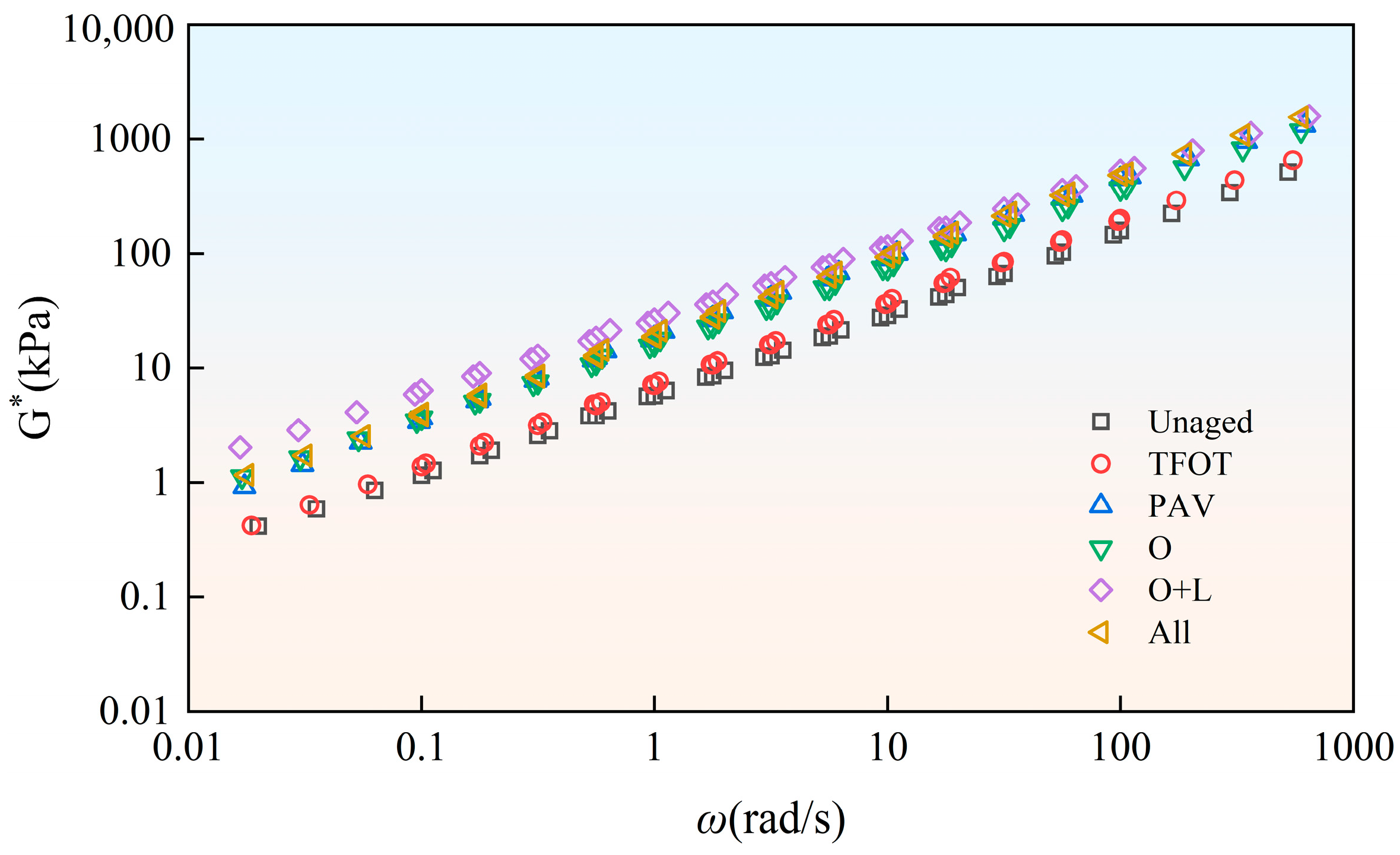

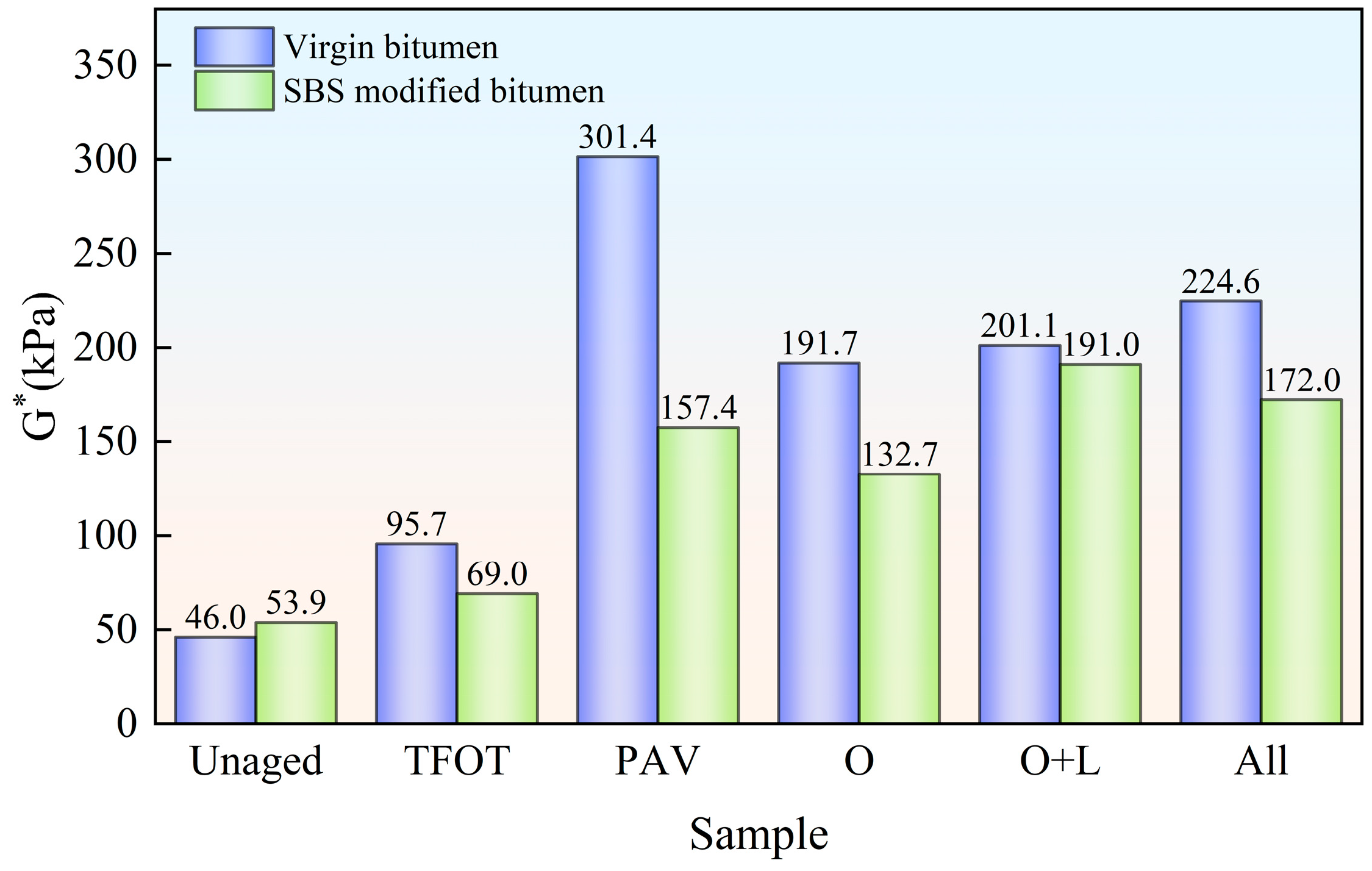

3.1.1. Influence of Various Aging Styles on Viscoelastic Performance of Bitumen

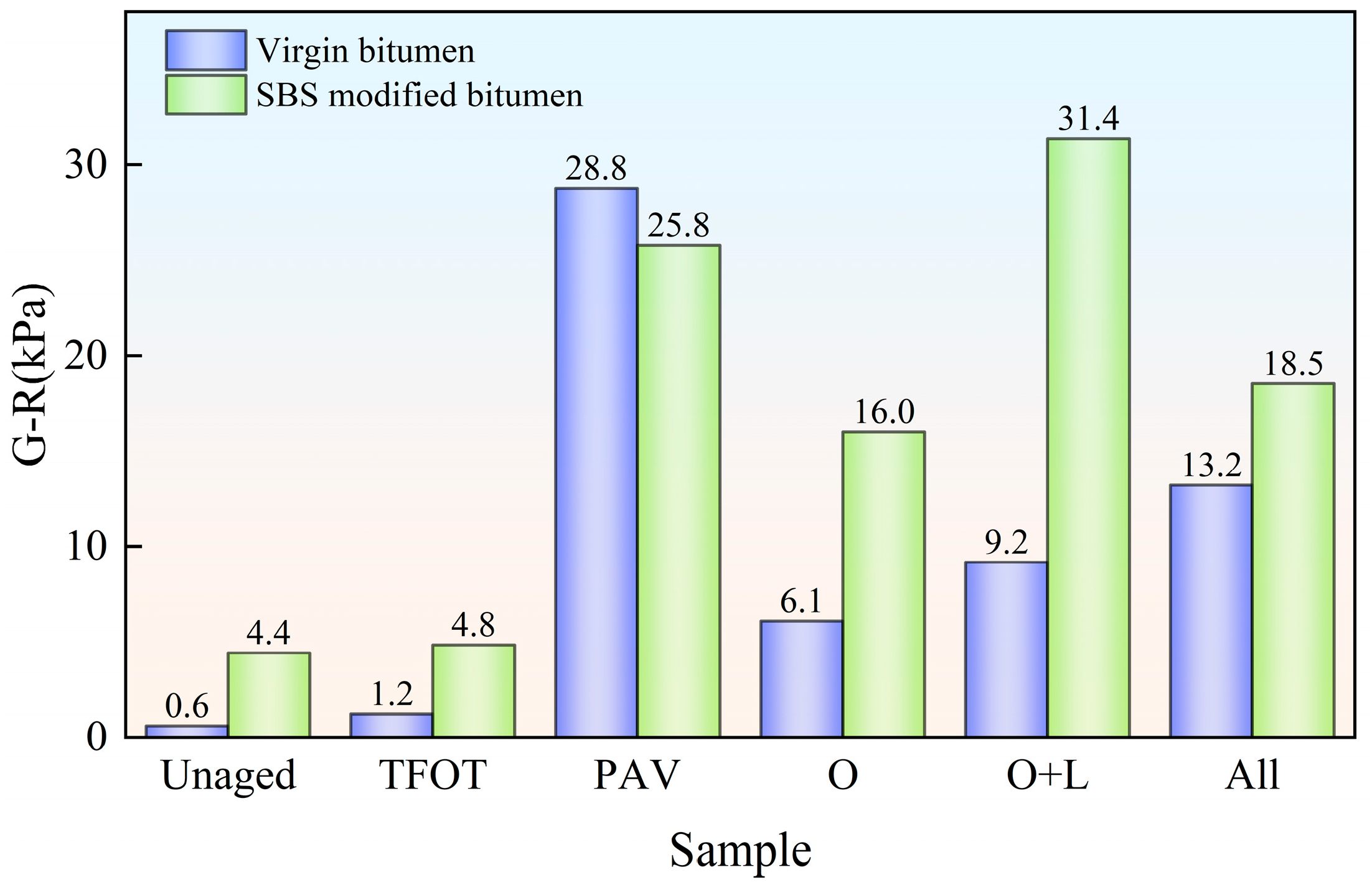

3.1.2. Influence of Various Aging Styles on Fatigue Performance of Bitumen

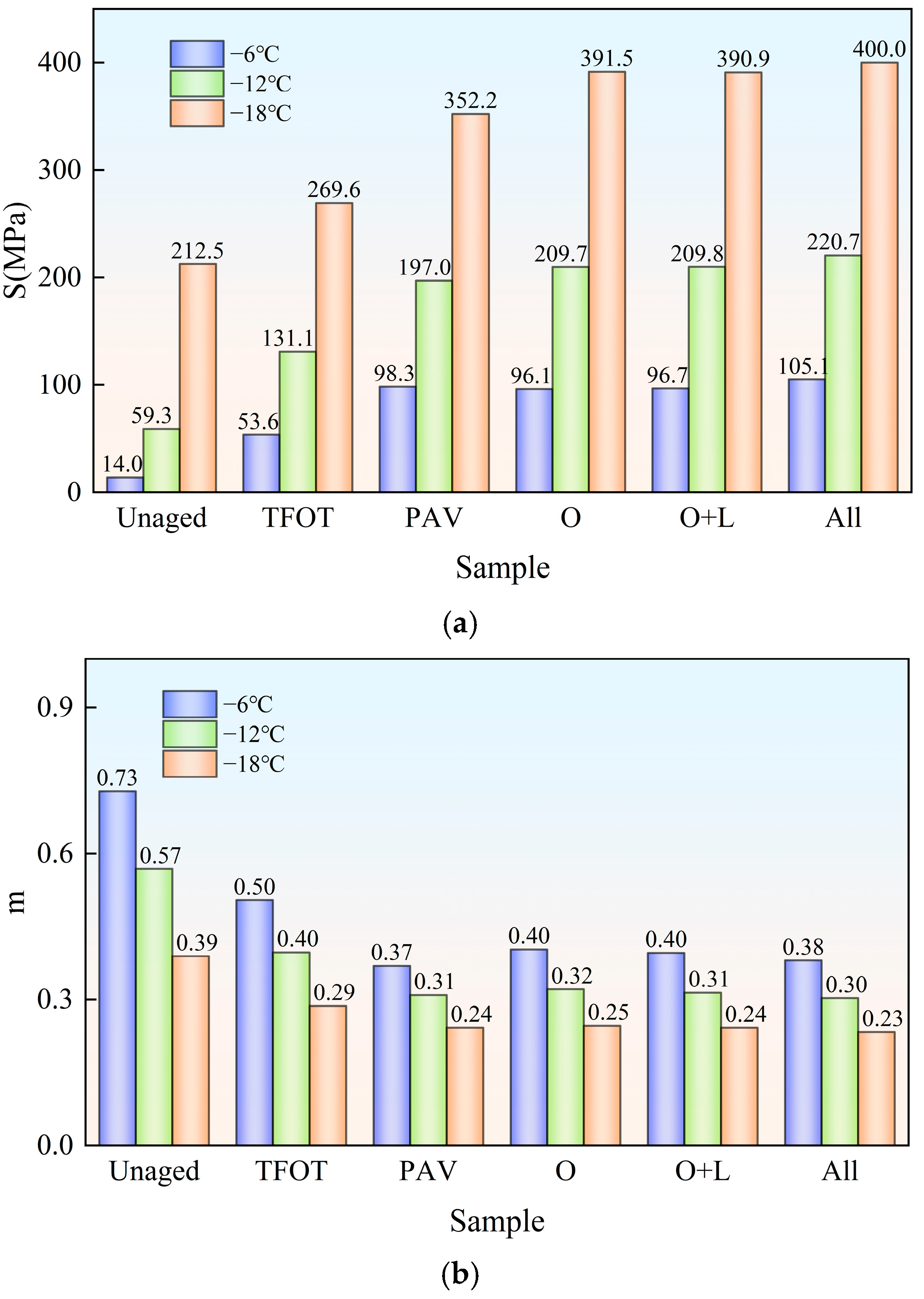

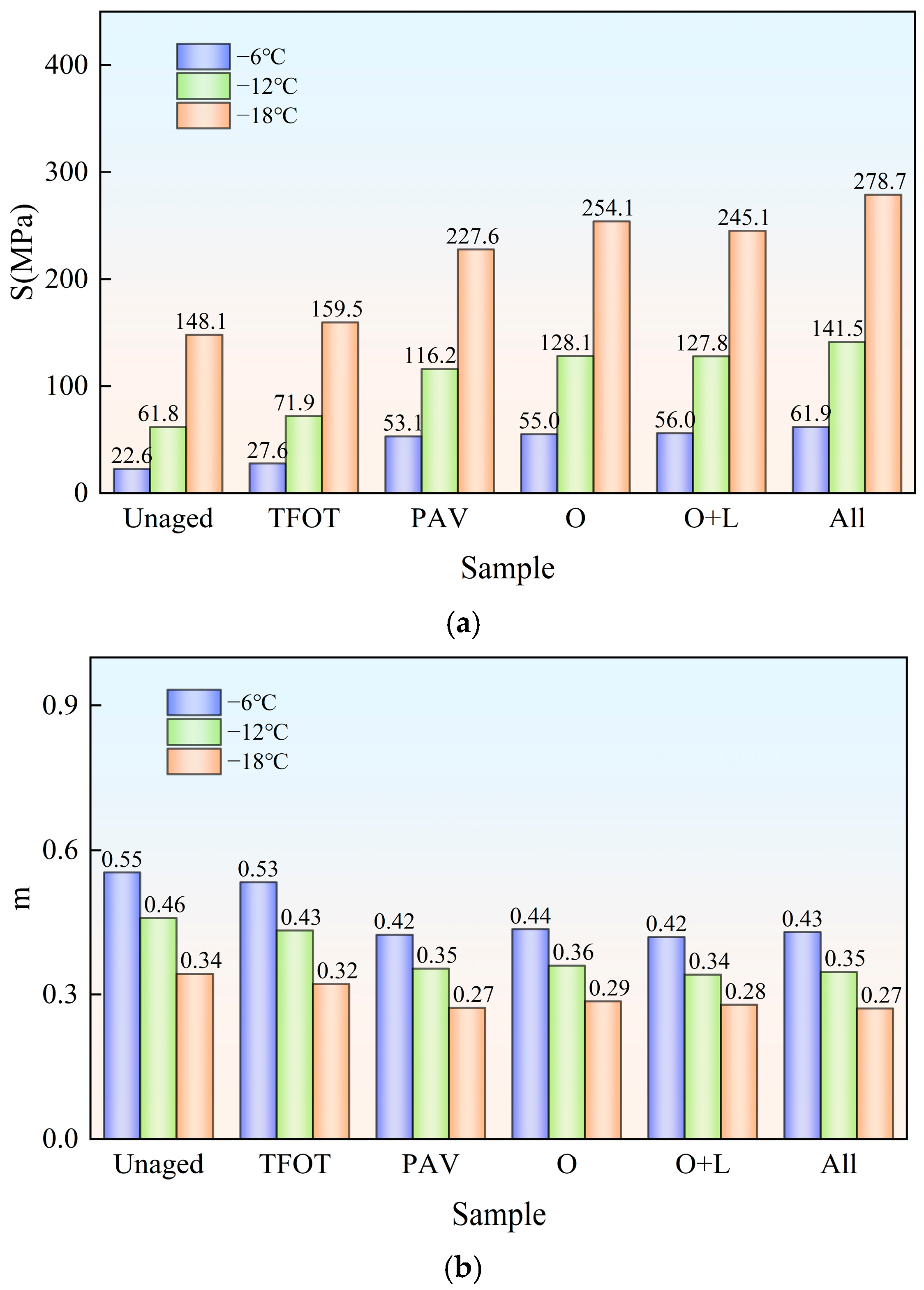

3.1.3. Influence of Various Aging Styles on Low-Temperature Performance of Bitumen

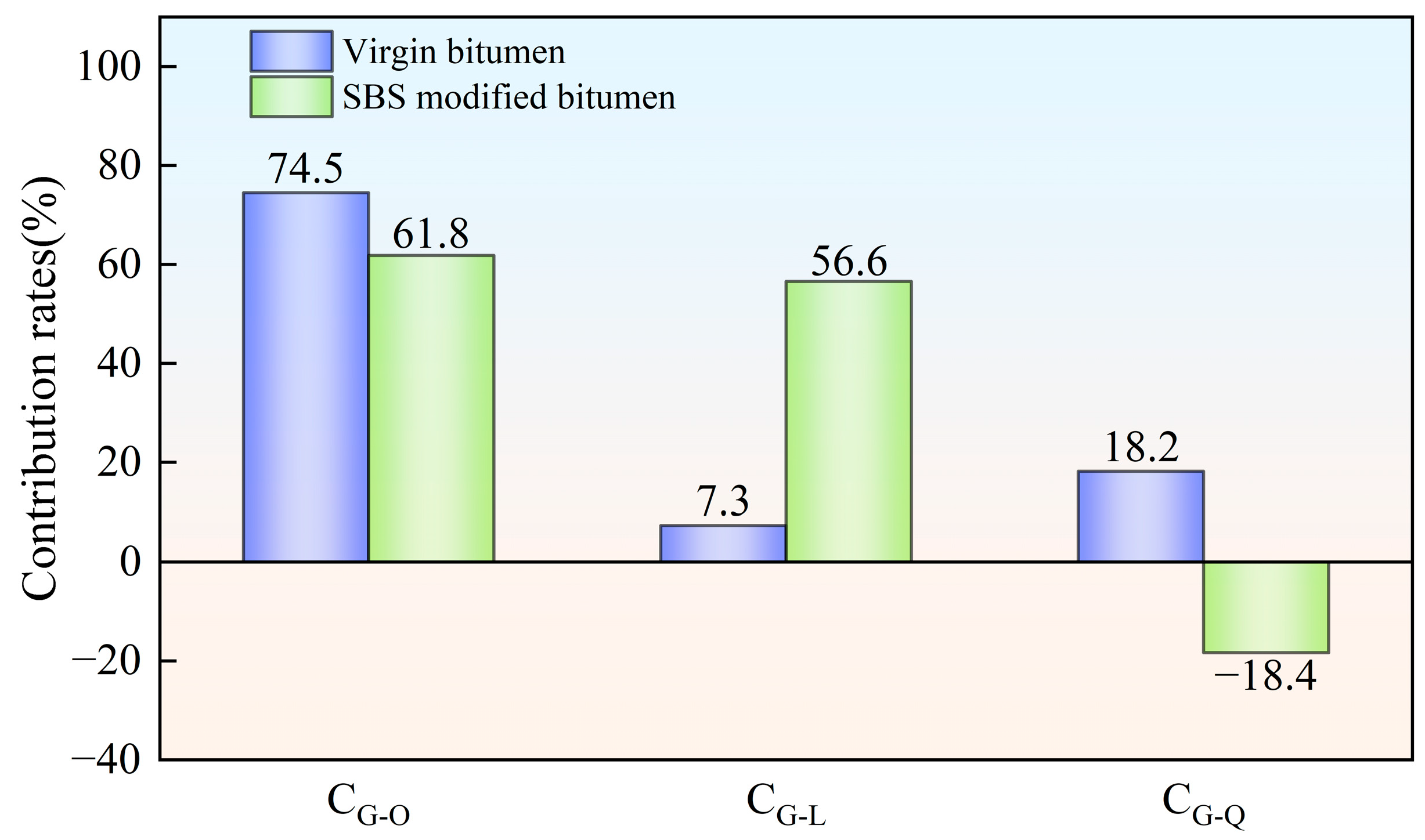

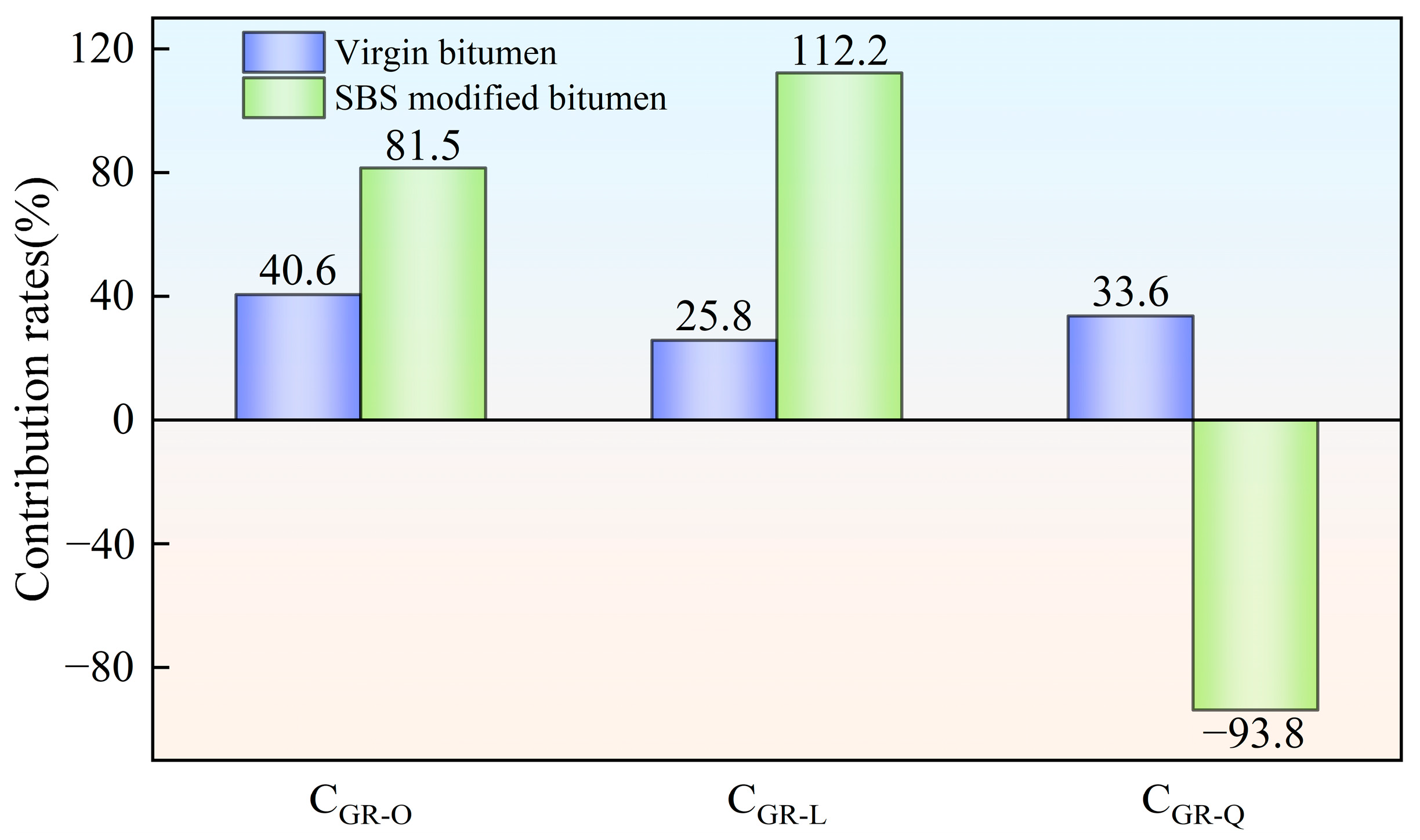

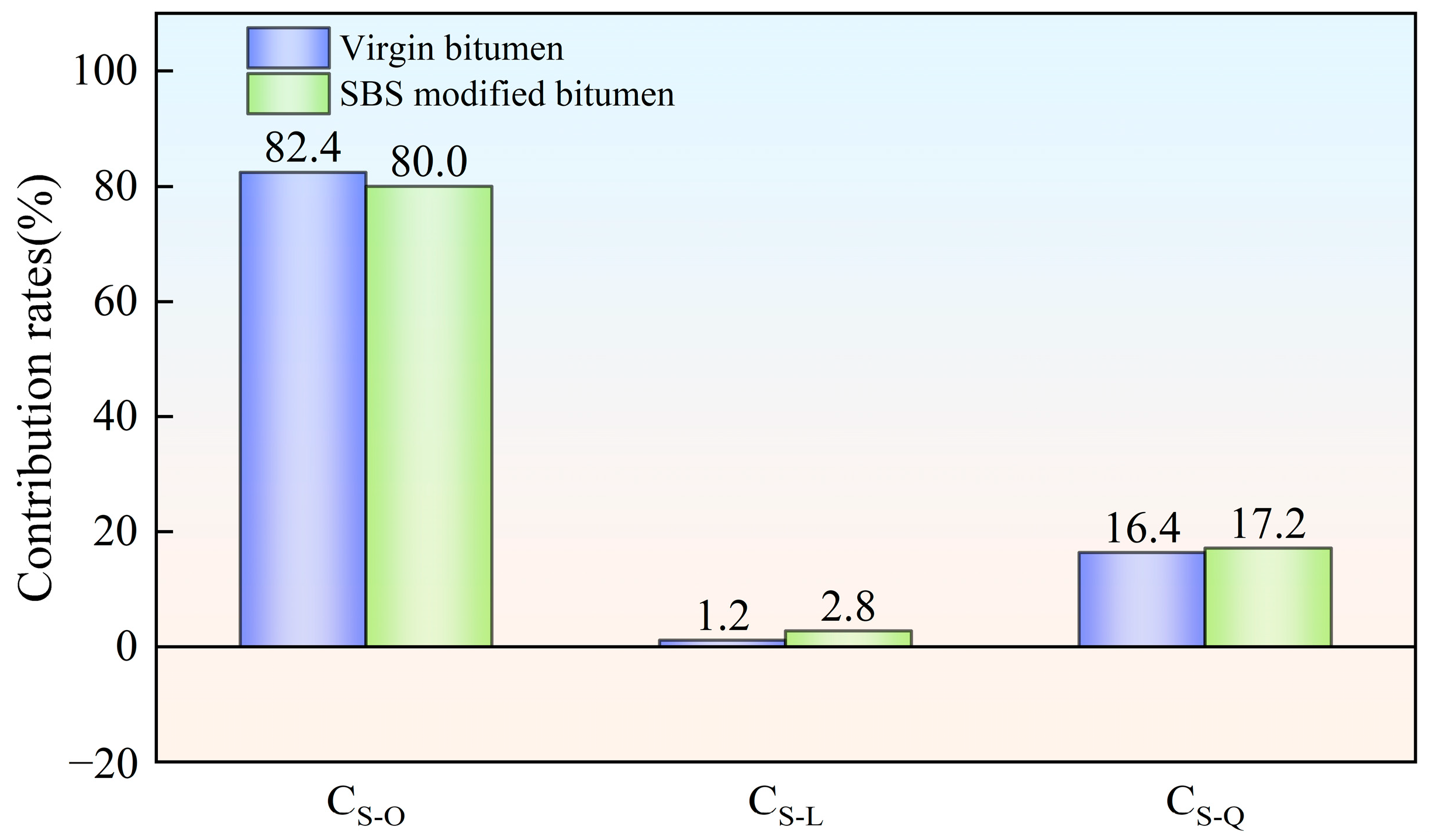

3.2. Analysis of Contribution Rates of Aging Factors Under Various Aging Styles

4. Conclusions

- The hot oxygen played a leading role in the aging process of the two types of bitumen, and the contribution rates to the rheological performance of the two types of bitumen were more than 40%. The complex modulus, G-R parameter and stiffness modulus of bitumen were significantly increased and the creep rate was reduced during the natural aging process of bitumen.

- The two types of bitumen had different sensitivity to light. The sensitivity of virgin bitumen to light aging was low. SBS-modified bitumen showed more sensitivity to light aging, especially for its fatigue performance.

- Other factors (wind, water, dust, etc.) show double effects on the aging of bitumen, which promote the aging of virgin bitumen. However, SBS-modified bitumen showed the effect of inhibiting aging for viscoelastic performance and fatigue performance. This may be related to the physical shielding effect of such factors.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pei, Z.; Xu, M.; Cao, J.; Feng, D.; Hu, W.; Ren, J.; Jing, R.; Yi, J. Analysis of the microcharacteristics of different kinds of asphalt based on different aging conditions. Mater. Struct. 2022, 55, 250. [Google Scholar] [CrossRef]

- Li, Y.; Feng, J.; Yang, F.; Wu, S.; Liu, Q.; Bai, T.; Liu, Z.; Li, C.; Gu, D.; Chen, A.; et al. Gradient aging behaviors of asphalt aged by ultraviolet lights with various intensities. Constr. Build. Mater. 2021, 295, 123618. [Google Scholar] [CrossRef]

- Lyu, L.; Pei, J.; Burnham, N.A.; Fini, E.H.; Poulikakos, L.D. Nanoscale evolution of rubber-oil modified asphalt binder after thermal and UV aging. J. Clean. Prod. 2023, 426, 139098. [Google Scholar] [CrossRef]

- Rahmani, H.; Shirmohammadi, H.; Hamedi, G.H. Effect of Asphalt Binder Aging on Thermodynamic Parameters and Its Relationship with Moisture Sensitivity of Asphalt Mixes. J. Mater. Civ. Eng. 2018, 30, 04018278. [Google Scholar] [CrossRef]

- Xu, S.; Yu, J.; Hu, C.; Qin, D.; Xue, L. Laboratory evaluation of rejuvenation effect of reactive rejuvenator on aged SBS modified bitumen. Mater. Struct. 2017, 50, 233. [Google Scholar] [CrossRef]

- Ruan, Y.H.; Davison, R.R.; Glover, C.J. Oxidation and viscosity hardening of polymer-modified asphalts. Energy Fuels 2003, 17, 991–998. [Google Scholar] [CrossRef]

- Guo, M.; Liang, M.; Sreeram, A.; Bhasin, A.; Luo, D. Characterisation of rejuvenation of various modified asphalt binders based on simplified chromatographic techniques. Int. J. Pavement Eng. 2022, 23, 4333–4343. [Google Scholar] [CrossRef]

- Hofko, B.; Porot, L.; Cannone, A.F.; Poulikakos, L.; Huber, L.; Lu, X.; Mollenhauer, K.; Grothe, H. FTIR spectral analysis of bituminous binders: Reproducibility and impact of ageing temperature. Mater. Struct. 2018, 51, 45. [Google Scholar] [CrossRef]

- Li, C.; Xie, X.; Wang, L.; Guo, Y.; Zhang, L.; Xue, Z. Evaluation of the effect of thermal oxygen aging on base and SBS-modified bitumen at micro and macroscales. Constr. Build. Mater. 2022, 324, 126623. [Google Scholar] [CrossRef]

- Guo, M.; Xie, X.; Du, X.; Sun, C.; Sun, Y. Study on the multi-phase aging mechanism of crumb rubber modified asphalt binder. Int. J. Pavement Eng. 2025, 26, 2449114. [Google Scholar] [CrossRef]

- Zhao, K.; Wang, Y.; Li, F. Influence of ageing conditions on the chemical property changes of asphalt binders. Road Mater. Pavement Des. 2021, 22, 653–681. [Google Scholar] [CrossRef]

- Liang, M.; Guo, M.; Xu, X.; Liu, X.; Liu, H.; Bi, Y. Study on accelerated aging rate of asphalt binder under multi-factors coupling conditions. Constr. Build. Mater. 2023, 400, 132819. [Google Scholar] [CrossRef]

- Traxler, R.N. Relation between asphalt composition and hardening by volatilization and oxidation. Assoc Asphalt Paving Technol Proc. 1961, 30, 359–372. [Google Scholar]

- Li, Y.; Wu, S.; Liu, Q.; Dai, Y.; Li, C.; Li, H.; Nie, S.; Song, W. Aging degradation of asphalt binder by narrow-band UV radiations with a range of dominant wavelengths. Constr. Build. Mater. 2019, 220, 637–650. [Google Scholar] [CrossRef]

- Qian, G.; Yu, H.; Jin, D.; Bai, X.; Gong, X. Different water environment coupled with ultraviolet radiation on ageing of asphalt binder. Road Mater. Pavement Des. 2021, 22, 2410–2423. [Google Scholar] [CrossRef]

- Song, S.; Wang, L.; Fu, C.; Guo, M.; Jiang, X.; Liang, M.; Yan, L. Study on the Aging Behavior of Asphalt Binder Exposed to Different Environmental Factors. Appl. Sci. 2023, 13, 12651. [Google Scholar] [CrossRef]

- Ran, L.; Li, Q.; Luo, W.; Xu, H.; Kong, L. Viscoelastic Behavior and Characterization of Bitumen under Natural Exposure Aging in the Tibetan Areas. J. Mater. Civ. Eng. 2024, 36, 04024020. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, X.; Zhou, X.; Yang, G.; Zhang, L. Evaluation of the Physical and Adhesive Properties of Natural Weathering Asphalt. Adv. Mater. Sci. Eng. 2021, 2021, 5783256. [Google Scholar] [CrossRef]

- Song, S.; Liang, M.; Wang, L.; Li, D.; Guo, M.; Yan, L.; Zhang, X.; Ding, W. Effects of Different Natural Factors on Rheological Properties of SBS Modified Asphalt. Materials 2022, 15, 5628. [Google Scholar] [CrossRef]

- Ministry of Transport. Standard Test Methods of Bitumen and Bituminous Mixtures for Highway Engineering: JTG E20-2011; Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Camargo, I.G.D.N.; Hofko, B.; Mirwald, J.; Grothe, H. Effect of Thermal and Oxidative Aging on Asphalt Binders Rheology and Chemical Composition. Materials 2020, 13, 4438. [Google Scholar] [CrossRef]

- Abouelsaad, A.; White, G. Comparing the Effect of Thermal-Oxidation and Photo-Oxidation of Asphalt Mixtures on the Rhe-ological and Chemical Properties of Extracted Bituminous Binder. Materials 2022, 15, 6793. [Google Scholar] [CrossRef] [PubMed]

- Xiao, J.; Liu, X.; Zhang, H.; Bi, Y.; Zhang, J.; Xu, R. A Novel Application of Red Mud in Improving Aging Resistance of Asphalt. J. Test. Eval. 2023, 51, 2687–2699. [Google Scholar] [CrossRef]

- Yu, H.; Bai, X.; Qian, G.; Wei, H.; Gong, X.; Jin, J.; Li, Z. Impact of Ultraviolet Radiation on the Aging Properties of SBS-Modified Asphalt Binders. Polymers 2019, 11, 1111. [Google Scholar] [CrossRef] [PubMed]

- Zhang, D.; Zhang, H.; Shi, C. Investigation of aging performance of SBS modified asphalt with various aging methods. Constr. Build. Mater. 2017, 145, 445–451. [Google Scholar] [CrossRef]

- Zheng, X.; Xu, W.; Xie, S. Study on Ultraviolet Aging Mechanism of Carbon Nanotubes/SBS Composite-Modified Asphalt in Two-Dimensional Infrared Correlation Spectroscopy. Materials 2021, 14, 5672. [Google Scholar] [CrossRef]

- Liu, L.; Liu, Z.; Hong, L.; Huang, Y. Effect of ultraviolet absorber (UV-531) on the properties of SBS-modified asphalt with different block ratios. Constr. Build. Mater. 2020, 234, 117388. [Google Scholar] [CrossRef]

- Guo, M.; Zhang, R.; Du, X.; Liu, P. A State-of-the-Art Review on the Functionality of Ultra-Thin Overlays Towards a Future Low Carbon Road Maintenance. Engineering 2024, 32, 82–98. [Google Scholar] [CrossRef]

- Guan, M.; Guo, M.; Liu, X.; Du, X.; Tan, Y. Effect of Multifactor Coupling Aging on Rheological Properties of Asphalt Binders and Correlations between Various Rheological Indexes. J. Mater. Civ. Eng. 2024, 36, 04024088. [Google Scholar] [CrossRef]

| Tests | Results | Limits | Standards | |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s)/0.1 mm | 81.5 | 80~100 | T0604-2011 | |

| Softening point (R and B)/℃ | 45 | ≥44 | T0606-2011 | |

| Ductility (5 cm/min, 10 °C)/cm | 100 | ≥30 | T0605-2011 | |

| Aging tests (163 °C, 5 h) | The quality change/% | −0.13 | ≤±0.4 | T0610-2011 |

| Penetration ratio/% | 64 | ≥57 | T0604-2011 | |

| Residual ductility ratio/% | 11 | ≥8 | T0605-2011 | |

| Month | Temperature (℃) | Cumulative Value of Ultraviolet Radiation (Mj/m2) | Relative Humidity (%) | 2 min Average Wind Speed (m/s) | Precipitation (mm) | Number of Sand Raising Days (day) |

|---|---|---|---|---|---|---|

| 1 | −6.8 | 10.9 | 42.1 | 1.4 | 0.0 | 0.0 |

| 2 | −3.4 | 13.6 | 36.2 | 1.7 | 2.2 | 1.0 |

| 3 | 8.0 | 16.8 | 33.2 | 2.0 | 9.6 | 1.0 |

| 4 | 14.5 | 25.5 | 22.6 | 1.9 | 0.0 | 2.0 |

| 5 | 21.7 | 29.8 | 26.0 | 2.6 | 0.0 | 5.0 |

| 6 | 25.9 | 30.5 | 27.4 | 1.8 | 0.9 | 1.0 |

| 7 | 27.2 | 29.6 | 32.0 | 1.7 | 1.0 | 1.0 |

| 8 | 25.5 | 25.2 | 37.4 | 1.9 | 0.2 | 2.0 |

| 9 | 20.3 | 22.9 | 37.2 | 1.4 | 0.2 | 0.0 |

| 10 | 9.0 | 17.4 | 43.6 | 1.5 | 0.0 | 0.0 |

| 11 | 1.7 | 11.1 | 42.4 | 1.8 | 3.2 | 0.0 |

| 12 | −8.0 | 9.7 | 48.0 | 1.7 | 0.0 | 0.0 |

| Tests | Results | Limits | Standards | |

|---|---|---|---|---|

| Penetration (25 °C, 100 g, 5 s)/0.1 mm | 66 | 60~80 | T0604-2011 | |

| Softening point (R and B)/°C | 87.5 | ≥75 | T0606-2011 | |

| Ductility (5 cm/min, 10 °C)/cm | 42 | ≥35 | T0605-2011 | |

| Aging tests (163 °C, 5 h) | The quality change/% | −0.4 | ≤±1.0 | T0610-2011 |

| Penetration ratio/% | 75 | ≥65 | T0604-2011 | |

| Residual ductility ratio/% | 30 | ≥20 | T0605-2011 | |

| Samples | G * (Average) | G-R | S (−6 °C) | ||||

|---|---|---|---|---|---|---|---|

| Average | RSD | Average | RSD | Average | RSD | ||

| Virgin bitumen | Unaged | 46.0 | 4.4% | 0.6 | 7.3% | 14.0 | 6.3% |

| TFOT | 95.7 | 1.6% | 1.2 | 7.0% | 53.6 | 6.1% | |

| PAV | 301.4 | 3.2% | 28.8 | 5.2% | 98.3 | 7.4% | |

| O | 191.7 | 7.6% | 6.1 | 9.9% | 96.1 | 9.0% | |

| O + L | 201.1 | 11.8% | 9.2 | 14.9% | 96.7 | 3.4% | |

| All | 224.6 | 10.8% | 13.2 | 9.1% | 105.1 | 9.4% | |

| SBS-modified bitumen | Unaged | 53.9 | 4.7% | 4.4 | 8.0% | 22.6 | 5.3% |

| TFOT | 69.0 | 5.8% | 4.8 | 3.8% | 27.6 | 8.3% | |

| PAV | 157.4 | 4.8% | 25.8 | 7.6% | 53.1 | 5.3% | |

| O | 132.7 | 10.1% | 16.0 | 11.7% | 55.0 | 7.1% | |

| O + L | 191.0 | 7.1% | 31.4 | 13.2% | 56.0 | 10.2% | |

| All | 172.0 | 11.0% | 18.5 | 10.2% | 61.9 | 12.2% | |

| Performance) | Contribution Rates | ||

|---|---|---|---|

| G* (average) | 74.5% | 7.3% | 18.2% |

| G-R | 40.6% | 25.8% | 33.6% |

| S (−6 °C) | 82.4% | 1.2% | 16.4% |

| average value | 65.8% | 11.4% | 22.7% |

| Performance) | Contribution Rates | ||

|---|---|---|---|

| G * (average) | 61.8% | 56.6% | −18.4% |

| G-R | 81.5% | 112.3% | −93.8% |

| S (−6 °C) | 80.0% | 2.8% | 17.2% |

| average value | 74.4% | 57.2% | −31.7% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Song, S.; Zhu, Y.; Wang, Z.; Gao, Z.; Guo, M.; Huang, J.; Jiang, X. Study on the Influence and Contribution Rates of Field Aging Factors on Rheological Performance of Bitumen. Materials 2025, 18, 1775. https://doi.org/10.3390/ma18081775

Song S, Zhu Y, Wang Z, Gao Z, Guo M, Huang J, Jiang X. Study on the Influence and Contribution Rates of Field Aging Factors on Rheological Performance of Bitumen. Materials. 2025; 18(8):1775. https://doi.org/10.3390/ma18081775

Chicago/Turabian StyleSong, Shanglin, Yunding Zhu, Zhen Wang, Ziyang Gao, Meng Guo, Jing Huang, and Xiaoqiang Jiang. 2025. "Study on the Influence and Contribution Rates of Field Aging Factors on Rheological Performance of Bitumen" Materials 18, no. 8: 1775. https://doi.org/10.3390/ma18081775

APA StyleSong, S., Zhu, Y., Wang, Z., Gao, Z., Guo, M., Huang, J., & Jiang, X. (2025). Study on the Influence and Contribution Rates of Field Aging Factors on Rheological Performance of Bitumen. Materials, 18(8), 1775. https://doi.org/10.3390/ma18081775