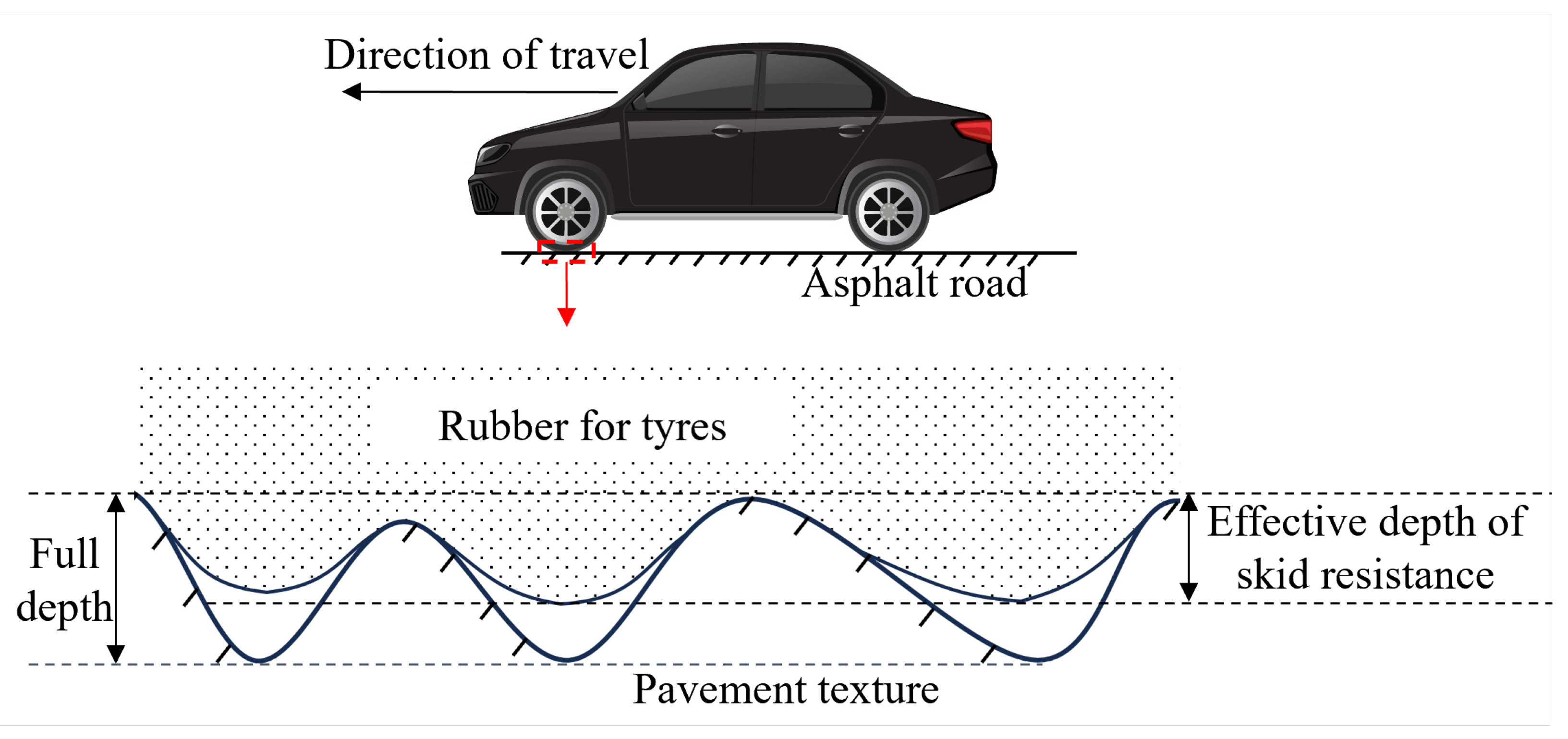

The Effective Depth of Skid Resistance (EDSR): A Novel Approach to Detecting Skid Resistance in Asphalt Pavements

Abstract

1. Introduction

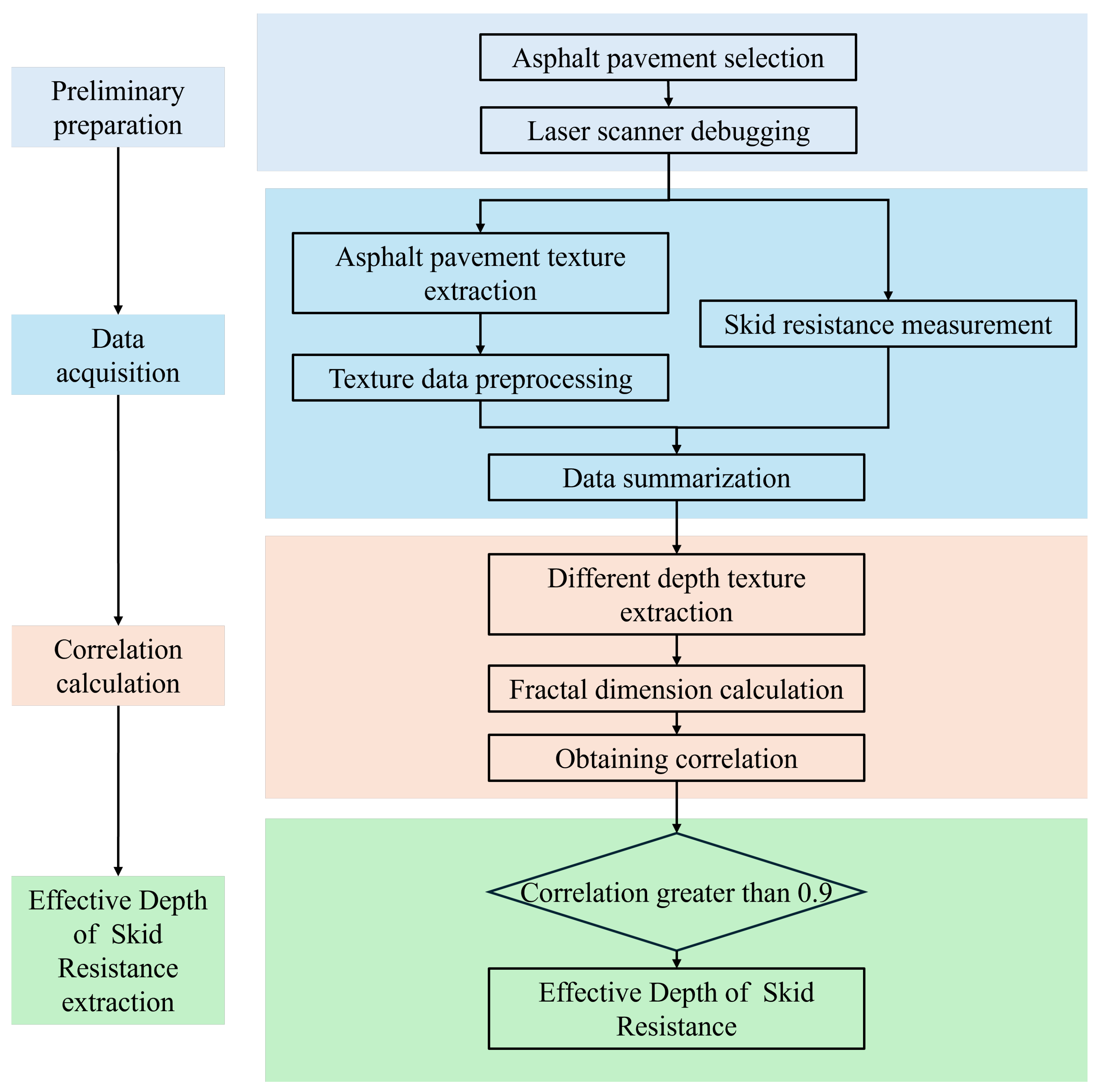

2. Materials and Methods

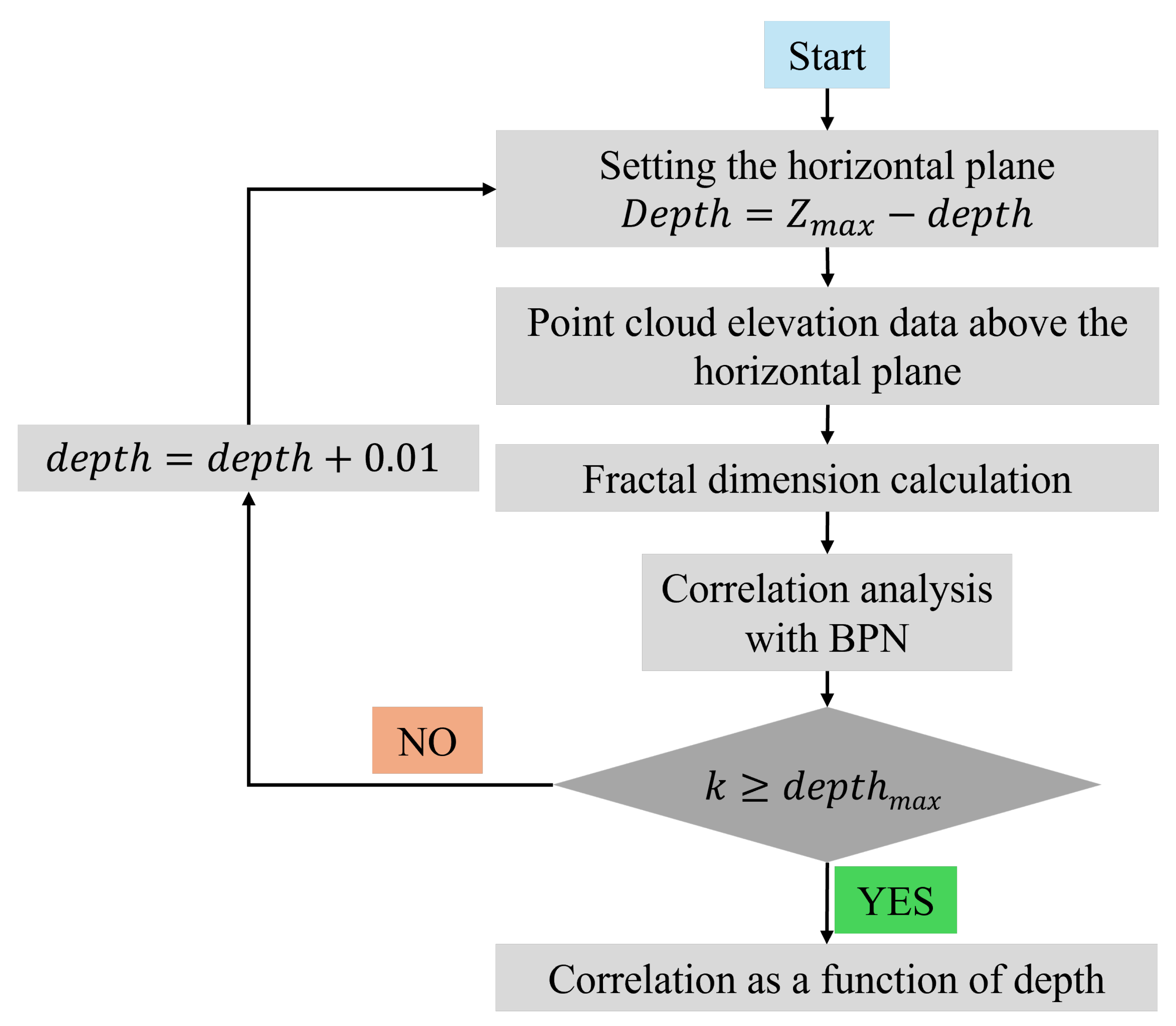

2.1. Framework

2.2. Field Pavement Selection

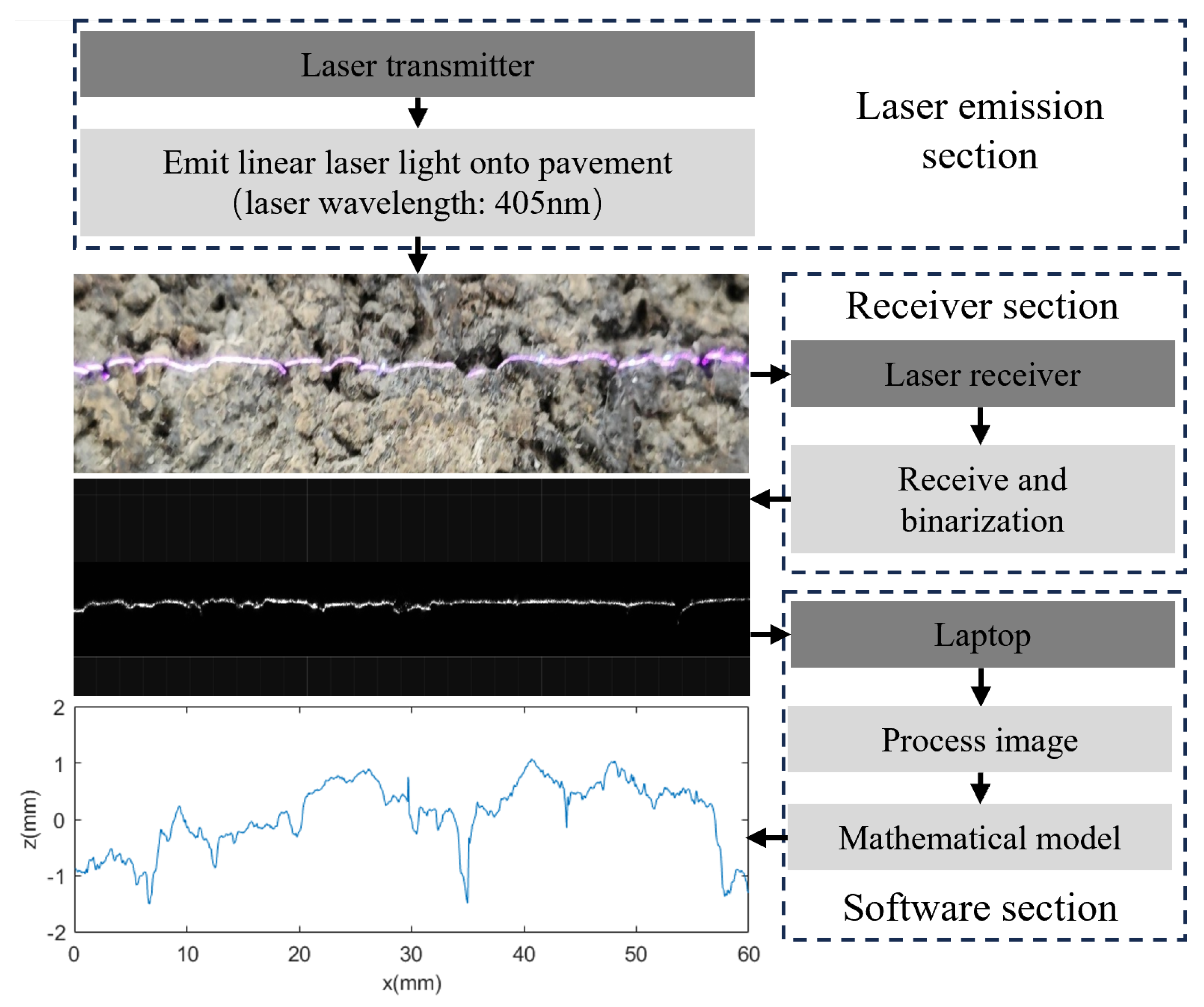

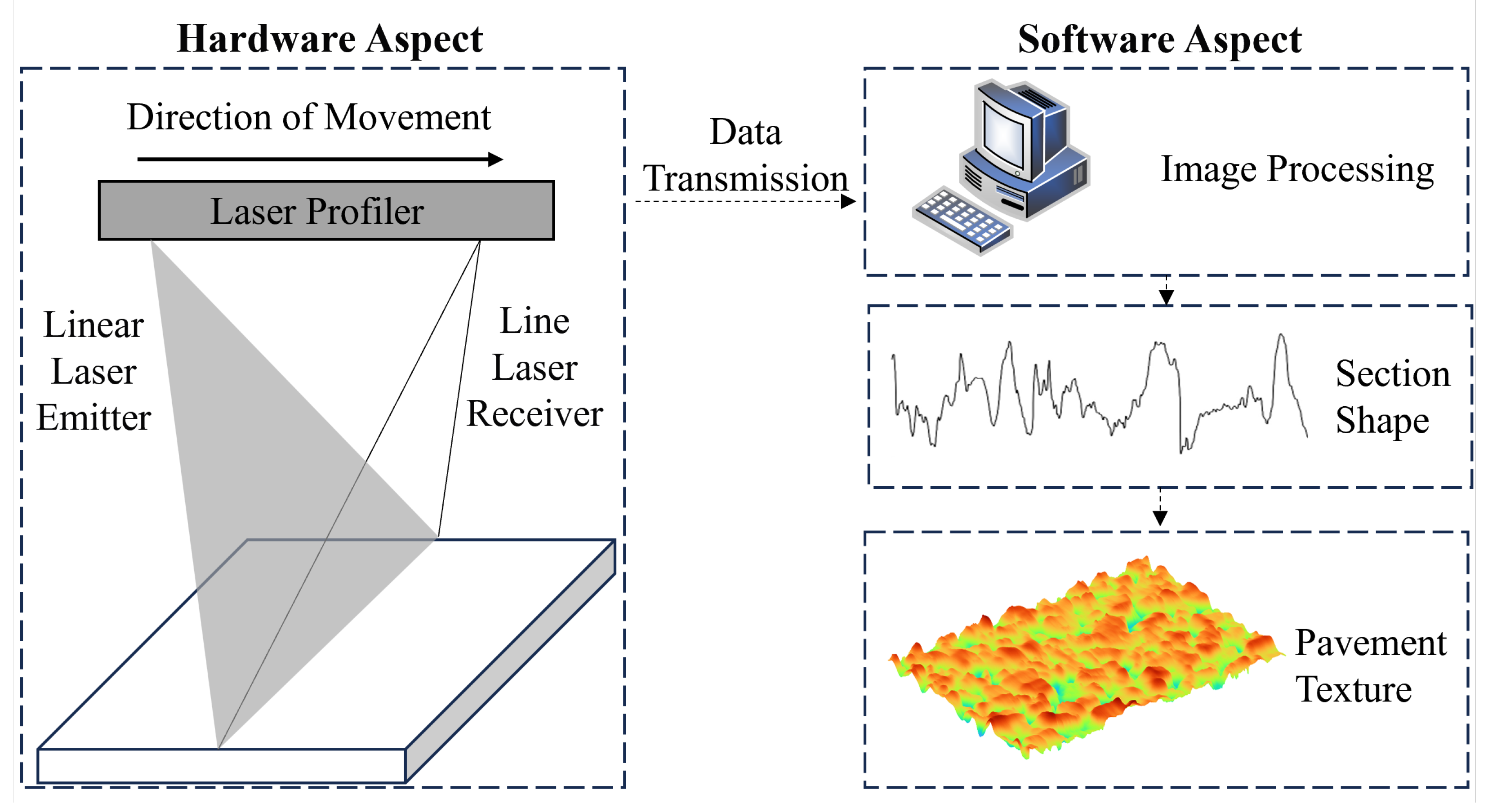

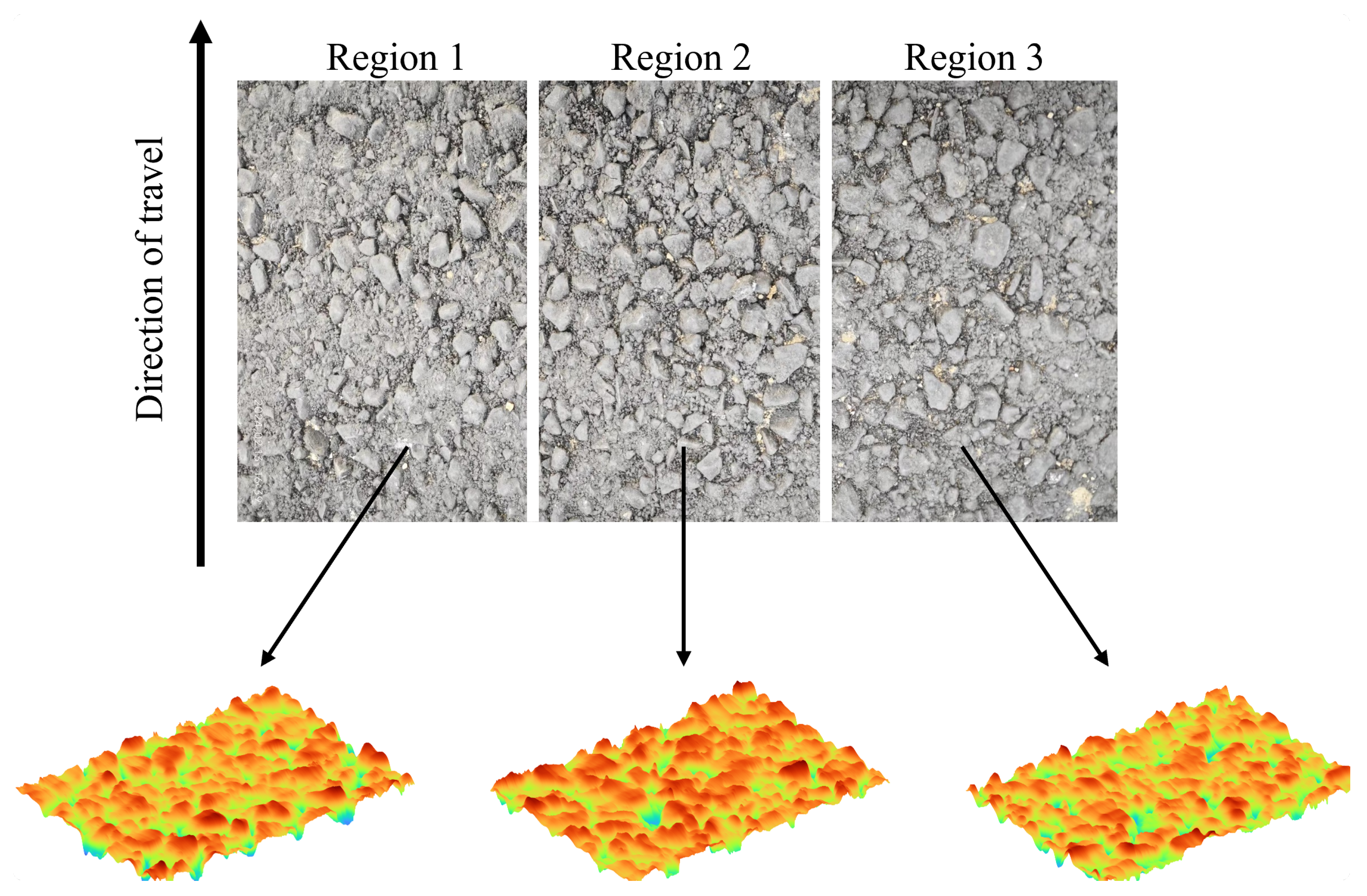

2.3. Pavement Texture Acquisition

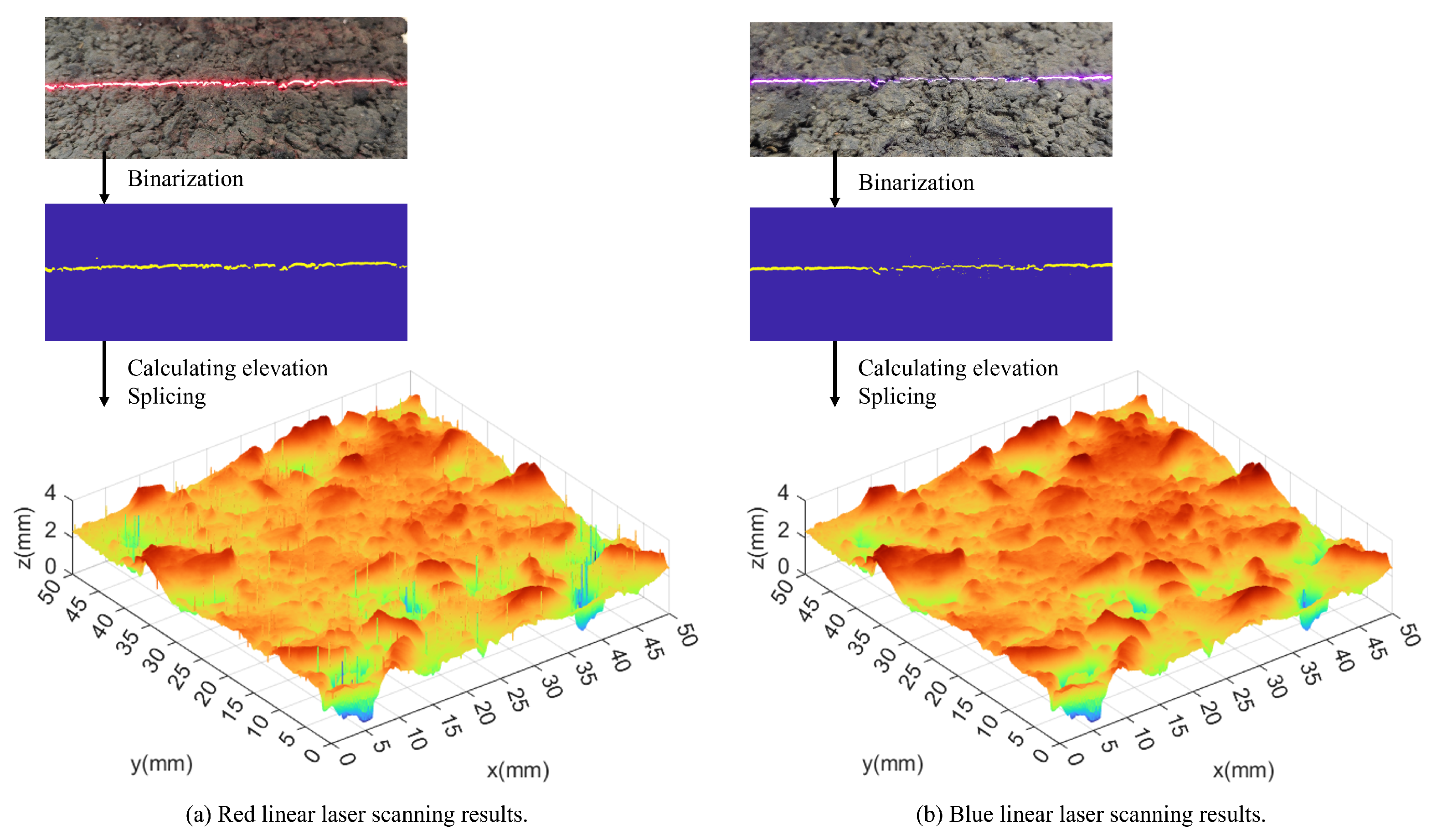

2.4. Linear Laser Selection

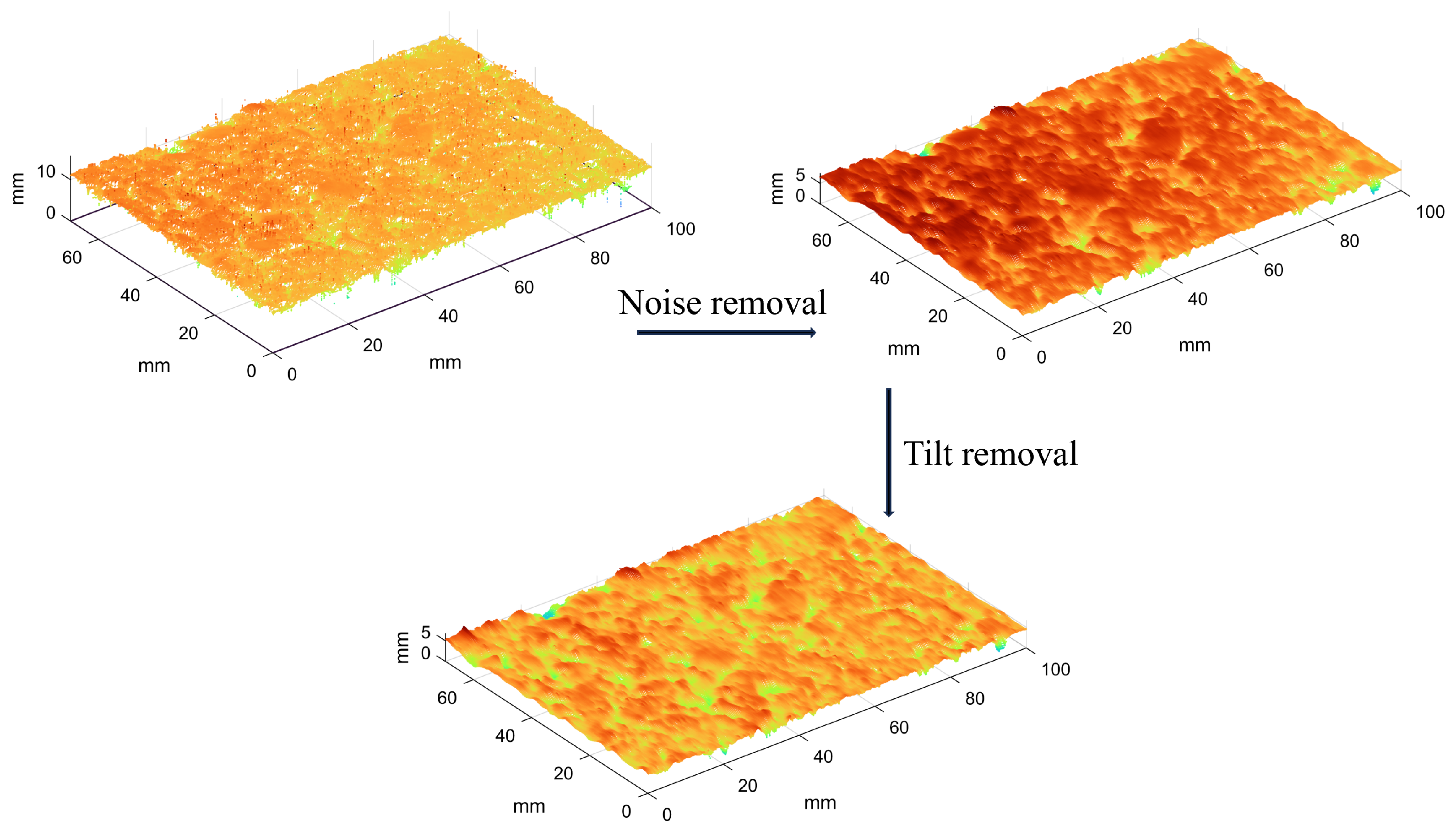

2.5. Pre-Processing of Pavement Texture Data

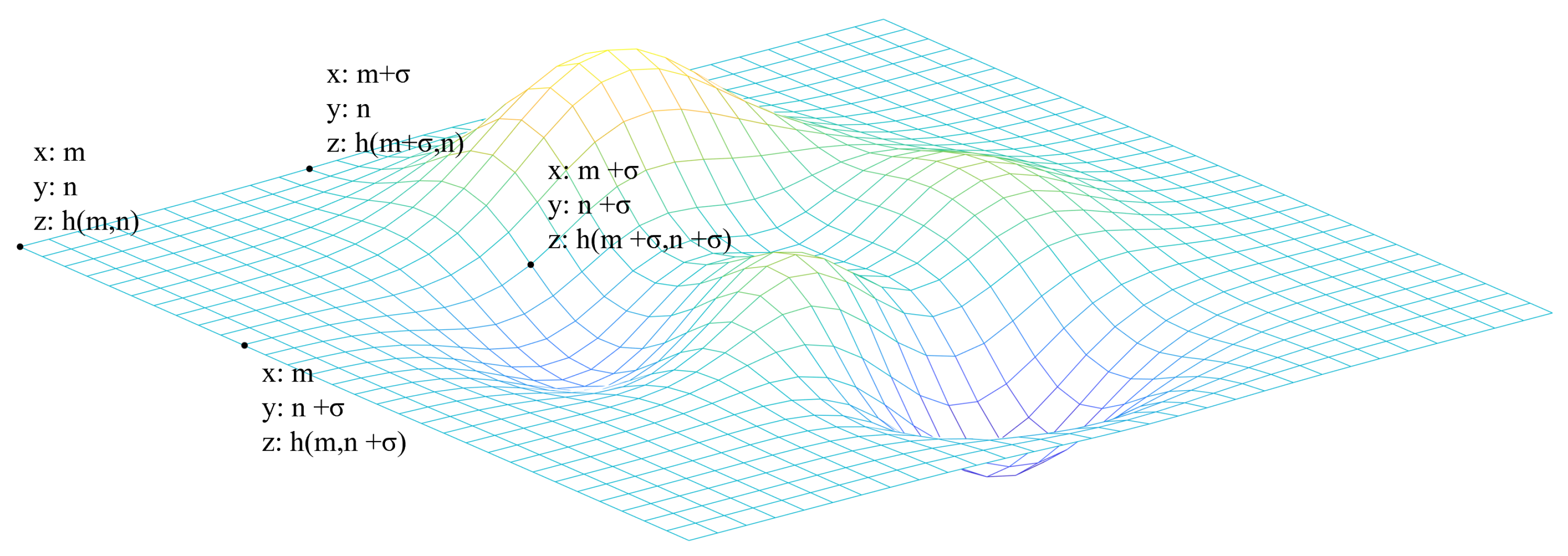

2.6. Fractal Dimension Calculation

3. Results

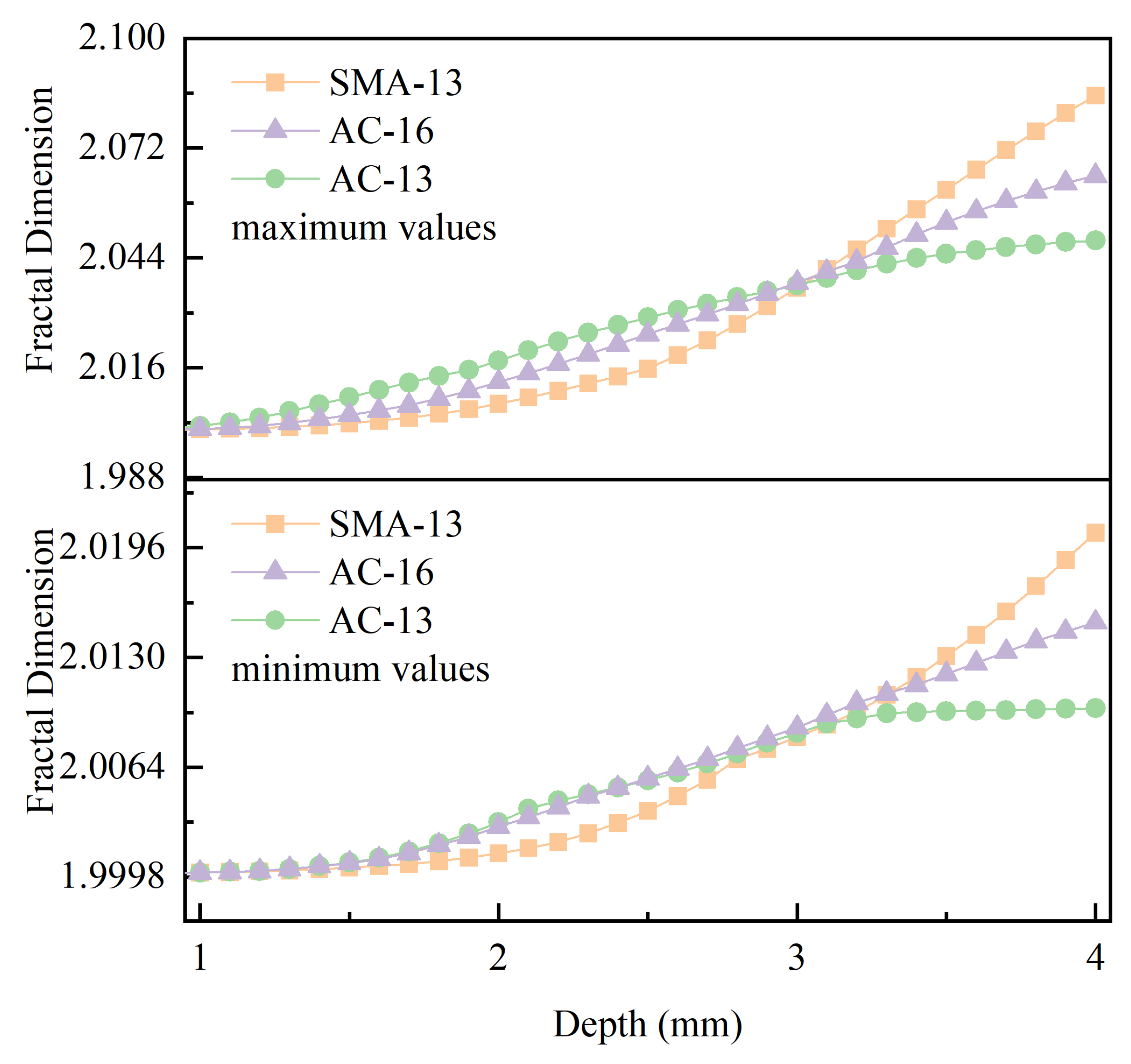

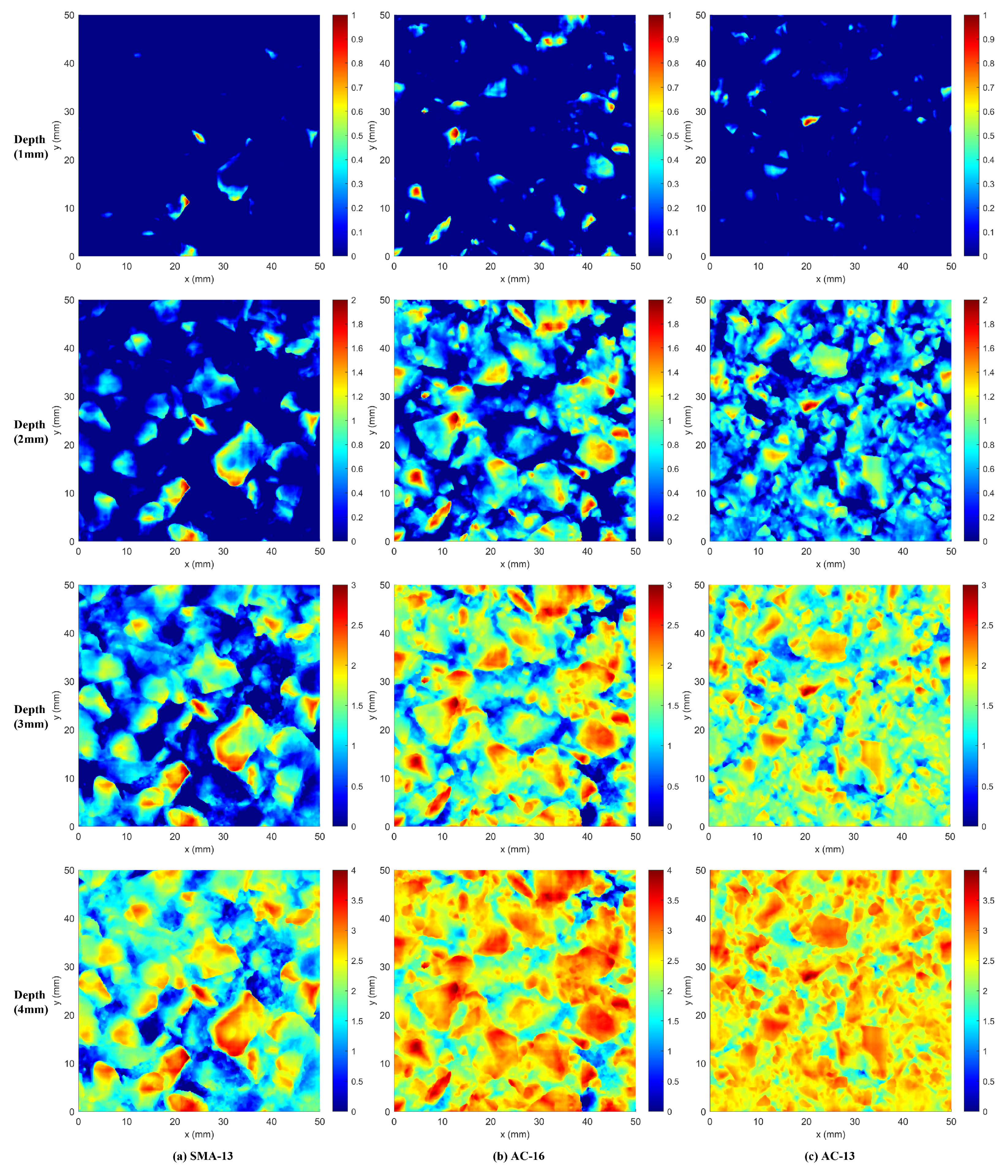

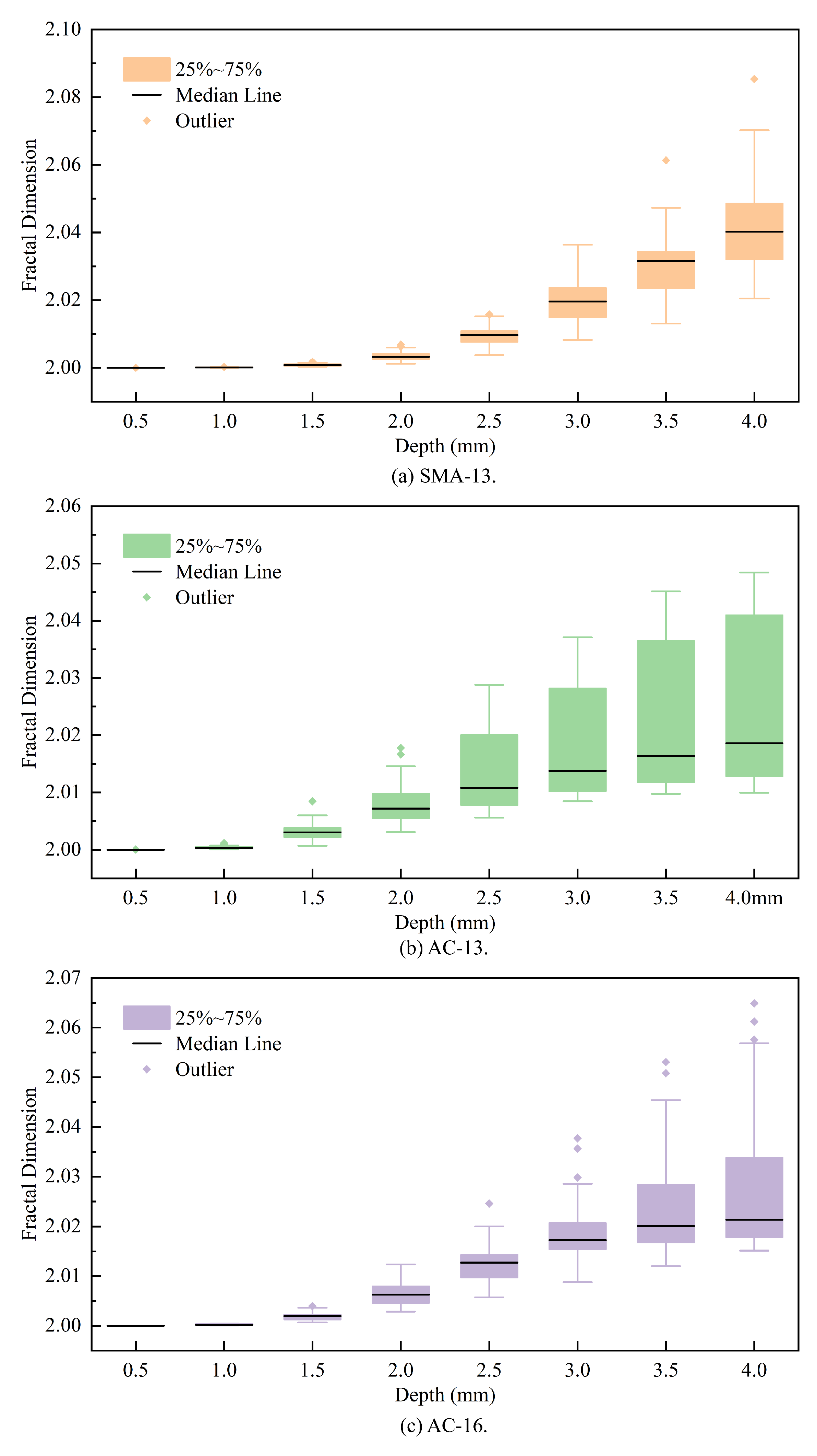

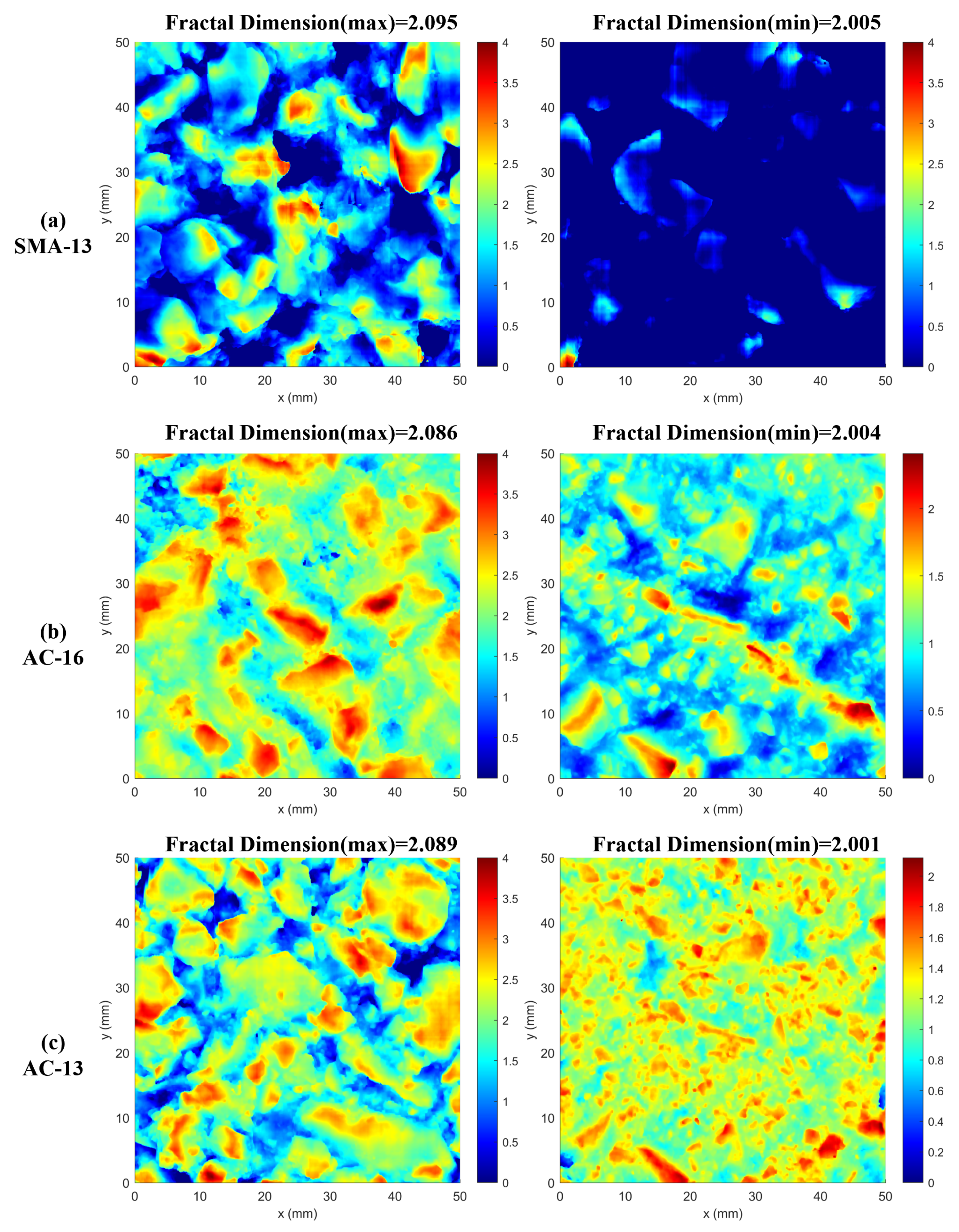

3.1. Fractal Dimensions at Different Depths

3.2. Pavement Texture Analysis

3.3. Abnormal Data Removal

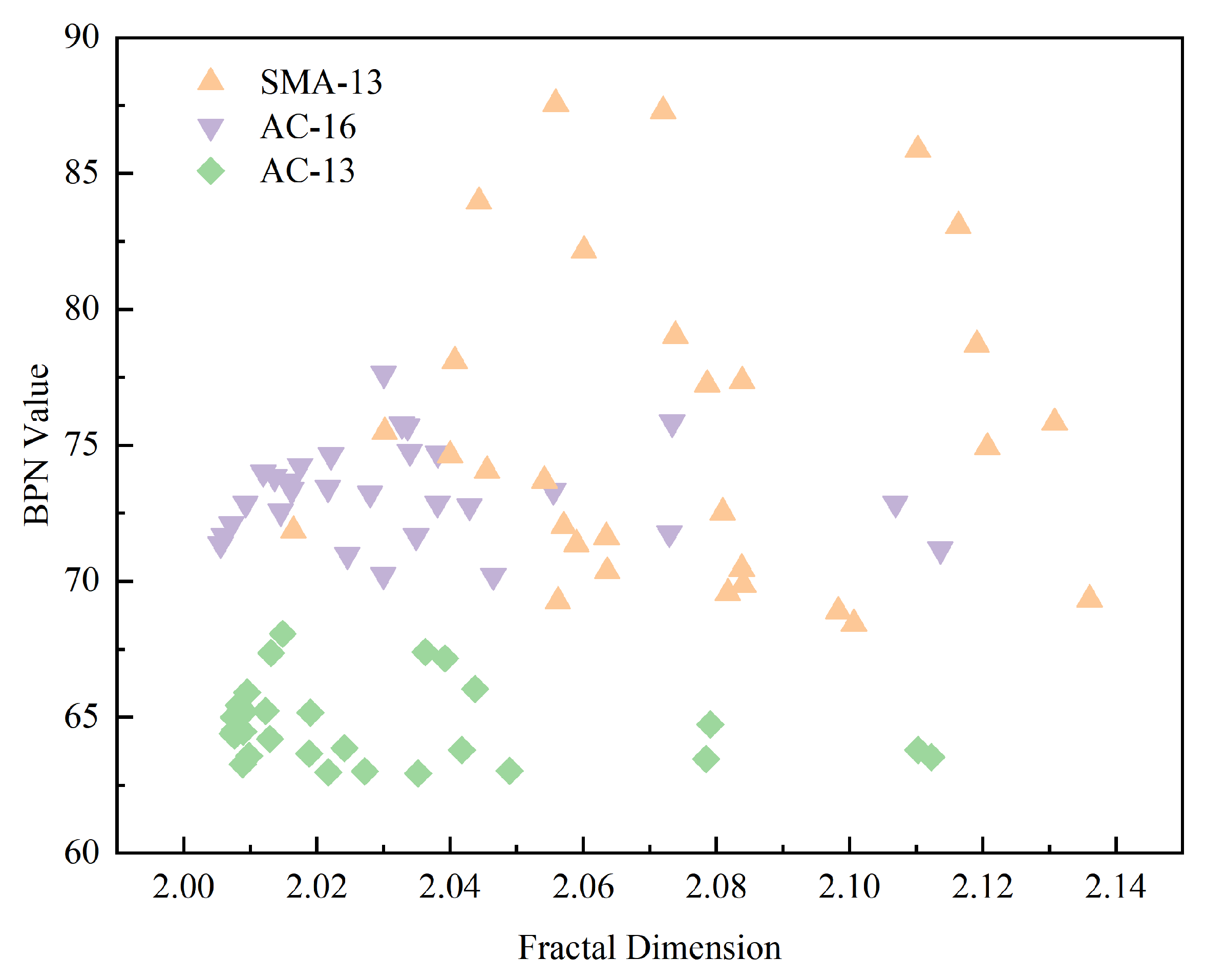

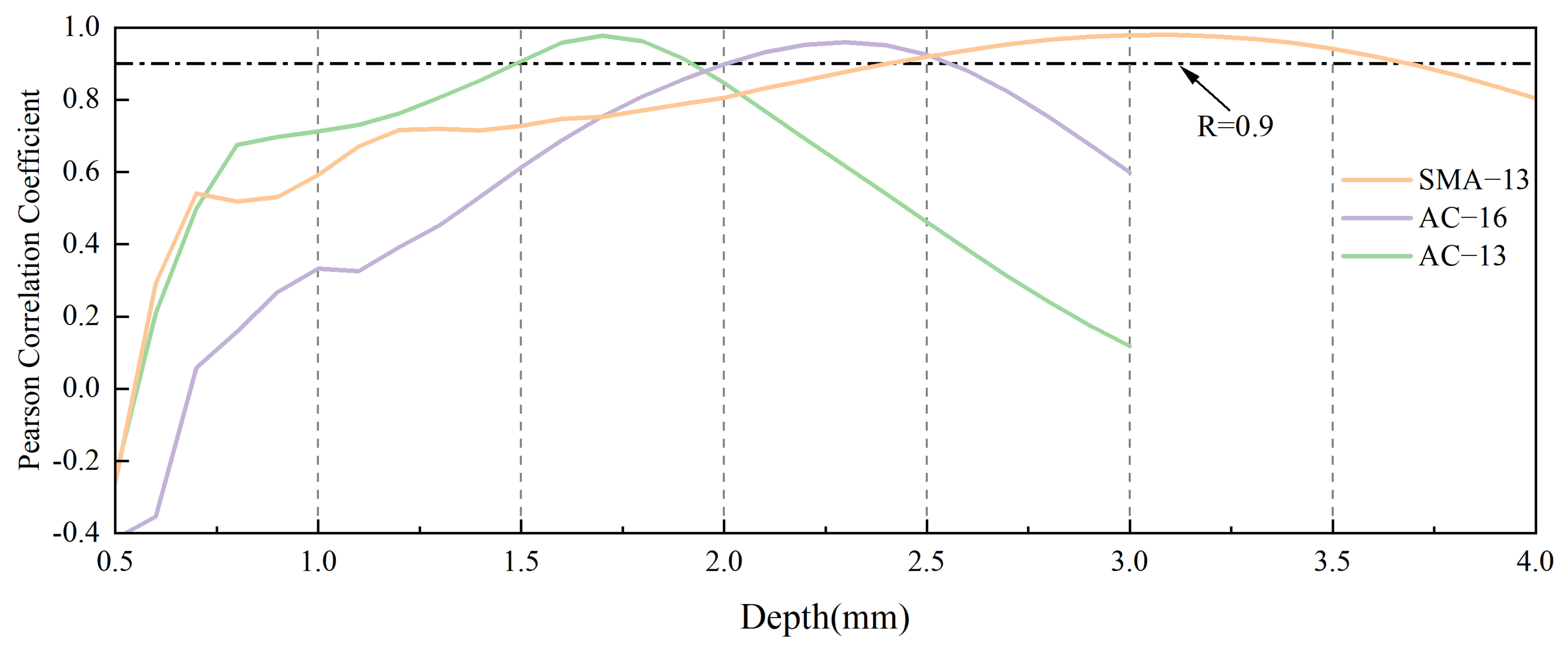

3.4. Correlation Analysis Between Textural Fractal Dimension and Pavement Friction

3.5. Validation of Skid Resistance Model

4. Conclusions

- The research found that the fractal dimension of asphalt pavement serves as an effective indicator of the pavement’s overall roughness. However, no significant correlation was observed between the fractal dimension and the pavement’s skid resistance performance. Considering this finding, the concept of the “EDSR (Effective Depth of Skid Resistance)” was introduced to better understand and quantify the depth at which pavement surface characteristics contribute most effectively to skid resistance.

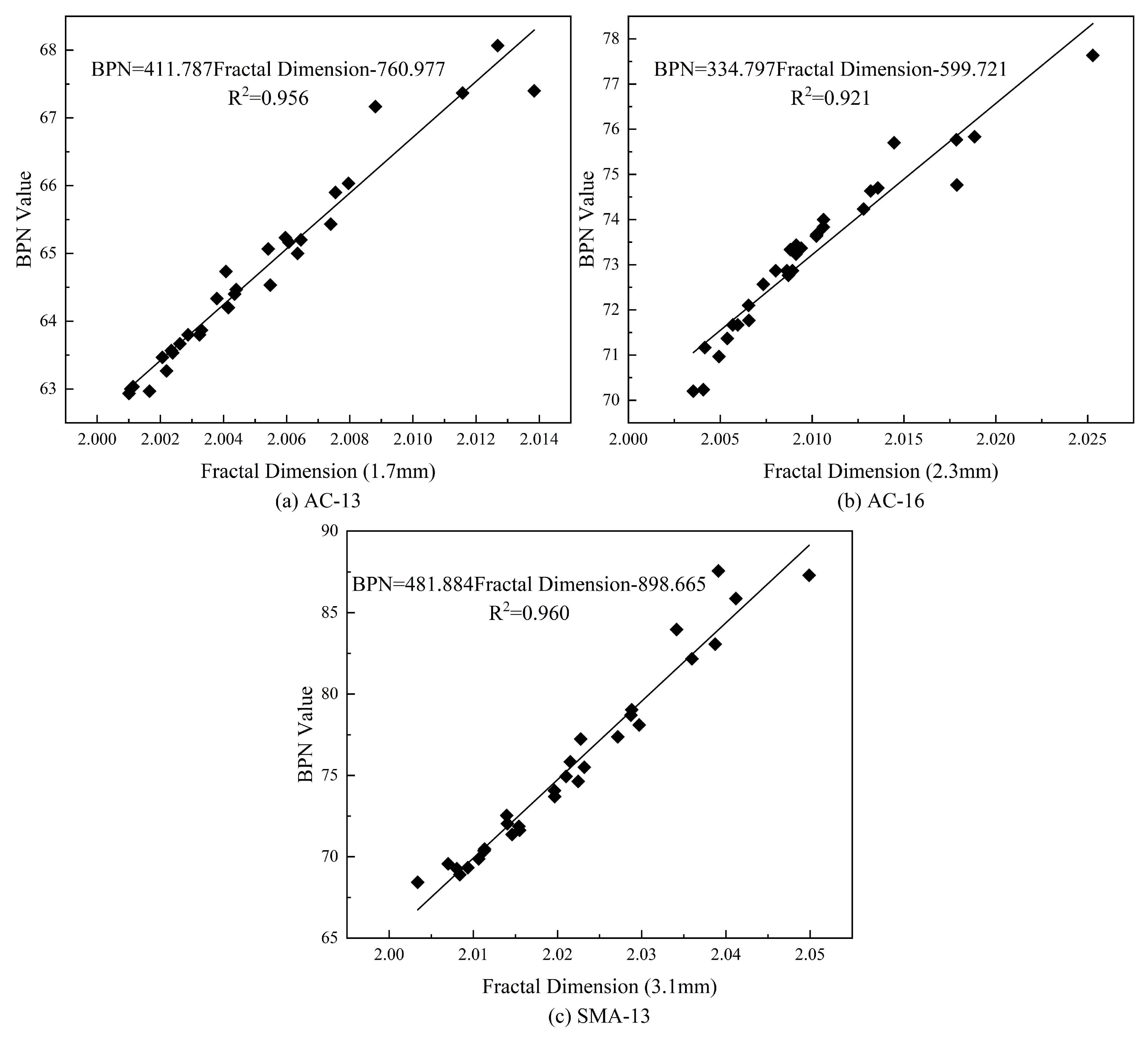

- Through an analytical approach that assessed the relationship between pavement fractal dimensions at different depths and the BPN values, this research pinpointed the EDSR ranges for various asphalt wearing courses with different aggregate grain sizes. For dense-graded AC-13, the interval of pronounced correlation is confined between 1.5 mm and 1.8 mm, while for AC-16, it spans from 2.0 mm to 2.6 mm. Open-graded SMA-13 reveals a strong correlation within a deeper range of 2.4 mm to 3.6 mm.

- The linear regression analysis of fractal dimensions and BPN values for AC-13, AC-16, and SMA-13 asphalt pavements, conducted at the depths that contribute most to skid resistance, yielded R2 values of 0.956, 0.921, and 0.960, respectively.

- This study aimed to create a reliable theoretical model for predicting asphalt pavement skid resistance. Validated against real-world data, our model demonstrated over 80% accuracy in all instances.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhong, J.; Zhang, J.; Huang, K.; Blankenship, P.; Ma, Y.; Xiao, R.; Huang, B. An investigation of texture-friction relationship with laboratory ring-shaped asphalt mixture specimens via close-range photogrammetry. Constr. Build. Mater. 2024, 442, 137508. [Google Scholar] [CrossRef]

- Luo, H.; Chen, S.; Zheng, Y.; Wu, X.; Chen, C.; Huang, X. Improving skid-resistance durability of ultra-thin friction course in asphalt pavements through recycled steel slags as basalt replacements. Constr. Build. Mater. 2024, 426, 136138. [Google Scholar] [CrossRef]

- He, C.; Jiang, W.; Wang, T.; Yuan, D.; Sha, A. The evolution of tire-road wear particles and road surface texture under rolling friction. Constr. Build. Mater. 2024, 447, 138167. [Google Scholar] [CrossRef]

- Kogbara, R.B.; Masad, E.A.; Kassem, E.; Scarpas, A.T.; Anupam, K. A state-of-the-art review of parameters influencing measurement and modeling of skid resistance of asphalt pavements. Constr. Build. Mater. 2016, 114, 602–617. [Google Scholar] [CrossRef]

- Qian, G.; Wang, Z.; Yu, H.; Shi, C.; Zhang, C.; Ge, J.; Dai, W. Research on surface texture and skid resistance of asphalt pavement considering abrasion effect. Case Stud. Constr. Mater. 2024, 20, e02949. [Google Scholar] [CrossRef]

- Dong, S.; Han, S.; Zhang, Q.; Han, X.; Zhang, Z.; Yao, T. Three-dimensional evaluation method for asphalt pavement texture characteristics. Constr. Build. Mater. 2021, 287, 122966. [Google Scholar] [CrossRef]

- Ding, S.; Wang, K.C.P.; Yang, E.; Zhan, Y. Influence of effective texture depth on pavement friction based on 3D texture area. Constr. Build. Mater. 2021, 287, 123002. [Google Scholar] [CrossRef]

- Reichert, J. Surface Characteristics of Roadways: International Research and Technologies. In Proceedings of the First International Symposium on Surface Characteristics, State College, PA, USA, 8–9 June 1988. [Google Scholar]

- Puzzo, L.; Loprencipe, G.; Tozzo, C.; D’Andrea, A. Three-dimensional survey method of pavement texture using photographic equipment. Measurement 2017, 111, 146–157. [Google Scholar] [CrossRef]

- Dong, S.; Han, S.; Luo, Y.; Han, X.; Xu, O. Evaluation of tire-pavement noise based on three-dimensional pavement texture characteristics. Constr. Build. Mater. 2021, 306, 124935. [Google Scholar] [CrossRef]

- Khasawneh, M.A.; Alsheyab, M.A. Effect of nominal maximum aggregate size and aggregate gradation on the surface frictional properties of hot mix asphalt mixtures. Constr. Build. Mater. 2020, 244, 118355. [Google Scholar] [CrossRef]

- Fernlund, J.M.R. Image analysis method for determining 3-D shape of coarse aggregate. Cem. Concr. Res. 2005, 35, 1629–1637. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Gao, S.; Liu, S.; Gephart, N.C. Pavement texture from high-speed laser for pavement management system. Int. J. Pavement Eng. 2013, 14, 697–705. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Gao, S. Evaluation of pavement skid resistance using high speed texture measurement. J. Traffic Transp. Eng. Engl. Ed. 2015, 2, 382–390. [Google Scholar] [CrossRef]

- Meegoda, J.N.; Rowe, G.M.; Jumikis, A.A. Estimation of Surface Macrotexture in Hot Mix Asphalt Concrete Pavements Using Laser Texture Data. J. Test. Eval. 2005, 33, 262–265. [Google Scholar] [CrossRef]

- Yu, M.; You, Z.; Wu, G.; Kong, L.; Liu, C.; Gao, J. Measurement and modeling of skid resistance of asphalt pavement: A review. Constr. Build. Mater. 2020, 260, 119878. [Google Scholar] [CrossRef]

- Chen, S.; Liu, X.; Luo, H.; Yu, J.; Chen, F.; Zhang, Y.; Ma, T.; Huang, X. A state-of-the-art review of asphalt pavement surface texture and its measurement techniques. J. Road Eng. 2022, 2, 156–180. [Google Scholar] [CrossRef]

- Hong, S.J.; Park, S.W.; Lee, S.W. Tire-Pavement Noise Prediction using Asphalt Pavement Texture. KSCE J. Civ. Eng. 2018, 22, 3358–3362. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, T.; Liu, C.; Chen, Z. Research on skid resistance of asphalt pavement based on three-dimensional laser-scanning technology and pressure-sensitive film. Constr. Build. Mater. 2014, 69, 49–59. [Google Scholar] [CrossRef]

- Chen, B.; Zhang, X.; Yu, J.; Wang, Y. Impact of contact stress distribution on skid resistance of asphalt pavements. Constr. Build. Mater. 2017, 133, 330–339. [Google Scholar] [CrossRef]

- Zong, Y.; Xiong, R.; Wang, Z.; Zhang, B.; Tian, Y.; Sheng, Y.; Xie, C.; Wang, H.; Yan, X. Effect of morphology characteristics on the polishing resistance of coarse aggregates on asphalt pavement. Constr. Build. Mater. 2022, 341, 127755. [Google Scholar] [CrossRef]

- Gao, L.; de Fortier Smit, A.; Prozzi, J.A.; Buddhavarapu, P.; Murphy, M.; Song, L. Milled pavement texturing to optimize skid improvements. Constr. Build. Mater. 2015, 101, 602–610. [Google Scholar] [CrossRef]

- Wang, H.; Wang, C.; Bu, Y.; You, Z.; Yang, X.; Oeser, M. Correlate aggregate angularity characteristics to the skid resistance of asphalt pavement based on image analysis technology. Constr. Build. Mater. 2020, 242, 118150. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, H.; Chi, M.; Xu, Z.; Xu, G. Experimental investigation on wear behavior of asphalt pavement based on three-dimensional surface texture scan technology. Constr. Build. Mater. 2024, 412, 134851. [Google Scholar] [CrossRef]

- Li, S.; Hu, J.; Tan, Y.; Xiao, S.; Han, M.; Li, S.; Li, J.; Wang, W. A review of non-contact approach for pavement skid resistance evaluation based on texture. Tribol. Int. 2024, 196, 109737. [Google Scholar] [CrossRef]

- He, Y.; Fan, Z.; Yang, X.; Wang, D.; Zhao, Z.; Lu, G.; Lv, S. Study on the influence of tire polishing on surface texture durability and skid resistance deterioration of asphalt pavement. Wear 2024, 556–557, 205518. [Google Scholar] [CrossRef]

- EN 13036-4:2011; Method for measurement of slip/skid resistance of a surface: The pendulum test. European Standard: Plzen, Czech Republic, 2011.

- Hu, L.; Yun, D.; Liu, Z.; Du, S.; Zhang, Z.; Bao, Y. Effect of three-dimensional macrotexture characteristics on dynamic frictional coefficient of asphalt pavement surface. Constr. Build. Mater. 2016, 126, 720–729. [Google Scholar] [CrossRef]

- Wang, L.; Wang, L.D.; Fei, W.D. Fractal analysis of fracture surfaces in aluminum borate whisker-reinforced aluminum alloy 6061 composite. Trans. Nonferrous Met. Soc. China 2011, 21, 461–466. [Google Scholar] [CrossRef]

- Issa, M.A.; Issa, M.A.; Islam, M.S.; Chudnovsky, A. Fractal dimension––A measure of fracture roughness and toughness of concrete. Eng. Fract. Mech. 2003, 70, 125–137. [Google Scholar] [CrossRef]

- Senga, Y.; Dony, A.; Colin, J.; Hamlat, S.; Berthaud, Y. Study of the skid resistance of blends of coarse aggregates with different polish resistances. Constr. Build. Mater. 2013, 48, 901–907. [Google Scholar] [CrossRef]

- Gagnepain, J.J.; Roques-Carmes, C. Fractal approach to two-dimensional and three-dimensional surface roughness. Wear 1986, 109, 119–126. [Google Scholar] [CrossRef]

| Asphalt Mixture | Pass Rate Through Different Apertures (mm)/% | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 19 | 16 | 13.2 | 9.5 | 4.75 | 2.36 | 1.18 | 0.6 | 0.3 | 0.15 | 0.075 | |

| AC-13 | 100 | 100 | 95 | 77 | 53 | 37.5 | 27.5 | 18.5 | 14 | 11 | 6.5 |

| AC-16 | 100 | 95 | 83 | 67 | 46 | 31 | 24.5 | 17.5 | 12.5 | 9.5 | 6 |

| SMA-13 | 100 | 100 | 96 | 65 | 27 | 18 | 20 | 15 | 11.5 | 9.5 | 8.5 |

| Parameter Name | Blue Laser Parameter Values | Red Laser Parameter Values |

|---|---|---|

| Wavelength | 405–500 nm | 630–750 nm |

| Power | 70 mw | 30 mw |

| Line width | 100–300 μm | 650 nm |

| Focal length | 130 mm | 130 mm |

| Depth of field | 100 mm | 100 mm |

| Linearity | <0.1% | <0.8% |

| Uniformity | >85% | >75% |

| Parameter Name | Parameter Value |

|---|---|

| Vertical resolution | 0.003 mm |

| Measured mileage (depth) | 30 mm |

| Maximum vertical resolution | 0.00635 mm |

| Maximum horizontal resolution | 0.0247 mm |

| Single scanning area | 104 mm × 72 mm |

| Maximum sampling speed | 3 kHz |

| Output file type | point cloud file |

| Data storage | via network cable |

| Instrument size | 800 mm × 685 mm × 610 mm |

| Weights | 12.5 kg |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Luo, Y.; Xu, Y.; Li, Y.; Wang, L.; Wang, H. The Effective Depth of Skid Resistance (EDSR): A Novel Approach to Detecting Skid Resistance in Asphalt Pavements. Materials 2025, 18, 1204. https://doi.org/10.3390/ma18061204

Luo Y, Xu Y, Li Y, Wang L, Wang H. The Effective Depth of Skid Resistance (EDSR): A Novel Approach to Detecting Skid Resistance in Asphalt Pavements. Materials. 2025; 18(6):1204. https://doi.org/10.3390/ma18061204

Chicago/Turabian StyleLuo, Yi, Yongli Xu, Yiming Li, Liming Wang, and Hongguang Wang. 2025. "The Effective Depth of Skid Resistance (EDSR): A Novel Approach to Detecting Skid Resistance in Asphalt Pavements" Materials 18, no. 6: 1204. https://doi.org/10.3390/ma18061204

APA StyleLuo, Y., Xu, Y., Li, Y., Wang, L., & Wang, H. (2025). The Effective Depth of Skid Resistance (EDSR): A Novel Approach to Detecting Skid Resistance in Asphalt Pavements. Materials, 18(6), 1204. https://doi.org/10.3390/ma18061204