Mechanical Properties of 3D Printed vs. Subtractively Manufactured Composite Resins for Permanent Restorations: A Systematic Review

Highlights

- The mechanical properties of 3D-printed resins for permanent restorations remain inferior to those of subtractively manufactured materials.

- While these resins appear suitable for single-tooth restorations, long-term degradation could significantly increase failure risks.

- Further laboratory and clinical research is essential to fully understand their long-term performance and clinical applications.

- Standardized testing protocols are urgently needed to ensure reliability and consistency.

Abstract

1. Introduction

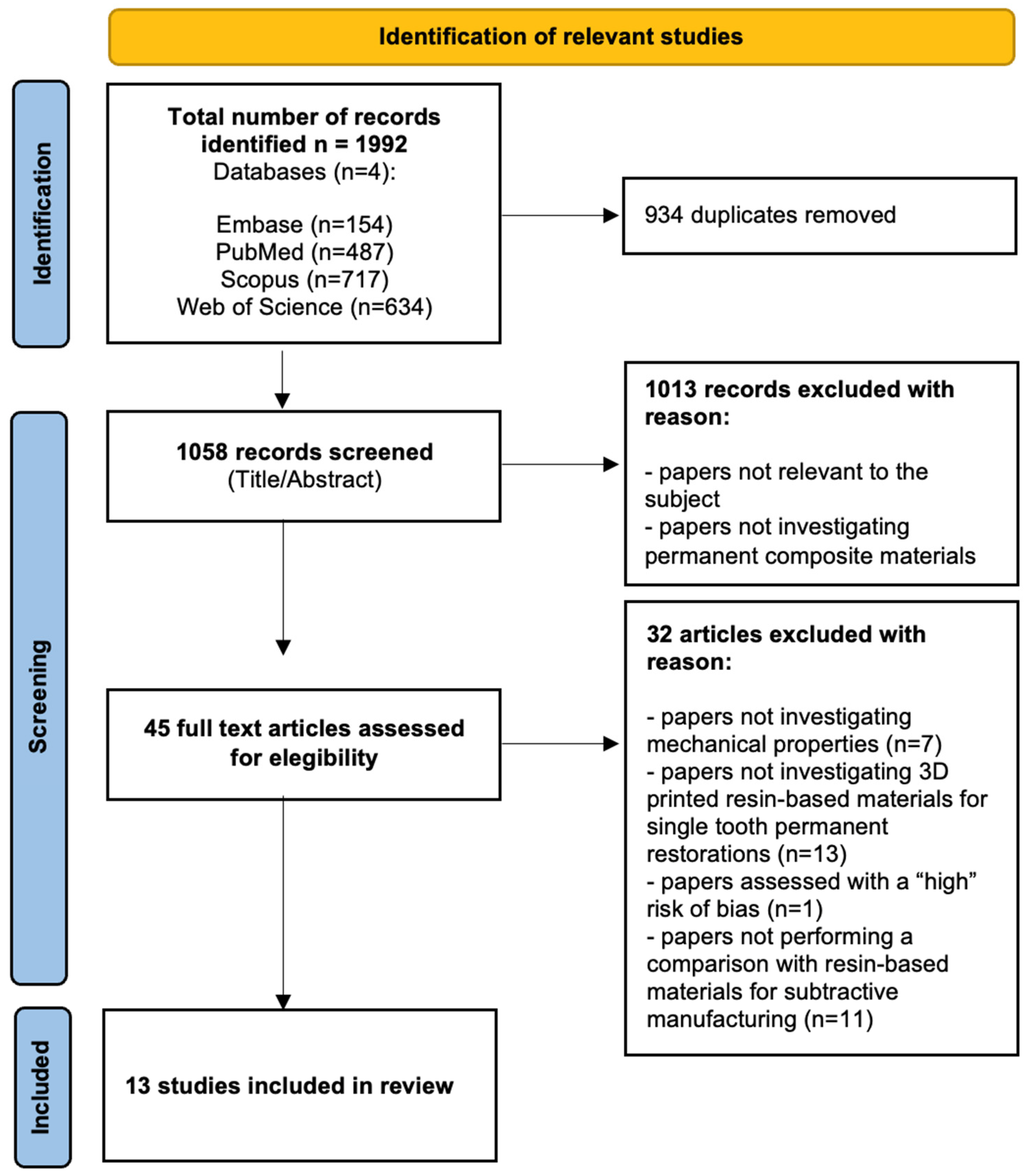

2. Materials and Methods

2.1. Information Sources

2.2. Search Strategy

2.3. Eligibility Criteria

- In vitro studies investigating the mechanical properties of resin-based 3D printed and subtractively manufactured specimens.

- Studies investigating resin-based materials designed for single-tooth permanent restorations.

- Studies reporting numerical values of the investigated mechanical properties.

- Studies written in English language.

- Studies assessed with a low or medium risk of bias.

- Clinical trials, case reports, reviews, or animal studies.

- Studies investigating mechanical properties of temporary materials, dentures, casts, surgical guides, or orthodontic attachments.

- Studies not reporting numerical values of the tested mechanical properties.

- Studies assessed with a high risk of bias.

2.4. Selection Process

2.5. Data Items

2.6. Risk of Bias Assessment

3. Results

3.1. Study Selection and Study Characteristics

3.2. Mechanical Properties Data

3.2.1. Results of Studies Analyzing Fracture Resistance

3.2.2. Results of Studies Analyzing Microhardness

3.2.3. Results of Studies Analyzing Flexural Strength

3.3. Results of Studies Analyzing Wear Behavior

3.4. Sensitivity Analysis

3.5. Correlation Analysis

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Manauta, J.; Salat, A.; Putignano, A.; Devoto, W.; Paolone, G.; Hardan, L.S. Stratification in Anterior Teeth Using One Dentine Shade and a Predefined Thickness of Enamel: A New Concept in Composite Layering—Part I. Odontostomatol. Trop. 2014, 37, 5–16. [Google Scholar] [PubMed]

- Manauta, J.; Salat, A.; Putignano, A.; Devoto, W.; Paolone, G.; Hardan, L.S. Stratification in Anterior Teeth Using One Dentine Shade and a Predefined Thickness of Enamel: A New Concept in Composite Layering—Part II. Odonto-Stomatol. Trop. = Trop. Dent. J. 2014, 37, 5–13. [Google Scholar]

- Paolone, G. Direct Composites in Anteriors: A Matter of Substrate. Int. J. Esthet. Dent. 2017, 12, 468–481. [Google Scholar] [PubMed]

- Della Bona, A.; Cantelli, V.; Britto, V.T.; Collares, K.F.; Stansbury, J.W. 3D Printing Restorative Materials Using a Stereolithographic Technique: A Systematic Review. Dent. Mater. 2021, 37, 336–350. [Google Scholar] [CrossRef]

- Paolone, G.; Mandurino, M.; De Palma, F.; Mazzitelli, C.; Scotti, N.; Breschi, L.; Gherlone, E.; Cantatore, G.; Vichi, A. Color Stability of Polymer-Based Composite CAD/CAM Blocks: A Systematic Review. Polymers 2023, 15, 464. [Google Scholar] [CrossRef]

- Kessler, A.; Hickel, R.; Reymus, M. 3D Printing in Dentistry-State of the Art. Oper. Dent. 2020, 45, 30–40. [Google Scholar] [CrossRef]

- Methani, M.M.; Revilla-León, M.; Zandinejad, A. The Potential of Additive Manufacturing Technologies and Their Processing Parameters for the Fabrication of All-Ceramic Crowns: A Review. J. Esthet. Restor. Dent. 2020, 32, 182–192. [Google Scholar] [CrossRef]

- Caussin, E.; Moussally, C.; Le Goff, S.; Fasham, T.; Troizier-Cheyne, M.; Tapie, L.; Dursun, E.; Attal, J.-P.; François, P. Vat Photopolymerization 3D Printing in Dentistry: A Comprehensive Review of Actual Popular Technologies. Materials 2024, 17, 950. [Google Scholar] [CrossRef]

- Revilla-León, M.; Meyers, M.J.; Zandinejad, A.; Özcan, M. A Review on Chemical Composition, Mechanical Properties, and Manufacturing Work Flow of Additively Manufactured Current Polymers for Interim Dental Restorations. J. Esthet. Restor. Dent. 2019, 31, 51–57. [Google Scholar] [CrossRef]

- Cadenaro, M.; Maravic, T.; Comba, A.; Mazzoni, A.; Fanfoni, L.; Hilton, T.; Ferracane, J.; Breschi, L. The Role of Polymerization in Adhesive Dentistry. Dent. Mater. 2019, 35, e1–e22. [Google Scholar] [CrossRef]

- Balestra, D.; Lowther, M.; Goracci, C.; Mandurino, M.; Cortili, S.; Paolone, G.; Louca, C.; Vichi, A. 3D Printed Materials for Permanent Restorations in Indirect Restorative and Prosthetic Dentistry: A Critical Review of the Literature. Materials 2024, 17, 1380. [Google Scholar] [CrossRef] [PubMed]

- Daher, R.; Ardu, S.; di Bella, E.; Krejci, I.; Duc, O. Efficiency of 3D Printed Composite Resin Restorations Compared with Subtractive Materials: Evaluation of Fatigue Behavior, Cost, and Time of Production. J. Prosthet. Dent. 2024, 131, 943–950. [Google Scholar] [CrossRef]

- Atria, P.J.; Bordin, D.; Marti, F.; Nayak, V.V.; Conejo, J.; Benalcázar Jalkh, E.; Witek, L.; Sampaio, C.S. 3D-Printed Resins for Provisional Dental Restorations: Comparison of Mechanical and Biological Properties. J. Esthet. Restor. Dent. 2022, 34, 804–815. [Google Scholar] [CrossRef] [PubMed]

- Grzebieluch, W.; Kowalewski, P.; Grygier, D.; Rutkowska-Gorczyca, M.; Kozakiewicz, M.; Jurczyszyn, K. Printable and Machinable Dental Restorative Composites for CAD/CAM Application-Comparison of Mechanical Properties, Fractographic, Texture and Fractal Dimension Analysis. Materials 2021, 14, 4919. [Google Scholar] [CrossRef] [PubMed]

- Page, M.J.; McKenzie, J.E.; Bossuyt, P.M.; Boutron, I.; Hoffmann, T.C.; Mulrow, C.D.; Shamseer, L.; Tetzlaff, J.M.; Akl, E.A.; Brennan, S.E.; et al. The PRISMA 2020 Statement: An Updated Guideline for Reporting Systematic Reviews. BMJ 2021, 372, n71. [Google Scholar] [CrossRef]

- Sheth, V.H.; Shah, N.P.; Jain, R.; Bhanushali, N.; Bhatnagar, V. Development and Validation of a Risk-of-Bias Tool for Assessing in Vitro Studies Conducted in Dentistry: The QUIN. J. Prosthet. Dent. 2022, 131, 1038–1042. [Google Scholar] [CrossRef]

- Çakmak, G.; Donmez, M.B.; de Paula, M.S.; Akay, C.; Fonseca, M.; Kahveci, Ç.; Abou-Ayash, S.; Yilmaz, B. Surface Roughness, Optical Properties, and Microhardness of Additively and Subtractively Manufactured CAD-CAM Materials after Brushing and Coffee Thermal Cycling. J. Prosthodont. 2023, 34, 68–77. [Google Scholar] [CrossRef]

- Corbani, K.; Hardan, L.; Skienhe, H.; Özcan, M.; Alharbi, N.; Salameh, Z. Effect of Material Thickness on the Fracture Resistance and Failure Pattern of 3D-Printed Composite Crowns. Int. J. Comput. Dent. 2020, 23, 225–233. [Google Scholar]

- Donmez, M.B.; Okutan, Y. Marginal Gap and Fracture Resistance of Implant-Supported 3D-Printed Definitive Composite Crowns: An in Vitro Study. J. Dent. 2022, 124, 104216. [Google Scholar] [CrossRef]

- Güntekin, N.; Tunçdemir, A.R. Comparison of Volumetric Loss and Surface Roughness of Composite Dental Restorations Obtained by Additive and Subtractive Manufacturing Methods. Heliyon 2024, 10, e26269. [Google Scholar] [CrossRef]

- Güven, M.E.; Çakmak, G.; Dönmez, M.B.; Yilmaz, B. Evaluation of Dimensional Stability and Occlusal Wear of Additively and Subtractively Manufactured Resin-Based Crowns after Thermomechanical Aging. Appl. Sci. 2023, 13, 11849. [Google Scholar] [CrossRef]

- Karaoğlanoğlu, S.; Aydın, N.; Oktay, E.A.; Ersöz, B. Comparison of the Surface Properties of 3D-Printed Permanent Restorative Resins and Resin-Based CAD/CAM Blocks. Oper. Dent. 2023, 48, 588–598. [Google Scholar] [CrossRef] [PubMed]

- Park, Y.; Kim, J.; Kang, Y.-J.; Shim, E.-Y.; Kim, J.-H. Comparison of Fracture Strength of Milled and 3D-Printed Crown Materials According to Occlusal Thickness. Materials 2024, 17, 4645. [Google Scholar] [CrossRef] [PubMed]

- Prause, E.; Malgaj, T.; Kocjan, A.; Beuer, F.; Hey, J.; Jevnikar, P.; Schmidt, F. Mechanical Properties of 3D-Printed and Milled Composite Resins for Definitive Restorations: An In Vitro Comparison of Initial Strength and Fatigue Behavior. J. Esthet. Restor. Dent. 2023, 36, 391–401. [Google Scholar] [CrossRef]

- Suksuphan, P.; Krajangta, N.; Didron, P.P.; Wasanapiarnpong, T.; Rakmanee, T. Marginal Adaptation and Fracture Resistance of Milled and 3D-Printed CAD/CAM Hybrid Dental Crown Materials with Various Occlusal Thicknesses. J. Prosthodont. Res. 2023, 68, 326–335. [Google Scholar] [CrossRef]

- Diken Türksayar, A.A.; Demirel, M.; Donmez, M.B.; Olcay, E.O.; Eyüboğlu, T.F.; Özcan, M. Comparison of Wear and Fracture Resistance of Additively and Subtractively Manufactured Screw-Retained, Implant-Supported Crowns. J. Prosthet. Dent. 2024, 132, 154–164. [Google Scholar] [CrossRef]

- Yılmaz, D.; Çakmak, G.; Güven, M.E.; Pieralli, S.; Yoon, H.-I.; Revilla-León, M.; Yilmaz, B. Effect of Hydrothermal Aging on the Flexural Strength and Microhardness of Materials Used for Additive or Subtractive Manufacturing of Definitive Restorations. Int. J. Prosthodont. 2024, 37, 133–141. [Google Scholar] [CrossRef]

- Zimmermann, M.; Ender, A.; Egli, G.; Özcan, M.; Mehl, A. Fracture Load of CAD/CAM-Fabricated and 3D-Printed Composite Crowns as a Function of Material Thickness. Clin. Oral. Investig. 2019, 23, 2777–2784. [Google Scholar] [CrossRef]

- Diken Turksayar, A.A.; Hisarbeyli, D.; Seçkin Kelten, Ö.; Bulucu, N.B. Wear Behavior of Current Computer-Aided Design and Computer-Aided Manufacturing Composites and Reinforced High Performance Polymers: An In Vitro Study. J. Esthet. Restor. Dent. 2021, 34, 527–533. [Google Scholar] [CrossRef]

- Paolone, G.; Saracinelli, M.; Devoto, W.; Putignano, A. Esthetic Direct Restorations in Endodontically Treated Anterior Teeth. Eur. J. Esthet. Dent. Off. J. Eur. Acad. Esthet. Dent. 2013, 8, 44–67. [Google Scholar]

- Alzahrani, A.H.; Aldosari, L.I.N.; Alshadidi, A.A.F.; Al Moaleem, M.M.; Dhamiri, R.A.A.; Aldossary, M.B.F.; Hazazi, Y.Y.; Awaji, F.A.M.; Ageeli, A.M. Influence of Surface Type with Coffee Immersion on Surface Topography and Optical and Mechanical Properties of Selected Ceramic Materials. Med. Sci. Monit. 2022, 28, e938354. [Google Scholar] [CrossRef] [PubMed]

- van Eijden, T.M. Three-Dimensional Analyses of Human Bite-Force Magnitude and Moment. Arch. Oral. Biol. 1991, 36, 535–539. [Google Scholar] [CrossRef] [PubMed]

- Varga, S.; Spalj, S.; Lapter Varga, M.; Anic Milosevic, S.; Mestrovic, S.; Slaj, M. Maximum Voluntary Molar Bite Force in Subjects with Normal Occlusion. Eur. J. Orthod. 2011, 33, 427–433. [Google Scholar] [CrossRef] [PubMed]

- Martín-Ortega, N.; Sallorenzo, A.; Casajús, J.; Cervera, A.; Revilla-León, M.; Gómez-Polo, M. Fracture Resistance of Additive Manufactured and Milled Implant-Supported Interim Crowns. J. Prosthet. Dent. 2022, 127, 267–274. [Google Scholar] [CrossRef]

- Ciecieląg, K. Machinability Measurements in Milling and Recurrence Analysis of Thin-Walled Elements Made of Polymer Composites. Materials 2023, 16, 4825. [Google Scholar] [CrossRef]

- Thompson, V.P.; Rekow, D.E. Dental Ceramics and the Molar Crown Testing Ground. J. Appl. Oral. Sci. 2004, 12, 26–36. [Google Scholar] [CrossRef]

- Scherrer, S.S.; de Rijk, W.G. The Fracture Resistance of All-Ceramic Crowns on Supporting Structures with Different Elastic Moduli. Int. J. Prosthodont. 1993, 6, 462–467. [Google Scholar]

- Awada, A.; Nathanson, D. Mechanical Properties of Resin-Ceramic CAD/CAM Restorative Materials Presented at the American Association of Dental Research/Canadian Association of Dental Research Annual Meeting, Charlotte, NC, March 2014. J. Prosthet. Dent. 2015, 114, 587–593. [Google Scholar] [CrossRef]

- Kinney, J.H.; Marshall, S.J.; Marshall, G.W. The Mechanical Properties of Human Dentin: A Critical Review and Re-Evaluation of the Dental Literature. Crit. Rev. Oral. Biol. Med. 2003, 14, 13–29. [Google Scholar] [CrossRef]

- Kim, K.-H.; Ong, J.L.; Okuno, O. The Effect of Filler Loading and Morphology on the Mechanical Properties of Contemporary Composites. J. Prosthet. Dent. 2002, 87, 642–649. [Google Scholar] [CrossRef]

- de Castro, E.F.; Nima, G.; Rueggeberg, F.A.; Giannini, M. Effect of Build Orientation in Accuracy, Flexural Modulus, Flexural Strength, and Microhardness of 3D-Printed Resins for Provisional Restorations. J. Mech. Behav. Biomed. Mater. 2022, 136, 105479. [Google Scholar] [CrossRef] [PubMed]

- Ferracane, J.L. Hygroscopic and Hydrolytic Effects in Dental Polymer Networks. Dent. Mater. 2006, 22, 211–222. [Google Scholar] [CrossRef] [PubMed]

- Yao, J.; Li, J.; Wang, Y.; Huang, H. Comparison of the Flexural Strength and Marginal Accuracy of Traditional and CAD/CAM Interim Materials before and after Thermal Cycling. J. Prosthet. Dent. 2014, 112, 649–657. [Google Scholar] [CrossRef] [PubMed]

- Alharbi, N.; Osman, R.; Wismeijer, D. Effects of Build Direction on the Mechanical Properties of 3D-Printed Complete Coverage Interim Dental Restorations. J. Prosthet. Dent. 2016, 115, 760–767. [Google Scholar] [CrossRef]

- Gad, M.M.; Fouda, S.M. Factors Affecting Flexural Strength of 3D-Printed Resins: A Systematic Review. J. Prosthodont. 2023. [Google Scholar] [CrossRef]

- Keßler, A.; Hickel, R.; Ilie, N. In Vitro Investigation of the Influence of Printing Direction on the Flexural Strength, Flexural Modulus and Fractographic Analysis of 3D-Printed Temporary Materials. Dent. Mater. J. 2021, 40, 641–649. [Google Scholar] [CrossRef]

- Gad, M.M.; Fouda, S.M.; Abualsaud, R.; Alshahrani, F.A.; Al-Thobity, A.M.; Khan, S.Q.; Akhtar, S.; Ateeq, I.S.; Helal, M.A.; Al-Harbi, F.A. Strength and Surface Properties of a 3D-Printed Denture Base Polymer. J. Prosthodont. 2022, 31, 412–418. [Google Scholar] [CrossRef]

- Ilie, N.; Hilton, T.J.; Heintze, S.D.; Hickel, R.; Watts, D.C.; Silikas, N.; Stansbury, J.W.; Cadenaro, M.; Ferracane, J.L. Academy of Dental Materials Guidance-Resin Composites: Part I-Mechanical Properties. Dent. Mater. 2017, 33, 880–894. [Google Scholar] [CrossRef]

- Palin, W.M.; Fleming, G.J.P.; Marquis, P.M. The Reliability of Standardized Flexure Strength Testing Procedures for a Light-Activated Resin-Based Composite. Dent. Mater. 2005, 21, 911–919. [Google Scholar] [CrossRef]

- Elhejazi, A.A.; Alosimi, A.; Alarifi, F.; Almuqayrin, A. The Effect of Depth of Cure on Microhardness between Bulk-Fill and Hybrid Composite Resin Material. Saudi Dent. J. 2024, 36, 381–385. [Google Scholar] [CrossRef]

- Farkas, A.Z.; Galatanu, S.-V.; Nagib, R. The Influence of Printing Layer Thickness and Orientation on the Mechanical Properties of DLP 3D-Printed Dental Resin. Polymers 2023, 15, 1113. [Google Scholar] [CrossRef] [PubMed]

- Oouchi, H.; Takamizawa, T.; Tamura, T.; Ishii, R.; Tsujimoto, A.; Miyazaki, M.; Kitahara, N. Flexural Properties and Wear Behavior of Computer-Aided Design/Computer-Aided Manufacturing Resin Blocks. Dent. Mater. J. 2021, 40, 979–985. [Google Scholar] [CrossRef] [PubMed]

| Search | Query |

|---|---|

| #1 | “print” [All fields] OR “manufactur*” [All fields] OR “technology” [All fields] OR “printed-resin” [All fields] OR “SLA” [All fields] OR “DLP” [All fields] OR “printing, three dimensional” [MeSH Terms] |

| #2 | “crown” [All fields] OR “restoration” [All fields] OR “inlay” [All fields] OR “onlay” [All fields] OR “overlay” [All fields] OR “veneer” [All fields] |

| #3 | “flexural” [All fields] OR “fracture load” [All fields] OR “hardness” [All fields] OR “elastic modulus” [All fields] OR “mechanic*” [All fields] OR “stress” [All fields] OR “compressive strength” [All fields] OR “Fracture resistance” [All fields] OR “fracture toughness” [All fields] OR “fatigue” [All fields] OR “Toughness” [All fields] OR “chip*” [All fields] OR “wear” [All fields] OR “mechanical properties” [All fields] OR “Mechanical processes” [All fields] OR “peak stress” [All fields] OR “Elastic strength” [All fields] OR “Microhardness” [All fields] OR “Brittleness” [All fields] OR “Flexibility” [All fields] OR “mechanical phenomena” [MeSH Terms] OR “stress, mechanical” [MeSH Terms] OR “Mechanical Tests” [MeSH Terms] OR “Flexural Strength” [MeSH Terms] OR “elasticity” [MeSH Terms] OR “elastic modulus” [MeSH Terms] OR “compressive strength” [MeSH Terms] OR “hardness” [MeSH Terms] OR “Hardness Tests” [MeSH Terms] OR “Dental Restoration Wear” [MeSH Terms] |

| #4 | “composite” [All fields] OR “resin based” [All fields] OR “resin-based” [All fields] OR “resin” [All fields] |

| #5 | “3D” [All Fields] OR “three dimensional” [All Fields] OR “addit*” [All Fields] OR “stereolithography” [All Fields] OR “stereolithography” [MeSH Terms] |

| #6 | “interim” [All Fields] OR “provisional” [All Fields] OR “temporary” [All Fields] |

| #7 | #1 AND #2 AND #3 AND #4 AND #5 AND NOT #6 |

| Author, Year | Clearly Stated Aims/Objectives | Detailed Explanation of Sample Size Calculation | Detailed Explanation of Sampling Technique | Details of the Comparison Group | Detailed Explanation of Methodology | Operator Details | Randomization | Method of Measurement of Outcome | Outcome Assessor Details | Blinding | Statistical Analysis | Presentation of Results | Total | Score |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cakmak 2023 [17] | 2 | 0 | 2 | 2 | 2 | 2 | 2 | 2 | 2 | 0 | 2 | 2 | 20 | Low |

| Corbani 2020 [18] | 2 | 0 | 1 | 0 | 2 | 2 | 0 | 2 | 0 | 0 | 2 | 2 | 13 | Medium |

| Donmez 2022 [19] | 2 | 2 | 2 | 1 | 2 | 1 | 1 | 2 | 1 | 0 | 2 | 2 | 18 | Low |

| Grzbieluch 2021 [14] | 2 | 1 | 1 | 2 | 2 | 1 | 2 | 2 | 0 | 0 | 2 | 2 | 17 | Low |

| Guntekin 2024 [20] | 2 | 2 | 2 | 1 | 1 | 1 | 1 | 2 | 0 | 0 | 2 | 2 | 16 | Medium |

| Guven 2023 [21] | 2 | 2 | 2 | 1 | 2 | 2 | 1 | 2 | 1 | 0 | 2 | 2 | 19 | Low |

| Karaoglanoglu 2023 [22] | 2 | 2 | 2 | 2 | 2 | 0 | 2 | 2 | 0 | 0 | 2 | 2 | 18 | Low |

| Park 2024 [23] | 2 | 2 | 2 | 2 | 2 | 0 | 0 | 2 | 0 | 0 | 2 | 2 | 16 | Medium |

| Prause 2023 [24] | 2 | 2 | 1 | 2 | 2 | 1 | 0 | 2 | 0 | 0 | 2 | 2 | 16 | Medium |

| Suksuphan 2023 [25] | 2 | 1 | 1 | 1 | 2 | 1 | 0 | 2 | 0 | 0 | 2 | 2 | 14 | Medium |

| Türksayar 2023 [26] | 2 | 2 | 1 | 2 | 2 | 0 | 1 | 2 | 0 | 0 | 2 | 2 | 16 | Medium |

| Yilmaz, 2024 [27] | 2 | 2 | 2 | 2 | 2 | 0 | 0 | 2 | 0 | 0 | 2 | 2 | 16 | Medium |

| Zimmermann 2019 [28] | 2 | 2 | 2 | 2 | 2 | 0 | 0 | 2 | 0 | 0 | 2 | 2 | 16 | Medium |

| Author, Year | Permanent 3D Printed Resin-Based Material Tested | Milled Resin-Based Material Tested | Printing Method | Printing Layer Orientation | Printing Layer Thickness (mm) | Specimen Shape | Specimen Thickness (mm) | Residual Resin Cleaning Method | Post-Printing Polimerization Method | Aging Procedures | Fatigue Simulation | Mechanical Properties Tested |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Zimmermann, 2019 [28] | Els-3d Harz (Saremco Dental Ag) | Lava Ultimate (3m Espe); Cerasmart (GC Corporation); Brilliant Crios (Coltène) | DLP | N.r. | 50 | Crown | 0.5; 1.0; 1.5 | Ultrasonic bath in isopropanol 98% for 2 × 3 min | 4000 lighting exposures using the Otoflash g171 device under a nitrogen oxide gas atmosphere. | N.r. | 1.2 million cycles, 1.7 hz, invariable occlusal load 49 n ± 0.7 n, thermal cycling 5–55 degrees, dwell time 120 s, 12,000 cycles, water change time 10 s. Load was applied to the central fissure by the cusp of a natural molar. | Fracture resistance |

| Corbani, 2020 [18] | Irix Max (DWS) | Brilliant Crios (Coltène) | SLA | N.r. | 50 | Crown | 0.5; 1.0; 1.5 | 95% ethanol for 1 min | Ultraviolet curing unit (Dcure; DWS) for 6 min | N.r. | 5000 cycles in distilled water at 5 °C and 55 °C, with 30 s of dwell time and 5 s of transfer time. axial loading force of 50 n, frequency of 1.6 hz in the center of the occlusal surfaces with a stainless steel ball of 3-mm diameter for 1,200,000 cycles. | Fracture resistance |

| Grzebieluch, 2021 [14] | Varseosmile Crown Plus (Bego) | Grandio Blocs (Voco); Brilliant Crios (Coltène) | LCD/MSLA | Varseosmile group A: samples were printed vertically to the platform, without supports. Varseosmile group B: samples were rotated in the x and y axes by 45 degrees, with medium sized supports. | 50 | Bar | 1.5 | Ethanol (according to the user manual) | Final curing was performed in form cure (Formlabs), 2 times by 45 min (samples were rotated after the first exposure), with the temperature set on 0. | N.r. | N.r. | Flexural strength; Flexural modulus; Microhardness |

| Donmez M.B. 2022 [19] | Crowntec (Saremco Dental Ag) | Brilliant Crios (Coltène); Cerasmart 270 (GC Corporation) | DLP | Z compensation of 0 μm; XY compensation of 0 μm. | 50 | Crown | 1.5–2.5 | The external surfaces of the crowns were cleaned with an alcohol-soaked (96%) cloth; the internal surfaces were cleaned with a brush soaked in an alcohol solution. | 4000 lighting exposures by using a xenon lamp-curing device (Otoflash g171; NK Optik) under nitrogen oxide gas atmosphere. | N.r. | N.r. | Fracture resistance |

| Karaoğlanoğlu S, 2023 [22] | Crowntec (Saremco Dental Ag); Permanent Crown (Formlabs) | Cerasmart 270 (GC Corporation); Grandio Blocs (Voco) | DLP; SLA | N.r. | 50; 50 | N.r. | N.r. | 99% isopropyl alcohol; in an automatic washing machine (Form wash, Formlabs) using 99% isopropyl alcohol for 3 min. | Labolight duo (GC Corporation) for 6 min; Formcure (Formlabs) for 20 min at 60 °C | Specimens were immersed in beverages (tea, coffee, and water) for 30 days. | N.r. | Microhardness |

| Suksuphan P, 2023 [25] | Varseosmile Crown Plus (Bego) | Cerasmart 270 (GC Corporation) | DLP | N.r. | 50 | Crown | 0.8; 1; 1.5 | Ultrasonic baths | Post-cured according to the manufacturer’s recommendations. | N.r. | N.r. | Fracture resistance |

| Türksayar A.A.D. 2023 [26] | Crowntec (Saremco Dental Ag); Varseosmile Crown Plus (Bego) | Brilliant Crios (Coltène) | DLP | N.r. | 50 | Crown | N.r. | 96% alcohol-soaked cloth; ultrasonic bath containing 96% ethanol solution for a total of 5 min (3 min of precleaning in reusable ethanol and 2 min of cleaning in fresh ethanol). | Otoflash g171 (NK Optik) under nitrogen oxide gas atmosphere (2000 × 2 lighting exposures); Otoflash g171 (NK Optik) under nitrogen oxide gas atmosphere (1500 × 2 lighting exposures). | N.r. | Distilled water under a 50-n load with 1.2 million cycles and 0.7-mm lateral sliding (5 °C to 55 °C, dwell time 30 s) by using a mastication simulator (chewing simulator CS-4.10; SD Mechatronik). | Fracture resistance; Wear behavior |

| Prause E. 2023 [24] | Varseosmile Crown Plus (Bego) | Grandio Blocks (Voco) | DLP | Vertically on the build platform at a distance of 2 mm above the platform. | 50 | Disc | 1.5 | Ultrasonically cleaned in 99% isopropanol, first for 3 min of rough cleaning, followed by 2 min of final cleaning. | Otoflash (Bego) for 2 × 1500 flashes | N.r. | N.r. | Flexural strength |

| Cakmak, 2023 [17] | Varseosmile Crown Plus (Bego); Crowntec (Saremco Dental Ag) | Brilliant Crios (Coltène) | DLP | N.r. | 50 | Disc | N.r. | Alcohol-soaked (96%) cloth; ultrasonically cleaned in ethanol for 5 min (3 min of precleaning in reusable ethanol and an additional 2 min in fresh ethanol). | 4000 (ct, 2 × 2000) or 3000 (vs, 2 × 1500) light exposures with Otoflash g171 (NK Optik) under a nitrogen oxide gas atmosphere. | N.r. | 25,000 cycles of artificial brushing (50,000 strokes, each cycle considered as a linear back-and-forth brushing action at a frequency of 1.5 hz) with an automatic brushing machine (bürstmaschine linear lr1); 10,000 thermal cycles (SD Mechatronik thermocycler; SD Mechatronik GMBH) at 5 °C–55 °C in a coffee solution with a dwell time of 30 s and a transfer time of 10 s. | Microhardness |

| Güven, 2023 [21] | Crowntec (Saremco Dental Ag) | Brilliant Crios (Coltène) | DLP | N.r. | 50 | Crown | 1 | N.r. | N.r. | N.r. | 1.7 hz frequency for 1.2 million cycles under 50 n load with a lateral movement of 1 mm and a vertical and lateral sliding speed of 60 mm/s to simulate 5 years of functional loading. The load was applied with 3 mm stainless steel sphere antagonists, which contacted the central fossae of the crowns; simultaneously thermocycled for 6000 cycles between 5–55 °C with 30 s holding and 15 s transfer time in distilled water. | Wear behavior |

| Yilmaz 2024 [27] | Tera Harz Tc-80dp (Graphy); C and B Permanent (ODS) | Brilliant Crios (Coltène) | DLP | Long axis parallel to the platform, with the thinner side (1.5 mm) on the bottom. | 50 | Bar | 1.5 | Ultrasonic bath of 96% ethanol (ethanol absolut, Grogg chemie) for 45 s, and further cleansed with an ethanol-soaked (96% ethanol) cloth to remove any unpolymerized resin on the surface. To ensure that no alcohol residue was left on the specimens, they were then completely dried with an air syringe and allowed to dry thoroughly for at least 10 min. | 2000 flash exposures, repeated twice on the top and bottom surfaces of each specimen with a xenon lamp-curing device (Otoflash g171, NK-Optik) under a nitrogen oxide gas atmosphere. | 10,000 thermal cycles (thermocycler, sd mechatronik) from 5 °C to 55 °C with 10 s of transfer time (30-s dwell time) in distilled water. | N.r. | Flexural strength; Microhardness |

| Guntekin 2024 [20] | Permanent Crown Resin (FormLabs) | Cerasmart (GC Corporation); Grandio Blocks (Voco) | SLA | N.r. | N.r. | Square | 2 | Ultrasonic cleaner (Sonorex RK 102 Transistor, Bandelin) for 2 × 3 min with isopropyl alcohol (98%). | Light cured with an illumination exposure of 4000 lux under an atmosphere consisting of nitrogen oxide gas. | N.r. | Thermomechanical aging in a specially designed 8-chamber chewing device (Multifunctional chewing simulator, Analitik Medikal, Gaziantep, Turkey). Four hundred thousand cycles were completed under a vertical occlusal force of 49 ± 0.7 N with a thermal cycle of 1.7 Hz 5–55 °C and with a dwell time of 120 s, mimicking 2 years of aging. | Wear |

| Park 2024 [23] | Tera Harz Tc-80dp (Graphy); Permanent Crown Resin (FormLabs) | Mazic Duro (Vericom) | DLP; SLA | Occlusal plane parallel to the platform. | N.r. | Crown | 0.5; 1.0; 1.5 | 95% isopropyl alcohol for 5 min in an ultrasonic cleaner (Shinhan 200H 3 L, Shinhan-sonic, Incheon, Republic of Korea) and then washed with a light-emitting diode (wavelength 405 nm and light intensity of 400 mW/cm). | Post-cured for 30 min in a polymerization device (Cure-M 102H, Sona Global Co., Ltd., Seoul, Republic of Korea). | N.r. | N.r. | Fracture resistance |

| Product | Matrix | Filler | Manufacturer |

|---|---|---|---|

| Els-3d Harz | Not Available | Not Available | Saremco Dental Ag |

| Irix Max | Not Available | Inorganic fillers 42 wt. % | DWS |

| Varseosmile Crown Plus | Esterification products of 4,4′-isopropylidiphenol, ethoxylated and 2-methylprop-2enoic acid, methyl benzoylformate, diphenyl (2,4,6-trimethylbenzoyl) | Silanized dental glass, phosphine oxide, 30–50 wt. % inorganic fillers (particle size 0.7 μm) | Bego |

| Crowntec | Esterification products of 4,4’isopropylidiphenol, ethoxylated and 2-methylprop-2enoic acid, initiators | Inorganic silica fillers, 30–50 wt. % (particle size 0.7 μm) | Saremco Dental Ag |

| Permanent Crown | 4,4′-isopropylidiphenol, ethoxylated and 2-methylprop-2enoic acid, methyl benzoylformate, diphenyl (2,4,6-trimethyl benzoyl) | Inorganic fillers, 30–50 wt. %(particle size 0.7 μm) | Formlabs |

| Tera Harz Tc-80dp | Urethane acrylate oligomer, bisphenol A ethoxylated dimethacrylate, 2-HEMA, diphenyl (2,4,6-trimethylbenzoyl) | Phosphine oxide and additives | Graphy |

| C and B Permanent | Diurethane dimethacrylate, 2-propenoic acid, 2-methyl-, (1-methylethylidene) bis (4, 1-phenyleneoxy [1-methyl-2, 1-ethanediyll) ester, 2-HEMA, diphenyl (2,4,6-trimethylbenzoyl) | phosphine oxide and additives | ODS |

| Author, Year | Printing Method | Dye Material | Fatigue Simulation | Cross-Head Speed | 3D printed Specimens’ Mean Fracture Load (N; 1 mm Thickness) | Milled Specimens’ Mean Fracture Load (N; 1 mm Thickness) | 3D Printed Specimens’ Mean Fracture Load (N; 1.5 mm Thickness) | Milled Specimens’ Mean Fracture Load (N; 1.5 mm Thickness) |

|---|---|---|---|---|---|---|---|---|

| Zimmermann, 2019 [28] | DLP | SLA-printed resin | Yes | 1 mm/min | els-3D: 1055.1 ± 133.8 | Lava Ultimate: 831.4 ± 251.4; Cerasmart: 1170.2 ± 279.7; Brilliant Crios: 1255.7 ± 233.9; | els-3D: 1478.7 ± 168.2 | Lava Ultimate: 1516.2 ± 282.9; Cerasmart: 1251.1 ± 430.9; Brilliant Crios: 1580.4 ± 521.0; |

| Corbani, 2020 [18] | SLA | SLA-printed resin | Yes | 0.5 mm/min | Iris Max: 1945.9 ± 65.3 | Brilliant Crios: 932.1 ± 41.2 | Iris Max: 2383.5 ± 188.5 | Brilliant Crios: 1284.7 ± 77.6 |

| Donmez, 2022 [19] | DLP | Metal | N.r. | 1 mm/min | / | / | Crowntec: 1413.9 ± 140.5 | Brilliant Crios: 1333.2 ± 144.7; Cerasmart: 1274.3 ± 135.8; |

| Suksuphan, 2023 [25] | DLP | SLA-printed resin | N.r. | 1 mm/min | Varseosmile Crown Plus: 1629.4 ± 118.5 | Cerasmart: >2000 | Varseosmile Crown Plus: 1747.2 ± 108.7 | Cerasmart: >2000 |

| Park, 2024 [23] | DLP, SLA | Titanium alloy 3D printing material | N.r. | 1 mm/min | Tera Harz TC-80DP: 2677.3 ± 398.2; Permanent Crown: 1638.0 ± 148.1 | Mazic Duro: 2326.3 ± 225.0 | Tera Harz TC-80DP: 2176.8 ± 362.0; Permanent Crown: 1307.5 ± 102.0 | Mazic Duro: 3218.8 ± 228.7 |

| Author, Year | Printing Method | Type of Test | Specimen Polished | Printing Layer Orientation | 3D Printed Specimens’ Mean Microhardness Values | Milled Specimens’ Mean Microhardness Values |

|---|---|---|---|---|---|---|

| Grzebieluch, 2021 [14] | LCD/LMSAD | Vickers | Composite rubbers HiLusterPlus® Polishing System (Kerr Corp., Orange, CA, USA) | Varseosmile group A: samples were printed vertically to the platform, without supports. Varseosmile group B: samples were rotated in the x and y axes by 45 degrees, with medium size supports. | Varseosmile Crown Plus A: 25.8 ± 0.7; Varseosmile Crown Plus B: 28.16 ± 1.42 | Grandio Blocks: 140.43 ± 5.47; Brilliant Crios: 75.40 ± 2.18 |

| Karaoğlanoğlu, 2023 [22] | DLP/SLA | Vickers | A two-step diamond polishing kit (Clearfil Twist Dia, Kuraray, Japan) | N.r. | Crowntec: 30.0 ± 1.3; Permanent Crown: 37.4 ± 1.3 | Grandio Blocks: 203.9± 3.6; Cerasmart: 103.8 ± 2.7 |

| Cakmak, 2023 [17] | DLP | Vickers | Vareosmile Crown Plus and Crowntec: A slurry of coarse pumice in water (Pumice fine; Benco Dental) was used to conventionally polish one surface of all specimens for 90 s at 1500 rpm. Fine polishing was performed by using a polishing paste (Fabulustre; Grobet USA) for an additional 90 s | N.r. | Crowntec: 30.59 ± 2.95; Varseosmile Crown Plus: 34.57 ± 1.23 | Brilliant Crios: 82.2 ± 7.08 |

| Yilmaz, 2024 [27] | DLP | Vickers | A slurry of coarse pumice in water (Pumice fine; Benco Dental) was used to conventionally polish one surface of all specimens for 90 s at 1500 rpm. Fine polishing was performed by using a polishing paste (Fabulustre; Grobet USA) for an additional 90 s. | Long axis parallel to the platform, with the thinner side (1.5 mm) on the bottom. | Tera Harz Tc-80dp: 19.45 ± 1.68; C and B Permanent: 23.08 ± 4.7 | Brilliant Crios: 85.39 ± 2.77 |

| Author, Year | Type of Test | Printing Method | Specimen Thickness (mm) | Cross-Head Speed | Printing Layer Orientation | 3D Printed Specimens’ Mean Flexural Strength Values (Mpa) | Milled Specimens’ Mean Flexural Strength Values (Mpa) |

|---|---|---|---|---|---|---|---|

| Grzebieluch, 2021 [14] | Three-point bending test | LCD/LMSAD | 1.5 | 1 mm/min | Varseosmile group A: samples were printed vertically to the platform, without supports. Varseosmile group B: samples were rotated in the x and y axes by 45 degrees, with medium sized supports. | Varseosmile Crown Plus A: 119.85 ± 17.95; Varseosmile Crown Plus B: 143.39 ± 12.88 | Grandio Blocks: 186.02 ± 10.49; Brilliant Crios: 170.29 ± 9.41 |

| Prause, 2023 [24] | Biaxial bending test | DLP | 1.5 | N.r. | Vertically on the build platform at a distance of 2 mm above the platform. | Varseosmile Crown Plus: 83.5 ± 18.5 | Grandio Blocks: 237.3 ± 31.6 |

| Yilmaz, 2024 [27] | Three-point bending test | DLP | 1.5 | 1 mm/min | Long axis parallel to the platform, with the thinner side (1.5 mm) on the bottom. | Tera Harz Tc-80dp: 107.55 ± 15.69; C and B Permanent: 90.82 ± 4.33 | Brilliant Crios: 211.35 ± 16.98 |

| Metric | Full Dataset Mean | Low Risk Only Mean | Difference |

|---|---|---|---|

| Fracture Resistance (N) | 1641.54 | 1630.00 | 11.54 |

| Flexural Strength (MPa) | 126.38 | 126.60 | −0.22 |

| Microhardness (VHN) | 30.54 | 31.00 | −0.46 |

| Wear Behavior (µm) | 50.15 | 51.40 | −1.25 |

| Metric | Filler Content (%) | Fracture Resistance (N) | Flexural Strength (Mpa) |

|---|---|---|---|

| Filler Content (%) | 1.00 | 0.88 | 0.67 |

| Fracture Resistance (N) | 0.88 | 1.00 | 0.08 |

| Flexural Strength (Mpa) | 0.67 | 0.08 | 1.00 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mandurino, M.; Cortili, S.; Coccoluto, L.; Greco, K.; Cantatore, G.; Gherlone, E.F.; Vichi, A.; Paolone, G. Mechanical Properties of 3D Printed vs. Subtractively Manufactured Composite Resins for Permanent Restorations: A Systematic Review. Materials 2025, 18, 985. https://doi.org/10.3390/ma18050985

Mandurino M, Cortili S, Coccoluto L, Greco K, Cantatore G, Gherlone EF, Vichi A, Paolone G. Mechanical Properties of 3D Printed vs. Subtractively Manufactured Composite Resins for Permanent Restorations: A Systematic Review. Materials. 2025; 18(5):985. https://doi.org/10.3390/ma18050985

Chicago/Turabian StyleMandurino, Mauro, Silvia Cortili, Luca Coccoluto, Katia Greco, Giuseppe Cantatore, Enrico Felice Gherlone, Alessandro Vichi, and Gaetano Paolone. 2025. "Mechanical Properties of 3D Printed vs. Subtractively Manufactured Composite Resins for Permanent Restorations: A Systematic Review" Materials 18, no. 5: 985. https://doi.org/10.3390/ma18050985

APA StyleMandurino, M., Cortili, S., Coccoluto, L., Greco, K., Cantatore, G., Gherlone, E. F., Vichi, A., & Paolone, G. (2025). Mechanical Properties of 3D Printed vs. Subtractively Manufactured Composite Resins for Permanent Restorations: A Systematic Review. Materials, 18(5), 985. https://doi.org/10.3390/ma18050985