Microstructure and Mechanical Properties of Fe-Rich Thixotropic Deep-Cavity Al-1.2Si-1.1Fe-0.8Zn Cylindrical Components with Inconsistent Wall Thickness

Abstract

1. Introduction

2. Materials and Methods

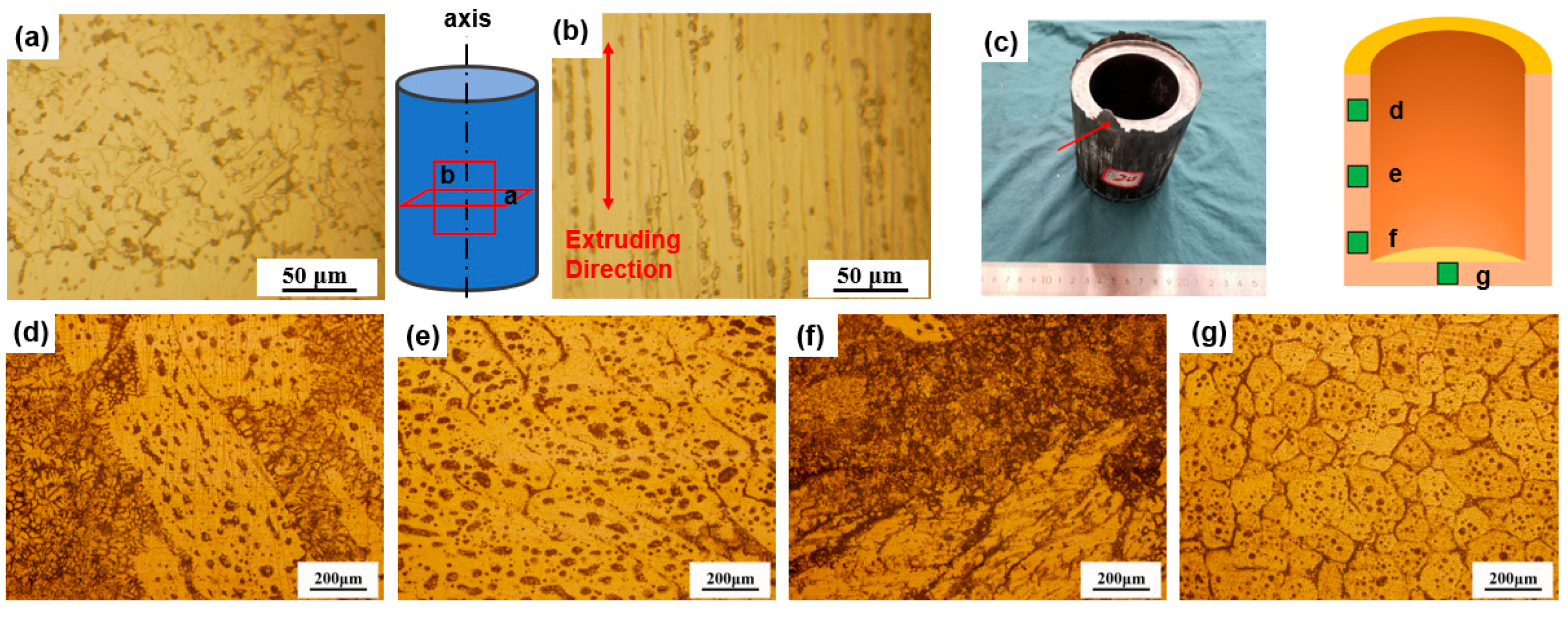

2.1. Raw Material

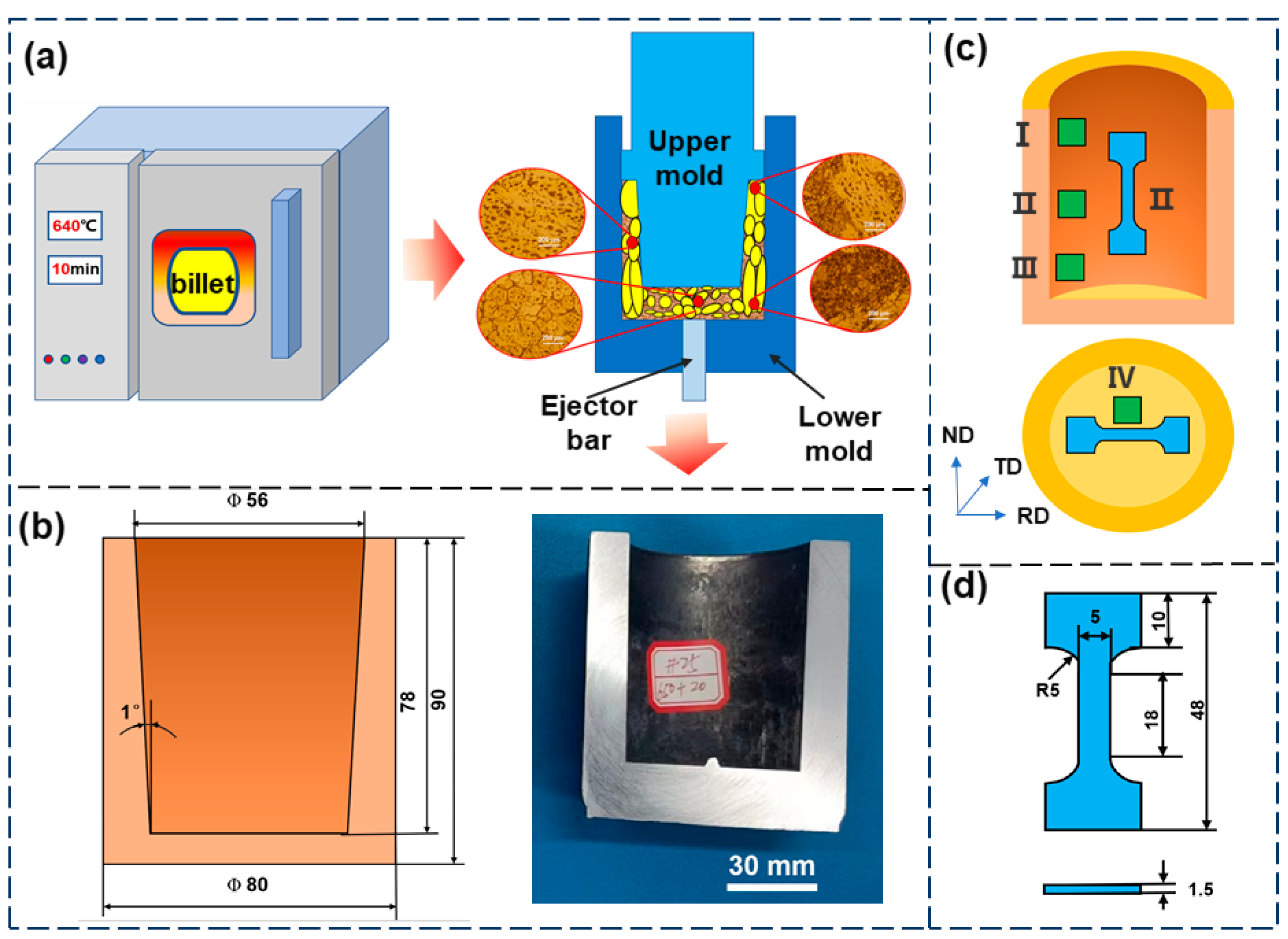

2.2. Preparation of Semi-Solid Billets

2.3. Thixoforming Experiment

2.4. Characterization of Microstructure and Mechanical Properties

3. Results and Discussion

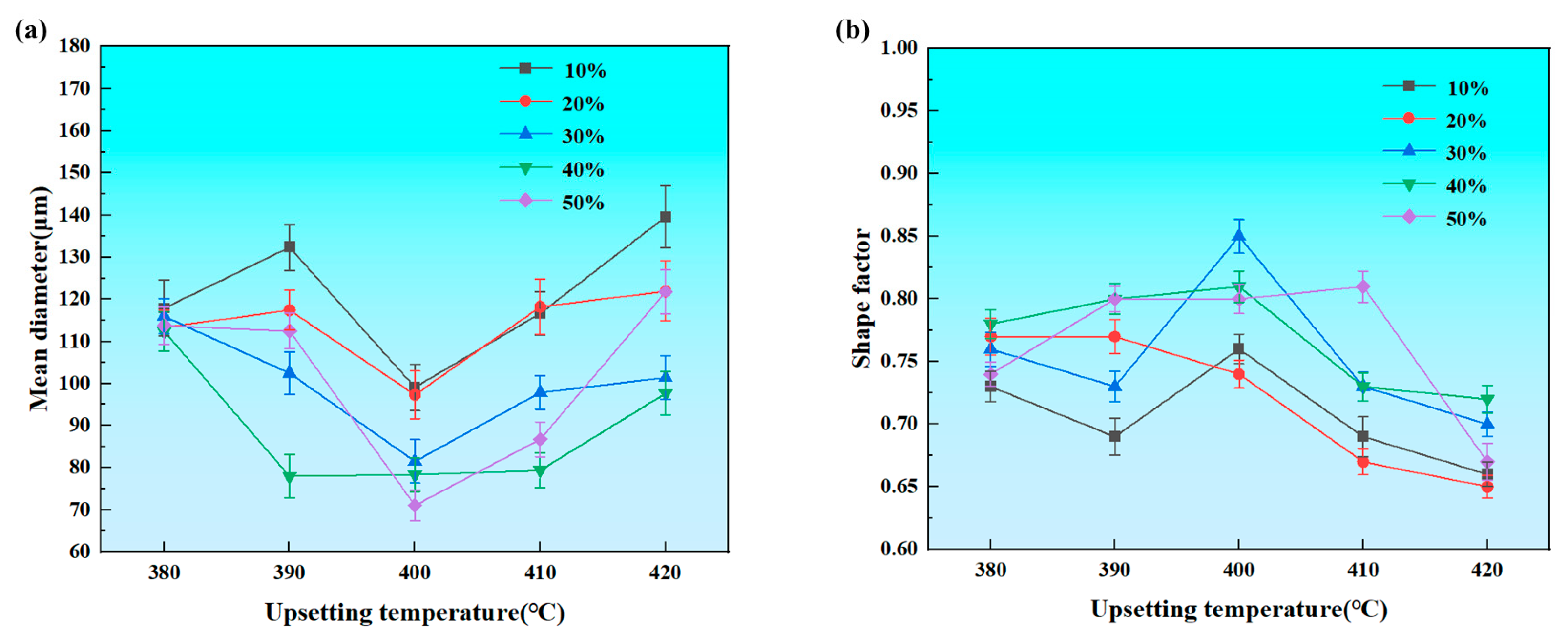

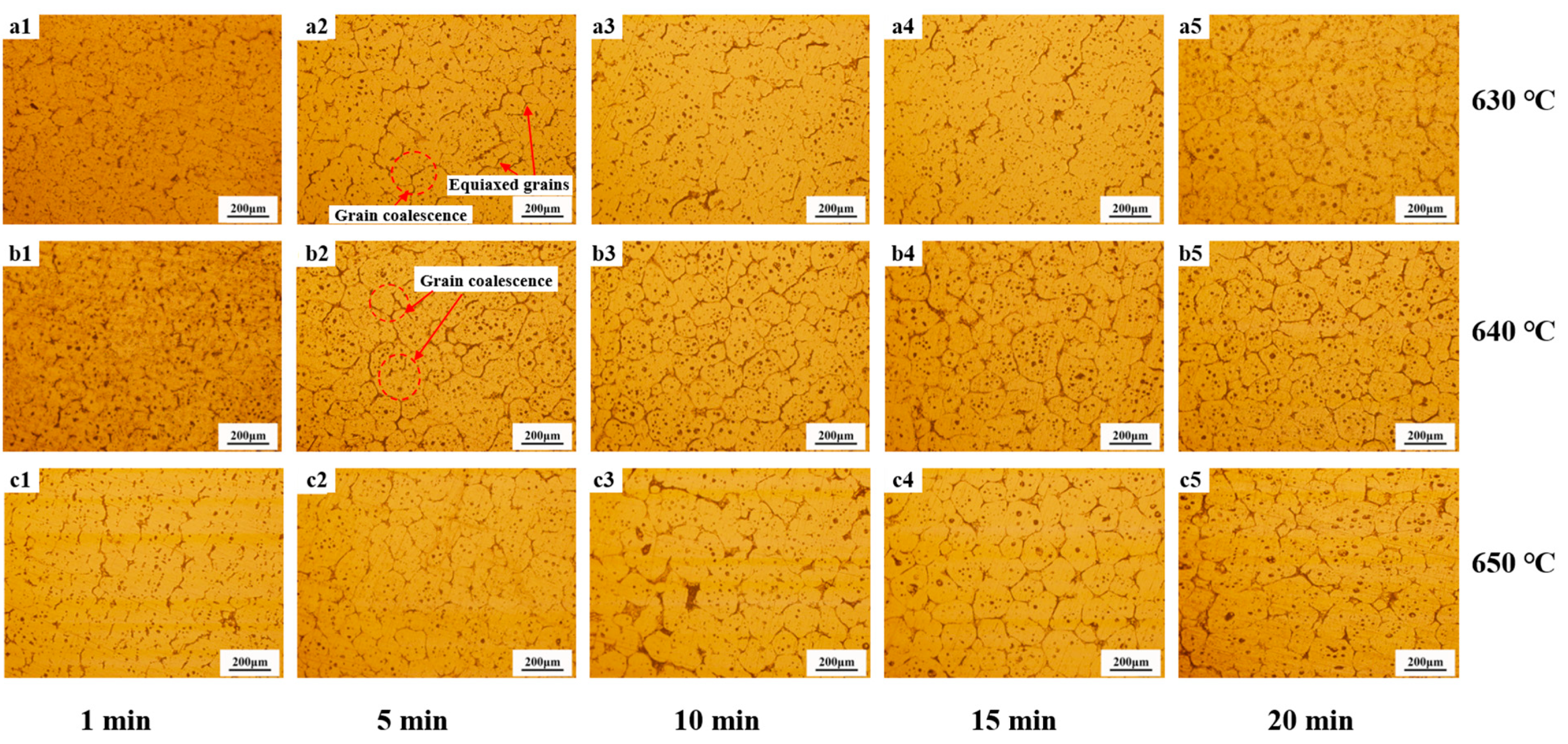

3.1. Microstructural Evolution of Semi-Solid Billets Prepared by TDIIS

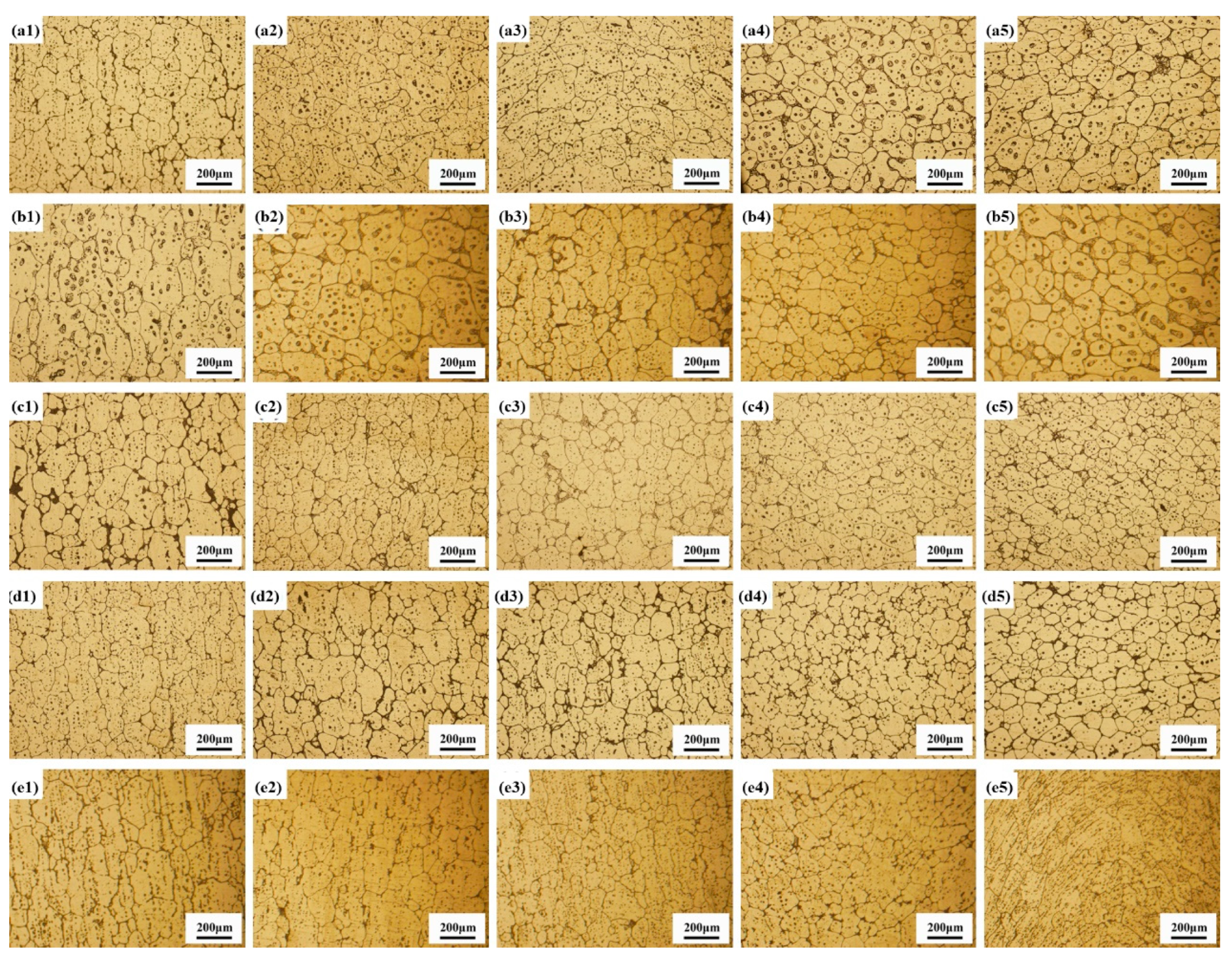

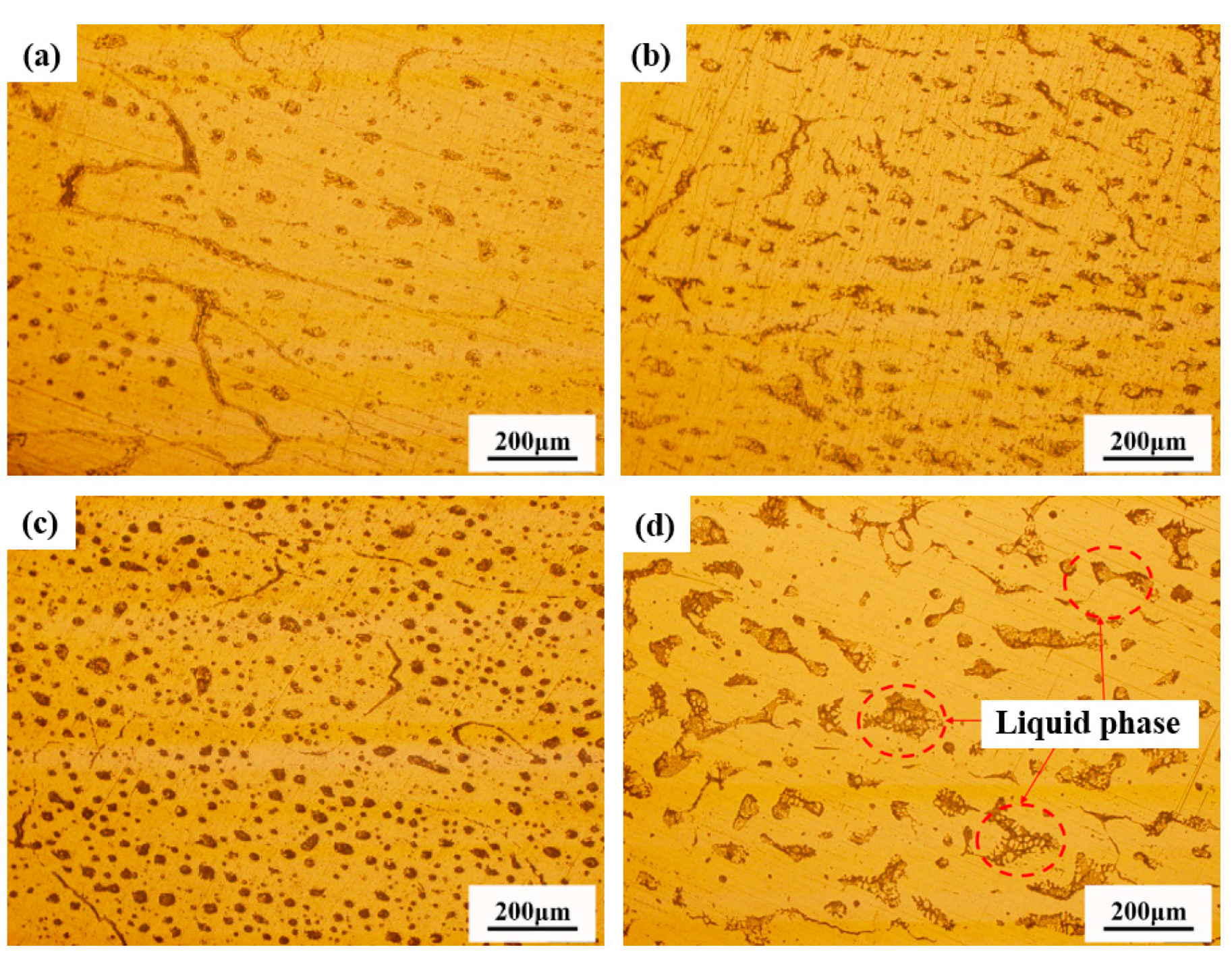

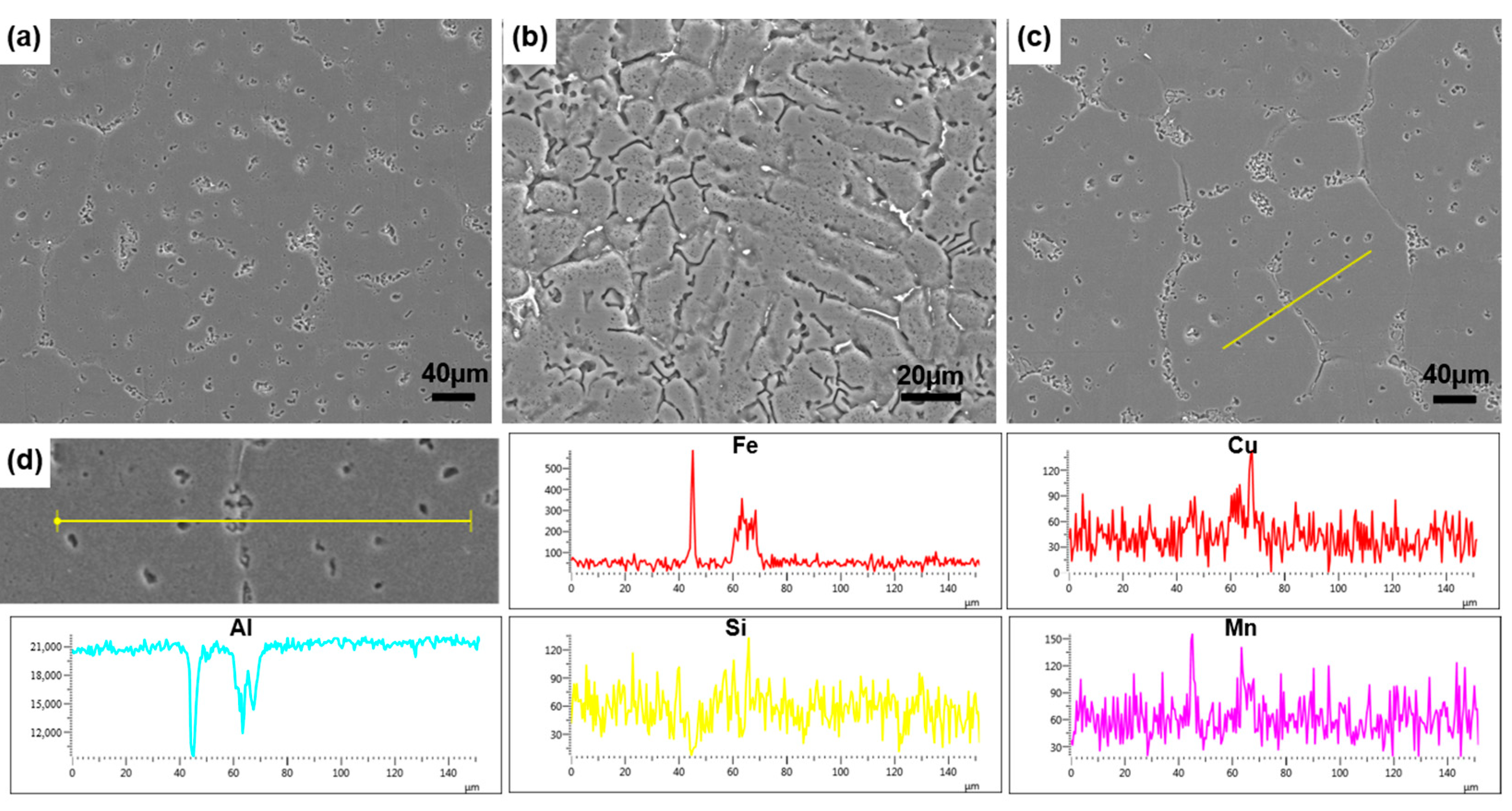

3.2. Microstructural Evolution of Deep-Cavity Al-1.2Si-1.1Fe-0.8Zn Cylindrical Components

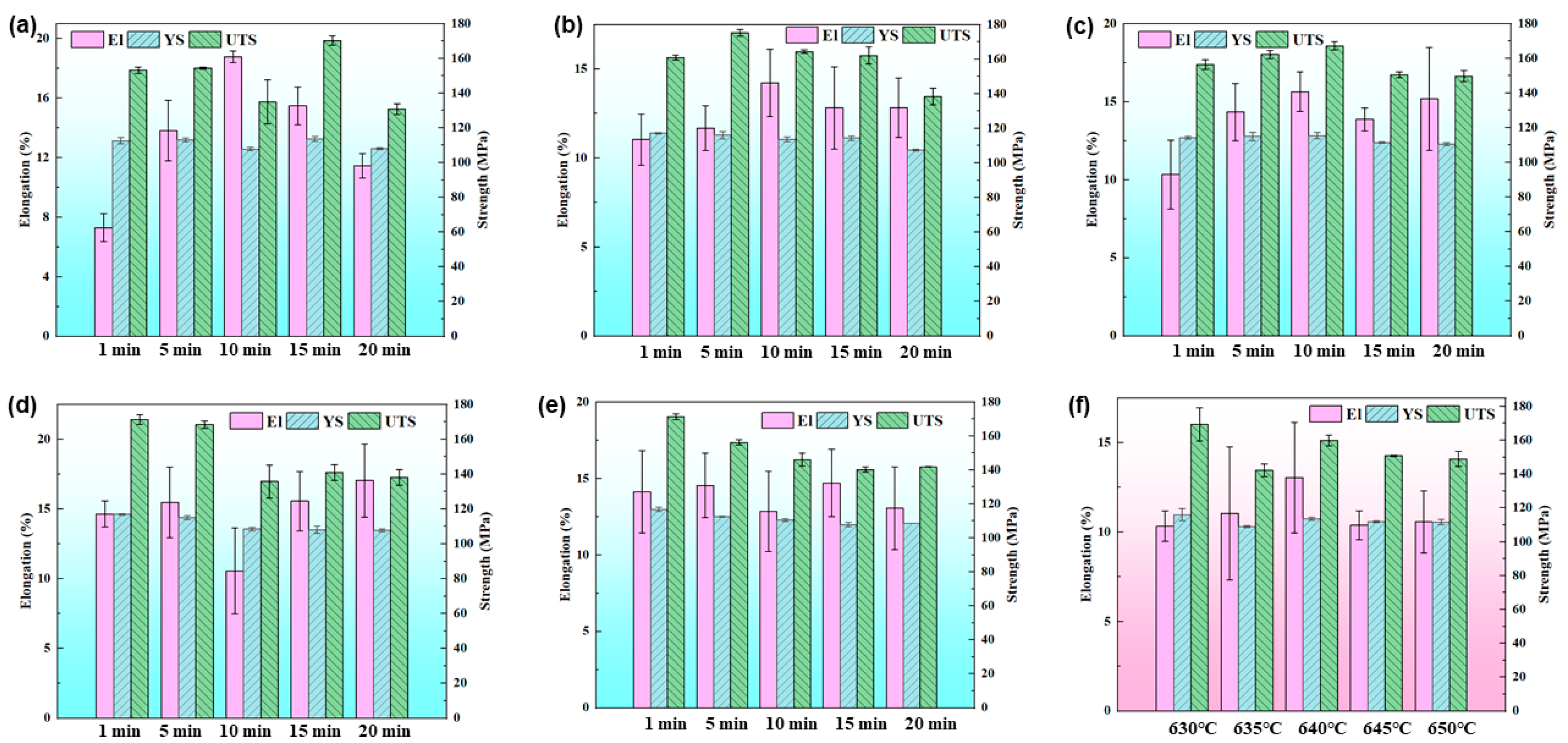

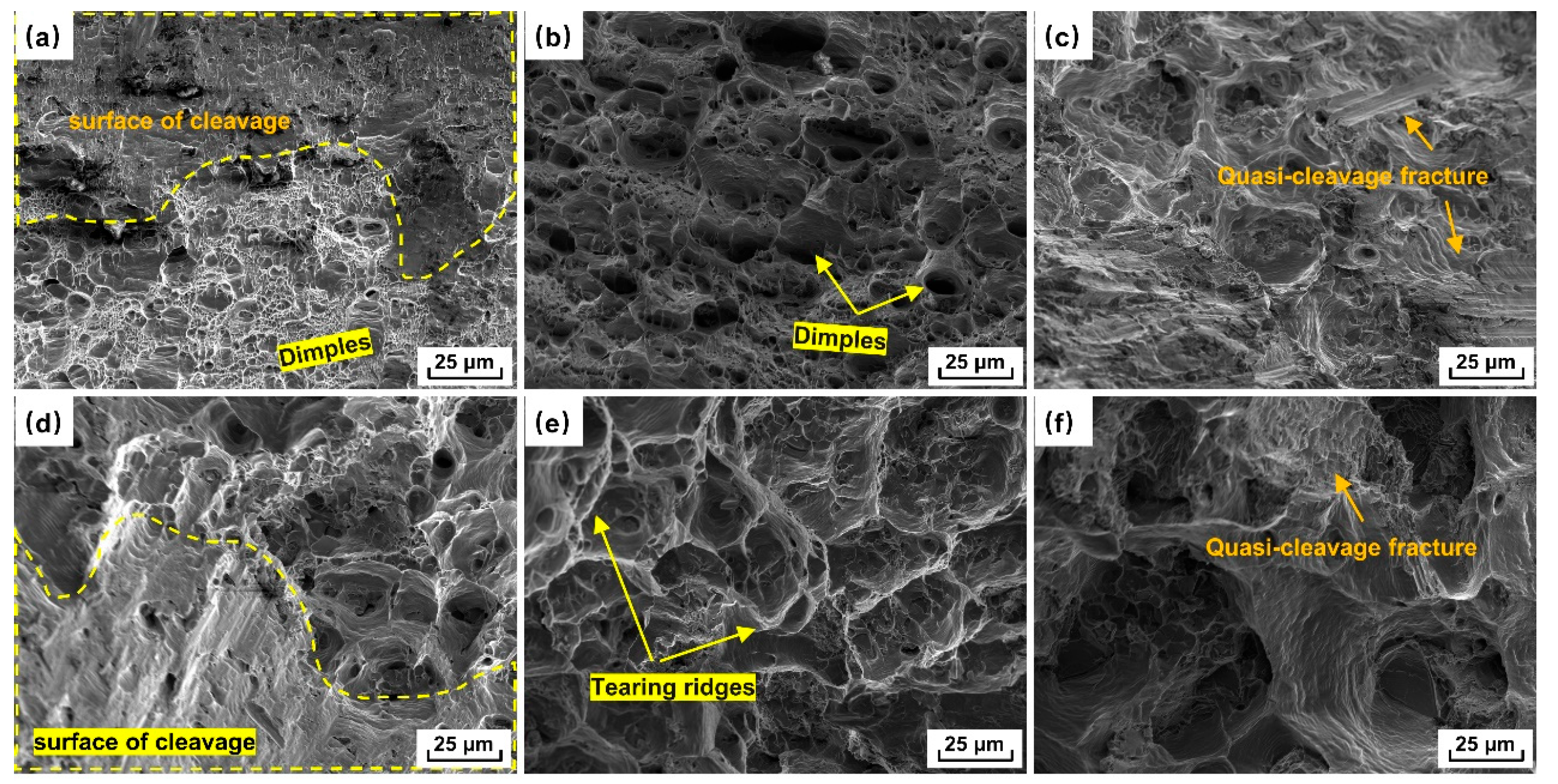

3.3. Mechanical Properties of Deep-Cavity Al-1.2Si-1.1Fe-0.8Zn Cylindrical Components

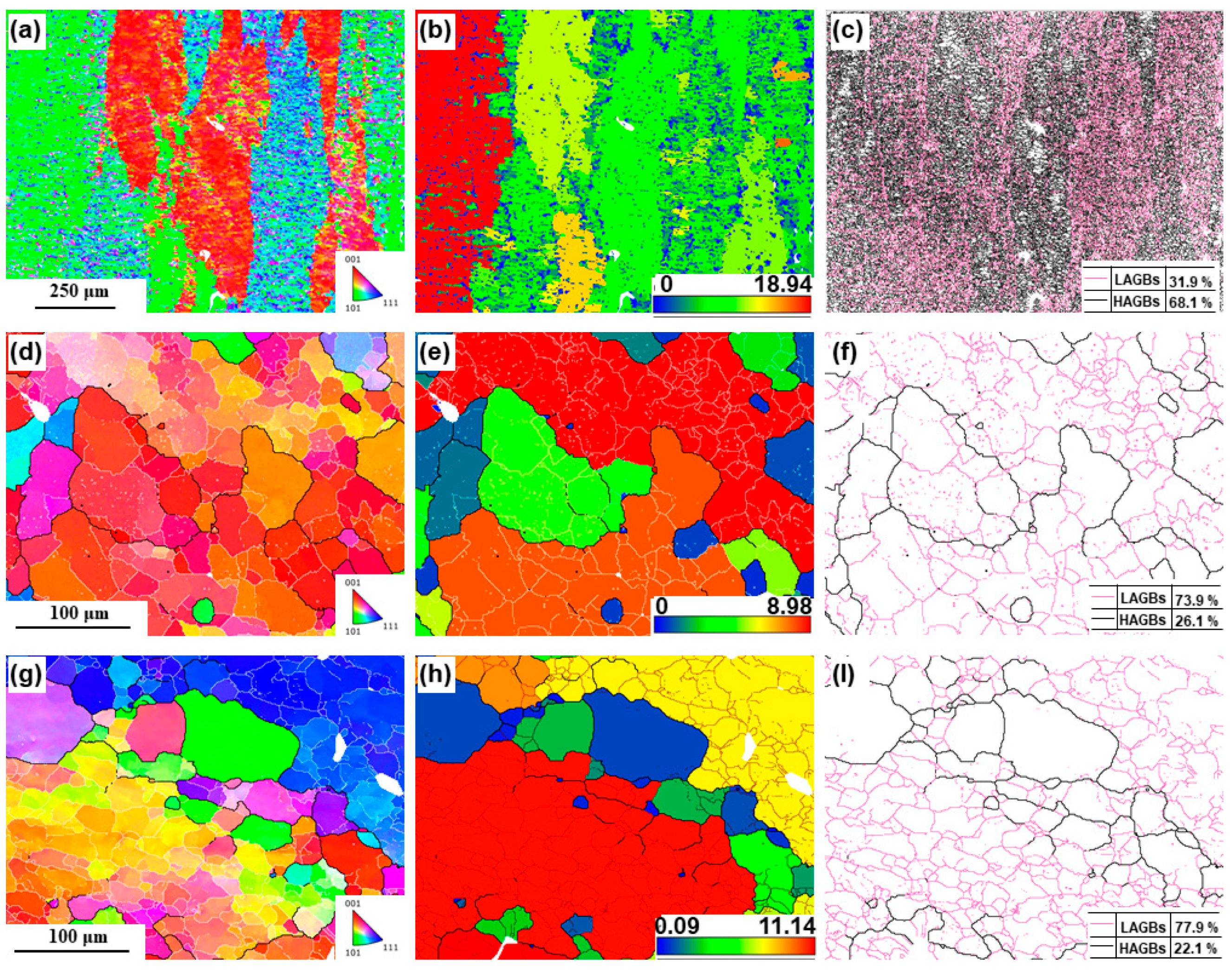

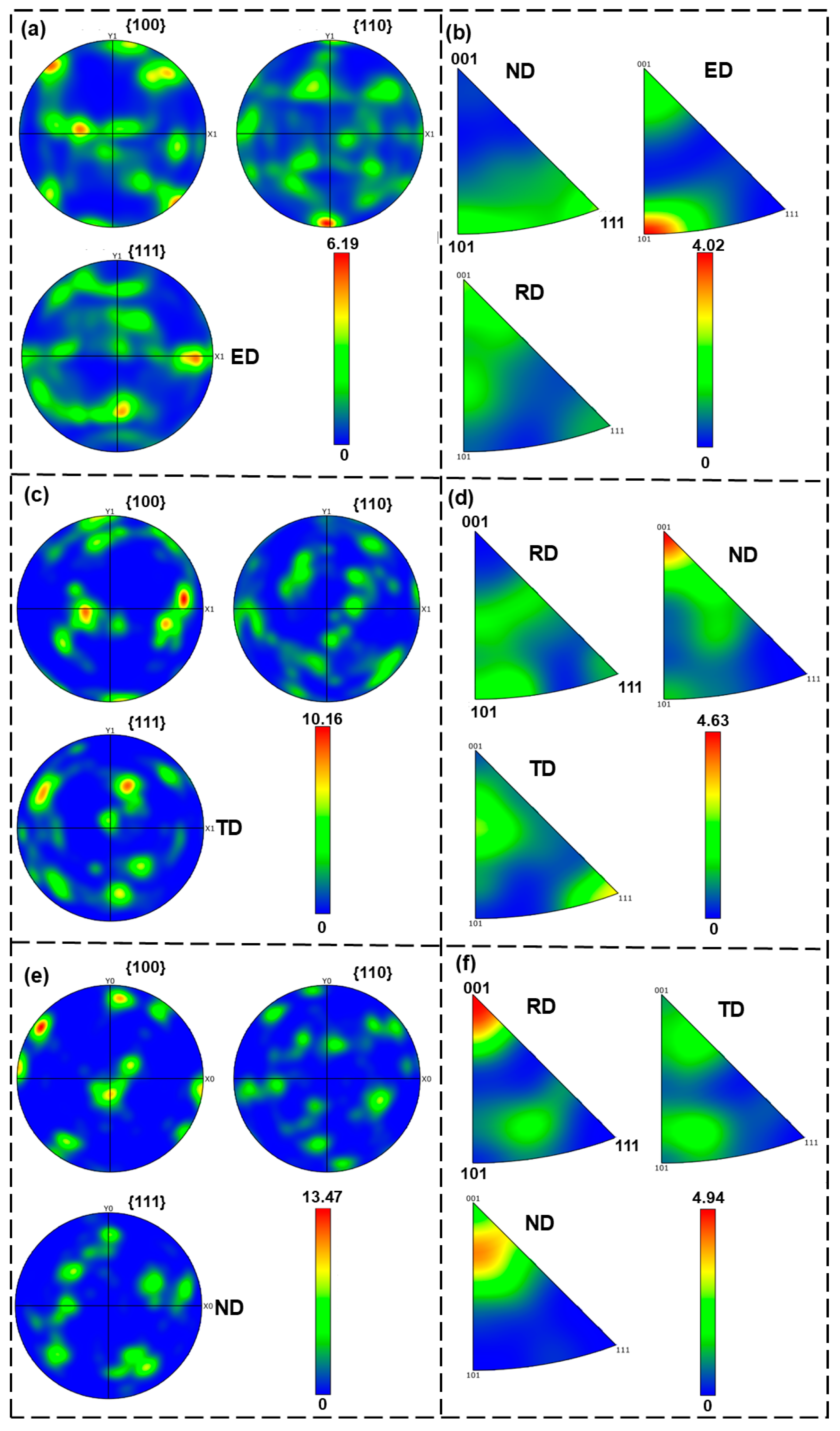

3.4. Recrystallization of Deep-Cavity Al-1.2Si-1.1Fe-0.8Zn Cylindrical Components

4. Conclusions

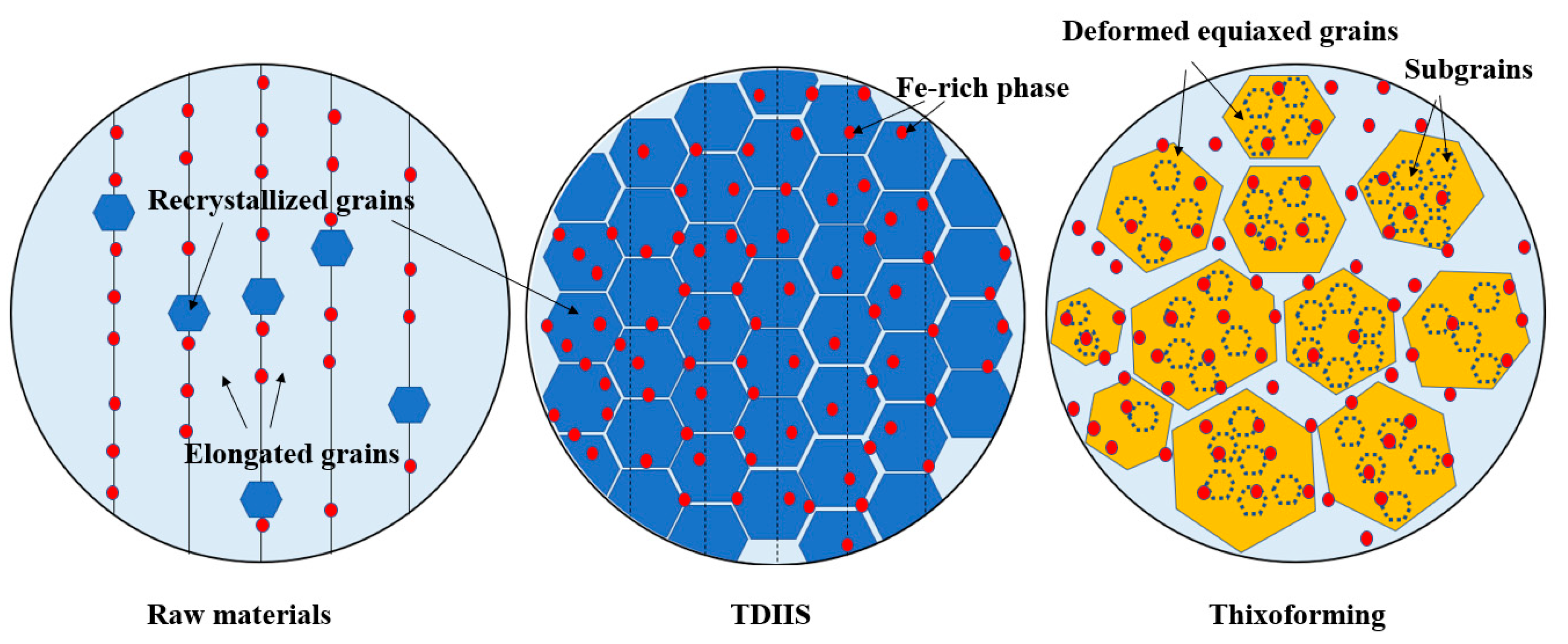

- Ideal semi-solid billets were successfully prepared through TDIIS. The variations in microstructural morphology and shape factor under different temperature and deformation amounts were systematically studied. SPD provided sufficient driving force for the recrystallization process. With an increase in the deformation amount, the uniformity of the microstructure improved significantly. At 400 °C, as the deformation amount increased, the recrystallized grains became progressively finer, reaching a minimum grain size of 71.1 μm at 50% deformation. Meanwhile, the shape factor exceeded 0.80, indicating excellent spheroidization. Therefore, the optimized preparation conditions were determined to be a preparation temperature of 400 °C and a deformation amount of 50%.

- Deep-cavity Al-1.2Si-1.1Fe-0.8Zn cylindrical components were prepared under different process parameters through thixoforming experiments. The microstructural analysis revealed a gradual transition in the microstructure from dendrites to spheroidal grains from the cylinder wall to the bottom. Simultaneously, the amount of precipitated liquid phase gradually decreased. Second-phase particles, primarily rich in Fe, were observed to be distributed in a point-like pattern along grain boundaries and within grains. The distribution of Mn was consistent with that of Fe, which helped alleviate tearing effects in the material. As the forming temperature increased, the amount of precipitated liquid phase gradually increased under the same holding time.

- Tensile mechanical property tests were conducted on the cylinder wall and bottom of selected components. Under conditions of 630 °C and 635 °C, the El of the cylinder bottom exhibited a trend of initially increasing and then decreasing with the extension of the holding time, with optimal mechanical properties achieved at 15 min of holding. As the temperature increased, the mechanical properties of the cylinder bottom reached their optimal state at 10 min of holding at 640 °C, 5 min at 645 °C, and 1 min at 650 °C. At the cylinder wall, the El reached its maximum at 640 °C, but the strength was slightly decreased due to liquid phase precipitation.

- The EBSD results indicated that a large number of subgrain boundaries existed within the grains at the cylindrical wall and the bottom of the components after holding at 640 °C for 10 min. The subgrains exhibited significant orientation differences due to the rotation of the dislocations between adjacent subgrains, serving as one of the primary sources of recrystallization. At the cylindrical wall and bottom, the content of LAGBs was relatively high. The maximum PF intensities at the cylindrical wall and bottom were 10.16 and 13.47, respectively, indicating that the grain orientation at the bottom was more concentrated than at the cylindrical wall.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ingarao, G.; Baffari, D.; Bracquene, E.; Fratini, L.; Duflou, J. Energy demand reduction of aluminum alloys recycling through friction stir extrusion processes implementation. Procedia Manuf. 2019, 33, 632–638. [Google Scholar] [CrossRef]

- Cardinale, A.M.; Maccio, D.; Luciano, G.; Canepa, E.; Traverso, P. Thermal and corrosion behavior of as cast Al-Si alloys with rare earth elements. J. Alloys Compd. 2017, 695, 2180. [Google Scholar] [CrossRef]

- Li, Y.; Li, H.; Katgerman, L.; Du, Q.; Zhang, J.; Zhuang, L. Recent advances in hot tearing during casting of aluminium alloys. Prog. Mater. Sci. 2021, 117, 100741. [Google Scholar] [CrossRef]

- Zhang, C.; Liao, W.; Shan, Z.; Song, W.; Dong, X. Squeeze casting of 4032 aluminum alloy and the synergetic enhancement of strength and ductility via Al-Ti-Nb-B grain refiner. Mater. Sci. Eng. A 2024, 896, 146233. [Google Scholar] [CrossRef]

- Chang, M.; Liu, B.; Wang, Y.; Li, S.; Zhao, S. Effect of cross-sectional reduction ratio on microstructure evolution of semi-solid 7075 aluminum alloy prepared by RFSIMA process. J. Alloys Compd. 2024, 989, 174355. [Google Scholar] [CrossRef]

- Sun, B.; Sun, N.; Wang, L.; Zhang, S.; Guo, Z. A new process for efficient purification of 6061 aluminum alloy scrap under semi-solid and super-gravity conditions. J. Clean. Prod. 2023, 402, 136825. [Google Scholar] [CrossRef]

- Arcaleni, R.; Mantelli, A.; Girelli, L.; Tonelli, L.; Morri, A.; Pola, A.; Ceschini, L. Microstructural characterization of primary and recycled aluminum AlSi7Mg alloy processed by the semi-solid thixocasting method. Mater. Charact. 2025, 220, 114657. [Google Scholar] [CrossRef]

- Chausse De Freitas, C.; Campo, K.N.; Caram, R. Thixoforming of titanium: The microstructure and processability of semisolid Ti-Cu-Fe alloys. Vacuum 2020, 180, 109567. [Google Scholar] [CrossRef]

- Boluri Gashti, A.H.; Abedi, H.R.; Salehi, M.T. Microstructure evolution and constitutive modeling of as-cast A356 aluminum alloy in semi-solid deformation regime. J. Mater. Res. Technol. 2023, 24, 7720. [Google Scholar] [CrossRef]

- Hassas-Irani, S.B.; Zarei-Hanzaki, A.; Bazaz, B.; Roostaei, A.A. Microstructure evolution and semi-solid deformation behavior of an A356 aluminum alloy processed by strain induced melt activated method. Mater. Des. 2013, 46, 579. [Google Scholar] [CrossRef]

- Chen, X.; Zhang, Z.; Xu, J. Effects of annular electromagnetic stirring processing parameters on semi-solid slurry production. T. Nonferr. Metal. Soc. 2010, 20, s873–s988. [Google Scholar] [CrossRef]

- Lu, S.; Wu, S.; Lin, C.; Hu, Z.; An, P. Preparation and rheocasting of semisolid slurry of 5083 Al alloy with indirect ultrasonic vibration process. Mater. Sci. Eng. A 2011, 528, 8635. [Google Scholar] [CrossRef]

- Chen, L.; Li, J.; Chen, W.; Pei, X.; Hou, H.; Zhao, Y. Comprehensive assessment and multiple-response optimization of serpentine channel pouring process for achieving high-quality semi-solid slurry. J. Mater. Res. Technol. 2023, 24, 3839. [Google Scholar] [CrossRef]

- Das, P. Effect of process variables and melt treatment conditions during cooling slope semi solid slurry generation process of Al-7Si-0.3 Mg alloy. Mater. Today Commun. 2022, 33, 104944. [Google Scholar] [CrossRef]

- Jiang, J.; Pan, X.; Ren, Y.; Liu, H.; Liu, L.; Zhang, K.; Li, J.; Zhang, M. Mechanical properties and micro-structural of Al-Zn-Mg-Cu alloy by semi-solid SIMA processed. Mater. Today Commun. 2023, 37, 107126. [Google Scholar] [CrossRef]

- Meng, Y.; Sugiyama, S.; Yanagimoto, J. Microstructural evolution during RAP process and deformation behavior of semi-solid SKD61 tool steel. J. Mater. Process. Technol. 2012, 212, 1731–1741. [Google Scholar] [CrossRef]

- Chang, M.; Liu, B.; Fan, S.Q.; Wang, Y.F.; Li, S.J.; Li, K.; Zhao, S. Microstructure and texture evolution of 2A12 aluminum alloy semi-solid billet prepared by SIMA process. J. Mater. Res. Technol. 2024, 33, 9484–9494. [Google Scholar] [CrossRef]

- Ragheb, Z.D.; Shabestari, S.G.; Najafi, Y. Effect of strain-induced melt activation process and thixoforming on microstructure and mechanical properties of 319 aluminum alloy. J. Alloys Compd. 2023, 954, 170152. [Google Scholar] [CrossRef]

- Salleh, M.S.; Omar, M.Z.; Alhawari, K.S.; Mohammed, M.N.; Ali, M.A.M.; Mohamad, E. Microstructural evolution and mechanical properties of thixoformed A319 alloys containing variable amounts of magnesium. T. Nonferr. Metal. Soc. 2016, 26, 2029. [Google Scholar] [CrossRef]

- Nazarizade, B.; Shabestari, S.G.; Najafi, Y. The effect of Cu–8%P master alloy, SIMA process, thixoforming, and heat treatment on the microstructure and mechanical properties of Al–20%Mg2Si composite. J. Mater. Res. Technol. 2024, 30, 9183–9195. [Google Scholar] [CrossRef]

- Shabestari, S.G.; Abdi, M.; Naghdali, S. Effect of thixoforming and precipitation hardening on microstructure and mechanical properties of Al-10.5Si–3Cu-0.2Mg alloy produced by strain induced melt activation process. J. Mater. Res. Technol. 2021, 15, 4981. [Google Scholar] [CrossRef]

- Liu, G.F.; Chen, T.J. Synthesis of heterogeneity-improved heterostructured 2024Al alloy with excellent synergy of strength and ductility via powder thixoforming. J. Alloys Compd. 2023, 932, 167661. [Google Scholar] [CrossRef]

- Huang, Y.; Sun, X.; Chang, Y.; Meng, X.; Mao, D.; Ma, X.; Wang, N.; Xie, Y. High thermal stability and mechanical properties of nanosized-Fe-reinforced aluminum matrix composites via deformation-driven metallurgy. Mater. Sci. Eng. A 2024, 913, 147092. [Google Scholar] [CrossRef]

- Xue, H.; Wang, Z.; Meng, Q.; Ke, C.; Luo, J. Microstructure evolution and mechanical properties for oxygen-rich ZrTiAlV alloy during in-situ semi-solid processing. J. Alloys Compd. 2024, 993, 174654. [Google Scholar] [CrossRef]

- Aghajani, S.; Alizadeh, R. Severe plastic deformation of Zn and Zn-based alloys. J. Mater. Res. Technol. 2024, 33, 6508. [Google Scholar] [CrossRef]

- Seo, P.K.; Kang, C.G. The effect of raw material fabrication process on microstructural characteristics in reheating process for semi-solid forming. J. Mater. Process. Technol. 2005, 162–163, 402. [Google Scholar] [CrossRef]

- Long, M.; Jiang, F.; Su, Y.; Xiao, Z. Dynamic recrystallization mechanisms and microstructure evolution of a novel Al-Zn-Mg-Cu-Zr alloy by isothermal compression. J. Mater. Res. Technol. 2024, 33, 1740. [Google Scholar] [CrossRef]

- Zhao, H.; Qin, F.; Jiang, J.; Cui, Y.; Wang, H.; Kang, Y.; Zhang, L. Study on dynamic recrystallization and precipitation behavior of hot compressed Al-20Zn-0.5Mg-0.5Sc alloy. Mater. Today. Commun. 2024, 41, 110452. [Google Scholar] [CrossRef]

- Li, Z.; Hu, X.G.; Qu, W.Y.; Zhou, Y.; Guo, C.; Lu, H.X.; M, X.X.; Mohagheghian, I.; Whiting, M.J.; Zhu, Q. Slurry preparation for semi-solid metal direct writing by a novel approach of mixed powder remelting. Powder. Technol. 2023, 426, 118673. [Google Scholar] [CrossRef]

- Li, M.; Zu, Y.; Chen, G.; Li, Y.; Li, X. Ultrafast recrystallization and grain refinement of 2A97 Al-Cu-Li alloy by electropulsing assisted annealing at lower temperature. J. Alloys Compd. 2024, 1003, 175662. [Google Scholar] [CrossRef]

- Zhang, Y.; Wu, D.; Hu, Y.; Tu, X.; Yan, B.; Xu, W. Strength-ductility synergy of Mg-7.5 wt% Sn binary alloys promoted by semisolid isothermal treatment coupled with hot extrusion. J. Alloys Compd 2025, 1010, 177236. [Google Scholar] [CrossRef]

- Wang, X.; Ding, X.; Chen, R.; Ding, J.; Qian, M.; Zhang, Y.; Wu, S. Tailoring the microstructure, phase transition characteristics and one-way shape memory effect of Ni-Mn-Ga alloys by dual treatment of annealing and directional solidification. Mater. Sci. Eng. A 2024, 918, 147463. [Google Scholar] [CrossRef]

- Tian, N.; Zhang, Y.; He, Z.; Liu, H.; Zhang, Z.; Liu, J.; Zhao, G.; Qin, G. The formation of three phases containing Fe and Mn in 5182 aluminum alloy. Mater. Charact. 2024, 207, 113497. [Google Scholar] [CrossRef]

- Huang, X.; Gao, C.; Jiang, X.; Li, L.; Gui, X.; Liu, H.; Yang, S.; Zhao, P.; Luo, H.; Ma, Y. Mechanism of homogenization temperature and time on Fe-containing phase transition in AA8014 aluminum alloy. Mater. Today Commun. 2024, 41, 110588. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, J.; Wang, Y.; Liu, Y.; Huang, M. Microstructural evolution and anisotropic tensile properties of a bimodal 6A02 Al semi-solid billet. J. Alloys Compd. 2022, 910, 164937. [Google Scholar] [CrossRef]

- Zhang, L.; Shibuta, Y. Inverse Hall-Petch relationship of high-entropy alloy by atomistic simulation. Mater. Lett. 2020, 274, 128024. [Google Scholar] [CrossRef]

- Atkinson, H.V.; Burke, K.; Vaneetveld, G. Recrystallisation in the semi-solid state in 7075 aluminium alloy. Mater. Sci. Eng. A 2008, 490, 266. [Google Scholar] [CrossRef]

- Liu, T.; Huang, W.; Hu, Y.; Luo, J.; Wu, J.; Zhu, L. Influence of in-situ TiB2 particles on microstructure and mechanical properties of ZL101A alloy. Mater. Today. Commun. 2024, 42, 111368. [Google Scholar] [CrossRef]

- Huang, X.; Gao, C.; Liu, Z.; Ma, K.; Shi, X.; Wu, G.; Xu, W.; Zhao, P.; Ma, Y. Evolution of Fe-bearing phases during the fabrication and its effect on the mechanical properties of AA8014 aluminum alloy. Mater. Today Commun. 2024, 38, 108482. [Google Scholar]

- Allain-Bonasso, N.; Wagner, F.; Berbenni, S.; Field, D.P. A study of the heterogeneity of plastic deformation in IF steel by EBSD. Mater. Sci. Eng. A 2012, 548, 56. [Google Scholar] [CrossRef]

- Jiang, J.; Wang, Y.; Liu, Y.; Xiao, G.; Li, H. Microstructure and mechanical properties of 7005 aluminum alloy processed by one-pass equal channel reciprocating extrusion. T. Nonferr. Metal. Soc. 2021, 31, 609. [Google Scholar] [CrossRef]

- Zhang, Z.; Cheng, Y.; Wang, X.; Song, S.; Ren, X. Investigation on tensile property and mechanism of partially recrystallized Al0.1CoCrFeNi high-entropy alloy after cold rolling and annealing treatment. Mater. Sci. Eng. A 2025, 921, 147572. [Google Scholar] [CrossRef]

- Shi, J.; Shuai, M.; Chen, X.; Wu, Y.; Chu, Z.; Tuo, L. Dynamic recrystallization behavior and numerical simulation of 2209 duplex stainless steel. Mater. Today. Commun. 2024, 41, 110892. [Google Scholar] [CrossRef]

- Li, J.; Luo, K.; An, Q. Unraveling the Hall-Petch to inverse Hall-Petch transition in nanocrystalline CdTe. Int. J. Mech. Sci. 2025, 286, 109852. [Google Scholar] [CrossRef]

| Element | Si | Mg | Zn | Fe | Cu | Mn | Cr | Al |

| wt % | 1.237 | 0.703 | 0.824 | 1.064 | 0.504 | 0.346 | 0.144 | balance |

| Serial Number | Holding Temperature (°C) | Deformation (%) | Serial Number | Holding Temperature (°C) | Deformation (%) |

|---|---|---|---|---|---|

| 1 | 380 | 10 | 14 | 400 | 40 |

| 2 | 380 | 20 | 15 | 400 | 50 |

| 3 | 380 | 30 | 16 | 410 | 10 |

| 4 | 380 | 40 | 17 | 410 | 20 |

| 5 | 380 | 50 | 18 | 410 | 30 |

| 6 | 390 | 10 | 19 | 410 | 40 |

| 7 | 390 | 20 | 20 | 410 | 50 |

| 8 | 390 | 30 | 21 | 420 | 10 |

| 9 | 390 | 40 | 22 | 420 | 20 |

| 10 | 390 | 50 | 23 | 420 | 30 |

| 11 | 400 | 10 | 24 | 420 | 40 |

| 12 | 400 | 20 | 25 | 420 | 50 |

| 13 | 400 | 30 |

| Serial Number | Holding Temperature (°C) | Holding Time (min) | Serial Number | Holding Temperature (°C) | Holding Time (min) |

|---|---|---|---|---|---|

| 1 | 630 | 1 | 14 | 640 | 15 |

| 2 | 630 | 5 | 15 | 640 | 20 |

| 3 | 630 | 10 | 16 | 645 | 1 |

| 4 | 630 | 15 | 17 | 645 | 5 |

| 5 | 630 | 20 | 18 | 645 | 10 |

| 6 | 635 | 1 | 19 | 645 | 15 |

| 7 | 635 | 5 | 20 | 645 | 20 |

| 8 | 635 | 10 | 21 | 650 | 1 |

| 9 | 635 | 15 | 22 | 650 | 5 |

| 10 | 635 | 20 | 23 | 650 | 10 |

| 11 | 640 | 1 | 24 | 650 | 15 |

| 12 | 640 | 5 | 25 | 650 | 20 |

| 13 | 640 | 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, L.; Jiang, J.; Wang, Y.; Zhang, X.; Tang, S.; Song, T. Microstructure and Mechanical Properties of Fe-Rich Thixotropic Deep-Cavity Al-1.2Si-1.1Fe-0.8Zn Cylindrical Components with Inconsistent Wall Thickness. Materials 2025, 18, 741. https://doi.org/10.3390/ma18040741

Kong L, Jiang J, Wang Y, Zhang X, Tang S, Song T. Microstructure and Mechanical Properties of Fe-Rich Thixotropic Deep-Cavity Al-1.2Si-1.1Fe-0.8Zn Cylindrical Components with Inconsistent Wall Thickness. Materials. 2025; 18(4):741. https://doi.org/10.3390/ma18040741

Chicago/Turabian StyleKong, Lingbo, Jufu Jiang, Ying Wang, Xiaodong Zhang, Shanyong Tang, and Tao Song. 2025. "Microstructure and Mechanical Properties of Fe-Rich Thixotropic Deep-Cavity Al-1.2Si-1.1Fe-0.8Zn Cylindrical Components with Inconsistent Wall Thickness" Materials 18, no. 4: 741. https://doi.org/10.3390/ma18040741

APA StyleKong, L., Jiang, J., Wang, Y., Zhang, X., Tang, S., & Song, T. (2025). Microstructure and Mechanical Properties of Fe-Rich Thixotropic Deep-Cavity Al-1.2Si-1.1Fe-0.8Zn Cylindrical Components with Inconsistent Wall Thickness. Materials, 18(4), 741. https://doi.org/10.3390/ma18040741