Abstract

Residual stress (RS) is one of the main reasons for component failure during an additive manufacturing (AM) process, especially using selective laser melting (SLM) technology. This paper reviews RS’s investigation methods, formation mechanisms and regularities of distribution. When considering recent research progress, studies indicate that the dominant stress is primarily attributed to thermal stress induced by significant laser temperature gradients during the rapid melting and forming process, which subsequently transforms into RS upon cooling to room temperature, as verified by simulation and experiments. Then, the distribution regularities of RS are analyzed. SLM RS gradually increases when it is measured from the surface layer to the substrate. In the plane direction, at the center and edge of the part, tensile stresses are found; as for the middle area, which is the transition area of compressive stress, the whole plane stress remains in an equilibrium state. Based on the forementioned conclusions, the three-dimensional distribution diagram of RS on the sample was constructed. Finally, the strategic approaches for stress mitigation are briefly discussed. The excessive stress in forming can be reduced by process parameter matching, and the RS can be greatly remitted by pre-treatment/post-treatment, so as to improve the quality of formed parts. This review provides a valuable theoretical basis for practical applications of SLM.

1. Background

Additive manufacturing (AM) is an advanced technique for producing complex geometries and small production batches, including parts that are challenging to manufacture with conventional methods; the technique has been subjected to a tremendous amount of research and industrial interest in recent years [1]. Selective laser melting (SLM) is one of the most widely used metal AM techniques, utilizing a laser as an energy source to achieve high-quality and efficient fabrication [2]. However, the SLM process also results in large and anisotropic residual stresses (RS). RS can lead to deformation and failure in some cases, but under certain conditions, it may enhance mechanical properties, depending on grain orientation and size [3]. Some facts show that large residual stress can cause excessive deformation or production failure, which seriously affects the implementation of the process scheme in workpiece manufacturing [4]. Therefore, a thorough understanding of how RS forms and distributes is crucial for optimizing SLM process parameters and minimizing defects. Recently, many research institutes, including some teams, have analyzed and explored residual stress-related mechanisms from different perspectives and methods [5,6], yet a review encompassing this information is not yet available.

According to the current state-of-the-art research, there are mainly two approaches to study the residual stress for SLM: experimental and simulation methods. In one experiment, RS was quantified by different measuring instruments or methods, including multi-point measurement in the plane area and in-depth measurement after stripping. However, the measurement error and range of different methods are not enough to reach a solid conclusion [7,8]. The simulation method can analyze the thermal evolution process of its stress, from the previous static small-scale single-layer or single-channel simulation [9] to dynamic multi-layer and multi-channel simulation [10,11,12].These studies revealed that the thermal coupling response is more in line with the actual process characteristics [6,13].

Furthermore, for additive components, RS may be alleviated by post-process heat treatment; the development of large residual stresses in-process can lead to excessive distortion, which can cause production failure or errors [1]. In this review, the knowledge available in the literature regarding RS was assembled and analyzed through the combination of simulation and experimentation. From thermal stress generation, residual stress formation, regularities of distribution and the effect of RS in the SLM process are described in a clear and concise manner. Finally, the mitigation and control of RS are summarized and prospected; the magnitude and distribution of RS may be alleviated by post-process heat treatment or by adjusting the combination of process parameters. The aim of this review is to serve as a concise yet thorough reference for researchers, as well as to provide a technical reference for the industrial application of SLM technology.

2. RS Investigation Methods

As mentioned before, residual stress in SLM is typically analyzed using two approaches: experimental methods and simulations. The experimental method is measured by different measuring methods, including mechanical contact and non-contact sensing. Those methods can be used for multi-point measurement in the plane area and depth measurement after stripping. However, the accuracy and range limitations of these methods pose challenges for advancing research in this area. Simulation methods, which can analyze the thermal evolution process of stress, include the finite difference method (FDM), finite element method (FEM) and finite volume method (FVM) et al. The methods are developing from the previous static small-scale, single-layer and single-channel simulation to dynamic multi-layer and multi-channel simulations. Such studies have revealed that the thermal coupling response is more in line with the actual process characteristics.

2.1. Typical Experimental Method

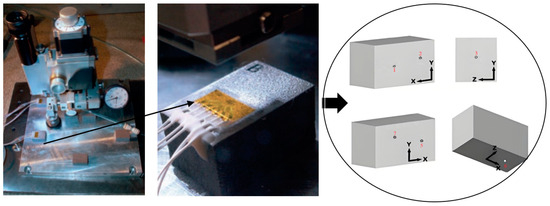

- Hole-drilling method

Despite being an invasive technique, hole-drilling (HD) measurements are widely considered accurate and reliable in industrial applications. The principle of the HD method is to drill a small hole in a stress field with a special drill bit, as shown in Figure 1. Usually, the diameter of the borehole is 2 mm and the depth is 1–1.5 mm [14,15]. If the balance of the stress is damaged, the stress around the hole will be readjusted. By measuring the elastic strain increment near the hole, the residual stress in the hole can be calculated using the principle of elastic mechanics according to the ASTM E837-13/20 standard [16]. The accuracy of the results of the small-hole method depends on the accuracy of the sticking position of the strain gauge. The smaller the aperture, the higher the accuracy of the relative position. In particular, the HD method has its advantages in measuring the distribution of stress along the depth [15]. Its measurement principle, using the stress release method, has been studied for several years, and the calculation accuracy is considered to be high. According to many references, residual stress data showed that specimens without support exhibit lower residual stresses in comparison to those with support [15,17]. Results also revealed that RS on the top surface was reduced when a substrate with no overhang was used [18,19,20].

Figure 1.

Measuring position and principle of hole-drilling method [14].

- 2.

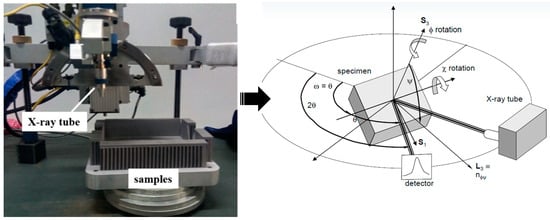

- X-ray diffraction measured

X-ray diffraction (XRD) measurement is a simple and efficient test method, as shown in Figure 2, but its measurement mechanism is complex; it is the most widely used method for RS [21,22,23]. In fact, the basic principle of X-ray diffraction measurement of residual stress is to measure the displacement of the diffraction line as the original data, and the measured result is actually the residual strain. Therefore, the residual stress is calculated from the residual strain using Hooke’s Law. When there is residual stress in the sample, the distance between crystal faces will vary. When Bragg diffraction occurs, the diffraction peak will change, and the moving distance is directly related to the stress [24,25]. The residual stress σ can be calculated by irradiating the X-ray at different incidence angles on the sample for several times; the calculation is carried out by measuring the corresponding diffraction angle 2θ and finding the slope M of 2θ to sin2ψ [26]. The XRD measurement method is mainly used to characterize the surface stress [27]. If the measurement is carried out along the depth, the corrosion method, electropolishing is required to strip the part for layer-by-layer testing [28].

Figure 2.

Measuring position and principle of X-ray diffraction method [28].

- 3.

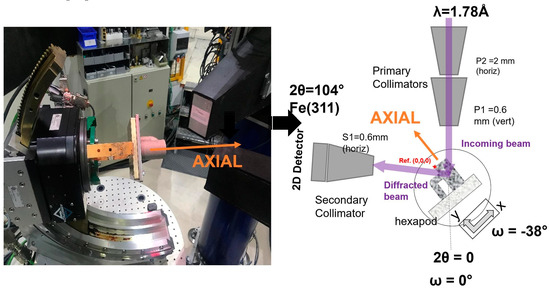

- Neutron diffraction measurement

Neutron diffraction (ND), as illustrated in Figure 3, is another widely used technique, particularly effective for measuring stress in thick and dense materials. The principle of the ND method is to employ the wave property of neutrons in order to obtain the RS information in the material by analyzing the scattering of neutrons. The neutron diffraction method is a very effective method to measure RS [29,30], it can measure the residual stress in some dense and thick material. It has also good adaptability to different material with different properties. In particular, it focuses on three-dimensional stress testing, which has good application prospects in engineering. Some valuable conclusions are obtained where, by increasing the layer thickness, the stress magnitudes and gradients are significantly reduced [31]. Non-destructive neutron diffraction was utilized to measure residual stresses and their distributions across wall thickness [32] and over cross-sections [33].

Figure 3.

Measuring position and principle of neutron diffraction method [34].

Furthermore, some other measurement means, such as crack compliance, incremental slitting, the ultrasonic method, and other complex methods to investigate residual stress, have also been reported. Such methods as the hole-drilling method combined with the X-ray diffraction method [19,35], and the hole-drilling method combined with simulation [20,36], and even X-ray-diffraction, hole-drilling, and the contour-method approaches [37] have been employed for RS measurement. The error of the hole-drilling measurements was found to be less than the XRD measurements (always less than 5% of the measured value) [37].

The residual stress testing literature for SLM forming is shown in Table 1. It shows that the data trends are similar but the data values of measurements widely vary. This also indicates that XRD, as a simple and efficient measurement method, has been adopted by many scholars and institutions, and some subsequent practical measurements in this paper mainly adopt this method.

Table 1.

Statistical table of residual stress test results.

2.2. Typical Simulation Methods

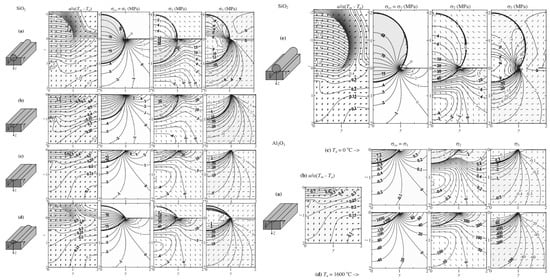

- Plane stress calculation

Residual stress prediction has gained increasing attention from researchers, particularly through the use of the finite element method (FEM) [45,46]. Based on the discrete method of finite elements, the elastic mechanics of plane stress is solved, and the continuous regional stress distribution curve is obtained. The stress trend can be reflected by the density and the divergence direction of the curve in Figure 4 [46]. However, the current analysis of plane stress lacks sufficient clarity and intuitive representation, especially for three-dimensional (3D) distribution.

Figure 4.

Plane stress distribution of simulation diagram [46].

- 2.

- Three-dimensional stress simulation

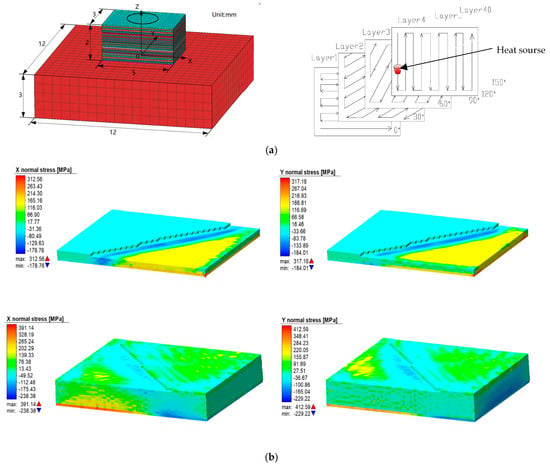

With the development of finite element extension algorithms and the improvement of computing power, three-dimensional stress simulation with layer distribution has become a research hotspot [47,48]. The definition of the 3D simulation heat source, the design of the workpiece model, the setting of the process parameters and the setting of the calculation conditions have become more user friendly and efficient. The scope of simulations has expanded from single-layer and single-channel models [49] to multi-layer and multi-channel analyses, allowing for more accurate cyclic stress predictions [50], and the statistical change of stress over time has become more accurate, as shown in Figure 5 [51,52]. Hence, the stress variation with respect to layer thickness can now be well analyzed by simulation.

Figure 5.

Three−dimensional stress distribution of simulation diagram. (a) Simulation modeling. (b) Results of residual stress [51].

- 3.

- Comparison of simulation and experiment

In fact, the simulation method inevitably simplifies the environmental conditions for reflecting a complex multi-scale physical field of laser melting [53,54]. There are also many supporting studies for real verification of the simulation, as shown in Table 2. By comparing the simulation and experiment, a literature review shows that there may be some errors between simulation and actual measured values, but the general trend of stress evolution is consistent, which has good practical significance for correcting the finite element simulation model. Therefore, the simulation results trend is developing in the direction of high precision and high efficiency.

Table 2.

Residual stress statistical table of simulation calculation compared with experimental investigation.

3. Main Research Results

3.1. The Formation of RS [58]

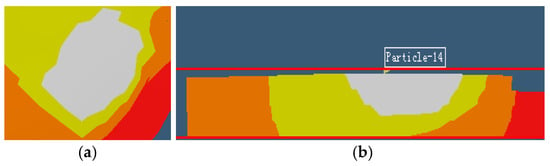

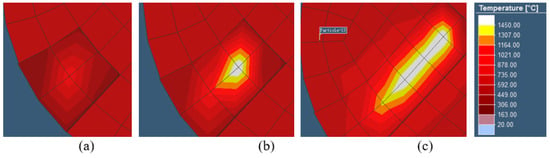

According to the pyrogen model established by experimental analysis, the heat source is in accordance with the Gauss pyrogen model; the laser beam radiates heat from the center to the surrounding area. Due to the high intensity and concentrated energy of the laser, the temperature of the laser irradiation zone rapidly exceeds 2000 K, leading to the immediate formation of a molten pool with distinct length, width, and depth. The simulation results reveal that the molten pool exhibits an inverted conical shape, as shown in Figure 6a,b. As the laser beam travels, the molten pool evolves into a continuous molten pool strip during the forming process, as shown in Figure 7.

Figure 6.

Topography of melting pool due to laser heating in SLM simulation. (a) Top view. (b) Section view [58].

Figure 7.

Development of melting pool of single track heating in SLM as the laser beam travels (a) 0.2 mm, (b) 0.3 mm, and (c) 0.6 mm [58].

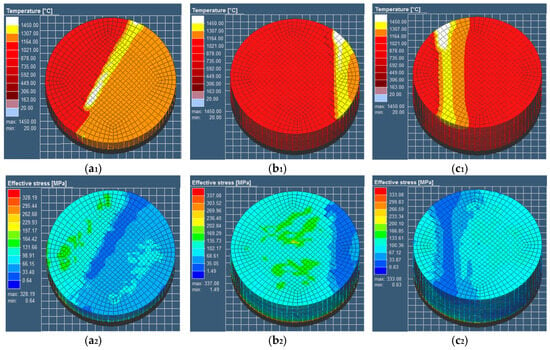

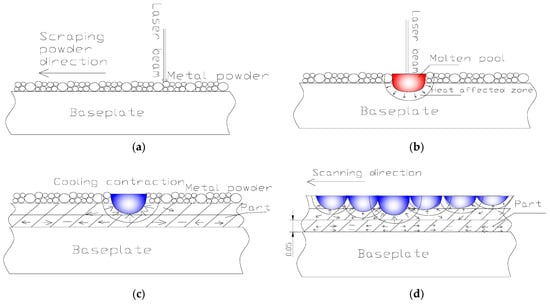

Figure 8 presents the temperature and stress history of representative points across different layers in the component simulation model, corresponding to the laser scanning path. As evident from Figure 6, the first layer initially exhibits ambient temperature conditions. Upon irradiation by the laser heat source, the temperature experiences a rapid increase, peaking at 2100 K—significantly above the material’s melting point. This instantaneous heating induces complete melting of the metal powder particles. Following laser source removal, the temperature precipitously drops below 1000 K, indicating an extreme thermal gradient. Subsequently, when a fresh powder layer is deposited and subjected to laser scanning, a molten pool forms and propagates into the underlying solidified layer. This thermal interaction between layers induces reheating of the previously deposited material through conductive heat transfer from the newly melted zone. As shown in Figure 8(a1–c1), the temperature of the laser source is continuously heated at different deposition heights. The pool size is very close to the geometrical size of the melting pool obtained in the experiment under similar conditions in the literature [61,62]. However, the magnitude of temperature fluctuations diminishes with successive layer deposition due to thermal attenuation effects. Note that the subsequent heating may produce a “micro annealing” effect of the underlying materials [58,63]. The oscillatory behavior dissipates as the process transitions to the pure cooling stage at 50 s, ultimately allowing the temperature to decay to ambient levels. Correspondingly, it can be observed from Figure 8(a2–c2) that the stress is very small when the sample is heated at the same moment as Figure 8(a1–c1), because the metal is in a molten state. After cooling, the residual stress of the bottom part is larger. The thermal attenuation cycles propagate uniformly through the material, with their characteristic number and penetration depth being governed by two key factors: the total number of overlying layers and the specific laser energy parameters employed.

Figure 8.

Temperature fields and equivalent stress distributions at simulation moments. (a1,a2) Tenth layer (t = 10 s). (b1,b2) Twenty-eighth layer (t = 33 s). (c1,c2) Thirty-ninth layer (t = 48 s) [58].

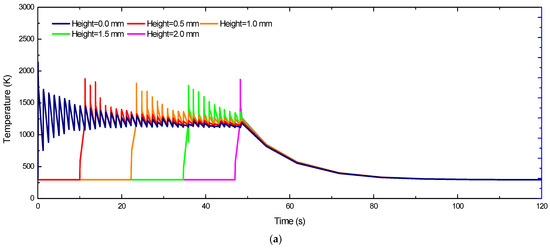

By referring to the coordinate system shown in the reference [58], the same position points near the center of samples of different layers in the same direction were selected. The thermal stress evolution curves in different directions are plotted, as shown in Figure 9.

Figure 9.

Temperature evolution curve and stress evolution curve in simulation. (a) Temperature. (b) X−stress component. (c) Y−stress component. (d) Z−stress component [58].

According to the stress curves of the five layers tracked by the simulation, the X/Y stress has a similar evolution trend. In the process of laser layer-by-layer scanning, it is in an alternating state of tension and compression stress. After cooling to the final room temperature, the state of tensile stress changes into residual stress. Finally, with the change of layer thickness, the residual stress will also vary. The Z-direction stress is negligible in the laser scanning, and after stabilizing to room temperature, the RS will be in an alternating state between tension and compression, showing a relatively low and stable stress distribution.

3.2. The Evolution Mechanism of RS

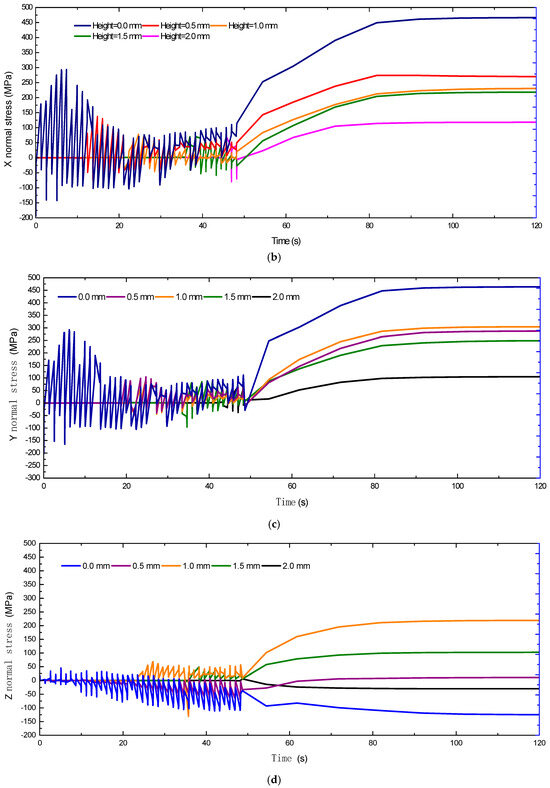

Based on the simulation results, the process of stripe scanning a path in the same direction is analyzed as an example; the evolution of cyclic thermal stress throughout the deposition process is clearly demonstrated in Figure 10. The process comprises four distinct stages, as illustrated in Figure 10a–d. (a) The initial stage involves powder deposition, where the re-coater spreads fresh powder across the substrate while the laser system prepares to scan the new layer. (b) During the second stage, laser irradiation heats and melts the powder, forming a characteristic conical molten pool. (c) In the third stage, as the laser beam moves away, the molten material undergoes solidification. This process creates a thermal gradient where the periphery cools faster than the core, generating tensile stresses that radiate outward from the center. (d) The final stage occurs during subsequent layer deposition, where the newly formed molten pool thermally interacts with the underlying layer. The resulting heat transfer causes reheating of the previous layer, followed by directional solidification (edge-to-center) that further amplifies the tensile stress field.

Figure 10.

The evolution process of cyclic thermal stress in SLM. (a) Powder spreading. (b) Melting pool formation. (c) Solidification contraction. (d) Cyclic cooling (renewed from [58]).

Based on internal stress diffraction analysis, this study investigates thermally induced residual stresses generated during the SLM process. The inherent temperature gradient between heated and cooled regions results in non-uniform thermal expansion/contraction, thereby inducing significant thermal stresses. During rapid thermal cycling, atomic displacement caused by differential expansion may generate three distinct types of intrinsic stresses [64]: the first type is the macroscopic stress caused by different orientations and different spacing of grains; the second type is the pseudo-macroscopic stress produced by the inter-planar crystal spacing at similar grains; and the third type is microscopic stress by atomic motion, caused by crystal defects, vacancy, interstitial atoms and dislocation, etc. All three stress types (Type I macroscopic, Type II intergranular, and Type III microstresses) are inherently present in the SLM process. However, thermal–mechanical coupling analysis confirms that Type I macroscopic stresses dominate due to their system-scale influence on part distortion and residual stress accumulation. Additionally, phase-separated precipitates can induce transformation stresses during cooling and solidification, leading to non-uniform volumetric changes. These stresses, combined with thermal cycling effects, ultimately result in residual stress formation. The evolution of cyclic thermal stresses in selective laser melting (SLM) can be characterized by the following stages. First: The molten pool formation under laser irradiation increases atomic kinetic energy. Second: As the laser moves away, constrained atomic rearrangement during solidification creates tensile stresses due to crystallographic anisotropy and varying interplanar distances. Third: Subsequent heating–cooling cycles during multilayer deposition cause progressive stress attenuation [65]. Fourth: Temperature gradient-dependent solidification generates additional tensile stresses when cooling rates exceed heating rates [66]. Finally: The accumulated cyclic stresses converge to form the final residual stress state in the fabricated component.

3.3. The Regularities Distribution of RS

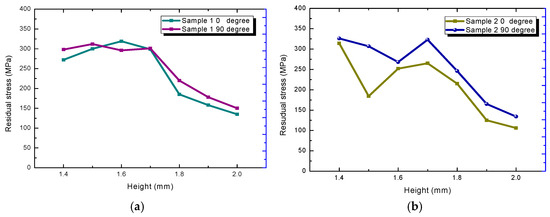

- Residual stress along depth

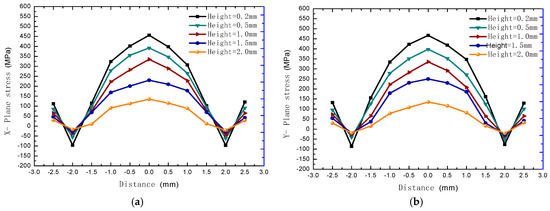

For the measurement of residual stress along the height direction, the simulation model and the experimental sample results were quantified simultaneously (Φ5 × 2 cylinder). In the simulation results, for the purpose of brevity, only the final RS distributions along the build direction from 1.1 mm to 2.0 mm height are shown, and can be seen in Figure 11a,b. For the experimental analysis, XRD tests were conducted on a total of seven layers of the deposition sample from the upper surface to the lower layer, as shown in Figure 12, from 2.0 mm to 1.4 mm. The results demonstrate a consistent decrease in tensile residual stresses along the build direction (Z-axis) for both X- and Y-oriented stress components, with the lowest stresses observed on the top surface [61,67]. Furthermore, residual stress measurements reveal strong correlations among multiple material points within the same layer.

Figure 11.

The simulated residual stress distribution along the build orientation shows (a) X−axis stress component and (b) Y−axis stress component.

Figure 12.

The residual stress distribution of two SLM specimens from XRD measurement, (a) sample 1, and (b) sample 2.

- 2.

- Residual stress along plane direction

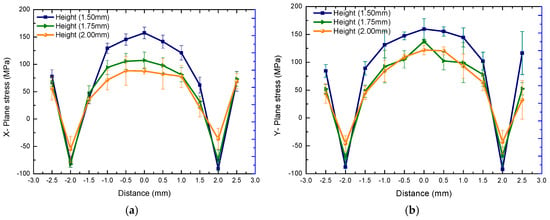

Because the speed of laser motion is much higher than the cooling rate, a whole layer is cooled after melting close to the initial layer. Therefore, the cooling rate is higher in the edge than the middle position, and the molten material is cooled from the edge; the edge tension is formed by compressive stress, and the pressure is applied inwardly. Finally, the cooled center is subjected to tensile stress surrounding the resistance to contraction [68]. The stress variation trend diagram of the X-plane at the center section to the edge along the x-coordinate and the Y-plane stress at the middle section to the edge along the y-coordinate is formed as shown in Figure 13. Further, after the specimen is fully formed, it finally transitions from slow diffusion, and the outward tensile stress from the center changes to the compressive stress, then changes to the tensile stress at the edge. Finally, the whole plane stress reaches an equilibrium state. The same results were obtained when the test locations of the experimental samples were similar, as shown in Figure 14. In addition, due to the cyclic thermal effect of laser layer-by-layer scanning on the bottom layer, the plane distribution of residual stress in this layer is accumulated, and a trend of higher stress is also obtained as the measurement gets closer to the bottom layer. It can be seen that there are similar result trends at different layer depths.

Figure 13.

The plane residual stress distribution trend with forming height in simulation. (a) X−axis stress component and (b) Y−axis stress component.

Figure 14.

The plane residual stress distribution trend with forming height in experiment. (a) X−axis stress component. (b) Y−axis stress component.

4. Discussion

Residual stress is the internal stress that remains inside the material in the equilibrium state when no external force is applied. It is caused by non-uniform temperature change, non-uniform phase transformation and non-uniform plastic deformation in a machining process [69]. Laser forming has the characteristics of an extremely fast cooling rate. In a laser additive manufacturing heating process, as a result of different temperature distributions, melting and solidification are not synchronized during the cooling process; this will cause different parts of the expansion and contraction trend to be inconsistent, resulting in thermal stress [70,71]. At the same time, due to the inconsistency of the temperature distribution, the phase changes in different parts of the deposition-formed parts are not synchronized, the specific volumes between different phases will vary, and the phase transition and stress have a close correlation with each other during expansion or contraction [72,73,74].

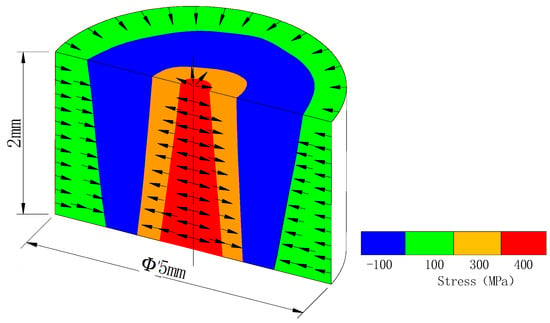

4.1. Three-Dimensional Residual Stress Distribution

According to the above analysis of thermal field effects and surface stress depths of a layer-by-layer cycle, the distribution trend of thermal stress accumulated along the height and the evolution trend of plane stress from the center to the edge are obtained, as in the earlier cylinder experiment. The three-dimensional stress distribution diagram after SLM forming can be comprehensively analyzed from a three-dimensional model, as shown in Figure 15. In the plane layers, the cross-section diagram from the central part is used as a representation, and the plane stress at the position of each plane layer conforms to the equilibrium stress distribution trend of alternating tension and compression at each layer, as shown in Figure 13 and Figure 14. In the vertical direction, the accumulation of thermal stress makes the bottom stress greater than the top stress, as shown in Figure 11 and Figure 12. Hence, the plane stress is combined with the in-depth stress distribution to form a three-dimensional stress distribution trend diagram, such as the three-dimensional cylindrical simulation model. Therefore, the regional distribution and evolution process of the overall stress are clearly presented in Figure 15. Tensile stress is dominant at the core and edge of the sample, while compressive stress occurs in other transition regions. With the increase in the forming height, the tensile stress range decreases, and the compressive stress range increases; in particular, the blue compressive stress area changes with the forming height. The diagram accurately and comprehensively expresses the stress distribution effect of the formed specimen in its original state.

Figure 15.

Three−dimensional residual stress distribution trend diagram of SLM-formed parts (i.e., material: 316LSS).

It should be noted that these results were obtained while the laser was scanning straight along the stripe. When the process parameters of SLM, such as laser power [75,76,77], scanning speed [78,79], overlap rate [80], layer thickness [81] et al. change, such changes will have a direct impact on the stress distribution. These results are also valid when different laser scanning paths [82], such as a checkerboard pattern, are scanned in the micro island region. Differences in the scanning area can only cause changes in the tensile and compressive stress areas depending on the scanning path [75,83] This explains why some literature measure the surface area as tensile stress [42,84,85] while others measure the surface as compressive stress [86,87]. Even in the same material with the similar process parameters, the measured residual stress values differ greatly, as shown in Table 2. Therefore, RS values at each position of the specimen after cooling differ greatly with a different cooling rate, a different cooling sequence and different process parameters. However, the existence of a large residual stress is inevitable due to the characteristics of laser processing technology [88,89,90]. As a result, RS adjustment in the SLM process is required to ensure the quality of a fabricated part.

4.2. Residual Stress Adjustment Method

- Process parameter regulation

Recently, numerous studies have examined residual stress distribution in SLM-manufactured parts, such as significant improvements in microstructure and residual stress after the process parameters are regulated in a single or collective way; i.e., as the microstructure of the specimen is regulated [91,92,93], the mechanical properties are improved [94,95] and the residual stresses are reduced to a certain extent [96,97] by optimizing the process parameters of SLM forming. For instance, higher laser power [98] combined with lower scanning speed [99] generally results in increased residual stress levels. The key to process parameter regulation lies in achieving an appropriate balance of laser energy flux density [100]. Through experimental comparison or simulation research, the literature has some typical data cases in the process parameter matching for practical reference [99,101]. However, in order to further improve the quality of the SLM-formed specimens, it is also very necessary to carry out substrate preheating before printing and heat treatment regulation after printing.

- 2.

- Pre-treatment regulation

The pre-treatment of SLM forming by substrate preheating can effectively regulate the structural properties of the specimen [102,103,104]. Substrate preheating can reduce the cooling rate of the melt pool and coarsen the grains, thus affecting the microstructure and mechanical properties of the specimen. Furthermore, it can reduce the thermal stress caused by the temperature gradient, thus reducing the residual stress of the specimen [105,106]. However, preheating also increases the evaporation rate of the powder and the steam recoil pressure, thereby increasing the probability of pore formation [107], so it is very important to set an appropriate preheating temperature [108].

- 3.

- Post-processing regulation

As mentioned before, it is necessary to perform subsequent heat treatment on SLM-formed parts [26,109] for homogenizing the microstructure of the specimens, reducing internal defects, and eliminating residual stresses, thus reducing the anisotropy of the mechanical properties [110,111]. In addition, it has been proved that heat treatment can greatly improve the comprehensive mechanical properties [112]. Near the upper surface of the formed part, equiaxed grains are formed due to the rapid cooling. After heat treatment, the grains change to equiaxed grains. Heat treatment can gradually reduce and eliminate the anisotropy caused by the microstructure. With the increase in heat treatment temperature, the grain diameter at the side and top of the sample tends to be equal [113], the boundary of the molten pool gradually disappears, and the columnar crystal recrystallizes into equiaxed crystal [114,115].

- 4.

- Other adjustment methods

The hot isostatic pressing process (HIP) can lead the material to creep and plastically deform by applying high pressure in all directions to the specimen in a high-temperature environment, thus eliminating defects such as tiny pores and cracks that cannot be eliminated by ordinary heat treatment [116]. In addition, after a high-temperature solution treatment, the phase in the alloy can be transformed, thus further changing the mechanical properties of the specimen. In the future, some intelligent algorithms will also be applied to process allocation [117,118,119]. At the same time, several papers also carry out some reliable design research on the topology optimization of component ontology [120,121]. These methods will significantly affect the thermal distribution and residual stress in SLM forming, so as to continuously improve the comprehensive mechanical properties of SLM-formed parts.

5. Conclusions

This paper reviews recent research on residual stress in SLM, analyzing its formation mechanisms, influencing factors, and both experimental and simulation approaches. By combining simulation and experiment, the residual stress evolution processes of the SLM process are deeply researched. The main conclusions include:

- Residual stress formation: Due to the high laser energy input, the temperature gradient is high, which makes the hot-melt metal molecules displace and forms the thermal stress. With the conduction and radiation of the temperature field to the surroundings, the metal expands the crystallization and forms the orientation angle of the grain, which is retained as internal forces, and the thermal stress evolves into the residual stress.

- Residual stress detection: SLM residual stress measurement uses the experimental testing method and finite element prediction method. The stress values exhibit variations depending on material properties, processing parameters, and even the structure type. However, a consistent overall stress distribution trend is observed across all conditions.

- Residual stress distribution: The residual stress increases gradually from the surface layer to the bottom layer near the substrate in the vertical direction of the forming part. Meanwhile, the residual stress is distributed in the plane of the forming parts; at the center and edge, tensile stress is found; the compression plane in the middle is in a balanced state; the X and Y directions show basically the same distribution trend, and the Z-direction stress is negligible.

- Residual stress adjustment: The magnitude and distribution characteristics of residual stress can be effectively optimized through either pre/post-process heat treatment or strategic adjustment of processing parameter combinations.

Author Contributions

P.B.: Conceptualization, Methodology, Supervision, Writing original draft. A.J.: Investigation, Writing and Editing. K.X.: Methodology, Writing. F.Y. and N.Z.: Analysis, Methodology, Investigation. Y.S.: Investigation, Visualization, Data curation. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by The Youth Innovation Team of Shaanxi Universities, CH. The authors are also grateful for financial support from the Shaanxi Provincial Natural Science Foundation Project (2023-JC-YB-409), Shaanxi Province Technology Innovation Guidance Special Fund (2024ZC-YYDP-47).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The datasets used and analyzed during this study are available from the corresponding author on reasonable request.

Acknowledgments

This work was supported by Xi’an Key Laboratory on Intelligent Additive Manufacturing Technologies and Shaanxi Key Laboratory of Surface Engineering and Remanufacturing, CH.

Conflicts of Interest

We declare that we have no conflicts of interest with other people or organizations. We also claim not to use any AI technology for this article.

References

- Bartlett, J.L.; Li, X. An overview of residual stresses in metal powder bed fusion. Addit. Manuf. 2019, 27, 131–149. [Google Scholar] [CrossRef]

- Li, C.; Liu, Z.Y.; Fang, X.Y.; Guo, Y.B. Residual Stress in Metal Additive Manufacturing. Procedia CIRP 2018, 71, 348–353. [Google Scholar] [CrossRef]

- Withers, P.J. Residual stress and its role on failure. Rep. Prog. Phys. 2007, 70, 2211. [Google Scholar] [CrossRef]

- Bian, P.; Shao, X.; Du, J. Finite Element Analysis of Thermal Stress and Thermal Deformation in Typical Part during SLM. Appl. Sci. 2019, 9, 2231. [Google Scholar] [CrossRef]

- Szost, B.A.; Terzi, S.; Martina, F.; Boisselier, D.; Prytuliak, A.; Pirling, T.; Hofmann, M.; Jarvis, D.J. A comparative study of additive manufacturing techniques: Residual stress and microstructural analysis of CLAD and WAAM printed Ti–6Al–4V components. Mater. Des. 2016, 89, 559–567. [Google Scholar] [CrossRef]

- Bian, P.; Shi, J.; Shao, X.; Du, J.; Dai, J.; Xu, K. An Investigation on Residual Stress in 316L Stainless Steel by Selective Laser Melting. In Proceedings of the ASME 2018 13th International Manufacturing Science and Engineering Conference, College Station, TX, USA, 18–22 June 2018. [Google Scholar]

- Lan, L.; Xin, R.; Jin, X.; Gao, S.; Min, N. Effects of Laser Shock Peening on Microstructure and Properties of Ti–6Al–4V Titanium Alloy Fabricated via Selective Laser Melting. Materials 2020, 13, 3261. [Google Scholar] [CrossRef] [PubMed]

- Acevedo, R.B.O.; Kantarowska, K.; Santos, E.C.; Fredel, M.C. Residual stress measurement techniques for Ti6Al4V parts fabricated using selective laser melting: State of the art review. Rapid Prototyp. J. 2020, 29, 1549–1564. [Google Scholar] [CrossRef]

- Hussein, A.; Hao, L.; Yan, C.; Everson, R. Finite element simulation of the temperature and stress fields in single layers built without-support in selective laser melting. Mater. Des. 2013, 52, 638–647. [Google Scholar] [CrossRef]

- Parry, L.; Ashcroft, I.A.; Wildman, R.D. Understanding the effect of laser scan strategy on residual stress in selective laser melting through thermo-mechanical simulation. Addit. Manuf. 2016, 12, 1–15. [Google Scholar] [CrossRef]

- Zhang, X.; Kang, J.; Rong, Y.; Wu, P.; Feng, T. Effect of Scanning Routes on the Stress and Deformation of Overhang Structures Fabricated by SLM. Materials 2018, 12, 47. [Google Scholar] [CrossRef]

- Li, X.; Wei, X.; Zhang, L.; Lv, Q. Numerical simulation for the effect of scanning speed and in situ laser shock peening on molten pool and solidification characteristics. Int. J. Adv. Manuf. Technol. 2023, 125, 5031–5046. [Google Scholar] [CrossRef]

- Jia, Y.; Naceur, H.; Saadlaoui, Y.; Dubar, L.; Bergheau, J.M. A comprehensive comparison of modeling strategies and simulation techniques applied in powder-based metallic additive manufacturing. J. Manuf. Process. 2024, 110, 1–29. [Google Scholar] [CrossRef]

- Salmi, A.; Atzeni, E.; Iuliano, L.; Galati, M. Experimental Analysis of Residual Stresses on AlSi10Mg Parts Produced by Means of Selective Laser Melting (SLM). Procedia CIRP 2017, 62, 458–463. [Google Scholar] [CrossRef]

- Georgilas, K.; Khan, R.H.U.; Kartal, M.E. The influence of pulsed laser powder bed fusion process parameters on Inconel 718 material properties. Mater. Sci. Eng. A 2020, 769, 138527. [Google Scholar] [CrossRef]

- ASTM E837-13a; Standard Test Method for Determining Residual Stresses by the Hole-Drilling Strain-Gage Method. ASTM International: West Conshohocken, PA, USA, 2013. Available online: http://www.astm.org/ (accessed on 21 February 2025).

- Salmi, A.; Atzeni, E. History of residual stresses during the production phases of AlSi10Mg parts processed by powder bed additive manufacturing technology. Virtual Phys. Prototyp. 2017, 12, 153–160. [Google Scholar] [CrossRef]

- Casavola, C.; Carnpanelli, S.L.; Pappalettere, C. Preliminary investigation on distribution of residual stress generated by the selective laser melting process. J. Strain Anal. Eng. Des. 2009, 44, 93–104. [Google Scholar] [CrossRef]

- Statnik, E.S.; Uzun, F.; Lipovskikh, S.A.; Kan, Y.V.; Eleonsky, S.I.; Pisarev, V.S.; Somov, P.A.; Salimon, A.I.; Malakhova, Y.V.; Seferyan, A.G.; et al. Comparative Multi-Modal, Multi-Scale Residual Stress Evaluation in SLM 3D-Printed Al-Si-Mg Alloy (RS-300) Parts. Metals 2021, 11, 2064. [Google Scholar] [CrossRef]

- Fojtik, F.; Potrok, R.; Hajnys, J.; Ma, Q.-P.; Kudrna, L.; Mesicek, J. Quantification and Analysis of Residual Stresses in Braking Pedal Produced via Laser-Powder Bed Fusion Additive Manufacturing Technology. Materials 2023, 16, 5766. [Google Scholar] [CrossRef] [PubMed]

- Chen, J.; Yang, Y.; Song, C.; Wang, D.; Wu, S.; Zhang, M. Influence mechanism of process parameters on the interfacial characterization of selective laser melting 316L/CuSn10. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2020, 792, 139316. [Google Scholar] [CrossRef]

- Zhang, H.; Xu, M.; Liu, Z.; Li, C.; Kumar, P.; Liu, Z.; Zhang, Y. Microstructure, surface quality, residual stress, fatigue behavior and damage mechanisms of selective laser melted 304L stainless steel considering building direction. Addit. Manuf. 2021, 46, 102147. [Google Scholar] [CrossRef]

- Song, C.; Huang, J.; Liu, L.; Hu, Z.; Yang, Y.; Wang, D.; Yang, C. Study on phase transformation behavior and mechanical properties of equiatomic ratio NiTi alloy formed by selective laser melting. Rapid Prototyp. J. 2023, 29, 731–740. [Google Scholar] [CrossRef]

- Ko, K.-H.; Kang, H.-G.; Huh, Y.-H.; Park, C.-J.; Cho, L.-R. Effects of heat treatment on the microstructure, residual stress, and mechanical properties of Co-Cr alloy fabricated by selective laser melting. J. Mech. Behav. Biomed. Mater. 2022, 126, 105051. [Google Scholar] [CrossRef]

- Mao, S.; Zhang, D.Z.; Ren, Z.; Fu, G.; Ma, X. Effects of process parameters on interfacial characterization and mechanical properties of 316L/CuCrZr functionally graded material by selective laser melting. J. Alloys Compd. 2022, 899, 163256. [Google Scholar] [CrossRef]

- Nagesha, B.K.; Vinodh, K.; Tigga, A.K.; Barad, S.; Kumar, S.A. Influence of post-processing techniques on residual stresses of SLM processed HPNGV. J. Manuf. Process. 2021, 66, 189–197. [Google Scholar]

- Chen, Y.; Sun, H.; Li, Z.; Wu, Y.; Xiao, Y.; Chen, Z.; Zhong, S.; Wang, H. Strategy of Residual Stress Determination on Selective Laser Melted Al Alloy Using XRD. Materials 2020, 13, 451. [Google Scholar] [CrossRef] [PubMed]

- Jiang, X.; Yu, C.; Guo, H.; Gao, S.; Zhang, Y. Effect of supporting structure design on residual stresses in selective laser melting of AlSi10Mg. Int. J. Adv. Manuf. Technol. 2022, 118, 1597–1608. [Google Scholar]

- Wu, A.S.; Brown, D.W.; Kumar, M.; Gallegos, G.F.; King, W.E. An Experimental Investigation into Additive Manufacturing-Induced Residual Stresses in 316L Stainless Steel. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2014, 45A, 6260–6270. [Google Scholar] [CrossRef]

- Brown, D.W.; Bernardin, J.D.; Carpenter, J.S.; Clausen, B.; Spernjak, D.; Thompson, J.M. Neutron diffraction measurements of residual stress in additively manufactured stainless steel. Mater. Sci. Eng. A 2016, 678, 291–298. [Google Scholar] [CrossRef]

- Ghasri-Khouzani, M.; Peng, H.; Rogge, R.; Attardo, R.; Ostiguy, P.; Neidig, J.; Billo, R.; Hoelzle, D.; Shankar, M.R. Experimental measurement of residual stress and distortion in additively manufactured stainless steel components with various dimensions. Mater. Sci. Eng. A 2017, 707, 689–700. [Google Scholar] [CrossRef]

- Anderson, L.S.; Venter, A.M.; Vrancken, B.; Marais, D.; Humbeeck, J.V.; Becker, T.H. Investigating the Residual Stress Distribution in Selective Laser Melting Produced Ti-6AI-4V using Neutron Diffraction. In International Conference on Mechanical Stress Evaluation by Neutrons and Synchrotron Radiation; Materials Research Foundation: Millersville, PA, USA, 2018. [Google Scholar]

- Yan, J.-J.; Li, J.; Yang, Z.-L.; Gu, R.-N.; Yan, M.; Quach, W.-M. Neutron diffraction residual stress analysis and mechanical properties of additively manufactured high strength steel hollow sections. Thin-Walled Struct. 2022, 179, 109729. [Google Scholar] [CrossRef]

- Sanchez-Poncela, M.; Cabeza, S.; Martinez, J.M.; Cabrera, A.; Rementeria, R. Microstructural and neutron residual stress characterization of 316L laser-powder bed fusion simplified end-use part: A modelling benchmark. Mater. Des. 2024, 237, 17. [Google Scholar] [CrossRef]

- Martinez-Garcia, V.; Pedrini, G.; Weidmann, P.; Killinger, A.; Gadow, R.; Osten, W.; Schmauder, S. Non-contact residual stress analysis method with displacement measurements in the nanometric range by laser made material removal and SLM based beam conditioning on ceramic coatings. Surf. Coat. Technol. 2019, 371, 14–19. [Google Scholar] [CrossRef]

- Quoc-Phu, M.; Mesicek, J.; Fojtik, F.; Hajnys, J.; Krpec, P.; Pagac, M.; Petru, J. Residual Stress Build-Up in Aluminum Parts Fabricated with SLM Technology Using the Bridge Curvature Method. Materials 2022, 15, 6057. [Google Scholar] [CrossRef] [PubMed]

- Levkulich, N.C.; Semiatin, S.L.; Gockel, J.E.; Middendorf, J.R.; Klingbeil, N.W. The Effect of Process Parameters on Residual Stress Evolution and Distortion in the Laser Powder Bed Fusion of Ti-6Al-4V. Addit. Manuf. 2019, 28, 475–484. [Google Scholar] [CrossRef]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Residual stress development in selective laser-melted Ti6Al4V: A parametric thermal modelling approach. Int. J. Adv. Manuf. Technol. 2018, 97, 2621–2633. [Google Scholar] [CrossRef]

- Zaeh, M.F.; Branner, G. Investigations on residual stresses and deformations in selective laser melting. Prod. Eng. 2010, 4, 35–45. [Google Scholar] [CrossRef]

- An, K.; Yuan, L.; Dial, L.; Spinelli, I.; Stoica, A.D.; Gao, Y. Neutron residual stress measurement and numerical modeling in a curved thin-walled structure by laser powder bed fusion additive manufacturing. Mater. Des. 2017, 135, 122–132. [Google Scholar] [CrossRef]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Wang, L.; Jiang, X.; Zhu, Y.; Zhu, X.; Sun, J.; Yan, B. An approach to predict the residual stress and distortion during the selective laser melting of AlSi10Mg parts. Int. J. Adv. Manuf. Technol. 2018, 97, 3535–3546. [Google Scholar] [CrossRef]

- Ben-Artzy, A.; Demir, K.; Peterson, J.; Maloy, S.; Xgu, G.; Hosemann, P. Residual Stress Measurement Techniques for Additive Manufacturing Applications. J. Mater. Sci. Eng. A 2022, 1, 1–12. [Google Scholar] [CrossRef]

- Zhang, C.; Yao, M.; Liang, H.; Wang, Y.; Jiang, X. Designing of additive auxiliary support structure in the selective laser melting considering the milling of thin-walled parts. Int. J. Adv. Manuf. Technol. 2024, 130, 837–849. [Google Scholar]

- Foroozmehr, A.; Badrossamay, M.; Foroozmehr, E.; Golabi, S.i. Finite Element Simulation of Selective Laser Melting process considering Optical Penetration Depth of laser in powder bed. Mater. Des. 2016, 89, 255–263. [Google Scholar] [CrossRef]

- Gusarov, A.V.; Pavlov, M.; Smurov, I. Residual Stresses at Laser Surface Remelting and Additive Manufacturing. Phys. Procedia 2011, 12, 248–254. [Google Scholar] [CrossRef]

- Tan, P.; Shen, F.; Li, B.; Zhou, K. A thermo-metallurgical-mechanical model for selective laser melting of Ti6Al4V. Mater. Des. 2019, 168, 107642. [Google Scholar] [CrossRef]

- Dikova, T.; Maximov, J.; Gagov, Y. Experimental and FEM investigation of adhesion strength of dental ceramic to milled and SLM fabricated Ti6Al4V alloy. Eng. Fract. Mech. 2023, 291, 109528. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, L.J.; Du, X.Z.; Yang, Y.P. Finite element analysis of thermal behavior of metal powder during selective laser melting. Int. J. Therm. Sci. 2016, 104, 146–157. [Google Scholar] [CrossRef]

- Alexopoulou, V.E.; Papazoglou, E.L.; Karmiris-Obratański, P.; Markopoulos, A.P. 3D finite element modeling of selective laser melting for conduction, transition and keyhole modes. J. Manuf. Process. 2022, 75, 877–894. [Google Scholar] [CrossRef]

- Bian, P.; Shi, J.; Liu, Y.; Xie, Y. Influence of laser power and scanning strategy on residual stress distribution in additively manufactured 316L steel. Opt. Laser Technol. 2020, 132, 106477. [Google Scholar] [CrossRef]

- Zhao, M.; Duan, C.; Luo, X. Heat Transfer, Laser Remelting/Premelting Behavior and Metallurgical Bonding During Selective Laser Melting of Metal Powder. Met. Mater. Int. 2022, 28, 2225–2238. [Google Scholar] [CrossRef]

- Kremer, R.; Khani, S.; Appel, T.; Palkowski, H.; Foadian, F. Selective Laser Melting of CuSn10: Simulation of Mechanical Properties, Microstructure, and Residual Stresses. Materials 2022, 15, 3902. [Google Scholar] [CrossRef]

- Kazemi, Z.; Soleimani, M.; Rokhgireh, H.; Nayebi, A. Melting pool simulation of 316L samples manufactured by Selective Laser Melting method, comparison with experimental results. Int. J. Therm. Sci. 2022, 176, 107538. [Google Scholar] [CrossRef]

- Gu, D.; He, B. Finite element simulation and experimental investigation of residual stresses in selective laser melted Ti–Ni shape memory alloy. Comput. Mater. Sci. 2016, 117, 221–232. [Google Scholar] [CrossRef]

- Song, J.; Wu, W.; Zhang, L.; He, B.; Lu, L.; Ni, X.; Long, Q.; Zhu, G. Role of scanning strategy on residual stress distribution in Ti-6Al-4V alloy prepared by selective laser melting. Optik 2018, 170, 342–352. [Google Scholar] [CrossRef]

- Wu, J.; Wang, L.; An, X. Numerical analysis of residual stress evolution of AlSi10Mg manufactured by selective laser melting. Optik 2017, 137, 65–78. [Google Scholar] [CrossRef]

- Bian, P.; Shi, J.; Shao, X.; Du, J. Evolution of cyclic thermal stress in selective laser melting of 316L stainless steel: A realistic numerical study with experimental verification. Int. J. Adv. Manuf. Technol. 2019, 104, 3867–3882. [Google Scholar] [CrossRef]

- Khan, H.M.; Waqar, S.; Koc, E. Evolution of temperature and residual stress behavior in selective laser melting of 316L stainless steel across a cooling channel. Rapid Prototyp. J. 2022, 28, 1272–1283. [Google Scholar] [CrossRef]

- Xu, P.; Zuo, H.; Zhou, L.; Qiu, W.; Tang, J. Finite element simulation and experimental validation of the thermomechanical behavior in selective laser melting of Ti55531 alloy. Int. J. Adv. Manuf. Technol. 2024, 132, 5567–5584. [Google Scholar] [CrossRef]

- Waqar, S.; Guo, K.; Sun, J. FEM analysis of thermal and residual stress profile in selective laser melting of 316L stainless steel. J. Manuf. Process. 2021, 66, 81–100. [Google Scholar] [CrossRef]

- Waqar, S.; Guo, K.; Sun, J. Evolution of residual stress behavior in selective laser melting (SLM) of 316L stainless steel through preheating and in-situ re-scanning techniques. Opt. Laser Technol. 2022, 149, 107806. [Google Scholar] [CrossRef]

- Kreitcberg, A.; Brailovski, V.; Turenne, S. Effect of heat treatment and hot isostatic pressing on the microstructure and mechanical properties of Inconel 625 alloy processed by laser powder bed fusion. Mater. Sci. Eng. A 2017, 689, 1–10. [Google Scholar] [CrossRef]

- Jiang, C.; Yang, C. Internal Stress Diffraction Analysis; Science Publishing Company: New York, NY, USA, 2013. [Google Scholar]

- Scurria, M.; Mller, B.; Wagener, R.; Bein, T. Characterization of the Cyclic Material Behavior of AlSi10Mg and Inconel 718 Produced by SLM. In Mechanical Fatigue of Metals; Structural Integrity; Springer: Cham, Switzerland, 2019; pp. 115–121. [Google Scholar]

- Chen, S.-g.; Zhang, Y.-d.; Wu, Q.; Gao, H.-j.; Gao, Z.-h.; Li, X. Effect of solid-state phase transformation on residual stress of selective laser melting Ti6Al4V. Mater. Sci. Eng. A 2021, 819, 141299. [Google Scholar] [CrossRef]

- Fang, Z.-C.; Wu, Z.-L.; Huang, C.-G.; Wu, C.-W. Review on residual stress in selective laser melting additive manufacturing of alloy parts. Opt. Laser Technol. 2020, 129, 106283. [Google Scholar] [CrossRef]

- Somashekara, M.A.; Naveenkumar, M.; Kumar, A.; Viswanath, C.; Simhambhatla, S. Investigations into effect of weld-deposition pattern on residual stress evolution for metallic additive manufacturing. Int. J. Adv. Manuf. Technol. 2017, 90, 2009–2025. [Google Scholar] [CrossRef]

- Ma, P.; Ji, P.; Jia, Y.; Shi, X.; Yu, Z.; Prashanth, K.G. Effect of Substrate Plate Heating on the Microstructure and Properties of Selective Laser Melted Al-20Si-5Fe-3Cu-1Mg Alloy. Materials 2021, 14, 330. [Google Scholar] [CrossRef]

- Cai, L.; Liang, S.Y. Analytical Modelling of Temperature Distribution in SLM Process with Consideration of Scan Strategy Difference between Layers. Materials 2021, 14, 1869. [Google Scholar] [CrossRef]

- Anand, N.; Chang, K.-C.; Yeh, A.-C.; Chen, Y.-B.; Lee, M.-T. An efficient transient three-dimensional thermomechanical model ing of dynamic thermal stress building and releasing in a selective laser melting process. J. Mater. Process. Technol. 2022, 309, 117741. [Google Scholar] [CrossRef]

- Yang, Y.P.; Jamshidinia, M.; Boulware, P.; Kelly, S.M. Prediction of microstructure, residual stress, and deformation in laser powder bed fusion process. Comput. Mech. 2017, 61, 599–615. [Google Scholar] [CrossRef]

- Furumoto, T.; Ogura, R.; Hishida, K.; Hosokawa, A.; Koyano, T.; Abe, S.; Ueda, T. Study on deformation restraining of metal structure fabricated by selective laser melting. J. Mater. Process. Technol. 2017, 245, 207–214. [Google Scholar] [CrossRef]

- Wei, S.; Wang, G.; Wang, L.; Rong, Y. Characteristics of microstructure and stresses and their effects on interfacial fracture behavior for laser-deposited maraging steel. Mater. Des. 2018, 137, 56–67. [Google Scholar] [CrossRef]

- Shi, X.; Ma, S.; Liu, C.; Wu, Q. Parameter optimization for Ti-47Al-2Cr-2Nb in selective laser melting based on geometric characteristics of single scan tracks. Opt. Laser Technol. 2017, 90, 71–79. [Google Scholar] [CrossRef]

- Mugwagwa, L.; Dimitrov, D.; Matope, S.; Yadroitsev, I. Influence of process parameters on residual stress related distortions in selective laser melting. Procedia Manuf. 2018, 21, 92–99. [Google Scholar] [CrossRef]

- Park, H.S.; Ansari, M.J. Estimation of Residual Stress and Deformation in Selective Laser Melting of Ti6Al4V Alloy. Procedia CIRP 2020, 93, 44–49. [Google Scholar] [CrossRef]

- Miao, X.; Wu, M.; Han, J.; Li, H.; Ye, X. Effect of Laser Rescanning on the Characteristics and Residual Stress of Selective Laser Melted Titanium Ti6Al4V Alloy. Materials 2020, 13, 3940. [Google Scholar] [CrossRef]

- Xiao, Z.; Lei, Y.; Hu, Z.; Chen, C.; Chen, B.; Zhu, H. Influence of rescanning parameters on selective laser melting of Ti6Al4V. J. Manuf. Process. 2022, 82, 530–542. [Google Scholar] [CrossRef]

- Chen, C.; Yin, J.; Zhu, H.; Xiao, Z.; Zhang, L.; Zeng, X. Effect of overlap rate and pattern on residual stress in selective laser melting. Int. J. Mach. Tools Manuf. 2019, 145, 103433. [Google Scholar] [CrossRef]

- Chen, C.; Yin, J.; Zhu, H.; Zeng, X.; Wang, G.; Ke, L.; Zhu, J.; Chang, S. The effect of process parameters on the residual stress of selective laser melted Inconel 718 thin-walled part. Rapid Prototyp. J. 2019, 25, 1359–1369. [Google Scholar] [CrossRef]

- Ravichander, B.B.; Mamidi, K.; Rajendran, V.; Farhang, B.; Ganesh-Ram, A.; Hanumantha, M.; Moghaddam, N.S.; Amerinatanzi, A. Experimental investigation of laser scan strategy on the microstructure and properties of Inconel 718 parts fabricated by laser powder bed fusion. Mater. Charact. 2022, 186, 111765. [Google Scholar] [CrossRef]

- Wang, M.; Cao, R.; Chang, H.; Liang, D. The effect of rescanning strategy on residual stress and deformation of laser-based powder bed fusion of 316L stainless steel thin-walled parts. Rapid Prototyp. J. 2023, 29, 1044–1060. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Ali, H.; Ma, L.; Ghadbeigi, H.; Mumtaz, K. In-situ residual stress reduction, martensitic decomposition and mechanical properties enhancement through high temperature powder bed pre-heating of Selective Laser Melted Ti6Al4V. Mater. Sci. Eng. A 2017, 695, 211–220. [Google Scholar] [CrossRef]

- Cottam, R.; Wang, J.; Luzin, V. Characterization of microstructure and residual stress in a 3D H13 tool steel component produced by additive manufacturing. J. Mater. Res. 2014, 29, 1978–1986. [Google Scholar] [CrossRef]

- Syed, A.K.; Ahmad, B.; Guo, H.; Machry, T.; Eatock, D.; Meyer, J.; Fitzpatrick, M.E.; Zhang, X. An experimental study of residual stress and direction-dependence of fatigue crack growth behaviour in as-built and stress-relieved selective-laser-melted Ti6Al4V. Mater. Sci. Eng. A Struct. Mater. Prop. Misrostructure Process. 2019, 755, 246–257. [Google Scholar] [CrossRef]

- Ali, H. Evolution of Residual Stress in ti6al4v Components Fabricated Using Selective Laser Melting. Ph.D. Thesis, University of Sheffield, Sheffield, UK, 2017. [Google Scholar]

- Xiao, Z.; Chen, C.; Zhu, H.; Hu, Z.; Nagarajan, B.; Guo, L.; Zeng, X. Study of residual stress in selective laser melting of Ti6Al4V. Mater. Des. 2020, 193, 108846. [Google Scholar] [CrossRef]

- Sharma, D.; Hiremath, S.S.; Kenchappa, N.B. Effect of heat treatment on the variable amplitude fatigue life and microstructure of the novel bioinspired Ti-6Al-4V thin tubes fabricated using Selective Laser Melting process. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 975–986. [Google Scholar] [CrossRef]

- AlMangour, B.; Grzesiak, D.; Cheng, J.; Ertas, Y. Thermal behavior of the molten pool, microstructural evolution, and tribological performance during selective laser melting of TiC/316L stainless steel nanocomposites: Experimental and simulation methods. J. Mater. Process. Technol. 2018, 257, 288–301. [Google Scholar] [CrossRef]

- Guo, M.; Ye, Y.; Jiang, X.; Wang, L. Microstructure, Mechanical Properties and Residual Stress of Selective Laser Melted AlSi10Mg. J. Mater. Eng. Perform. 2019, 28, 6753–6760. [Google Scholar] [CrossRef]

- Bian, P.; Wang, C.; Xu, K.; Ye, F.; Zhang, Y.; Li, L. Coupling Analysis on Microstructure and Residual Stress in Selective Laser Melting (SLM) with Varying Key Process Parameters. Materials 2022, 15, 1658. [Google Scholar] [CrossRef]

- Tian, C.; Li, X.; Liu, Z.; Zhi, G.; Guo, G.; Wang, L.; Rong, Y. Study on Grindability of Inconel 718 Superalloy Fabricated by Selective Laser Melting (SLM). Stroj. Vestn. -J. Mech. Eng. 2018, 64, 319–328. [Google Scholar]

- Měsíček, J.; Čegan, T.; Ma, Q.-P.; Halama, R.; Skotnicová, K.; Hajnyš, J.; Juřica, J.; Krpec, P.; Pagáč, M. Effect of artificial aging on the strength, hardness, and residual stress of SLM AlSi10Mg parts prepared from the recycled powder. Mater. Sci. Eng. A 2022, 855, 143900. [Google Scholar] [CrossRef]

- Ali, H.; Ghadbeigi, H.; Mumtaz, K. Processing Parameter Effects on Residual Stress and Mechanical Properties of Selective Laser Melted Ti6Al4V. J. Mater. Eng. Perform. 2018, 27, 4059–4068. [Google Scholar] [CrossRef]

- Chen, Y.; Rong, P.; Men, X.; Deng, A.; Liu, Y.; Chen, H.; Zhang, Z.; Liu, Y.; Ren, L. An Experimental Investigation into Residual Stress Control of 24CrNiMo Alloy Steel by Selective Laser Melting. Coatings 2023, 13, 321. [Google Scholar] [CrossRef]

- Amoako, E.D.; Mensah, P.; Akwaboa, S.; Ibekwe, S.; Li, G. Parametric Study of SLM Processing Parameters on In-Situ Residual Stress. In Proceedings of the ASME 2019 Heat Transfer Summer Conference, Bellevue, WA, USA, 14–17 July 2019. [Google Scholar]

- Chenglin, Z.; Yan, W.; Haiyi, L.; Mengcan, Y.; Xiaohui, J. Effect of process parameters on residual stresses in SLM-formed bionic porous titanium alloy structures. Mater. Today Commun. 2024, 39, 108539. [Google Scholar] [CrossRef]

- Mishurova, T.; Artzt, K.; Haubrich, J.; Requena, G.; Bruno, G. New aspects about the search for the most relevant parameters optimizing SLM materials. Addit. Manuf. 2019, 25, 325–334. [Google Scholar] [CrossRef]

- Sopcisak, J.J.; Ouyang, M.; Macatangay, D.A.; Croom, B.P.; Montalbano, T.J.; Sprouster, D.J.; Kelly, R.G.; Trelewicz, J.R.; Srinivasan, R.; Storck, S.M. Improving the Pitting Corrosion Performance of Additively Manufactured 316L Steel Via Optimized Selective Laser Melting Processing Parameters. Jom 2022, 74, 1719–1729. [Google Scholar] [CrossRef]

- Li, W.; Liu, J.; Zhou, Y.; Wen, S.; Wei, Q.; Yan, C.; Shi, Y. Effect of substrate preheating on the texture, phase and nanohardness of a Ti–45Al–2Cr–5Nb alloy processed by selective laser melting. Scr. Mater. 2016, 118, 13–18. [Google Scholar] [CrossRef]

- Song, J.; Chew, Y.; Jiao, L.; Yao, X.; Moon, S.K.; Bi, G. Numerical study of temperature and cooling rate in selective laser melting with functionally graded support structures. Addit. Manuf. 2018, 24, 543–551. [Google Scholar] [CrossRef]

- Zhou, L.; Sun, J.; Chen, J.; Chen, W.; Ren, Y.; Niu, Y.; Li, C.; Qiu, W. Study of substrate preheating on the microstructure and mechanical performance of Ti-15Mo alloy processed by selective laser melting. J. Alloys Compd. 2022, 928, 167130. [Google Scholar] [CrossRef]

- Ma, W.; Ning, J.; Zhang, L.-J.; Na, S.-J. Regulation of microstructures and properties of molybdenum-silicon-boron alloy subjected to selective laser melting. J. Manuf. Process. 2021, 69, 593–601. [Google Scholar] [CrossRef]

- Bang, G.B.; Park, J.H.; Kim, W.R.; Hyun, S.-K.; Park, H.-K.; Lee, T.W.; Kim, H.G. Study on the effect of preheating temperature of SLM process on characteristics of CoCrMo alloy. Mater. Sci. Eng. A 2022, 841, 143020. [Google Scholar] [CrossRef]

- Zhao, Y.; Aoyagi, K.; Yamanaka, K.; Chiba, A. Role of operating and environmental conditions in determining molten pool dynamics during electron beam melting and selective laser melting. Addit. Manuf. 2020, 36, 101559. [Google Scholar] [CrossRef]

- Xie, W.; Yang, X.; Yang, H.; Duan, X. The effects of TiC particle on microstructure and mechanical properties of Inconel 718 fabricated by selective arc melting. J. Manuf. Process. 2024, 131, 1132–1142. [Google Scholar] [CrossRef]

- Korkmaz, M.E.; Gupta, M.K.; Waqar, S.; Kuntoğlu, M.; Krolczyk, G.M.; Maruda, R.W.; Pimenov, D.Y. A short review on thermal treatments of Titanium & Nickel based alloys processed by selective laser melting. J. Mater. Res. Technol. 2022, 16, 1090–1101. [Google Scholar]

- Limbasiya, N.; Jain, A.; Soni, H.; Wankhede, V.; Krolczyk, G.; Sahlot, P. A comprehensive review on the effect of process parameters and post-process treatments on microstructure and mechanical properties of selective laser melting of AlSi10Mg. J. Mater. Res. Technol. 2022, 21, 1141–1176. [Google Scholar] [CrossRef]

- Jalali, M.; Mohammadi, K.; Movahhedy, M.R.R.; Karimi, F.; Sadrnezhaad, S.K.; Chernyshikhin, S.V.V.; Shishkovsky, I.V.V. SLM Additive Manufacturing of NiTi Porous Implants: A Review of Constitutive Models, Finite Element Simulations, Manufacturing, Heat Treatment, Mechanical, and Biomedical Studies. Met. Mater. Int. 2023, 29, 2458–2491. [Google Scholar] [CrossRef]

- Yadav, B.N.; Lin, D.-W.; Lin, M.-C.; Tseng, Y.-J.; Yen, H.-W.; Van Tran, X.; Lin, P.-C. Implemented in-situ heat treatment process for controlling the residual thermal stresses during the fabrication of Ti-6Al-4V titanium alloy through additive manufacturing. Mater. Lett. 2024, 356, 135580. [Google Scholar] [CrossRef]

- Huang, Z.; Wang, B.; Liu, F.; Song, M.; Ni, S.; Liu, S. Microstructure evolution, martensite transformation and mechanical properties of heat treated Co-Cr-Mo-W alloys by selective laser melting. Int. J. Refract. Met. Hard Mater. 2023, 113, 106170. [Google Scholar] [CrossRef]

- Song, H.Y.; Lam, M.C.; Chen, Y.; Wu, S.; Hodgson, P.D.; Wu, X.H.; Zhu, Y.M.; Huang, A.J. Towards creep property improvement of selective laser melted Ni-based superalloy IN738LC. J. Mater. Sci. Technol. 2022, 112, 301–314. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, X.; Li, D.; Zhou, D.; Jiang, Y.; Yang, X.; Liu, C.; Leen, S.B.; Gong, J. Experimental characterization and strengthening mechanism of process-structure-property of selective laser melted 316 L. Mater. Charact. 2023, 198, 112753. [Google Scholar] [CrossRef]

- Ren, D.; Zhang, L.; Liu, Y.; Ji, H.; Li, S.; Jin, W.; Lei, J. Effect of hot isostatic pressing on the mechanical and corrosive properties of Ti–Ni alloy fabricated by selective laser melting. J. Mater. Res. Technol. 2023, 26, 4595–4605. [Google Scholar] [CrossRef]

- Su, C.; Cao, J.; Li, G.; Wang, E.; Naveen, B.S.; Lou, S.; Huang, W.M. Experimental investigation on the factors affecting the quality of titanium alloy overhang via selective laser melting forming. Int. J. Adv. Manuf. Technol. 2023, 128, 3391–3402. [Google Scholar] [CrossRef]

- Centola, A.; Ciampaglia, A.; Tridello, A.; Paolino, D.S. Machine learning methods to predict the fatigue life of selectively laser melted Ti6Al4V components. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 4350–4370. [Google Scholar] [CrossRef]

- Mashhood, M.; Peters, B.; Zilian, A.; Baroli, D.; Wyart, E. Developing the AM G-code based thermomechanical finite element platform for the analysis of thermal deformation and stress in metal additive manufacturing process. J. Mech. Sci. Technol. 2023, 37, 1103–1112. [Google Scholar] [CrossRef]

- Javidrad, H.R.; Javidrad, F. Review of state-of-the-art research on the design and manufacturing of support structures for powder-bed fusion additive manufacturing. Prog. Addit. Manuf. 2023, 8, 1517–1542. [Google Scholar] [CrossRef]

- Cordero, M.Z.; Dedic, R.; Jelacic, Z.; Toshev, R. Optimizing Mechanical Design for an Additively Manufactured Prosthetic Leg. Procedia Comput. Sci. 2024, 232, 2973–2983. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).