Investigating the Effects of Iron Dilution on the Corrosion Resistance of Inconel 625 Welding Overlay on Carbon Steel

Highlights

- Inconel 625 overlays exhibited refined dendritic microstructures.

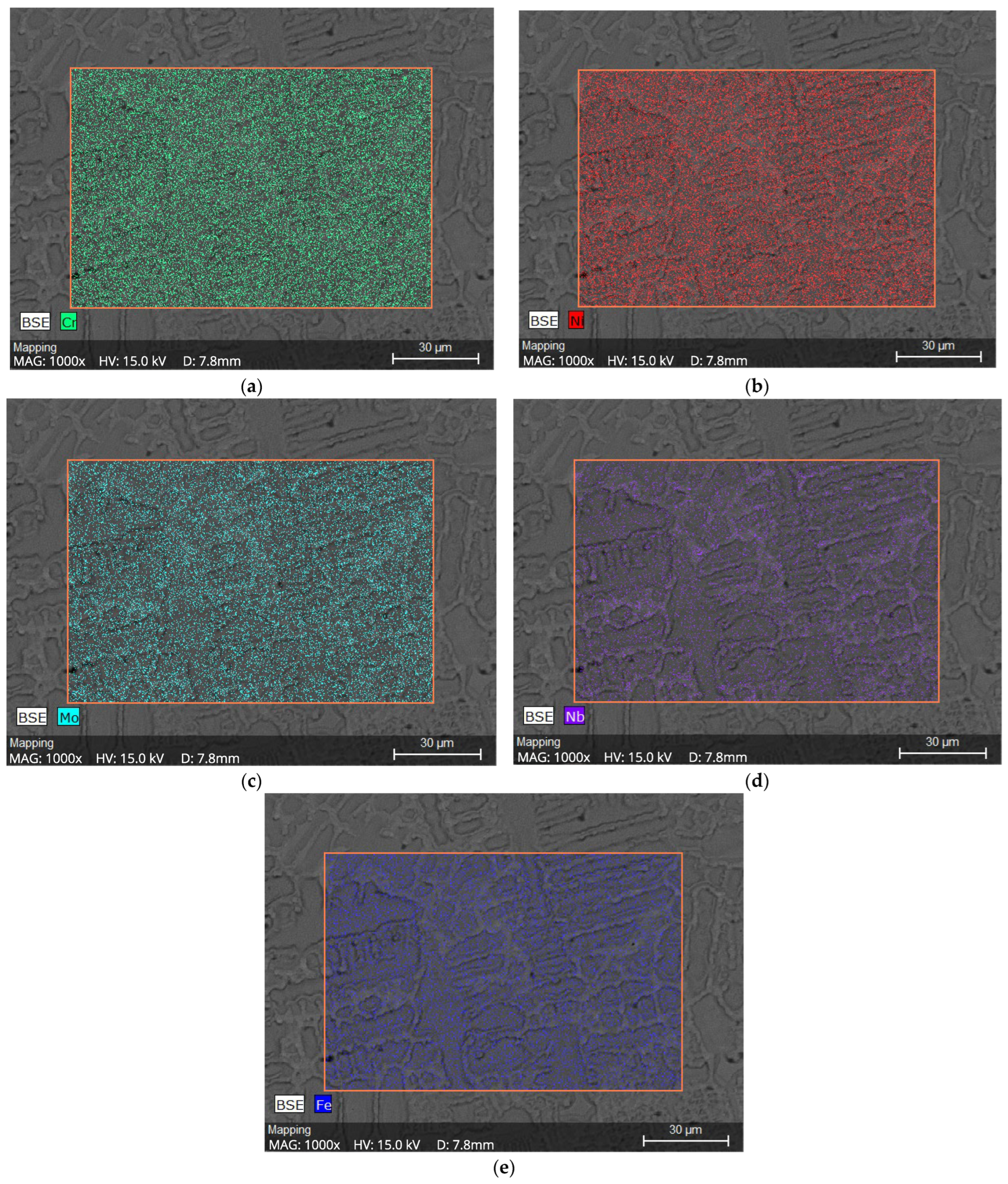

- Iron dilution modified the distribution of Ni, Cr, Mo, and Nb.

- Pitting corrosion occurred only at ~19% Fe.

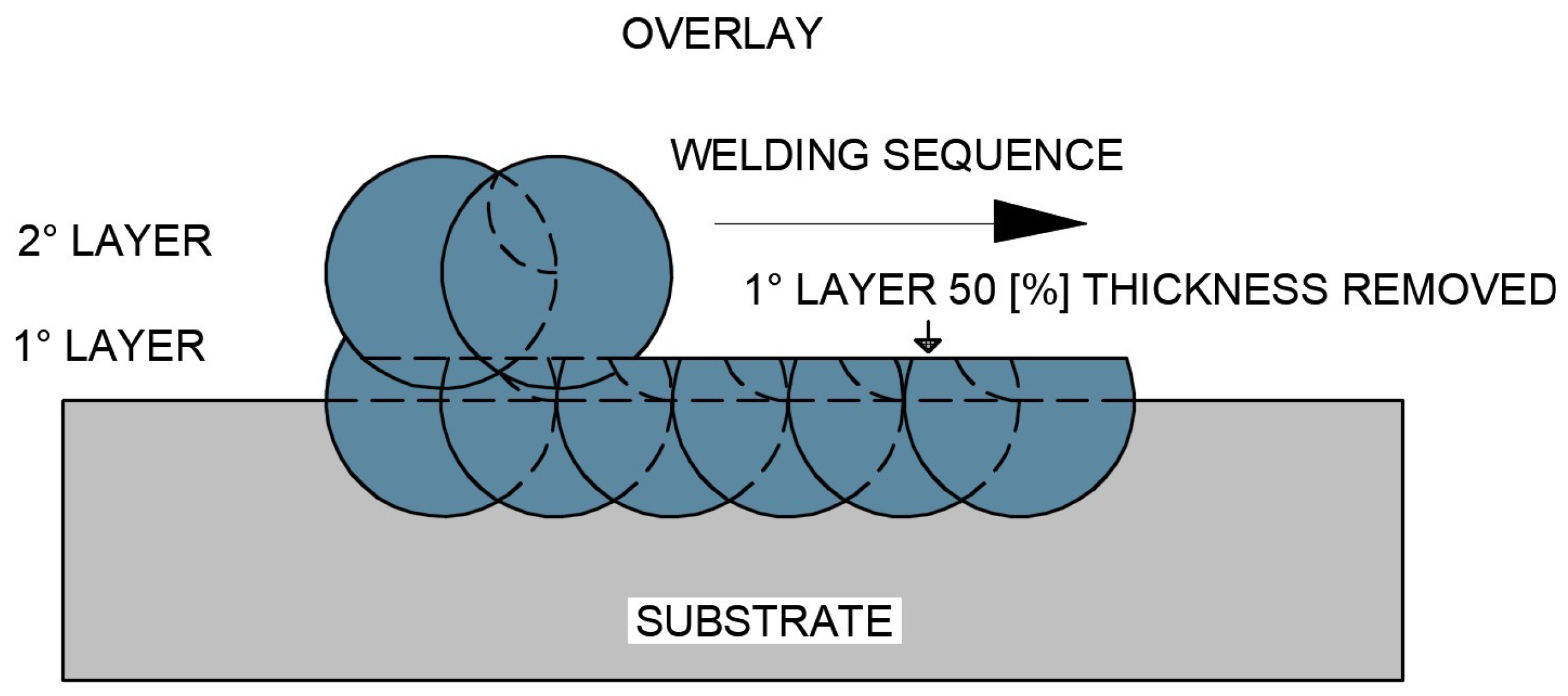

- Low-Fe overlays matched ERNiCrMo-3 composition and showed high integrity.

- Multiple buttering layers effectively reduce Fe dilution.

- A ~19% Fe limit is conservative under ASTM G48 Method A conditions.

- Optimized GMAW overlays improve corrosion resistance offshore.

- Results support relaxed Fe limits for cost-efficient cladding design.

Abstract

1. Introduction

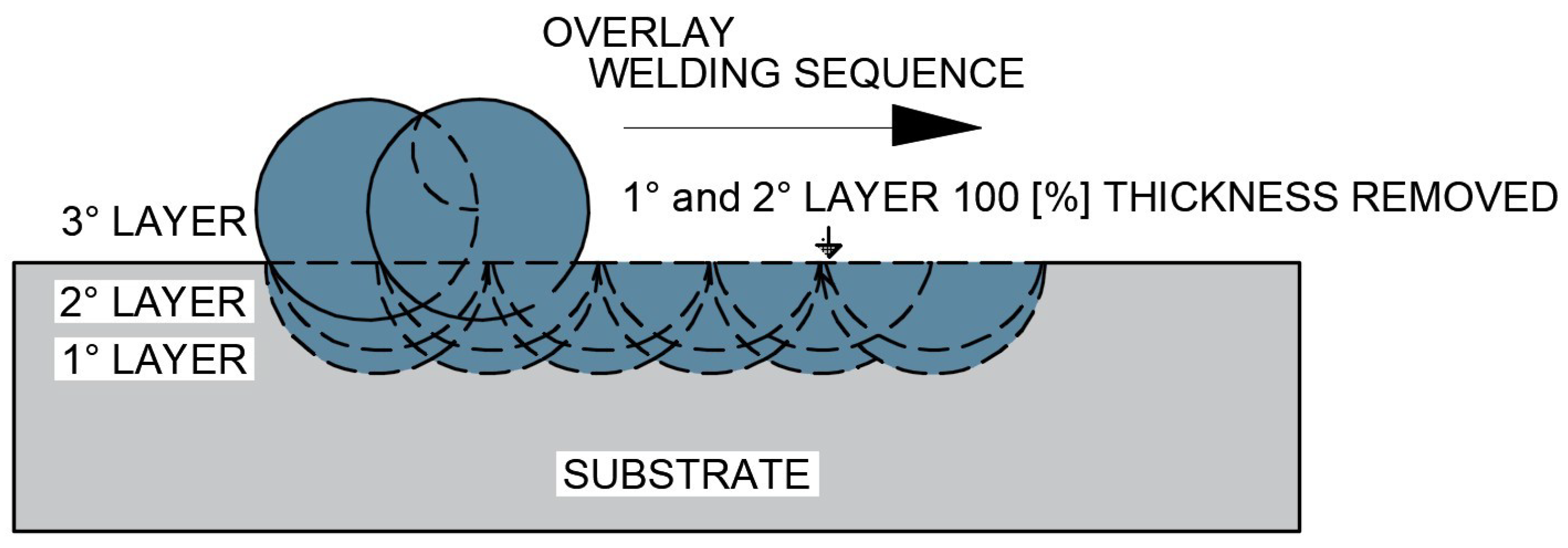

2. Materials and Methods

3. Results

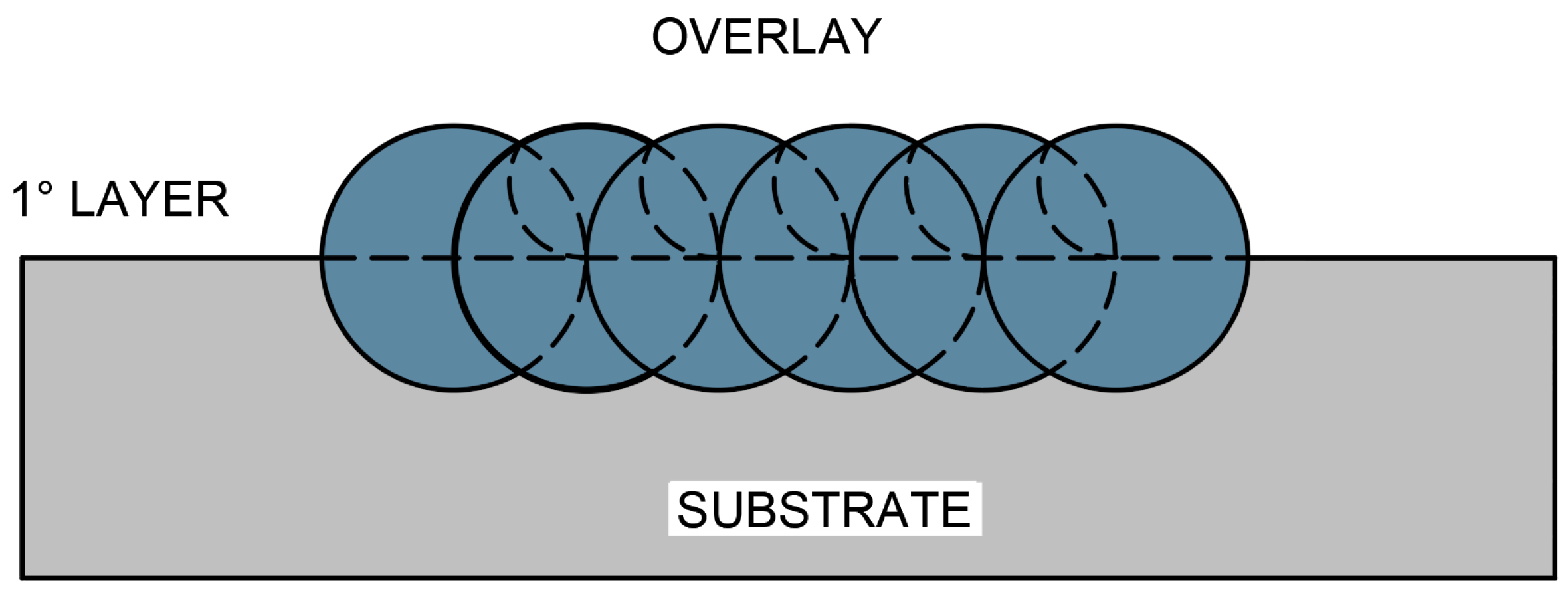

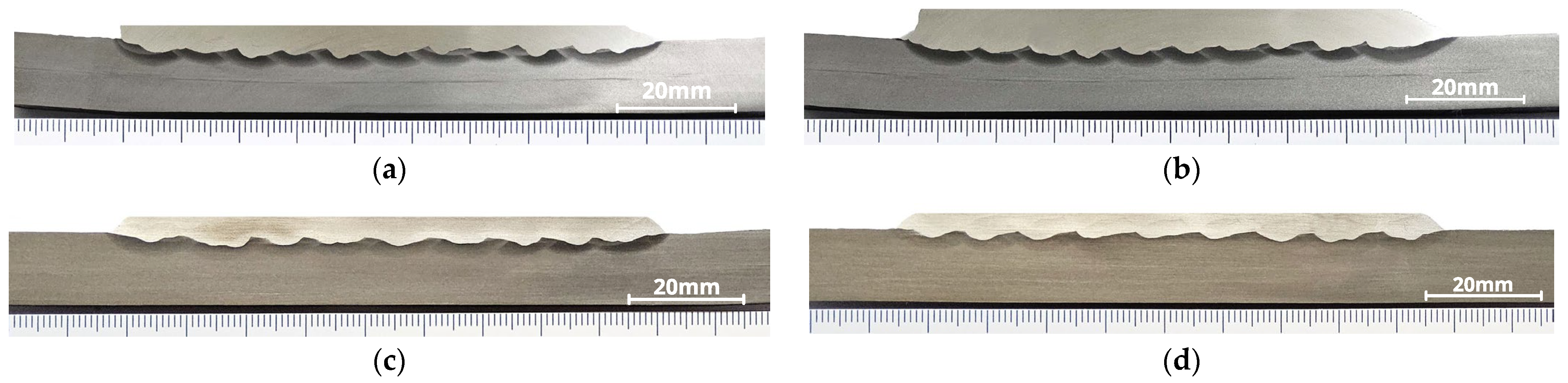

3.1. Weld Integrity

3.2. Chemical Analysis

3.2.1. Composition Results

3.2.2. Summary of Observations

- CP1 presented the highest Fe content ~19 wt.% and greatest deviation from nominal composition;

- CP2 and CP3 showed intermediate dilution effects;

- CP4 demonstrated the lowest Fe content and composition closest to the filler wire.

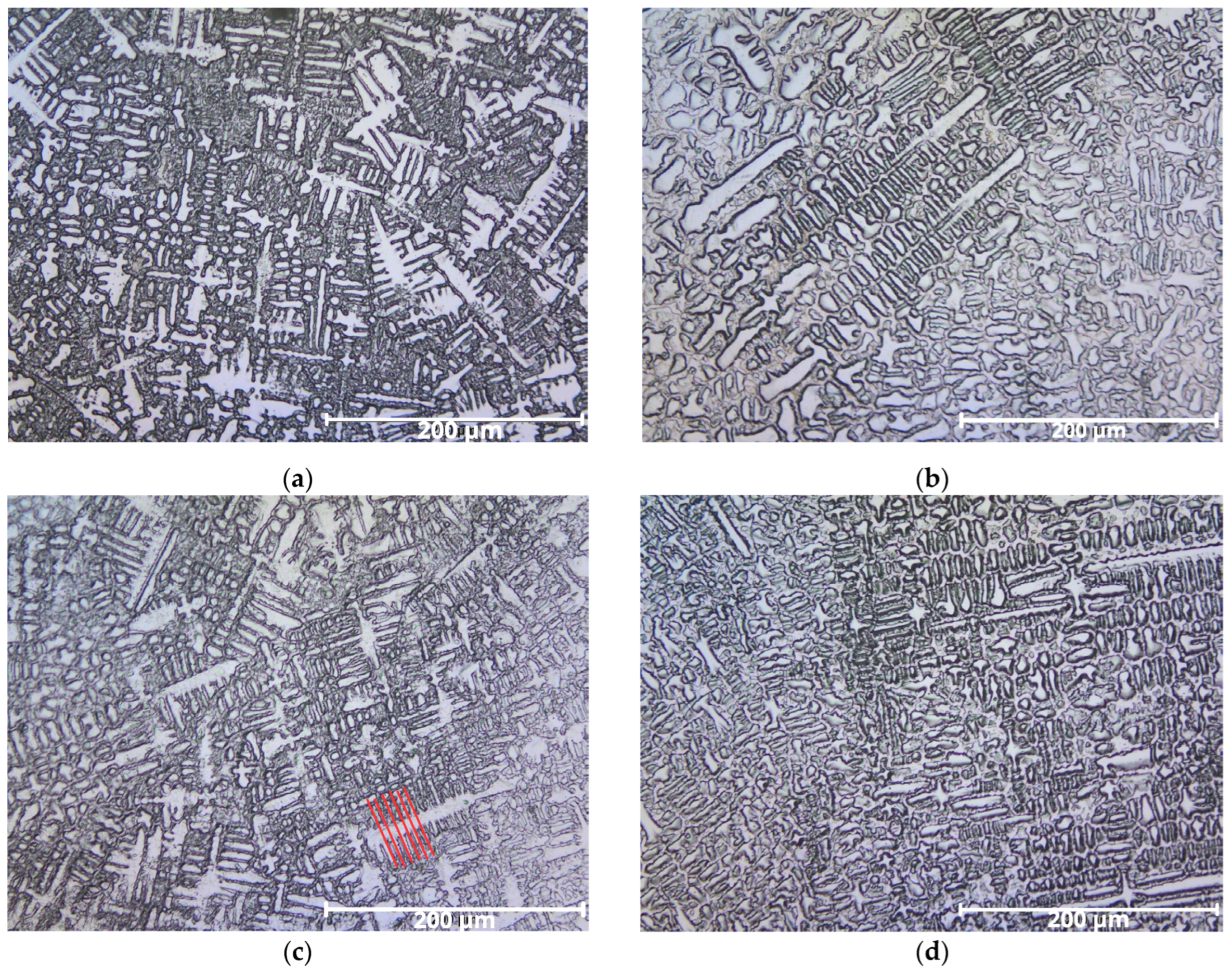

3.3. Microstructural Analysis

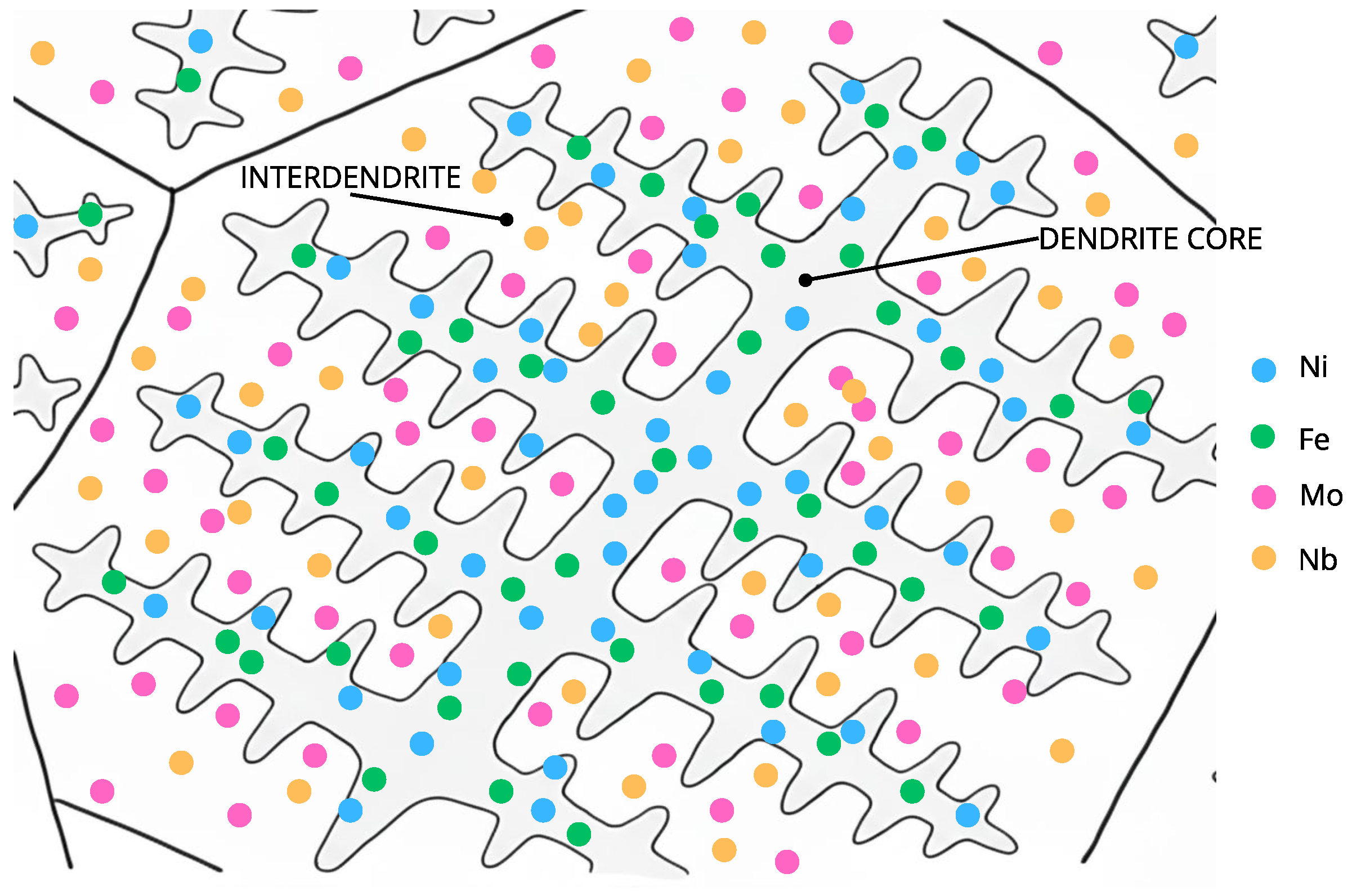

3.3.1. Morphological Features

3.3.2. Comparative Analysis of Specimens

- CP1 (high dilution): finer dendrites and more evident interdendritic segregation;

- CP2 (moderate dilution): dendrites closer in composition to filler metal;

- CP3 (buttered): intermediate morphology;

- CP4 (multiple buttering layers): dendritic pattern similar to ERNiCrMo-3 wire with minimal Fe contamination.

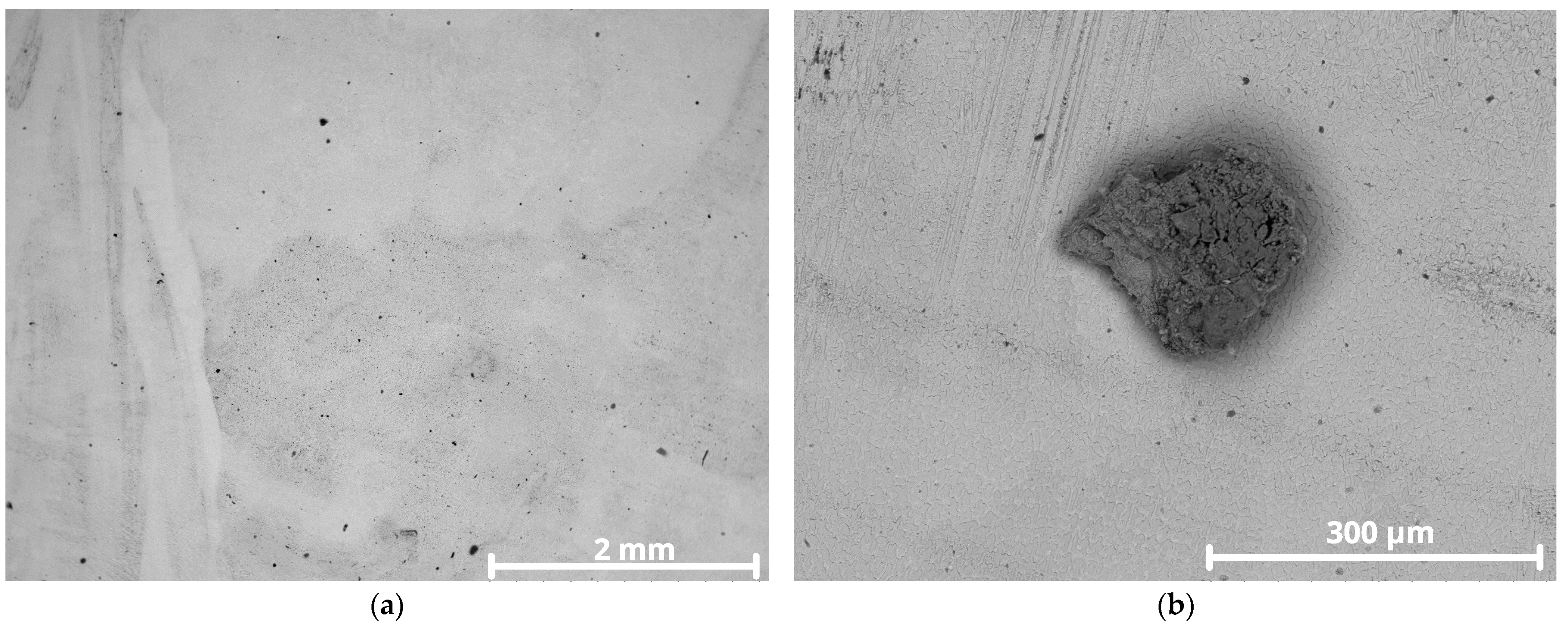

3.4. Corrosion Testing and Pit Detection

3.4.1. Test Description

3.4.2. Pit Detection Results

3.5. Metallurgical Characterization of the Corroded Region

3.5.1. Secondary Phase Identification

3.5.2. Elemental Segregation

3.5.3. Chemical Mapping

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| Abbreviations | |

| API RP 582 | Welding Guidelines for the Chemical, Oil, and Gas Industries |

| ASME | American Society of Mechanical Engineers |

| ASTM G48 | Standard Test Method for Pitting and Crevice Corrosion Using Ferric Chloride |

| CP | Test specimen |

| EDS | Energy Dispersive Spectroscopy |

| ERNiCrMo-3 | Nickel-based alloy welding filler metal (Inconel 625 classification) |

| FCC | Face-Centered Cubic |

| GMAW | Gas Metal Arc Welding |

| GTAW | Gas Tungsten Arc Welding |

| HAZ | Heat-Affected Zone |

| NORSOK M-601 | Materials and Welding Requirements for Offshore Structures |

| PREN | Pitting Resistance Equivalent Number |

| SEM | Scanning Electron Microscopy |

| XRF | X-ray Fluorescence |

| Symbols and Variables | |

| HV | Vickers Hardness |

| K | Partition coefficient |

| Cs | Element concentration in the dendrite core (solid phase) |

| Cl | Element concentration in the interdendritic region (liquid phase) |

| γ | Gamma nickel solid solution phase |

| t | Time [h] |

| T | Temperature [°C] |

| i | Current [A] |

| wt.% | Weight percentage |

| µm | Micrometer |

| mm | Millimeter |

| V | Voltage (Volts) |

| A | Electric current (Ampers) |

| L/min | Gas flow rate |

| kJ/mm | Heat input |

| Chemical Compounds and Phases | |

| FeCl3 | Ferric chloride |

| HCl | Hydrochloric acid |

| HNO3 | Nitric acid |

| γ | Gamma nickel solid solution (matrix phase) |

| γ″ | Gamma double-prime strengthening phase (Ni3Nb) |

| δ | Delta phase (orthorhombic Ni3Nb) |

| TCP | Topologically close-packed intermetallic phases |

| Laves | Intermetallic Laves phase (Ni,Fe)2(Nb,Mo) |

| Carbides | Secondary carbide precipitates |

References

- Casillas, A.S.; Freitas, G.; Polette, M.; Vargas, T.A.D. A promissora província petrolífera do pré-sal. Rev. Dir. GV 2011, 7, 57. [Google Scholar] [CrossRef]

- Riccomini, C.; Sant’anna, L.G.; Tassinari, C.C.G. Pré-sal: Geologia e exploração. Rev. USP 2012, 95, 33–42. [Google Scholar] [CrossRef]

- Kim, J.S.; Park, Y.I.; Lee, H.W. Effects of heat input on the pitting resistance of Inconel 625 welds by overlay welding. Metall. Mater. Int. 2015, 21, 350–355. [Google Scholar] [CrossRef]

- Alves, I.A.S.; Aragão, A.F.L.; Bastos, B.; Falcão, J.L.; Fartes, E. Pre-salt Santos Basin—Well construction learning curve acceleration. In Proceedings of the Offshore Technology Conference (OTC 20177), Houston, TX, USA, 4–7 May 2009. [Google Scholar] [CrossRef]

- Seabra, A.A.; Khosrovyan, A.; Del Valls, T.A.; Polette, M. Management of pre-salt oil royalties: Wealth or poverty for Brazilian coastal zones as a result? Resour. Policy 2015, 45, 1–8. [Google Scholar] [CrossRef]

- Silva, C.; Afonso, C.R.M.; Ramirez, A.J.; Motta, M.F.; Miranda, H.C.; Farias, J.P. Metallurgical aspects of dissimilar weld overlays of Inconel 625 nickel-based superalloys. Soldag. Insp. 2012, 17, 251–263. [Google Scholar] [CrossRef]

- Xu, L.; Shao, C.; Tian, L.; Zhang, J.; Han, Y.; Zhao, L.; Jing, H. Intergranular corrosion behavior of Inconel 625 deposited by CMT/GTAW. Corros. Sci. 2022, 201, 110295. [Google Scholar] [CrossRef]

- Rivolta, B.; Gerosa, R.; Panzeri, D. Influence of Single- and Double-Aging Treatments on the Mechanical and Corrosion Resistance of Alloy 625. Metals 2024, 14, 823. [Google Scholar] [CrossRef]

- Donnini, R.; Varone, A.; Palombi, A.; Spiller, S.; Ferro, P.; Angella, G. High energy density welding of Ni-based superalloys: An overview. Metals 2025, 15, 30. [Google Scholar] [CrossRef]

- Scherm, F.; Daoud, H.; Glatzel, U. Influence of Printing Strategies on the Microstructure and Mechanical Properties of Additively Manufactured Alloy 625 Using Directed Energy Deposition (DED-LB-p). Metals 2024, 14, 1041. [Google Scholar] [CrossRef]

- ASM International. ASM Specialty Handbook: Nickel, Cobalt, and Their Alloys; ASM International: Materials Park, OH, USA, 2000. [Google Scholar]

- Liu, D.; Zhang, W.; Liu, X.; Li, Y.; Zhang, J.; Yu, H. Effects of heating and hot extrusion process on microstructure and properties of Inconel 625 alloy. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2016, 31, 1368–1376. [Google Scholar] [CrossRef]

- Souza, D.; Moura, B.B.; Silva, M.O.; Osorio, A.G. Corrosion resistance of thermal-pulsed Inconel 625 MIG/MAG weld overlays. Surf. Topogr. Metrol. Prop. 2021, 9, 025036. [Google Scholar] [CrossRef]

- Prabu, S.S.; Muthu, S.M.; Sujai, S.; Devendranath Ramkumar, K.; Beemkumar, N.; Kariappan, E. Failure assessment and high-temperature corrosion behavior of Inconel 625 welds in simulated K2SO4 + 60% NaCl boiler environment. J. Mater. Eng. Perform. 2023, 32, 11024–11039. [Google Scholar] [CrossRef]

- Peng, J.; Li, K.; Xie, Z.; Tan, L.; Wang, Y.; Liu, F.; Liu, Y. Effect of grain size on high-temperature corrosion performance of laser-cladding Inconel 625 coating. J. Mater. Res. Technol. 2024, 33, 3809–3817. [Google Scholar] [CrossRef]

- Li, H.; Wang, S.; Liu, Y.; Zhang, Y.; Chen, J. Preliminary investigation on underwater wet welding of Inconel 625 alloy: Microstructure, mechanical properties and corrosion resistance. J. Mater. Res. Technol. 2022, 20, 2394–2407. [Google Scholar] [CrossRef]

- Carvalho, P.S.L.M.; Silva, R.M.; Gomes, L.P.; Lima, J.C. Panorama de tendências de mercado de níquel. BNDES Setorial 2015, 42, 245–295. [Google Scholar]

- Smith, L.M. Engineering with Clad Steel, 2nd ed.; Nickel Institute: Toronto, ON, Canada, 2012. [Google Scholar]

- Rozmus-Górnikowska, M.; Blicharski, M. TEM microstructure and chemical composition of transition zone between steel tube and an Inconel 625 weld overlay coating produced by CMT method. Arch. Metall. Mater. 2017, 62, 787–793. [Google Scholar] [CrossRef]

- DuPont, J.N. Solidification of an alloy 625 weld overlay. Metall. Mater. Trans. A 1996, 27, 3612–3620. [Google Scholar] [CrossRef]

- Frei, J.; Alexandrov, B.T.; Rethmeier, M. Low heat input gas metal arc welding for dissimilar metal weld overlays, part III: Hydrogen-assisted cracking susceptibility. Weld. World 2019, 63, 591–598. [Google Scholar] [CrossRef]

- Sandes, S.S.; Silva, C.C.; Lima, E.S.; Alvarães, C.P.; Mendes, M.C.; Araújo, L.S.; Souza, L.F.G.; Jorge, J.C.F. Avaliação de revestimentos de liga de níquel 625 depositados pelo processo eletroescória. Soldag. Insp. 2016, 21, 417–427. [Google Scholar] [CrossRef][Green Version]

- Subramanian, R.; Natarajan, B.; Kaliyaperumal, B.; Chinnasamy, R. Effect of MIG welding process parameters on microstructure and tensile behavior of Hastelloy C-276 using response surface methodology. Mater. Res. Express 2019, 6, 066540. [Google Scholar] [CrossRef]

- Costa, J.F.M.; Jorge, J.C.F.; Souza, L.F.G.; Mendes, M.C.; Farneze, H.N.; Magalhães, H.A.Y. Microstructural evaluation of Inconel 625 weld cladding deposited by the GMAW and GMAW with rotating electrode processes. Tecnol. Metal. Mater. Min. 2024, 21, e2848. [Google Scholar] [CrossRef]

- Pessoa, A.R.P.; Farias, J.P.; Miranda, H.C.; Motta, M.F.; Afonso, C.R.M. Seleção de parâmetros através do método Taguchi para welding de revestimento com ligas de níquel pelo processo MIG/MAG. Soldag. Insp. 2010, 15, 317–324. [Google Scholar] [CrossRef]

- Petrobras. N-1707 Projeto de Vaso de Pressão com Revestimento Metálico; Rev. E 02/2023; Petrobras: Rio de Janeiro, Brazil, 2023. [Google Scholar]

- API RP 582; Welding Guidelines for the Chemical, Oil, and Gas Industries. American Petroleum Institute: Washington, DC, USA, 2021.

- Lourenço, J.C.; Souza, L.P.; Faria, M.I.S.T.; Nunes, C.A.; Tomachuk, C.R.; Baker, M.A. Influence of the Iron Content on the Microstructure and Electrochemical Behavior of as-Cast Modified Inconel 625. Corros. Sci. 2021, 193, 109892. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, Z.; Shen, Y.; Kong, Y.; Li, J.; Zhang, Y.; Ning, H. Effect of Iron Content on the Pitting Corrosion Behavior of Laser-Cladded Ni–Cr–Mo Alloy Coating in a Simulated Seawater Environment. Coatings 2024, 14, 459. [Google Scholar] [CrossRef]

- ASTM G48–23; Standard Test Methods for Pitting and Crevice Corrosion Resistance of Stainless Steels and Related Alloys by Use of Ferric Chloride Solution. ASTM International: West Conshohocken, PA, USA, 2023.

- NORSOK M-601; Welding and Inspection of Piping. Standards Norway: Lysaker, Norway, 2016.

- Senthil, T.S.; Puviyarasan, M.; Ramesh Babu, S.; Ram Prabhu, T. Pitting Corrosion Studies on Functionally Graded Inconel 825–SS316L Wall Manufactured by Wire Arc Additive Manufacturing. Eng. Res. Express 2022, 4, 035013. [Google Scholar] [CrossRef]

- ASME. Boiler and Pressure Vessel Code. Section II—Materials, Part A: Ferrous Material Specifications; ASME: New York, NY, USA, 2023. [Google Scholar]

- ASME. Boiler and Pressure Vessel Code. Section II—Materials, Part C: Specifications for Welding Rods, Electrodes, and Filler Metals; ASME: New York, NY, USA, 2023. [Google Scholar]

- Xu, L.; Zhang, H.; Liu, H.; Zhao, L.; Jing, H. Insights into the intergranular corrosion of overlay welded joints of X65/Inconel 625 clad pipe and its relationship to damage penetration. Corros. Sci. 2019, 160, 108169. [Google Scholar] [CrossRef]

- Wang, X.; Ren, X.; Xue, Y.; Luan, B. Investigation on microstructure and high-temperature wear properties of high-speed laser cladding Inconel 625 alloy. J. Mater. Res. Technol. 2024, 31, 626–639. [Google Scholar] [CrossRef]

- ASM International. Properties and Selection: Nonferrous Alloys and Special Purpose Materials; ASM International: Materials Park, OH, USA, 1993; Volume 2. [Google Scholar]

- Lippold, J.C.; Kiser, D.; DuPont, J.N. Welding Metallurgy and Weldability of Nickel-Base Alloys; Wiley: Hoboken, NJ, USA, 2011; ISBN 978-1-118-21003-1. [Google Scholar]

- Filho, D.F.; Silva, R.A.; Pereira, L.C.; Lima, C.R.C. Influence of substrate on the tribological behavior of Inconel 625 GMAW overlays. Coatings 2023, 13, 1454. [Google Scholar] [CrossRef]

- Petrzak, P.; Kowalski, K.; Blicharski, M. Analysis of phase transformations in Inconel 625 alloy during annealing. Acta Phys. Pol. A 2016, 130, 1041–1044. [Google Scholar] [CrossRef]

- Petrzak, P.; Blicharski, M.; Kowalski, K.; Kania, Z. Electron microscopy investigation of Inconel 625 weld overlay on boiler steel. Solid State Phenom. 2015, 231, 113–118. [Google Scholar] [CrossRef]

- Yan, N.; Wang, Z.; Ruan, Y.; Wei, B. Solute redistribution and micromechanical properties of rapidly solidified multicomponent Ni-based alloys. Sci. China Technol. Sci. 2019, 62, 472–477. [Google Scholar] [CrossRef]

- Soldevilla, N.; Caballero, O. Correlation of secondary dendrite arm spacing with the mechanical behaviour of cast 718 alloy. In Proceedings of the 8th International Symposium on Superalloy 718 and Derivatives, Pittsburgh, PA, USA, 11 November 2014; pp. 757–768. [Google Scholar] [CrossRef]

- Silva, C.C.; Ramirez, A.J.; Farias, J.P. New insight on the solidification path of an alloy 625 weld overlay. J. Mater. Res. Technol. 2013, 2, 228–237. [Google Scholar] [CrossRef]

- Tabaie, S.; Greene, T.; Benoit, M.J. Optimization of GMAW process parameters for weld overlay of Inconel 686 superalloy on low-carbon steel. Int. J. Adv. Manuf. Technol. 2023, 127, 4769–4788. [Google Scholar] [CrossRef]

- Vladár, M.T.; Postek, M.T. Electron beam-induced sample contamination in the SEM. J. Res. Natl. Inst. Stand. Technol. 2005, 110, 445–458. [Google Scholar] [CrossRef]

- Pessoa, E.F. Soldagem de Revestimento com Ligas de Níquel Empregando o Processo MIG/MAG com Duplo Arame para Aplicações em Componentes do Setor de Petróleo e Gás Natural. Ph.D. Thesis, Universidade Federal do Ceará, Fortaleza, Brazil, 2014; 214p. [Google Scholar]

- Xing, X.; Di, X.; Wang, B. The effect of post-weld heat treatment temperature on the microstructure of Inconel 625 deposited metal. J. Alloys Compd. 2014, 593, 110–116. [Google Scholar] [CrossRef]

| Elements wt.% | Fe | C | Mn | Si | Cr | Ni | Mo | Cu | S | P | Nb + Ta |

|---|---|---|---|---|---|---|---|---|---|---|---|

| SA-516 Gr 70 | Rest. | 0.23 | 1.0 | 0.2 | 0.01 | 0.01 | 0.00 | - | 0.004 | 0.013 | - |

| ERNiCrMo-3 | 0.35 | 0.01 | 0.03 | 0.1 | 21.9 | 64.6 | 8.91 | 0.02 | 0.001 | 0.005 | 3.63 |

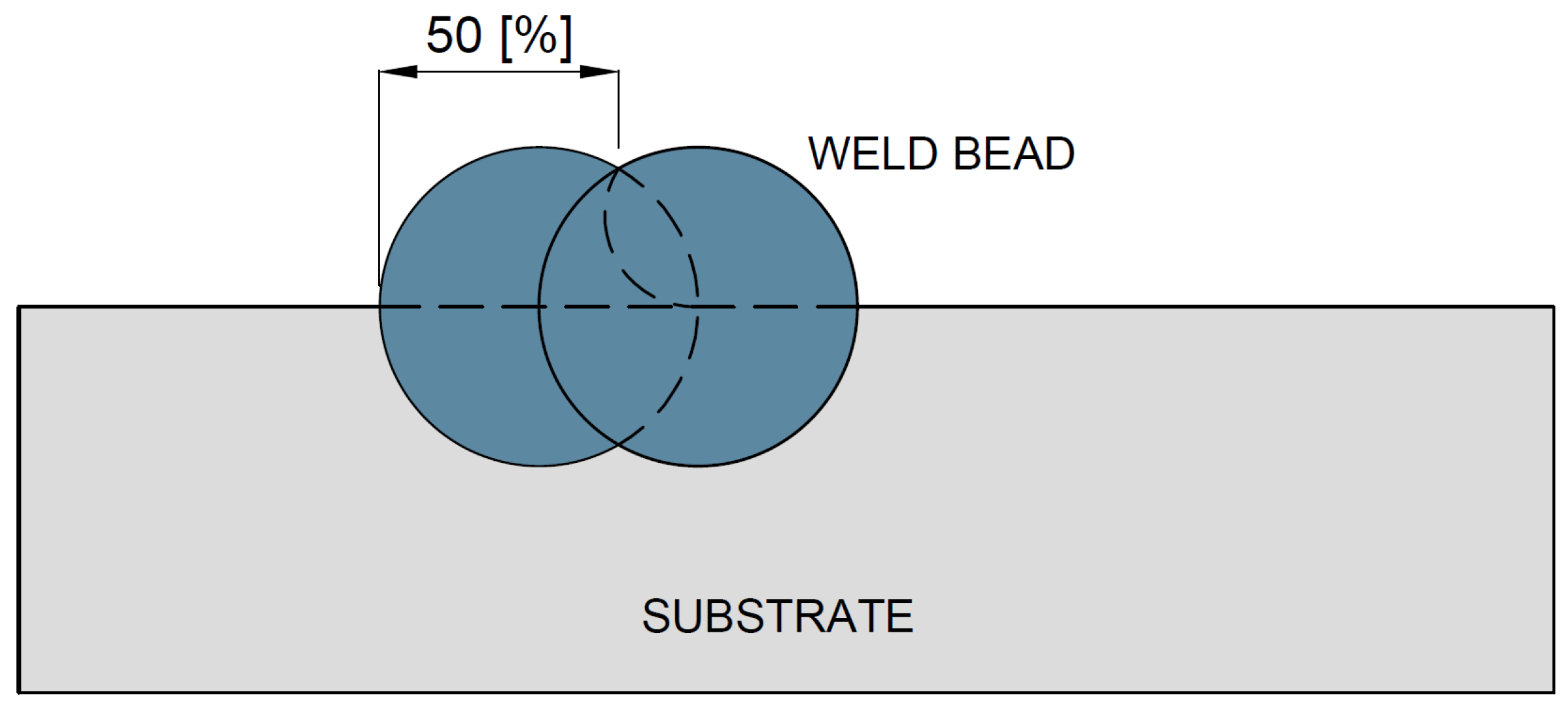

| Parameter | Value 1 | Parameter | Value 1 |

|---|---|---|---|

| Voltage [V] | 30–31 | Shielding gas flow rate [L/min] | 14–18 |

| Current [A] | 190–210 | Bead width [mm] | 7 |

| Torch travel speed [cm/min] | 35 | Bead height [mm] | 4 |

| Transfer mode | Globular | Wire feed speed [m/min] | 31 |

| Heat input [kJ/mm] | 1.2 | Torch angle [°] | 91 |

| Maximum temperature [°C] | 145 | Wire diameter [mm] | 1.2 |

| Specimen | Fe 1 [%] | Cr 1 [%] | Ni 1 [%] | Mo 1 [%] | Ti 1 [%] | Nb 1 [%] | |

|---|---|---|---|---|---|---|---|

| ERNiCrMo-3 | 5.00 | 20.00–23.00 | Min. 58.00 | 8.00–10.00 | 0.40 | 3.15–4.15 | |

| CP1 | Found Deviation | 19.16 +14.16 | 19.23 −0.77 | 51.2 −6.80 | 7.40 −0.60 | 0.20 - | 2.77 −0.38 |

| CP2 | Found Deviation | 7.47 +2.47 | 21.63 | 59.50 | 8.57 | 0.20 | 3.23 |

| - | - | - | - | - | |||

| CP3 | Found Deviation | 12.06 +7.06 | 20.60 - | 55.83 −2.17 | 8.03 - | 0.20 - | 3.03 −0.12 |

| CP4 | Found Deviation | 3.83 - | 21.16 - | 61.50 - | 8.87 - | 0.20 - | 3.33 - |

| Specimen | Cr (K) 1 | Cr (seg.) 1 | Mo (K) 1 | Mo (seg.) 1 | Nb (K) 1 | Nb (seg.) 1 |

|---|---|---|---|---|---|---|

| CP1 | 1.10 | Core ↑ | 0.82 | Inter ↑ | 0.36 | Inter ↑ |

| CP2 | 1.08 | Core ↑ | 0.86 | Inter ↑ | 0.47 | Inter ↑ |

| CP3 | 1.05 | ≈ | 0.90 | Inter ↑ | 0.60 | Inter ↑ |

| CP4 | 1.02 | ≈ | 0.95 | ≈ | 0.78 | Inter ↑ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cunha, A.B.; Vatavuk, J.; Lima, C.R.C. Investigating the Effects of Iron Dilution on the Corrosion Resistance of Inconel 625 Welding Overlay on Carbon Steel. Materials 2025, 18, 5574. https://doi.org/10.3390/ma18245574

Cunha AB, Vatavuk J, Lima CRC. Investigating the Effects of Iron Dilution on the Corrosion Resistance of Inconel 625 Welding Overlay on Carbon Steel. Materials. 2025; 18(24):5574. https://doi.org/10.3390/ma18245574

Chicago/Turabian StyleCunha, Alexandre Borghi, Jan Vatavuk, and Carlos Roberto Camello Lima. 2025. "Investigating the Effects of Iron Dilution on the Corrosion Resistance of Inconel 625 Welding Overlay on Carbon Steel" Materials 18, no. 24: 5574. https://doi.org/10.3390/ma18245574

APA StyleCunha, A. B., Vatavuk, J., & Lima, C. R. C. (2025). Investigating the Effects of Iron Dilution on the Corrosion Resistance of Inconel 625 Welding Overlay on Carbon Steel. Materials, 18(24), 5574. https://doi.org/10.3390/ma18245574