Improved Wire Quality of Twinning-Induced Plasticity Steel During Wire Drawing Through Temperature Gradient with Warm Die

Abstract

1. Introduction

2. Experimental and Numerical Simulation Procedures

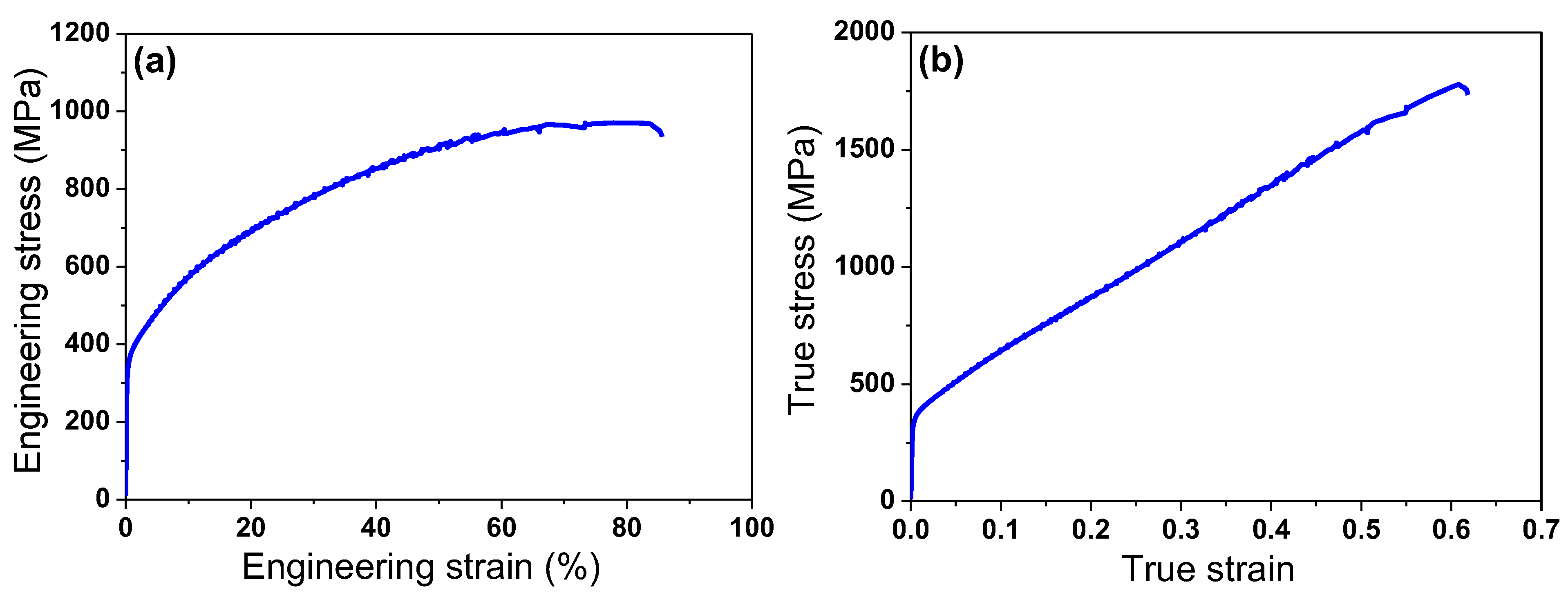

2.1. Material Preparation of TWIP Steel

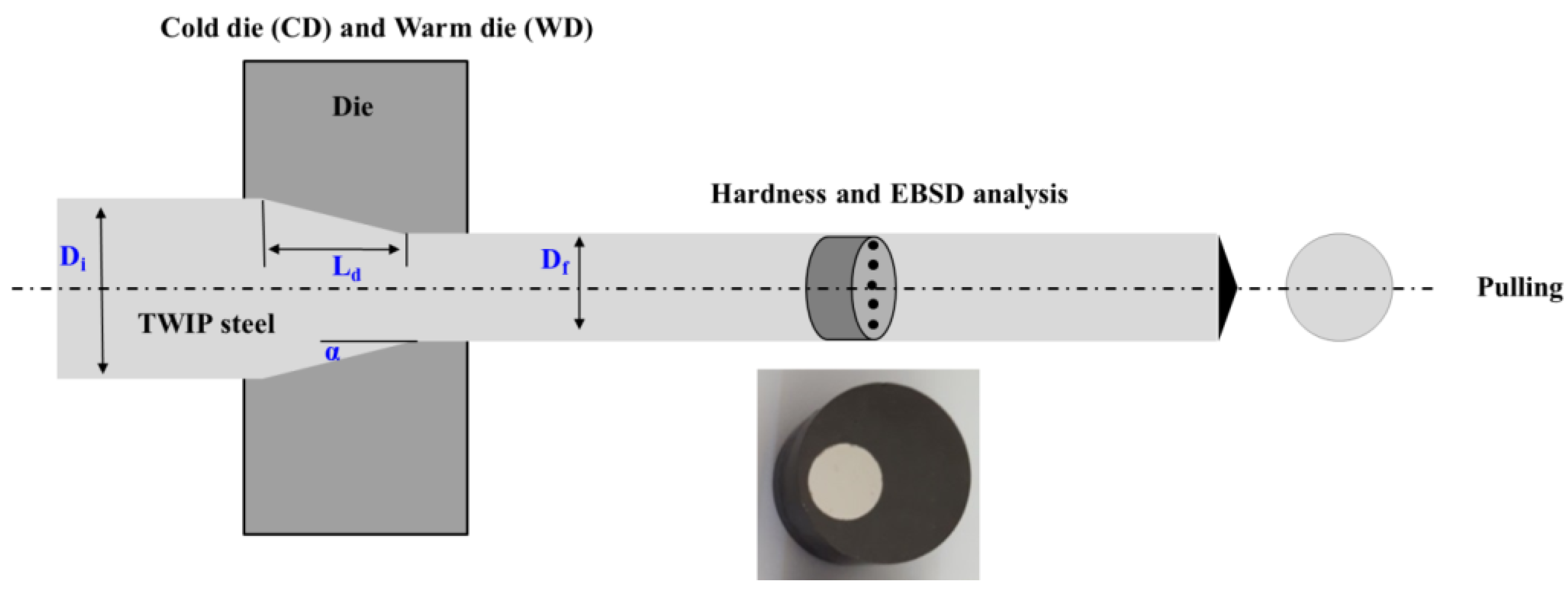

2.2. Wire Drawing Test Under CD and WD Process Conditions

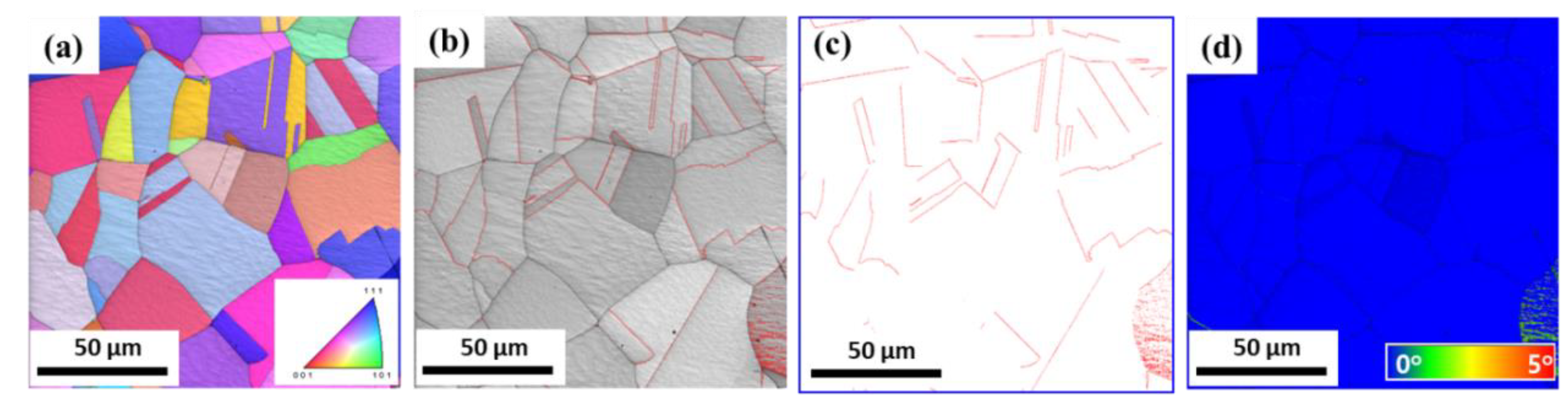

2.3. Measurements of Mechanical Properties and Microstructure

2.4. Finite Element Analysis of Wire Drawing Process

3. Results

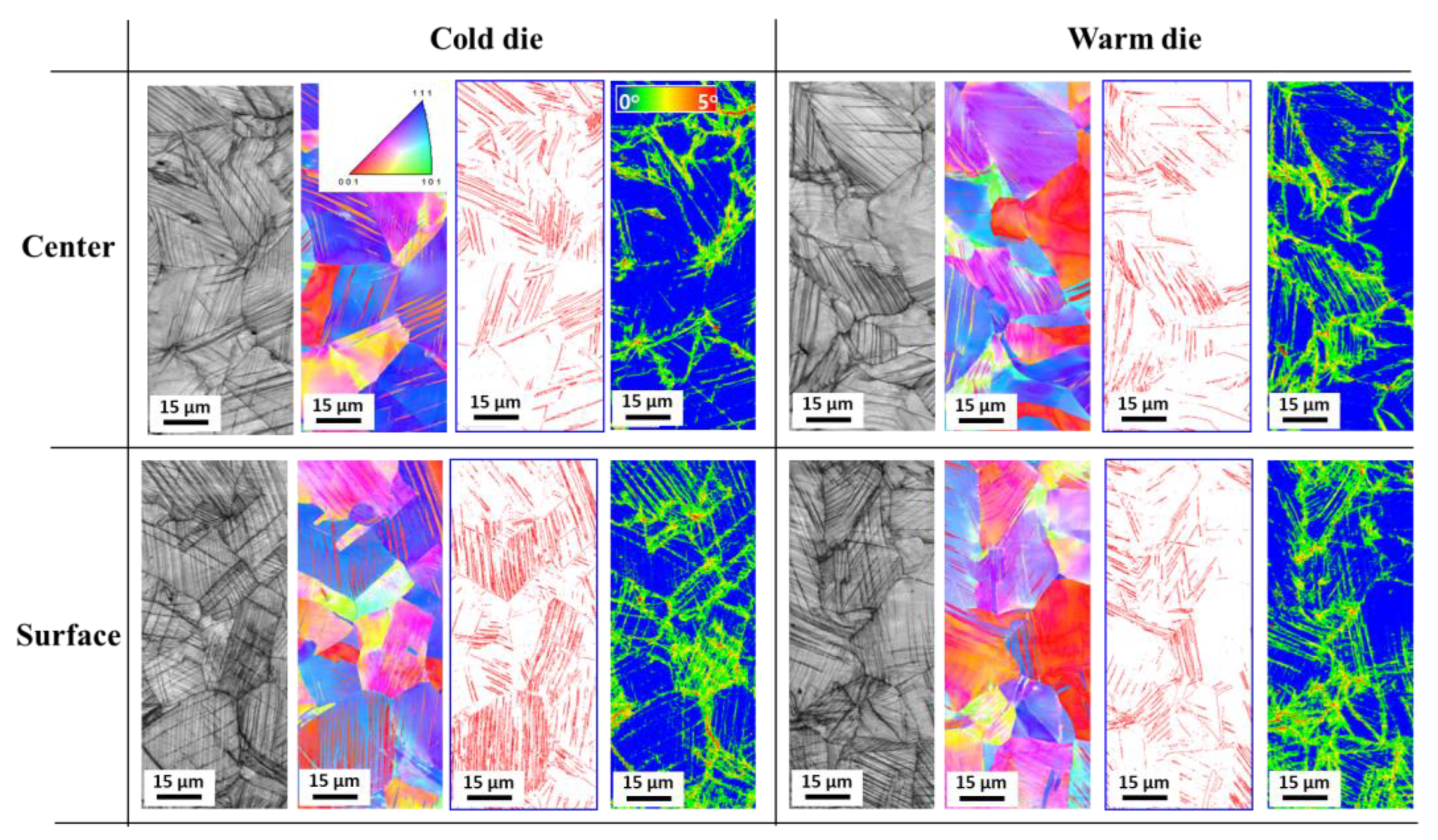

3.1. Microstructure Evolution

3.2. Mechanical Properties

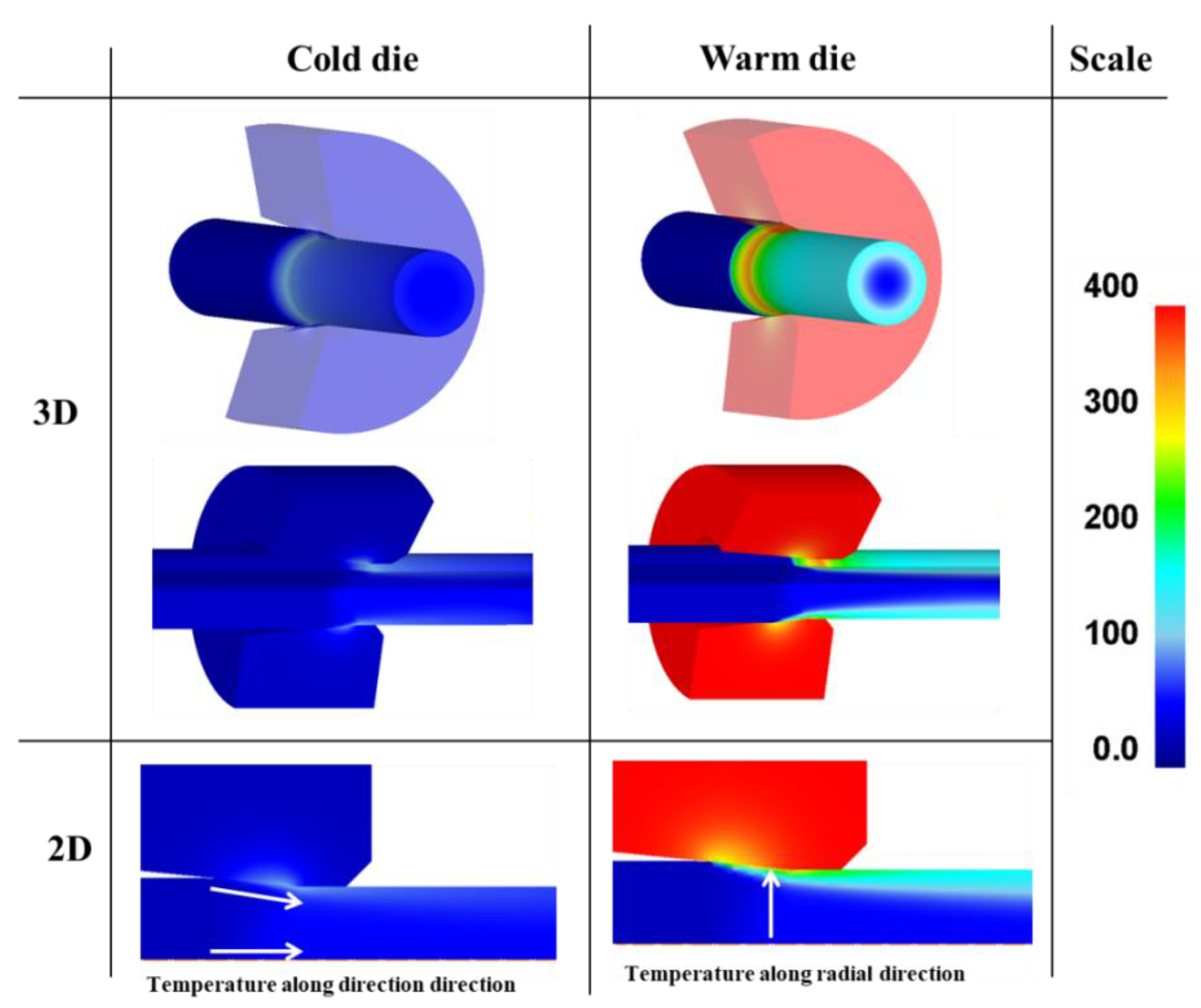

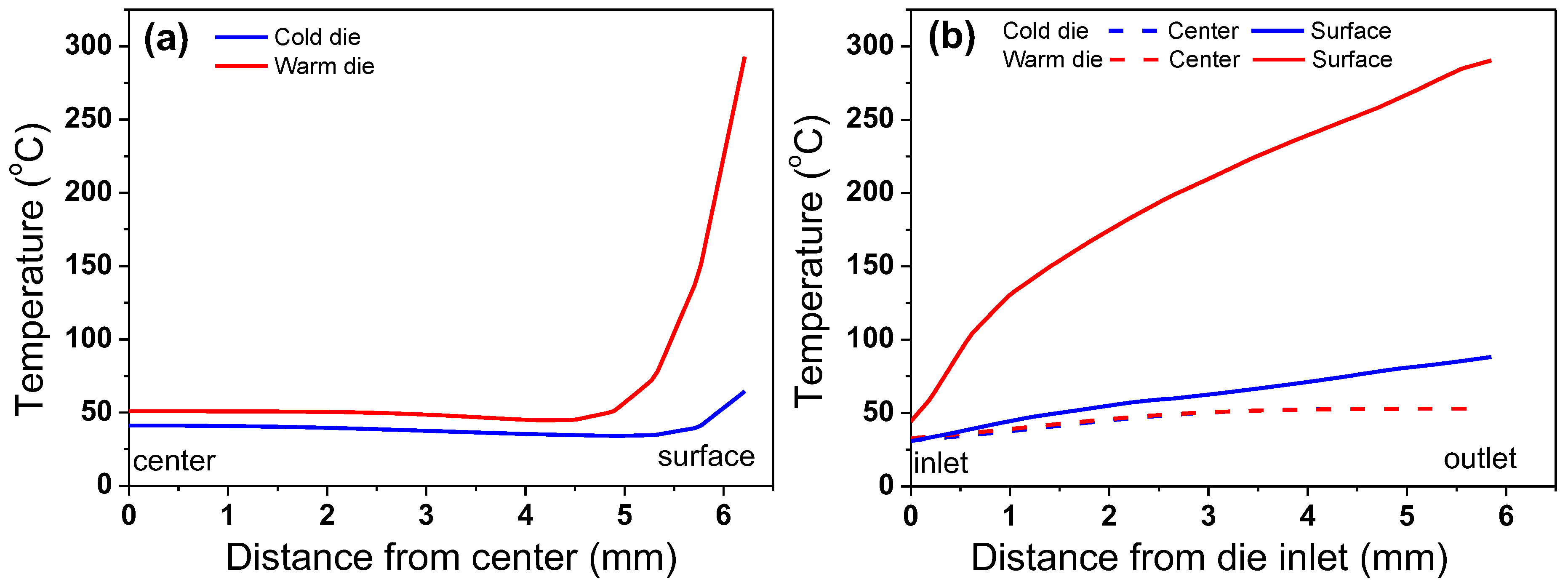

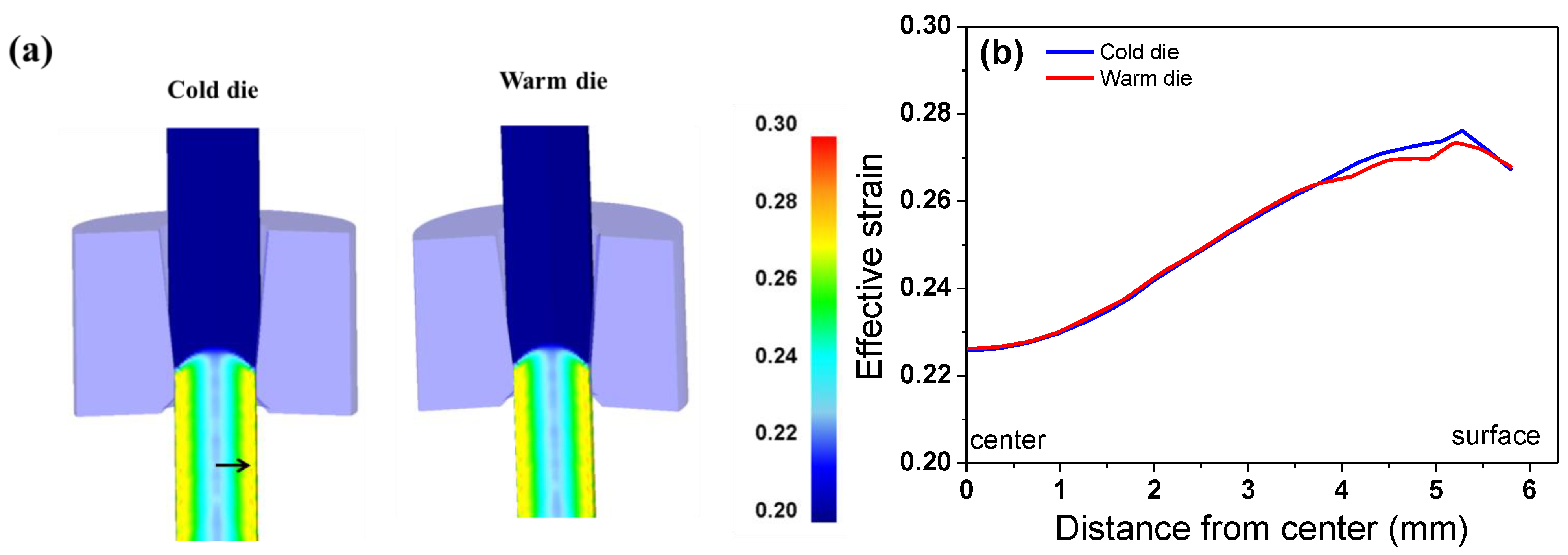

3.3. Numerical Analysis

4. Discussion

5. Conclusions

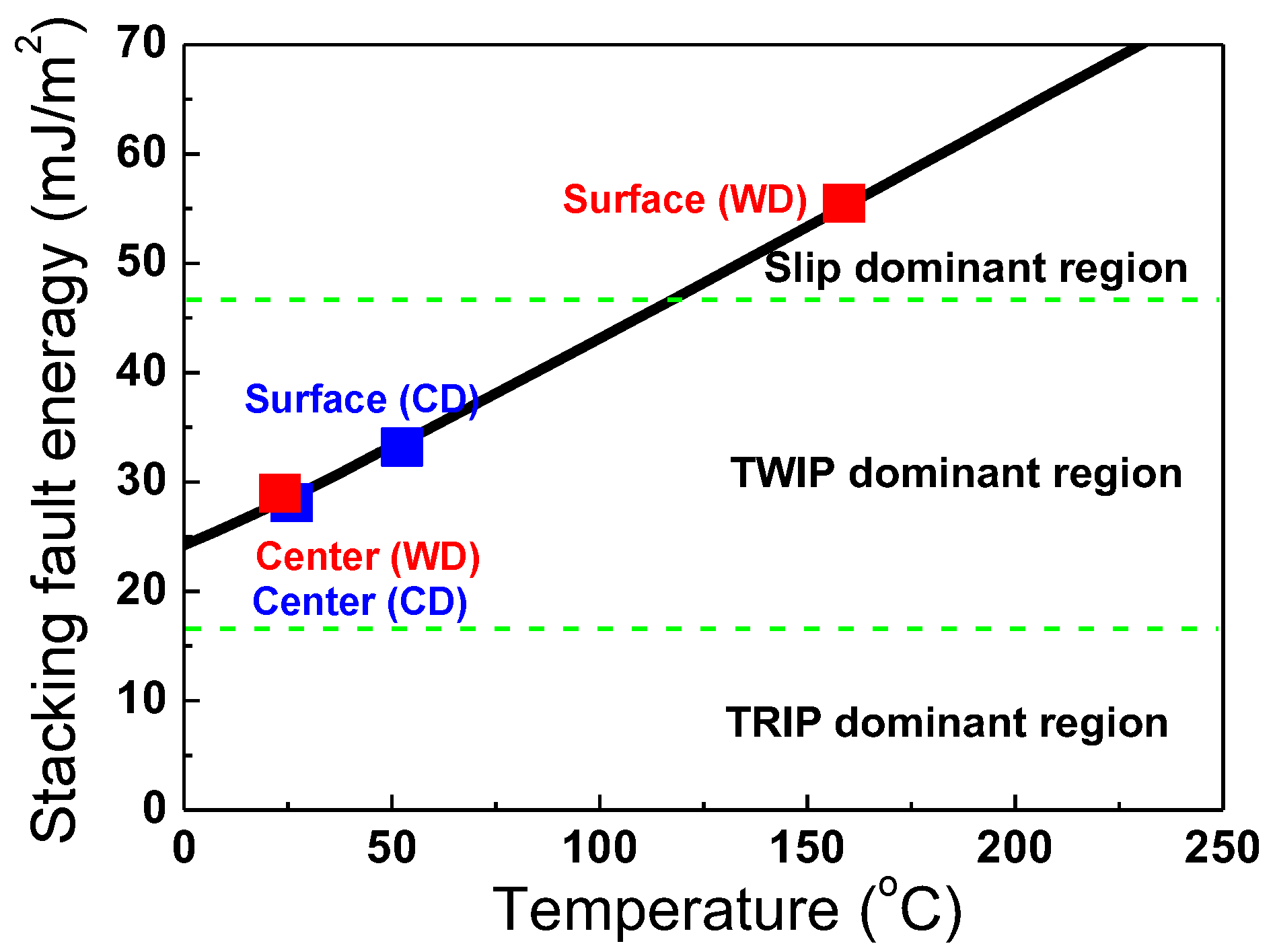

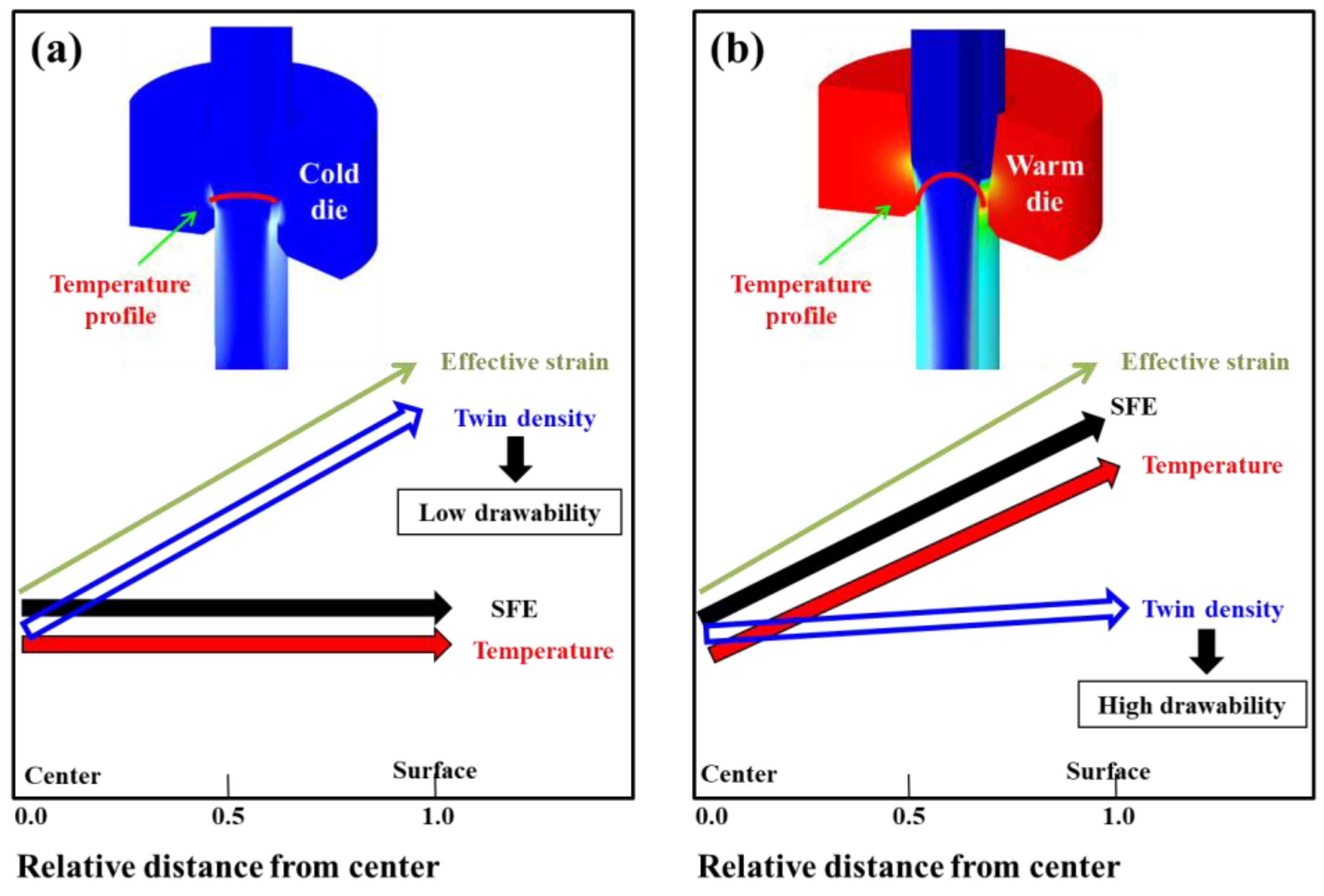

- Drawability as well as the homogeneity of the microstructure and mechanical properties in TWIP steel were improved using a temperature gradient along the radial direction of the wire using a WD of 400 °C. A higher temperature of about 300 °C at the surface region of the wire with the WD suppressed the twinning rate at the surface region owing to the increase in the SFE from 34 to 55 mJ/m2, leading to a uniform twinning rate along the wire’s radial direction compared with the CD wire, finally, resulting in an improvement of the microstructural homogeneity and drawability of the wire.

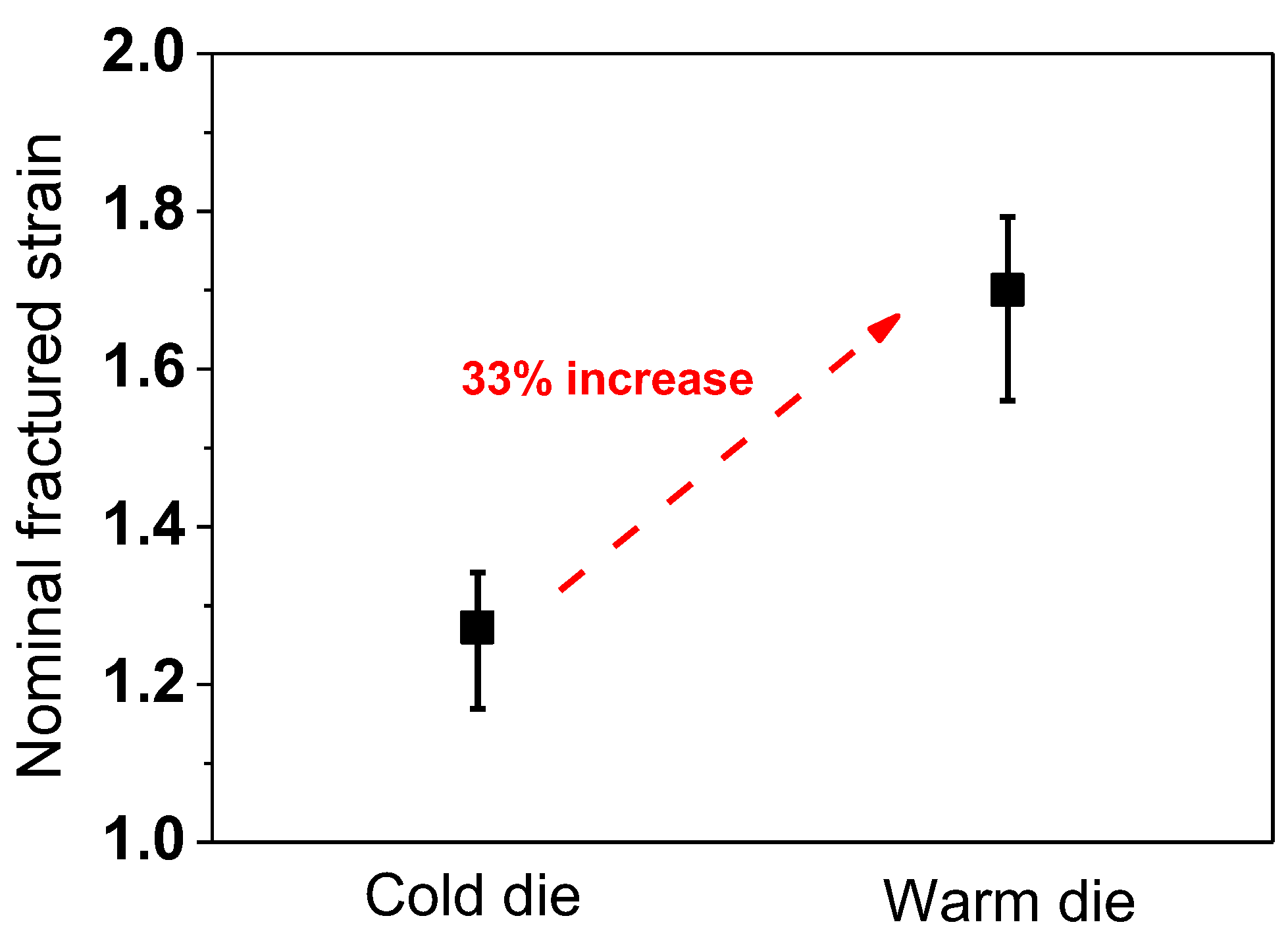

- The steel wire subjected to the WD process exhibited an approximately 33% higher drawability compared to that of the conventional CD process. However, the hardness of the WD wire slightly decreased compared to the CD wire.

- This die design concept can provide valuable insights for improving productivity in the wire drawing industry. In addition, the general conclusion was derived that controlling the SFE within an area of the workpiece by tailoring the temperature can improve the formability in TWIP steels during the plastic forming process.

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Nomenclature

| A | area of wire (mm2) |

| btwin | total length of twin boundary in measured area (mm) |

| cp | specific heat capacity (J/kg°C) |

| D | diameter of wire (mm) |

| k | thermal conductivity (W/m°C) |

| K | strain hardening coefficient (MPa) |

| Ld | deformation zone length (mm) |

| n | strain hardening exponent |

| Rmea | total measured area (mm2) |

| Rtwin | relative twin density (mm/mm2) |

| T | temperature (°C) |

| V | drawing speed (mm/s) |

| Greek symbols | |

| α | semi-die angle (°) |

| β | fraction factor between mechanical work and heat energy |

| ε | strain |

| strain rate (1/s) | |

| εN | nominal drawing strain |

| σ | stress (MPa) |

| ρ | density (kg/m3) |

| Subscript | |

| i | initial value of wire |

| f | final value of wire |

References

- Barbier, D.; Gey, N.; Allain, S.; Bozzolo, N.; Humbert, M. Analysis of the tensile behavior of a TWIP steel based on the texture and microstructure evolutions. Mater. Sci. Eng. A 2009, 500, 196–206. [Google Scholar] [CrossRef]

- De Cooman, B.C.; Estrin, Y.; Kim, S.K. Twinning-induced plasticity (TWIP) steels. Acta Mater. 2018, 142, 283–362. [Google Scholar] [CrossRef]

- Lee, Y.K. Microstructural evolution during plastic deformation of twinning-induced plasticity steels. Scr. Mater. 2012, 66, 1002–1006. [Google Scholar] [CrossRef]

- Dastur, Y.N.; Leslie, W.C. Mechanism of work hardening in Hadfield manganese steel. Metall. Trans. A 1981, 12, 749–759. [Google Scholar] [CrossRef]

- Luo, Z.C.; Huang, M.X. The role of interstitial carbon atoms on the strain-hardening rate of twinning-induced plasticity steels. Scr. Mater. 2020, 178, 264–268. [Google Scholar] [CrossRef]

- Kim, S.J.; Lee, T.; Hwang, J.K. High-strength bolt manufactured by an extrusion-based forming process using twinning-induced plasticity steel. J. Manuf. Process 2020, 59, 33–42. [Google Scholar] [CrossRef]

- Hwang, J.K.; Yi, I.C.; Son, I.H.; Yoo, J.Y.; Kim, B.; Zargaran, A.; Kim, N.J. Microstructural evolution and deformation behavior of twinning-induced plasticity (TWIP) steel during wire drawing. Mater. Sci. Eng. A 2015, 644, 41–52. [Google Scholar] [CrossRef]

- Wright, R.N. Wire Technology: Process Engineering and Metallurgy; Butterworth-Heinemann: Oxford, UK, 2011. [Google Scholar]

- Yang, F.; Ma, C.; Jiang, J.Q.; Feng, H.P.; Zhai, S.Y. Effect of cumulative strain on texture characteristics during wire drawing of eutectoid steels. Scr. Mater. 2008, 59, 850–853. [Google Scholar] [CrossRef]

- Allain, S.; Chateau, J.P.; Bouaziz, O.; Migot, S.; Guelton, N. Correlations between the calculated stacking fault energy and the plasticity mechanisms in Fe-Mn-C alloys. Mater. Sci. Eng. A 2004, 387–389, 158–4162. [Google Scholar] [CrossRef]

- Remy, L. Temperature variation of the intrinsic stacking fault energy of a high manganese austenitic steel. Acta Mater. 1997, 25, 173–179. [Google Scholar] [CrossRef]

- Saeed-Akbari, A.; Imlau, J.; Prahl, U.; Bleck, W. Derivation and variation in composition-dependent stacking fault energy maps based on subregular solution model in high-manganese steels. Metall. Mater. Trans. A 2009, 40, 3076–3090. [Google Scholar] [CrossRef]

- Dumay, A.; Chateau, J.P.; Allain, S.; Migot, S.; Bouaziz, O. Influence of addition elements on the stacking-fault energy and mechanical properties of an austenite Fe-Mn-C steel. Mater. Sci. Eng. A 2008, 483–484, 184–4187. [Google Scholar] [CrossRef]

- Curtze, S.; Kuokkala, V.T. Dependence of tensile deformation behavior of TWIP steels on stacking fault energy, temperature and strain rate. Acta Mater. 2010, 58, 5129–5141. [Google Scholar] [CrossRef]

- Bouaziz, O.; Allain, S.; Scott, C.P.; Cugy, P.; Barbier, D. High manganese austenitic twinning induced plasticity steels: A review of the microstructure properties relationships. Curr. Opin. Solid State Mater. Sci. 2011, 15, 141–168. [Google Scholar] [CrossRef]

- Yang, H.K.; Zhang, Z.J.; Dong, F.Y.; Duan, Q.Q.; Zhang, Z.F. Strain rate effects on tensile deformation behaviors for Fe-22Mn-0.6C-(1.5Al) twinning-induced plasticity steel. Mater. Sci. Eng. A 2014, 607, 551–558. [Google Scholar] [CrossRef]

- Haddi, A.; Imad, A.; Vega, G. Analysis of temperature and speed effects on the drawing stress for improving the wire drawing process. Mater. Des. 2011, 32, 4310–4315. [Google Scholar] [CrossRef]

- El-Domiaty, A.; Kassab, S.Z. Temperature rise in wire-drawing. J. Mater. Process. Technol. 1998, 83, 72–78. [Google Scholar] [CrossRef]

- Incropera, F.P.; Dewitt, D.P.; Bergman, T.L.; Lavine, A.S. Fundamentals of Heat and Mass Transfer, 7th ed.; John Wiley and Sons Ltd.: Chichester, UK, 2012. [Google Scholar]

- Chin, R.K.; Stelf, P.S. A computational study of strain inhomogeneity in wire drawing. Int. J. Mach. Tools Manuf. 1995, 35, 1087–1098. [Google Scholar] [CrossRef]

- Ghasri-Khouzani, M.; McDermid, J.R. Effect of carbon content on the mechanical properties and microstructure evolution of Fe-22Mn-C steels. Mater. Sci. Eng. A 2015, 621, 118–127. [Google Scholar] [CrossRef]

- Kim, J.K.; De Cooman, B.C. Stacking fault energy and deformation mechanisms in Fe-xMn-0.6C-yAl TWIP steel. Mater. Sci. Eng. A 2016, 676, 216–231. [Google Scholar] [CrossRef]

- Hasani, G.H.; Mahmudi, R.; Karimi-Taheri, A. On the strain inhomogeneity in drawn copper wires. Int. J. Mater. Form. 2010, 3, 59–64. [Google Scholar] [CrossRef]

- Moon, C.; Kim, N. Analysis of wire-drawing process with friction and thermal conditions obtained by inverse engineering. J. Mech. Sci. Technol. 2012, 26, 2903–2911. [Google Scholar] [CrossRef]

- Hwang, J.K. Effect of Plastic Deformation on Thermal Properties in Twinning-Induced Plasticity Steel. Materials 2024, 17, 5263. [Google Scholar] [CrossRef]

- Felder, E.; Levrau, C.; Mantel, M.; Truong Dinh, N.G. Identification of the work of plastic deformation and the friction shear stress in wire drawing. Wear 2012, 286–287, 27–34. [Google Scholar] [CrossRef]

- Avitzur, B. Analysis of wire drawing and extrusion through conical dies of large cone angle. J. Eng. Ind. 1964, 86, 305–314. [Google Scholar] [CrossRef]

- Hwang, J.K. Significantly Enhanced Strength of a Drawn Twinning-Induced Plasticity Steel Wire and its Deformation Twinning Dependency. J. Mater. Eng. Perform. 2023, 32, 117–134. [Google Scholar] [CrossRef]

- Saleh, A.A.; Pereloma, E.V.; Gazder, A.A. Texture evolution of cold rolled and annealed Fe-24Mn-3Al-2Si-1Ni-0.06C TWIP steel. Mater. Sci. Eng. A 2011, 528, 4537–4549. [Google Scholar] [CrossRef]

- Saleh, A.A.; Gazder, A.A.; Pereloma, E.V. EBSD observations of recrystallisation and tensile deformation in twinning induced plasticity steel. Trans. Indian Inst. Met. 2013, 66, 621–629. [Google Scholar] [CrossRef]

- Badji, R.; Chauveau, T.; Bacroix, B. Texture, misorientation and mechanical anisotropy in a deformed dual phase stainless steel weld joint. Mater. Sci. Eng. A 2013, 575, 94–103. [Google Scholar] [CrossRef]

- Chen, L.; Kim, H.S.; Kim, S.K.; DeCooman, B.C. Localized deformation due to Portevin-LeChatelier effect in 18Mn-0.6C TWIP austenitic steel. ISIJ Int. 2007, 47, 1804–1812. [Google Scholar] [CrossRef]

- Qian, L.; Guo, P.; Zhang, F.; Meng, J.; Zhang, M. Abnormal room temperature serrated flow and strain rate dependence of critical strain of a Fe-Mn-C twin-induced plasticity steel. Mater. Sci. Eng. A 2013, 561, 266–269. [Google Scholar] [CrossRef]

- Zambrano, O.A. Stacking Fault Energy Maps of Fe–Mn–Al–C–Si Steels: Effect of Temperature, Grain Size, and Variations in Compositions. J. Eng. Mater. Technol. 2016, 138, 041010. [Google Scholar] [CrossRef]

- Xu, Q.; Peng, Z.; Zhu, J.; Li, M.; Zong, Y.; Yan, L.; Li, C.; Peng, K.; Cheng, Z.; Liu, J. The effect of drawing deformation rate induced inhomogeneous local distortion on phase transformation of 304H stainless wire. Metals 2020, 10, 1304. [Google Scholar] [CrossRef]

- Hwang, J.K. Influence of strain hardening rate of material on temperature and strain distributions during wire drawing. Materials 2023, 16, 5203. [Google Scholar] [CrossRef] [PubMed]

- Kemp, I.P.; Pollard, G.; Bramley, A.N. Temperature distributions in the high speed drawing of high strength steel wire. Int. J. Mech. Sci. 1985, 27, 803–811. [Google Scholar] [CrossRef]

- Vega, G.; Haddi, A.; Imad, A. Investigation of process parameters effect on the copper-wire drawing. Mater. Des. 2009, 30, 3308–3312. [Google Scholar] [CrossRef]

- Bache, M.R.; Evans, W.J. Impact of texture on mechanical properties in an advanced titanium alloy. Mater. Sci. Eng. A 2001, 319–321, 409–414. [Google Scholar] [CrossRef]

- Gonela, K.K.; Vijayavarman, C.; Palanivel, M.; Mariappan, L.; Ramasubramanian, L.N.; Kannan, A.R. Effect of robotic weaving motion on mechanical and microstructural characteristics of wire arc additively manufactured NiTi shape memory alloy. Int. J. Mater. Res. 2023, 114, 947–954. [Google Scholar] [CrossRef]

- Kibey, S.; Liu, J.B.; Johnson, D.D.; Sehitoglu, H. Energy pathways and directionality in deformation twinning. Appl. Phys. Lett. 2007, 91, 181916. [Google Scholar] [CrossRef]

- Karaman, I.; Sehitoglu, H.; Beaudoin, A.; Chumlyakov, Y.I.; Maier, H.J.; Tome, C.N. Modeling the deformation behavior of Hadfield steel single and polycrystals due to twinning and slip. Acta Mater. 2000, 48, 2031–2047. [Google Scholar] [CrossRef]

- Yang, P.; Xie, Q.; Meng, L.; Ding, H.; Tang, Z. Dependence of deformation twinning on grain orientation in a high manganese steel. Scr. Mater. 2006, 55, 629–631. [Google Scholar] [CrossRef]

- Meng, L.; Yang, P.; Xie, Q.; Ding, H.; Tang, Z. Dependence of deformation twinning on grain orientation in compressed high manganese steels. Scr. Mater. 2007, 56, 931–934. [Google Scholar] [CrossRef]

- Chin, K.G.; Kang, C.Y.; Shin, S.Y.; Hong, S.; Lee, S.; Kim, H.S.; Kim, K.; Kim, N.J. Effects fo Al addition on deformation and fracture mechanisms in two high manganese TWIP steels. Mater. Sci. Eng. A 2011, 528, 2922–2928. [Google Scholar] [CrossRef]

- Renard, K.; Jacques, P.J. On the relationship between work hardening and twinning rate inTWIP steels. Mater. Sci. Eng. A 2012, 542, 8–14. [Google Scholar] [CrossRef]

| Chemical Composition (wt.%) | SFE (mJ/m2) | |||

|---|---|---|---|---|

| C | Mn | Al | Fe | |

| 0.91 | 19.9 | 1.02 | Balance | 29.5 |

| Number of Pass | Diameter (mm) | Die Angle (°) | RA Per Pass (%) | RA in Total (%) | Nominal Drawing Strain | Initial Die Temperature (°C) | |

|---|---|---|---|---|---|---|---|

| CD Process | WD Process | ||||||

| - | 13.00 | - | - | 0 | 0 | - | - |

| 1 | 11.63 | 12 | 19.97 | 19.97 | 0.22 | 26 | 400 |

| 2 | 10.40 | 12 | 20.03 | 36.00 | 0.45 | 26 | 400 |

| 3 | 9.30 | 12 | 20.04 | 48.82 | 0.67 | 26 | 400 |

| 4 | 8.32 | 12 | 19.96 | 59.04 | 0.89 | 26 | 400 |

| 5 | 7.44 | 12 | 20.04 | 67.25 | 1.17 | 26 | 400 |

| 6 | 6.66 | 12 | 19.87 | 73.75 | 1.34 | 26 | 400 |

| 7 | 5.95 | 12 | 20.18 | 79.05 | 1.56 | 26 | 400 |

| 8 | 5.30 | 12 | 20.66 | 83.38 | 1.79 | 26 | 400 |

| 9 | 4.75 | 12 | 19.68 | 86.65 | 2.01 | 26 | 400 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hwang, J.-K. Improved Wire Quality of Twinning-Induced Plasticity Steel During Wire Drawing Through Temperature Gradient with Warm Die. Materials 2025, 18, 1209. https://doi.org/10.3390/ma18061209

Hwang J-K. Improved Wire Quality of Twinning-Induced Plasticity Steel During Wire Drawing Through Temperature Gradient with Warm Die. Materials. 2025; 18(6):1209. https://doi.org/10.3390/ma18061209

Chicago/Turabian StyleHwang, Joong-Ki. 2025. "Improved Wire Quality of Twinning-Induced Plasticity Steel During Wire Drawing Through Temperature Gradient with Warm Die" Materials 18, no. 6: 1209. https://doi.org/10.3390/ma18061209

APA StyleHwang, J.-K. (2025). Improved Wire Quality of Twinning-Induced Plasticity Steel During Wire Drawing Through Temperature Gradient with Warm Die. Materials, 18(6), 1209. https://doi.org/10.3390/ma18061209