Analyzing the Bonding Resistance of the Ribbed Stainless-Steel Bar in the Refractory Castable After High-Temperature Treatment

Abstract

1. Introduction

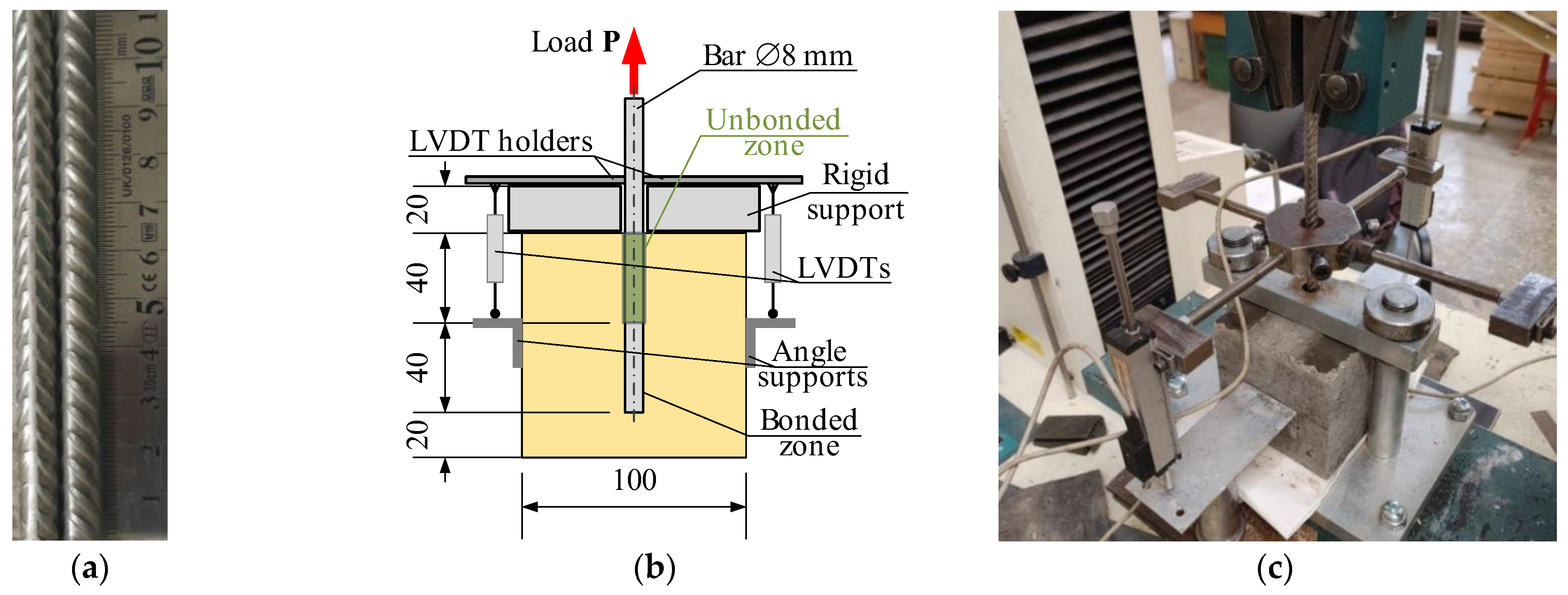

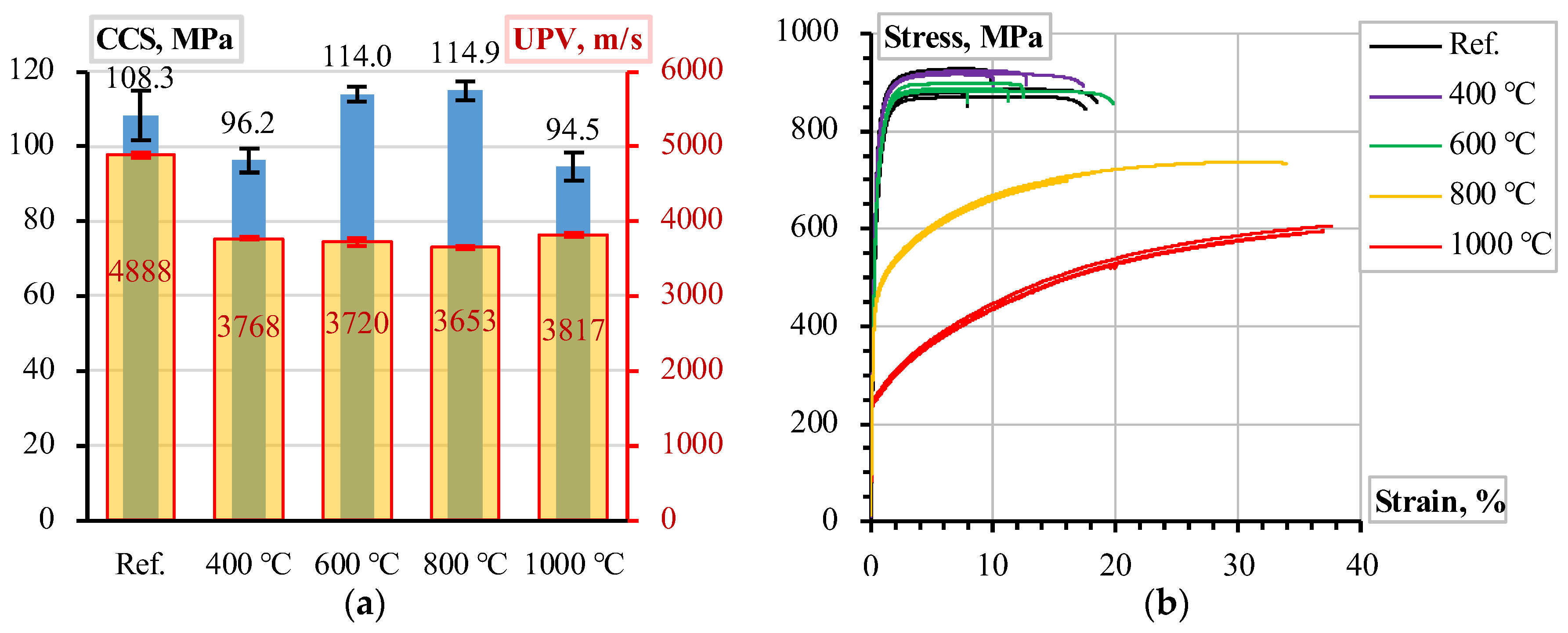

2. Experimental Database

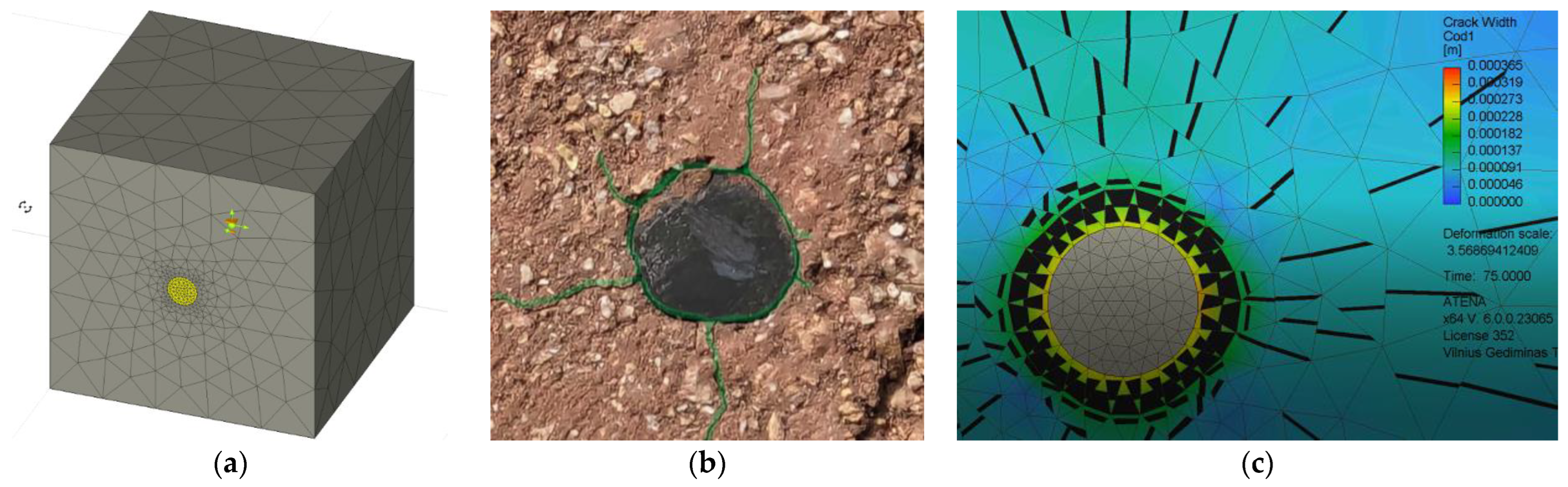

3. Finite Element Model of Pull-Out Test

3.1. Modeling Concept

3.2. Modeling Pull-Out Resistance

3.3. Analyzing Uneven Expansion of Materials

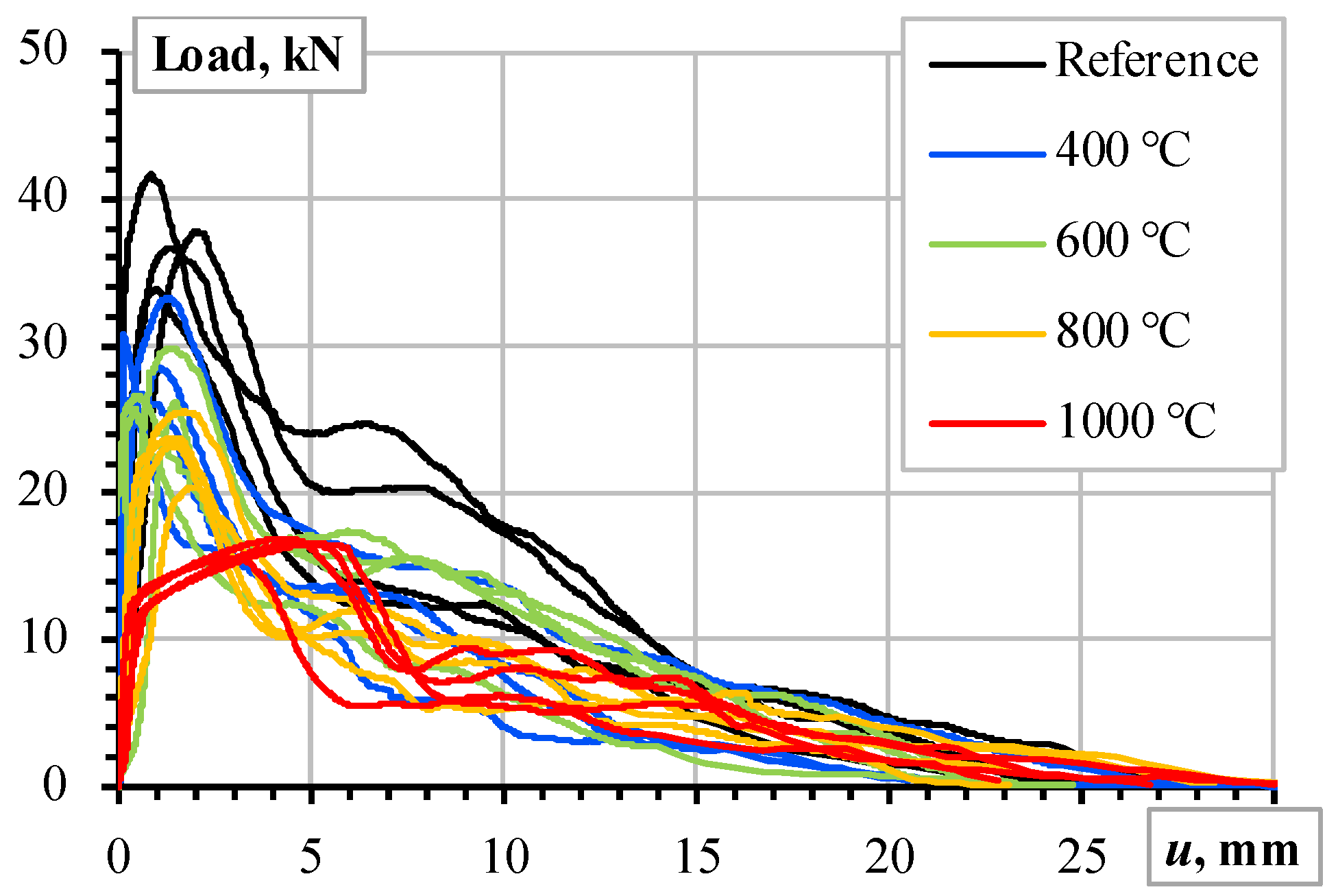

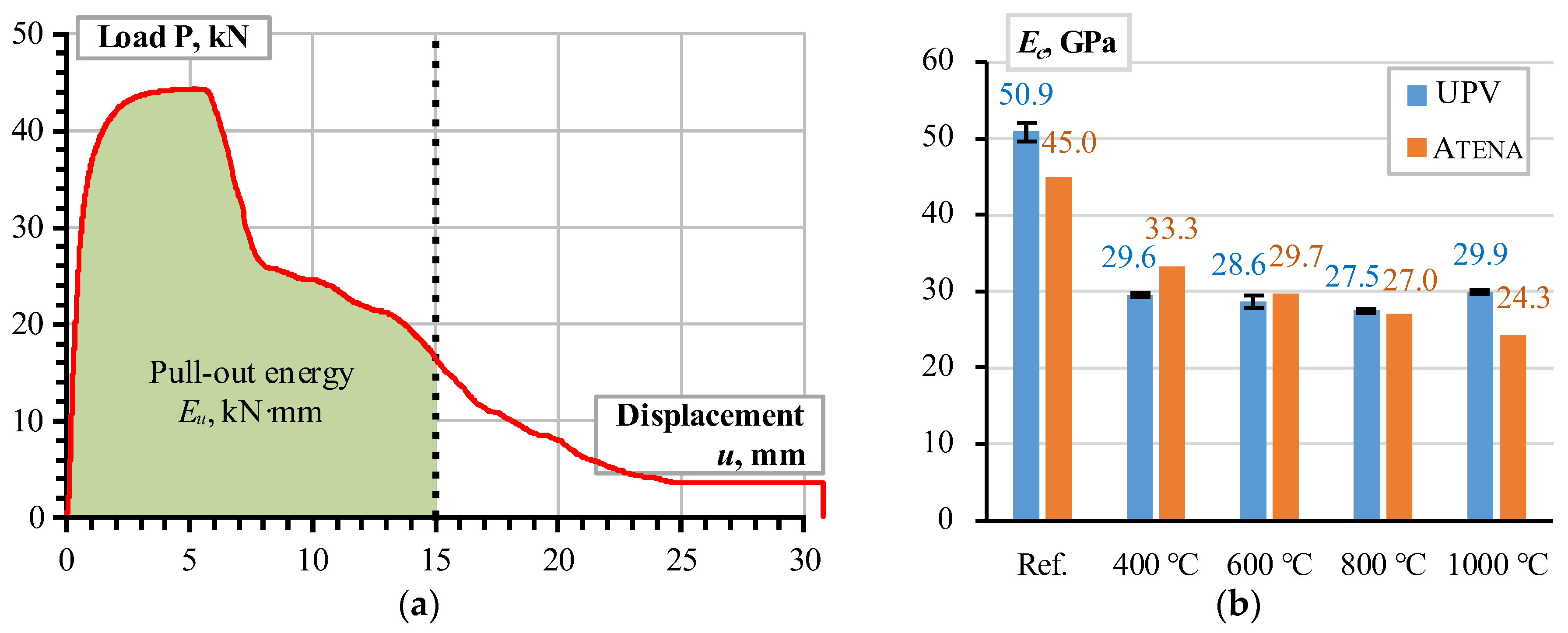

4. Discussion of Results

4.1. The Modeling Adequacy Analysis

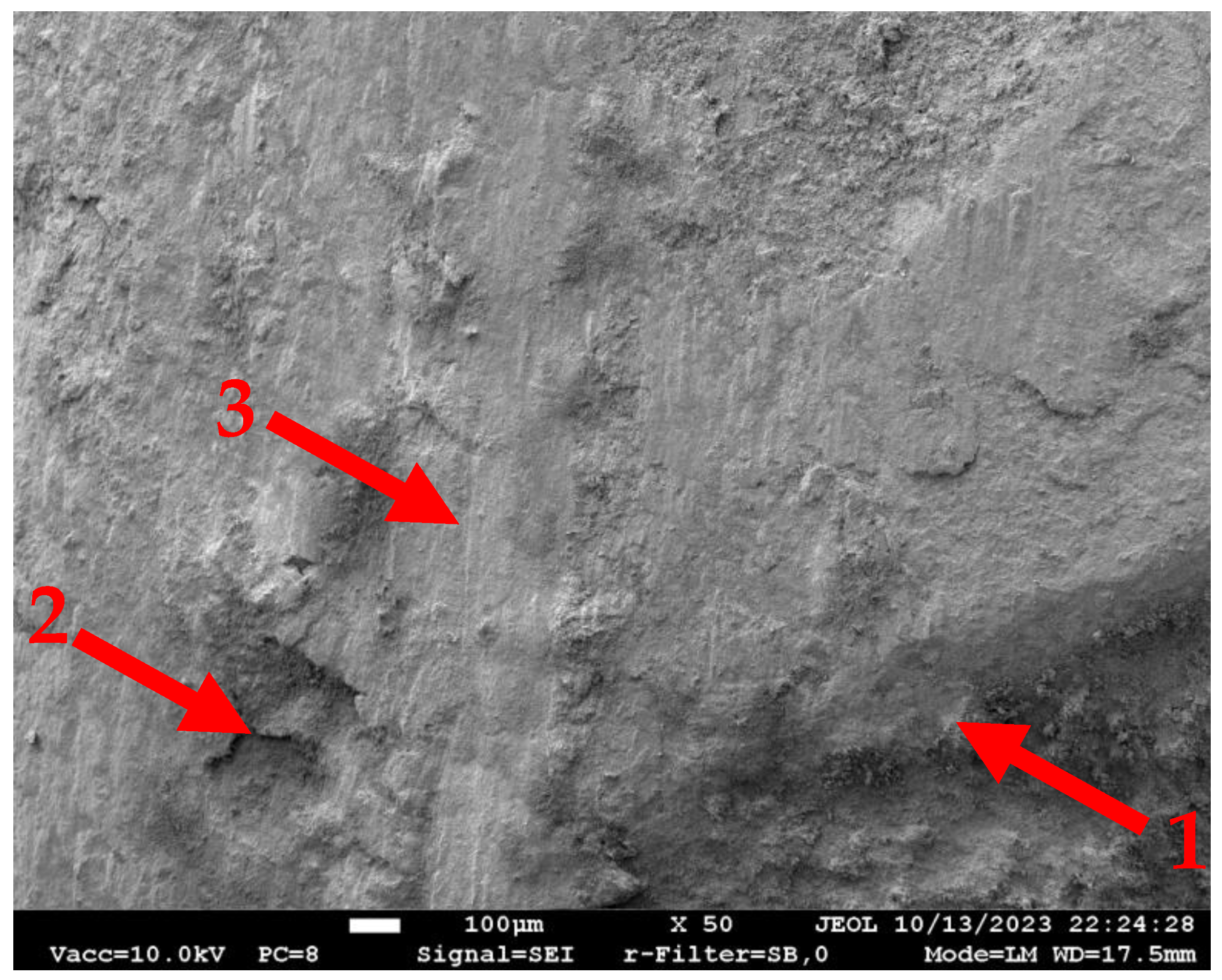

4.2. The Bond Deterioration Mechanisms

4.3. Further Research

5. Conclusions

- The castable’s compressive strength controls the bonding resistance of reinforcement. For the selected materials, the geometry of the test specimens, and simplified modeling assumptions (i.e., the perfect bond model), the maximal bond stress , where fc is the castable’s compressive strength, determine the bonding resistance of the refractory composite. Still, this parameter alone is insufficient for the bond model.

- The ASTM standard methodology (ASTM E1876-09) is adequate for estimating the selected castable’s deformation modulus, using the ultrasonic pulse velocity (UPV) measurements. These estimations can be used for the chosen castable’s modeling. However, the bonding resistance of steel bars in refractory composite decreases after high-temperature treatment. Therefore, this study proposes the empirical equation for the deformation modulus of concrete to represent the adverse temperature effect on the bonding resistance.

- Despite the simplicity of the modeling assumptions, i.e., the deformation modulus of the concrete simulates the adverse temperature effects on the bonding resistance, the proposed model adequately predicted the mechanical resistances of the pull-out tests. Independently of the heating temperature, the average pull-out energy prediction error does not reach 4%. The standard deviation of the pull-out deformation energy, assessed during the tests, varies from 11.7% to 22.4% depending on the heating temperature with the 16.2% average value. Thus, the obtained model is considered experimentally verified and reliable for estimating the deformation modulus of the selected refractory castable reinforced with the stainless-steel ribbed bars.

- This model may serve as a reference for assessing the mechanical efficiency of the reinforced refractory composite: the experimental outcome of a new (enhanced) material must outperform the numerical prediction result to be considered efficient.

- Further research is necessary to experimentally verify the proposed model’s predictions of the mechanical resistance of structural elements with extended bonding lengths subjected to high-temperature treatments.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bezerra, B.P.; Luz, A.P. Geopolymers: A viable binder option for ultra-low-cement and cement-free refractory castables. J. Eur. Ceram. Soc. 2024, 44, 5241–5251. [Google Scholar] [CrossRef]

- Bayoumi, I.M.; Ewais, E.M.; El-Amir, A.A. Rheology of refractory concrete: An article review. Boletín De La Soc. Española De Cerám. Y Vidr. 2022, 61, 453–469. [Google Scholar] [CrossRef]

- Piippo, A.; Ruotanen, K.; Visuri, V.; Poutiainen, N.; Heikkinen, E. Experimental study on the effect of calcium aluminate cement addition on the drying and physical properties of refractory castables containing colloidal silica. Materials 2024, 17, 5308. [Google Scholar] [CrossRef]

- Xiying, C. Unshaped refractories. In The ECPH Encyclopedia of Mining and Metallurgy; Springer Nature: Singapore, 2024; pp. 2250–2253. [Google Scholar] [CrossRef]

- Farias, T.W.; da Luz, A.P. Enhancing semi-insulating refractory performance with polymeric microspheres and distinct calcium aluminate cements. Int. J. Appl. Ceram. Technol. 2024, 21, 1668–1677. [Google Scholar] [CrossRef]

- Gasser, A.; Boisse, P.; Dutheillet, Y.; Poirier, J. Experimental and numerical analyses of thermomechanical refractory lining behaviour. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2001, 215, 41–54. [Google Scholar] [CrossRef]

- Dai, Y.; Wang, Z.; Chen, Q.; Meng, D.; Wang, F.; Liao, N.; Yan, W.; Li, Y. Thermomechanical behavior of alumina–magnesia castables and numerical modeling of the steel ladle thermal process. Int. J. Appl. Ceram. Technol. 2024, 22, e14936. [Google Scholar] [CrossRef]

- Pereira, C.I.; Santos, M.F.; Angélico, R.A.; Moreira, M.H.; Braulio, M.; Iwanaga, T.; Pandolfelli, V.C. Insights into thermomechanical behavior and design parameters of alumina calciner refractory lining. Ceram. Int. 2024, 50, 44008–44016. [Google Scholar] [CrossRef]

- Willam, K.; Rhee, I.; Xi, Y. Thermal degradation of heterogeneous concrete materials. ASCE J. Mater. Civ. Eng. 2005, 17, 276–285. [Google Scholar] [CrossRef]

- El Khatib, L.W.; Khatib, J.; Assaad, J.J.; Elkordi, A.; Ghanem, H. Refractory concrete properties—A review. Infrastructures 2024, 9, 137. [Google Scholar] [CrossRef]

- Naus, D.J.; Graves, H.L. A Review of the Effects of Elevated Temperature on Concrete Materials and Structures. In Proceedings of the 14th International Conference on Nuclear Engineering, Miami, FL, USA, 17–20 July 2006; pp. 615–624. [Google Scholar] [CrossRef]

- Plioplys, L.; Kudžma, A.; Sokolov, A.; Antonovič, V.; Gribniak, V. Bond behavior of stainless-steel and ordinary reinforcement bars in refractory castables under elevated temperatures. J. Compos. Sci. 2023, 7, 485. [Google Scholar] [CrossRef]

- Plioplys, L.; Antonovič, V.; Boris, R.; Kudžma, A.; Gribniak, V. Investigating the high-temperature bonding performance of refractory castables with ribbed stainless-steel bars. Materials 2024, 17, 2916. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Amran, M.; Tang, W.; Betoush, N.; Alhassan, M.; Rashid, R.S.; Yasin, M.F.; Bayagoob, K.; Onaizi, S.A. Radiation-shielding concrete: A review of materials, performance, and the impact of radiation on concrete properties. J. Build. Eng. 2024, 97, 110800. [Google Scholar] [CrossRef]

- Gribniak, V.; Bacinskas, D.; Kaklauskas, G. Numerical simulation strategy of bearing reinforced concrete tunnel members in fire. Balt. J. Road Bridge Eng. 2006, 1, 5–9. [Google Scholar]

- Ergün, A.; Kürklü, G.; Başpınar, M.S. The effects of material properties on bond strength between reinforcing bar and concrete exposed to high temperature. Constr. Build. Mater. 2016, 112, 691–698. [Google Scholar] [CrossRef]

- Liu, C.; Zhou, B.; Guo, X.; Liu, C.; Wang, L. Analysis and prediction methods for the static properties of reinforced concrete beams under fire. Structures 2023, 47, 2319–2330. [Google Scholar] [CrossRef]

- Das, A.; Sharma, A.; Bošnjak, J. Experimental and numerical investigations on the residual bond capacity of RC flexural members exposed to fire considering twin rebars. Dev. Built Environ. 2024, 20, 100551. [Google Scholar] [CrossRef]

- Plioplys, L.; Kudžma, A.; Sokolov, A.; Antonovič, V.; Gribniak, V. Reinforcement bonding performance in refractory castables under elevated temperatures. Proc. Int. Struct. Eng. Constr. 2022, 9, MAT-26. [Google Scholar] [CrossRef]

- Zapata, J.F.; Azevedo, A.; Fontes, C.; Monteiro, S.N.; Colorado, H.A. Environmental impact and sustainability of calcium aluminate cements. Sustainability 2022, 14, 2751. [Google Scholar] [CrossRef]

- Nespor, B.; Chromkova, I.; Szklorzova, H.; Prachar, V.; Svitak, O.; Stanek, L.; Nejedlik, M. A new approach for the determination of thermal shock resistance of refractories. J. Phys. Conf. Ser. 2022, 2341, 012006. [Google Scholar] [CrossRef]

- Kudžma, A.; Plioplys, L.; Antonovič, V.; Stonys, R.; Gribniak, V. Curing temperatures effect on explosive spalling in alumina cement-based concretes. Proc. Int. Struct. Eng. Constr. 2022, 9, MAT-27. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Zhu, B.; Chen, P. Microstructure evolution during the heating process and its effect on the elastic properties of CAC-bonded alumina castables. Ceram. Int. 2016, 42, 11355–11362. [Google Scholar] [CrossRef]

- Antonovich (Antonovič), V.; Goberis, S.; Pundene, I.; Stonys, R. A new generation of deflocculants and microsilica used to modify the properties of a conventional refractory castable based on a chamotte filler. Refract. Ind. Ceram. 2006, 47, 178–182. [Google Scholar] [CrossRef]

- López-Perales, J.F.; Contreras, J.E.; Vázquez-Rodríguez, F.J.; Gómez-Rodríguez, C.; Díaz-Tato, L.; Banda-Muñoz, F.; Rodríguez, E.A. Partial replacement of a traditional raw material by blast furnace slag in developing a sustainable conventional refractory castable of improved physical-mechanical properties. J. Clean. Prod. 2021, 306, 127266. [Google Scholar] [CrossRef]

- Peng, H.; Myhre, B. Improved explosion resistance of low cement refractory castables using drying agents. Int. J. Ceram. Eng. Sci. 2022, 4, 84–91. [Google Scholar] [CrossRef]

- Brown, D.S.; Eckert, C.H.; Kline, C.H. Advanced polymer composites—Five keys to success. Mater. Des. 1985, 6, 203–206. [Google Scholar] [CrossRef]

- Carlson, C.W. Polymer composites: Adjusting to the commercial marketplace. JOM 1993, 45, 56–57. [Google Scholar] [CrossRef]

- Oliver, M.; Strickland, B. Synchronized manufacture of composites knowledge study (SMACKS). Compos. Manuf. 1990, 1, 103–108. [Google Scholar] [CrossRef]

- Karbhari, V.M. Fabrication, quality and service-life issues for composites in civil engineering. In Durability of Composites for Civil Structural Applications; Woodhead Publishing: Amsterdam, The Netherlands, 2007; pp. 13–30. [Google Scholar] [CrossRef]

- Chatzimichali, A.P.; Potter, K.D. From composite material technologies to composite products: A cross-sectorial reflection on technology transitions and production capability. Transl. Mater. Res. 2015, 2, 026001. [Google Scholar] [CrossRef]

- Huang, X.; Su, S.; Xu, Z.; Miao, Q.; Li, W.; Wang, L. Advanced composite materials for structure strengthening and resilience improvement. Buildings 2023, 13, 2406. [Google Scholar] [CrossRef]

- Okafor, C.E.; Iweriolor, S.; Ani, O.I.; Ahmad, S.; Mehfuz, S.; Ekwueme, G.O.; Chukwumuanya, O.E.; Abonyi, S.E.; Ekengwu, I.E.; Chikelu, O.P. Advances in machine learning-aided design of reinforced polymer composite and hybrid material systems. Hybrid Adv. 2023, 2, 100026. [Google Scholar] [CrossRef]

- Locke, J.; Valencia, U.; Ishikawa, K. Design studies for twist-coupled wind turbine blades. ASME Wind Energy Symp. 2003, 75944, 324–331. [Google Scholar] [CrossRef]

- Wu, W.; Xia, R.; Qian, G.; Liu, Z.; Razavi, N.; Berto, F.; Gao, H. Mechanostructures: Rational mechanical design, fabrication, performance evaluation, and industrial application of advanced structures. Prog. Mater. Sci. 2023, 131, 101021. [Google Scholar] [CrossRef]

- Hunde, B.R.; Woldeyohannes, A.D. Future prospects of computer-aided design (CAD)—A review from the perspective of artificial intelligence (AI), extended reality, and 3D printing. Results Eng. 2022, 14, 100478. [Google Scholar] [CrossRef]

- Garnevičius, M.; Gribniak, V. Developing a hybrid FRP-concrete composite beam. Sci. Rep. 2022, 12, 16237. [Google Scholar] [CrossRef] [PubMed]

- Chu, S.H.; Kwan, A.K.H. A new method for pull out test of reinforcing bars in plain and fibre reinforced concrete. Eng. Struct. 2018, 164, 82–91. [Google Scholar] [CrossRef]

- ISO 1927-5:2012; Monolithic (Unshaped) Refractory Products—Part 5: Preparation and Treatment of Test Pieces. ISO: Geneva, Switzerland, 2012; p. 18.

- Dehestani, M.; Asadi, A.; Mousavi, S. On discrete element method for rebar-concrete interaction. Constr. Build. Mater. 2017, 151, 220–227. [Google Scholar] [CrossRef]

- Gribniak, V.; Jakubovskis, R.; Rimkus, A.; Ng, P.-L.; Hui, D. Experimental and numerical analysis of strain gradient in tensile concrete prisms reinforced with multiple bars. Constr. Build. Mater. 2018, 187, 572–583. [Google Scholar] [CrossRef]

- Jin, L.; Liu, M.; Zhang, R.; Du, X. 3D meso-scale modelling of the interface behavior between ribbed steel bar and concrete. Eng. Fract. Mech. 2020, 239, 107291. [Google Scholar] [CrossRef]

- Nguyen, T.K.; Nguyen, N.T.; Tran, H.A.; Nguyen, H.G.; Tran, P. Three-dimensional nonlinear finite element analysis of corroded reinforced concrete beams strengthened by CFRP sheets. Eur. J. Environ. Civ. Eng. 2024, 28, 2217–2243. [Google Scholar] [CrossRef]

- Červenka, V.; Červenka, J.; Rimkus, A.; Gribniak, V. Finite element modeling of crack width and localization in reinforced concrete. Buildings 2025, 15, 529. [Google Scholar] [CrossRef]

- Jirásek, M.; Bažant, Z.P. Inelastic Analysis of Structures, 1st ed.; John Willey & Sons: Chichester, UK, 2002; p. 758. [Google Scholar]

- Garnevičius, M.; Plioplys, L.; Ng, P.-L.; Chu, S.; Gribniak, V. Investigation and improvement of bond performance of synthetic macro-fibres in concrete. Materials 2020, 13, 5688. [Google Scholar] [CrossRef]

- Červenka, V.; Jendele, L.; Červenka, J. Atena Program Documentation, Part 1: Theory; Cervenka Consulting s.r.o.: Prague, Czech Republic, 2021; p. 360. Available online: www.cervenka.cz (accessed on 5 January 2025).

- Červenka, J.; Červenka, V.; Eligehausen, R. Fracture-plastic material model for concrete, application to analysis of powder actuated anchors. In Proceedings of the Third International Conference on Fracture Mechanics of Concrete and Concrete Structures, FRAMCOS-3, Gifu, Japan, 12–16 October 1998; pp. 1107–1116. [Google Scholar]

- Červenka, J.; Papanikolaou, V.K. Three dimensional combined fracture–plastic material model for concrete. Int. J. Plast. 2008, 24, 2192–2220. [Google Scholar] [CrossRef]

- Hordijk, D.A. Local Approach to Fatigue of Concrete. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 1991; p. 216. [Google Scholar]

- Bažant, Z.P.; Oh, B.H. Crack band theory for fracture of concrete. Mater. Struct. 1983, 16, 155–177. [Google Scholar] [CrossRef]

- Červenka, J.; Červenka, V.; Laserna, S. On finite element modelling of compressive failure in brittle materials. In Computational Modeling of Concrete Structures, 1st ed.; Bicanic, N., Mang, H., Meschke, G., René de Borst, R., Eds.; CRC Press: St. Anton, Austria, 2014; Volume 1, pp. 273–282. [Google Scholar]

- Menetrey, P.; Willam, K.J. Triaxial failure criterion for concrete and its generalization. ACI Struct. J. 1995, 92, 311–318. [Google Scholar] [CrossRef]

- Červenka, V.; Margoldová, J. Tension stiffening effect in smeared crack model. In Engineering Mechanics: Proceedings of 10th Conference; Sture, S., Ed.; ASCE: New York, NY, USA, 1995; Volume 1, pp. 655–658. [Google Scholar]

- Naser, M.Z.; Hawileh, R.A.; Abdalla, J. Modeling strategies of finite element simulation of reinforced concrete beams strengthened with FRP: A review. J. Compos. Sci. 2021, 5, 19. [Google Scholar] [CrossRef]

- Dey, A.; Valiukas, D.; Jakubovskis, R.; Sokolov, A.; Kaklauskas, G. Experimental and numerical investigation of bond-slip behavior of high-strength reinforced concrete at service load. Materials 2022, 15, 293. [Google Scholar] [CrossRef]

- Trad, M.; Bitar, I.; Grange, S.; Richard, B. A multiscale steel–concrete interface model for structural applications. Structures 2024, 68, 107137. [Google Scholar] [CrossRef]

- Burdziński, M.; Niedostatkiewicz, M. Experimental-numerical analysis of the effect of bar diameter on bond in pull-out test. Buildings 2022, 12, 1392. [Google Scholar] [CrossRef]

- Croce, P.; Formichi, P.; Landi, F. Experimental assessment and numerical modeling of the bond–slip correlation for steel rebars in R.C. members. Materials 2022, 15, 951. [Google Scholar] [CrossRef]

- Casanova, A.; Jason, L.; Davenne, L. Bond slip model for the simulation of reinforced concrete structures. Eng. Struct. 2012, 39, 66–78. [Google Scholar] [CrossRef]

- Mang, C.; Jason, L.; Davenne, L. A new bond slip model for reinforced concrete structures: Validation by modelling a reinforced concrete tie. Eng. Comput. 2015, 32, 1934–1958. [Google Scholar] [CrossRef]

- Rimkus, A.; Cervenka, V.; Gribniak, V.; Cervenka, J. Uncertainty of the smeared crack model applied to RC beams. Eng. Fract. Mech. 2020, 233, 107088. [Google Scholar] [CrossRef]

- Cervenka, V.; Rimkus, A.; Gribniak, V.; Cervenka, J. Simulation of the crack width in reinforced concrete beams based on concrete fracture. Theor. Appl. Fract. Mech. 2022, 121, 103428. [Google Scholar] [CrossRef]

- Filho, A.F.M.; De Nardin, S.; El Debs, A.L.H.C. Numerical approach of the steel-concrete bond behavior using pull-out models. Rev. Matéria 2019, 24, e-12341. [Google Scholar] [CrossRef]

- Senthil, K.; Aswa, S.; Aswin, C.P. Influence of concrete strength and diameter of reinforcing bar on pullout tests using finite element analysis. J. Struct. Eng. Appl. Mech. 2018, 1, 105–116. [Google Scholar] [CrossRef]

- ASTM E1876-09; Standard Test Method for Dynamic Young’s Modulus, Shear Modulus, and Poisson’s Ratio by Impulse Excitation of Vibration. ASTM International: West Conshohocken, PA, USA, 2016; p. 16. [CrossRef]

- Mullinger, P.; Jenkins, B. Industrial and Process Furnaces: Principles, Design and Operation, 3rd ed.; Butterworth-Heinemann: Oxford, UK, 2022; p. 718. [Google Scholar]

- Toulouklan, Y.S.; Ho, C.Y. Thermophysical Properties of Selected Aerospace Materials. In Part II: Thermophysical Properties of Seven Materials; Purdue University: West Lafayette, IN, USA, 1977; p. 242. [Google Scholar]

- Lee, J.; Sheesley, E.; Jing, Y.; Xi, Y.; Willam, K. The effect of heating and cooling on the bond strength between concrete and steel reinforcement bars with and without epoxy coating. Constr. Build. Mater. 2018, 177, 230–236. [Google Scholar] [CrossRef]

- Kadri, E.H.; Aggoun, S.; Kenai, S.; Kaci, A. The compressive strength of high-performance concrete and ultrahigh-performance. Adv. Mater. Sci. Eng. 2012, 2012, 361857. [Google Scholar] [CrossRef]

- Prince, M.B.; Sen, D. A numerical study on predicting bond-slip relationship of reinforced concrete using surface based cohesive behavior. Fract. Struct. Integr. 2024, 18, 154–180. [Google Scholar] [CrossRef]

- Gribniak, V.; Sultani, H.A.; Rimkus, A.; Boris, R.; Sokolov, A.; Torres, L. Quantifying the flexural stiffness changes in the concrete beams with externally bonded carbon fiber sheets under elevated environment temperature. Alex. Eng. J. 2024, 104, 688–700. [Google Scholar] [CrossRef]

| Parameter | Value [Unit] | Description |

|---|---|---|

| Castable | ||

| Ec | Variable in this study | Modulus of elasticity |

| νc * | 0.17 [–] | Poison’s ratio |

| ft⁑ | 3.0 [MPa] | Tensile strength |

| GF⁑ | 75 [N/m] | Fracture energy |

| fc⁂ | 25.5 [MPa] | Compressive strength |

| fc0 ⁑ | 3.194 [MPa] | Onset of nonlinear behavior in compression |

| εcp⁑ | 0.00067 [–] | Plastic strain at fc |

| β * | 0 [–] | Parameter controlling the return direction during the concrete crushing |

| wd * | 0.5 [mm] | Critical displacement in compression |

| cfix * | 0.7 [–] | Coefficient controlling the switch from rotated to fixed crack model |

| cc * | 0.05 [m] | Crack spacing |

| cts * | 0.4 [–] | Tension stiffening parameter |

| ρc | 2308 [kg/m3] | Density |

| da | 5 [mm] | Maximum aggregate size |

| αc‡ | 0.62 × 10–5 [1/°C] | Thermal expansion coefficient (at 1500 °C) |

| Reinforcement | ||

| Es | 172.2 [GPa] | Modulus of elasticity |

| νs * | 0.27 [–] | Poison’s ratio |

| fy | 623.5 [MPa] | Yield strength |

| fu | 859.3 [MPa] | Tensile strength |

| εu | 0.1 [–] | Rupture strain |

| ρc * | 7930 [kg/m3] | Density |

| αs‡ | 2.13 × 10–5 [1/°C] | Thermal expansion coefficient (at 1000 °C) |

| Bond model | ||

| Perfect bond | – | No slip allowed through the bonded contact |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Plioplys, L.; Kudžma, A.; Antonovič, V.; Gribniak, V. Analyzing the Bonding Resistance of the Ribbed Stainless-Steel Bar in the Refractory Castable After High-Temperature Treatment. Materials 2025, 18, 1282. https://doi.org/10.3390/ma18061282

Plioplys L, Kudžma A, Antonovič V, Gribniak V. Analyzing the Bonding Resistance of the Ribbed Stainless-Steel Bar in the Refractory Castable After High-Temperature Treatment. Materials. 2025; 18(6):1282. https://doi.org/10.3390/ma18061282

Chicago/Turabian StylePlioplys, Linas, Andrius Kudžma, Valentin Antonovič, and Viktor Gribniak. 2025. "Analyzing the Bonding Resistance of the Ribbed Stainless-Steel Bar in the Refractory Castable After High-Temperature Treatment" Materials 18, no. 6: 1282. https://doi.org/10.3390/ma18061282

APA StylePlioplys, L., Kudžma, A., Antonovič, V., & Gribniak, V. (2025). Analyzing the Bonding Resistance of the Ribbed Stainless-Steel Bar in the Refractory Castable After High-Temperature Treatment. Materials, 18(6), 1282. https://doi.org/10.3390/ma18061282