A Life Prediction Model Considering Material Ductility in Multiaxial Fatigue Damage Analysis

Abstract

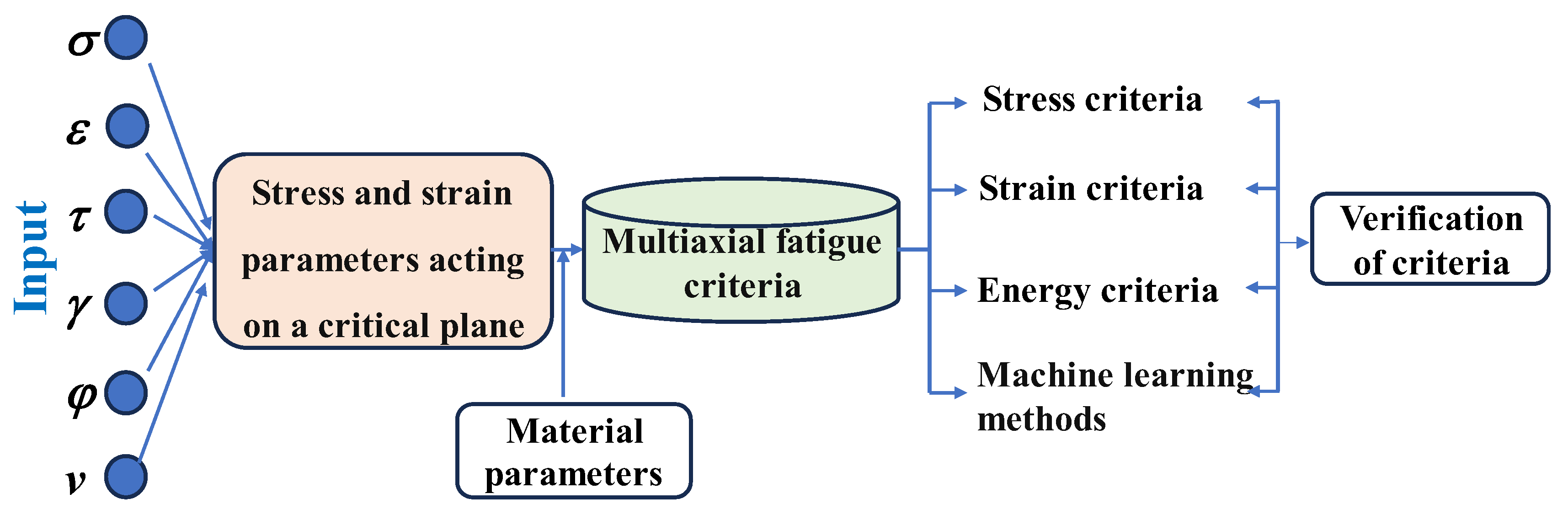

1. Introduction

| Criteria | Expression | Refs. | |

|---|---|---|---|

| Stress | Findley | [16] | |

| Strain | MSSM | [12] | |

| KBM | [14] | ||

| WB | [13] | ||

| FS | [15] | ||

| Energy | SWT | [20] | |

| Liu I | [21] | ||

| Liu II | [21] | ||

| Varvani | [24] | ||

| CHX | [25] |

2. Experimental Tests and Results

2.1. Uniaxial Fatigue Experiment

2.2. Multiaxial Fatigue Test

3. Effect of Materials’ Ductility on Multiaxial Fatigue Life

4. Proposed Critical Plane-Energy Model

4.1. Establishing a Damage Parameter

4.2. Relationship Between Damage Parameter and Fatigue Life

5. Proposed Model Validation and Comparison

5.1. AA2024-T351

5.2. Other Materials

6. Conclusions

- (1)

- Practice demonstrates that the new damage parameter satisfies the following presumptions: (1) The plane exhibiting the maximum shear strain range is the critical plane of a material with shear failure characteristics. (2) The greater the ductility, the more sensitive the material is to an out-of-phase load, the greater the damage parameter, and the shorter the fatigue life. (3) The normal work and shear work on the critical plane leading to fatigue failure do not have the same weights. (4) The shear component and the normal component on the crack surface have mutually reinforcing effects.

- (2)

- Most of the lifetime prediction results of the proposed model for AA2024-T351 are within the ±2 times scattering band.

- (3)

- The fatigue life predictions of the proposed model for five materials in the literature under multiaxial loading fall within the range of ±3 times the scattering band. In contrast to the model without a ductility adjustment function, the prediction results of the new model are less scattered and safer, and more accurate.

- (4)

- Compared with the MSSM and SWT models, the proposed model can give more accurate and safer prediction results for the fatigue life under both proportional and non-proportional loads. In contrast to the popular FS model, the new model performs better life prediction under non-proportional loading.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| Δγmax | the maximum shear strain range acting on the critical plane |

| σn,max | maximum normal stress acting on the critical plane |

| Δτt | shear stress acting on the critical plane |

| Δσn | normal stress acting on the critical plane |

| Δεn | normal strain acting on the critical plane |

| k | material constant of FS model |

| σy | the yield strength |

| σu | the ultimate strength |

| Hv | Vickers hardness |

| φ | phase difference |

| v | Poisson’s ratio |

| shear fatigue strength coefficient | |

| shear fatigue ductility coefficient | |

| b0 | shear fatigue strength exponent |

| c0 | shear fatigue ductility exponent |

| fatigue strength coefficient | |

| fatigue ductility coefficient | |

| b | fatigue strength exponent |

| c | fatigue ductility exponent |

| E | modulus of elasticity |

| G | shear modulus |

| Nipf | fatigue life under proportional load |

| Nf | fatigue life |

| Nnonpf | fatigue life under non-proportional load |

| Nd | the degree of life reduction due to non-proportional loading |

| Ψ | load non-proportional factor |

| δ | elongation |

| Δγe/2 | elastic strain amplitude |

| Δγp/2 | plastic strain amplitude |

| Δγ/2 | total strain amplitude |

| Perror | life prediction error |

| Nfp | predicted life |

| Nft | actual life |

References

- Almamoori, M.; Alizadeh, Y. A novel approach to multiaxial fatigue life prediction using the critical plane and phase difference angle. Eng. Fail. Anal. 2023, 154, 107654. [Google Scholar]

- Susmel, L.; Hattingh, D.G.; James, M.N.; Tovo, R. Multiaxial fatigue assessment of friction stir welded tubular joints of Al 6082-T6. Int. J. Fatigue 2017, 101, 282–296. [Google Scholar]

- He, Y.B.; Liu, J.H.; Lu, J.M.; Wang, J.; Feng, R.; Ren, J. Probabilistic fatigue evaluation of notched specimens considering small sample properties under multiaxial loading. Theor. Appl. Fract. Mech. 2024, 130, 104316. [Google Scholar]

- Tao, Z.Q.; Pan, X.N.; Zhang, Z.L.; Chen, H.; Li, L.-X. Multiaxial fatigue lifetime estimation based on the new equivalent strain energy damage model under variable amplitude loading. Crystals 2024, 14, 825. [Google Scholar] [CrossRef]

- Liu, X.L.; Song, X.D.; Guo, W.J.; Liu, J.; Dong, Y. Research on probability model and reliability of multiaxial fatigue life based on Huffman model. Int. J. Fatigue 2025, 191, 108675. [Google Scholar]

- Fatemi, A.; Shamsaei, N. Multiaxial fatigue: An overview and some approximation models for life estimation. Int. J. Fatigue 2011, 149, 948–958. [Google Scholar]

- Yakovchuk, P.V.; Savchuk, E.V.; Shukayev, S.M. Critical Plane Approach-Based Fatigue Life Prediction for Multiaxial Loading: A New Model and its Verification. Strength Mater. 2024, 56, 281–291. [Google Scholar]

- Yang, S.; Sun, J. Multiaxial fatigue life assessment of 304 austenitic stainless steel with a novel energy-based criterion. Int. J. Fatigue 2022, 159, 106728. [Google Scholar]

- Zhao, B.F.; Song, J.X.; Xie, L.Y.; Ma, H.; Li, H.; Ren, J.; Sun, W. Multiaxial fatigue life prediction method based on the back-propagation neural network. Int. J. Fatigue 2023, 166, 107274. [Google Scholar]

- Pałczynsk, K.; Skibicki, D.; Pejkowski, Ł. Application of machine learning methods in multiaxial fatigue life prediction. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 416–432. [Google Scholar] [CrossRef]

- Abasolo, M.; Santasmartas, L.P.; Eizmendi, M. A New Critical Plane Multiaxial Fatigue Criterion with an Exponent to Account for High Mean Stress Effect. Metals 2024, 14, 964. [Google Scholar] [CrossRef]

- Wu, Z.R.; Hu, X.T.; Song, Y.D. Multiaxial fatigue life prediction for titanium alloy TC4 under proportional and nonproportional loading. Int. J. Fatigue 2014, 59, 170–175. [Google Scholar]

- Wang, C.H.; Brown, M.W. Life prediction techniques for variable amplitude multiaxial fatigue—Part Ⅰ: Theories. J. Eng. Mater. Technol. 1996, 118, 367–370. [Google Scholar]

- Brown, M.W.; Miller, K.J. A Theory for Fatigue Failure under Multiaxial Stress-Strain Conditions. Mech. Eng. 1973, 187, 745–755. [Google Scholar]

- Fatemi, A.; Socie, D.F. A critical plane approach to multiaxial fatigue damage including out-of-phase loading. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 149–165. [Google Scholar] [CrossRef]

- Findley, W.N. A Theory for the Effect of Mean Stress on Fatigue of Metals Under Combined Torsion and Axial Load or Bending. J. Manuf. Sci. Eng. 1959, 81, 301–305. [Google Scholar]

- Gan, L.; Fan, Z.M.; Wu, H.; Zhong, Z. Prediction of multiaxial fatigue life with a data-driven knowledge transfer model. Int. J. Fatigue 2025, 190, 108636. [Google Scholar]

- Xu, S.; Zhu, S.P.; Hao, Y.Z. A new critical plane-energy model for multiaxial fatigue life prediction of turbine disc alloys. Eng. Fail. Anal. 2018, 93, 55–63. [Google Scholar]

- Arora, P.; Gupta, S.K.; Samal, M.K.; Chattopadhyay, J. Development of new critical plane model for assessment of fatigue life under mult-iaxial loading conditions. Int. J. Fatigue 2019, 129, 105209. [Google Scholar]

- Smith, K.N.; Watson, P.; Topper, T.H. A stress-strain function for the fatigue of metals. J. Mater. 1970, 5, 767–778. [Google Scholar]

- Liu, K. Method based on virtual strain-energy parameters for multiaxial fatigue life prediction. ASTM Int. 1993, 1191, 67–84. [Google Scholar]

- Gates, N.; Fatemi, A. Friction and roughness induced closure effects on shear-mode crack growth and branching mechanisms. Int. J. Fatigue 2016, 92, 442–458. [Google Scholar]

- Li, J.; Wang, X.; Li, R.T. Multiaxial fatigue life prediction for metals by means of an improved strain energy density-based critical plane criterion. Eur. J. Mech./A Solids 2021, 90, 104253. [Google Scholar] [CrossRef]

- Varvani-Farahani, A. A new energy-critical plane parameter for fatigue life assessment of various metallic materials subjected to in-phase and out-of-phase multiaxial fatigue loading conditions. Int. J. Fatigue 2000, 22, 295–305. [Google Scholar]

- Chen, X.; Xu, S.; Huang, D. A critical plane-strain energy density criterion for multiaxial low-cycle fatigue under non-proportional loading. Fatigue Fract. Eng. Mater. Struct. 2003, 22, 679–686. [Google Scholar]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Chinese Standard Press: Beijing, China, 2021.

- ASTM E606; Standard Test Method for Strain-Controlled Fatigue Testing. ASTM: West Conshohocken, PA, USA, 2021.

- Liu, X.T.; Guo, W.J.; Song, X.D.; Dong, Y.; Yang, Z. Experimental study of the fatigue failure behavior of aluminum alloy 2024-T351 under multiaxial loading. Eng. Fail. Anal. 2024, 164, 108684. [Google Scholar] [CrossRef]

- Sonsino, C.M. Influence of material’s ductility and local deformation mode on multiaxial fatigue response. Int. J. Fatigue 2011, 33, 930–947. [Google Scholar] [CrossRef]

- Sonsino, C.M. Multiaxial fatigue life response depending on proportionality grade between normal and shear strains/stresses and material ductility. Int. J. Fatigue 2020, 135, 105468. [Google Scholar]

- Mei, J.F.; Dong, P.S. Modeling of path-dependent multi-axial fatigue damage in aluminum alloys. Int. J. Fatigue 2017, 95, 252–263. [Google Scholar]

- Zhao, T.; Jiang, Y. Fatigue of 7075-T651 aluminum alloy. Int. J. Fatigue 2008, 30, 834–849. [Google Scholar] [CrossRef]

- Wang, X.J. Multiaxial Fatigue of 2024-T4 Aluminum Alloy. Chin. J. Mech. Eng. 2011, 24, 33–39. [Google Scholar]

- Wu, Z.R.; Li, X.; Fang, L.; Song, Y.D. Evaluation of multiaxial fatigue life prediction criteria for Ni-based superalloy GH4169. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2017, 232, 1823–1837. [Google Scholar]

- Socie, D. Multiaxial fatigue damage models. J. Eng. Mater. Technol. 1987, 109, 293–298. [Google Scholar]

- Borodii, M.; Shukaev, S. Additional cyclic strain hardening and its relation to material structure, mechanical characteristics, and lifetime. Int. J. Fatigue 2007, 29, 1184–1191. [Google Scholar]

- Shamsaei, N.; Fatemi, A. Effect of hardness on multiaxial fatigue behaviour and some simple approximations for steels. Fatigue Fract. Eng. Mater. Struct. 2009, 32, 631–646. [Google Scholar]

- Ren, Z.; Qin, X.; Zhang, Q.; Sun, Y. Multiaxial fatigue life prediction model based on an improved strain energy density criterion. Int. J. Press. Vessel. Pip. 2022, 199, 104724. [Google Scholar]

- Arora, P.; Gupta, S.K.; Bhasin, V.; Singh, R.K.; Sivaprasad, S.; Tarafder, S. Testing and assessment of fatigue life prediction models for Indian PHWRs piping material under multi-axial load cycling. Int. J. Fatigue 2016, 85, 98–113. [Google Scholar]

- Gates, N.R.; Fatemi, A. On the consideration of normal and shear stress interaction in multiaxial fatigue damage analysis. Int. J. Fatigue 2017, 100, 322–336. [Google Scholar]

- Xu, S.; Zhu, S.P.; Hao, Y.Z. Critical plane–based multiaxial fatigue life prediction of turbine disk alloys by refining normal stress sensitivity. JSA 2018, 53, 719–729. [Google Scholar]

- Noban, M.; Jahed, H.; Ibrahim, E.; Ince, A. Load path sensitivity and fatigue life estimation of 30CrNiMo8HH. Int. J. Fatigue 2012, 37, 123–133. [Google Scholar]

- Golos, K.; Ellyin, F. A Total Strain Energy Density Theory for Cumulative Fatigue Damage. J. Press. Vessel Technol. 1988, 110, 36–41. [Google Scholar]

- Zhu, S.P.; Lei, Q.; Huang, H.Z.; Yang, Y.J.; Peng, W. Mean stress effect correction in strain energy-based fatigue life prediction of metals. Int. J. Damage Mech. 2016, 26, 1219–1241. [Google Scholar]

- McClaflin, D. Torsional deformation and fatigue of hardened steel including mean stress and stress gradient effects. Int. J. Fatigue 2004, 26, 773–784. [Google Scholar]

- Li, Y.; Ren, B.; Chen, X. Cyclic Deformation and Low-Cycle Fatigue for 316LN Stainless Steel under Non-Proportional Loading. MATEC Web Conf. 2019, 300, 08002. [Google Scholar]

- Jiang, Y.; Hertel, O.; Vormwald, M. An experimental evaluation of three critical plane multiaxial fatigue criteria. Int. J. Fatigue 2007, 29, 1490–1502. [Google Scholar]

- Shamsaei, N.; Gladskyi, M.; Panasovskyi, K.; Shukaev, S.; Fatemi, A. Multiaxial fatigue of titanium including step loading and load path alteration and sequence effects. Int. J. Fatigue 2010, 32, 1862–1874. [Google Scholar]

- An, X.L.; Chu, C.L.; Zhou, L.; Chu, P.K. Evolution of microstructures and properties of the GH4169 superalloy during short-term and high-temperature processing. Mater. Sci. Eng. A 2019, 744, 255–266. [Google Scholar]

- Feng, E.S.; Wang, X.G.; Jiang, C. A new multiaxial fatigue model for life prediction based on energy dissipation evaluation. Int. J. Fatigue 2019, 122, 1–8. [Google Scholar]

- Zerres, P.; Brüning, J.; Vormwald, M.M. Fatigue crack growth behavior of fine-grained steel S460N under proportional and non-proportional loading. Eng. Fract. Mech. 2010, 77, 1822–1834. [Google Scholar]

- Liu, B.X.; Huang, L.J.; Wang, B.; Geng, L. Effect of pure Ti thickness on the tensile behavior of laminated Ti-TiBw/Ti composites. Mater. Sci. Eng. A 2014, 617, 115–120. [Google Scholar]

| σy [MPa] | σu [MPa] | E [GPa] | Hv [HV] | δ [%] | G [GPa] |

|---|---|---|---|---|---|

| 300.1 | 460 | 73 | 137 | 10 | 27 |

[MPa] | [−] | b [−] | c [−] |

|---|---|---|---|

| 1066.3 | 0.2332 | −0.14 | −0.66 |

| No. | Strain Path | Δεeq/2 [%] | Δε/2 [%] | Δγ/2 [%] | Strain Amplitude Ratio | Nf [Cycles] | Mean Value [Cycles] |

|---|---|---|---|---|---|---|---|

| N1 |  | 0.55 | 0.391 | 0.676 | 1.73 | 7709 | 7229 |

| N2 | 5530 | ||||||

| N3 | 8448 | ||||||

| N4 | 0.45 | 0.56 | 1.24 | 6905 | 6905 | ||

| N5 |  | 0.55 | 0.391 | 0.676 | 1.73 | 11,107 | 11,191 |

| N6 | 12,854 | ||||||

| N7 | 9613 | ||||||

| N8 | 0.45 | 0.56 | 1.24 | 12,712 | 12,175 | ||

| N9 | 11,637 |

| Materials | TC4 | GH4169 | 316LN | S460N | Pure Ti |

|---|---|---|---|---|---|

| Refs. | [12] | [34] | [46] | [47] | [48] |

| E [GPa] | 108.4 | 198.5 | 190 | 208.5 | 112 |

| G [GPa] | 43.2 | 67 | 79 | 80.2 | 40 |

| [MPa] | 2.24 | 4.46 | 0.766 | - | 0.417 |

| [MPa] | 716.9 | 1091.6 | 688 | - | 485 |

| b0 [−] | −0.06 | −0.07 | −0.135 | - | −0.069 |

| c0 [−] | −0.8 | −0.77 | −0.451 | - | −0.523 |

| [−] | 0.579 | 0.45 | - | 0.281 | 0.548 |

| [MPa] | 1116.9 | 1815.5 | - | 969.6 | 647 |

| b [−] | −0.049 | −0.06 | - | −0.086 | −0.033 |

| c [−] | −0.679 | −0.63 | - | −0.493 | −0.646 |

| ve [−] | 0.25 | 0.48 | 0.3 | 0.3 | 0.4 |

| [MPa] | 942.5 | 1083.1 | 292 | 500 | 475 |

| Elongation [%] | 18.3 [28] | 26 [49] | 81 [50] | 26.2 [51] | 17.5 [52] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Song, X.; Dong, Y.; Guo, W. A Life Prediction Model Considering Material Ductility in Multiaxial Fatigue Damage Analysis. Materials 2025, 18, 1597. https://doi.org/10.3390/ma18071597

Liu X, Song X, Dong Y, Guo W. A Life Prediction Model Considering Material Ductility in Multiaxial Fatigue Damage Analysis. Materials. 2025; 18(7):1597. https://doi.org/10.3390/ma18071597

Chicago/Turabian StyleLiu, Xiaoting, Xuding Song, Yuanzhe Dong, and Wanjin Guo. 2025. "A Life Prediction Model Considering Material Ductility in Multiaxial Fatigue Damage Analysis" Materials 18, no. 7: 1597. https://doi.org/10.3390/ma18071597

APA StyleLiu, X., Song, X., Dong, Y., & Guo, W. (2025). A Life Prediction Model Considering Material Ductility in Multiaxial Fatigue Damage Analysis. Materials, 18(7), 1597. https://doi.org/10.3390/ma18071597