Effect of Fabric Topology and Axial Yarn Condition on the Compressive Properties of 3D Stepwise Rotary Braided Composites

Abstract

1. Introduction

2. Materials and Methods

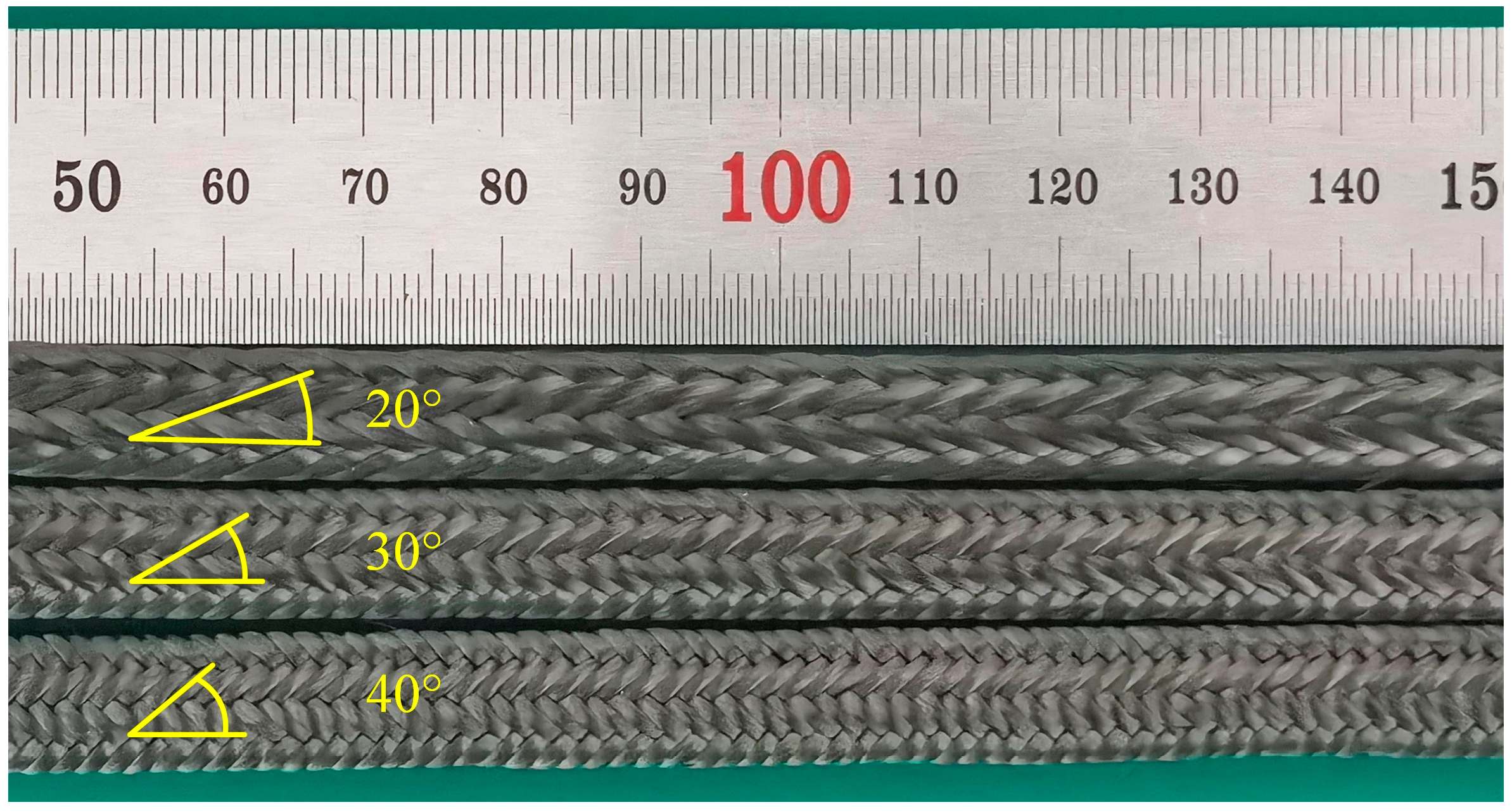

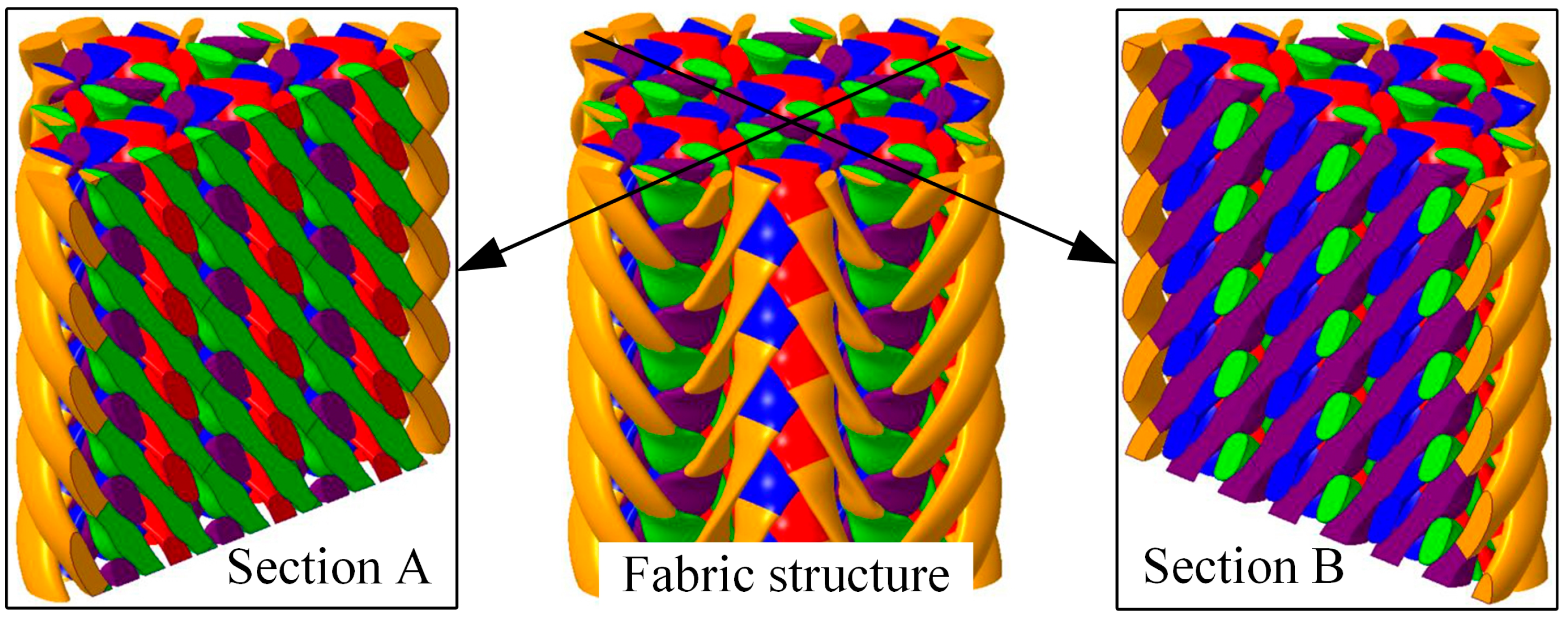

2.1. Fabric Design

2.2. Sample Fabrication

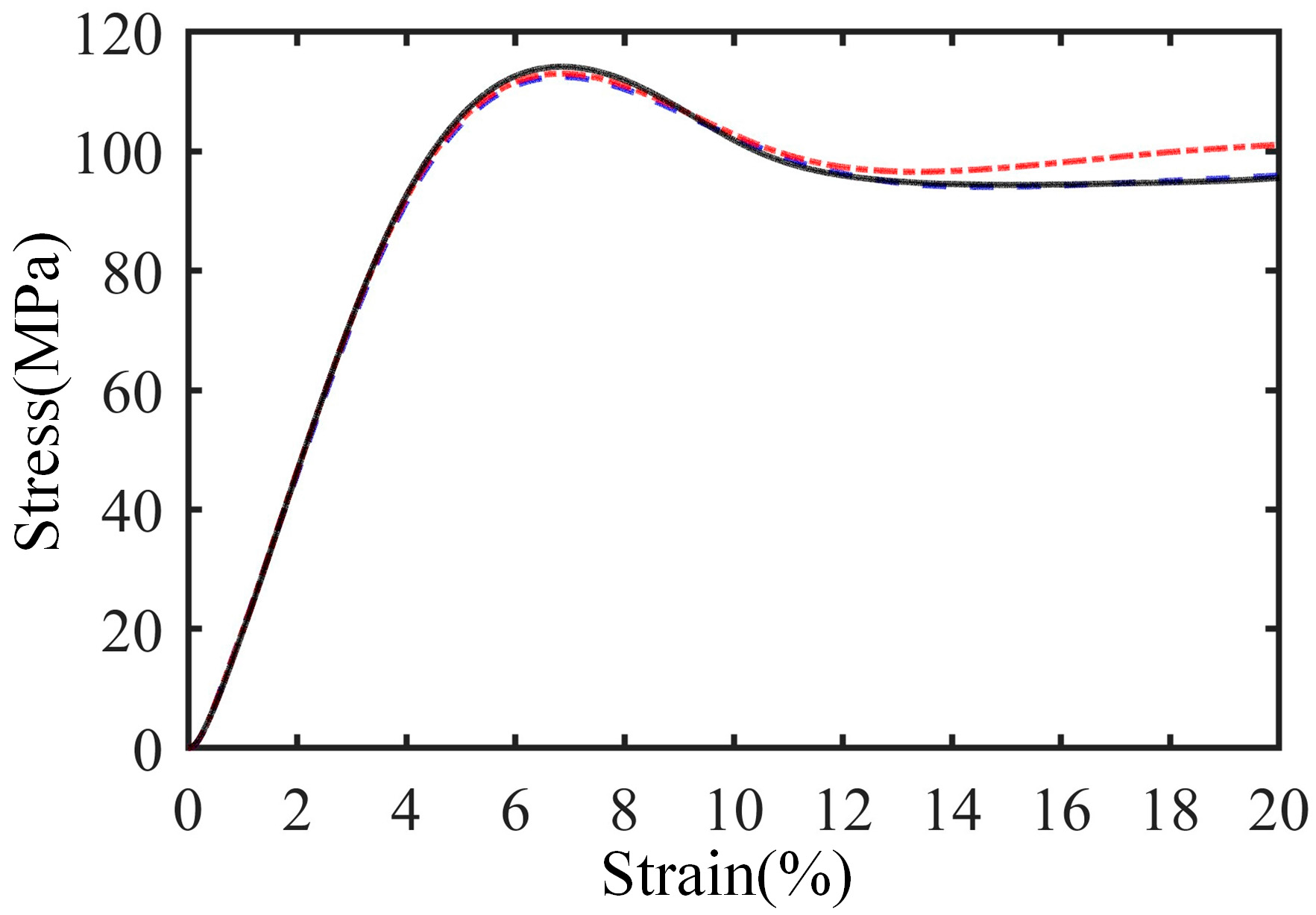

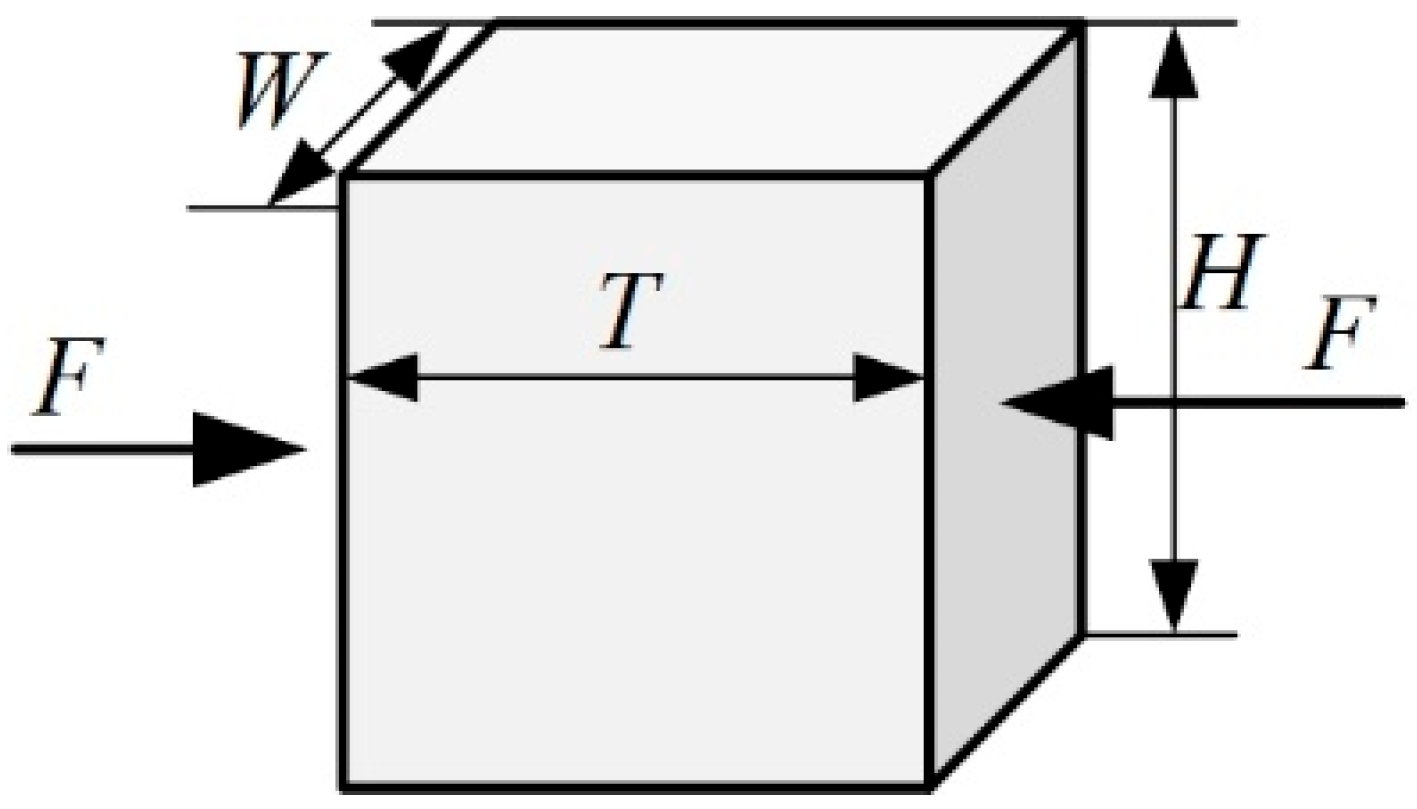

2.3. Experimental Procedure

3. Results

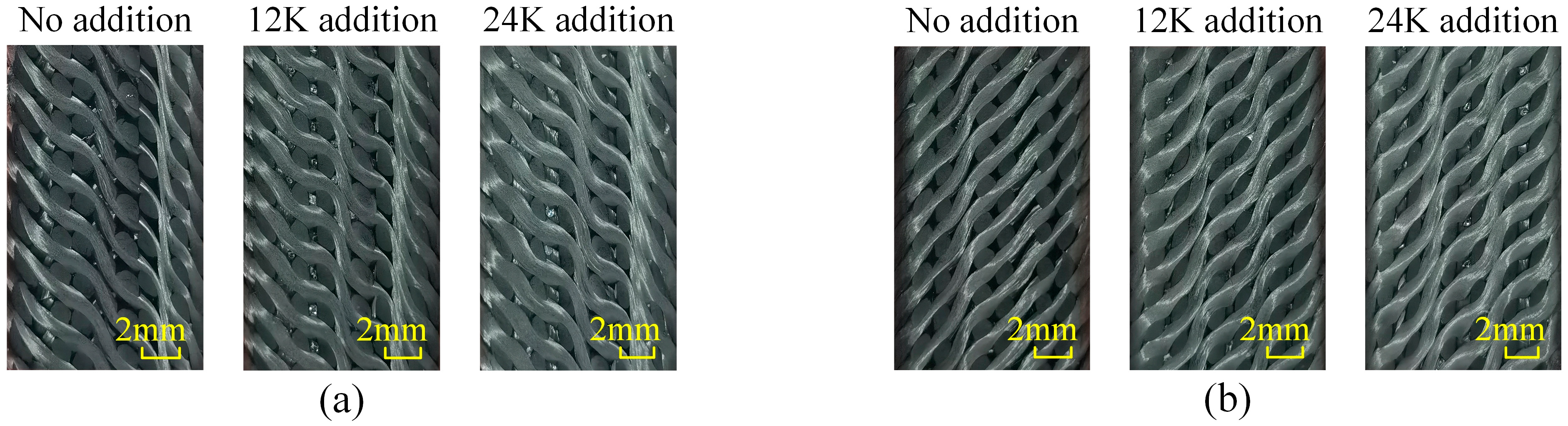

3.1. Yarn Morphology in Composites

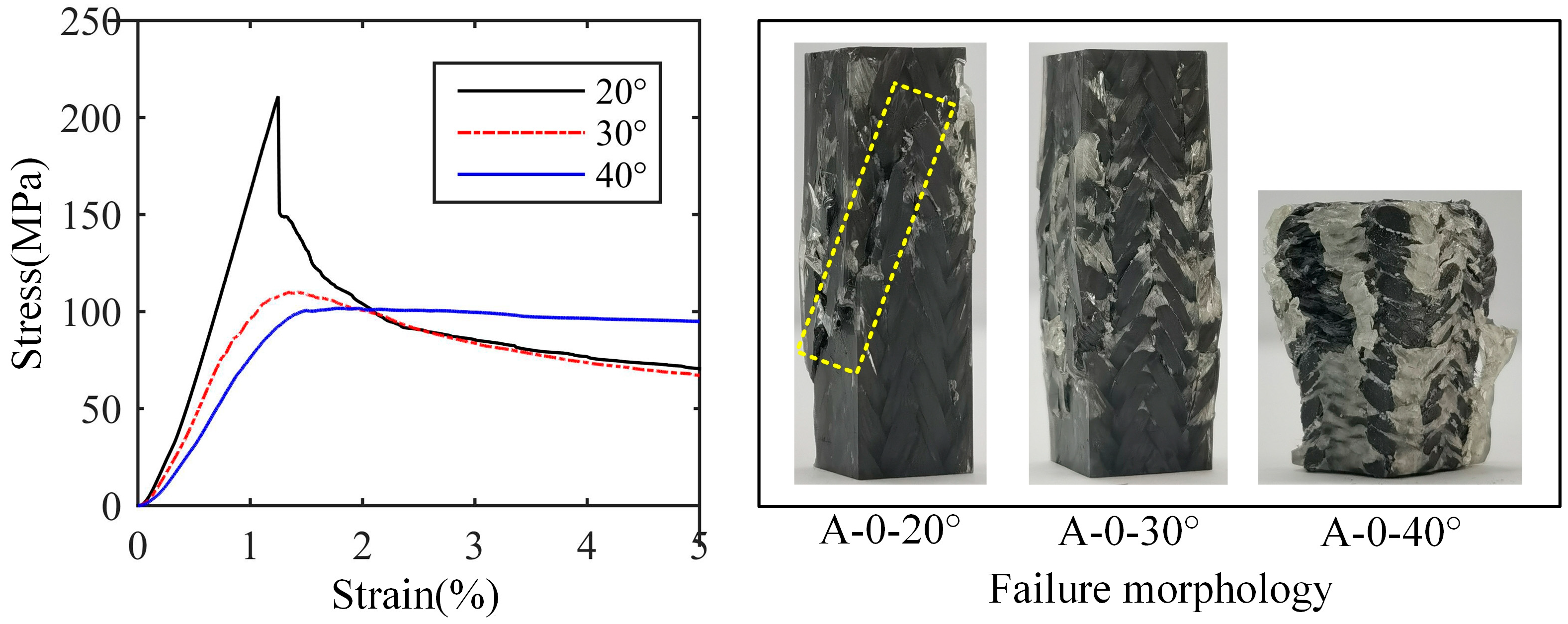

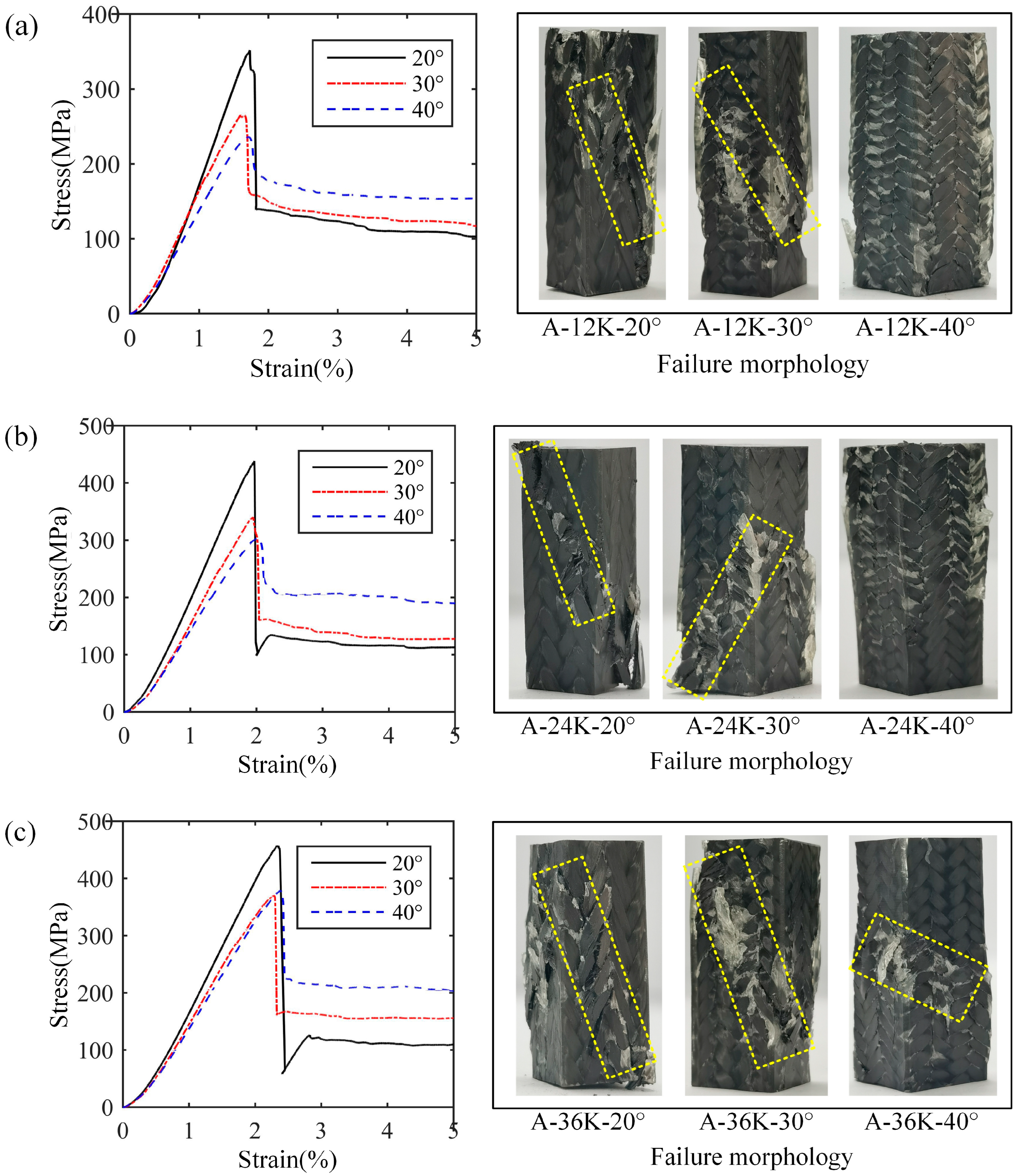

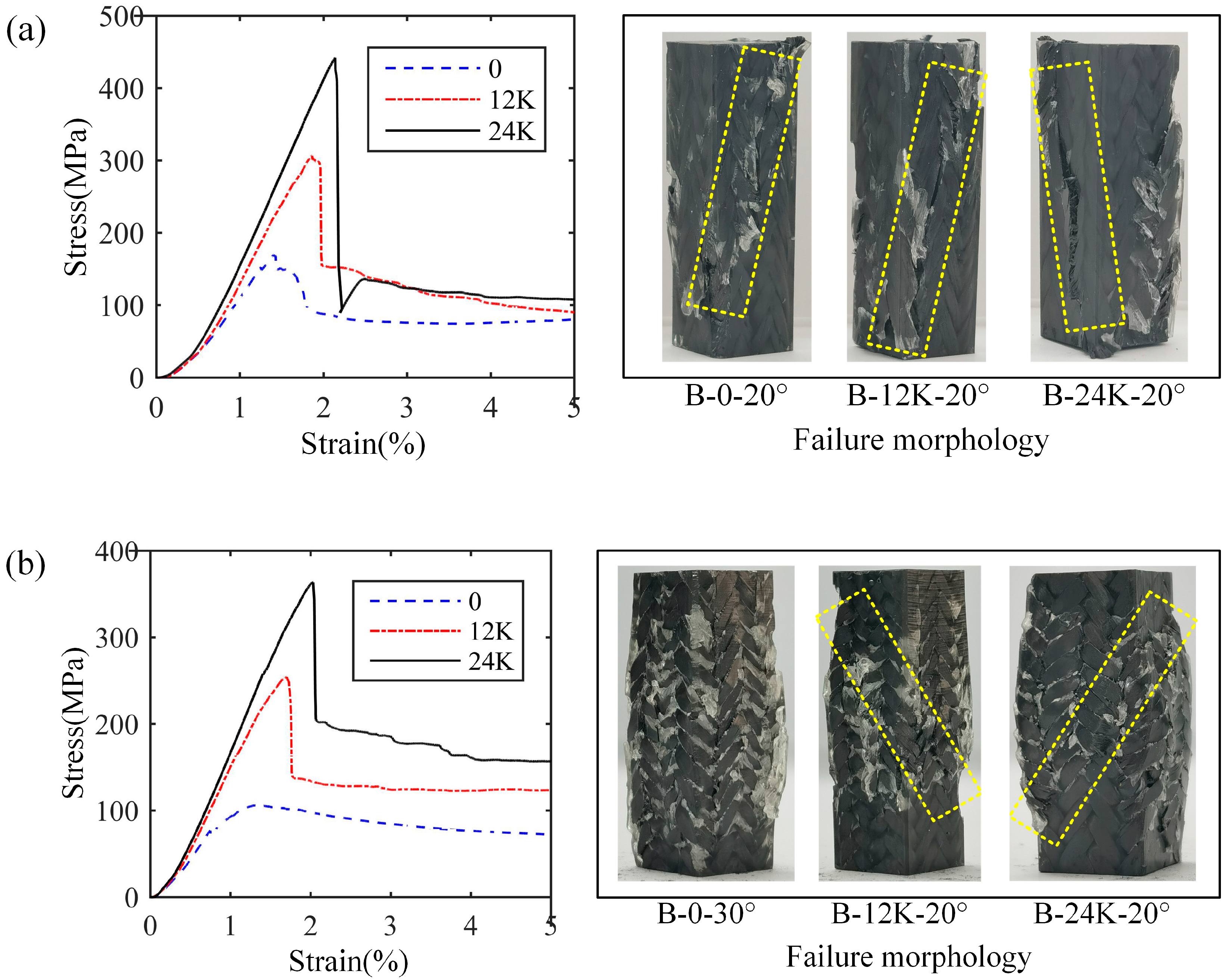

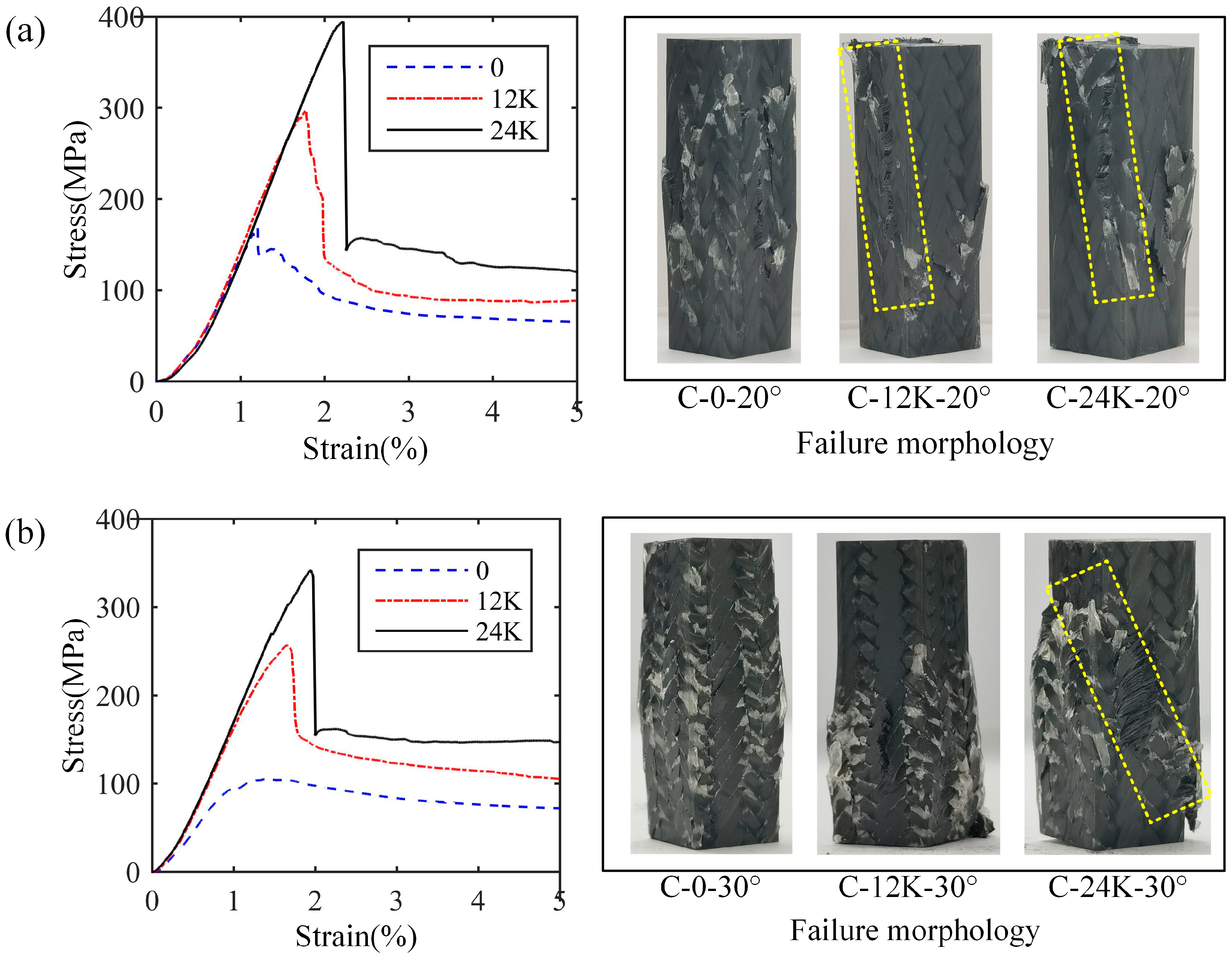

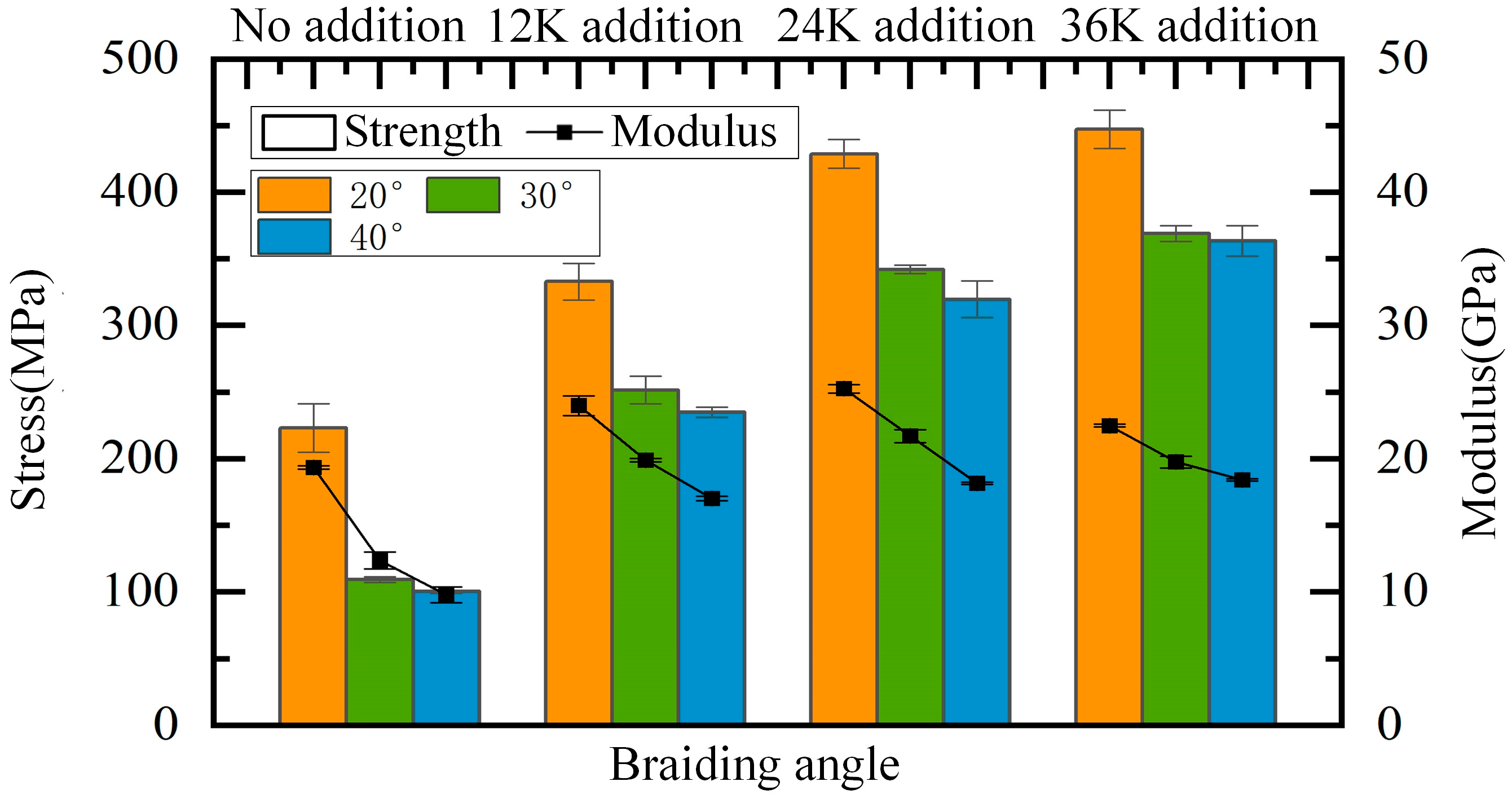

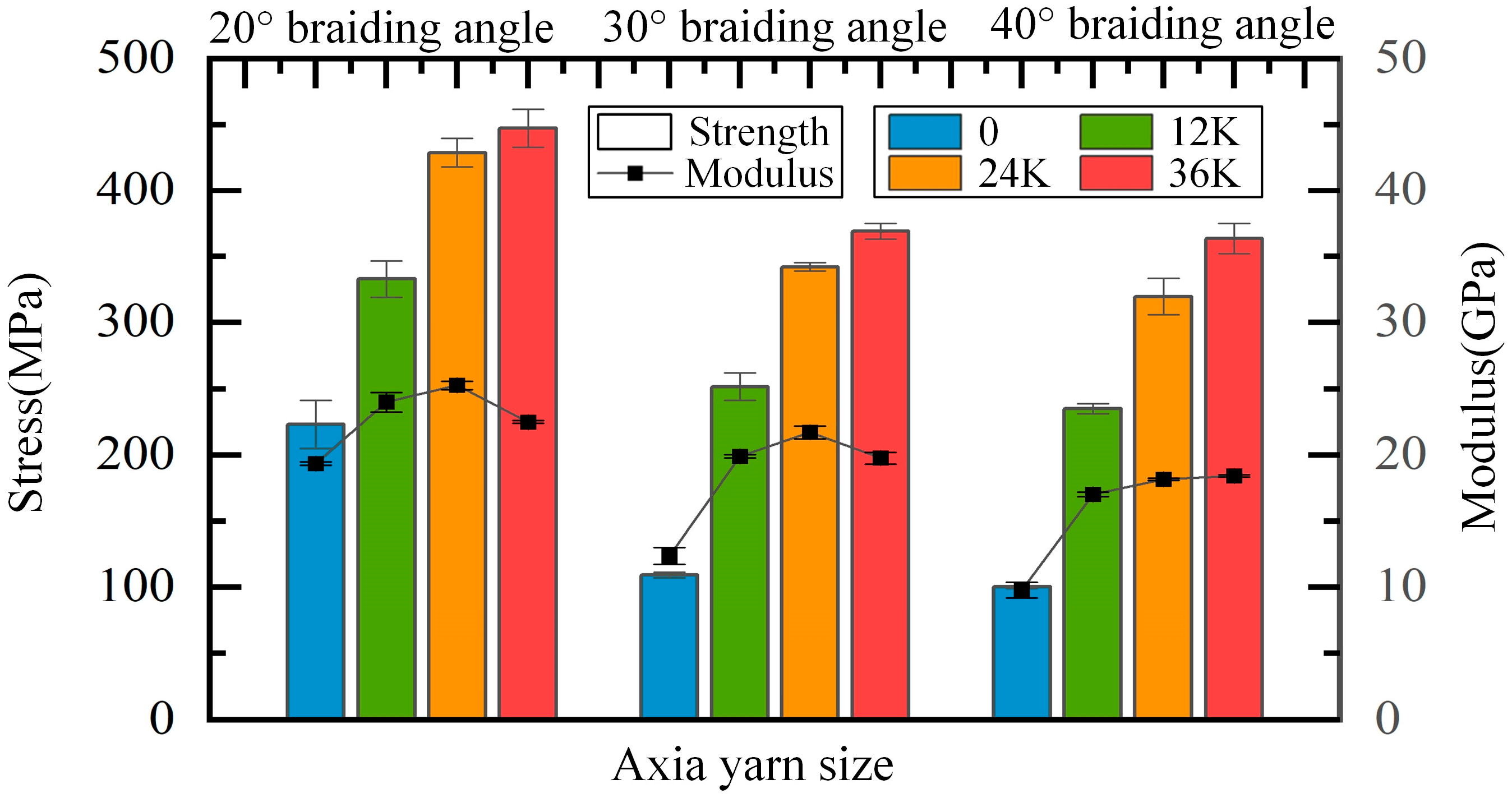

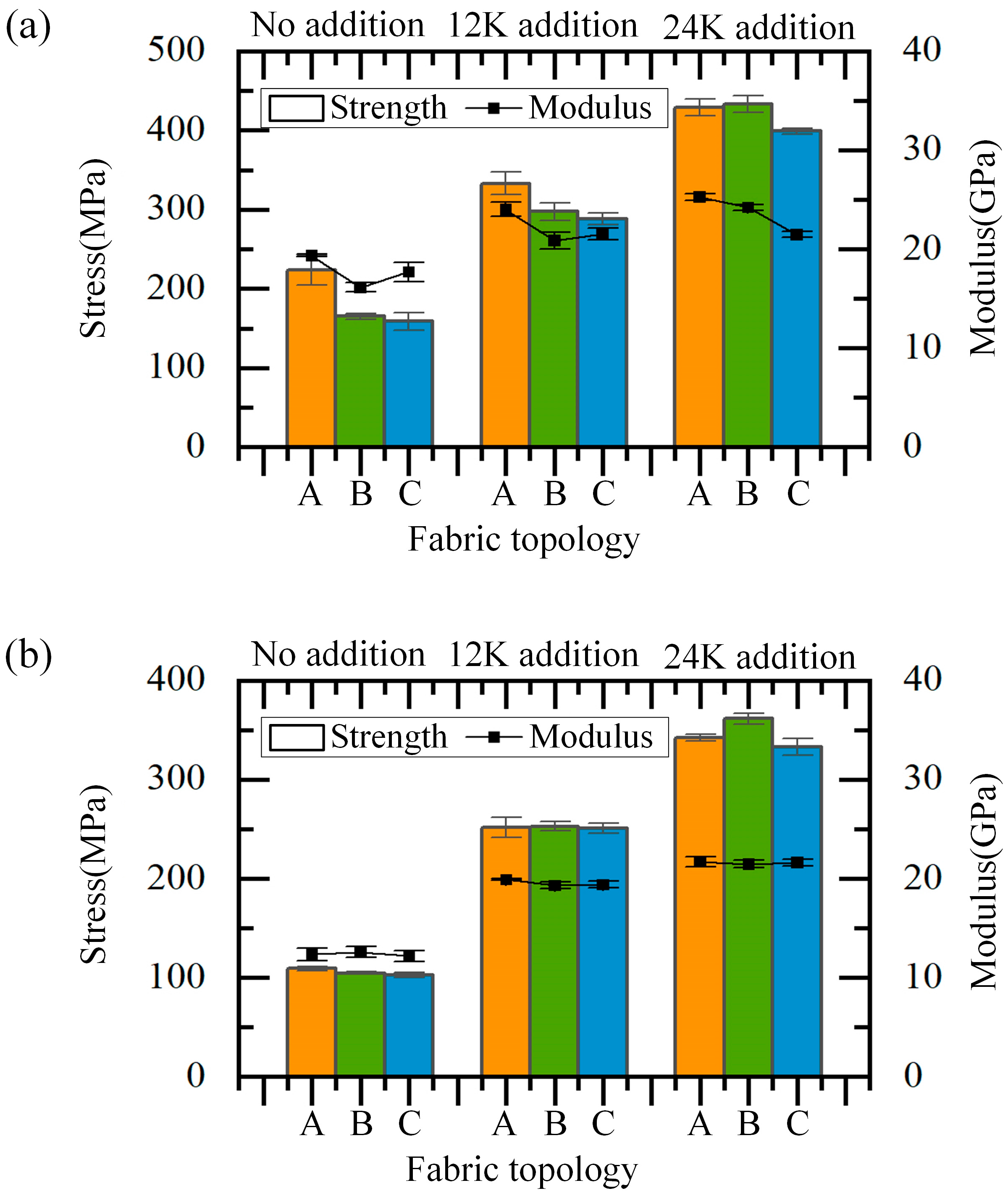

3.2. Longitudinal Compressive Properties of 3D Braided Composites

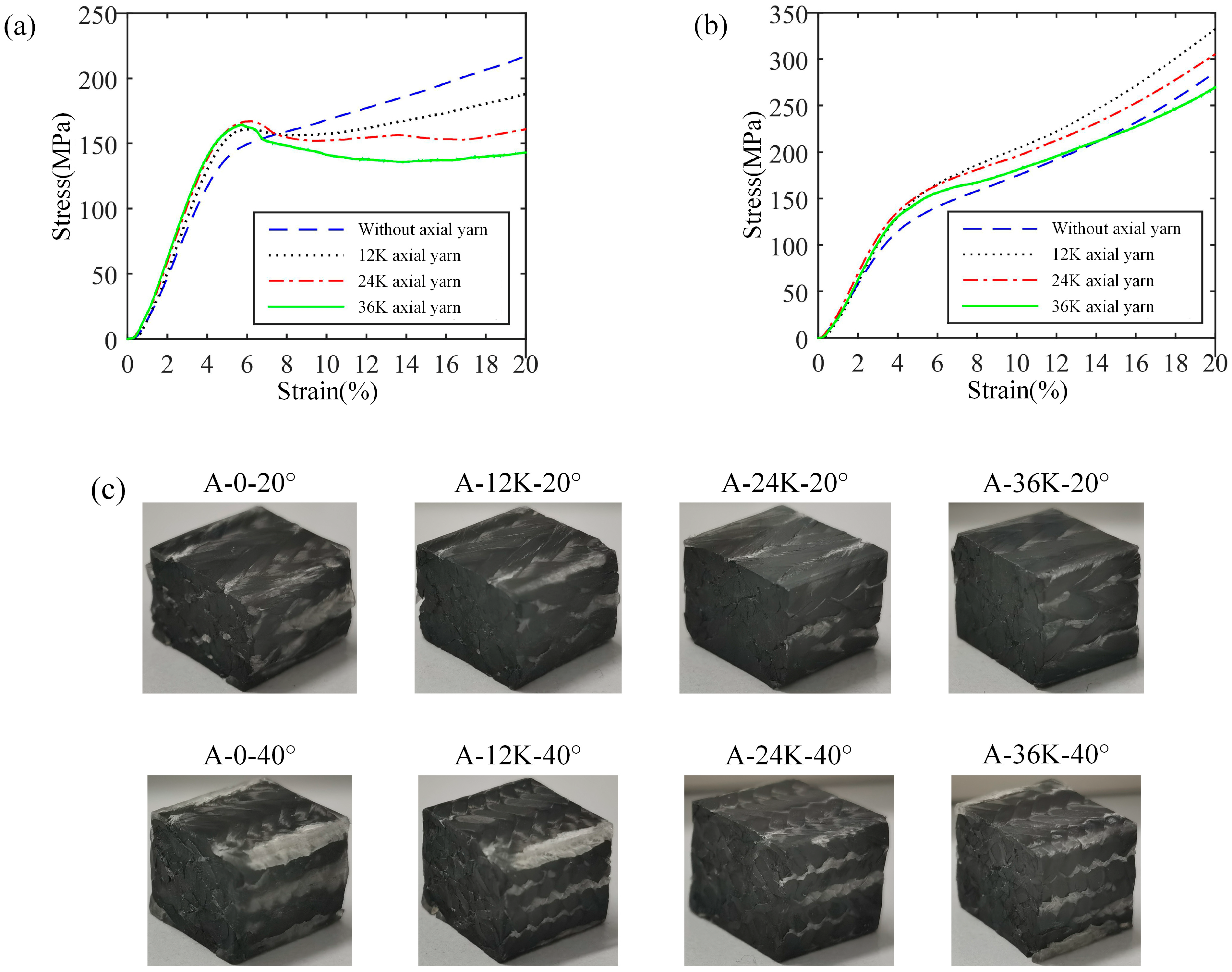

3.3. Transverse Compressive Properties of 3D Braided Composites

4. Discussion

4.1. Effect of the Braiding Angle on the Longitudinal Compressive Properties

4.2. Effect of the Axial Yarn Condition on the Longitudinal Compressive Properties

4.3. Effect of the Fabric Topology on the Longitudinal Compressive Properties

5. Conclusions

- (1)

- The fabric topology and axial yarn condition affect the yarn morphology in the composites, and the effect of these on the compressive properties depends on the braiding angle.

- (2)

- The fabric topology does affect the compressive property when the braiding angle is small, which makes it a non-negligible factor to be considered.

- (3)

- For composites with large braiding angles, the addition of axial yarn significantly improves the compressive strength, which more than doubles. However, the compressive modulus has an extremum at certain braiding angles, which indicates that the size of axial yarns should be properly selected according to specific demands.

- (4)

- The axial yarn condition has little effect on the transverse compressive property for composites of Type A with a large braiding angle, and it is interesting that the composites with a small braiding angle and no axial yarns perform like linear strengthening materials.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Guo, Z.; Kong, X.; Zhai, J.; Zhang, N.; Yan, S.; Guo, R. A review of defect formation, detection, and effect on mechanical properties of three-dimensional braided composites. Rev. Adv. Mater. Sci. 2025, 64, 20250112. [Google Scholar] [CrossRef]

- Chen, Z.; Yue, C.; Zhang, Y.; Wang, P.; Li, Y. Mechanical response and failure mechanism of three-dimensional braided composites under various strain-rate loadings by experimental and simulation research: A review. Text. Res. J. 2022, 92, 296–314. [Google Scholar] [CrossRef]

- Liu, Q.; Li, J.; Li, X. Research of bending and compression properties of 3D braided composite materials. J. Mater. Eng. 2000, 8, 3–6. [Google Scholar]

- Lu, Z.; Hu, Q. Experimental investigation into the compressive mechanical properties of three-dimensional braided composites. Acta Mater. Compos. Sin. 2003, 20, 67–72. [Google Scholar]

- Yan, S.; Li, D.; Pan, S. Analysis of compressive fracture process in 3D braided composites by acoustic emission. J. Mater. Eng. 2013, 2, 22–28. [Google Scholar] [CrossRef]

- Fang, G.; Liang, J.; Lu, Q.; Wang, B.; Wang, Y. Investigation on the compressive properties of the three dimensional four-directional braided composites. Compos. Struct. 2011, 93, 392–405. [Google Scholar] [CrossRef]

- Zhu, H.; Du, X.; Li, D.; Jiang, L. Investigation of parameterized braiding parameters and loading directions on compressive behavior and failure mechanism of 3D four-directional braided composites. Compos. Struct. 2022, 287, 115357. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, H.; Yan, S.; Wang, X.; Guan, Y.; Du, C.; Jiang, L.; Zhai, J. Experimental Analysis of the Low-Velocity Impact and CAI Properties of 3D Four-Directional Braided Composites after Hygrothermal Aging. Materials 2024, 17, 3151. [Google Scholar] [CrossRef]

- Niu, Y.; Bu, L.; Yan, S.; Cai, S.; Meng, Z. Analysis of Residual Compressive Strength in 3D Four-Directional Braided Composites After Hygrothermal Aging. Materials 2025, 18, 1368. [Google Scholar] [CrossRef]

- Wang, X.; Li, H.; Zhang, Y.; Guan, Y.; Yan, S.; Zhai, J. Compressive failure characteristics of 3D four-directional braided composites with prefabricated holes. Materials 2024, 17, 3821. [Google Scholar] [CrossRef]

- Gao, X.; Sun, B.; Gu, B. Damage mechanisms of 3-D rectangular braided composite under multiple impact compressions. Aerosp. Sci. Technol. 2018, 82, 46–60. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, J.; Shi, B.; Wang, L.; Gu, B.; Sun, B. Damage and failure mechanism of 3D carbon fiber/epoxy braided composites after thermo-oxidative ageing under transverse impact compression. Compos. Part B Eng. 2019, 161, 677–690. [Google Scholar] [CrossRef]

- Long, J.; Xu, F.; Wu, Y.; Xue, Y.; Sun, B.; Gu, B.; Zhang, W. Impact compression damages of 3D braided composites with/without axial yarns after thermo-oxidative ageing. Int. J. Damage Mech. 2022, 31, 1349–1372. [Google Scholar] [CrossRef]

- Guo, J.; Sun, B.; Gu, B.; Zhang, W. Failure behaviors of 3D braided composites with defects in different locations under low-velocity impact compression. Text. Res. J. 2022, 92, 196–209. [Google Scholar] [CrossRef]

- Cui, C.; Dong, J.; Mao, X. Effect of braiding angle on progressive failure and fracture mechanism of 3-D five-directional carbon/epoxy braided composites under impact compression. Compos. Struct. 2019, 229, 111412. [Google Scholar] [CrossRef]

- Zhang, D.; Zheng, X.; Zhou, J.; Song, X.; Jia, P.; Liu, H.; Liu, X. Effect of braiding architectures on the mechanical and failure behavior of 3D braided composites: Experimental investigation. Polymers 2022, 14, 1916. [Google Scholar] [CrossRef] [PubMed]

- Liang, S.; Chen, G.; Zhou, Q. Compression property of notched 3-D braided composites. J. Text. Res. 2020, 41, 79–84. [Google Scholar]

- Cao, H.; Qian, K.; Xu, W.; Li, Y.; Zang, H. Compressive properties of three-dimensional full five-directional braided composites. J. Text. Res. 2013, 34, 68–71. [Google Scholar]

- Zuo, H.; Li, D.; Jiang, L. Experimental study on compressive fatigue behavior and failure mechanism of 3D five-directional braided composites. Compos. Part A Appl. Sci. Manuf. 2020, 139, 106097. [Google Scholar] [CrossRef]

- Chen, L.; Liu, J.; Ma, Z.; Liang, Z.; Li, J. Experimental investigation on longitudinal compression properties of 3D multidirectional braided composite. J. Solid Rocket. Technol. 2006, 29, 63–66. [Google Scholar]

- Zhu, H.; Li, D.; Han, W.; Jiang, L. Experimental and numerical study of in-plane compressive properties and failure of 3D six-directional braided composites with large braiding angle. Mater. Des. 2020, 195, 108917. [Google Scholar] [CrossRef]

- Han, W.F.; Li, D.S.; Jiang, L. High-temperature properties and failure mechanism of 3D six-directional braided composites under out-of-plane compression. Polym. Compos. 2020, 41, 2233–2244. [Google Scholar] [CrossRef]

- Wang, X.; Wang, Z.; Zhang, D.; Qian, K. Damage evolution and failure mechanism of 3D6d braided composite tubes under quasi-static lateral compression. Compos. Commun. 2024, 46, 101825. [Google Scholar] [CrossRef]

- Wang, X.; Sun, J.; Pang, Z.; Qian, K.; Zhang, D. Design and fabrication of bioinspired bamboo-node three-dimensional six-directional braided composite tubes for superior axial compression capacity. Constr. Build. Mater. 2025, 458, 139593. [Google Scholar] [CrossRef]

- Li, X.; He, X.; Liang, J.; Song, Y.; Zhang, L.; Wang, B.; Ma, J.; Kong, G. Research status of 3D braiding technology. Appl. Compos. Mater. 2022, 29, 147–157. [Google Scholar] [CrossRef]

- Zhou, Z.; Sun, Z.; Shan, Z.; Guo, K.; Yang, T.; Yang, H.; Deng, Z.; Guo, Z. Advanced composite preform forming technology for structures and its digitization: A review. Thin-Walled Struct. 2025, 211, 113053. [Google Scholar] [CrossRef]

- Mei, H.; Han, Z.; Lu, G.; Jin, H. A methodology for modeling the relationship between process and topological yarn structure of 3D rotary braided rectangular preforms. Compos. Sci. Technol. 2018, 168, 188–194. [Google Scholar] [CrossRef]

- Mei, H.; Jin, H.; Han, Z.; Ko, F.K. Effect of carrier configuration on the 3D four-directional and full five-directional rotary braided fabric structures. Compos. Struct. 2019, 219, 179–184. [Google Scholar] [CrossRef]

- Carvelli, V.; Pazmino, J.; Lomov, S.V.; E Bogdanovich, A.; Mungalov, D.D.; Verpoest, I. Quasi-static and fatigue tensile behavior of a 3D rotary braided carbon/epoxy composite. J. Compos. Mater. 2013, 47, 3195–3209. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.G.; Wei, Y.C.; Li, Z.J.; Yi, Y.P.; Wang, Y.B. Novel processing technology and mesoscopic geometric modeling of a new three-dimensional (3D) braided composite and the study on its longitudinal mechanical properties. Compos. Struct. 2020, 251, 112525. [Google Scholar] [CrossRef]

- Huang, H.; Guo, Z.; Shan, Z.; Sun, Z.; Liu, J.; Wang, D.; Wang, W.; Liu, J.; Tan, C. Prediction of elastic properties of 3D4D rotary braided composites with voids using multi-scale finite element and surrogate models. Compos. Struct. 2024, 328, 117579. [Google Scholar] [CrossRef]

- Li, Z.J.; Dai, H.L.; Liu, Z.G.; Wang, Y. Micro-CT based parametric modeling and damage analysis of three-dimensional rotary-five-directional braided composites under tensile load. Compos. Struct. 2023, 309, 116734. [Google Scholar] [CrossRef]

- Li, Z.J.; Liu, Z.G.; Wang, Y.; Yi, Y.P.; Wang, Y.B. Process-structure-performance modelling and progressive damage analysis of 3D rotary-four-directional rectangular braided composites under tensile load. Mater. Des. 2023, 225, 111523. [Google Scholar] [CrossRef]

- GB/T 1448-2005; National Technical Committee for Standardization of Fiber Reinforced Plastics Test Method for Compression Performance of Fiber-Reinforced Plastics. China Standard Press: Beijing, China, 2005.

| Type | Tensile Strength | Tensile Modulus | Density | Elongation | Filament Diameter |

|---|---|---|---|---|---|

| TZ700S | 4900 MPa | 230 GPa | 1.8 g/cm3 | 2.1% | 7 μm |

| Type | Density | Compressive Strength | Compressive Modulus |

|---|---|---|---|

| JC-02 (100:85) | 1.19 g/cm3 | 113.24 MPa | 2.54 GPa |

| Fabric Structure | Pitch Length (mm) | Width (mm) | Thickness (mm) | Fiber Volume Fraction (%) | Density (g/cm3) | Transverse Compression |

|---|---|---|---|---|---|---|

| A-0-20° | 3.1 | 8.51 | 8.70 | 43.66 | 1.44 | Yes |

| A-0-30° | 2.0 | 8.89 | 9.03 | 44.51 | 1.44 | No |

| A-0-40° | 1.6 | 8.97 | 9.04 | 47.96 | 1.47 | Yes |

| A-12K-20° | 3.4 | 8.81 | 8.70 | 56.39 | 1.51 | Yes |

| A-12K-30° | 2.1 | 9.01 | 9.15 | 57.03 | 1.52 | No |

| A-12K-40° | 1.7 | 9.42 | 9.44 | 58.99 | 1.52 | Yes |

| A-24K-20° | 3.7 | 9.54 | 9.51 | 60.56 | 1.55 | Yes |

| A-24K-30° | 2.4 | 9.90 | 9.88 | 59.89 | 1.54 | No |

| A-24K-40° | 1.8 | 10.24 | 10.21 | 60.97 | 1.54 | Yes |

| A-36K-20° | 4.1 | 10.47 | 10.58 | 59.55 | 1.54 | Yes |

| A-36K-30° | 2.6 | 10.84 | 10.85 | 59.76 | 1.53 | No |

| A-36K-40° | 2.0 | 11.15 | 11.15 | 60.75 | 1.53 | Yes |

| B-0-20° | 3.1 | 8.63 | 8.54 | 43.70 | 1.44 | No |

| B-0-30° | 2.0 | 8.98 | 9.03 | 44.78 | 1.44 | No |

| B-12K-20° | 3.4 | 8.75 | 8.78 | 55.60 | 1.50 | No |

| B-12K-30° | 2.1 | 9.02 | 9.06 | 58.28 | 1.52 | No |

| B-24K-20° | 3.7 | 9.54 | 9.50 | 59.53 | 1.54 | No |

| B-24K-30° | 2.4 | 9.81 | 9.92 | 60.75 | 1.55 | No |

| C-0-20° | 3.1 | 8.59 | 8.51 | 44.14 | 1.43 | No |

| C-0-30° | 2.0 | 8.97 | 9.05 | 46.10 | 1.45 | No |

| C-12K-20° | 3.4 | 8.72 | 8.77 | 56.71 | 1.49 | No |

| C-12K-30° | 2.1 | 9.02 | 9.06 | 58.24 | 1.53 | No |

| C-24K-20° | 3.7 | 9.55 | 9.52 | 59.31 | 1.54 | No |

| C-24K-30° | 2.4 | 9.81 | 9.91 | 59.63 | 1.54 | No |

| Fabric Structure | Compressive Strength (MPa) | Standard Deviation (MPa) | Compressive Modulus (GPa) | Standard Deviation (GPa) |

|---|---|---|---|---|

| A-0-20° | 223.05 | 18.24 | 19.36 | 0.12 |

| A-0-30° | 109.31 | 2.01 | 12.35 | 0.64 |

| A-0-40° | 100.17 | 1.15 | 9.78 | 0.59 |

| A-12K-20° | 333.06 | 13.85 | 23.99 | 0.73 |

| A-12K-30° | 251.69 | 10.52 | 19.91 | 0.12 |

| A-12K-40° | 235.06 | 3.79 | 17.02 | 0.16 |

| A-24K-20° | 428.95 | 10.72 | 25.27 | 0.32 |

| A-24K-30° | 342.24 | 3.05 | 21.71 | 0.49 |

| A-24K-40° | 319.77 | 13.79 | 18.16 | 0.08 |

| A-36K-20° | 447.55 | 14.54 | 22.50 | 0.11 |

| A-36K-30° | 369.03 | 5.87 | 19.76 | 0.44 |

| A-36K-40° | 363.70 | 11.27 | 18.42 | 0.07 |

| B-0-20° | 164.96 | 3.69 | 16.14 | 0.45 |

| B-12K-20° | 297.16 | 11.36 | 20.88 | 0.85 |

| B-24K-20° | 433.04 | 10.63 | 24.20 | 0.31 |

| B-0-30° | 104.56 | 1.09 | 12.59 | 0.58 |

| B-12K-30° | 252.84 | 4.56 | 19.3 | 0.35 |

| B-24K-30° | 361.34 | 5.50 | 21.47 | 0.38 |

| C-0-20° | 158.51 | 10.87 | 17.68 | 0.96 |

| C-12K-20° | 288.00 | 7.28 | 21.49 | 0.6 |

| C-24K-20° | 398.78 | 3.54 | 21.47 | 0.29 |

| C-0-30° | 102.80 | 2.39 | 12.19 | 0.53 |

| C-12K-30° | 251.07 | 5.03 | 19.38 | 0.35 |

| C-24K-30° | 332.93 | 8.07 | 21.62 | 0.35 |

| Fabric Structure | Compressive Strength (MPa) | Standard Deviation (MPa) | Compressive Modulus (GPa) | Standard Deviation (GPa) |

|---|---|---|---|---|

| A-0-20° | 120.67 | 1.47 | 3.76 | 0.02 |

| A-12K-20° | 156.60 | 3.80 | 4.19 | 0.03 |

| A-24K-20° | 167.53 | 0.45 | 4.35 | 0.02 |

| A-36K-20° | 163.53 | 1.59 | 4.42 | 0.01 |

| A-0-40° | 105.33 | 0.97 | 3.63 | 0.08 |

| A-12K-40° | 120.50 | 4.21 | 4.21 | 0.11 |

| A-24K-40° | 118.67 | 0.37 | 4.40 | 0.05 |

| A-36K-40° | 114.07 | 3.57 | 4.25 | 0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mei, H.; Sun, L.; Yang, R.; Zhang, Q.; Guo, Y.; Han, Z. Effect of Fabric Topology and Axial Yarn Condition on the Compressive Properties of 3D Stepwise Rotary Braided Composites. Materials 2025, 18, 5561. https://doi.org/10.3390/ma18245561

Mei H, Sun L, Yang R, Zhang Q, Guo Y, Han Z. Effect of Fabric Topology and Axial Yarn Condition on the Compressive Properties of 3D Stepwise Rotary Braided Composites. Materials. 2025; 18(24):5561. https://doi.org/10.3390/ma18245561

Chicago/Turabian StyleMei, Haiyang, Long Sun, Ran Yang, Qian Zhang, Yankuo Guo, and Zhenyu Han. 2025. "Effect of Fabric Topology and Axial Yarn Condition on the Compressive Properties of 3D Stepwise Rotary Braided Composites" Materials 18, no. 24: 5561. https://doi.org/10.3390/ma18245561

APA StyleMei, H., Sun, L., Yang, R., Zhang, Q., Guo, Y., & Han, Z. (2025). Effect of Fabric Topology and Axial Yarn Condition on the Compressive Properties of 3D Stepwise Rotary Braided Composites. Materials, 18(24), 5561. https://doi.org/10.3390/ma18245561