Accelerated Aging Method of Performance Attenuation of Crystalline Silicon Photovoltaic Modules Under Full-Spectrum Conditions

Abstract

1. Introduction

2. Establishment of an Accelerated Performance Aging Model for Crystalline Silicon Photovoltaic Modules with Full-Spectrum Conditions

3. Study on the Strict Test Conditions of Factors Affecting the Accelerated Aging of Crystalline Silicon Photovoltaic Modules

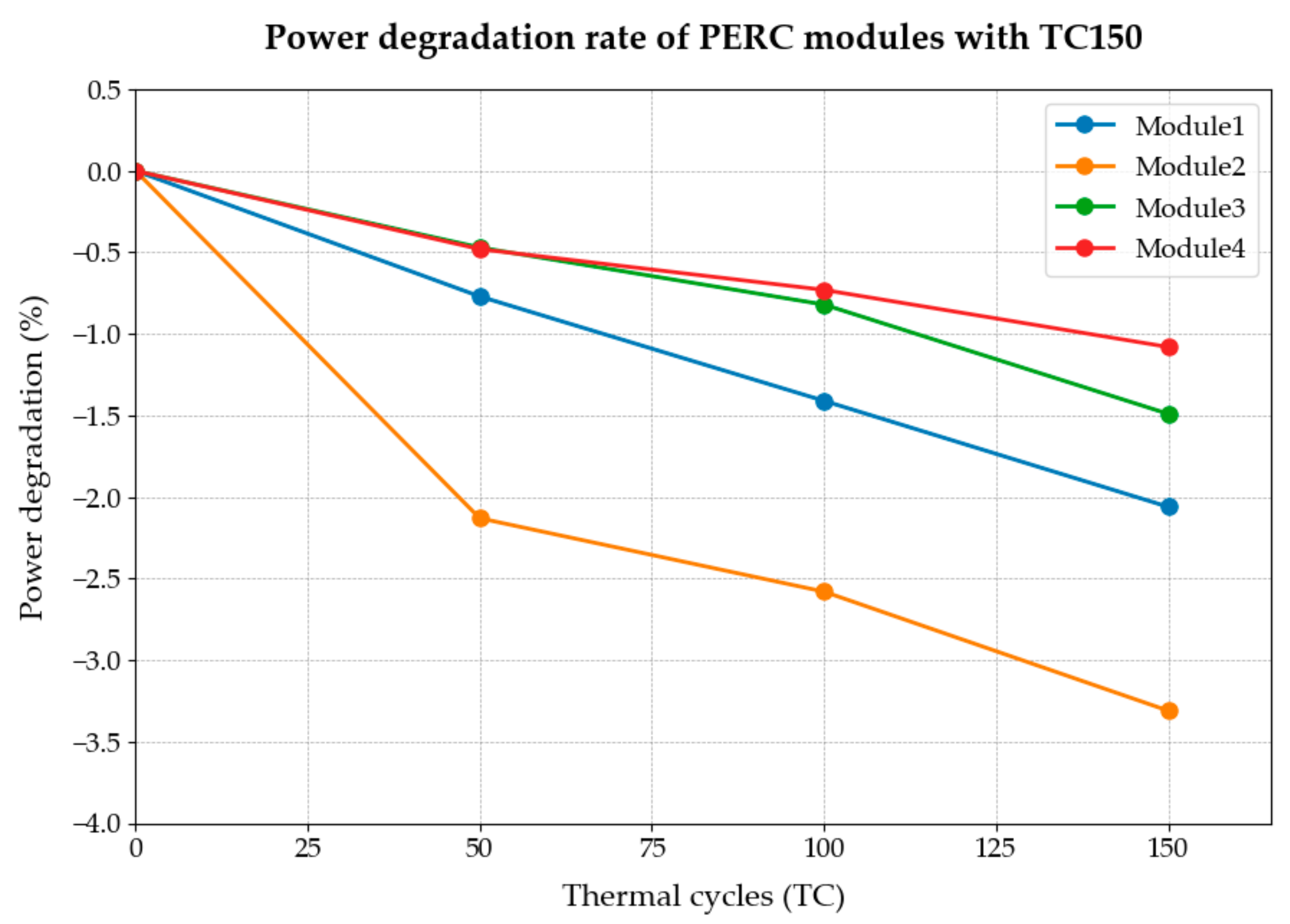

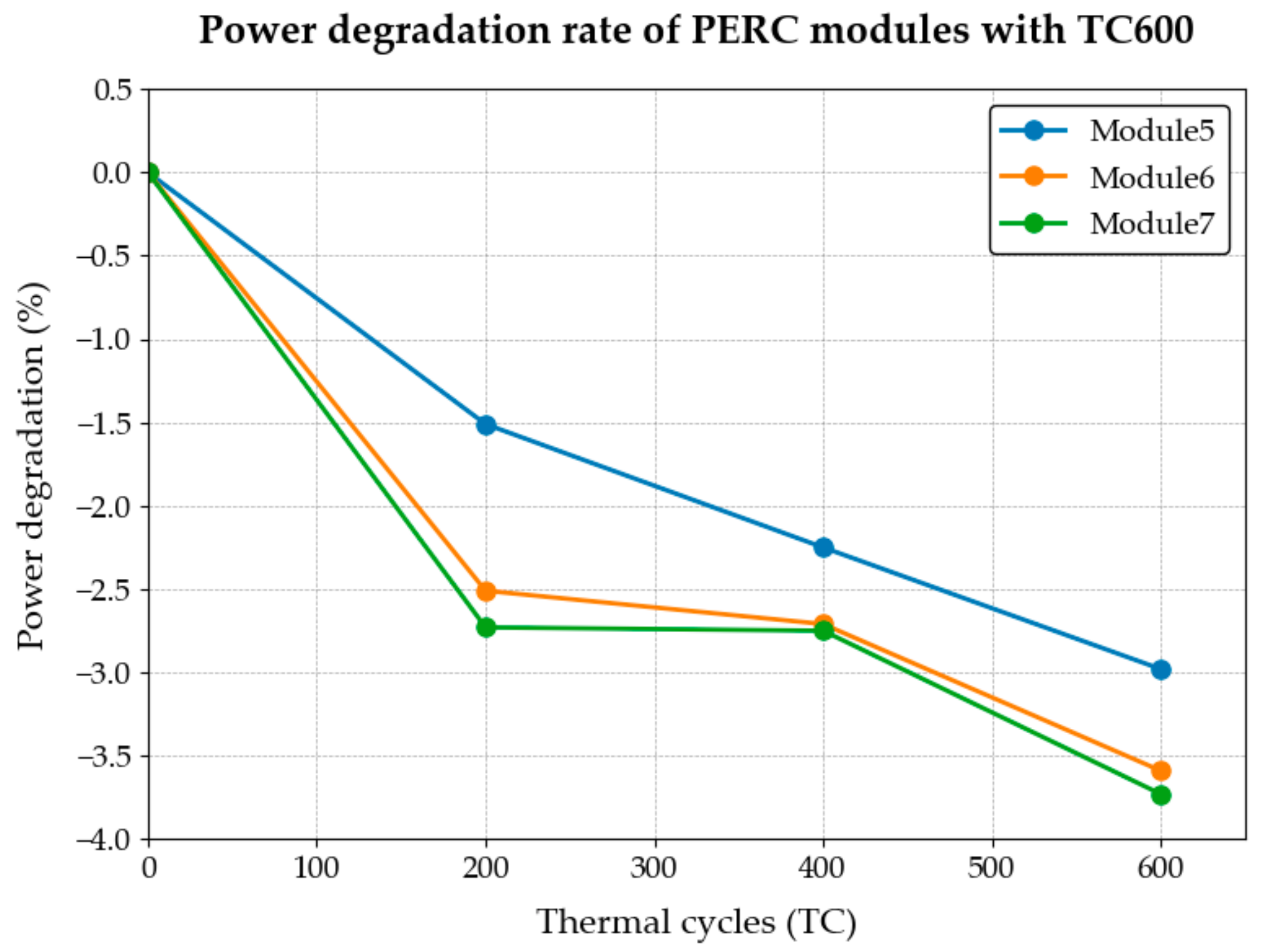

3.1. Multiple Thermal Cycle (TC) Tests

3.1.1. Sample Preparation

3.1.2. Test Content

3.1.3. Experimental Results and Discussion

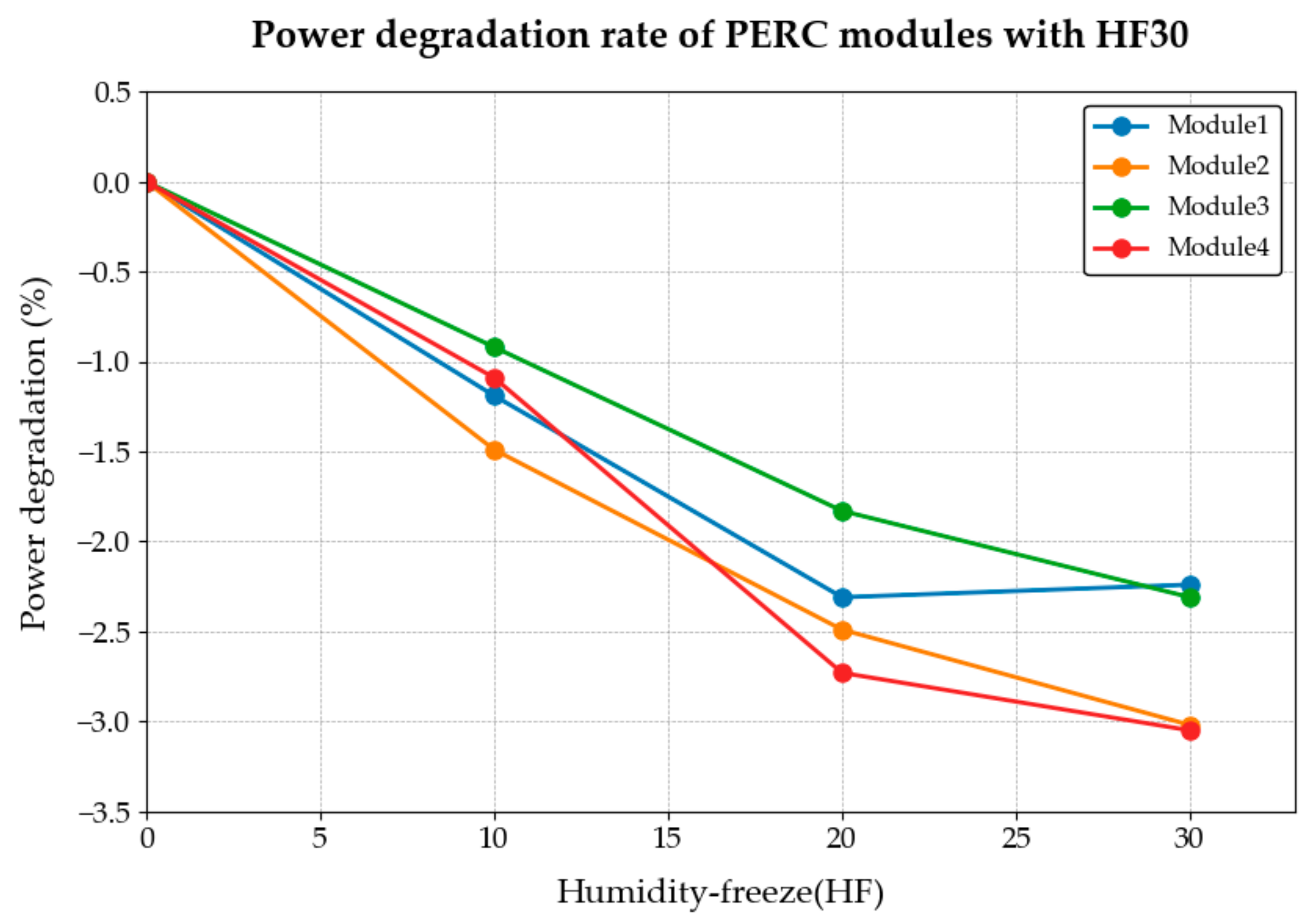

3.2. Multiple Humidity–Freeze (HF) Aging Tests

3.2.1. Sample Preparation

3.2.2. Test Content

3.2.3. Experimental Results and Discussion

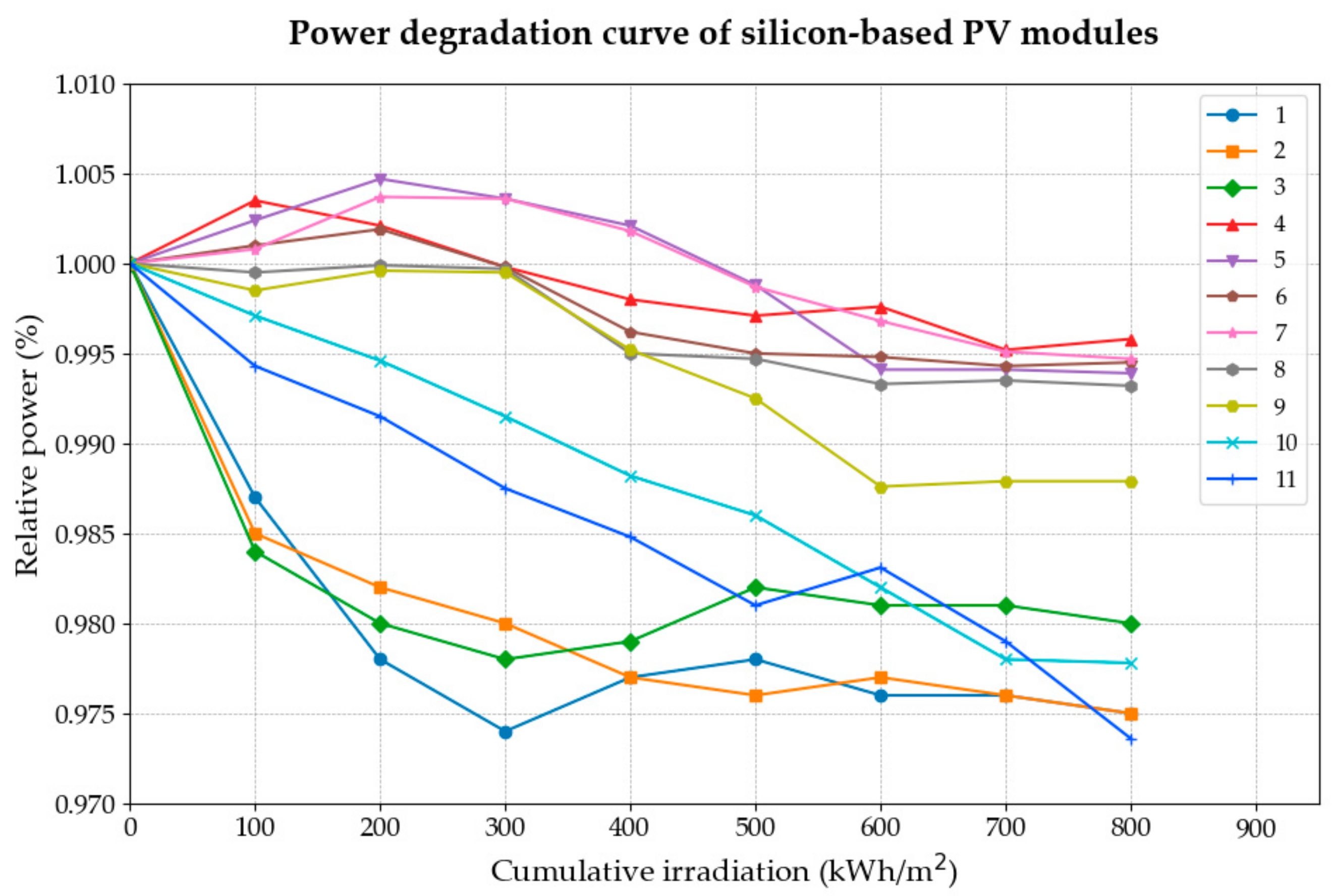

4. Test Results and Discussion

4.1. Experimental Conditions

4.2. Sample Preparation

4.3. Experimental Results and Discussion

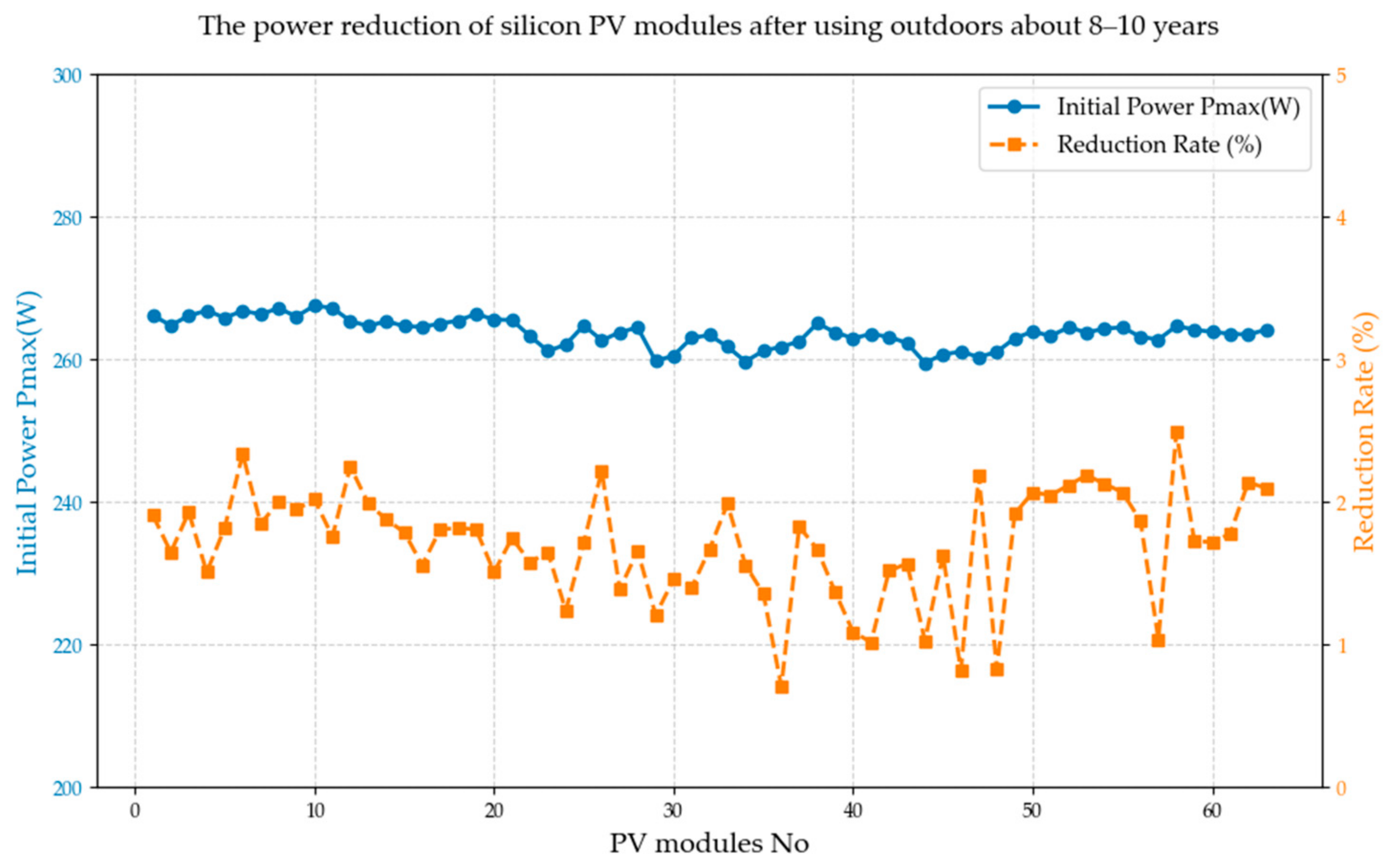

5. The Power Reduction of Crystalline Silicon Photovoltaic Modules Under Outdoor Application Conditions

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Herrmann, W.; Bogdanski, N. Outdoor Weathering of PV Modules—Effects of Various Climates and Comparison with Accelerated Laboratory testing. In Proceedings of the 2011 37th IEEE Photovoltaic Specialists Conference, Seattle, WA, USA, 19–24 June 2011. [Google Scholar]

- Peike, C.; Hoffmann, S.; Dürr, I.; Weiß, K.A.; Bogdanski, N.; Köhl, M. PV module degradation in the field and in the lab—How does it fit together? In In Proceedings of the 29th European PV Solar Energy Conference and Exhibition, Amsterdam, The Netherlands, 22–26 September 2014. [Google Scholar]

- Characterization of Polymer Aging: A Review. Polym. Sci. 2024, 42, 1642–1660. [CrossRef]

- An, Z.; Xu, Z.; Ye, Y.; Yang, R. A Rapid and Highly Sensitive Evaluation of Polymer Composite Aging with Linear Correlation to Real-Time Aging. Anal. Chim. Acta 2021, 1169, 338632. [Google Scholar] [CrossRef] [PubMed]

- Mohammadi, H.; Morovati, V.; Poshtan, E.; Dargazany, R. Understanding decay functions and their contribution in modeling of thermal-induced aging of cross-linked polymers. Polym. Degrad. Stab. 2020, 175, 109108. [Google Scholar] [CrossRef]

- Cheng, S.J. The Study on Aging and Stability of Polymer Materials. Synth. Mater. Aging Appl. 2006, 35, 27–30. [Google Scholar]

- Krauklis, A.E.; Karl, C.W.; Rocha, I.B.; Burlakovs, J.; Ozola-Davidane, R.; Gagani, A.I.; Starkova, O. Modelling of Environmental Ageing of Polymers and Polymer Composites—Modular and Multiscale Methods. Polymers 2022, 14, 216. [Google Scholar] [CrossRef] [PubMed]

- Maraveas, C.; Kyrtopoulos, I.V.; Arvanitis, K.G.; Bartzanas, T. The Aging of Polymers under Electromagnetic Radiation. Polymers 2024, 16, 689. [Google Scholar] [CrossRef] [PubMed]

- Frigione, M.; Rodríguez-Prieto, A. Can Accelerated Aging Procedures Predict the Long Term Behavior of Polymers Exposed to Different Environments? Polymers 2021, 13, 2688. [Google Scholar] [CrossRef] [PubMed]

- Čubrić, I.S.; Čubrić, G.; Križmančić, I.K.; Kovačević, M. Evaluation of changes in polymer material properties due to aging in different environments. Polymers 2022, 14, 1682. [Google Scholar] [CrossRef]

- Gan, F.; Lin, A. A Suggestion about the Research for the Fast Aging of Polymer Materials in the Natural Environment of Western China. Fundam. Res. 2005, 6, 331–333. [Google Scholar]

- IEC 61215-2:2005; Crystalline Silicon Terrestrial Photovoltaic (PV) Modules—Design Qualification and Type Approval. IEC (International Electrotechnical Commission): Geneva, Switzerland, 2005.

- IEC 61730-2; Photovoltaic(PV) Module Safety Qualification—Part 2. Requirements for Testing. IEC (International Electrotechnical Commission): Geneva, Switzerland, 2023.

- Xinhua News Agency. Opinions on Fully and Accurately Implementing the New Development Concept to Achieve Carbon Peak and Carbon Neutrality. Available online: https://www.gov.cn/xinwen/2021-10/25/content_5644687.htm (accessed on 20 March 2024).

- Tanesab, J.; Parlevliet, D.; Whale, J.; Urmee, T.; Pryor, T. The contribution of dust to performance degradation of PV modules in a temperate climate zone. Solar Energy 2015, 120, 147–157. [Google Scholar]

- Haillant, O. Accelerated weathering testing principles to estimate the service life of organic PV modules. Sol. Energy Mater. Sol. Cells 2011, 95, 1284–1292. [Google Scholar]

- Al-Falahat, A.M.; Abu Qadourah, J.; Alrwashdeh, S.S.; Khater, R.; Qatlama, Z.; Alddibs, E.; Noor, M. Energy performance and economics assessments of a photovoltaic-heat pump system. Results Eng. 2022, 13, 100324. [Google Scholar] [CrossRef]

- Susan, S.; Wardhani, D. Building integrated photovoltaic as GREENSHIP’S on site renewable energy tool. Results Eng. 2020, 7, 100153. [Google Scholar] [CrossRef]

- International Energy Agency (IEA). Key World Energy Statistics 2014. Available online: https://www.oecd.org/en/publications/key-world-energy-statistics-2014_key_energ_stat-2014-en.html (accessed on 27 March 2024).

- Ye, T.; Liu, C.; Xu, J.; Yuan, X.; Zhou, G.; Hu, J. A Review of Accelerated Aging Testing Methods for Photovoltaic Modules Using Comprehensive Sequence. Sol. Energy 2022, 11, 34–43. [Google Scholar]

- Tung, C.M.; Li, Y.T.; Yang, W.L.; Wu, H.S.; Yu, P. Investigation of degradation of single-cell PV module by pressure cooker test and damp heat test. In Proceedings of the 2016 IEEE 43rd Photovoltaic Specialists Conference (PVSC), Portland, OR, USA, 5–10 June 2016; IEEE: New York, NY, USA, 2016. [Google Scholar]

- Li, Y.T.; Lin, W.Y.; Yang, W.L.; Hsieh, C.F. Sequential acceleration tests with pressure cooker test (PCT) and UV for backsheets of PV modules. Energy Procedia 2018, 150, 44–49. [Google Scholar] [CrossRef]

- Nam, W.; Choi, J.; Kim, G.; Hyun, J.; Ahn, H.; Park, N. Predicting Photovoltaic Module Lifespan Based on Combined Stress Tests and Latent Heat Analysis. Energies 2025, 18, 304. [Google Scholar] [CrossRef]

- Osterwald, C.R.; McMahon, T.J. History of accelerated and qualification testing of terrestrial photovoltaic modules: A literature review. Prog. Photovolt. Res. Appl. 2008, 17, 11–33. [Google Scholar] [CrossRef]

- Ishii, T.; Masuda, A. Annual degradation rates of recent crystalline silicon photovoltaic modules. Prog. Photovolt. Res. Appl. 2017, 25, 953–967. [Google Scholar] [CrossRef]

- Ransom, S. Understanding kWh/kWp by comparing measured data with modeling predictions and performance claims. In Proceedings of the 34th IEEE Photovoltaic Specialists Conference, Philadelphia, PA, USA, 7–12 June 2009; pp. 465–470. [Google Scholar]

- Thomas, R.E.; Carmichael, D.C. Terrestrial Service Environments for Selected Geographic Locations; Battelle Columbus Labs.: Columbus, OH, USA, 1976. [Google Scholar]

- Koehl, M. Development and application of a UV light source for PV module testing. Proc. SPIE 2009, 741202, 11–17. [Google Scholar] [CrossRef]

- Subramaniyan, A.B.; Pan, R.; Kuitche, J.; TamizhMani, G. Prediction of Acceleration Factor for Accelerated Testing of Photovoltaic Modules Installed Around the World. In Proceedings of the 2018 Annual Reliability and Maintainability Symposium (RAMS), Reno, NV, USA, 22–25 January 2018. [Google Scholar] [CrossRef]

- Luceño-Sánchez, J.A.; Díez-Pascual, A.M.; Capilla, R.P. Materials for Photovoltaics: State of Art and Recent Developments. Int. J. Mol. Sci. 2019, 20, 976. [Google Scholar] [CrossRef] [PubMed]

| Materials | Activation Energy (Ea) |

|---|---|

| Oxide film | 0.3 eV |

| Ionicity (Na ion drift in SiO2) | 1.0~1.4 eV |

| Ionicity (slow collapse of Si-SiO2 interface) | 1.0 eV |

| Electron migration disconnection | 0.6 eV |

| Aluminum corrosion | 0.6~0.9 eV |

| Intermetallic compound growth | 0.5~0.7 eV |

| No. | Power Degradation (%) | ||

|---|---|---|---|

| TC50 | TC100 | TC150 | |

| Module 1 | 0.77 | 1.41 | 2.06 |

| Module 2 | 2.13 | 2.58 | 3.31 |

| Module 3 | 0.47 | 0.82 | 1.49 |

| Module 4 | 0.48 | 0.73 | 1.08 |

| No. | Power Degradation (%) | ||

|---|---|---|---|

| TC200 | TC400 | TC600 | |

| Module 5 | 1.51 | 2.25 | 2.98 |

| Module 6 | 2.51 | 2.71 | 3.59 |

| Module 7 | 2.73 | 2.75 | 3.73 |

| No. | Modules Power Degradation Rate (%) | ||

|---|---|---|---|

| HF10 | HF20 | HF30 | |

| Module 1 | 1.19 | 2.31 | 2.24 |

| Module 2 | 1.49 | 2.49 | 3.02 |

| Module 3 | 0.92 | 1.83 | 2.31 |

| Module 4 | 1.09 | 2.73 | 3.05 |

| No. | Specification | Battery Size | Type | Quantity (Pcs) | Power (W) |

|---|---|---|---|---|---|

| 1 | 6 cell × 10 cell | 156 mm × 156 mm | Polycrystalline | 6 | 260 |

| 2 | 6 cell × 6 cell | 156 mm × 156 mm | Polycrystalline | 6 | 150 |

| 3 | 3 cell × 3 cell | 156 mm × 156 mm | Polycrystalline | 20 | 38 |

| 4 | 3 cell × 3 cell | 156 mm × 156 mm | Monocrystalline | 20 | 40 |

| 5 | 3 cell × 3 cell | 156 mm × 156 mm | PERC Monocrystalline | 20 | 50 |

| 6 | 3 cell × 3 cell | 156 mm × 156 mm | N-type Monocrystalline | 20 | 50 |

| 7 | 3 cell × 3 cell | 156 mm × 156 mm | Monocrystalline | 20 | 45 |

| 8 | 3 cell × 3 cell | 156 mm × 156 mm | Monocrystalline | 20 | 40 |

| 9 | 3 cell × 3 cell | 156 mm × 156 mm | Monocrystalline | 20 | 40 |

| 10 | 3 cell × 3 cell | 156 mm × 156 mm | Monocrystalline | 20 | 40 |

| 11 | 3 cell × 3 cell | 156 mm × 156 mm | Monocrystalline | 20 | 40 |

| Total | 192 |

| No. | Cumulative Radiation Exposure (kWh/m2) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 0 | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 | ||

| 1 | Polycrystalline | l | 0.987 | 0.978 | 0.974 | 0.977 | 0.978 | 0.976 | 0.976 | 0.975 |

| 2 | 1 | 0.985 | 0.982 | 0.98 | 0.977 | 0.976 | 0.977 | 0.976 | 0.975 | |

| 3 | 1 | 0.984 | 0.98 | 0.978 | 0.979 | 0.982 | 0.981 | 0.981 | 0.980 | |

| 4 | Monocrystalline | 1 | 1.0035 | 1.0021 | 0.9998 | 0.9980 | 0.9971 | 0.9976 | 0.9952 | 0.9958 |

| 5 | 1 | 1.0024 | 1.0047 | 1.0036 | 1.0021 | 0.9988 | 0.9941 | 0.9941 | 0.9939 | |

| 6 | 1 | 1.0010 | 1.0019 | 0.9998 | 0.9962 | 0.9950 | 0.9948 | 0.9943 | 0.9945 | |

| 7 | 1 | 1.0008 | 1.0037 | 1.0036 | 1.0018 | 0.9987 | 0.9968 | 0.9951 | 0.9947 | |

| 8 | 1 | 0.9995 | 0.9999 | 0.9997 | 0.9950 | 0.9947 | 0.9933 | 0.9935 | 0.9932 | |

| 9 | 1 | 0.9985 | 0.9996 | 0.9995 | 0.9952 | 0.9925 | 0.9876 | 0.9879 | 0.9879 | |

| 10 | 1 | 0.9971 | 0.9946 | 0.9915 | 0.9882 | 0.9860 | 0.9820 | 0.9780 | 0.9778 | |

| 11 | 1 | 0.9943 | 0.9915 | 0.9875 | 0.9848 | 0.9810 | 0.9831 | 0.9790 | 0.9736 | |

| No. | Initial Power Pmax (W) | 8 Years Using Pmax (W) | Reduction Value (W) | Reduction Rate |

|---|---|---|---|---|

| 1 | 266.19 | 261.11 | 5.08 | 1.91% |

| 2 | 264.82 | 260.45 | 4.37 | 1.65% |

| 3 | 266.16 | 261.02 | 5.14 | 1.93% |

| 4 | 266.89 | 262.86 | 4.03 | 1.51% |

| 5 | 265.89 | 261.04 | 4.85 | 1.82% |

| 6 | 266.84 | 260.59 | 6.25 | 2.34% |

| 7 | 266.39 | 261.47 | 4.92 | 1.85% |

| 8 | 267.2 | 261.86 | 5.34 | 2.00% |

| 9 | 266.07 | 260.88 | 5.19 | 1.95% |

| 10 | 267.58 | 262.18 | 5.4 | 2.02% |

| 11 | 267.25 | 262.54 | 4.71 | 1.76% |

| 12 | 265.43 | 259.47 | 5.96 | 2.25% |

| 13 | 264.7 | 259.44 | 5.26 | 1.99% |

| 14 | 265.42 | 260.44 | 4.98 | 1.88% |

| 15 | 264.69 | 259.96 | 4.73 | 1.79% |

| 16 | 264.6 | 260.47 | 4.13 | 1.56% |

| 17 | 265.05 | 260.25 | 4.8 | 1.81% |

| 18 | 265.49 | 260.67 | 4.82 | 1.82% |

| 19 | 266.4 | 261.57 | 4.83 | 1.81% |

| 20 | 265.65 | 261.64 | 4.01 | 1.51% |

| 21 | 265.55 | 260.89 | 4.66 | 1.75% |

| 22 | 263.32 | 259.17 | 4.15 | 1.58% |

| 23 | 261.21 | 256.91 | 4.3 | 1.65% |

| 24 | 262.13 | 258.87 | 3.26 | 1.24% |

| 25 | 264.81 | 260.26 | 4.55 | 1.72% |

| 26 | 262.71 | 256.89 | 5.82 | 2.22% |

| 27 | 263.85 | 260.17 | 3.68 | 1.39% |

| 28 | 264.5 | 260.11 | 4.39 | 1.66% |

| 29 | 259.81 | 256.66 | 3.15 | 1.21% |

| 30 | 260.58 | 256.77 | 3.81 | 1.46% |

| 31 | 263.05 | 259.37 | 3.68 | 1.40% |

| 32 | 263.46 | 259.07 | 4.39 | 1.67% |

| 33 | 261.83 | 256.63 | 5.2 | 1.99% |

| 34 | 259.75 | 255.71 | 4.04 | 1.56% |

| 35 | 261.24 | 257.69 | 3.55 | 1.36% |

| 36 | 261.81 | 259.94 | 1.87 | 0.71% |

| 37 | 262.57 | 257.76 | 4.81 | 1.83% |

| 38 | 265.1 | 260.68 | 4.42 | 1.67% |

| 39 | 263.84 | 260.23 | 3.61 | 1.37% |

| 40 | 263 | 260.14 | 2.86 | 1.09% |

| 41 | 263.61 | 260.93 | 2.68 | 1.02% |

| 42 | 263.19 | 259.2 | 3.99 | 1.52% |

| 43 | 262.34 | 258.21 | 4.13 | 1.57% |

| 44 | 259.55 | 256.88 | 2.67 | 1.03% |

| 45 | 260.74 | 256.5 | 4.24 | 1.63% |

| 46 | 261.12 | 258.97 | 2.15 | 0.82% |

| 47 | 260.37 | 254.66 | 5.71 | 2.19% |

| 48 | 261.1 | 258.92 | 2.18 | 0.83% |

| 49 | 263.01 | 257.96 | 5.05 | 1.92% |

| 50 | 263.95 | 258.49 | 5.46 | 2.07% |

| 51 | 263.34 | 257.95 | 5.39 | 2.05% |

| 52 | 264.54 | 258.94 | 5.6 | 2.12% |

| 53 | 263.81 | 258.04 | 5.77 | 2.19% |

| 54 | 264.37 | 258.75 | 5.62 | 2.13% |

| 55 | 264.53 | 259.06 | 5.47 | 2.07% |

| 56 | 263.2 | 258.29 | 4.91 | 1.87% |

| 57 | 262.83 | 260.1 | 2.73 | 1.04% |

| 58 | 264.72 | 258.13 | 6.59 | 2.49% |

| 59 | 264.23 | 259.66 | 4.57 | 1.73% |

| 60 | 263.88 | 259.35 | 4.53 | 1.72% |

| 61 | 263.65 | 258.96 | 4.69 | 1.78% |

| 62 | 263.51 | 257.86 | 5.65 | 2.14% |

| 63 | 264.22 | 258.68 | 5.54 | 2.10% |

| average value | 263.851 | 259.338 | 4.51 | 1.71% |

| Item | Cumulative Radiation Exposure (kW·h/m2) | ||||||||

|---|---|---|---|---|---|---|---|---|---|

| lab | Cumulative radiation exposure | 100 | 200 | 300 | 400 | 500 | 600 | 700 | 800 |

| Temperature | 70 °C | 70 °C | 70 °C | 70 °C | 70 °C | 70 °C | 70 °C | 70 °C | |

| Humidity | 60% | 60% | 60% | 60% | q60% | 60% | 60% | 60% | |

| Accelerating factor | 143.35 | ||||||||

| Correction factor | 0.3–0.5 | ||||||||

| Correction accelerating factor | 43–71.68 | ||||||||

| Corresponding cumulative time (year) | 3.27 | 6.54 | 9.82 | 13.08 | 16.35 | 19.62 | 22.89 | 26.16 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, R.; Li, X.; Liu, Y.; Zhang, Z.; Wu, M. Accelerated Aging Method of Performance Attenuation of Crystalline Silicon Photovoltaic Modules Under Full-Spectrum Conditions. Materials 2025, 18, 1507. https://doi.org/10.3390/ma18071507

Liu R, Li X, Liu Y, Zhang Z, Wu M. Accelerated Aging Method of Performance Attenuation of Crystalline Silicon Photovoltaic Modules Under Full-Spectrum Conditions. Materials. 2025; 18(7):1507. https://doi.org/10.3390/ma18071507

Chicago/Turabian StyleLiu, Rui, Xin Li, Ying Liu, Zhuoyuan Zhang, and Mingli Wu. 2025. "Accelerated Aging Method of Performance Attenuation of Crystalline Silicon Photovoltaic Modules Under Full-Spectrum Conditions" Materials 18, no. 7: 1507. https://doi.org/10.3390/ma18071507

APA StyleLiu, R., Li, X., Liu, Y., Zhang, Z., & Wu, M. (2025). Accelerated Aging Method of Performance Attenuation of Crystalline Silicon Photovoltaic Modules Under Full-Spectrum Conditions. Materials, 18(7), 1507. https://doi.org/10.3390/ma18071507