Highlights

- Several Constitutive models (CP, MZA, S1-MJC, S2-MJC) are proposed to predict the hot flow behavior of Al-Mg-Si alloy.

- Advanced mathematical techniques are used to determine their material parameters.

- The CP model achieves superior predictions by connecting Al-Mg-Si microstructure and mechanical behavior.

- The S2-MJC model accurately predicts Al-Mg-Si flow behavior by linking softening and dynamic recovery.

Abstract

The hot-flow behaviors of Al-Mg-Si alloy are complex because they depend on , , and . Hence, it is vital to understand and determine the Al-Mg-Si alloy’s flow behaviors under several deformation conditions. Therefore, in this study, Crystal Plasticity (CP) modeling, modified Zerilli–Armstrong (MZA), and two JC models were developed to precisely determine the hot deformation behaviors of this alloy. The reliability and predictability of these models were evaluated via comparisons of the determined and experimental results acquired in the range of 10−3 to 1 s−1 and range of 400–550 °C. Additionally, statistical parameters including the RMSE, AARE, and R were utilized to assess these models’ reliability for determining this alloy’s flow behaviors under several forming conditions. By analyzing these statistical parameters and comparing the predicted and experimental stresses, it can be concluded that the flow stresses predicted by the CP modeling and S2-MJC model exhibit a strong alignment with the experimental flow stresses. This contrasts with the results from the MZA and S1-MJC models. These results are attributed to the ability of CP modeling to couple the microstructure state of this alloy and the interactions between and on the one hand and between , , and on the other hand, facilitated by a comprehensive set of parameters that link the dynamic recovery and softening mechanisms components in the S2‐MJC model.

1. Introduction

Al alloys are widely recognized as a green material because of their exceptional environmental benefits and sustainable characteristics, making them highly valued across construction, automotive, and aerospace industries [1]. A key factor in their sustainability is their high recyclability as Al can be recycled indefinitely without losing its properties [2]. Recycling Al requires only 5% of the energy used in primary production processes such as the Hall–Héroult and Bayer methods, significantly reducing greenhouse gas emissions and promoting a circular economy [3].

In addition to recyclability, Al alloys offer a combination of valuable attributes. Their low density reduces the weight in large structures and vehicles, improving efficiency and reducing material consumption [4]. Coupled with high strength and corrosion resistance, Al alloys provide long-term durability and structural integrity, even in harsh environments such as marine settings [5]. These characteristics make Al alloys ideal for applications in high-rise buildings, where they ensure durability and resistance to corrosion; large-span structures, such as stadiums and airports, where their strength-to-weight ratio allows for open, functional designs; bridge construction, where they reduce structural weight and maintenance costs; and shipbuilding, where their corrosion resistance and lightweight nature improve fuel efficiency and minimize maintenance in challenging marine environments [6,7,8].

By combining environmental benefits, energy efficiency, and versatility, Al alloys directly contribute to advancing Sustainable Development Goals (SDGs), including SDG 12, by promoting resource efficiency, reducing material waste, and encouraging circular economy practices. Additionally, their lightweight nature and high strength enable the production of energy-efficient vehicles and sustainable infrastructure, supporting SDG 9 and SDG 11. Al alloys support sustainable practices and drive innovation in modern industries, solidifying their importance in achieving global sustainability goals [9,10,11].

The Al-Mg-Si 6xxx-series alloy has gained significant attention in the automobile and aerospace industries because of its high specific strength, excellent formability, and excellent corrosion resistance, making it ideal for lightweight structural components [12,13,14]. Its use supports improved fuel efficiency, reduced emissions, and sustainable manufacturing practices, aligning with industry priorities [15]; however, its low formability at room temperature poses challenges in shaping complex components, leading to material waste and limiting its broader industrial applications in designs requiring high precision and minimal waste [13,14].

High-speed and elevated-temperature deformation techniques are commonly employed to enhance alloy formability, enabling the production of complex shapes while minimizing defects such as cracks [15,16,17,18,19,20,21,22,23]. For example, Abd El-Aty et al. [16] examined the tensile behavior of several Al alloys at high strain rates. They reported that high-speed forming is an effective technique for enhancing the formability of Al alloys at room temperature. Elevated-temperature forming is often preferred because it significantly improves alloy formability, facilitating deformation without fracturing and reducing the risk of defects [24]. This method allows for better control over the forming process and creates more complex geometries while lowering the stress on tools and equipment, extending their lifespan and reducing production costs [25]. In contrast, while effective for certain applications, high-speed forming can lead to challenges such as non-uniform strain distribution and a greater risk of surface defects due to rapid force application, making it harder to control [26]. For these reasons, elevated-temperature forming is a more reliable and controlled option in many industrial applications.

The flow behavior of Al alloys at elevated temperatures is complex because of interactions among , , and microstructural changes during deformation [27,28,29,30]. Therefore, understanding their deformation behaviors is critical for optimizing the forming process to ensure that components retain their mechanical properties and dimensional accuracy. For Al-Mg-Si alloys, experimental investigations under various , , and loading conditions are essential for evaluating their mechanical properties and deformation behavior. However, due to the complexity of hot deformation, computational tools are also necessary to predict and enhance material performance in industrial applications [29].

Advanced modeling techniques coupled with the FEM are essential for simulating and predicting the deformation behavior of metallic materials. The FEM enables manufacturers to optimize the strain distribution, temperature effects, and microstructural changes in a virtual environment before practical implementation [28,29,30]. Recent advances have led to the development of various constitutive models to predict the hot-flow behavior of metals, including phenomenological such as the JC model, physically based such as Zerilli–Armstrong (ZA) and CP modeling, as well as artificial neural network (ANN) models [31,32,33,34,35,36,37,38,39,40,41,42,43,44,45,46,47,48,49,50,51,52,53,54,55,56,57,58,59,60,61,62].

From the aforementioned discussion, it is summarized that predicting the hot-flow behaviors of Al-Mg-Si alloys is crucial for analyzing the influence of the interactions , , and microstructural changes during the deformation process. This understanding is essential for optimizing the forming processes to ensure that components maintain their mechanical properties and dimensional accuracy under high-temperature conditions. Thus, this study aims to develop and evaluate four advanced constitutive models including CP modeling, the MZA model, and two modified Johnson–Cook (JC) models to predict the hot deformation behavior of Al-Mg-Si alloys accurately. This work provides valuable insights for improving the efficiency and precision of industrial forming processes. The accuracy and predictability of these models are evaluated by comparing their results with the experimental results obtained from the investigation of Ghosh et al. [54]. Several statistical parameters, including R, AARE, and RMSE, were subsequently used to further validate the reliability of the proposed models in predicting the hot-flow behaviors of Al-Mg-Si alloys. A detailed discussion of each constitutive model is presented in the following sections.

2. Experimental Section

In the present study, the experimental results obtained by Ghosh et al. [54] were used to verify the predictability and reliability of the developed models. Their investigation explored the hot deformation behavior of an Al-Mg-Si alloy (AA6082) via a Gleeble-3800 thermomechanical simulator under 16 combinations of ranging from 0.001/s to 1/s as well as from 400 to 550 °C. The flow curves revealed that the deformation behavior aligns with typical alloys under similar elevated conditions, showing increased stress with higher strain rates due to dislocation interactions and decreased stress at higher temperatures due to dynamic recovery and recrystallization [54,55]. These findings provide a robust dataset for validating the proposed models and their accuracy in predicting material behavior under various forming conditions [56,57,58,59].

3. Physically Based Models

3.1. CP Modeling

As presented in Equation (1), which describes the deformation gradient is decomposed to and [60,61]. The following conditions are necessary due to the incompressibility during plastic deformation, described as . Since , Fe, and Fp are invertible.

Similarly, as explained in Equation (1), L describing the velocity gradient tensor was decomposed to and , where ; thus, L is written as described in Equation (2):

The plastic flow can be expressed as outlined below:

Elastic deformation is responsible for carrying the distortion of these slip systems. Thus, , and in the present configuration is determined to their forms in by and , respectively. Given that elastic deformation is minimal in comparison to plastic deformations, the following can be written:

is determined via the temperature-dependent stiffness parameters, written in Equation (6) as follows:

The parameters of temperature-dependent stiffness and elastic compliance are written in Table 1.

Table 1.

The temperature-dependent stiffness and elastic compliance parameters.

Thus, the following can be obtained:

Under quasistatic conditions, is described below:

where

Thus, the evolutions of the rate of crystallographic shearing are described as follows:

Total dislocations’ densities are presented as the competition of the storage and recovery mechanisms as . Assuming that dislocation nucleation is the dominant source, the rate of athermal storage is described using Equation (11):

is decomposed to and . Thus, is described using Equation (12) as presented below:

is defined by Equation (13), which was proposed by Nix et al. [61]:

Based on the Taylor equation [63,64,65,66], is determined using Equation (14).

For simplicity, is described using Equation (15) as follows:

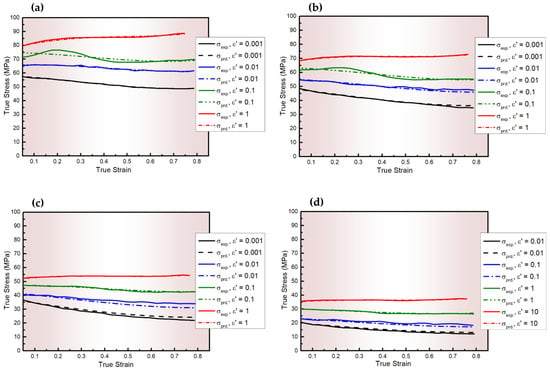

To assess the predictability of the proposed CP model, the predicted and experimental results were compared as shown in Figure 1. The results indicate a high degree of agreement between the predicted and experimental stresses across all tested conditions. Further validation was conducted by calculating key statistical parameters including R, AARE, and RMSE [67,68] to evaluate the model’s reliability and quantify its predictive accuracy. These parameters were computed using Equations (16)–(18), with their respective values in Table 2. R indicates the strength of the linear relationship between observed and predicted values but it can be biased at extreme values; RMSE measures deviations from the mean, potentially influenced by outliers; in contrast, AARE provides a more reliable assessment by evaluating the average error magnitude relative to the actual values.

Figure 1.

The experimental stresses of AA6082 and those predicted by CP modeling at values of 0.001–1 s−1 and values of (a) 400, (b) 450, (c) 500, and (d) 550 °C.

Table 2.

The values of statistical parameters of the proposed CP modeling of the AA6082 Al-Mg-Si alloy.

3.2. Modified ZA (MZA) Constitutive Model

The ZA model [69] is a well-known physical model developed based on the principles of dislocation mechanisms. In this model, flow stresses are divided into athermal and thermal parts, as presented in Equation (19).

The ZA model offers a comparatively simple expression compared to other dislocation-based models. A key feature of the ZA model is that its formulation varies depending on the material’s structure (i.e., F.C.C. or B.C.C.), capturing the unique controlling mechanisms specific to each of these structures. The equations for the thermal activation flow stress are provided below.

By combining with the effect of yield stresses on grains sizes into a single component (), Equations (20) and (21) are expressed as follows:

Although the ZA model incorporates dislocation mechanisms, it does not consider the impact of forming conditions, which diverge from those in practical forming processes, thereby reducing its predictive accuracy. To overcome these shortcomings, Samantaray et al. [69] introduced the MZA model expressed in Equation (24). The MZA model links softening with and to more accurately predict the flow behaviors of metals under hot working conditions. The MZA model thoroughly accounts for the effects of strain hardening, strain rate hardening, and thermal softening on the flow behaviors of metals under hot forming conditions, as introduced in Equation (24).

To determine the constants for the MZA model, the corresponding equations are rearranged to isolate the constants on the right-hand side. Although the relationships between the predictors , , and and the response (the equation’s output on the left-hand side) are nonlinear, the equations are linear with respect to the constants (coefficients). Therefore, a linear regression model using the least-squares method is employed to compute the constants for the three models in MATLAB.

To obtain the model’s constants of the current study, and are set as 400 °C and 0.001 s−1. Consequently, Equation (24) simplifies to the following:

where is measured as 58 MPa. By regression, the and were determined to be 0.847 and −12.738 MPa, respectively.

After modifications and at = 0.001 s−1, Equation (24) is written as outlined below:

Through regression analysis, and were determined to be −0.0049 and −0.0041, respectively. After rearrangements, Equation (24) is reformulated as presented in Equation (27).

The other values of and were then utilized to calculate and through regression as 0.0923 and −0.00005. All of the MZA model’s constants of the AA6082 Al-Mg-Si alloy are presented in Table 3.

Table 3.

MZA model constants of the AA6082 Al‐Mg‐Si alloy.

Therefore, the MZA model of the AA6082 alloy is written as follows:

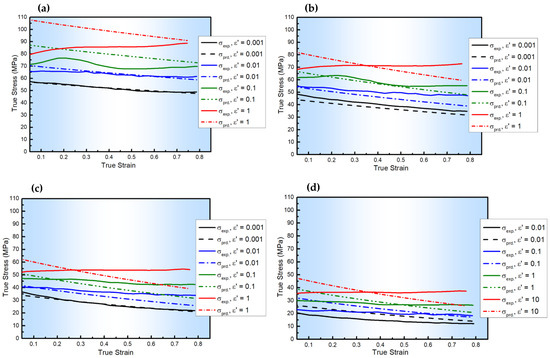

Figure 2 shows the comparison between the experimental flow behaviors of AA6082 Al-Mg-Si and those predicted by the MZA model, with R = 0.951, AARE = 11.67%, and RMSE = 7.23 MPa, as listed in Table 4. As depicted, the MZA model shows a good level of accuracy for determining the flow stresses under hot conditions across all given values, notably at or near and . This level of accuracy is due to the model’s integration of isotropic hardening, strain rate hardening, and thermal softening, along with the combined influence of , , and on the flow stresses.

Figure 2.

The experimental stresses of AA6082 and those predicted by the MZA model at values of 0.001–1 s−1 and values of (a) 400, (b) 450, (c) 500, and (d) 550 °C.

Table 4.

The values of statistical parameters of the MZA model of the AA6082 Al-Mg-Si alloy.

4. Phenomenological Models

4.1. Shokry’s MJC-1 (S1-MJC)

The MJC model developed by Shokry [70] is modified in this study to improve its accuracy in predicting the deformation behavior of AA6082 at several values of and by incorporating a linear relationship that directly links with and . The S1-MJC model is formulated below:

For obtaining the S1-MJC model’s constants, and are set as 400 °C and 0.001 s−1. Therefore, Equation (29) simplifies to the following:

Through regression analysis, was determined to be 58.071 MPa, was −11.065 MPa, was −22.881 MPa, and was 27.824 MPa.

After modifications and at = 400 °C, Equation (29) is described below:

Using regression, was determined to be 0.0616 and was 0.0641. After applying the natural logarithm and simplifying, Equation (29) can be expressed in various values as follows:

Using regression, was determined to be 1.4884 and was determined to be −0.3467. The S1-MJC model constants of the AA6082 alloy are written in Table 5.

Table 5.

S1-MJC model constants of AA6082 alloy.

Therefore, the S1-MJC model of AA6082 alloy is presented below:

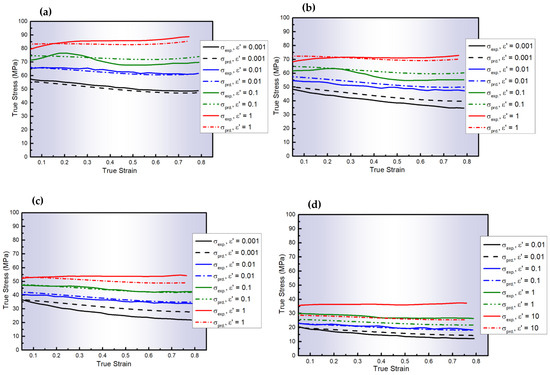

Figure 3 compares the experimental flow stresses of AA6082 and those determined via the S1-MJC model, with R = 0.983, AARE = 7.09%, and RMSE = 3.56 MPa, as listed in Table 6. As depicted, the results predicted by the S1-MJC model align closely with the experimental data, demonstrating a better fit than the MZA model; however, the S1-MJC model still does not outperform the accuracy achieved with CP modeling. This improved accuracy is because the S1-MJC model integrated both and the softening effects and strain hardening in the model. It is well-established that dislocations are influenced by and softening.

Figure 3.

The experimental stresses of AA6082 and those predicted by the S1-MJC model at values of 0.001–1 s−1 and values of (a) 400, (b) 450, (c) 500, and (d) 550 °C.

Table 6.

The values of statistical parameters of the modified S1-MJC model of the AA6082 alloy.

4.2. Shokry’s MJC-2 (S2-MJC)

The MJC model developed by Shokry et al. [71] is implemented in this study for determining the hot-flow behavior of AA6082 Al-Mg-Si over a wide range of and . Their model is represented below:

In this investigation, to determine the S2-MJC model’s constants, was adjusted to 0.001 s−1, and was adjusted to 400 °C. Consequently, Equation (34) is simplified to the following:

Expanding Equation (35) results in four parts including , each associated with four constants. Through regression, these constants were 58.071 MPa, −11.065 MPa, −22.881 MPa, and 27.824 MPa. Thus, at 400 °C, and after performing some adjustments, Equation (34) is presented below:

Expanding Equation (36) results in nine parts, including and , each linked to a corresponding constant. Through regression, these constants were 0.0550, 0.0828, −0.0888, 0.1637, −1.2841, 1.2652, −0.1126, 1.0707, and −1.0288. After applying the natural logarithm and making adjustments, Equation (34) can be expressed in various values as follows:

Expanding the right side of Equation (37) results in 27 parts, including , and . Through regression, these constants were obtained to be −0.6668, 2.7593, −2.4307, −0.2755, −5.5232, 5.0762, −0.1888, 2.1973, −1.5661, −0.0198, −10.3673, 9.3805, −2.597, 56.627, −53.125, 2.2348, −35.0907, 32.2649, −1.6642, 16.4578, −14.7332, 3.5334, −73.087, 68.9637, −2.7157, 52.349, and −49.0335, as listed in Table 7.

Table 7.

S2-MJC model constants of the AA6082 Al-Mg-Si alloy.

To determine the constants for the SI-MJC and S2-MJC models, the corresponding equations are rearranged to isolate the constants on the right-hand side. Although the relationships between the predictors , , and and the response (the equation’s output on the left-hand side) are nonlinear, the equations are linear with respect to the constants (coefficients). Therefore, a linear regression model using the least-squares method is employed to compute the constants for the three models in MATLAB.

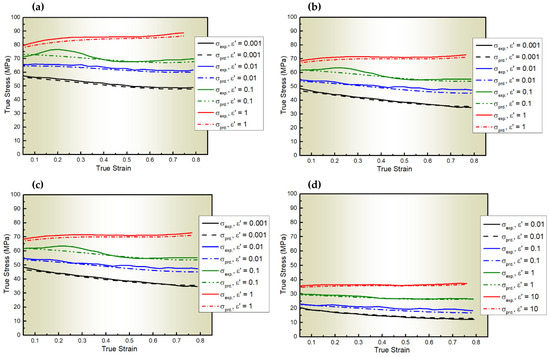

Figure 4 shows comparisons between the experimental stresses of AA6082 and those determined via the S2-MJC model, with R = 0.99, AARE = 1.87%, and RMSE = 0.95 MPa. As depicted in Figure 4 and Table 8, the result predicted by the S2-MJC model closely aligns with the experimentation, showing a better fit than the previous models and close to the accuracy achieved with CP modeling. This improved accuracy is because the S2-MJC model integrated both and on the one hand, and , and on the other hand, facilitated by an extensive set of constants that link the softening and dynamic recovery components.

Figure 4.

The experimental stresses of AA6082 and those predicted by the S2-MJC model at values of 0.001–1 s−1 and values of (a) 400, (b) 450, (c) 500, and (d) 550 °C.

Table 8.

The values of statistical parameters of the proposed S2-MJC models of the AA6082 alloy.

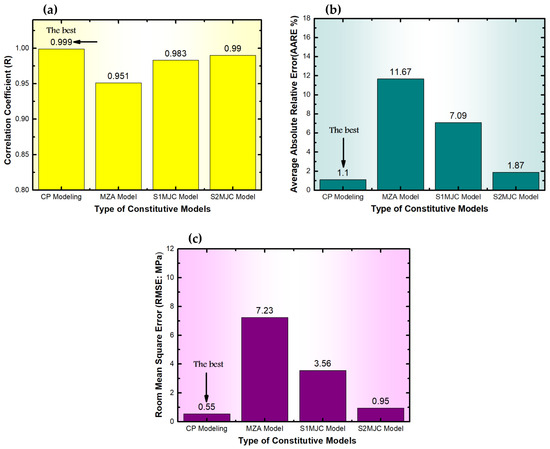

The R values for the developed models are presented in Figure 5a. The CP and S2-MJC models achieve the highest R values close to 1, with values of 0.999 and 0.99, respectively. In contrast, R for the MZA is 0.951 and for S1-MJC is 0.983. Similarly, Figure 5b,c display these models’ AARE and RMSE values. The CP and S2-MJC models exhibit the best performance with the lowest values of AARE, which are 1.1% and 1.87%, respectively. The values of RMSE are 0.55 MPa and 0.95 MPa, respectively. Moreover, the MZA and S1-MJC models yield higher AARE values of 11.67% and 7.09% and RMSE values of 7.23 MPa and 3.56 MPa, respectively. The obtained values of R, AARE, and RMSE indicate that the MZA and S1-MJC models can be used to predict the flow behavior of the studied alloy but with limited accuracy. The MZA model accounts for the coupling effects between and as well as between and . In contrast, the S1-MJC model considers the coupling effects between and as well as between and . Moreover, the CP and S2-MJC models incorporate the coupling effects between , and . Given the nonlinear nature of the flow behavior of the studied alloy, models that account for the more comprehensive coupling between , and are expected to provide more accurate predictions.

Figure 5.

Comparisons between the proposed models’ (a) R, (b) AARE, and (c) RMSE for verifying their predictability.

5. Conclusions

The hot-flow behaviors of Al-Mg-Si alloy are complex due to their reliance on ε, , and ; thus, determining its deformation behavior across a broad range of forming conditions is crucial. Consequently, CP modeling and the MZA, S1-MJC, and S2-MJC models were developed in this investigation to predict the hot deformation behavior of Al-Mg-Si alloy precisely. The accuracy of these models was evaluated via comparisons of the predicted and experimental results at values of 0.001–10 s−1 and values of 400–550 °C. Additional validations were performed by calculating statistical parameters to assess the accuracy of the developed models. Through comparing the experimental and determined stresses and confirming these findings through the statistical values, it is concluded that the flow stresses predicted by the CP and S2-MJC models closely align with the experimentation stresses. This contrasts with the results from the MZA and S1-MJC models. These findings are attributed to the ability of CP modeling to couple the microstructure state of the Al-Mg-Si alloy with its mechanical behavior. In addition, the ability of the S2-MJC model to integrate both and on the one hand, and , and on the other hand, is facilitated by extensive constants that link the softening and dynamic recovery components.

Author Contributions

Conceptualization, B.A., A.A.E.-A., Y.X. and A.S.; methodology, A.A.E.-A., Y.X., A.S., Y.H. and S.-H.Z.; software, B.A., A.A.E.-A. and A.S.; formal analysis, B.A., A.A.E.-A., Y.H., A.S. and M.M.Z.A.; investigation, Y.X., S.-H.Z., A.A. and M.M.Z.A.; writing—original draft preparation, A.A.E.-A., B.A., Y.H. and A.S.; writing—review and editing, A.A., S.-H.Z., Y.X. and M.M.Z.A.; supervision, A.A.E.-A., A.S. and Y.X.; funding acquisition, B.A., A.A. and S.-H.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The authors extend their appreciation to Prince Sattam bin Abdulaziz University for funding this research work through the project number (PSAU/2024/01/29598).

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

The original contributions presented in the study are included in the article, further inquiries can be directed to the corresponding author.

Acknowledgments

The authors extend their appreciation to Prince Sattam bin Abdulaziz University for funding this research work through the project number (PSAU/2024/01/29598).

Conflicts of Interest

The authors declare no conflict of interest.

Nomenclature

| Symbol | Abbreviations |

| Temperature | |

| Strain rate | |

| Deformation gradient | |

| Elastic component of deformation gradient | |

| Plastic component of deformation gradient | |

| Velocity gradient tensor | |

| Elastic component of velocity gradient tensor | |

| Plastic component of velocity gradient tensor | |

| locally stress-free intermediate configuration | |

| shearing rate on the α-slip system | |

| potential slip system’s number | |

| Schmid tensor , and are orthogonal to each other | |

| Slip plane direction | |

| Slip plane normal | |

| Slipping direction | |

| Equivalent slip plane normal | |

| The second Paola-Kirchhoff stress tensor | |

| Cauchy stress tensor | |

| The elastic Green-Lagrange strain tensor | |

| The elastic right Cauchy-Green deformation tensor | |

| Identity tensor | |

| The absolute temperature (K) | |

| The resolved shear stress tensor | |

| The magnitude of the Burgers vector | |

| The mobile dislocations density on the slip system. | |

| The average velocity of mobile dislocations on the slip system. | |

| The average dislocation velocity | |

| The average distance between each obstacle on the slip plane. | |

| The waiting time for a dislocation to surpass the local obstacles. | |

| The Debye frequency | |

| The Boltzmann constant | |

| The difference in the activation-free enthalpy when the dislocation segment moves from the stable configuration to the unstable configuration | |

| The reference slip rate | |

| The fraction of the shearing rate by the total dislocation | |

| The mean free path | |

| The critical annihilation distance for canceling out the two dislocations with opposite polarities | |

| The total dislocation density | |

| Edge dislocation component | |

| Screw dislocation component | |

| The dislocation density evaluation, where: | |

| The reference critical annihilation distance | |

| Constant = 0.001 | |

| Constant = 8.617E-5 | |

| The total athermal slip resistance parameters | |

| b | The Burgers vector’s magnitude |

| The shear modulus, | |

| λ | For identifying the deviations from the regular spatial arrangements of dislocation density |

| The matrix of dislocation interaction | |

| The Kronecker delta | |

| , | The interaction coefficients |

| correlation coefficient | |

| average absolute relative error | |

| root mean square error | |

| The total number of points included in the analysis | |

| The experimental stress values | |

| The predicted stress values | |

| The mean values of experimental stress | |

| The mean values of predicted stress | |

| The athermal activation flow stress | |

| The thermal activation flow stress. | |

| Body-centered cubic | |

| face-centered cubic | |

| , , , , | material constants |

| The testing temperature | |

| Von-Mises flow stress | |

| equivalent plastic strain | |

| reference strain rates | |

| the ratio between the testing and () | |

| Reference temperatures | |

| The difference between testing and ( | |

| , | material constants |

| The melting temperature of AA6082 Al-Mg-Si | |

| constants correlate with the | |

| representing the strain-hardening component | |

| constants associate with the | |

| constants related to the softening parameter |

References

- Abd El-Aty, A.; Xu, Y.; Guo, X.; Zhang, S.; Ma, Y.; Chen, D. Strengthening mechanisms, deformation behavior, and anisotropic mechanical properties of Al-Li alloys: A review. J. Adv. Res. 2018, 10, 49–67. [Google Scholar] [CrossRef] [PubMed]

- Alami, A.H.; Olabi, A.G.; Alashkar, A.; Alasad, S.; Aljaghoub, H.; Rezk, H.; Abdelkareem, M.A. Additive manufacturing in the aerospace and automotive industries: Recent trends and role in achieving sustainable development goals. Ain Shams Eng. J. 2023, 14, 102516. [Google Scholar] [CrossRef]

- Sun, Y. The use of aluminum alloys in structures: Review and outlook. Structures 2023, 57, 105290. [Google Scholar] [CrossRef]

- Blanco, D.; Rubio, E.M.; Lorente-Pedreille, R.M.; Sáenz-Nuño, M.A. Sustainable Processes in Aluminium, Magnesium, and Titanium Alloys Applied to the Transport Sector: A Review. Metals 2022, 12, 9. [Google Scholar] [CrossRef]

- Emadi, P.; Andilab, B.; Ravindran, C. Engineering Lightweight Aluminum and Magnesium Alloys for a Sustainable Future. J. Indian Inst. Sci. 2022, 102, 405–420. [Google Scholar] [CrossRef]

- Hou, Y.; Myung, D.; Park, J.K.; Min, J.; Lee, H.-R.; El-Aty, A.A.; Lee, M.-G. A Review of Characterization and Modelling Approaches for Sheet Metal Forming of Lightweight Metallic Materials. Materials 2023, 16, 836. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Khorshidi, M.; Mohammadzadeh, R.; Khajeh, R.; Mofarrehi, M.; Javidani, M.; Chen, X.G. Multipass friction stir processing of laser-powder bed fusion AlSi10Mg: Microstructure and mechanical properties. Materials 2023, 16, 1559. [Google Scholar] [CrossRef]

- Xia, L.; Zhang, S.-H.; Xu, Y.; Chen, S.; El-Aty, A.A.; Pokrovsky, A.I.; Bakinovskaya, A.A. Study of the ductility enhancement of 5A90 Al–Mg–Li alloy sheets with stress relaxation. Philos. Mag. 2021, 101, 2449–2472. [Google Scholar] [CrossRef]

- Cao, L.; Liao, B.; Wu, X.; Li, C.; Huang, G.; Cheng, N. Hot Deformation Behavior and Microstructure Characterization of an Al-Cu-Li-Mg-Ag Alloy. Crystals 2020, 10, 416. [Google Scholar] [CrossRef]

- Zheng, K.; Politis, D.; Wang, L.; Lin, J. A review on forming techniques for manufacturing lightweight complex-shaped aluminium panel components. Int. J. Light. Mater. Manuf. 2018, 1, 55–80. [Google Scholar] [CrossRef]

- Hu, M.; Sun, Y.; He, J.; Li, C.; Li, H.; Yu, L.; Liu, Y. Hot deformation behaviour and microstructure evolution of Al-3%Mg2Si alloy. Mater. Charact. 2022, 183, 111623. [Google Scholar] [CrossRef]

- Liang, H.; Nan, Y.; Ning, Y.; Li, H.; Zhang, L.; Shi, Z.; Guo, H. Correlation between strain-rate sensitivity and dynamic softening behavior during hot processing. J. Alloys Compd. 2013, 632, 478–485. [Google Scholar] [CrossRef]

- Lin, Y.C.; Li, L.T.; Xia, Y.C.; Jiang, Y.Q. Hot deformation and processing map of a typical Al-Zn-Mg-Cu alloy. J. Alloys Compd. 2013, 550, 438–445. [Google Scholar] [CrossRef]

- Liang, Z.; Zhang, Q.; Niu, L.; Luo, W. Hot deformation behavior and processing maps of as-cast hypoeutectic Al-Si-Mg alloy. J. Mater. Eng. Perform. 2019, 28, 4871–4881. [Google Scholar] [CrossRef]

- Huang, Y.; Liu, L.; Xiao, Z.; Wang, S. Hot deformation behavior of 6063 aluminum alloy studied using processing maps and microstructural analysis. Phys. Met. Metallogr. 2019, 120, 1115–1125. [Google Scholar] [CrossRef]

- El-Aty, A.A.; Xu, Y.; Zhang, S.-H.; Ha, S.; Ma, Y.; Chen, D. Impact of high strain rate deformation on the mechanical behavior, fracture mechanisms, and anisotropic response of 2060 Al-Cu-Li alloy. J. Adv. Res. 2019, 18, 19–37. [Google Scholar] [CrossRef]

- Lei, C.; Wang, Q.; Tang, H.; Liu, T.; Li, Z.; Jiang, H.; Wang, K.; Ebrahimi, M.; Ding, W. Hot deformation constitutive model and processing maps of homogenized Al–5Mg–3Zn–1Cu alloy. J. Mater. Res. Technol. 2021, 14, 324–339. [Google Scholar] [CrossRef]

- Lei, C.; Wang, Q.; Ebrahimi, M.; Li, D.; Tang, H.; Zhang, N.; Cai, H. Hot Deformation Behavior and Processing Maps of an As-Cast Al-5Mg-3Zn-1Cu (wt%) Alloy. Materials 2023, 16, 4093. [Google Scholar] [CrossRef]

- Wu, H.; Wen, S.P.; Huang, H.; Gao, K.Y.; Wu, X.L.; Wang, W.; Nie, Z.R. Hot deformation behavior and processing map of a new type Al-Zn-Mg-Er-Zr alloy. J. Alloys Compd. 2016, 685, 869–880. [Google Scholar] [CrossRef]

- Wei, T.; Wang, Y.; Tang, Z.; Xiao, S. The constitutive modeling and processing map of homogenized Al-Mg-Si-Cu-Zn alloy. Mater. Today Commun. 2021, 27, 102471. [Google Scholar] [CrossRef]

- Heidarzadeh, A.; Mohammadzadeh, R.; Jafarian, H.R.; Pruncu, C.I.; Simar, A. Role of geometrically necessary dislocations on mechanical properties of friction stir welded single-phase copper with medium stacking fault energy. J. Mater. Res. Technol. 2022, 16, 194–200. [Google Scholar] [CrossRef]

- Liu, S.; Pan, Q.; Li, H.; Huang, Z.; Li, K.; He, X.; Li, X. Characterization of hot deformation behavior and constitutive modeling of Al–Mg–Si–Mn–Cr alloy. J. Mater. Sci. 2019, 54, 4366–4383. [Google Scholar] [CrossRef]

- Abedrabbo, N.; Pourboghrat, F.; Carsley, J. Forming of AA5182-O and AA5754-O at elevated temperatures using coupled thermo-mechanical finite element models. Int. J. Plast. 2007, 23, 841–875. [Google Scholar] [CrossRef]

- Clayton, D. Dynamic plasticity and fracture in high density polycrystals: Constitutive modeling and numerical simulation. J. Mech. Phys. Solids 2005, 53, 261–301. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X. A critical review of experimental results and constitutive descriptions for metals and alloys in hot working. Mater. Des. 2011, 32, 1733–1759. [Google Scholar] [CrossRef]

- Ou, L.; Zheng, Z.; Nie, Y.; Jian, H. Hot deformation behavior of 2060 alloy. J. Alloys Compd. 2015, 648, 681–689. [Google Scholar] [CrossRef]

- Yaich, M.; Gavrus, A. New phenomenological material constitutive models for the description of the Ti6Al4V titanium alloy behavior under static and dynamic loadings. Proc. Manuf. 2020, 47, 1496–1503. [Google Scholar] [CrossRef]

- Ma, L.; Wan, M.; Li, W.; Shao, J.; Bai, X.; Zhang, J. Superplastic deformation mechanical behavior and constitutive modelling of a near-a titanium alloy TNW700 sheet. Mater. Sci. Eng. A 2021, 817, 141419. [Google Scholar] [CrossRef]

- Shrot, A.; Beaker, M. Determination of Johnson-Cook parameters from machining simulations. Comput. Mater. Sci. 2012, 52, 298–304. [Google Scholar] [CrossRef]

- Qiao, L.; Zhu, J. Constitutive modeling of hot deformation behavior of AlCrFeNi multi-component alloy. Vacuum 2022, 201, 111059. [Google Scholar] [CrossRef]

- Wang, H.; Qin, G.; Li, C. A modified Arrhenius constitutive model of 2219-O aluminum alloy based on hot compression with simulation verification. J. Mater. Res. Technol. 2022, 19, 3302–3320. [Google Scholar] [CrossRef]

- Jia, W.; Xu, S.; Le, Q.; Fu, L.; Ma, L.; Tang, Y. Modified Fields- Backofen model for constitutive behavior of as-cast AZ31B magnesium alloy during hot deformation. Mater. Des. 2016, 106, 120–132. [Google Scholar] [CrossRef]

- Shen, J.; Hu, L.; Sun, Y.; Wan, Z.; Feng, X.; Ning, Y. A comparative study on artificial neural network, phenomenological-based constitutive and modified fields-backofen models to predict flow stress in Ti-4Al-3V-2Mo-2Fe alloy. J. Mater. Eng. Perform. 2019, 28, 4302.e15. [Google Scholar] [CrossRef]

- Seshacharyulu, K.; Mahalle, G.; Kotkunde, N.; Singh, S.K.; Balu Naik, B. High temperatures deformation and formability behavior of DP590 steel: Mechanical characterization and modeling. J. Braz. Soc. Mech. Sci. Eng. 2021, 43, 1–23. [Google Scholar] [CrossRef]

- Mahalle, G.; Salunke, O.; Kotkunde, N.; Kumar Gupta, A.; Singh, S.K. Study of Khan-Huang-liang (KHL) anisotropic deformation model for deep drawing behaviour of inconel 718 alloy. IOP Conf. Ser. Mater. Sci. Eng. 2020, 967, 12054. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A constitutive model and data formetals subjected to large strains, high strain rates and hightemperatures. In Proceedings of the 7th International Symposium on Ballistics, Hague, The Netherlands, 19–21 April 1983; pp. 541–547. [Google Scholar]

- Johnson, G.R.; Cook, W.H. Fracture characteristics of three metals subjected to various strains, strain rates, temperatures and pressures. Eng. Fract. Mech. 1985, 21, 31–48. [Google Scholar] [CrossRef]

- Laasraoui, A.; Jonas, J.J. Prediction of Steel Flow Stresses at High Temperatures and Strain Rates. Metall. Trans. A 1991, 22, 1545–1558. [Google Scholar] [CrossRef]

- Zheng, X.; Luo, A.A.; Dong, J.; Sachdev, A.K.; Ding, W. Plastic flow behavior of a high-strength magnesium alloy NZ30K. Mater. Sci. Eng. A 2012, 532, 616–622. [Google Scholar] [CrossRef]

- Meng, Q.; Bai, C.; Xu, D. Flow behavior and processing map for hot deformation of ATI425 titanium alloy. J. Mater. Sci. Technol. 2018, 34, 679–688. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, X.; Liu, G. A modified Johnson-Cook model for tensile behaviors of typical high-strength alloy steel. Mater. Sci. Eng. A 2010, 527, 6980–6989. [Google Scholar] [CrossRef]

- Zener, C.; Hollomon, J.H. Effect of strain rate upon plastic flow of steel. J. Appl. Phys. 1944, 15, 22–32. [Google Scholar] [CrossRef]

- Shi, H.M.; McLaren, A.J.; Sellars, C.M.; Shahani, R.; Bolingbroke, R. Constitutive equations for high temperature flow stress of aluminium alloys. Mater. Sci. Technol. 1997, 13, 210–216. [Google Scholar] [CrossRef]

- Lin, Y.C.; Chen, M.; Zhong, J. Constitutive modeling for elevated temperature flow behavior of 42CrMo steel. Comput. Mater. Sci. 2008, 42, 470–477. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K.; Venugopal, S.; Sivaprasad, P.V. Analysis and mathematical modelling of elevated temperature flow behaviour of austenitic stainless steels. Mater. Sci. Eng. A 2011, 528, 1937–1943. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Borah, U.; Bhaduri, A.K.; Sivaprasad, P.V. A thermo-viscoplastic constitutive model to predict elevated-temperature flow behaviour in a titanium-modified austenitic stainless steel. Mater. Sci. Eng. A 2009, 526, 1–6. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. Constitutive analysis to predict high-temperature flow stress in modified 9Cre1Mo (P91) steel. Mater. Des. 2010, 31, 981–984. [Google Scholar] [CrossRef]

- Kumar, S.; Karmakar, A.; Nath, S.K. Construction of hot deformation processing maps for 9Cr-1Mo steel through conventional and ANN approach. Mater. Today Commun. 2021, 26, 101903. [Google Scholar] [CrossRef]

- Cheng, C.; Ji, Y.; Guo, X.; El-Aty, A.A. Coupling theoretical analysis and FE framework for revealing the size effect on the deformation characteristics of 304 stainless steel microtubes manufactured via free-bending forming technology. CIRP J. Manuf. Sci. Technol. 2024, 55, 1–15. [Google Scholar] [CrossRef]

- Zhao, P.; Cheng, C.; El-Aty, A.A.; Tao, J.; Guo, X.; Ji, Y. Multiscale framework-based crystal plasticity modeling and texture evolution of the deformation behavior of AISI 304 stainless steel microtubes manufactured through 3D-FBF technology. Sustain. Mater. Technol. 2024, 42, e01125. [Google Scholar] [CrossRef]

- Zhao, P.; Cheng, C.; EI-Aty, A.A.; Tao, J.; Guo, X.; Ji, Y. Integrating crystal plasticity and experimentation for investigating the size effect on the deformation characteristics of AISI304 microtubes manufactured by free bending technology. Manuf. Lett. 2024, 42, 21–25. [Google Scholar] [CrossRef]

- Shokry, A.; Ståhle, P. A methodology for using Kalman filter to determine material parameters from uncertain measurements. Mater. Discov. 2016, 2, 1–15. [Google Scholar] [CrossRef]

- Shokry, A.; Gowid, S.; Youssef, S.S. Modeling the flow behavior of Haynes 214 superalloy during hot deformation using mathematical and artificial intelligence-based models. Mater. Today Commun. 2022, 33, 104326. [Google Scholar] [CrossRef]

- Ghosh, A.; Ali, E.; Parson, N.; Chen, X.-G. Hot deformation behavior and processing maps for an Al-Mg-Si-Zr-Mn alloy. J. Alloys Metall. Syst. 2004, 6, 100077. [Google Scholar] [CrossRef]

- Li, T.; Lu, Y.; Li, Z.; Wang, T.; Li, T. Hot deformation behavior and microstructure evolution of non-equimolar Ti2ZrHfV0.5Ta0.2 refractory high-entropy alloy. Intermetallics 2022, 146, 107586. [Google Scholar] [CrossRef]

- Li, X.; Le, Q.; Li, D.; Wang, P.; Jin, P.; Cheng, C.; Cheng, X.; Ren, L. Hot tensile deformation behavior of extruded LAZ532 alloy with heterostructure. Mater. Sci. Eng. A 2021, 801, 140412. [Google Scholar] [CrossRef]

- Che, B.; Lu, L.; Kang, W.; Luo, J.; Ma, M.; Liu, L. Hot deformation behavior and processing map of a new type Mg-6Zn-1Gd-1Er alloy. J. Alloys Compd. 2021, 862, 158700. [Google Scholar] [CrossRef]

- Cheong, K.S.; Busso, E.P. Discrete dislocation density modelling of single phase F.C.C. polycrystal aggregates. Acta Mater. 2004, 52, 5665–5675. [Google Scholar] [CrossRef]

- Peirce, D.; Asaro, R.J.; Needleman, A. An analysis of non-uniform and localized deformation in ductile single crystals. Acta Metall. 1982, 30, 1087–1119. [Google Scholar] [CrossRef]

- Essman, U.; Mughrabi, H. Annihilation of dislocations during tensile and cyclic deformation and limits of dislocation densities. Philos. Mag. A 1979, 40, 731–756. [Google Scholar] [CrossRef]

- Nix, W.; Gibeling, J.; Hughes, D. Time-dependent deformation of metals. Metall. Trans. A 1985, 16, 2215–2226. [Google Scholar] [CrossRef]

- Chen, B.; Tian, X.; Li, X.; Lu, C. Hot deformation behavior and processing maps of 2099 Al-Li alloy. J. Mater. Eng. Perform. 2014, 23, 1929–1935. [Google Scholar] [CrossRef]

- Arsenlis, A.; Parks, D. Modeling the evolution of crystallographic dislocation density in crystal plasticity. J. Mech. Phys. Solids 2002, 50, 1979–2009. [Google Scholar] [CrossRef]

- Asaro, R.; Needleman, A. Texture development and strain hardening in rate dependent polycrystals. Acta Metall. 1985, 33, 923–953. [Google Scholar] [CrossRef]

- Deng, L.; Zhao, T.; Jin, J.; Wang, X. Flow behavior of 2024 aluminium alloy sheet during hot tensile and compressive processes. Procedia Eng. 2014, 81, 1049–1054. [Google Scholar] [CrossRef]

- Humphreys, F.; Hatherly, M. Hot Deformation and Dynamic Restoration. In Recrystallization and Related Annealing Phenomena, 2nd ed.; Humphreys, F., Hatherly, M., Eds.; Elsevier: Amsterdam, The Netherlands, 2004; pp. 415–450. [Google Scholar] [CrossRef]

- Alankar, A.; Mastorakos, I.; Field, D. A dislocation-density-based 3D crystal plasticity model for pure aluminum. Acta Mater. 2009, 57, 5936–5946. [Google Scholar] [CrossRef]

- Alzahrani, B.; Abd El-Aty, A.; Elatriby, S.A.; Sobh, A.S.; Bhlol, M.A.; Elfar, A.A.; Siddiqui, M.A.; Shokry, A. A Modified Johnson Cook Model-Based Kalman Filter Method to Determine the Hot Flow Behavior of Sustainable AA6082 Al Alloy. Materials 2024, 17, 5169. [Google Scholar] [CrossRef]

- Samantaray, D.; Mandal, S.; Bhaduri, A.K. A comparative study on Johnson Cook, modified Zerillie Armstrong and Arrhenius-type constitutive models to predict elevated temperature flow behaviour in modified 9Cre1Mo steel. Comput. Mater. Sci. 2009, 47, 568–576. [Google Scholar] [CrossRef]

- Shokry, A. A modified Johnson–Cook model for flow behavior of alloy 800H at intermediate strain rates and high temperatures. J. Mater. Eng. Perform. 2017, 26, 5723–5730. [Google Scholar] [CrossRef]

- Shokry, A.; Gowid, S.; Kharmanda, G. An improved generic Johnson-Cook model for the flow prediction of different categories of alloys at elevated temperatures and dynamic loading conditions. Mater. Today Commun. 2021, 27, 102296. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).