Multi-Class Concrete Defect Classification Using Guided Semantic–Spatial Fusion and Squeeze–Excitation Enhanced DenseNet Model

Abstract

1. Introduction

- A new multi-class image-based measurement concrete defect dataset for classification tasks is introduced.

- Aiming to significantly improve the concrete defect multi-class identification, a guided semantic–spatial fusion module with squeeze-and-excitation DenseNet201 called (GSSFSEDenseNet201) is designed and implemented.

- New experimental scenarios are conducted using different modifications of the core model to achieve the best-performing model supported by measurement-oriented validation (accuracy, interpretability, and uncertainty analysis).

2. Materials and Methods

2.1. Dataset

2.2. GSSFSEDenseNet201 Architecture

- -

- Dual-path feature guidance through the Guided Semantic–Spatial Fusion.

- -

- Cross-attention fusion mechanism and SE-based cross-attention, where channel recalibration is performed after semantic–spatial correlation.

- -

- The GSSFusion module is inserted into DenseNet as a parallel micro-architecture that changes the computational graph of DenseNet.

2.3. Performance Evaluation Measurements

3. Results

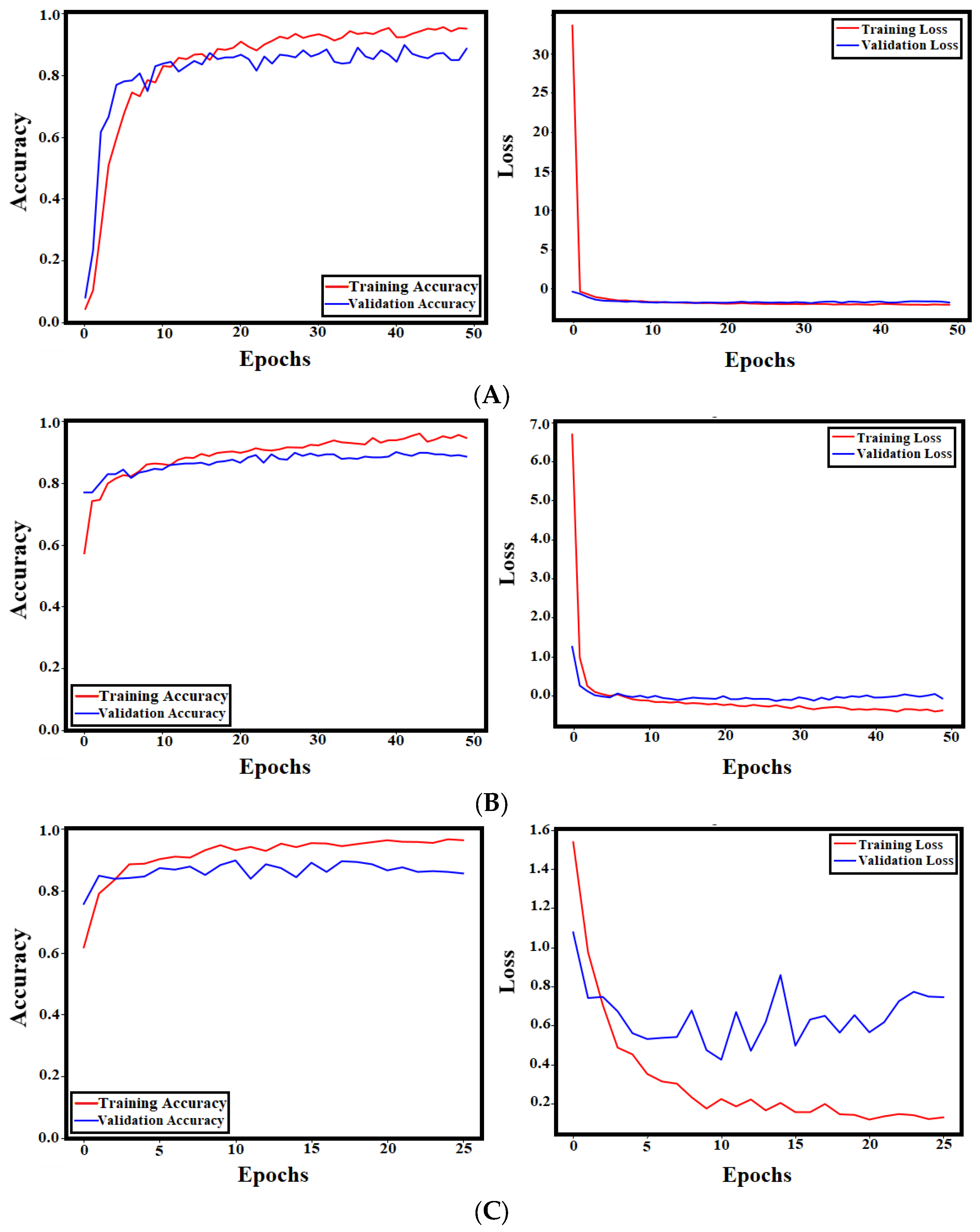

3.1. Model Training Options

3.2. Training and Validation Results of the Proposed

4. Discussion

4.1. Ablation Study: Modifying the DenseNet201 Architecture

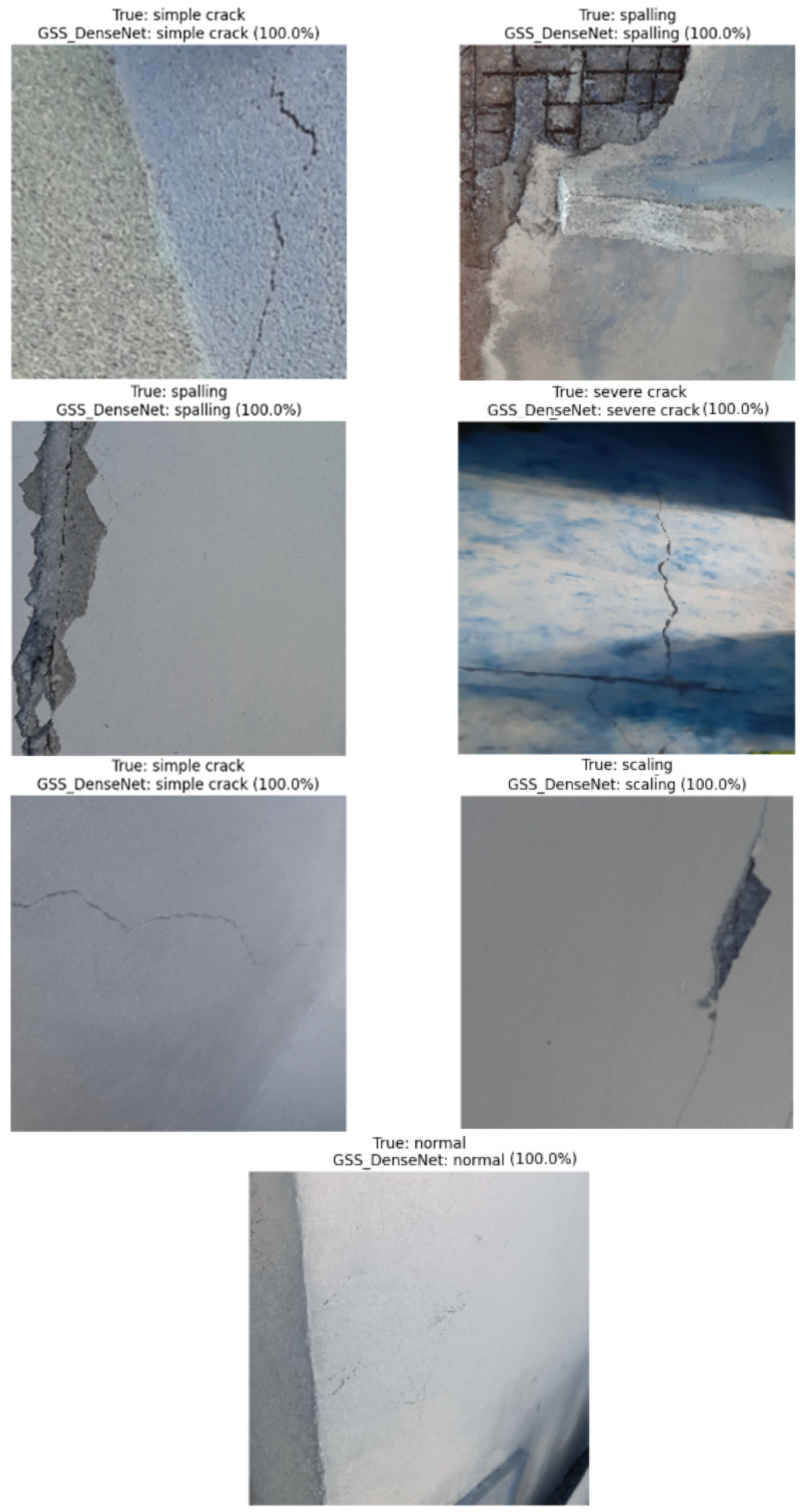

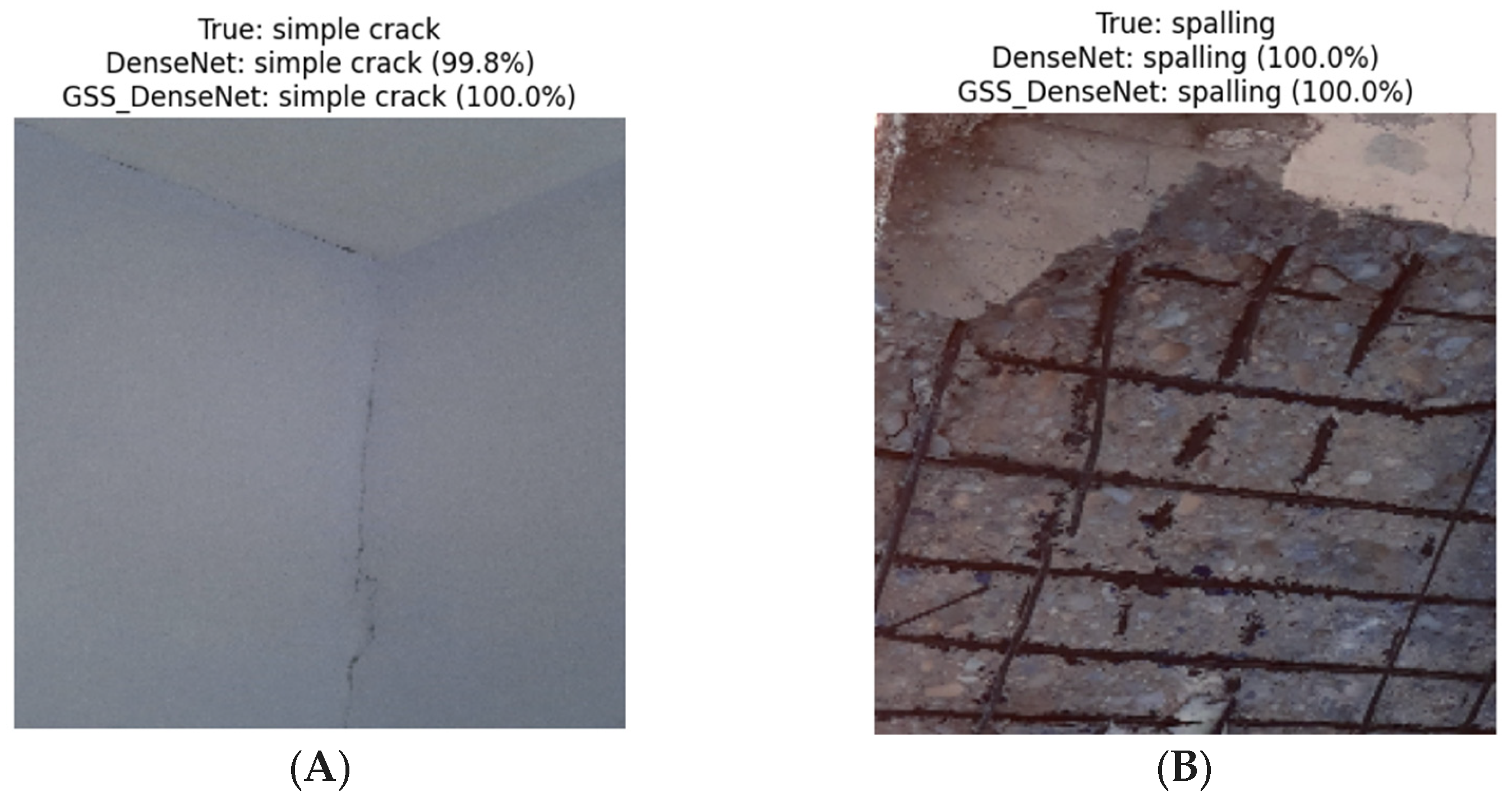

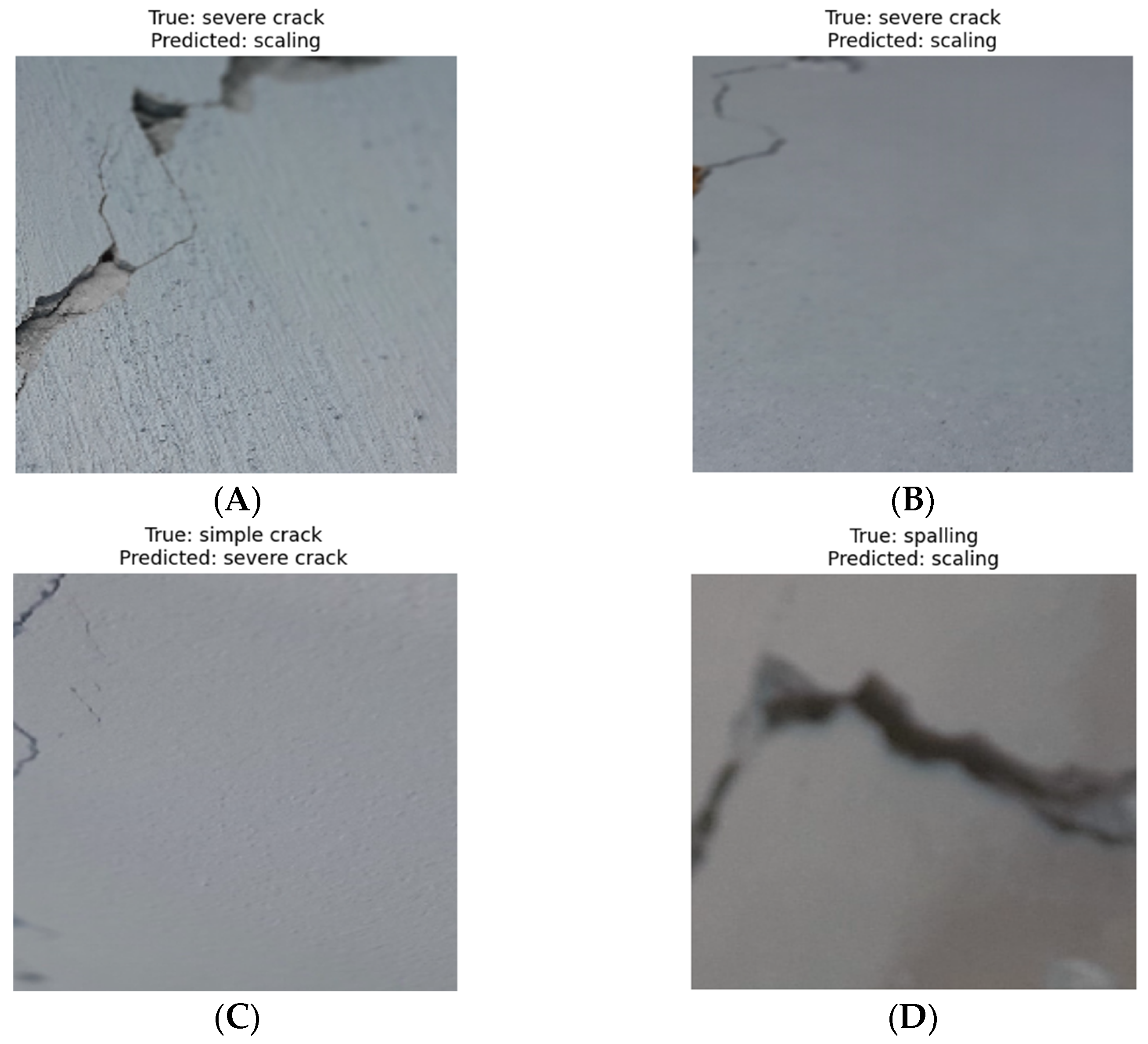

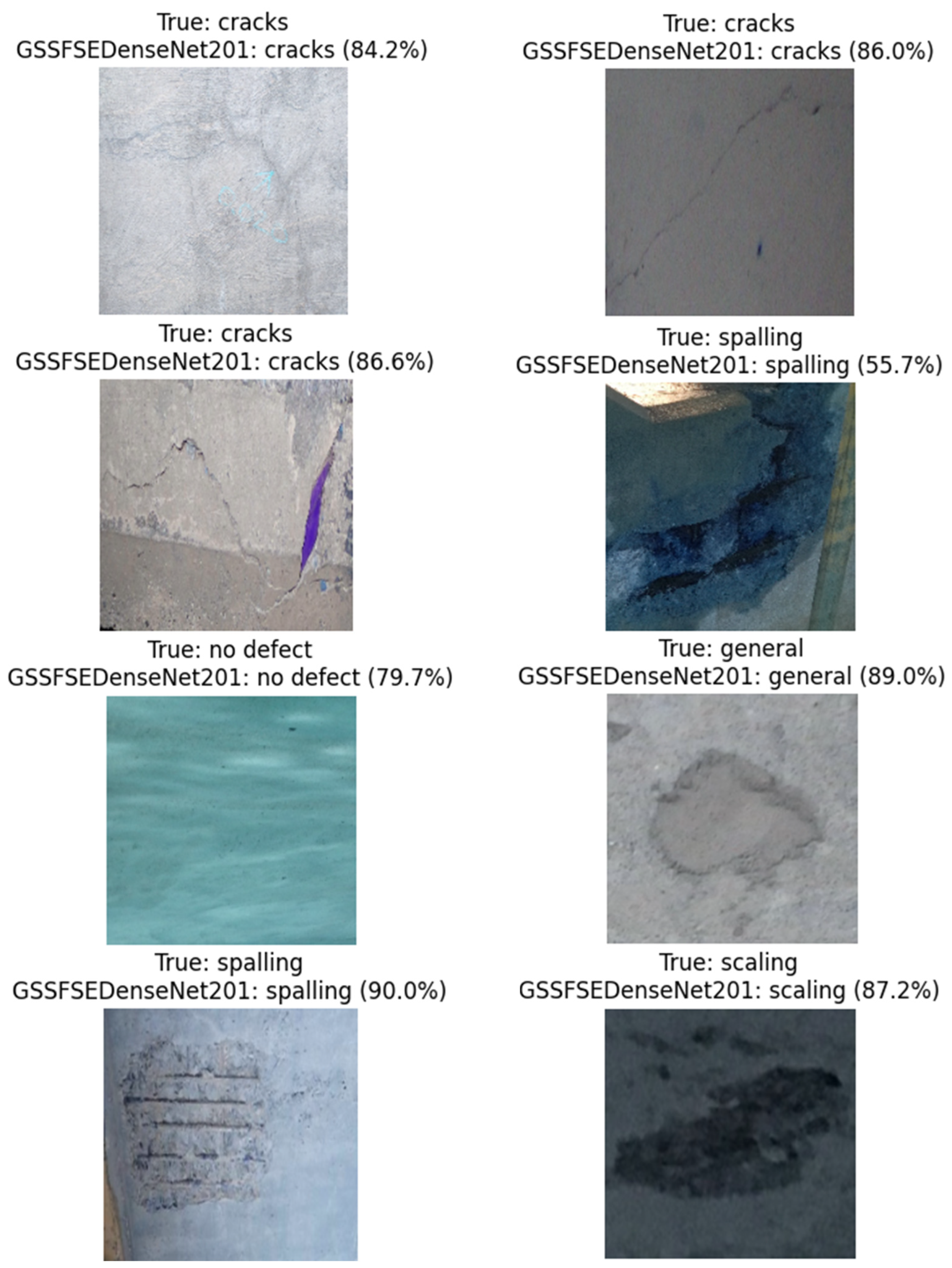

4.2. Misclassified Samples

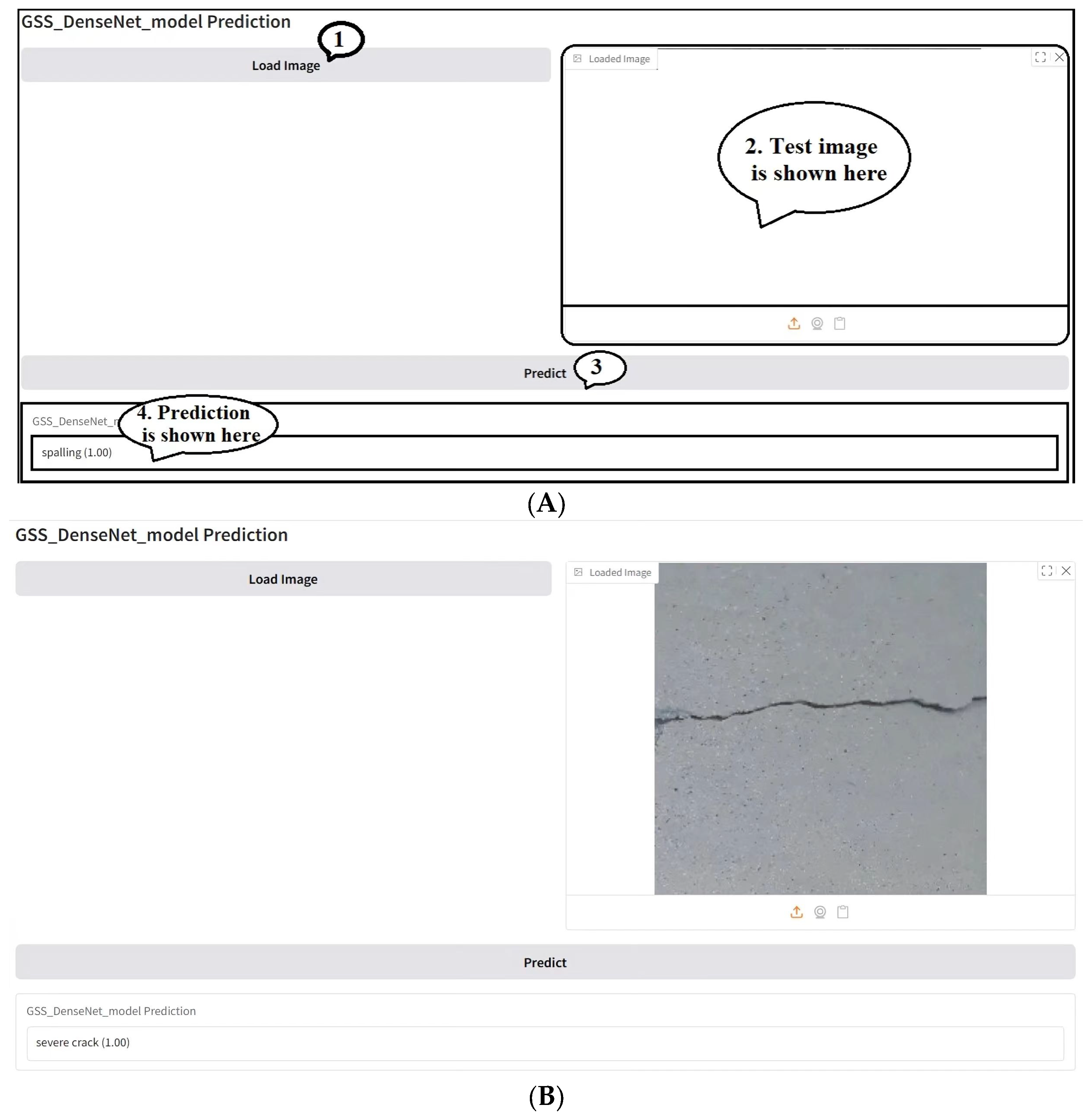

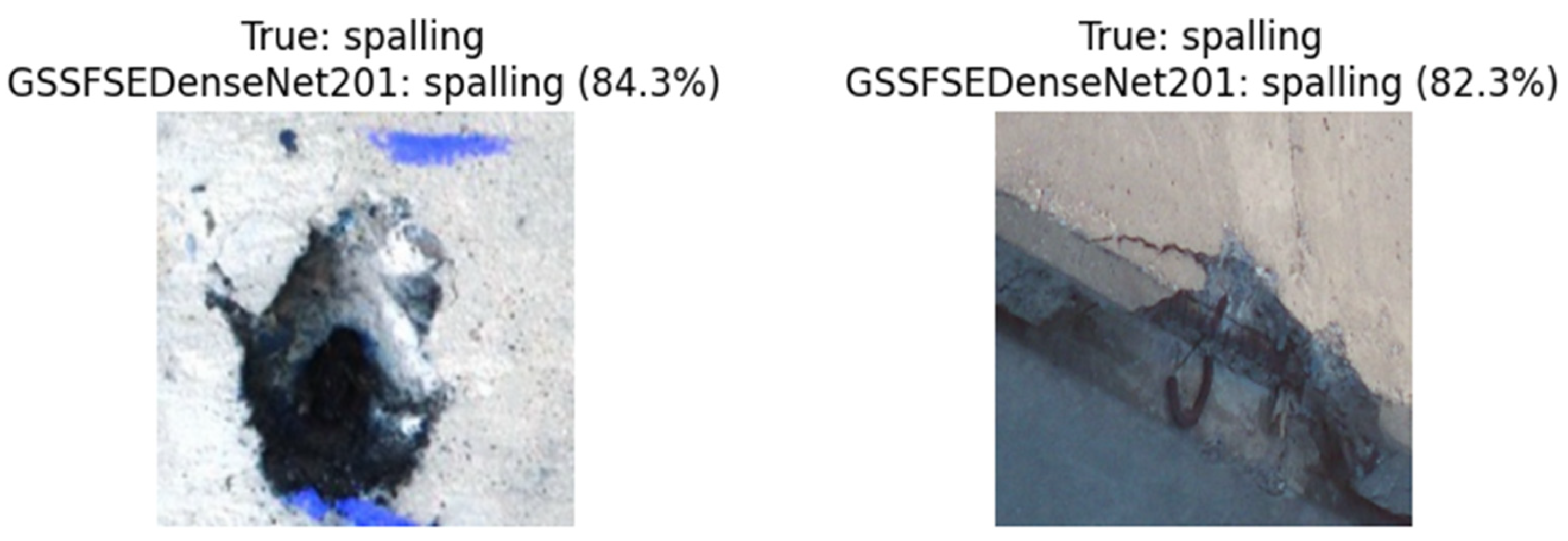

4.3. Real-World Application

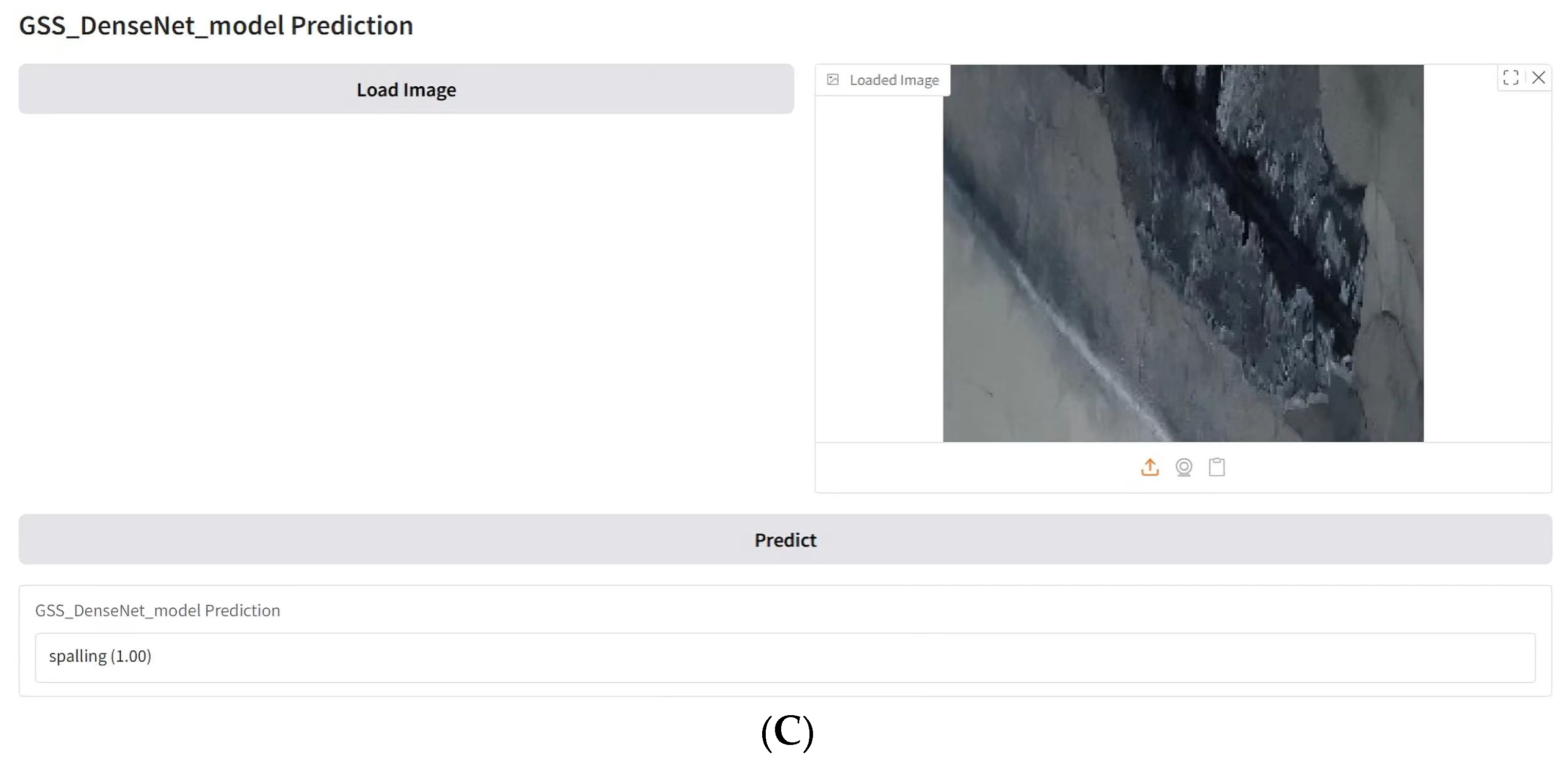

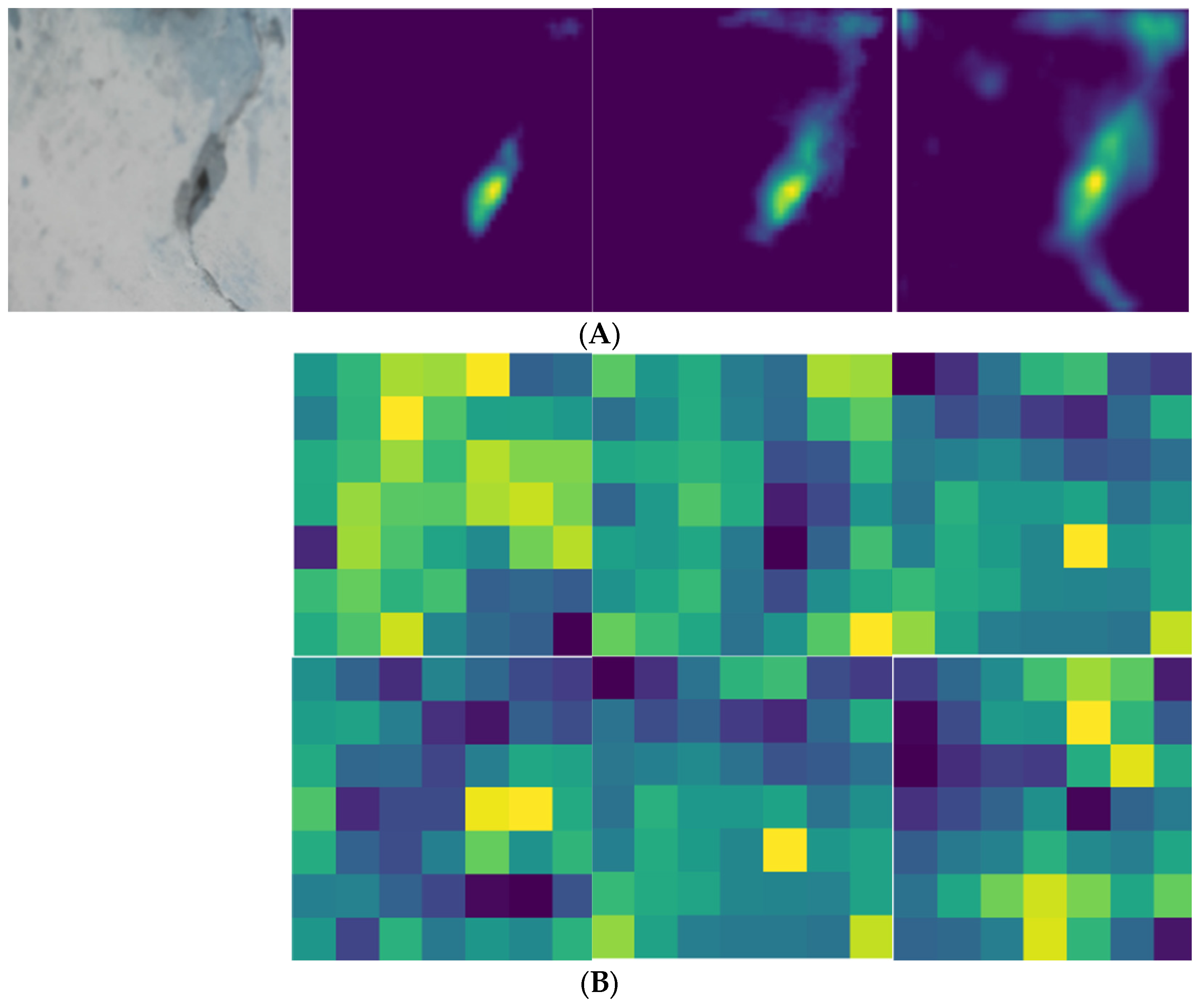

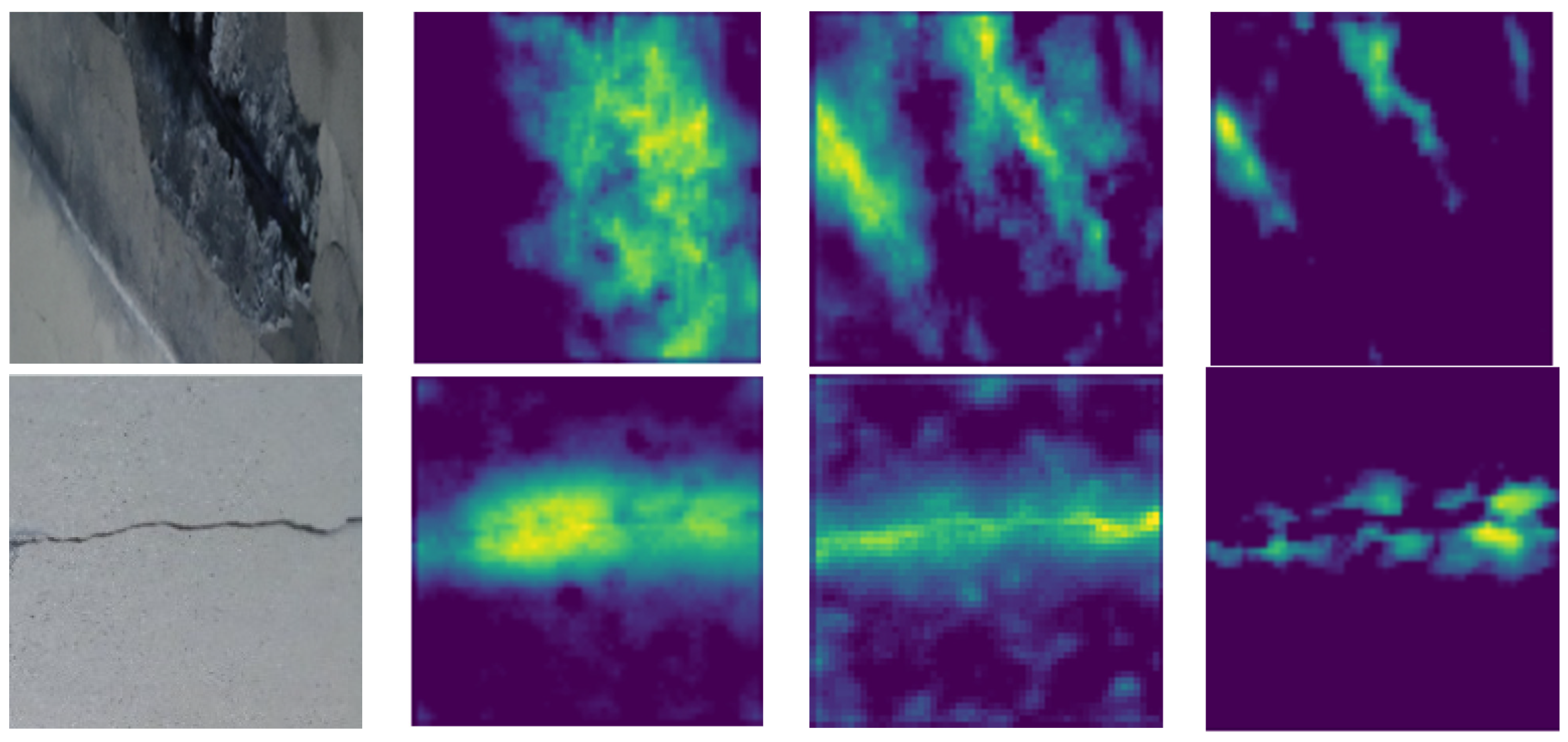

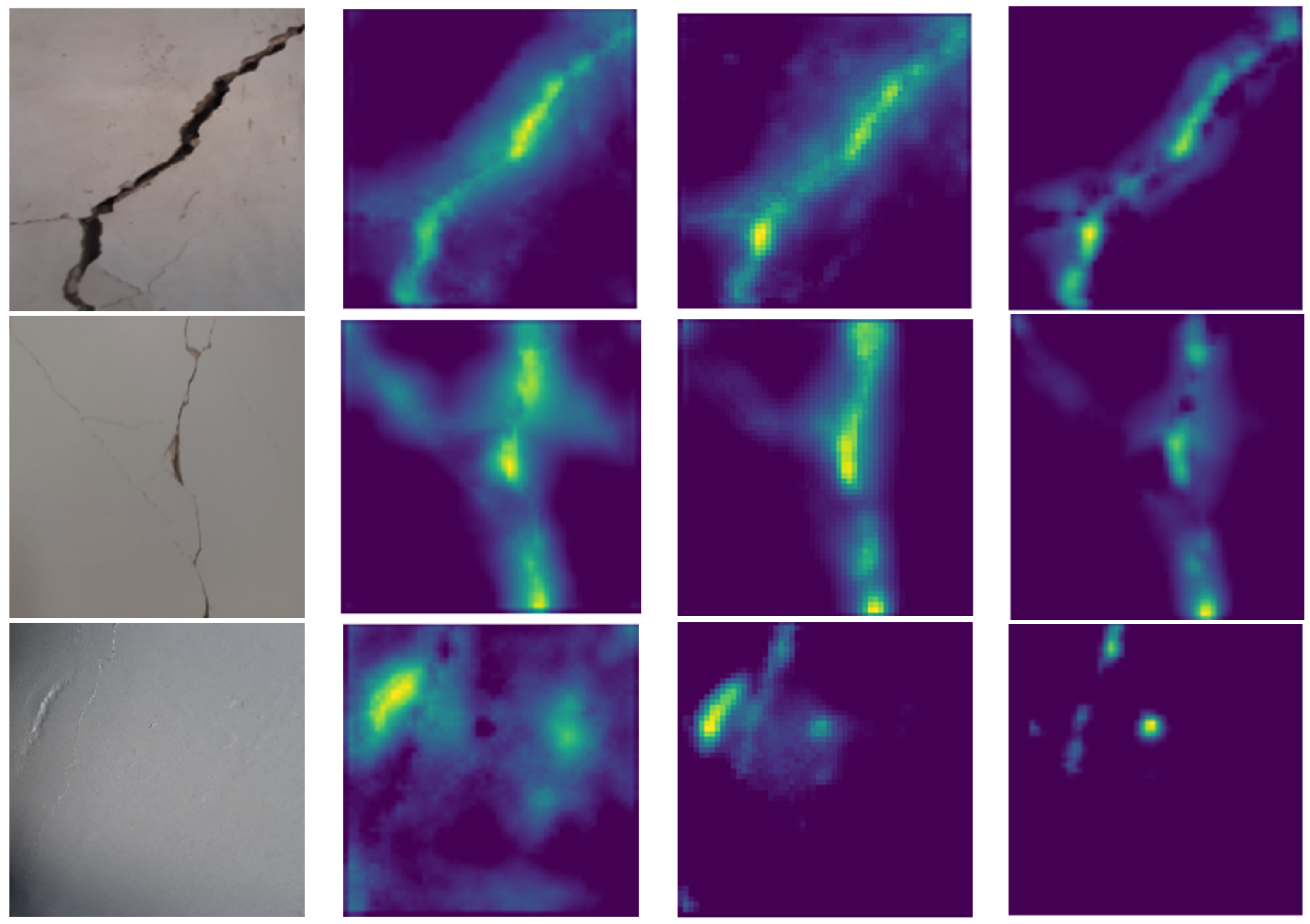

4.4. Model Interpretability

4.5. Comparison with State-of-the-Art Methodologies and Datasets

4.6. Generalization Study

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Rusnak, C.R. Sustainable strategies for concrete infrastructure preservation: A comprehensive review and perspective. Infrastructures 2025, 10, 99. [Google Scholar] [CrossRef]

- Hollaway, L.C. A review of the present and future utilisation of FRP composites in the civil infrastructure with reference to their important in-service properties. Constr. Build. Mater. 2010, 24, 2419–2445. [Google Scholar] [CrossRef]

- Li, R.; Zhao, L.; Wei, H.; Hu, G.; Xu, Y.; Ouyang, B. Multi-defect type beam bridge dataset: GYU-DET. Sci. Data 2025, 12, 1101. [Google Scholar] [CrossRef] [PubMed]

- Prakash, V.; Debono, C.J.; Musarat, M.A.; Borg, R.P.; Seychell, D.; Ding, W.; Shu, J. Structural health monitoring of concrete bridges through artificial intelligence: A narrative review. Appl. Sci. 2025, 15, 4855. [Google Scholar] [CrossRef]

- Fernandez Galarreta, J.; Kerle, N.; Gerke, M. UAV-based urban structural damage assessment using object-based image analysis and semantic reasoning. Nat. Hazards Earth Syst. Sci. 2015, 15, 1087–1101. [Google Scholar] [CrossRef]

- Senel, S.M.; Kayhan, A.H.; Palanci, M.; Demir, A. Assessment of damages in precast industrial buildings in the aftermath of Pazarcık and Elbistan earthquakes. J. Earthq. Eng. 2024, 1–30. [Google Scholar] [CrossRef]

- Kang, S.; Kim, S.; Kim, S. Automatic detection and classification process for concrete defects in deteriorating buildings based on image data. J. Asian Archit. Build. Eng. 2025, 24, 2773–2787. [Google Scholar] [CrossRef]

- Lan, C.; Liu, H.; Zhuang, S.; Wang, J.; Li, W.; Lin, G. Monitoring of crack repair in concrete using spherical smart aggregates based on electromechanical impedance (EMI) technique. Smart Mater. Struct. 2024, 33, 025031. [Google Scholar] [CrossRef]

- Alkayem, N.F.; Mayya, A.; Shen, L.; Zhang, X.; Asteris, P.G.; Wang, Q.; Cao, M. Co-CrackSegment: A new collaborative deep learning framework for pixel-level semantic segmentation of concrete cracks. Mathematics 2024, 12, 3105. [Google Scholar] [CrossRef]

- Xie, Y.; Feng, D.; Chen, H.; Liu, Z.; Mao, W.; Zhu, J.; Hu, Y.; Baik, S.W. Damaged building detection from post-earthquake remote sensing imagery considering heterogeneity characteristics. IEEE Trans. Geosci. Remote Sens. 2022, 60, 4708417. [Google Scholar] [CrossRef]

- Giri, P.; Kharkovsky, S. Detection of surface crack in concrete using measurement technique with laser displacement sensor. IEEE Trans. Instrum. Meas. 2016, 65, 1951–1953. [Google Scholar] [CrossRef]

- Mayya, A.M.; Alkayem, N.F. Triple-stage crack detection in stone masonry using YOLO-ensemble, MobileNetV2U-net, and spectral clustering. Autom. Constr. 2025, 172, 106045. [Google Scholar] [CrossRef]

- Dinh, T.; Anh, V.T.T.; Nguyen, T.; Le, C.H.; Trung, N.L.; Duc, N.D.; Lin, C.-T. Toward vision-based concrete crack detection: Automatic simulation of real-world cracks. IEEE Trans. Instrum. Meas. 2024, 72, 5032015. [Google Scholar] [CrossRef]

- Ritzy, R.; Umadevi, V.; Girija, K. Rajan Binary-class concrete surface crack detection using a transfer learning model. Knowl.-Based Syst. 2025, 324, 113953. [Google Scholar] [CrossRef]

- Hou, Y.; Shi, H.; Chen, N.; Liu, Z.; Wei, H.; Han, Q. Vision image monitoring on transportation infrastructures: A lightweight transfer learning approach. IEEE Trans. Intell. Transp. Syst. 2022, 24, 12888–12899. [Google Scholar] [CrossRef]

- Sun, X.; Yang, J.; Huang, W.; Teng, S. Concrete crack classification based on Fourier image enhancement and convolutional neural network. Discov. Civ. Eng. 2024, 1, 104. [Google Scholar] [CrossRef]

- Mayya, A.; Alkayem, N.F.; Shen, L.; Zhang, X.; Fu, R.; Wang, Q.; Cao, M. Efficient hybrid ensembles of CNNs and transfer learning models for bridge deck image-based crack detection. Structures 2024, 64, 106538. [Google Scholar] [CrossRef]

- Mayya, A.M.; Alkayem, N.F. Enhance the concrete crack classification based on a novel multi-stage YOLOV10-ViT framework. Sensors 2024, 24, 8095. [Google Scholar] [CrossRef]

- Kharthik, K.S.B.; Onyema, E.M.; Mallik, S.; Prasad, B.V.V.S.; Qin, H.; Selvi, C.; Sikha, O.K. Transfer learned deep feature based crack detection using support vector machine: A comparative study. Sci. Rep. 2024, 14, 14517. [Google Scholar] [CrossRef]

- Zhao, J. A RevVIT-based discrimination model for concrete crack images. In Proceedings of the 3rd International Conference on Communications, Information System, and Data Science (CISDS 2024), Nanjing, China, 22–24 November 2024; SPIE: Bellingham, WA, USA, 2025; Volume 13519, pp. 152–159. [Google Scholar] [CrossRef]

- Yang, J.; Li, H.; Zhang, L.; Zhao, L.; Jiang, S.; Xie, H. Multilabel concrete bridge damage classification using graph convolution. IEEE Trans. Instrum. Meas. 2024, 73, 5028614. [Google Scholar] [CrossRef]

- ALKannad, A.A.; Smadi, A.A.; Moeen, A.M.; Yang, S.; Feng, Z. CrackVisionX: A fine-tuned framework for efficient binary concrete crack detection. IEEE Trans. Intell. Transp. Syst. 2025, 26, 10353–10372. [Google Scholar] [CrossRef]

- Lin, Y.; Ahmadi, M.; Alnowibet, K.A.; Bukhari, F.A. Concrete crack detection using ridgelet neural network optimized by advanced human evolutionary optimization. Sci. Rep. 2025, 15, 4858. [Google Scholar] [CrossRef]

- Qin, T.; Yan, G.; Jiang, H.; Shen, M.; Settanni, A. Optimizing deep belief network for concrete crack detection via a modified design of ideal gas molecular dynamics. Sci. Rep. 2025, 15, 9070. [Google Scholar] [CrossRef] [PubMed]

- Hüthwohl, P.; Lu, R.; Brilakis, I. Multi-classifier for reinforced concrete bridge defects. Autom. Constr. 2019, 105, 102824. [Google Scholar] [CrossRef]

- Mayya, A.; Alkayem, N.; Saii, M.; Ahmad, M.; Bayat, M.; Asteris, P.G.; Cao, M. Multitype Concrete Defect Detection Using the New Post-Earthquake Concrete Crack Dataset and Extended YOLO Approach. SSRN. Available online: https://ssrn.com/abstract=5758816 (accessed on 11 December 2025).

- Wang, R.; Chen, R.; Guo, X. Lightweight concrete crack recognition model based on improved MobileNetV3. Sci. Rep. 2025, 15, 15704. [Google Scholar] [CrossRef]

- Ye, G.; Dai, W.; Qu, J.; Zhu, L.; Jin, Q. An improved transformer-based concrete crack classification method. Sci. Rep. 2024, 14, 6226. [Google Scholar] [CrossRef]

- Jing, J.; Ding, L.; Yang, X.; Cheng, H.; Qiu, Y.; Wang, H.; Heikkila, R. A hierarchical framework for three-dimensional pavement crack detection on point clouds with multi-scale abnormal region filtering and multimodal interaction fusion. Comput.-Aided Civ. Infrastruct. Eng. 2025. [Google Scholar] [CrossRef]

- Kumar, B.; Ghosh, S. Detection of Concrete Cracks Using Dual-channel Deep Convolutional Network. In Proceedings of the 2020 11th International Conference on Computing, Communication and Networking Technologies (ICCCNT), Kharagpur, India, 1–3 July 2020. [Google Scholar] [CrossRef]

- Del Savio, A.A.; Torres, A.L.; Cárdenas-Salas, D. Dataset for training neural networks in concrete crack detection: Laboratory-classified beam and column images. Data Brief 2025, 61, 111643. [Google Scholar] [CrossRef]

- Huang, G.; Liu, Z.; Van Der Maaten, L.; Weinberger, K.Q. Densely connected convolutional networks. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Honolulu, HI, USA, 21–26 July 2017; pp. 4700–4708. [Google Scholar] [CrossRef]

- Naidu, G.; Zuva, T.; Sibanda, E.M. A review of evaluation metrics in machine learning algorithms. In Artificial Intelligence Application in Networks and Systems, Proceedings of 12th Computer Science On-line Conference 2023, Online, 3–5 April 2023; Springer: Cham, Switzerland, 2023; pp. 15–25. [Google Scholar] [CrossRef]

- Padilla, R.; Netto, S.L.; Da Silva, E.A. A survey on performance metrics for object-detection algorithms. In Proceedings of the 2020 International Conference on Systems, Signals and Image Processing (IWSSIP), Niteroi, Brazil, 1–3 July 2020; pp. 237–242. [Google Scholar] [CrossRef]

- Sofaer, H.R.; Hoeting, J.A.; Jarnevich, C.S. The area under the precision-recall curve as a performance metric for rare binary events. Methods Ecol. Evol. 2019, 10, 565–577. [Google Scholar] [CrossRef]

- Dorafshan, S.; Thomas, R.J.; Maguire, M. SDNET2018: An annotated image dataset for non-contact concrete crack detection using deep convolutional neural networks. Data Brief 2018, 21, 1664–1668. [Google Scholar] [CrossRef]

- Hüthwohl, P.; Lu, R.; Brilakis, I. Multi-classifier for RC bridge defects. Zenodo 2019. [Google Scholar] [CrossRef]

| Metric | Definition | Equation | |

|---|---|---|---|

| True Positives TP | Number of correctly accepted crack-type detections (NtCd) out of all test samples (N) | (15) | |

| False Positives FP | Number of incorrectly accepted crack-type detections (NiaCd) out of all test samples (N) | (16) | |

| True Negatives TN | Number of correctly rejected non-crack-type detections (NcNd) out of all test samples (N) | (17) | |

| False Negatives FN | Number of incorrectly rejected crack-type detections (NirCd) out of all samples (N) | (18) | |

| Accuracy (ACC) | Number of all true detections divided by the number of all test samples (N) | (19) | |

| Precision (P) | Measure the ratio of true positives to the number of all positive samples | (20) | |

| Recall (R) | Measure of the ability of the trained model to correctly classify all actual positives (correctly classified crack-type samples that are actually cracks) | (21) | |

| F1-score (F1) | A mixture metric of precision and recall that unifies them and gives an overall performance value. | (22) | |

| Parameter | Value |

|---|---|

| Input size | 224 × 224 × 3 |

| Learning rate | 1 × 10−3 |

| Optimizer | Adam |

| Loss function | Categorical cross entropy |

| Training epochs | 50 |

| Early stop condition | Patience = 15 |

| Batch size | 128 |

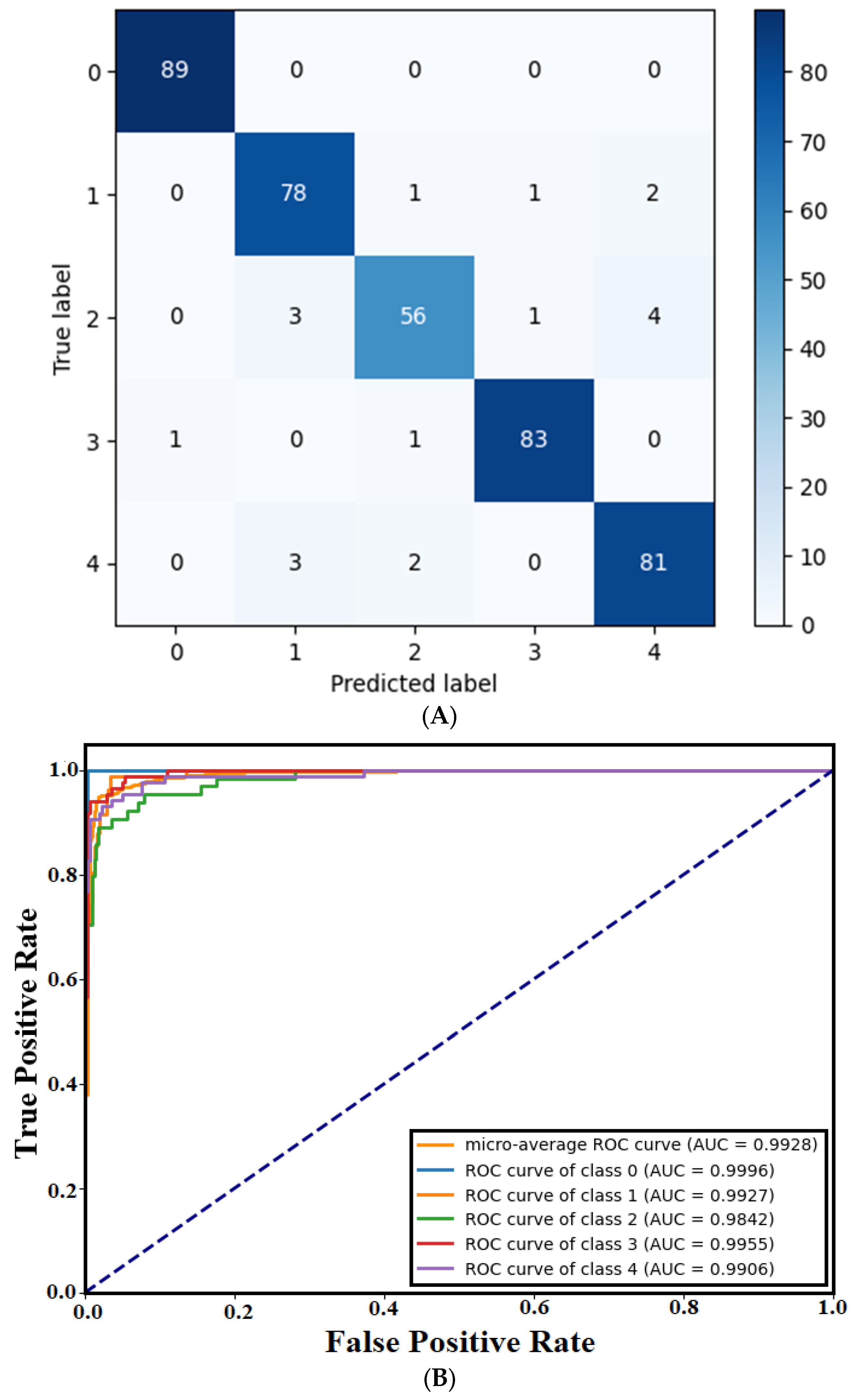

| Precision | Recall | F1 Score | Accuracy | |

|---|---|---|---|---|

| N | 0.9889 | 1.000 | 0.9944 | 0.9532 |

| SC | 0.9286 | 0.9512 | 0.9398 | |

| SV | 0.9333 | 0.8750 | 0.9032 | |

| SC | 0.9765 | 0.9765 | 0.9765 | |

| SP | 0.9310 | 0.9419 | 0.9364 | |

| M.avg | 0.9517 | 0.9489 | 0.9501 | |

| W.avg | 0.9531 | 0.9532 | 0.9530 |

| Precision | Recall | F1 Score | Accuracy | |||||

|---|---|---|---|---|---|---|---|---|

| New | Original | New | Original | New | Original | New | Original | |

| N | 0.9889 | 0.9545 | 1.000 | 0.9438 | 0.9944 | 0.9492 | 0.9532 | 0.8966 |

| SC | 0.9286 | 0.9079 | 0.9512 | 0.8415 | 0.9398 | 0.8734 | ||

| SV | 0.9333 | 0.7746 | 0.8750 | 0.8594 | 0.9032 | 0.8148 | ||

| SM | 0.9765 | 0.8736 | 0.9765 | 0.8941 | 0.9765 | 0.8837 | ||

| SP | 0.9310 | 0.9524 | 0.9419 | 0.9302 | 0.9364 | 0.9412 | ||

| M.avg | 0.9517 | 0.8926 | 0.9489 | 0.8938 | 0.9501 | 0.8925 | ||

| W.avg | 0.9531 | 0.8994 | 0.9532 | 0.8966 | 0.9530 | 0.8973 | ||

| Model | Precision | Recall | F1 Score | Accuracy | AUC |

|---|---|---|---|---|---|

| GSSFSEDenseNet201 | 0.9517 | 0.9489 | 0.9501 | 0.9532 | 0.9928 |

| GSSFDenseNet201 | 0.9209 | 0.9151 | 0.9169 | 0.9212 | 0.9877 |

| DenseNet201 with dual attention | 0.8970 | 0.8999 | 0.8962 | 0.8990 | 0.9843 |

| DenseNet201 | 0.8926 | 0.8938 | 0.8973 | 0.8966 | 0.9879 |

| Model | Precision | Recall | F1 Score | Accuracy | AUC |

|---|---|---|---|---|---|

| LR = 0.001 | 0.9517 | 0.9489 | 0.9501 | 0.9532 | 0.9928 |

| LR = 0.0001 | 0.9235 | 0.9246 | 0.9218 | 0.9261 | 0.9932 |

| LR = 0.00001 | 0.9020 | 0.9035 | 0.9022 | 0.9064 | 0.9905 |

| Model | Precision | Recall | F1 Score | Accuracy | AUC |

|---|---|---|---|---|---|

| DenseNet201 | 0.8926 | 0.8938 | 0.8973 | 0.8966 | 0.9879 |

| VGG16 | 0.8329 | 0.8315 | 0.8314 | 0.8374 | 0.9687 |

| MobileNetV3 | 0.8910 | 0.8919 | 0.8908 | 0.8966 | 0.9828 |

| Inception_ResNet | 0.8039 | 0.8018 | 0.8012 | 0.8079 | 0.9661 |

| InceptionV3 | 0.8522 | 0.8438 | 0.8457 | 0.8522 | 0.9694 |

| ViT | 0.7762 | 0.7676 | 0.7679 | 0.7783 | 0.9520 |

| Efficientnetv2B0 | 0.1388 | 0.2482 | 0.1622 | 0.2685 | 0.5350 |

| ConvNeXt | 0.1503 | 0.3474 | 0.2097 | 0.3744 | 0.5890 |

| Study | Dataset | Concrete Crack Types | Methodology | Results | Limitations |

|---|---|---|---|---|---|

| Hou et al. [15] | DDAP: 2500 pavement distress images DDCB: 906 concrete bridge images | Crack/Non-crack | MobileNet and MobileNet-SSD | Accuracy: 97.8% | Small Dataset Binary classification |

| Ritzy et al. [14] | 10,000 training images of crack and non-crack types | Crack/Non-crack | Modified InceptionV3 | Binary Accuracy: 99.67% | Binary classification |

| Sun et al. [16] | 2828 images collected from public sites | Crack/Non-crack | Fourier enhancement+ CNN | Accuracy: 91.6% | Binary classification |

| Mayya et al. [17] | SDNET2018: 13,620 bridge deck images | Crack/Non-crack | CNN-based fusion Transfer learning-based fusion | Accuracy: 98.62% | Binary classification |

| Mayya et al. [18] | 12,000 images | Normal, Simple crack, Multiple-crack | YOLOV10 + ViT | F1-score: 90.34% | The two-stage model required more computational time |

| Zhao et al. [20] | Collected dataset | Crack/Non-crack | Revised ViT | Accuracy: 99.03% | Binary classification |

| Yang et al. [21] | 2098 annotated bridge images | Corrosion, Spalling, Crack, and Rebar | MaxVit, GCN | Accuracy: 98.29% | Limited data size More complex architecture |

| ALKannad et al. [22] | SDNET2018 and METU | Crack/Non-crack | CrackVisionX | Accuracy > 99% for all scenarios | Binary classification |

| by Lin et al. [23] | SDNET2018 | Crack/Non-crack | Ridgelet model, AHEO | Accuracy: 99.66% | Binary classification |

| Qin et al. [24] | SDNET2018 | Crack/Non-crack | Deep belief network with IGMM | Accuracy: 90.189% | Binary classification |

| Proposed GSSFSEDenseNet201 model | Collected a dataset of 2029 images | Scaling Spalling Simple crack Severe crack Normal | Guided semantic–spatial fusion module with squeeze-and-excitation DenseNet | Accuracy: 95.32% | Limited data size |

| Dataset | Dataset Size | Structure | Classes | Image Variation Considered? | Binary or Multi-Class |

|---|---|---|---|---|---|

| DDCB [15] | 906 images | Concrete bridge | Crack No-Crack | Not mentioned | Binary classification |

| Ritzy et al. dataset [14] | 10,000 training images | Crack/Non-crack | Crack No-Crack | Not mentioned | Binary classification |

| Sun et al. dataset [16] | 2828 images | Concrete | Crack No-Crack | Not mentioned | Binary classification |

| SDNET2018 [36] | 56,000 bridge deck images | Bridge decks, walls, and pavement | Crack No-Crack | Yes | Binary classification |

| Multi-classifier for RC bridge defects [25] | 1959 images | Concrete bridge | Crack, General, Normal, Efflorescence, Scaling, Spalling | Yes | Multi-class classification |

| Yang et al. [21] | 2098 | Bridge | Corrosion, Spalling, Crack, and Rebar | Yes | Multi-class classification |

| Kumar and Ghosh dataset [30] | 3200 images | Concrete | Crack No-Crack | Yes | Binary classification |

| Del Savio et al. dataset [31] | 1132 images | Beam and column structures | Crack No-Crack | Not mentioned | Binary classification |

| Li dataset [3] | 11,123 images | Beam crack | Cracks, Spalling, Seepage, Honeycomb Surface, Exposed Rebar, and Holes | Yes | Object detection (YOLO annotations) |

| Proposed GSSFSEDenseNet201 model | 2029 images | Various concrete structures (walls, beams, columns, floor, roofs, etc.) | Scaling Spalling Simple crack Severe crack Normal | Yes | Multi-class classification |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mayya, A.M.; Alkayem, N.F. Multi-Class Concrete Defect Classification Using Guided Semantic–Spatial Fusion and Squeeze–Excitation Enhanced DenseNet Model. Materials 2025, 18, 5665. https://doi.org/10.3390/ma18245665

Mayya AM, Alkayem NF. Multi-Class Concrete Defect Classification Using Guided Semantic–Spatial Fusion and Squeeze–Excitation Enhanced DenseNet Model. Materials. 2025; 18(24):5665. https://doi.org/10.3390/ma18245665

Chicago/Turabian StyleMayya, Ali Mahmoud, and Nizar Faisal Alkayem. 2025. "Multi-Class Concrete Defect Classification Using Guided Semantic–Spatial Fusion and Squeeze–Excitation Enhanced DenseNet Model" Materials 18, no. 24: 5665. https://doi.org/10.3390/ma18245665

APA StyleMayya, A. M., & Alkayem, N. F. (2025). Multi-Class Concrete Defect Classification Using Guided Semantic–Spatial Fusion and Squeeze–Excitation Enhanced DenseNet Model. Materials, 18(24), 5665. https://doi.org/10.3390/ma18245665