Utilization of a PFA-GGBS-Based Precursor in Geopolymer Concrete Production as a Sustainable Substitute for Conventional Concrete

Abstract

1. Introduction

2. Materials

3. Methodology

3.1. Mix Design

3.2. Preparation of Alkaline Activator

3.3. Preparation of Traditional and Geopolymer Concrete Specimens

3.4. Casting and Curing Procedures

3.5. Geopolymer Concrete Specimen Testing Method

4. Results and Discussion

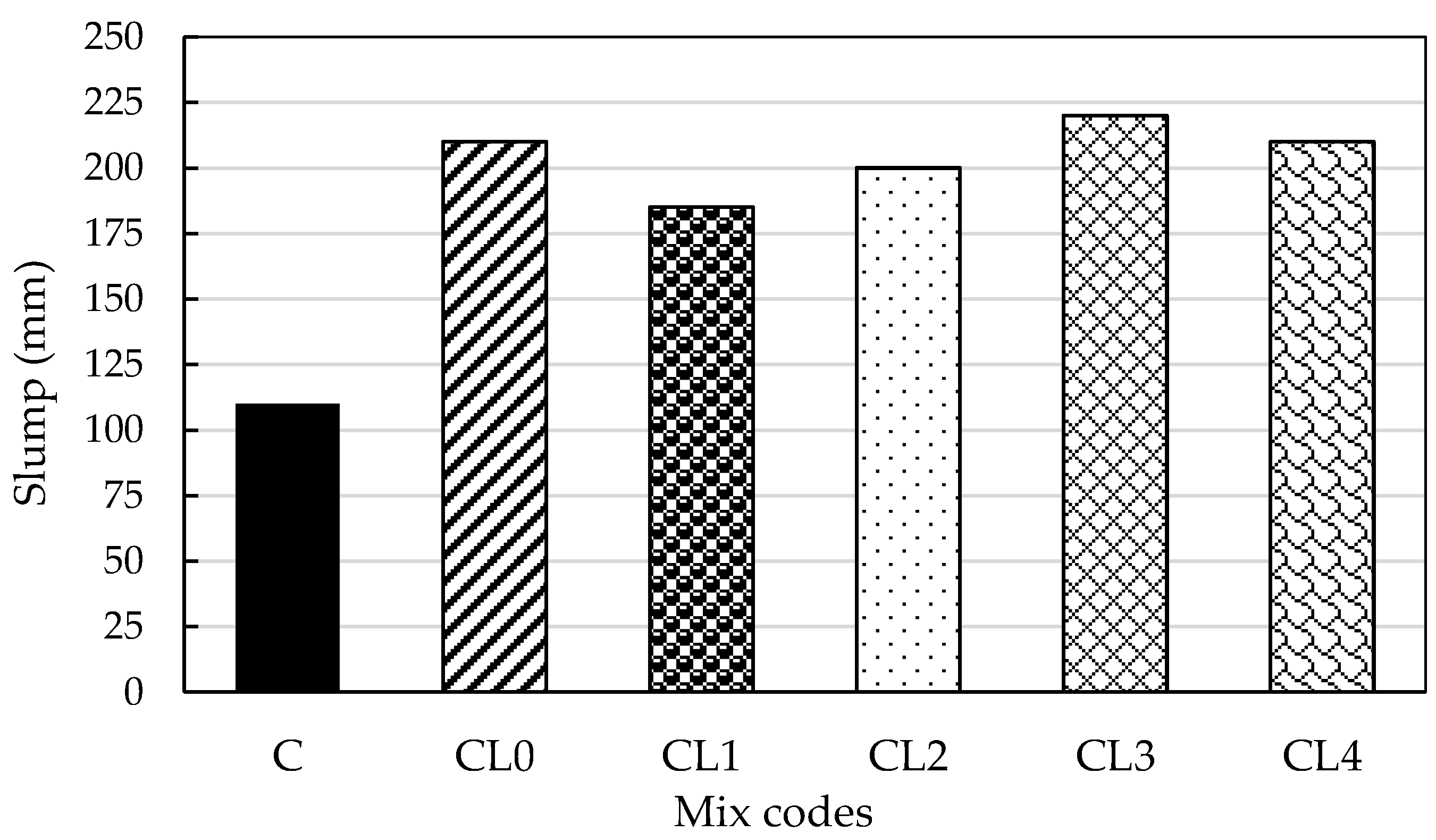

4.1. Slump Test

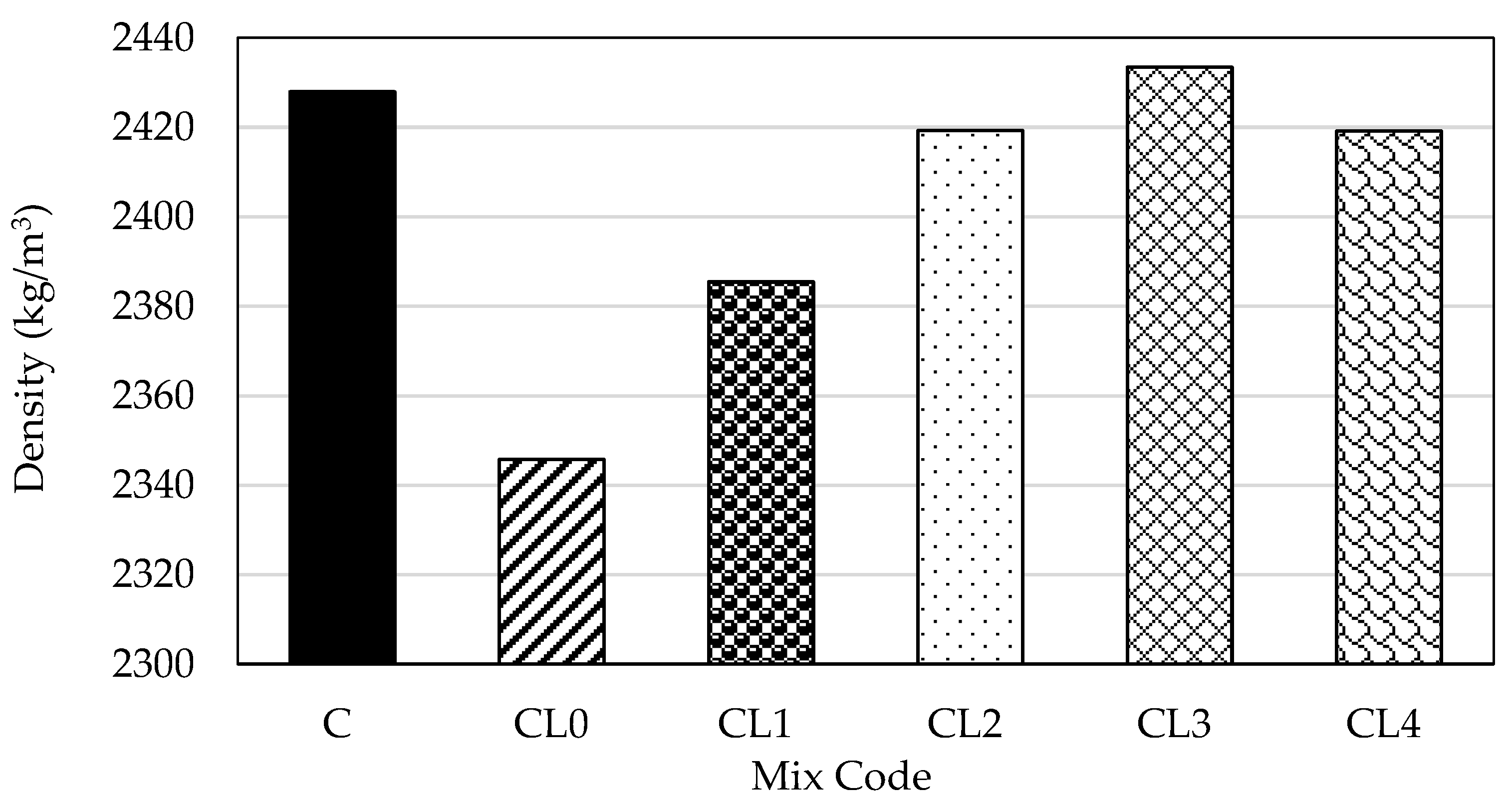

4.2. Density of Geopolymer Concrete

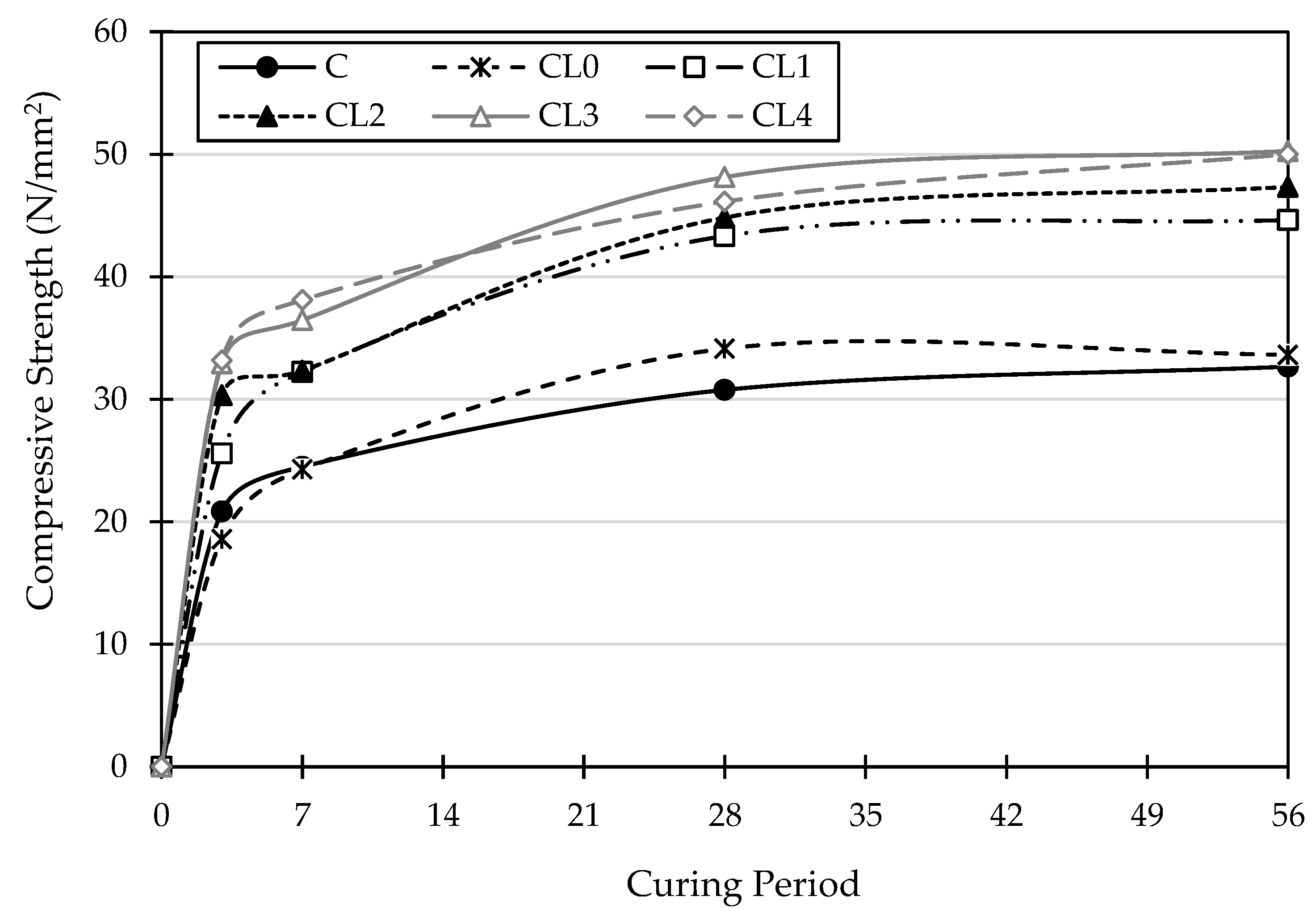

4.3. Compressive Strength of Hardened Geopolymer Concrete

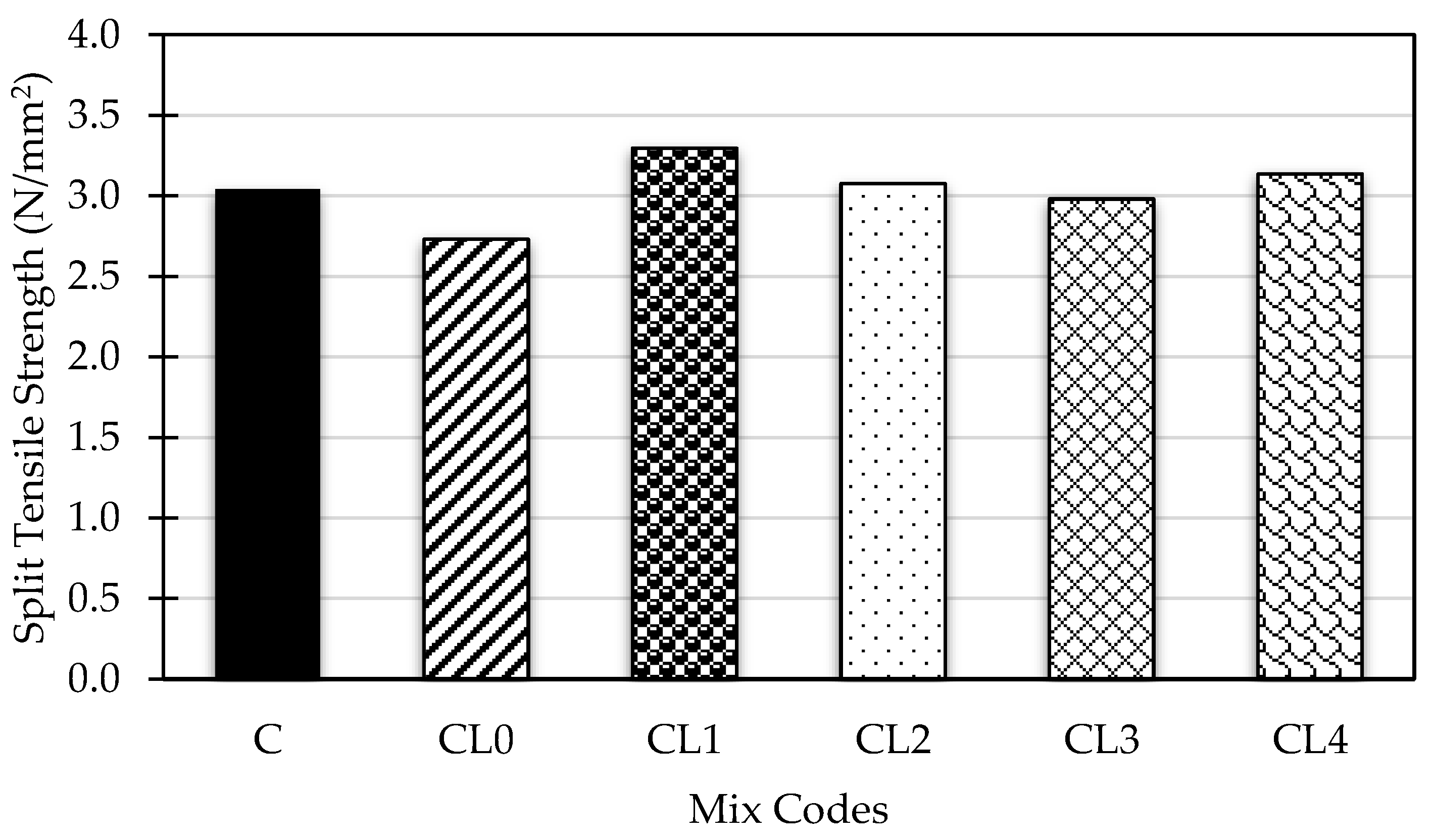

4.4. Split Tensile Strength

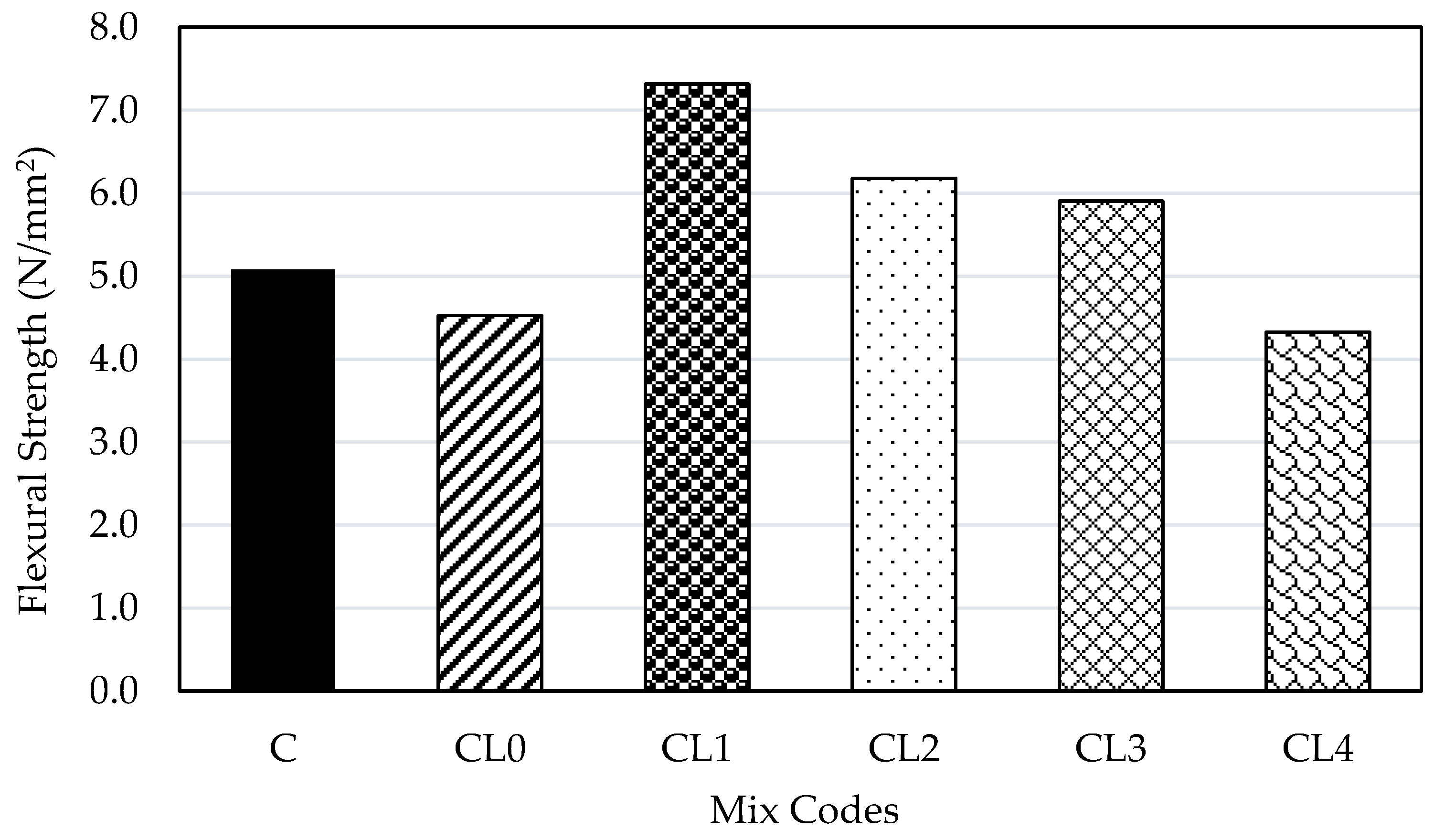

4.5. Flexural Strength

5. Conclusions

- The geopolymer concrete cured under ambient conditions achieved a mean compressive strength ranging from 27 N/mm2 to 42 N/mm2, with strength increasing as the GGBS content increased from CL0 to CL4. This shows the positive impact of a large GGBS content in the PFA-GGBS mix regime.

- All geopolymer mixes generally showed higher compressive strengths than the control mix. However, the split tensile strength did not increase proportionally, which may need consideration for tensile-critical applications.

- The geopolymer concrete with an A/P ratio of 0.4 and a W/B ratio of 0.55 showed excellent workability, strength, and density, making it suitable for practical use.

- Despite the positive outcomes of developing the PFA-GGB precursor-based geopolymer formulations, careful consideration and strategies such as proper material storage (activators and precursor) under appropriate conditions, machine mixing only, and ready-mix concrete should be adopted. This replicates the laboratory mixing programme, and batch mixing operators must have adequate knowledge of geopolymer concrete for it to be considered and adopted for large-scale production on a construction site.

- Generally, the drive to move to geopolymer concrete is expected to reduce the need for Portland cement, which will positively impact the drive for sustainability in the construction industry.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- MPA the Concrete Centre. Whole-Life Carbon and Buildings; Mineral Product Association: London, UK, 2016. [Google Scholar]

- Sentucq, E.; Clayton, M. Beyond Portland Cement: Low-Carbon Alternatives. Available online: https://www.istructe.org/resources/guidance/beyond-portland-cement-low-carbon-alternatives/ (accessed on 15 December 2024).

- Younes, A.; Elbeltagi, E.; Diab, A.; Tarsi, G.; Saeed, F.; Sangiorgi, C. Incorporating coarse and fine recycled aggregates into concrete mixes: Mechanical characterization and environmental impact. J. Mater. Cycles Waste Manag. 2023, 26, 654–668. [Google Scholar] [CrossRef]

- Tam, V.W.Y.; Soomro, M.; Evangelista, A.C.J. A review of recycled aggregate in concrete applications (2000–2017). Constr. Build. Mater. 2018, 172, 272–292. [Google Scholar] [CrossRef]

- Baltazar, L.G. Performance of Silica Fume-Based Geopolymer Grouts for Heritage Masonry Consolidation. Crystals 2022, 12, 288. [Google Scholar] [CrossRef]

- Simão, L.; Fernandes, E.; Hotza, D.; Ribeiro, M.J.; Montedo, O.R.K.; Raupp-Pereira, F. Controlling efflorescence in geopolymers: A new approach. Case Stud. Constr. Mater. 2021, 15, e00740. [Google Scholar] [CrossRef]

- Davidovits, J. (Ed.) Geopolymer Chemistry and Applications, 3rd ed.; Geopolymer Institute: Saint-Quentin, France, 2014. [Google Scholar]

- Altameemi, S.; Adeleke, B.O.; Kinuthia, J.M.; Oti, J. Understanding the Effect of Waiting for the Dissolution of Sodium Hydroxide in Geopolymer Concrete Mixes. Materials 2025, 18, 849. [Google Scholar] [CrossRef]

- Farhan, K.Z.; Johari, M.A.M.; Demirboğa, R. Assessment of important parameters involved in the synthesis of geopolymer composites: A review. Constr. Build. Mater. 2020, 264, 120276. [Google Scholar] [CrossRef]

- Kong, D.L.Y.; Sanjayan, J.G. Damage behavior of geopolymer composites exposed to elevated temperatures. Cem. Concr. Compos. 2008, 30, 986–991. [Google Scholar] [CrossRef]

- Davidovits, J. Properties of Geopolymer cements. In First International Conference on Alkaline Cements and Concretes; Scientific Research Institute on Binders and Materials: Kiev, Ukraine, 1994; pp. 131–149. [Google Scholar]

- Palomo, A.; Grutzeck, M.W.; Blanco, M.T. Alkali-activated fly ashes: A cement for the future. Cem. Concr. Res. 1999, 29, 1323–1329. [Google Scholar] [CrossRef]

- Lee, W.K.W.; van Deventer, J.S.J. The interface between natural siliceous aggregates and geopolymers. Cem. Concr. Res. 2004, 34, 195–206. [Google Scholar] [CrossRef]

- Herbert, G.; d’Espinose de La Caillerie, J.-B.; Roussel, D.N. Life cycle assessment (LCA) of alkali-activated cements and concretes. Cem. Concr. Res. 2011, 41, 442–450. [Google Scholar]

- Davidovits, J. Geopolymer Chemistry and Applications, 4th ed.; Institut Géopolymère: Saint-Quentin, France, 2013. [Google Scholar]

- Reddy, M.S.; Dinakar, P.; Rao, B.H. Mix design development of fly ash and ground granulated blast furnace slag based geopolymer concrete. J. Build. Eng. 2018, 20, 712–722. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Zhang, H.; Parkinson, S. Optimum mix design of geopolymer pastes and concretes cured in ambient condition based on compressive strength, setting time and workability. J. Build. Eng. 2019, 23, 301–313. [Google Scholar] [CrossRef]

- Rafeet, A.; Vinai, R.; Soutsos, M.; Sha, W. Guidelines for mix proportioning of fly ash/GGBS based alkali activated concretes. Constr. Build. Mater. 2017, 147, 130–142. [Google Scholar] [CrossRef]

- Li, N.; Shi, C.; Zhang, Z.; Zhu, D.; Hwang, H.-J.; Zhu, Y.; Sun, T. A mixture proportioning method for the development of performance-based alkali-activated slag-based concrete. Cem. Concr. Compos. 2018, 93, 163–174. [Google Scholar] [CrossRef]

- BS EN 197-1:2011; Cement. Part 1: Composition, Specifications and Conformity Criteria for Common Cements. European Committee For Standardisation: London, UK, 2011.

- Oti, J.; Adeleke, B.O.; Mudiyanselage, P.R.; Kinuthia, J. A Comprehensive Performance Evaluation of GGBS-Based Geopolymer Concrete Activated by a Rice Husk Ash-Synthesised Sodium Silicate Solution and Sodium Hydroxide. Recycling 2024, 9, 23. [Google Scholar] [CrossRef]

- Nath, P.; Sarker, P.K. Effect of GGBFS on setting, workability and early strength properties of fly ash geopolymer concrete cured in ambient condition. Constr. Build. Mater. 2014, 66, 163–171. [Google Scholar] [CrossRef]

- Hadi, M.N.S.; Farhan, N.A.; Sheikh, M.N. Design of geopolymer concrete with GGBFS at ambient curing condition using Taguchi method. Constr. Build. Mater. 2017, 140, 424–431. [Google Scholar] [CrossRef]

- Billong, N.; Oti, J.; Kinuthia, J. Using silica fume based activator in sustainable geopolymer binder for building application. Constr. Build. Mater. 2021, 275, 122177. [Google Scholar] [CrossRef]

- BS EN 12620:2002+A1:2008; Aggregates for Concrete. ASRO: Bucharest, Romania, 2008.

- Adeleke, B.O.; Kinuthia, J.M.; Oti, J.; Ebailila, M. Physico-Mechanical Evaluation of Geopolymer Concrete Activated by Sodium Hydroxide and Silica Fume-Synthesised Sodium Silicate Solution. Materials 2023, 16, 2400. [Google Scholar] [CrossRef]

- Xu, H.; Van Deventer, J.S.J. The geopolymerisation of alumino-silicate minerals. Int. J. Miner. Process. 2000, 59, 247–266. [Google Scholar] [CrossRef]

- Mallikarjuna Rao, G.; Gunneswara Rao, T.D. A quantitative method of approach in designing the mix proportions of fly ash and GGBS-based geopolymer concrete. Aust. J. Civ. Eng. 2018, 16, 53–63. [Google Scholar] [CrossRef]

- BS EN 12390-1:2021; Testing Hardened Concrete. Part 1: Shape, Dimensions and Other Requirements for Specimens and Moulds. British Standards Institute: Loughborough, UK, 2021.

- BS EN 12390-2:2019; Testing Hardened Concrete. Part 2: Making and Curing Specimens for Strength Tests. iTeh, Inc.: Newark, NJ, USA, 2019.

- BS EN 206:2013+A2:2021; Concrete. Specification, Performance, Production and Conformity. BSI: London, UK, 2021.

- BS EN 12350-2:2019; Testing Fresh Concrete. Part 1: Slump Test. BSI: London, UK, 2019.

- BS EN 12390-7:2019; Testing Hardened Concrete. Density of Hardened Concrete. BSI: London, UK, 2020.

- BS EN 12390-4:2019; Testing Hardenend Concrete. Part 4: Compressive Strength—Specification for Testing Machines. iTeh, Inc.: Newark, NJ, USA, 2019.

- BS EN 12390-6:2009; Testing Hardened Concrete. Part 6: Tensile Splitting Strength of Test Specimens. iTeh, Inc.: Newark, NJ, USA, 2009.

- BS EN 12390-5:2019; Testing Hardened Concrete. Flexural Strength of Test Specimens. BSI: London, UK, 2019.

- Rangan, B.V. Fly Ash-Based Geopolymer Concrete; Research Report GC4; Faculty of Engineering, Curtin University of Technology: Perth, Australia, 2008. [Google Scholar]

- Provis, J.L.; Bernal, S.A. Geopolymers and Related Alkali-Activated Materials. Annu. Rev. Mater. Res. 2014, 44, 299–327. [Google Scholar] [CrossRef]

- Adam, A.A. The Effects of Water to Solid Ratio, Activator to Binder Ratio, and Lime Proportion on the Compressive Strength of Ambient-Cured Geopolymer Concrete. J. Civ. Eng. Forum 2019, 5, 161–168. [Google Scholar] [CrossRef]

- Al Bakri, A.M.M.; Kamarudin, H.; Khairul Nizar, I.; Bnhussain, M.; Zarina, Y.; Rafiza, A.R. Correlation between Na2SiO3/NaOH ratio and fly ash/alkaline activator ratio to the strength of geopolymer. Mater. Manuf. Technol. II 2012, 341–342, 189–193. [Google Scholar] [CrossRef]

- Liyana, J.; Al Bakri, A.M.M.; Hussin, K.; Ruzaidi, C.M.; Azura, A.R. Effect of fly ash/alkaline activator ratio and sodium silicate/NaOH ratio on fly ash geopolymer coating strength. Key Eng. Mater. 2014, 594–595, 146–150. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Applications, 2nd ed.; Institute Geopolymer: Saint-Quentin, France, 2008. [Google Scholar]

- Smith, J.; Brown, L.; Green, A. The impact of fly ash and silica fume on the compressive strength of concrete. J. Mater. Civ. Eng. 2020, 32, 6. [Google Scholar]

- Choudhary, R.; Gupta, R.; Nagar, R. Impact on fresh, mechanical, and microstructural properties of high strength self-compacting concrete by marble cutting slurry waste, fly ash, and silica fume. Constr. Build. Mater. 2020, 239, 117888. [Google Scholar] [CrossRef]

- Prasad Lakshmi, T.; Rao, H.S.; Ghorpade, V.G. Flexural & Tensile Strength Properties of GGBS and Phosphogypsum Blended Geopolymer Concrete. Int. J. ChemTech Res. 2017, 10, 661–667. [Google Scholar]

| Constituents (wt%) | OPC | GGBS | PFA | SF |

|---|---|---|---|---|

| CaO | 61.49 | 37.99 | 2.27 | 0.2 |

| MgO | 3.54 | 8.78 | 1.05 | 0.1 |

| SiO2 | 18.84 | 35.54 | 62.2 | 97.1 |

| Al2O3 | 4.77 | 11.46 | 27.5 | 0.2 |

| Na2O | 0.02 | 0.37 | 0.52 | - |

| P2O5 | 0.1 | 0.02 | - | 0.03 |

| Fe2O3 | 2.87 | 0.42 | 0.56 | 0.01 |

| Mn2O3 | 0.05 | 0.43 | - | - |

| K2O | 0.57 | 0.43 | 0.86 | 0.2 |

| TiO2 | 0.26 | 0.7 | 1.54 | - |

| V2O5 | 0.06 | 0.04 | - | - |

| BaO | 0.05 | 0.09 | - | - |

| SO3− | 3.12 | 1.54 | 0.38 | 0.1 |

| Loss on ignition | 4.3 | 2 | 0.64 | 0.5 |

| Property | Fine Aggregates (Sand) | Coarse Aggregates | |

|---|---|---|---|

| 10 mm | 20 mm | ||

| Uniformity coefficient (CU) | 0.11 | 3.3 | 1.3 |

| Curvature coefficient (CC) | 1.75 | 1.5 | 7.5 |

| Flakiness index (%) | - | 30–35 | 23 |

| Elongation index (%) | - | 17–22 | 12 |

| Shape index (%) | - | 12 | 7 |

| Impact value | 23 | 15 | |

| Fineness modulus (mm) | 1.54 | 4 | - |

| Uncompacted bulk density (g/cm3) | 1.5 | 1.35 | 2.57 |

| Pre-dried particle density (g/cm3) | 2.6 | 2.69 | - |

| Water absorption (%) | 21 | 2 | 1.1 |

| Mix Code | Elaborated Abbreviation | Concrete Binder | Water (L) | Aggregates (kg) | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| PC (kg) | Geopolymer | Fine Agg. | Coarse Agg. | |||||||||

| GGBS (kg) | PFA (kg) | A/P Ratio | SSA:SH | Activator (mL) | ||||||||

| SSA | SH | 10 mm | 20 mm | |||||||||

| C | OPC (Control 1) | 8.9 | - | - | - | - | - | - | 4.9 | 17.7 | 8.8 | 17.8 |

| CL0 | CL0—50% GGBS—50% PFA | - | 3.2 | 3.2 | 0.4 | 01:01 | 865 | 865 | 3.1 | 17.7 | 8.8 | 17.8 |

| CL1 | CL1—60% GGBS—40% PFA | - | 3.8 | 2.5 | 0.4 | 01:01 | 865 | 865 | 3.1 | 17.7 | 8.8 | 17.8 |

| CL2 | CL2—70% GGBS—30% PFA | - | 4.4 | 1.9 | 0.4 | 01:01 | 865 | 865 | 3.1 | 17.7 | 8.8 | 17.8 |

| CL3 | CL3—80% GGBS—20% PFA | - | 5.1 | 1.3 | 0.4 | 01:01 | 865 | 865 | 3.1 | 17.7 | 8.8 | 17.8 |

| CL4 | CL4—90% GGBS—10% PFA | - | 5.7 | 0.6 | 0.4 | 01:01 | 865 | 865 | 3.1 | 17.7 | 8.8 | 17.8 |

| OPC—ordinary Portland cement, GGBS—Ground Granulated Blast Furnace Slag; A/P—activator/precursor ratio, SSA:SH—sodium silicate alternative to sodium hydroxide ratio, PFA—pulverised fly ash; W—Water. | ||||||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oti, J.; Adeleke, B.O.; Casabuena, L.R.; Kinuthia, J.M.; Sule, S. Utilization of a PFA-GGBS-Based Precursor in Geopolymer Concrete Production as a Sustainable Substitute for Conventional Concrete. Materials 2025, 18, 1309. https://doi.org/10.3390/ma18061309

Oti J, Adeleke BO, Casabuena LR, Kinuthia JM, Sule S. Utilization of a PFA-GGBS-Based Precursor in Geopolymer Concrete Production as a Sustainable Substitute for Conventional Concrete. Materials. 2025; 18(6):1309. https://doi.org/10.3390/ma18061309

Chicago/Turabian StyleOti, Jonathan, Blessing O. Adeleke, Lito R. Casabuena, John M. Kinuthia, and Samuel Sule. 2025. "Utilization of a PFA-GGBS-Based Precursor in Geopolymer Concrete Production as a Sustainable Substitute for Conventional Concrete" Materials 18, no. 6: 1309. https://doi.org/10.3390/ma18061309

APA StyleOti, J., Adeleke, B. O., Casabuena, L. R., Kinuthia, J. M., & Sule, S. (2025). Utilization of a PFA-GGBS-Based Precursor in Geopolymer Concrete Production as a Sustainable Substitute for Conventional Concrete. Materials, 18(6), 1309. https://doi.org/10.3390/ma18061309