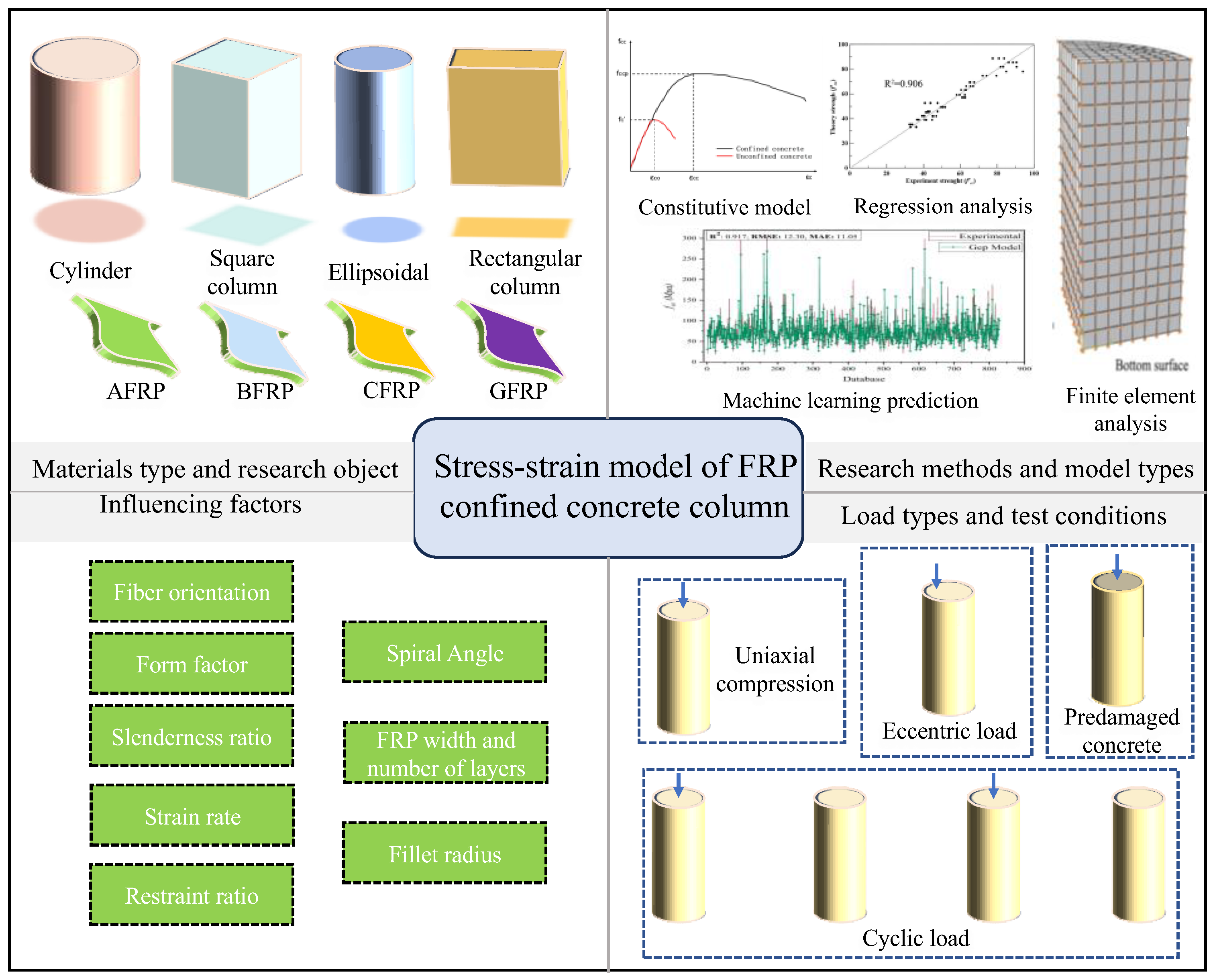

State-of-the-Art Review of the Performance of Fiber-Reinforced-Composite-Confined Concrete Columns at Ambient Temperatures

Abstract

1. Introduction

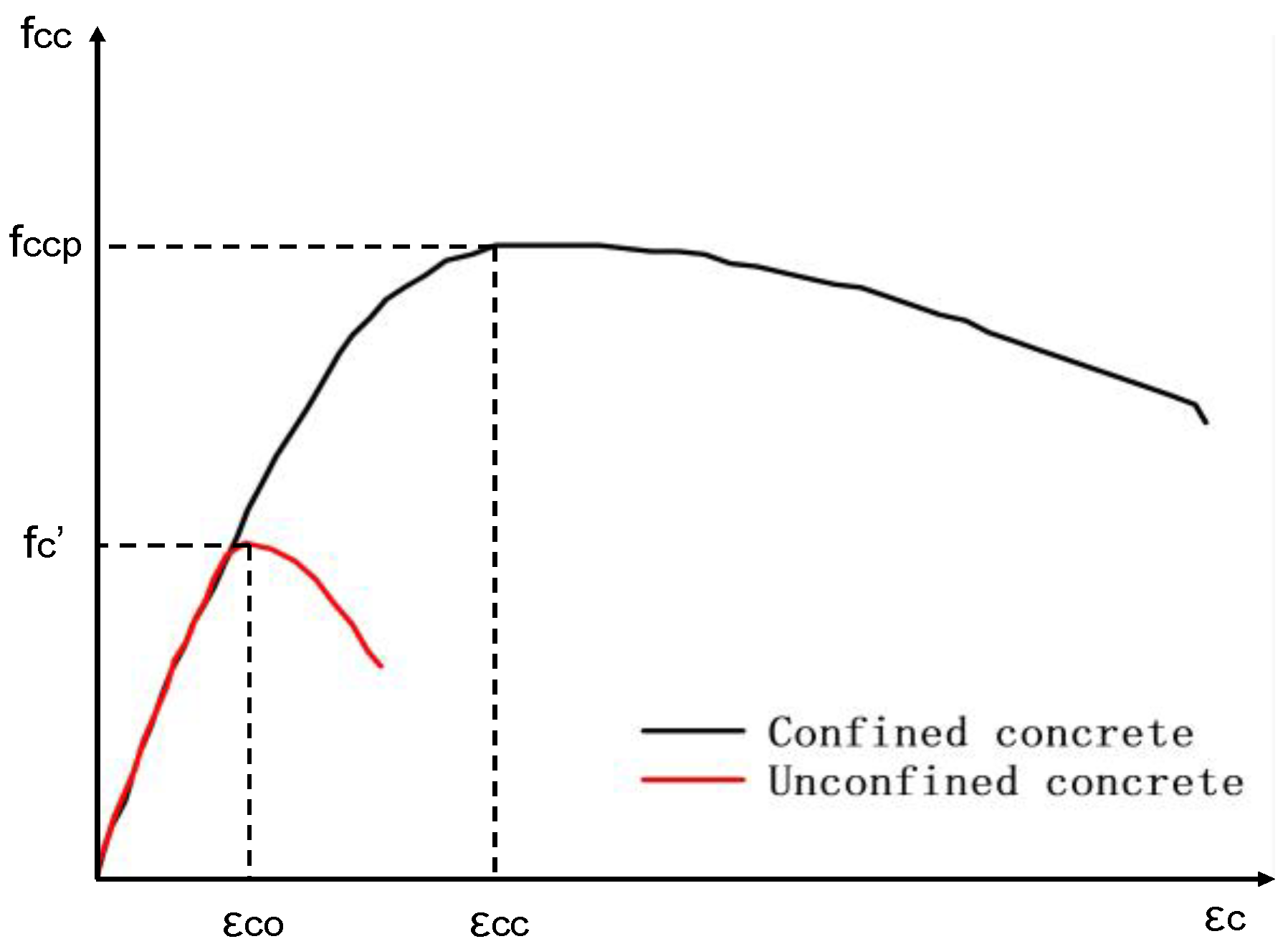

2. Passive Constrained Concrete Constitutive Model

- (1)

- Assumption of constant restraining stresses

- (2)

- It is assumed that the constraint stress is related to the loading history.

- 1.

- Design model.

- 2.

- Analytical model.

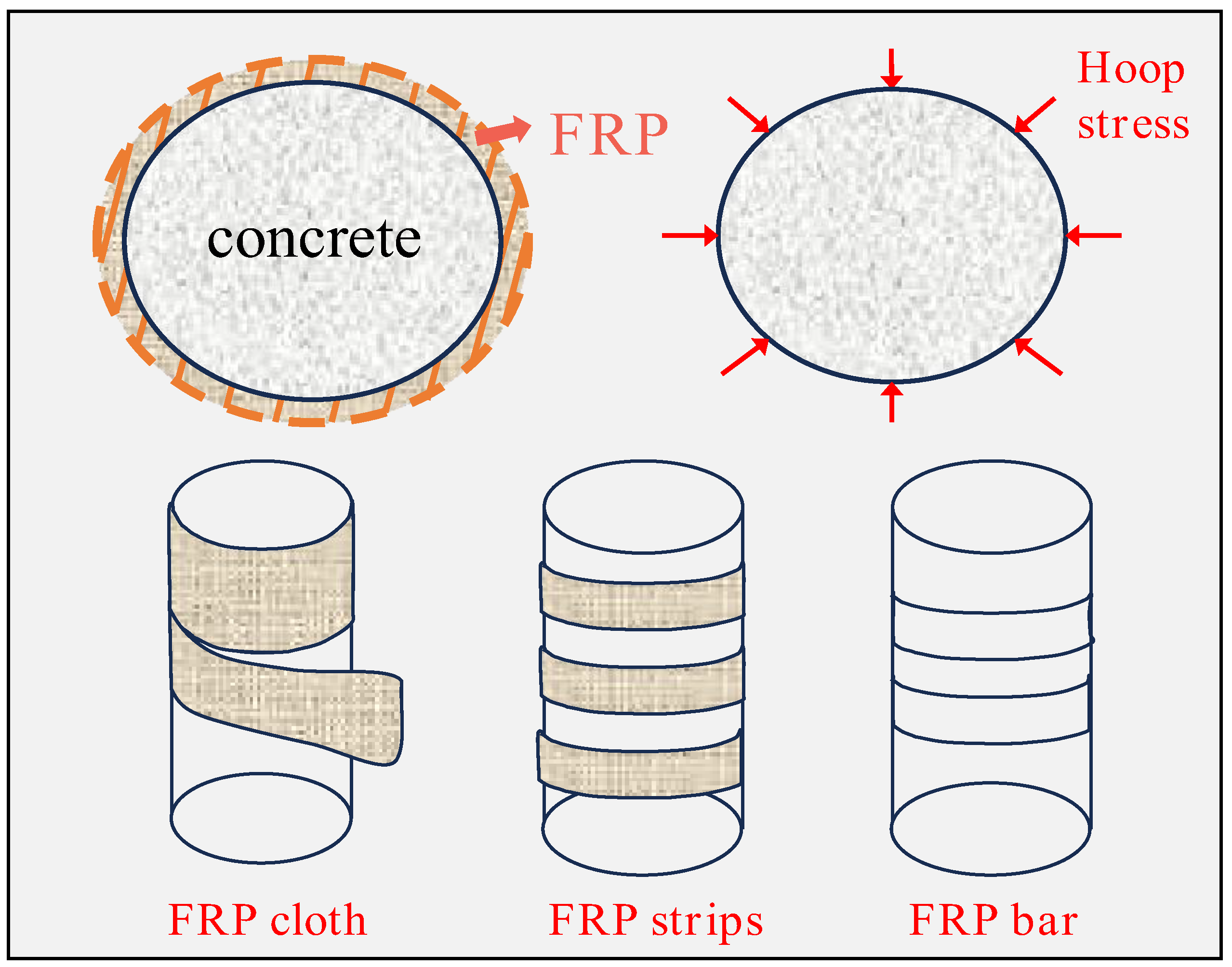

3. FRP Restrained Concrete Columns at Ambient Temperature

3.1. Bonding Ability of FRP to Concrete and Steel Reinforcement

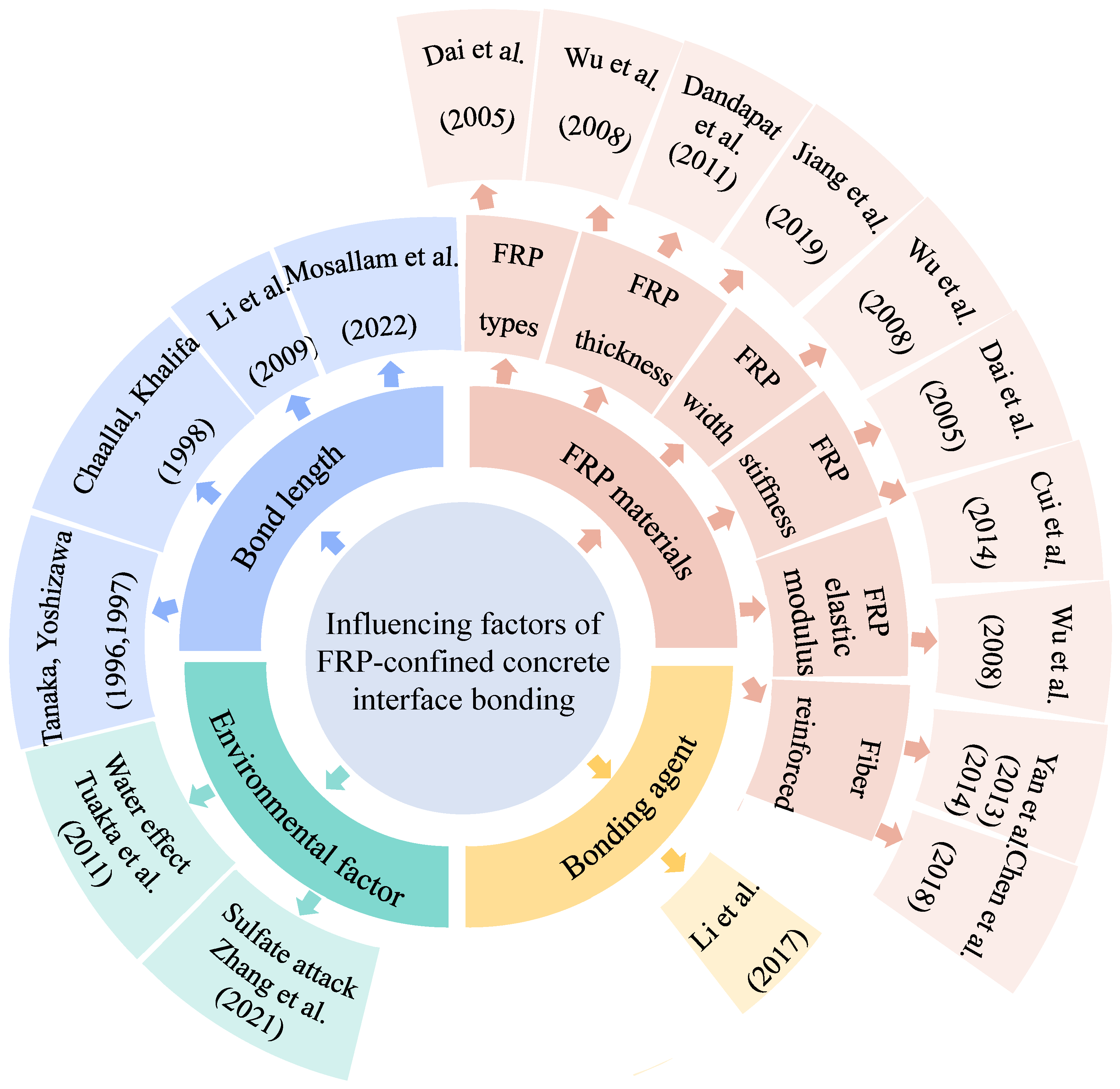

3.1.1. Factors Affecting FRP-Constrained Concrete Interfacial Bonding

3.1.2. FRP-Constrained Concrete Interfacial Bonding Methods

3.1.3. Detection of Bond Damage at the FRP-Constrained Concrete Interface

3.1.4. Machine Learning to Predict FRP-Constrained Concrete Bonds

3.2. Compressive Performance of FRP-Restrained Concrete Columns

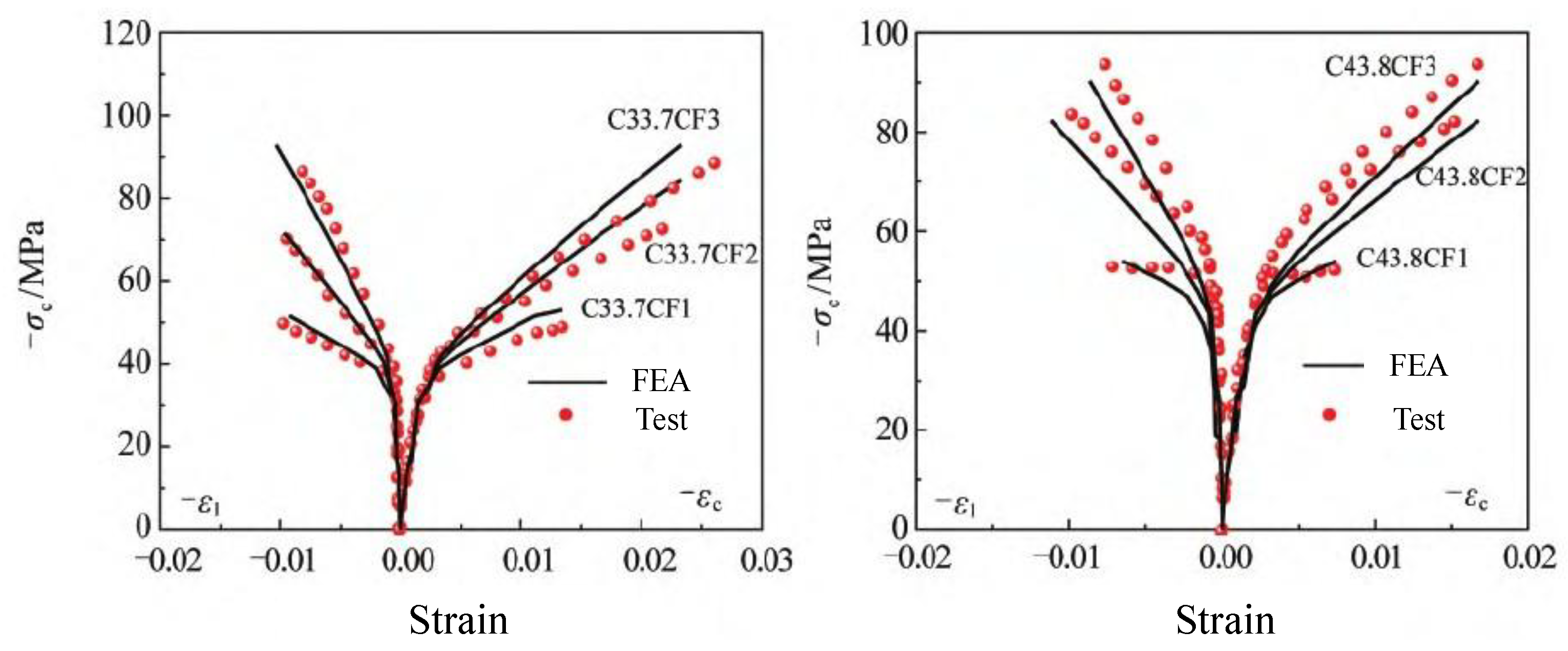

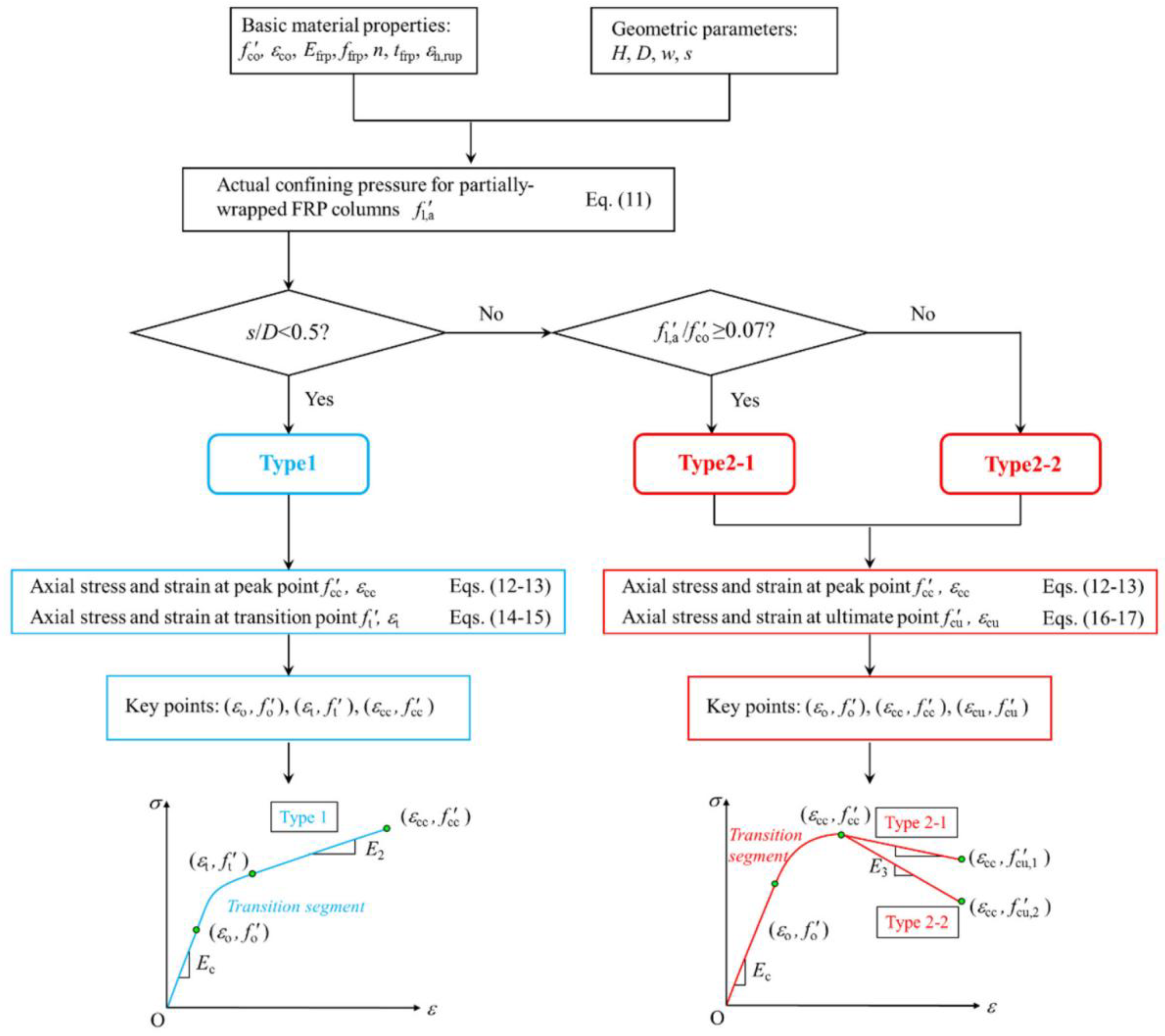

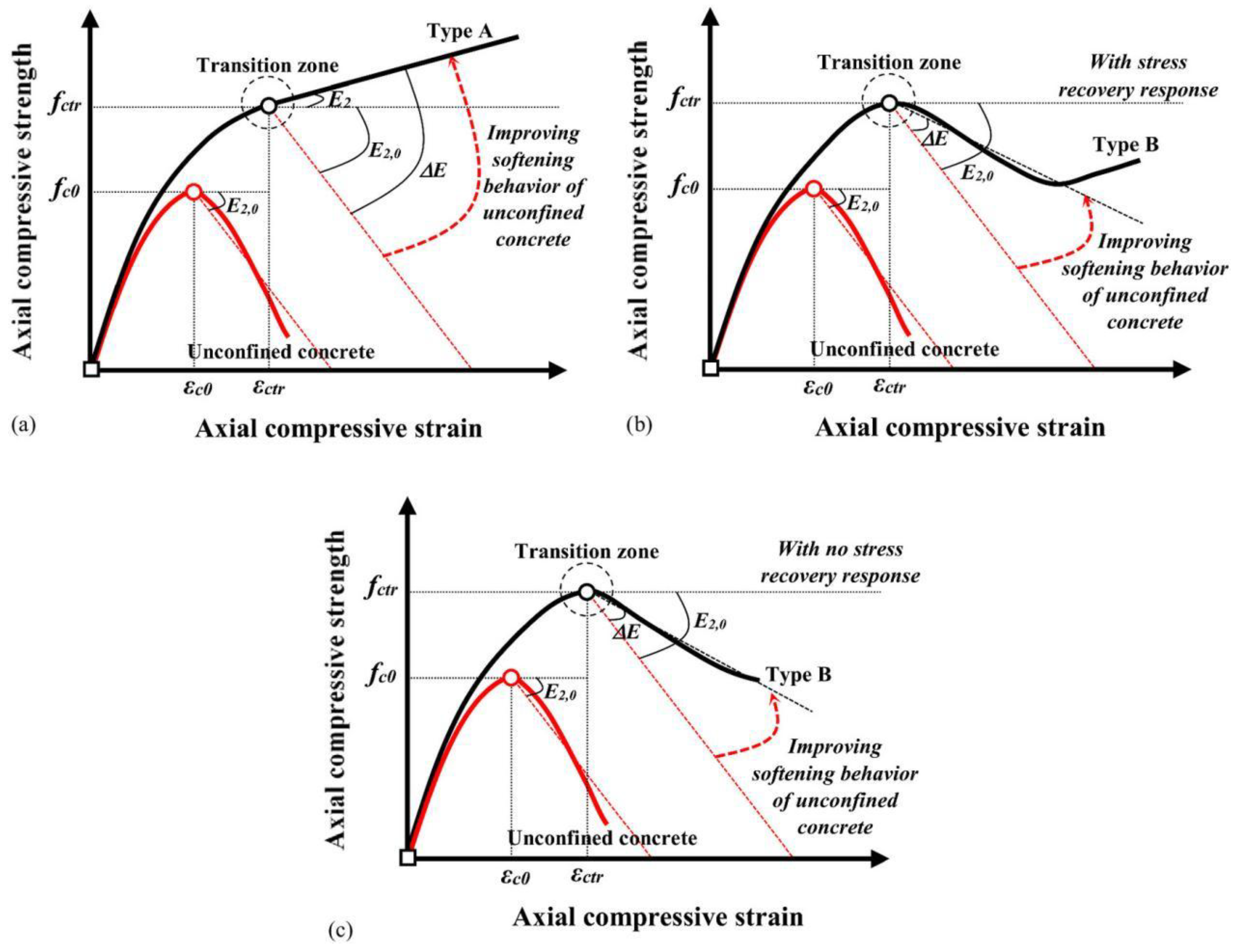

3.2.1. Stress–Strain Model and Curves for FRP-Restrained Concrete Columns

- (1)

- The stress–strain relationship can be categorized into strain-hardening type (Type 1) and strain-softening type (Type 2), and the curves with falling branches after the peak can be further categorized into Type 2-1 (fcu′ > fco′) and Type 2-2 (fcu′ < fco′);

- (2)

- Both types of stress–strain curves consist of three segments, i.e., two linear curves connected by transition branches;

- (3)

- The slope of the first line segment is equal to the modulus of elasticity of unconfined concrete, and the endpoint of the first line segment is (εo, 0.7fco′);

- (4)

- The slope of the third linear branch is directly determined by the two endpoints.

| Researchers | Research Method | Fiber Type | Obligatory Object | Cons Type | Variate | Data Set/ Validation Set | Statistical Indicators | |

|---|---|---|---|---|---|---|---|---|

| Ma et al. [114] | RA | BFRP | RC Cylinder | fully | Pl, n, Cl | 22/ | / | |

| Ma et al. [93] | RA | BFRP | Cylinder | fully | Sr, size | 70/75 | R2 | |

| Strength | 0.92 | |||||||

| αd | 0.91 | |||||||

| Ma et al. [94] | RA | BFRP | Prism | fully | n, Lot, Pl | 62/8 | R2 | |

| Turning point compressive stress | 0.80 | |||||||

| Turning point compressive strain | 0.65 | |||||||

| Limiting point compressive stress | 0.87 | |||||||

| Limiting point compressive strain | 0.76 | |||||||

| Cao et al. [101] | CM | / | Cylinder, Square column | fully | Shape, Pl, Cs | 313/ | / | |

| Tijani et al. [117] | CM | CFRP | Cylinder | fully | e0, Pl | 72/ | / | |

| Zheng et al. [119] | FEA | / | Square column | fully | shape | /16 | / | |

| Wang et al. [120] | RA | CFRP | RC Square column | fully and partially | e0, Pl, pos | 12/67 | R2 | |

| Strength | 0.926 | |||||||

| Strain | 0.961 | |||||||

| Fan et al. [122] | FEA | CFRP | RC Square column | fully | e0, Ra | /18 | / | |

| Wang et al. [100] | CM | CFRP | Cylinder | fully | n, Pll | /37 | R2 | |

| Strength | 0.931 | |||||||

| Strain | 0.932 | |||||||

| Researchers | Research Method | Fiber Type | Obligatory Object | Cons Type | Variate | Data Set | Statistical Indicators | |

|---|---|---|---|---|---|---|---|---|

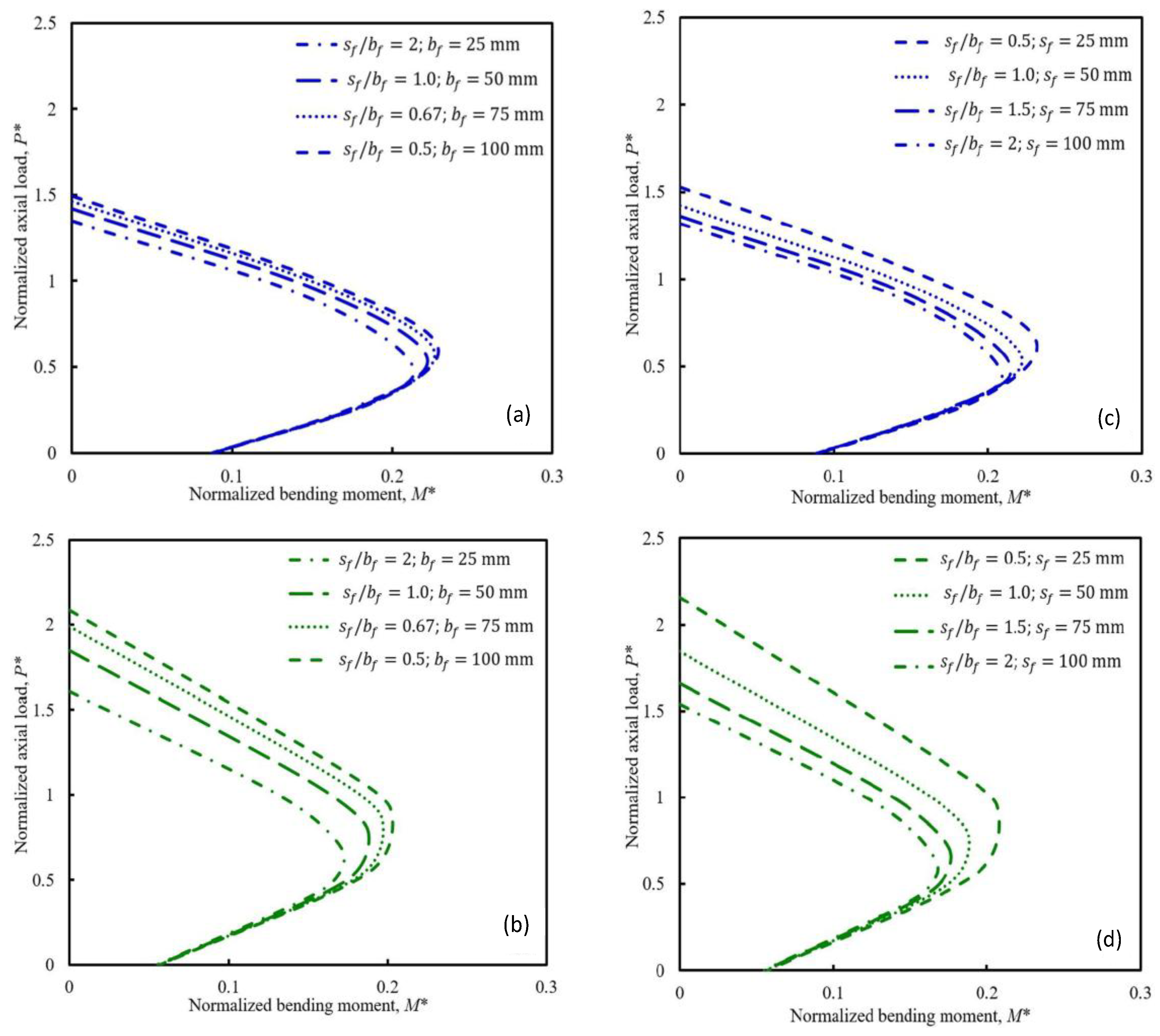

| Mai et al. [97] | CM | CFRP | Square and round RC columns | partially | St, bf, Cr | 16 | / | |

| Hao et al. [135] | CM | / | Rectangular and circular RC columns | fully | size | 23 | / | |

| Cao et al. [136] | CM | CFRP | Cylinder | fully and partially | pos, Str | 28 | IAE = 0.175 | |

| Zhang et al. [140] | CM | / | Cylinder, Square column | fully | shape, pt, pl, Cs | 900 | IAE = 0.106 | |

| Chen et al. [141] | CM | / | Elliptic cylinder | fully | Cq, csar, fc’ | 73 | R2 | |

| Strength | 0.920 | |||||||

| Strain | 0.816 | |||||||

| Chen et al. [142] | CM | / | Elliptic cylinder | fully | csar, n, Lot | 25 | / | |

| Saleh et al. [143] | CM | / | Rectangular column | fully | Sr | 200 | λ10% | 0.92 |

| λ5% | 0.93 | |||||||

| Liao et al. [144] | CM | / | RC Cylinder | fully | ha, bf, n | 40 | AAE | |

| Strength | 0.07 | |||||||

| Strain | 0.13 | |||||||

| Nadia Diboune et al. [98] | RA | CFRP | Square, Rectangular columns | fully | csar, shape, h | 360 | R2 | |

| Strength | 0.81 | |||||||

| Strain | 0.81 | |||||||

| Xie et al. [95] | CM | BFRP | RC Square column | fully | Ra, n | 272 | AAE = 0.07 | |

| Li et al. [148] | RA | BFRP | RC Cylinder | fully | d, sndb | 36 | Cov | |

| Strength | 0.07 | |||||||

| Strain | 0.22 | |||||||

| Jiang et al. [149] | CM | / | Cylinder | fully | n, Str | 45 | R2 | |

| Limiting axial stress | 0.78 | |||||||

| Chen et al. [150] | CM | CFRP | Cylinder | fully | d, size | 24 | / | |

| Zhang et al. [151] | CM, FEA | / | Cylinder | fully | n, fco’ | 57 | R2 | |

| Strength | 0.93 | |||||||

| Strain | 0.92 | |||||||

| Zhou et al. [152] | CM | / | RC Cylinder | partially | Rr, St, Lot | 24 | Unloading strain | R2 = 0.99 |

| Plastic strain | R2 = 0.97 | |||||||

| Li et al. [99] | CM, RA | CFRP | RC Cylinder | fully | Cde, n | 80 | MRE | |

| Strength | 14% | |||||||

| Strain | 32.6% | |||||||

| Zhong et al. [155] | CM | / | Cylinder | fully | Ucc, d, t | 369 | AAE | |

| Strength | 0.087 | |||||||

| Strain | 0.311 | |||||||

3.2.2. Machine Learning to Predict Compressive Performance of FRP-Constrained Concrete Columns

4. Discussions

5. Conclusions and Outlook

5.1. Conclusions

5.2. Outlook

- 1.

- Establishing more comprehensive and high-quality experimental databases to support the development and optimization of interface bonding performance and constitutive models for confinement.

- 2.

- Exploring multi-scale modeling methods that combine experiments, theory, and numerical simulations to enhance the physical interpretability of models.

- 3.

- A hybrid model combining traditional numerical analysis methods with machine learning techniques can improve the prediction accuracy and promote the integration of machine learning with traditional mechanics models. Specifically, numerical data generated from finite element analysis (FEA) can be used as input to train neural networks. The model’s performance is validated through cross-validation and test datasets to ensure its generalization ability and predictive accuracy. This approach aims to develop a more universal predictive framework, enhancing its applicability under complex stress conditions.

- 4.

- Developing standardized testing methods and evaluation systems to promote the internationalization and engineering application of FRP-related research.

- 5.

- Future research should focus on the performance of FRP-confined concrete under cyclic or dynamic loading conditions, which are critical for earthquake and impact-resistant design. Investigating how FRP materials behave under such loading conditions, including their stress–strain responses, bond performance, and failure mechanisms, will be crucial for improving the design of seismic infrastructure. Understanding the fatigue behavior of FRP-confined concrete, especially under cyclic loads, will enhance the resilience and durability of structures in earthquake-prone regions.

Funding

Data Availability Statement

Conflicts of Interest

References

- Navaratnam, S.; Selvaranjan, K.; Jayasooriya, D.; Rajeev, P.; Sanjayan, J. Applications of natural and synthetic fiber reinforced polymer in infrastructure: A suitability assessment. J. Build. Eng. 2023, 66, 105835. [Google Scholar] [CrossRef]

- Nejad, A.F.; Salim, M.Y.B.; Koloor, S.S.R.; Petrik, S.; Yahya, M.Y.; Hassan, S.A.; Shah, M.K.M. Hybrid and synthetic FRP composites under different strain rates: A review. Polymers 2021, 13, 3400. [Google Scholar] [CrossRef] [PubMed]

- Asyraf, M.R.M.; Khan, T.; Syamsir, A.; Supian, A.B.M. Synthetic and natural fiber-reinforced polymer matrix composites for advanced applications. Materials 2022, 15, 6030. [Google Scholar] [CrossRef] [PubMed]

- Mugahed Amran, Y.H.; Alyousef, R.; Rashid, R.S.M.; Alabduljabbar, H.; Hung, C.-C. Properties and applications of FRP in strengthening RC structures: A review. Structures 2018, 16, 208–238. [Google Scholar] [CrossRef]

- Rousakis, T. Retrofitting Strengthening of Contemporary Structures: Materials Used. In Encyclopedia of Earthquake Engineering; Beer, M., Kougioumtzoglou, I.A., Patelli, E., Au, I.S.-K., Eds.; Springer: Berlin/Heidelberg, Germany, 2010; pp. 1–15. [Google Scholar] [CrossRef]

- Bank, L.C. Composites for Construction—Structural Design with FRP Materials; John Wiley & Sons: Hoboken, NJ, USA, 2006. [Google Scholar]

- Correia, J.R. Fibre-Reinforced Polymer (FRP) Composites. In Materials for Construction and Civil Engineering, Science, Processing, and Design; Goncalves, M.C., Margarido, F., Eds.; Springer International Publishing: Cham, Switzerland, 2015; pp. 501–556. ISBN 978-3-319-08235-6. [Google Scholar]

- Qureshi, J. A Review of Recycling Methods for Fibre Reinforced Polymer Composites. Sustainability 2022, 14, 16855. [Google Scholar] [CrossRef]

- Qureshi, J.; Nadir, Y.; John, S.K. Bolted and Hybrid Beam-Column Joints between I-Shaped FRP Profiles. In Proceedings of the Eighth International Conference on Structural Engineering, Mechanics and Computation (SEMC 2022), Cape Town, South Africa, 5–7 September 2022; Zingoni, A., Ed.; CRC Press: Cape Town, South Africa, 2022; pp. 1497–1502. [Google Scholar]

- Ortiz, J.D.; Khedmatgozar Dolati, S.S.; Malla, P.; Nanni, A.; Mehrabi, A. FRP-reinforced/strengthened concrete: State-of-the-art review on durability and mechanical effects. Materials 2023, 16, 1990. [Google Scholar] [CrossRef]

- Khodadadi, N.; Roghani, H.; Harati, E.; Mirdarsoltany, M.; De Caso, F.; Nanni, A. Fiber-reinforced polymer (FRP) in concrete: A comprehensive survey. Constr. Build. Mater. 2024, 432, 136634. [Google Scholar] [CrossRef]

- Zeng, J.J.; Zheng, Y.-Z.; Long, Y.-L. Axial compressive behavior of FRP-concrete-steel double skin tubular columns with a rib-stiffened Q690 steel tube and ultra-high strength concrete. Compos. Struct. 2021, 268, 113912. [Google Scholar] [CrossRef]

- Kachlakev, D. Strengthening Bridges Using Composite Materials (No. FHWA-OR-RD-98-08); Oregon Department of Transportation Research: Salem, OR, USA, 1998. [Google Scholar]

- A.C.I.440, Guide for the Design and Construction of Concrete Reinforced with FRP Bars: ACI 440.1 R-03. American Concrete Institute: Farmington Hills, MI, USA, 2003. Available online: https://www.concrete.org/publications/internationalconcreteabstractsportal/m/details/id/12639 (accessed on 5 January 2025).

- Blontrock, H.; Taerwe, L.; Matthys, S. Properties of fiber reinforced plastics at elevated temperatures with regard to fire re-sistance of reinforced concrete members. Spec. Publ. 1999, 188, 43–54. [Google Scholar]

- Zhu, H.; Wu, G.; Zhang, L.; Zhang, J.; Hui, D. Experimental study on the fire resistance of RC beams strengthened with near-surface-mounted high-Tg BFRP bars. Compos. Part. B Eng. 2014, 60, 680–687. [Google Scholar] [CrossRef]

- Bolina, F.L.; Silva, D.B.; Pachla, E.C. The fire performance of GFRP-RC beams based on FE thermal analysis. J. Build. Rehabil. 2025, 10, 17. [Google Scholar] [CrossRef]

- Bolina, F.L.; Lago, B.D.; Rodríguez, E.D. Effects of thermal properties on temperature field of UHPC structures under fire conditions. Constr. Build. Mater. 2024, 411, 134254. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.; Park, R. Observed Stress-Strain Behavior of ConfinedConcrete. J. Struct. Eng. 1988, 114, 1827–1849. [Google Scholar] [CrossRef]

- William, K.J.; Warnke, E.P. Constitutive model for the triaxial behaviour of concrete. Int. Assoc. Bridge Struct. Eng. 1975, 19, 1–30. [Google Scholar]

- Schickert, G.; Winkler, H. Results of test concerning strength and strain of concrete subjected to multi-axial compressive stress. Dtsch. Aussch. Fyrstahlbeton 1977, 211, 123. [Google Scholar]

- Susantha KA, S.; Ge, H.; Usami, T. Uniaxial stress–strain relationship of concrete confined by various shaped steel tubes. Eng. Struct. 2001, 23, 1331–1347. [Google Scholar] [CrossRef]

- Tang, J.L.; Hino, S.; Kuroda, I.; Ohta, T. Modeling of stress-strain relationships for steel and concrete in concrete filled circular steel tubular columns. Kou Kouzou Rombunshuu 1996, 3, 35–46. [Google Scholar]

- Bing, L.; Park, R. Stress-strain behavior of high-strength concrete confined by ultra-high-and normal-strength transverse reinforcements. ACI Struct. J. 2001, 98, 395–406. [Google Scholar]

- Muguruma, H.; Watanabe, F. Ductility improvement of high-strength concrete columns with lateral confinement. ACI Symp. Publ. 1990, 121, 47–60. [Google Scholar]

- Khaloo, A.R.; Ahmad, S.H. Behavior of high-strength concrete under torsional triaxial compression. ACI Mater. J. 1989, 86, 550–558. [Google Scholar]

- Elremaily, A.; Azizinamini, A. Behavior and strength of circular concrete-filled tube columns. J. Constr. Steel Res. 2002, 58, 1567–1591. [Google Scholar] [CrossRef]

- Zhang, Y.R.; Wei, Y.; Bai, J.W.; Zhang, Y.X. Stress-strain model of an FRP-confinedconcrete filled steel tube under axial compression. Thin-Walled Struct. 2019, 142, 149–159. [Google Scholar] [CrossRef]

- Jiang, T.; Teng, J.G. Analysis-oriented stress–strain models for FRP–confined concrete. Eng. Struct. 2007, 29, 2968–2986. [Google Scholar] [CrossRef]

- Popovics, S. A numerical approach to the complete stress-strain curve of concrete. Cem. Concr. Res. 1973, 3, 583–599. [Google Scholar] [CrossRef]

- Xiao, Y.; Wu, H. Compressive behavior of concrete confined by carbon ciber compositejackets. J. Mater. Civ. Eng. 2000, 12, 139–146. [Google Scholar] [CrossRef]

- Attard, M.M.; Setunge, S. Stress-Strain relationship of confined and unconfinedconcrete. ACI Mater. J. 1996, 93, 432–442. [Google Scholar]

- Sargin, M. Stress-strain relationships for concrete and the analysis of structural concretesections. In Solid Mechanics Division; University of Waterloo: Waterloo, ON, Canada, 1971. [Google Scholar]

- Imran, I.; Pantazopoulou, S.J. Experimental study of plain concrete under triaxialstress. Mater. J.-Am. Concr. Inst. 1996, 93, 589–601. [Google Scholar]

- Chen, P.; Wang, Y.Y.; Liu, C.Y. Confinement path-dependent analytical model for FRP[56]confined concrete and concrete-filled steel tube subjected to axial compression. Compos. Struct. 2018, 201, 234–247. [Google Scholar] [CrossRef]

- Lim, J.C.; Ozbakkaloglu, T. Investigation of the Influence of the Application Path ofConfining Pressure: Tests on Actively Confined and FRP-Confined Concretes. J. Struct. Eng. 2015, 141, 4014203. [Google Scholar] [CrossRef]

- Li, P.D.; Wu, Y.F. Stress-strain behavior of actively and passively confined concreteunder cyclic axial load. Compos. Struct. 2016, 149, 369–384. [Google Scholar] [CrossRef]

- Xiong, H.B.; Li, B.B.; Jiang, J.F. Load path dependence of strain and stress for confinedconcrete. Mag. Concr. Res. 2016, 68, 604–618. [Google Scholar] [CrossRef]

- Wu, Y.F.; Cao, Y.G. Effect of load path on behavior of FRP-confined concretel. J. Compos. Constr. 2017, 21, 4017014. [Google Scholar] [CrossRef]

- Lin, S.O.; Zhao, Y.G.; He, L.S. Stress paths of confined concrete in axially loaded circularconcrete-filled steel tube stub columns. Eng. Struct. 2018, 173, 1019–1028. [Google Scholar] [CrossRef]

- Chang, Y.; Shi, J.; Cao, X.; Qiu, Y. Strain-path-dependent stress–strain model for ultrahigh-performance concrete columns constrained by stirrups. Adv. Struct. Eng. 2023, 26, 772–784. [Google Scholar] [CrossRef]

- Chen, Z.; Xu, R.; Liang, Y.; Xu, W.; Liang, Y. Experimental study and finite element analysis on axial compression performance of CFRP-PVC confined coral seawater and sea-sand concrete columns. Eng. Struct. 2024, 302, 117443. [Google Scholar] [CrossRef]

- Tanaka, T. Shear Resisting Mechanism of Reinforced Concrete Beams with CFS as Shear Reinforcement. Bachelor’s Thesis, Hokkaido University, Sapporo, Japan, 1996. [Google Scholar]

- Yoshizawa, H. Analysis of debonding fracture properties of CFS strengthened RC member subject to tension. In Non-Metallic (FRP) Reinforcement for Concrete Structures Proceedings 3rd International Symposium; The Japan Concrete Institute: Tokyo, Japan, 1997; pp. 287–294. [Google Scholar]

- Chaallal, O.; Nollet, M.J.; Dperraton, D. Strengthening of reinforced concrete beams with externally bonded fiber-reinforced-plastic plates: Design guidelines for shear flexure Can. J. Civ. Eng. 1998, 25, 692–704. [Google Scholar] [CrossRef]

- Khalifa, A.; Gold, W.J.; Nanni, A.; Aziz, M.A. Contribution of Externally Bonded FRP to Shear Capacity of RCFlexural Members. J. Compos. Constr. 1998, 4, 195–202. [Google Scholar] [CrossRef]

- Dai, J.; Ueda, T.; Sato, Y. Development of the Nonlinear Bond Stress-Slip Model of Fiber Reinforced Plastics Sheet-Concrete Interfaces with a Simple Method. J. Compos. Constr. 2005, 1, 52–62. [Google Scholar] [CrossRef]

- Wu, Z.; Islam, S.M.; Said, H. A Three-Parameter Bond Strength Model for FRP—Concrete Interface. J. Reinf. Plast. Compos. 2008, 19, 2309–2323. [Google Scholar] [CrossRef]

- Li, B.; Chua, H.Y. Grace, Seismic Performance of Strengthened Reinforced Concrete Beam-Column Joints Using FRP Composites. J. Struct. Eng. 2009, 135, 1177–1190. [Google Scholar] [CrossRef]

- Dandapat, R.; Deb, A.; Bhattacharyya, S. Failure modes for FRP wrapped cylindrical concrete columns. J. Reinf. Plast. Compos. 2011, 30, 561–579. [Google Scholar] [CrossRef]

- Tuakta, C.; Büyüköztürk, O. Conceptual Model for Prediction of FRP-constrained concrete Bond Strength under Moisture Cycles. J. Compos. Constr. 2011, 15, 743–756. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N. Experimental study of flax FRP tube encased coir fibre reinforced concrete composite column. Constr. Build. Mater. 2013, 40, 1118–1127. [Google Scholar] [CrossRef]

- Yan, L.; Chouw, N.; Jayaraman, K. Effect of column parameters on flax FRP confined coir fibre reinforced concrete. Constr. Build. Mater. 2014, 55, 299–312. [Google Scholar] [CrossRef]

- Choi, E.; Cho, B.-S.; Jeon, J.-S.; Yoon, S.-J. Bond behavior of steel deformed bars embedded in concrete confined by FRP wire jackets. Constr. Build. Mater. 2014, 68, 716–725. [Google Scholar] [CrossRef]

- Li, Y.; Liu, X.; Li, J. Experimental Study of Retrofitted Cracked Concrete with FRP and Nanomodified Epoxy Resin. J. Mater. Civ. Eng. 2017, 29, 04016275. [Google Scholar] [CrossRef]

- Chen, J.; Chouw, N. Effect of the interface condition on the bond between flax FRP tube and coconut fibre reinforced concrete composites. Constr. Build. Mater. 2018, 167, 597–604. [Google Scholar] [CrossRef]

- Jiang, C.; Yuan, F.; Wu, Y.-F.; Zhao, X.-M. Effect of Interfacial Bond on Plastic Hinge Length of FRP-Confined RC Columns. J. Compos. Constr. 2019, 23. [Google Scholar] [CrossRef]

- Liu, S.; Yang, Z.; Zhang, J.; Zhao, J. Study on bond-slip degradation model of CFRP and concrete interface under sulfate erosion environment. Compos. Struct. 2021, 267, 113877. [Google Scholar] [CrossRef]

- Mosallam, A.S.; Ghabban, N.; Mirnateghi, E.; Agwa, A.A.K. Nonlinear numerical simulation and experimental verification of bondline strength of CFRP strips embedded in concrete for NSM strengthening applications. Struct. Concr. 2022, 23, 1794–1815. [Google Scholar] [CrossRef]

- Niroomandi, A.; Maheri, A.; Maheri, M.R.; Mahini, S. Seismic performance of ordinary RC frames retrofitted at joints by FRP sheets. Eng. Struct. 2010, 32, 2326–2336. [Google Scholar] [CrossRef]

- Saeed, Y.M.; Aules, W.A.; Rad, F.N.; Raad, A.M. Tensile behavior of FRP anchors made from CFRP ropes epoxy-bonded to uncracked concrete for flexural strengthening of RC columns. Case Stud. Constr. Mater. 2020, 13, e00435. [Google Scholar] [CrossRef]

- Deb, A.; Bhattacharyya, S.K. Investigation into the Effect of Bonding on FRP-Wrapped Cylindrical Concrete Columns. J. Compos. Constr. 2010, 14, 706–719. [Google Scholar] [CrossRef]

- Moshiri, N.; Hosseini, A.; Mostofinejad, D. Strengthening of RC columns by longitudinal CFRP sheets: Effect of strengthening technique. Constr. Build. Mater. 2015, 79, 318–325. [Google Scholar] [CrossRef]

- Nossoni, G.; Harichandran, R.S.; Baiyasi, M.I. Rate of Reinforcement Corrosion and Stress Concentration in Concrete Columns Repaired with Bonded and Unbonded FRP Wraps. J. Compos. Constr. 2015, 19, 04014080. [Google Scholar] [CrossRef]

- Torabian, A.; Mostofinejad, D. Externally Bonded Reinforcement on Grooves Technique in Circular Reinforced Columns Strengthened with Longitudinal Carbon Fiber-Reinforced Polymer under Eccentric Loading. ACI Struct. J. 2017, 114, 861–873. [Google Scholar] [CrossRef]

- Saljoughian, A.; Mostofinejad, D. Grooving methods in square RC columns strengthened with longitudinal CFRP under cyclic axial compression. Eng. Struct. 2018, 174, 724–735. [Google Scholar] [CrossRef]

- Saljoughian, A.; Mostofinejad, D. Using grooving and corner strip-batten techniques for seismic strengthening of square reinforced concrete columns with fiber-reinforced polymer composites. Struct. Concr. 2020, 21, 2066–2082. [Google Scholar] [CrossRef]

- Mostofinejad, D.; Salimian, M.S.; Taherirani, M.; Noroozolyaee, M. Behavior of Square Slender RC Columns Strengthened with Longitudinal FRP Sheets Subjected to Eccentric Loading. J. Compos. Constr. 2021, 25, 04021006. [Google Scholar] [CrossRef]

- Taherirani, M.; Noroozolyaee, M.; Salimian, M.S.; Mostofinejad, D. Evaluation of square slender RC columns subjected to eccentric loading strengthened with longitudinal FRP sheets based on PIV analysis. Constr. Build. Mater. 2022, 324, 126635. [Google Scholar] [CrossRef]

- Ghaleh, R.Z.; Mostofinejad, D. Behaviour of EBRIG CFRP sheet-concrete joint: Comparative assessment with EBR and EBROG methods. Constr. Build. Mater. 2022, 346, 128374. [Google Scholar] [CrossRef]

- Sanginabadi, K.; Yazdani, A.; Mostofinejad, D.; Czaderski, C. Bond behavior of FRP composites attached to concrete using EBROG method: A state-of-the-art review. Compos. Struct. 2022, 299, 116060. [Google Scholar] [CrossRef]

- Ghosh, K.K.; Karbhari, V.M. Use of infrared thermography for quantitative non-destructive evaluation in FRP strengthened bridge systems. Mater. Struct. 2011, 44, 169–185. [Google Scholar] [CrossRef]

- Wang, Y.; Li, X.; Li, J.; Wang, Q.; Xu, B.; Deng, J. Debonding damage detection of the CFRP-constrained concrete interface based on piezoelectric ceramics by the wave-based method. Constr. Build. Mater. 2019, 210, 514–524. [Google Scholar] [CrossRef]

- Zhu, C.; Sun, L.; Wang, K.; Yuan, Y.; Wei, M. Effect of bond slip on the performance of FRP reinforced concrete columns under eccentric loading. Comput. Concr. 2019, 24, 73–83. [Google Scholar] [CrossRef]

- Deng, J.; Li, X.; Zhu, M.; Rashid, K.; Wang, Q. Debonding damage detection of the CFRP-constrained concrete interface based on piezoelectric ceramics by the electromechanical impedance method. Constr. Build. Mater. 2021, 303, 124431. [Google Scholar] [CrossRef]

- Kim, B.; Yuvaraj, N.; Park, H.W.; Preethaa, K.R.S.; Pandian, R.A.; Lee, D.-E. Investigation of steel frame damage based on computer vision and deep learning. Autom. Constr. 2021, 132, 103941. [Google Scholar] [CrossRef]

- Mashrei, M.A.; Seracino, R.; Rahman, M. Application of artificial neural networks to predict the bond strength of FRP-to-concrete joints. Constr. Build. Mater. 2013, 40, 812–821. [Google Scholar] [CrossRef]

- Golafshani, E.M.; Rahai, A.; Sebt, M.H. Artificial neural network and genetic programming for predicting the bond strength of GFRP bars in concrete. Mater. Struct. 2015, 48, 1581–1602. [Google Scholar] [CrossRef]

- Coelho, M.R.; Sena-Cruz, J.M.; Neves, L.A.; Pereira, M.; Cortez, P.; Miranda, T. Using data mining algorithms to predict the bond strength of NSM FRP systems in concrete. Constr. Build. Mater. 2016, 126, 484–495. [Google Scholar] [CrossRef]

- Köroğlu, M.A. Artificial neural network for predicting the flexural bond strength of FRP bars in concrete. Sci. Eng. Compos. Mater. 2019, 26, 12–29. [Google Scholar] [CrossRef]

- Wang, Y.-R.; Yu, C.-Y.; Chan, H.-H. Predicting construction cost and schedule success using artificial neural networks ensemble and support vector machines classification models. Int. J. Proj. Manag. 2012, 30, 470–478. [Google Scholar] [CrossRef]

- Saghi, H.; Behdani, M.; Saghi, R.; Ghaffari, A.R.; Hirdaris, S. Application of gene expression programming model to present a new model for bond strength of fiber reinforced polymer concrete. J. Mater. Civil. Eng. 2019, 3, 15–29. Available online: https://www.jcema.com/article_103847.html (accessed on 5 January 2025).

- Gao, J.; Koopialipoor, M.; Armaghani, D.J.; Ghabussi, A.; Baharom, S.; Morasaei, A.; Shariati, A.; Khorami, M.; Zhou, J. Evaluating the bond strength of FRP in concrete samples using machine learning methods. Smart Struct. Syst. 2020, 26, 403–418. [Google Scholar] [CrossRef]

- Zhang, R.; Xue, X. A predictive model for the bond strength of near-surface-mounted FRP bonded to concrete. Compos. Struct. 2021, 262, 113618. [Google Scholar] [CrossRef]

- Cascardi, A.; Micelli, F. ANN-Based Model for the Prediction of the Bond Strength between FRP and Concrete. Fibers 2021, 9, 46. [Google Scholar] [CrossRef]

- Wang, W.-C.; Nguyen, N.-M.; Cao, M.-T. Smart ensemble machine learner with hyperparameter-free for predicting bond capacity of FRP-to-concrete interface: Multi-national data. Constr. Build. Mater. 2022, 345, 128158. [Google Scholar] [CrossRef]

- Barkhordari, M.S.; Armaghani, D.J.; Sabri, M.M.S.; Ulrikh, D.V.; Ahmad, M. The Efficiency of Hybrid Intelligent Models in Predicting Fiber-Reinforced Polymer Concrete Interfacial-Bond Strength. Materials 2022, 15, 3019. [Google Scholar] [CrossRef]

- Amin, M.N.; Iqbal, M.; Jamal, A.; Ullah, S.; Khan, K.; Abu-Arab, A.M.; Al-Ahmad, Q.M.S.; Khan, S. GEP Tree-Based Prediction Model for Interfacial Bond Strength of Externally Bonded FRP Laminates on Grooves with Concrete Prism. Polymers 2022, 14, 2016. [Google Scholar] [CrossRef]

- Alabdullh, A.A.; Biswas, R.; Gudainiyan, J.; Khan, K.; Bujbarah, A.H.; Alabdulwahab, Q.A.; Amin, M.N.; Iqbal, M. Hybrid Ensemble Model for Predicting the Strength of FRP Laminates Bonded to the Concrete. Polymers 2022, 14, 3505. [Google Scholar] [CrossRef]

- Amin, M.N.; Salami, B.A.; Zahid, M.; Iqbal, M.; Khan, K.; Abu-Arab, A.M.; Alabdullah, A.A.; Jalal, F.E. Investigating the Bond Strength of FRP Laminates with Concrete Using LIGHT GBM and SHAPASH Analysis. Polymers 2022, 14, 4717. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.-F.; Chen, B.-Y.; Syu, J.-Y.; Ramanathan, G.K.; Lee, W.-H.; Huang, C.-H.; Lok, M.-H. A Constitutive Model for Circular and Square Cross-Section Concrete Confined with Aramid FRP Laminates. Buildings 2023, 13, 2895. [Google Scholar] [CrossRef]

- Huang, J.; Li, T.; Zhu, D.; Gao, P.; Zhou, A. Compressive behavior of circular and square concrete column externally confined by different types of basalt fiber–reinforced polymer. Adv. Struct. Eng. 2020, 23, 1534–1547. [Google Scholar] [CrossRef]

- Ma, G.; Chen, X.; Biçici, E.; Hou, C.; Sezen, H. Effect of Size and Slenderness on the Axial-Compressive Behavior of Basalt FRP-Confined Predamaged Concrete. J. Compos. Constr. 2021, 25, 04021012. [Google Scholar] [CrossRef]

- Ma, G.; Wu, C.; Hwang, H.-J.; Bai, J.; Zeng, Z. Behavior of pre-damaged normal-strength concrete prisms repaired with basalt FRP sheets under axial compressive monotonic and repeated loading. Eng. Struct. 2022, 269, 114786. [Google Scholar] [CrossRef]

- Xie, D.; Hu, Z.; Wang, B.; Zhao, K.; Shi, Y. Axial behavior of basalt FRP-confined reinforced concrete columns with square sections of different corner radii. Eng. Struct. 2023, 274, 115153. [Google Scholar] [CrossRef]

- Ahmad, A.; Khan, Q.U.Z.; Raza, A. Reliability analysis of strength models for CFRP-confined concrete cylinders. Compos. Struct. 2020, 244, 112312. [Google Scholar] [CrossRef]

- Mai, A.D.; Sheikh, M.N.; Hadi, M.N. Failure envelopes of square and circularized RC columns discretely confined with CFRP. Constr. Build. Mater. 2020, 261, 119937. [Google Scholar] [CrossRef]

- Diboune, N.; Benzaid, R.; Berradia, M. New strength–strain model and stress–strain relationship for square and rectangular concrete columns confined with CFRP wraps. Mech. Adv. Mater. Struct. 2022, 30, 2971–2994. [Google Scholar] [CrossRef]

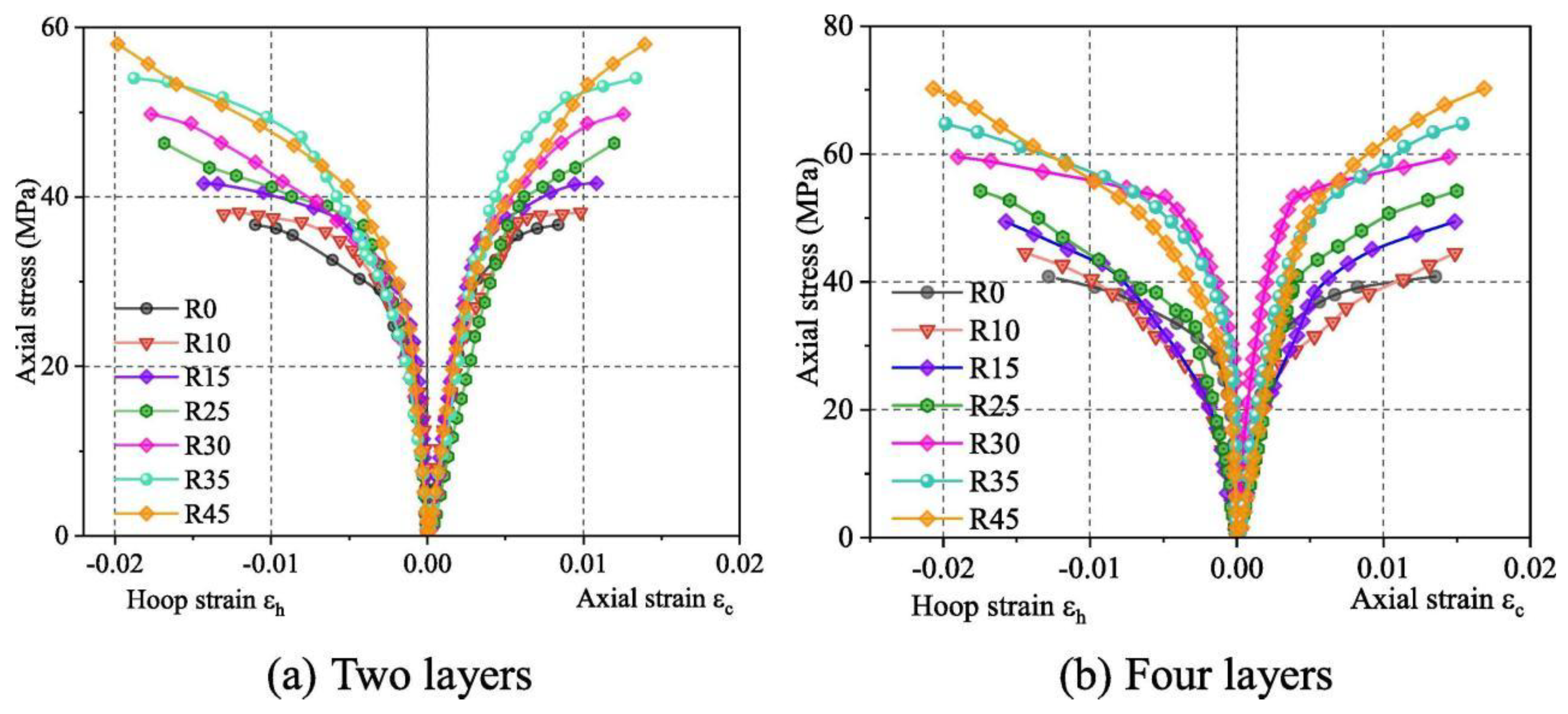

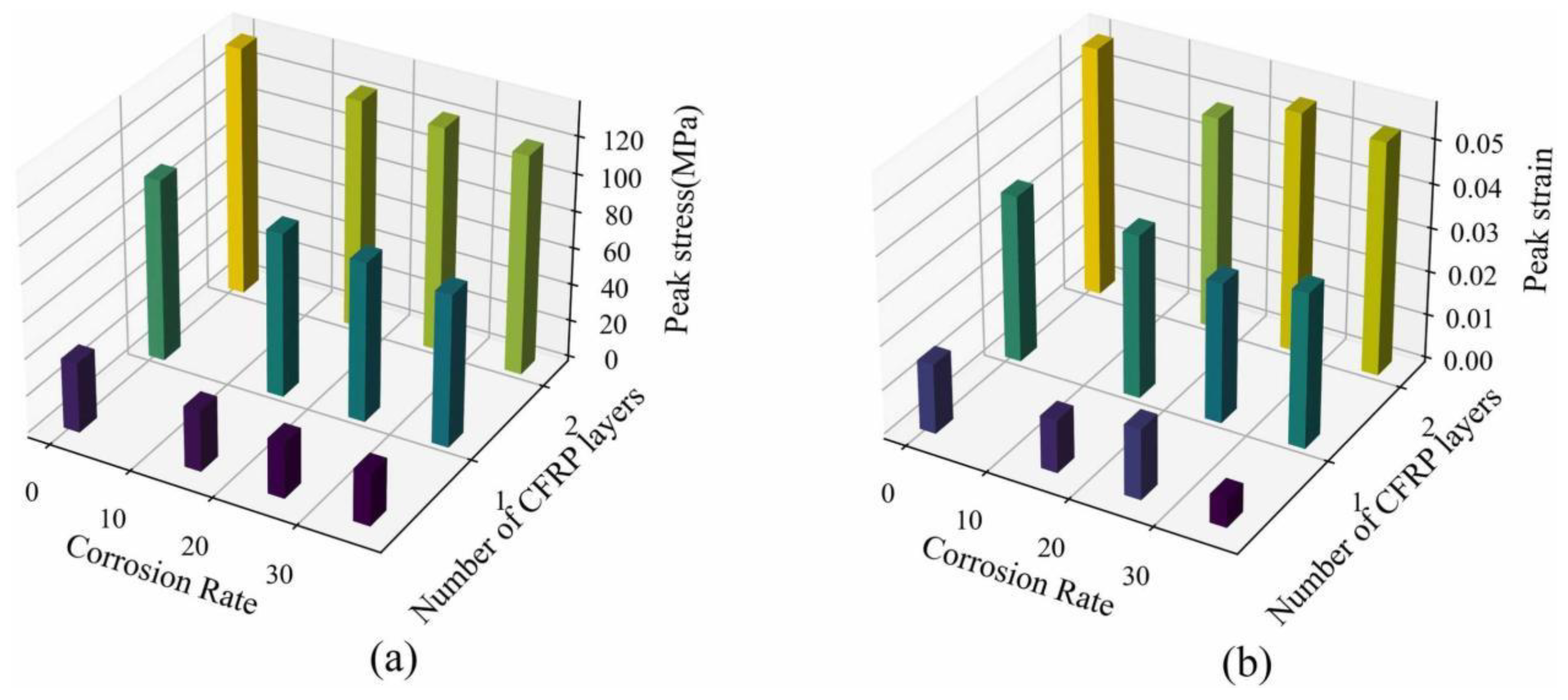

- Li, L.; Chen, J.; Wang, W.; Dai, K.; Hu, W. Experimental and prediction model of axial compressive responses of corroded RC cylinders strengthened with CFRP. Eng. Struct. 2024, 317, 118649. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, X.; Liu, Y.; Liang, X.; Lu, C. Axial stress-strain behavior of pre-stressed CFRP confined concrete columns. Constr. Build. Mater. 2024, 446, 138003. [Google Scholar] [CrossRef]

- Cao, Y.-G.; Zhang, Y.; Liu, M.-Y.; Lu, Z.-F.; Jiang, C. Analysis-oriented stress-strain model for FRP-confined predamaged concrete. J. Build. Eng. 2021, 36, 102121. [Google Scholar] [CrossRef]

- Yang, J.; Wang, J.; Wang, Z. Design-oriented axial stress–strain model for partially fiber-reinforced-polymer-confined normal-strength concrete. Adv. Struct. Eng. 2020, 23, 3481–3495. [Google Scholar] [CrossRef]

- Shayanfar, J.; Rezazadeh, M.; Barros, J.A. Analytical Model to Predict Dilation Behavior of FRP Confined Circular Concrete Columns Subjected to Axial Compressive Loading. J. Compos. Constr. 2020, 24, 04020071. [Google Scholar] [CrossRef]

- Shayanfar, J.; Barros, J.A.O.; Rezazadeh, M. Generalized Analysis-oriented model of FRP confined concrete circular columns. Compos. Struct. 2021, 270, 114026. [Google Scholar] [CrossRef]

- Shayanfar, J.; Barros, J.A.; Rezazadeh, M. Unified model for fully and partially FRP confined circular and square concrete columns subjected to axial compression. Eng. Struct. 2022, 251, 113355. [Google Scholar] [CrossRef]

- Shayanfar, J.; Barros, J.A.O.; Rezazadeh, M. Analysis-oriented model for partially FRP-and-steel-confined circular RC columns under compression. Eng. Struct. 2023, 276, 115330. [Google Scholar] [CrossRef]

- Li, B.; Jiang, J.; Xiong, H.; Zhan, Y.; Wu, Z.; Cunningham, L.S. Improved concrete plastic-damage model for FRP-confined concrete based on true tri-axial experiment. Compos. Struct. 2021, 269, 114051. [Google Scholar] [CrossRef]

- Jiang, J.-F.; Wu, Y.-F. Identification of material parameters for Drucker–Prager plasticity model for FRP confined circular concrete columns. Int. J. Solids Struct. 2012, 49, 445–456. [Google Scholar] [CrossRef]

- Teng, J.G.; Yu, T.; Wong, Y.L.; Dong, S.L. Hybrid FRP–concrete–steel tubular columns: Concept and behavior. Constr. Build. Mater. 2007, 21, 846–854. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Gholampour, A.; Lim, J.C. Damage-plasticity model for FRP-confined normal-strength and high-strength concrete. J. Compos. Constr. 2016, 20, 04016053. [Google Scholar] [CrossRef]

- Wang, W.; Sheikh, M.N.; Zeng, J.-J.; Hadi, M.N. Ultimate strain prediction of partially FRP confined concrete considering strain localization. Constr. Build. Mater. 2022, 346, 128486. [Google Scholar] [CrossRef]

- Wang, J.; Xiao, H.; Lu, L.; Yang, J.; Lu, S.; Shayanfar, J. Axial stress-strain model for concrete in partially FRP wrapped reinforced concrete columns. Constr. Build. Mater. 2024, 416, 135028. [Google Scholar] [CrossRef]

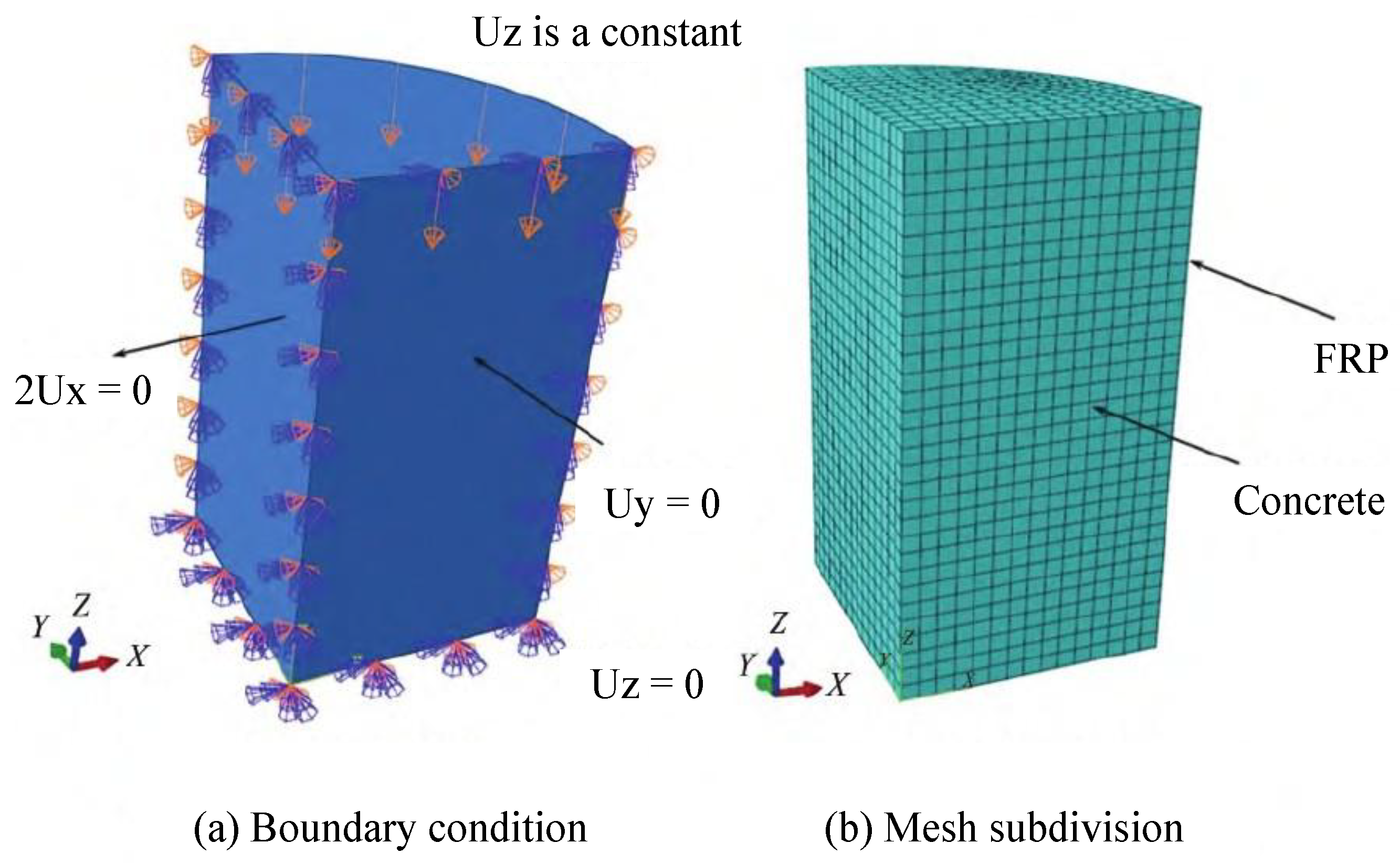

- Ji, Y.; Zou, Y. Study on strain response and numerical model of concrete columns partially constrained by FRP based on finite element and DIC tests. Compos. Mater. Sci. Eng. 2024, 76–86+94. [Google Scholar]

- Ma, G.; Chen, X.; Yan, L.; Hwang, H.-J. Effect of pre-damage on compressive properties of circular RC columns repaired with BFRP composites: Testing and modeling. Compos. Struct. 2020, 247, 112483. [Google Scholar] [CrossRef]

- Mander, J.B.; Priestley, M.J.N.; Park, R. Theoretical Stress-Strain Model for Confined Concrete. J. Struct. Eng. 1988, 114, 1804–1826. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, D.; Smith, S.T.; Lu, D. Experimental testing and analytical modeling of CFRP-confined large circular RC columns subjected to cyclic axial compression. Eng. Struct. 2012, 40, 64–74. [Google Scholar] [CrossRef]

- Tijani, I.A.; Jiang, C.; Lim, C.W.; Wu, Y.F. Effect of Load Eccentricity on the Mechanical Response of FRP-Confined Predamaged Concrete under Compression. J. Compos. Constr. 2020, 24, 04020057. [Google Scholar] [CrossRef]

- Tijani, I.A.; Jiang, C.; Lim, C.W.; Wu, Y.F. Eccentrically Loaded Concrete under Nonuniform Passive Confinement. J. Struct. Eng. 2022, 148, 04021247. [Google Scholar] [CrossRef]

- Zheng, B.T.; Teng, J.G. Finite-Element Modeling of FRP-Confined Noncircular Concrete Columns Using the Evolutionary Potential-Surface Trace Plasticity Constitutive Model for Concrete. J. Compos. Constr. 2023, 27, 04022089. [Google Scholar] [CrossRef]

- Wang, J.; Lu, S.; Yang, J. Behavior of eccentrically loaded rectangular RC columns wrapped with CFRP jackets under different preloading levels. J. Build. Eng. 2021, 34, 101943. [Google Scholar] [CrossRef]

- Lu, S.; Wang, J.; Yang, J.; Wang, L. Numerical analysis of preloaded FRP-strengthened concrete columns under axial compression. Constr. Build. Mater. 2022, 357, 129297. [Google Scholar] [CrossRef]

- Fan, L.; Jin, L.; Du, X. Effects of structural size and corner radius on eccentric failure of rectangular CFRP-wrapped RC columns: Meso-scale modellings. Eng. Struct. 2023, 283, 115893. [Google Scholar] [CrossRef]

- Yongchang, G.; Jianhe, X.; Zhihong, X.; Jian, Z. Experimental study on compressive behavior of damaged normal-and high-strength concrete confined with CFRP laminates. Constr. Build. Mater. 2016, 107, 411–425. [Google Scholar]

- Kobbekaduwa, D.; Nanayakkara, O.; Di Sarno, L.; Krevaikas, T. Strengthening and repair of deficient reinforced concrete columns using textile-reinforced mortar: State-of-the-art review. Structures 2024, 65, 106739. [Google Scholar] [CrossRef]

- Yan, Z.; Pantelides, C.P.; Reaveley, L.D. Posttensioned FRP composite shells for concrete confinement. J. Compos. Constr. 2007, 11, 81–90. [Google Scholar] [CrossRef]

- Tastani, S.P.; Stavroula, J. Pantazopoulou. Experimental evaluation of FRP jackets in upgrading RC corroded columns with substandard detailing. Eng. Struct. 2004, 26, 817–829. [Google Scholar] [CrossRef]

- Valdmanis, V.; De Lorenzis, L.; Rousakis, T.; Tepfers, R. Behaviour and capacity of CFRP-confined concrete cylinders subjected to monotonic and cyclic axial compressive load. Struct. Concr. 2007, 8, 187–200. [Google Scholar] [CrossRef]

- He, R.; Grelle, S.; Sneed, L.H.; Belarbi, A. Rapid repair of a severely damaged RC column having fractured bars using externally bonded, C.F.R.P. Compos. Struct. 2013, 101, 225–242. [Google Scholar] [CrossRef]

- Davide, L.; Nuti, C. Pseudo-dynamic tests on reinforced concrete bridges repaired and retrofitted after seismic damage. Eng. Struct. 2015, 94, 96–112. [Google Scholar]

- Yan, X.; Wu, W. Retrofit of reinforced concrete columns using partially stiffened steel jackets. J. Struct. Eng. 2003, 129, 725–732. [Google Scholar]

- Wu, Y.F.; Griffith, M.C.; Oehlers, D.J. Improving the strength and ductility of rectangular reinforced concrete columns through composite partial interaction: Tests. J. Struct. Eng. 2003, 129, 1183–1190. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, D.; Abdalla, J.A.; Hawileh, R.A.; Qin, F.; Xu, X. Flexural behavior of reinforced concrete beams externally strengthened with ECC and FRP grid reinforcement. Constr. Build. Mater. 2024, 446, 137964. [Google Scholar] [CrossRef]

- Li, G.; Hedlund, S.; Pang, S.-S.; Alaywan, W.; Eggers, J.; Abadie, C. Repair of damaged RC columns using fast curing FRP composites. Compos. Part. B Eng. 2003, 34, 261–271. [Google Scholar] [CrossRef]

- Yurdakul, Ö.; Vnenk, P.; Routil, L.; Culek, B.; Avşar, Ö. Post-damage recovery of substandard RC columns by CFRPs. Eng. Struct. 2024, 306, 117806. [Google Scholar] [CrossRef]

- Hao, X.-K.; Feng, Q.; Zheng, J.-J. A passive stress-strain model for concrete prisms reinforced by a combination of confinement reinforcement. Eng. Struct. 2021, 246, 112981. [Google Scholar] [CrossRef]

- Cao, Y.; Liu, M.; Wu, Y.-F. Effect of low strain rate on the axial behavior of concrete in CFRP-confined circular cylinders. Constr. Build. Mater. 2020, 255, 119351. [Google Scholar] [CrossRef]

- Zhang, B.C.; Pan, J.L. Stress-strain relation of FRP confined concrete subjected to fast load. Expl. Shock. Waves 2003, 23, 466–471. [Google Scholar]

- Zhang, B.C.; Pan, J.L.; Jiang, H.B. Computation of strength for FRP confined concrete under fast loading. J. Harbin Inst. Technol. 2003, 35, 958–961. [Google Scholar]

- Zhang, Y.M. Experimental Study of the Mechanical Properties of Concrete Under Different Strain Rates. Ph.D. Thesis, Beijing University of Technology, Beijing, China, 2012. (In Chinese). [Google Scholar]

- Zhang, Y.; Lu, Z.F.; Cao, Y.G. Unified strength model based on the Hoek-Brown failure criterion for fibre-reinforced polymer-confined pre-damaged concrete columns with circular and square cross sections. J. Cent. South. Univ. 2020, 27, 3807–3820. [Google Scholar] [CrossRef]

- Chen, G.; Wang, Y.; Yu, T.; Wan, B.; Zhang, B.; Liu, Q. Behavior and design-oriented model for elliptical FRP-confined concrete under axial compression. Eng. Struct. 2021, 249, 113387. [Google Scholar] [CrossRef]

- Chen, G.; Wang, Y.; Yu, T.; Zhang, B.; Zhang, Y. Cyclically loaded elliptical FRP-confined concrete: Behavioral characteristics and modeling. Eng. Struct. 2023, 285, 116044. [Google Scholar] [CrossRef]

- Saleh, E.; Tarawneh, A.; Almasabha, G.; Momani, Y. Slenderness limit of FRP-confined rectangular concrete columns. Structures 2022, 38, 435–447. [Google Scholar] [CrossRef]

- Liao, J.; Zeng, J.-J.; Jiang, C.; Li, J.-X.; Yuan, J.-S. Stress-strain behavior and design-oriented model for FRP spiral strip-confined concrete. Compos. Struct. 2022, 293, 115747. [Google Scholar] [CrossRef]

- Gharaei-Moghaddam, N.; Arabshahi, A.; Tavakkolizadeh, M. Predictive models for the peak stress and ultimate strain of FRP confined concrete cylinders with inclined fiber orientations. Results Eng. 2023, 18, 101044. [Google Scholar] [CrossRef]

- Arabshahi, A.; Gharaei-Moghaddam, N.; Tavakkolizadeh, M. Development of applicable design models for concrete columns confined with aramid fiber reinforced polymer using Multi-Expression Programming. Structures 2019, 23, 225–244. [Google Scholar] [CrossRef]

- ACI 440.2 R-17: Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Concrete Structures; American Concrete Institute: Farmington Hills, MI, USA, 2017.

- Li, P.; Jin, L.; Liang, J.; Fan, L.; Du, X. Size effect on the compressive behavior of BFRP RC circular columns: Experiments and a size-dependent stress-strain model. Compos. Struct. 2023, 321, 117276. [Google Scholar] [CrossRef]

- Jiang, Y.; Zhang, S.; Zhang, B.; Xue, G.; Wang, W. Experimental study and analytical modeling on dynamic compressive behavior of BFRP-confined concrete under high strain rates. Constr. Build. Mater. 2023, 398, 132515. [Google Scholar] [CrossRef]

- Chen, G.M.; Fu, M.Q.; Zhang, J.J.; Lin, G.; Chen, J.P.; Jiang, T. FRP spiral strip-confined concrete columns: Stress-strain behavior and size effect. Structures 2023, 57, 105223. [Google Scholar] [CrossRef]

- Luke, Z.; Feng, Z.; Guohao, Z. A Modified Drucker-Prager Model for FRP-Constrained Concrete Columns. Compos. Mater. Sci. Eng. 2023, 60–68+86. [Google Scholar] [CrossRef]

- Zhou, J.-K.; Zeng, J.-J.; Guo, Y.-C.; Zhuge, Y.; Liu, W.-T.; Xie, Z.H.; Zheng, Y. Behavior and theoretical model of FRP-RC columns under cyclic axial compression. Compos. Struct. 2024, 334, 117947. [Google Scholar] [CrossRef]

- Wu, Z.-X.; Lei, J.-J.; Ye, C.; Yu, C.; Zhao, J. Coupled FDM-DEM simulations of axial compression tests on FRP-confined concrete specimens. Constr. Build. Mater. 2022, 351, 128885. [Google Scholar] [CrossRef]

- Sun, P.-X.; Bai, Y.-L. Theoretical study on FRP-confined rectangular columns considering rebar buckling. Constr. Build. Mater. 2024, 420, 135480. [Google Scholar] [CrossRef]

- Zhong, S.; Zhang, L.; Zhu, J. A path-dependent stress-strain model of FRP-confined circular concrete columns derived from an energy balance approach. Eng. Struct. 2024, 321, 118919. [Google Scholar] [CrossRef]

- Shayanfar, J.; Barros, J.A.O. Design-Oriented Model of Unified Character to Determine Softening–Hardening Stress–Strain Behavior of FRP-Confined Concrete Columns of General Cross Section. J. Compos. Constr. 2024, 28, 04024059. [Google Scholar] [CrossRef]

- Naderpour, H.; Kheyroddin, A.; Amiri, G.G.; Vaez, S.H. Estimating the Behavior of FRP-Strengthened RC Structural Members Using Artificial Neural Networks. Procedia Eng. 2011, 14, 3183–3190. [Google Scholar] [CrossRef]

- Milad, A.; Hussein, S.H.; Khekan, A.R.; Rashid, M.; Al-Msari, H.; Tran, T.H. Development of ensemble machine learning approaches for designing fiber-reinforced polymer composite strain prediction model. Eng. Comput. 2022, 38, 3625–3637. [Google Scholar] [CrossRef]

- Ilyas, I.; Zafar, A.; Afzal, M.T.; Javed, M.F.; Alrowais, R.; Althoey, F.; Mohamed, A.M.; Mohamed, A.; Vatin, N.I. Advanced Machine Learning Modeling Approach for Prediction of Compressive Strength of FRP Confined Concrete Using Multiphysics Genetic Expression Programming. Polymers 2022, 14, 1789. [Google Scholar] [CrossRef]

- Pour, A.F.; Faradonbeh, R.S.; Gholampour, A.; Ngo, T.D. Predicting ultimate condition and transition point on axial stress–strain curve of FRP-confined concrete using a meta-heuristic algorithm. Compos. Struct. 2023, 304, 116387. [Google Scholar] [CrossRef]

- Chen, P.; Wang, H.; Cao, S.; Lv, X. Prediction of Mechanical Behaviours of FRP-Confined Circular Concrete Columns Using Artificial Neural Network and Support Vector Regression: Modelling and Performance Evaluation. Materials 2022, 15, 4971. [Google Scholar] [CrossRef]

- Hanteh, M.; Malek, H.; Kheyroddin, A. Proposing the combined MARS–PSO and ELM–PSO models for estimating the compressive strength of circular concrete columns wrapped with FRP sheets. Soft Comput. 2023, 27, 15937–15953. [Google Scholar] [CrossRef]

- Kumar, P.; Arora, H.C.; Bahrami, A.; Kumar, A.; Kumar, K. Development of a Reliable Machine Learning Model to Predict Compressive Strength of FRP-Confined Concrete Cylinders. Buildings 2023, 13, 931. [Google Scholar] [CrossRef]

- Cakiroglu, C. Explainable Data-Driven Ensemble Learning Models for the Mechanical Properties Prediction of Concrete Confined by Aramid Fiber-Reinforced Polymer Wraps Using Generative Adversarial Networks. Appl. Sci. 2023, 13, 11991. [Google Scholar] [CrossRef]

- Peng, F.; Li, Y.; Xue, W. Transfer learning-based confinement strength prediction of concrete confined by FRP transverse reinforcements. Eng. Struct. 2024, 310, 118116. [Google Scholar] [CrossRef]

- Xu, C.; Zhang, Y.; Isleem, H.F.; Qiu, D.; Zhang, Y.; Alsaadawi, M.M.; Tipu, R.K.; El-Demerdash, W.E.; Hamed, A.Y. Numerical and machine learning models for concentrically and eccentrically loaded CFST columns confined with FRP wraps. Struct. Concr. 2024. [CrossRef]

- Yue, C.; Isleem, H.F.; Qader, D.N.; Mahmoudian, A.; Weiming, T.; Jangir, P.; Arpita; Hamed, A.Y. Utilization finite element and machine learning methods to investigation the axial compressive behavior of elliptical FRP-confined concrete columns. Structures 2024, 70, 107681. [Google Scholar] [CrossRef]

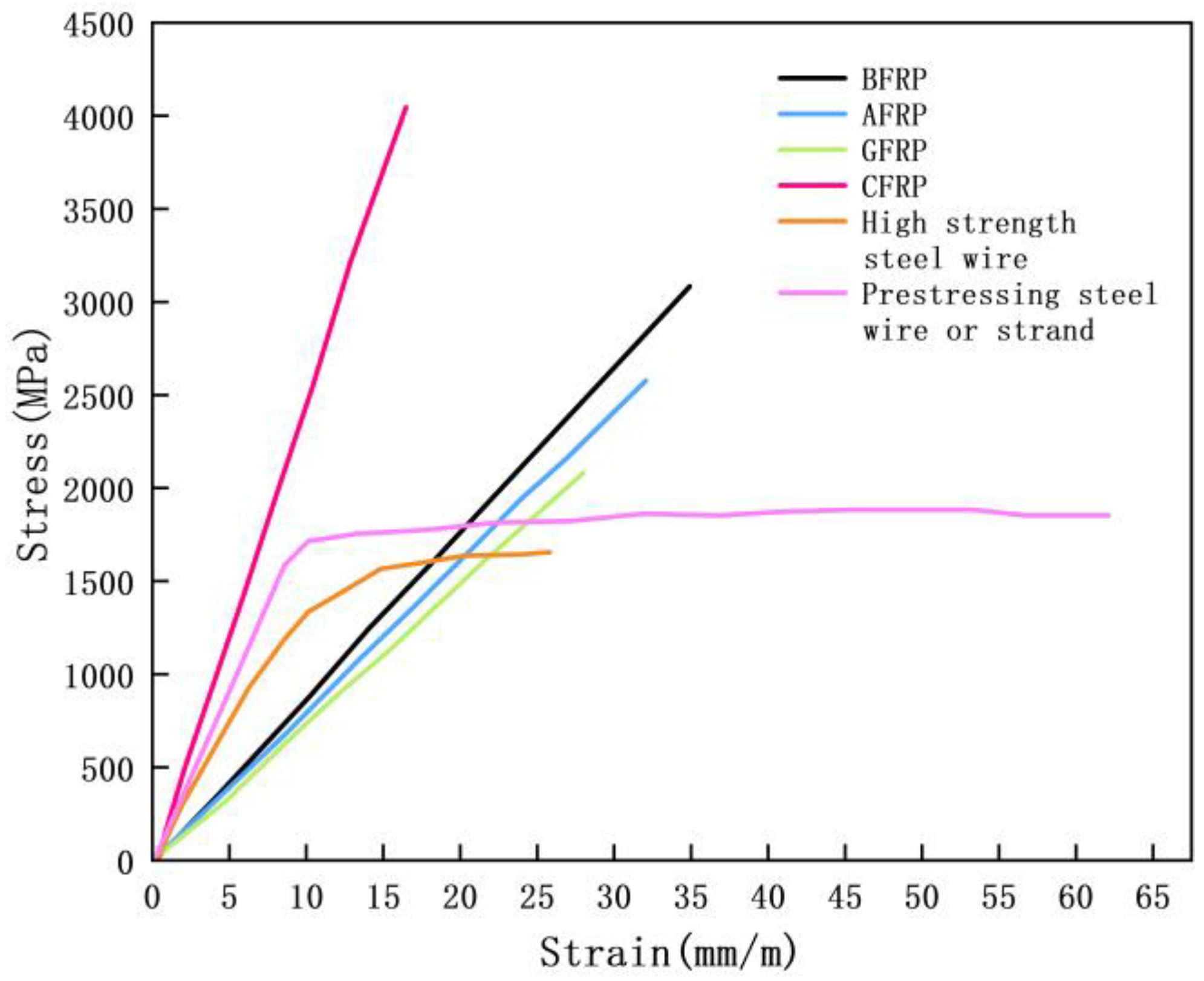

| CFRP | GFRP | AFRP | BFRP | |

|---|---|---|---|---|

| Tensile Strength/MPa | 1650–3000 | 517–1207 | 1200–2068 | 1500–2400 |

| Modulus of Elasticity/GPa | 152–165 | 41–55 | 50–74 | 90–130 |

| Rate of elongation/% | 1–1.5 | 3.5–5 | 2–2.6 | 1.2–1.6 |

| Specific gravity | 1.5–1.6 | 1.5–2.0 | 1.25–1.4 | 1.9–2.1 |

| Researchers | ML Model | Validation Set | Training Set | Test Set | Number of Input Layer Nodes/(Number) | Hidden Layers/Nodes | R | ||

|---|---|---|---|---|---|---|---|---|---|

| Mashrei [77] | BPNN | / | 83% | 17% | 6 | bc/(mm) | 100–228 | 2/5 | Train = 0.99 |

| fc’/(MP) | 16–50 | ||||||||

| bf/(mm) | 10–100 | ||||||||

| t/(mm) | 0.08–1.4 | Test = 0.99 | |||||||

| Efrp/(GPa) | 83–300 | ||||||||

| Lb/(mm) | 50–300 | ||||||||

| Amin [90] | LIGHT GBM | / | 70% | 30% | 5 | Efrp*t/(Gpa*mm) | 12.9–78.2 | / | Train = 0.942 |

| bf/(mm) | 30–60 | ||||||||

| fc’/(Mpa) | 22.7–48.2 | Test = 0.8 | |||||||

| Dg/(mm) | 5–10 | ||||||||

| Wg/(mm) | 5–15 | ||||||||

| Wang [86] | RBFNN, LSVR | / | 88% | 12% | 6 | bc/(mm) | 80–500 | RBF neuron | (R2) |

| fc’/(MP) | 8–75.5 | ||||||||

| bf/(mm) | 10–150 | Train = 0.92 | |||||||

| t/(mm) | 0.083–4 | Test = 0.85 | |||||||

| Efrp/(GPa) | 22.5–425 | Test = 0.85 | |||||||

| Lb/(mm) | 20–400 | ||||||||

| Golafshani [78] | ANN, GP | 15% | 70% | 15% | 7 | Pos | 1–2 | 1/12 | / |

| Surf | 1–3 | ||||||||

| db/(mm) | 9.53–28.58 | ||||||||

| fc’/(Mpa) | 23.43–48.86 | ||||||||

| C/db | 1–6.2 | ||||||||

| l/db | 3.56–97.24 | ||||||||

| Atr/sndb | 0–0.08 | ||||||||

| Köroğlu [80] | ANN | / | 88% | 12% | 8 | FRP type | 1–3 | 2/30 | R2 = 0.9 |

| Surf | 1–3 | ||||||||

| Confining | 1–2 | ||||||||

| db/(mm) | 6.38–28.58 | ||||||||

| fc’/(Mpa) | 4.29–8.08 | ||||||||

| C/db | 0.92–9.34 | ||||||||

| l/db | 2.5–115.79 | ||||||||

| Atr/sndb | 0–0.15 | ||||||||

| Zhang [84] | GEP, RF | / | 69% | 31% | 5 | Lb/(mm) | 30–508 | / | GEP |

| EfAf/(kN) | 1300–15,947 | RTrain2 = 0.871 | |||||||

| Dg/Wg | 1–6.875 | RTest2 = 0.800 | |||||||

| ffrp/(Mpa) | 6–90.7 | RF | |||||||

| RTrain2 = 0.962 | |||||||||

| fc’/(Mpa) | 19–64.8 | RTest2 = 0.780 | |||||||

| Researchers | Research Method | Fiber Type | Obligatory Object | Cons Type | Variate | Data Set/ Validation Set | Statistical Indicators | |

|---|---|---|---|---|---|---|---|---|

| Li et al. [91] | RA | AFRP | Cylinder, Square column | fully | n; w/c; shape | 156/42 | R2 | |

| 1 layer | 0.86 | |||||||

| 2 layer | 0.86 | |||||||

| 3 layer | 0.906 | |||||||

| 4 layer | 0.93 | |||||||

| Huang et al. [92] | RA | BFRP | Cylinder, Square column | fully | Fty; n; shape | 59/ | R2 | |

| Cylindrical strength | 0.98 | |||||||

| Square column strength | 0.92 | |||||||

| Cylindrical strain | 0.95 | |||||||

| Square column strain | 0.90 | |||||||

| Yang et al. [102] | RA | / | Cylinder | partially | St/d; fl,a′/Ucc | 100/100 | / | |

| Li et al. [107] | RA, CM | / | Cylinder, Square column | fully and partially | Ucc; Cl | 117/26 | Fully cylinder | IAE |

| Axial direction | 0.0499 | |||||||

| Partially cylinder | IAE | |||||||

| Axial direction | 0.0786 | |||||||

| Lateral direction | 0.0661 | |||||||

| Square column | IAE | |||||||

| Axial direction | 0.0733 | |||||||

| Lateral direction | 0.0926 | |||||||

| Wang et al. [111] | CM | / | Cylinder | partially | bf; St; n | 12/89 | R2 | |

| Strain | 0.906 | |||||||

| Strain localization | 0.992 | |||||||

| Wang et al. [112] | CM | CFRP | RC Cylinder | partially | Pos; n; bf; sndb | 27/24 | AAE | |

| Strength | 0.074 | |||||||

| Strain | 0.137 | |||||||

| Researchers | ML Model | VALIDATION SET | Training Set | Test Set | Number of Input Layer Nodes/(Number) | Hidden Layers/Nodes | Statistical Indicators | |||

|---|---|---|---|---|---|---|---|---|---|---|

| Naderpour et al. [157] | ANN | 20% | 60% | 17% | 6 | d/(mm) | / | 1/11 | MSE = 0.001 | |

| h/(mm) | / | |||||||||

| t/(mm) | / | |||||||||

| Ft/(Mpa) | / | |||||||||

| Ucc/(Mpa) | / | |||||||||

| Efrp/(Gpa) | / | |||||||||

| Raza et al. [96] | ANN | 20% | 60% | 20% | 5 | d/(mm) | 51–406 | 2/20 | R2 | |

| h/(mm) | 102–812 | 0.907 | ||||||||

| t/(mm) | 0.09–5.9 | RMSE | ||||||||

| Efrp/(Gpa) | 10–663 | 0.204 | ||||||||

| Ucc/(Mpa) | 12.41–188.2 | |||||||||

| Ilyas et al. [159] | GEP | / | 70% | 30% | 5 | d/(mm) | 0~400 | / | R2 | |

| h/(mm) | 100~800 | 0.917 | ||||||||

| t/(mm) | 0~6 | RMSE | ||||||||

| Efrp/(Gpa) | 10~612 | 12.30 | ||||||||

| Ucc/(Mpa) | 6.25~187.5 | |||||||||

| chen et al. [161] | ANN, SVR | / | 80% | 20% | 6 | d/t | 0–500 | 1/10 | ANN | R2 |

| fco/(Mpa) | 9.9–136.3 | Strength | 0.92 | |||||||

| εco/(uε) | 1500–3000 | Strain | 0.87 | |||||||

| ffrp/(Mpa) | 2000–4000 | SVR | R2 | |||||||

| Efrp/(Gpa) | 200–300 | Strength | 0.96 | |||||||

| εfrp/(uε) | 3×10−4~4.5×10−4 | Strain | 0.94 | |||||||

| Hanteh et al. [162] | MARS-PSO | / | 70% | 30% | 6 | d/(mm) | 51–219 | / | R | |

| h/(mm) | 102–438 | |||||||||

| Ucc/(MPa) | 0.089–5.9 | train | 0.997 | |||||||

| t/(mm) | 19.4–103 | |||||||||

| fl/(MPa) | 2.33–94.57 | test | 0.996 | |||||||

| ffrp/(MPa) | 229.76–3820.36 | |||||||||

| Kumaret al [163] | OP-GPR | / | 70% | 30% | 11 | d/(mm) | 50–310 | / | R | |

| fc’/(Mpa) | 8–204 | |||||||||

| h/(mm) | 100–1000 | |||||||||

| Ucc/(Mpa) | 6.2–200 | train | 0.998 | |||||||

| Fty | 1–4 | |||||||||

| n | 0.3–14 | |||||||||

| bf/(mm) | 15–1000 | |||||||||

| t/(mm) | 0.05–3.9 | test | 0.992 | |||||||

| Of | 1–2 | |||||||||

| Efrp/(Gpa) | 21.3–251 | |||||||||

| ffrp/(MPa) | 69–4580 | |||||||||

| Peng et al. [165] | NTLA | / | 80% | 20% | 7 | Acore/(mm2) | 19,855.7–360,000 | / | R2 | |

| Ucc/(Mpa) | 18.972–40.476 | |||||||||

| d/(mm) | 6.4–20 | |||||||||

| St/(mm) | 30–150 | train | 0.938 | |||||||

| ffrp/(MPa) | 640–2551 | |||||||||

| Efrp/(Gpa) | 44–157 | test | 0.909 | |||||||

| shape | 1–2 | |||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Z.; Sun, C.; Qu, J.; Mokhov, A. State-of-the-Art Review of the Performance of Fiber-Reinforced-Composite-Confined Concrete Columns at Ambient Temperatures. Materials 2025, 18, 1151. https://doi.org/10.3390/ma18051151

Liu Z, Sun C, Qu J, Mokhov A. State-of-the-Art Review of the Performance of Fiber-Reinforced-Composite-Confined Concrete Columns at Ambient Temperatures. Materials. 2025; 18(5):1151. https://doi.org/10.3390/ma18051151

Chicago/Turabian StyleLiu, Zhixin, Chaochao Sun, Jili Qu, and Alexander Mokhov. 2025. "State-of-the-Art Review of the Performance of Fiber-Reinforced-Composite-Confined Concrete Columns at Ambient Temperatures" Materials 18, no. 5: 1151. https://doi.org/10.3390/ma18051151

APA StyleLiu, Z., Sun, C., Qu, J., & Mokhov, A. (2025). State-of-the-Art Review of the Performance of Fiber-Reinforced-Composite-Confined Concrete Columns at Ambient Temperatures. Materials, 18(5), 1151. https://doi.org/10.3390/ma18051151