Development of High-Strength Aerogel Concrete

Highlights

- Aerogel can be used as a partial substitution of sand to enhance concrete’s thermal insulation

- Aerogel concrete can have enhanced thermal insulation in addition to high compressive strength

- Higher distribution of thermal conductivity was found for aerogel beads (compared to powder) mixes

Abstract

1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Preparation of the Examined Specimens and Testing

2.2.1. Mixing Procedure

2.2.2. Characterization of the Mixes

3. Results

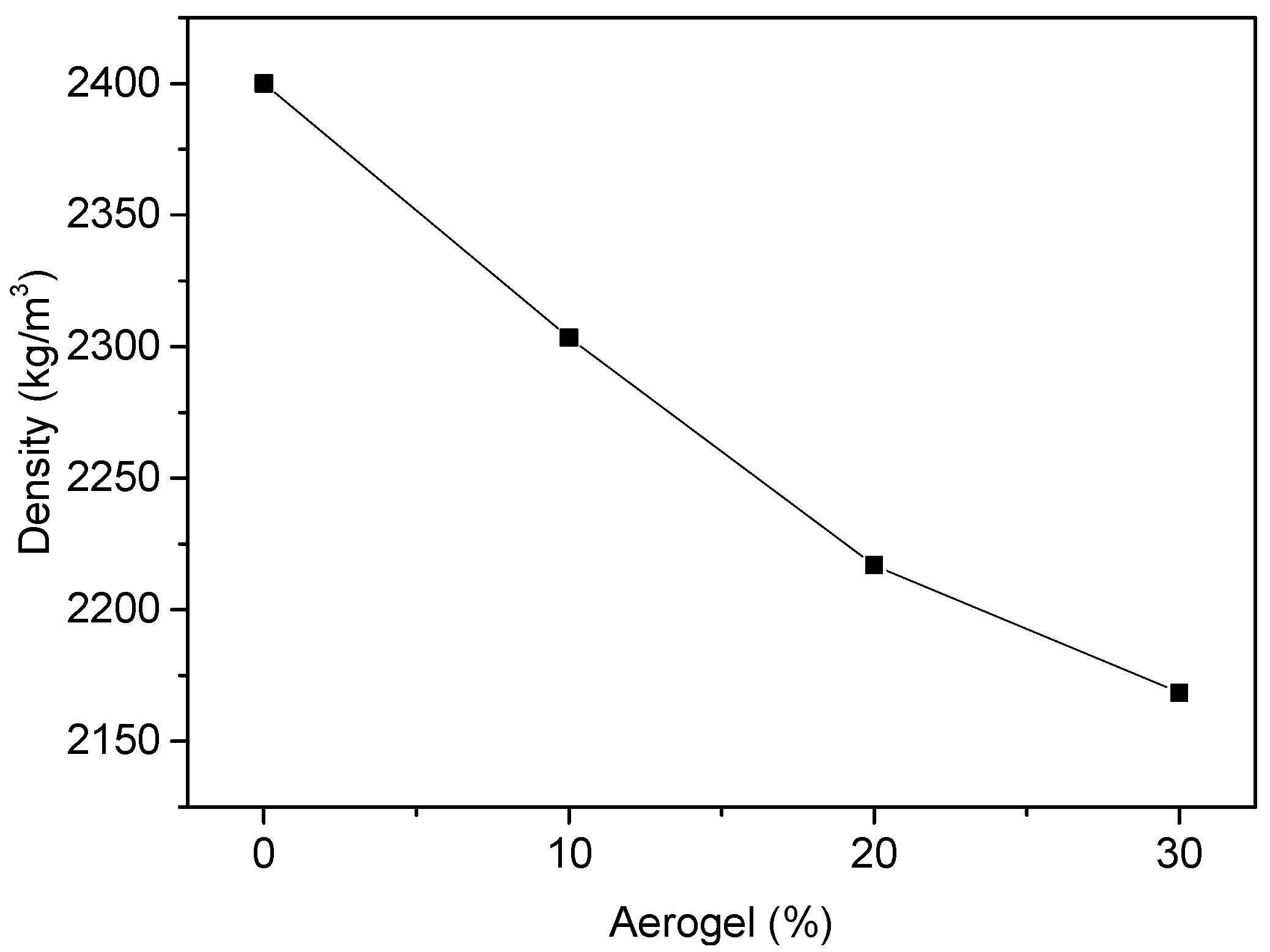

3.1. Concrete Density

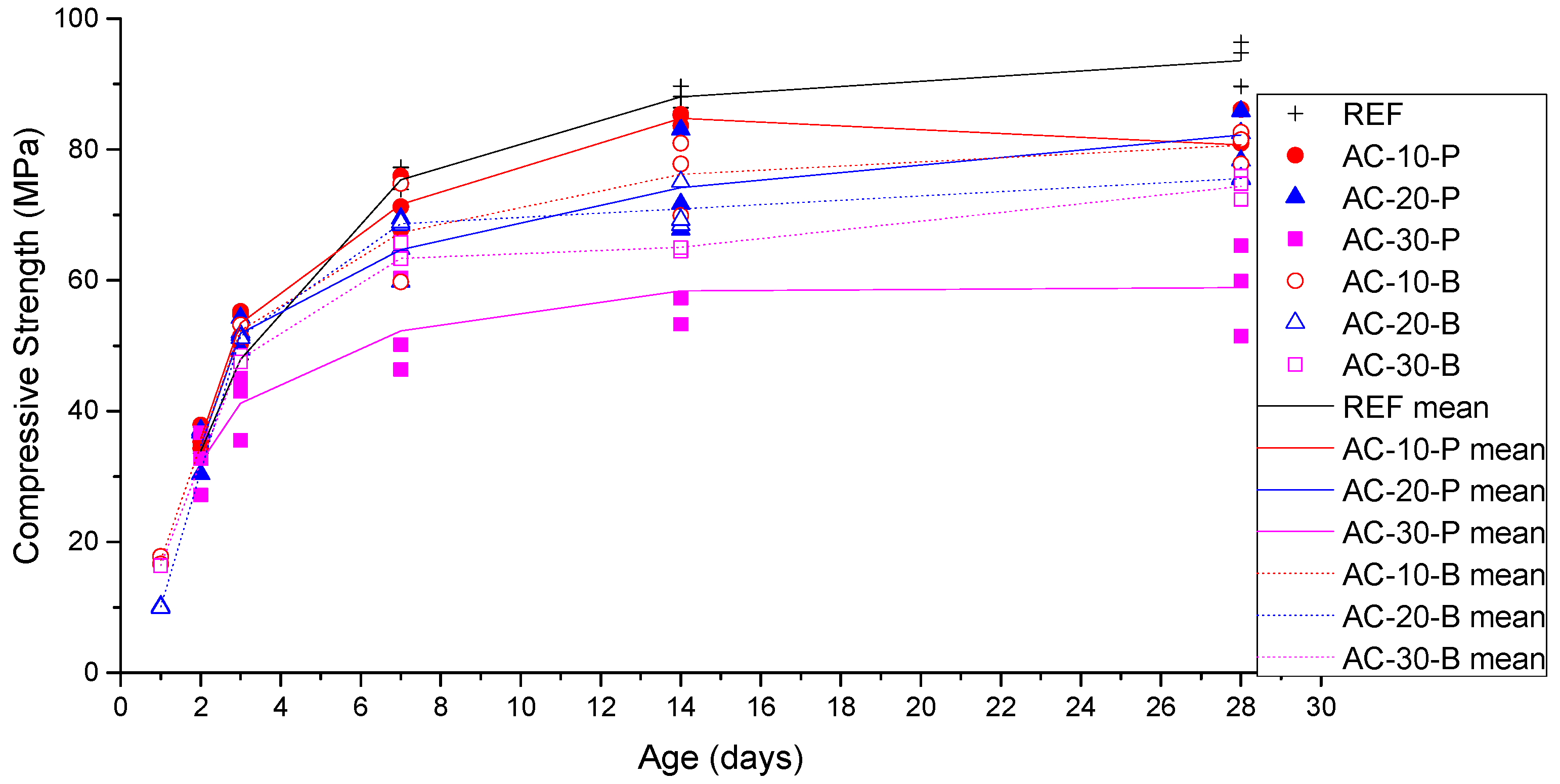

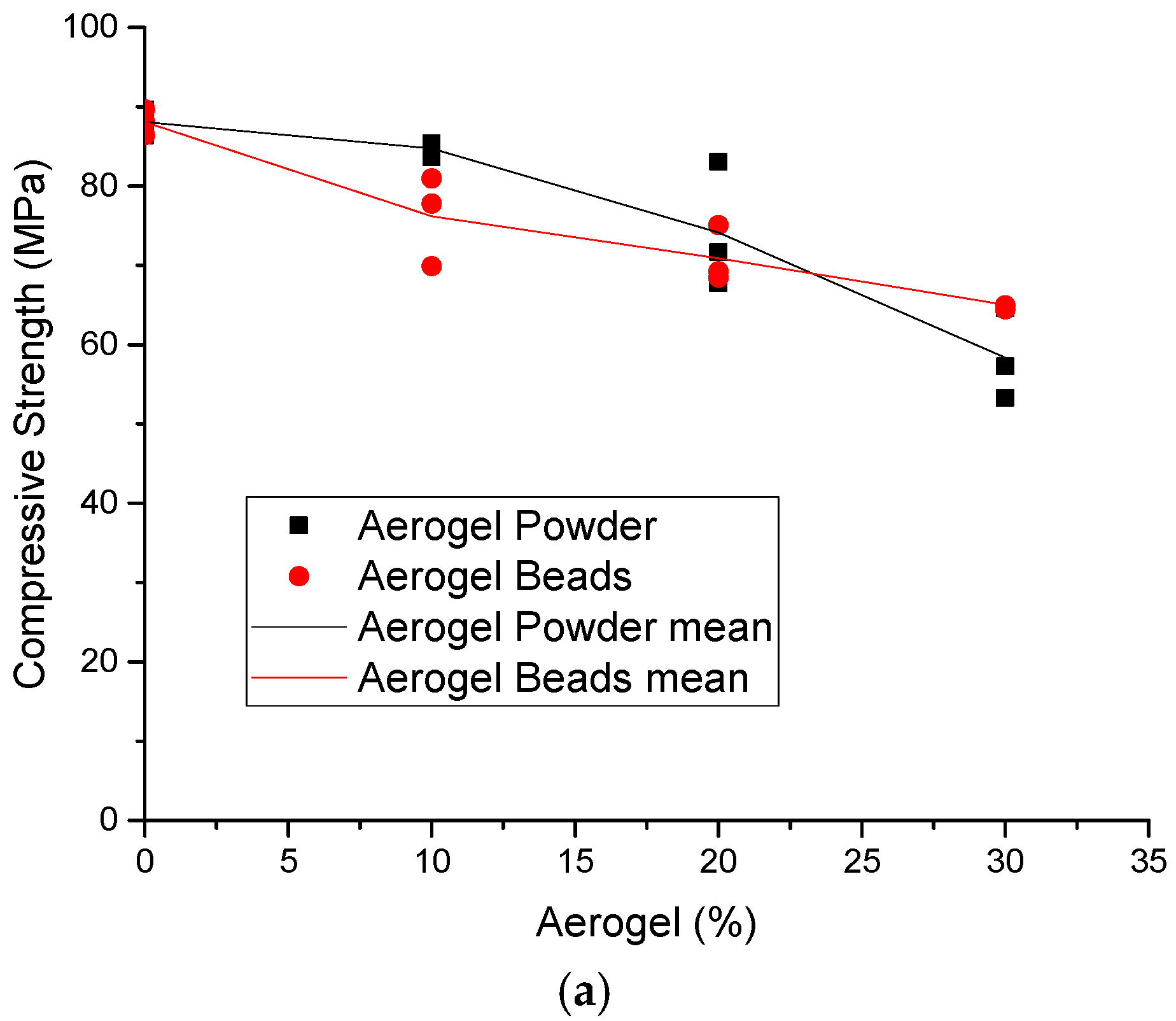

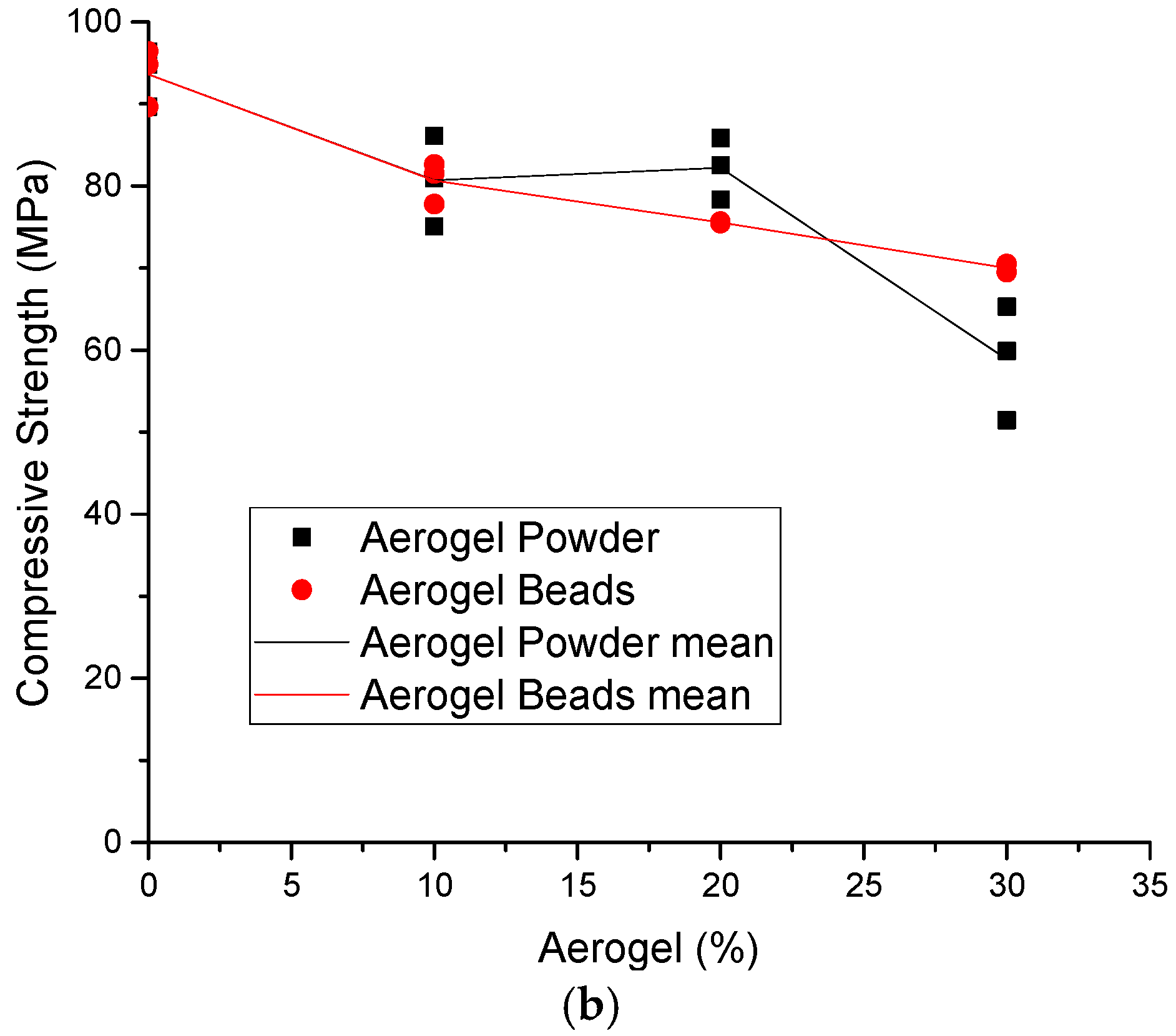

3.2. Compressive Strength Results

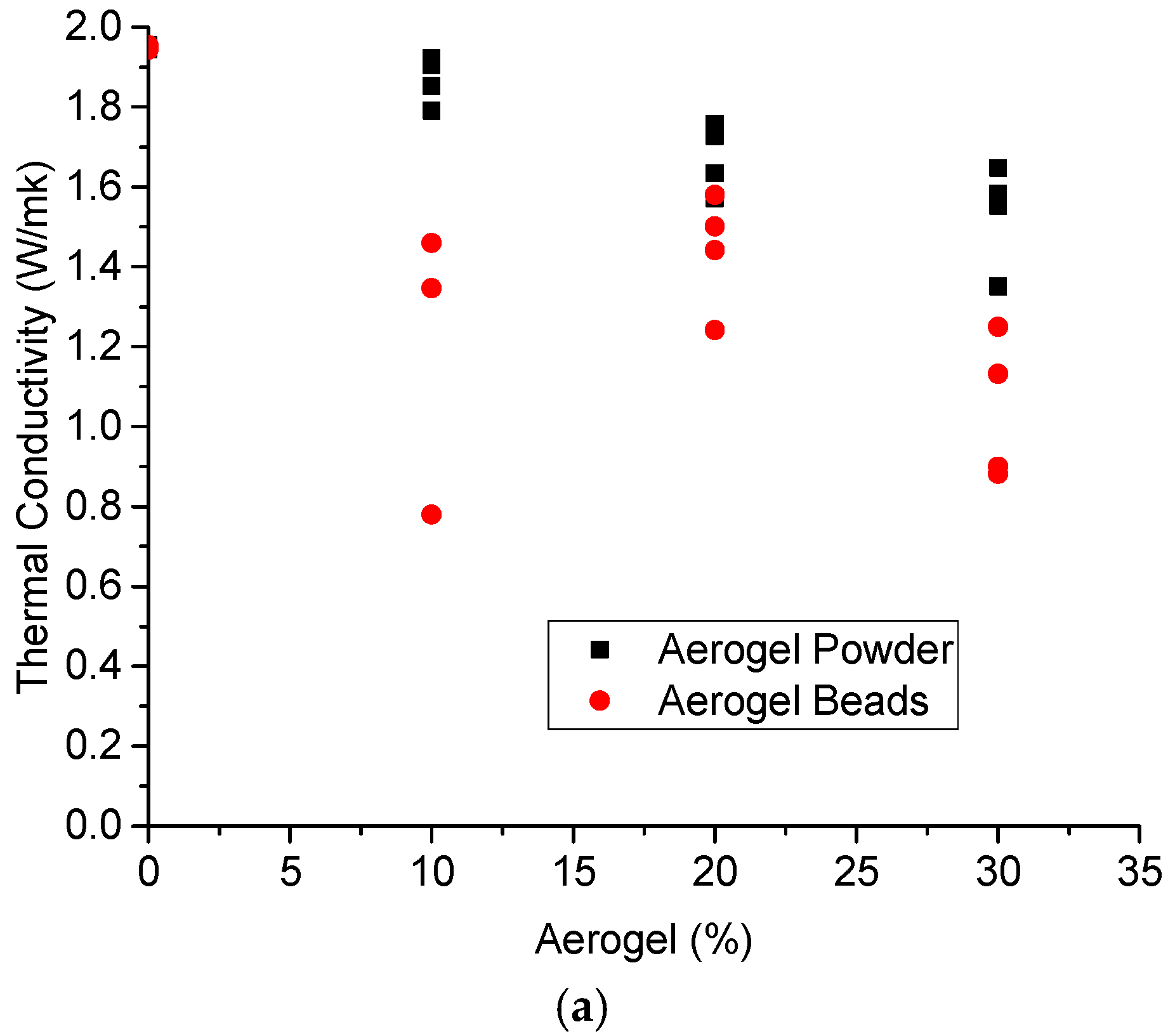

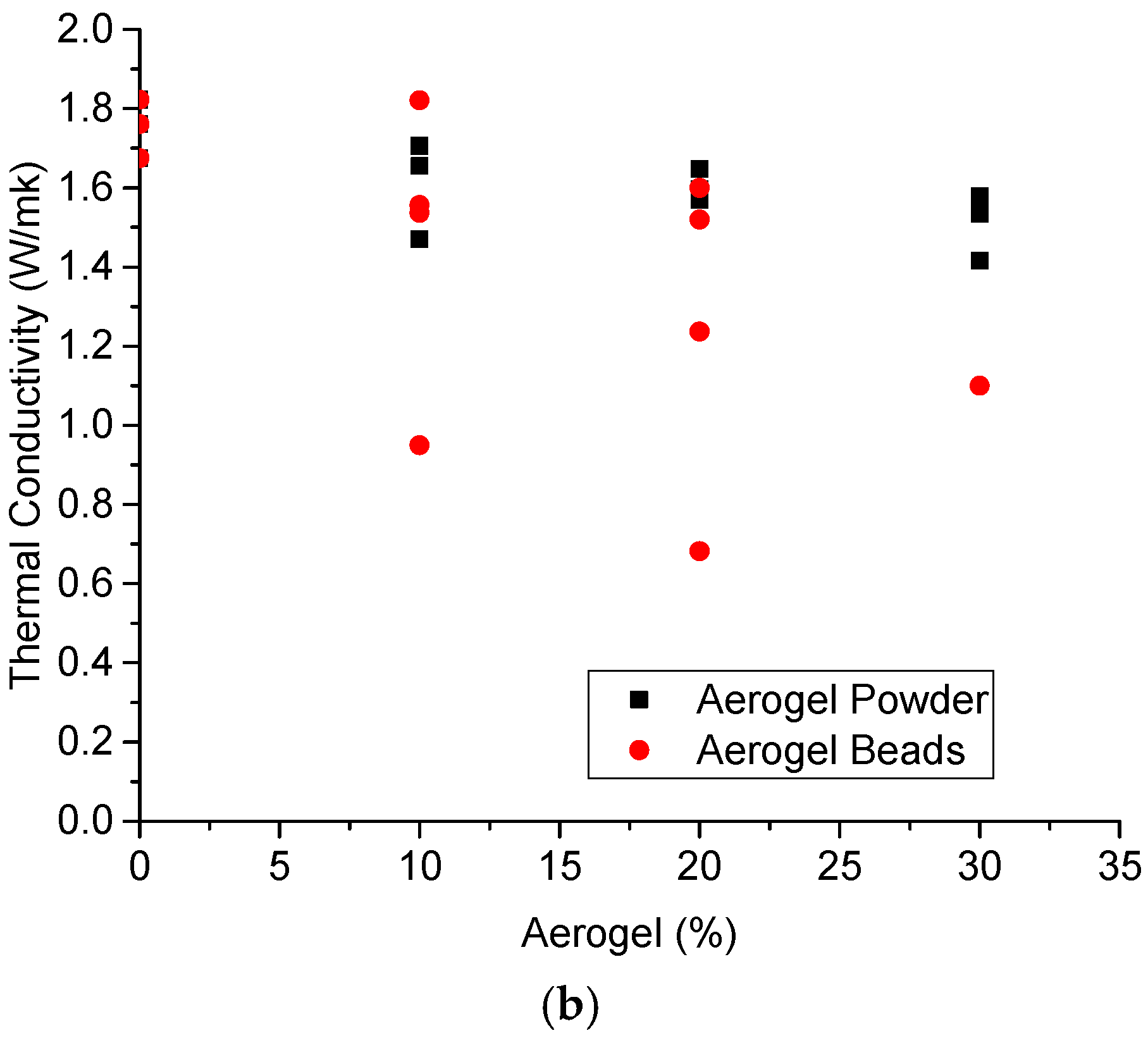

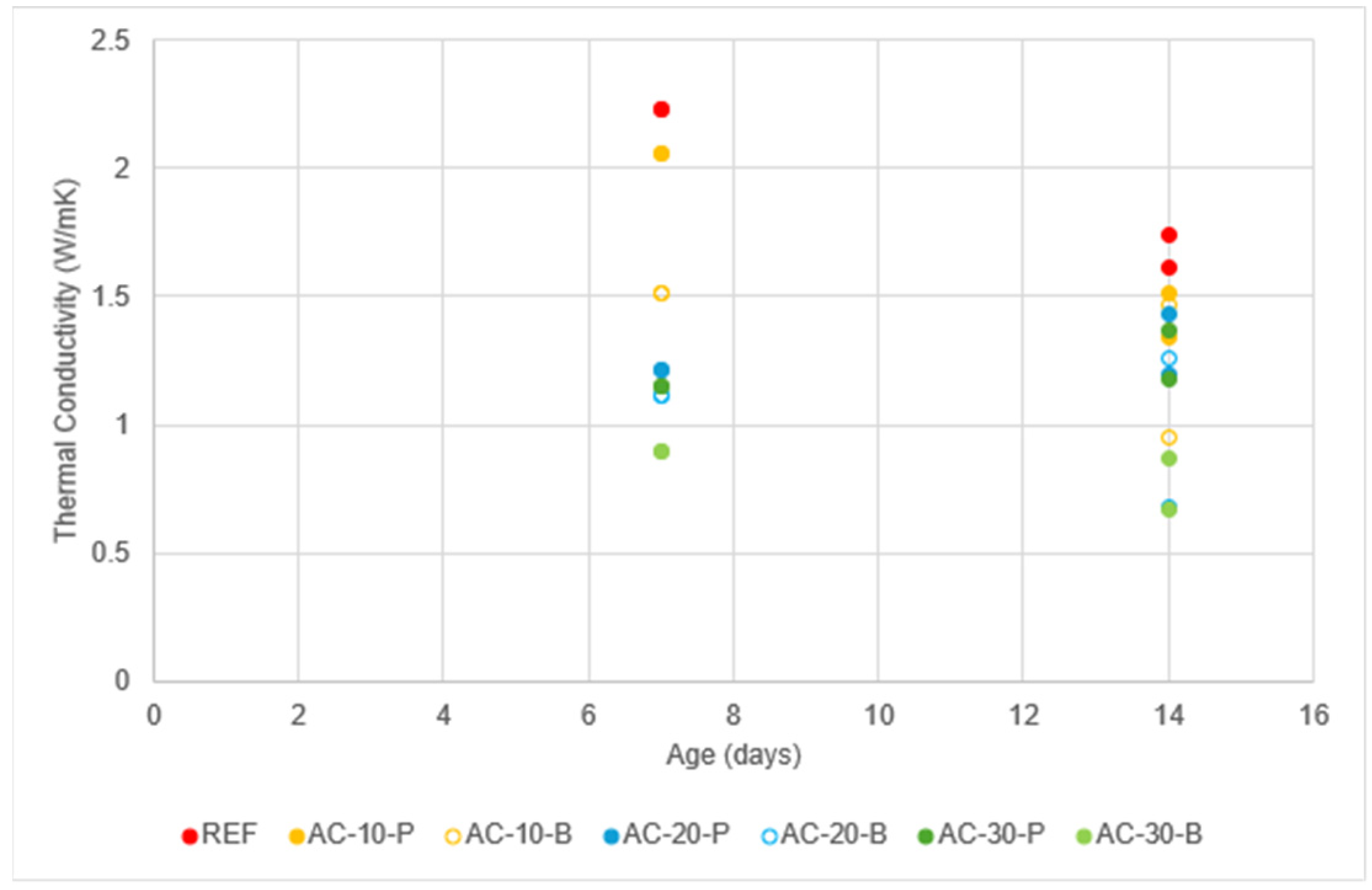

3.3. Thermal Conductivity

Distribution of Thermal Conductivity Measurements

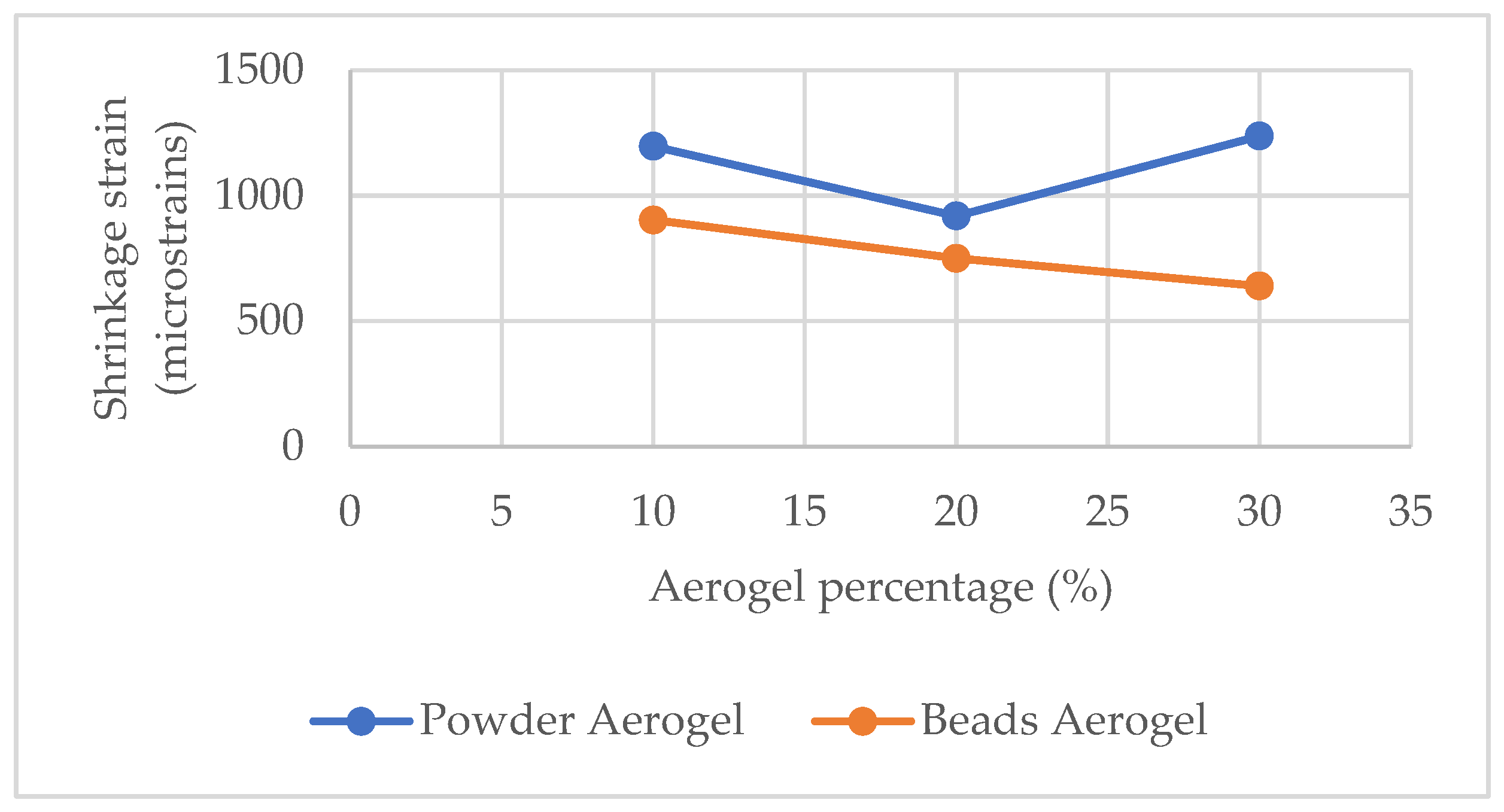

3.4. Shrinkage

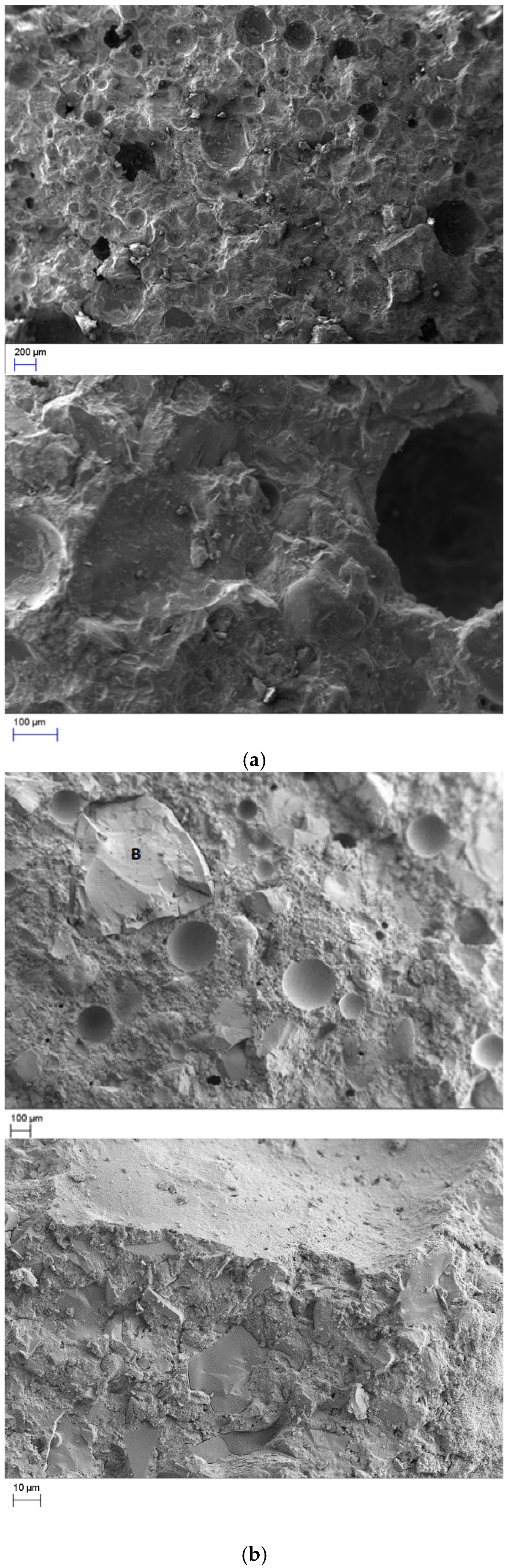

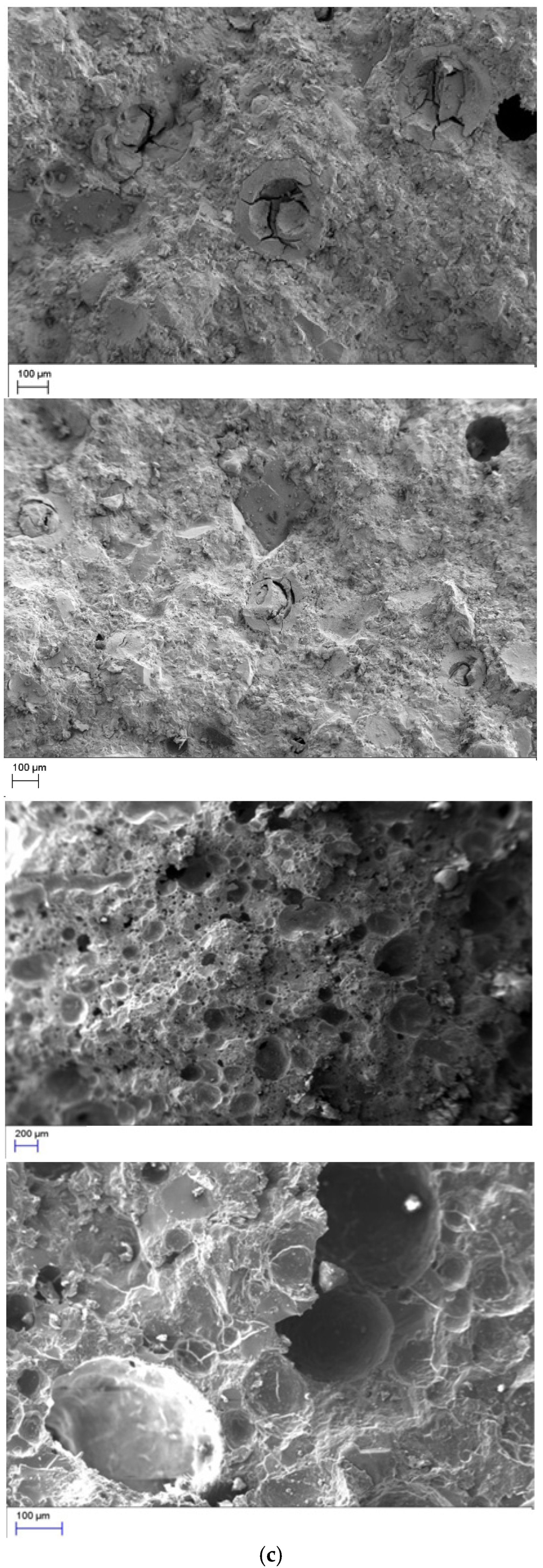

3.5. SEM Analyses

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- United Nations. Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/ (accessed on 8 January 2025).

- Kullman, J. ASU. 2023. Available online: https://news.asu.edu/20231017-curbing-concretes-carbon-emissions-innovations-cement-manufacturing?utm_source=chatgpt.com (accessed on 8 January 2025).

- Chandra, S.; Berntsson, L. Lightweight Aggregate Concrete; William Andrew Publishing: New York, NY, USA, 2002. [Google Scholar]

- Chen, B.; Liu, J. Mechanical properties of polymer-modified concretes containing expanded polystyrene beads. Constr. Build. Mater. 2007, 21, 7–11. [Google Scholar] [CrossRef]

- Kan, A.; Demirbogă, R. A novel material for lightweight concrete production. Cem. Concr. Compos. 2009, 31, 489–495. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Tiong-Huan, W. Effect of polystyrene aggregate size on strength and moisture migration characteristics of lightweight concrete. Cem. Concr. Compos. 2006, 28, 520–527. [Google Scholar] [CrossRef]

- Gao, T.; Jelle, B.; Gustavsen, A.; Jacobsen, S. Aerogel-incorporated concrete: An experimental study. Constr. Build. Mater. 2014, 52, 130–136. [Google Scholar] [CrossRef]

- Fickler, S.; Milow, B.; Ratke, L.; Schnellenbach-Held, M.; Welsch, T. Development of High Performance Aerogel Concrete. Energy Procedia. In Proceedings of the 6th International Building Physics Conference, IBPC 2015, Torino, Italy, 14–17 June 2015. [Google Scholar]

- Ng, S.; Jelle, B.; Sandberg, L.; Gao, T.; Wallevik, O. Experimental Investigations of aerogel-incorporated ultra-high performance concrete. Constr. Build. Mater. 2015, 77, 301–316. [Google Scholar] [CrossRef]

- Tsioulou, O.; Erpelding, J.; Lampropoulos, A. Development of novel low thermal conductivity concrete using Aerogel powder. In Proceedings of the Fib Symposium 2016 Performance-Based Approaches for Concrete Structures, University of Cape Town’s Graduate School of Business (GSB), Cape Town, South Africa, 21–23 November 2016. [Google Scholar]

- Lampropoulos, A.; Paschalis, S.; Tsioulou, O.; Dritsos, S. Strengthening of reinforced concrete beams using ultra high performance fibre reinforced concrete (UHPFRC). Eng. Struct. 2015, 106, 370–384. [Google Scholar] [CrossRef]

- Tsioulou, O.; Ayegbusi, J.; Lampropoulos, A. Experimental investigation on thermal conductivity and mechanical properties of a novel Aerogel concrete. In Proceedings of the Fib Symposium, Maastricht, The Netherlands, 12 June 2017. [Google Scholar]

- BS 1881-124; Testing Concrete. Methods for Analysis of Hardened Concrete. British Standards Institution: London, UK, 2015.

- ASTM D7984-21; Standard Test Method for Measurement of Thermal Effusivity of Fabrics Using a Modified Transient Plane Source (MTPS) Instrument. ASTM: West Conshohocken, PA, USA, 2021.

- Tangtermsirikul, S.; Choktaweekarn, P.; Saengsoy, W. A model for predicting thermal conductivity of concrete. Mag. Concr. Res. 2009, 61, 271–280. [Google Scholar]

| Sample | Cement (kg/m3) | Silica Fume (kg/m3) | GGBS (kg/m3) | Sand (kg/m3) | Aerogel (kg/m3) | Water (kg/m3) | Superplasticizer (kg/m3) |

|---|---|---|---|---|---|---|---|

| REF | 657 | 119 | 418 | 1051 | 0 | 185 | 59 |

| AC−10-P AC−10-B | 657 | 119 | 418 | 945.9 | 7.2 | 185 | 59 |

| AC−20-P AC−20-B | 657 | 119 | 418 | 840.8 | 14.4 | 185 | 59 |

| AC−30-P AC−30-B | 657 | 119 | 418 | 735.7 | 21.7 | 185 | 59 |

| Material | Density (kg/m3) |

|---|---|

| Cement | 3150 |

| Silica fume | 2200 |

| GGBS | 1900 |

| Sand | 1600 |

| Aerogel | 110 |

| fc in 0% Aerogel Mix | fc in 30% Aerogel Mix | Drop in fc (%) | Thermal Conductivity in 0% Aerogel Mix | Thermal Conductivity in 30% Aerogel Mix | Drop in Thermal Conductivity (%) | |

|---|---|---|---|---|---|---|

| Powder | 94 | 59 | 37.2 | 1.75 | 1.51 | 13.7 |

| Beads | 94 | 70 | 25.5 | 1.75 | 1.1 | 37.1 |

| (T. Gao, 2014) [7] | 62 | 30 | 52 | 2 | 1.05 | 47.5 |

| (S. Ng, 2015) [8] | 150 | 60 | 60 | 2.35 | 1.2 | 48.9 |

| 0.00% | 10.00% | 20.00% | 30.00% | ||||

|---|---|---|---|---|---|---|---|

| Day 14 k (W/mK) | k (W/mK) | k (W/mK) | k (W/mK) | ||||

| Powder | Beads | Powder | Beads | Powder | Beads | ||

| Point 1 | 1.791 | 0.78 | 1.727 | 1.44 | 1.648 | 1.25 | |

| Point 2 | 2.066 | 1.924 | 1.46 | 1.759 | 1.50 | 1.553 | 0.88 |

| Point 3 | 1.955 | 1.905 | 1.635 | 1.24 | 1.583 | 1.13 | |

| Point 4 | 1.944 | 1.853 | 1.35 | 1.572 | 1.58 | 1.351 | 0.90 |

| Average | 1.99 | 1.87 | 1.20 | 1.67 | 1.44 | 1.53 | 1.04 |

| CV | 0.034 | 0.032 | 0.305 | 0.051 | 0.101 | 0.084 | 0.173 |

| 0.00% | 10.00% | 20.00% | 30.00% | ||||

|---|---|---|---|---|---|---|---|

| Day 28 k (W/mK) | k (W/mK) | k (W/mK) | k (W/mK) | ||||

| Powder | Beads | Powder | Beads | Powder | Beads | ||

| Point 1 | 1.655 | 1.82 | 1.569 | 1.60 | 1.579 | ||

| Point 2 | 1.675 | 1.705 | 1.56 | 1.597 | 1.24 | 1.534 | |

| Point 3 | 1.761 | 1.47 | 0.95 | 1.577 | 1.52 | ||

| Point 4 | 1.823 | 1.707 | 1.54 | 1.648 | 0.68 | 1.416 | |

| Average | 1.75 | 1.63 | 1.47 | 1.60 | 1.26 | 1.51 | 1.1 |

| CV | 0.042 | 0.069 | 0.25064 | 0.022 | 0.33042 | 0.056 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tsioulou, O.; Lampropoulos, A.; Cacciola, P. Development of High-Strength Aerogel Concrete. Materials 2025, 18, 1040. https://doi.org/10.3390/ma18051040

Tsioulou O, Lampropoulos A, Cacciola P. Development of High-Strength Aerogel Concrete. Materials. 2025; 18(5):1040. https://doi.org/10.3390/ma18051040

Chicago/Turabian StyleTsioulou, Ourania, Andreas Lampropoulos, and Pierfrancesco Cacciola. 2025. "Development of High-Strength Aerogel Concrete" Materials 18, no. 5: 1040. https://doi.org/10.3390/ma18051040

APA StyleTsioulou, O., Lampropoulos, A., & Cacciola, P. (2025). Development of High-Strength Aerogel Concrete. Materials, 18(5), 1040. https://doi.org/10.3390/ma18051040