Bioinspired Microcavities Enhancing the Interface of Fe–Carbon Fiber-Reinforced Polymer

Abstract

1. Introduction

2. Experiment Details

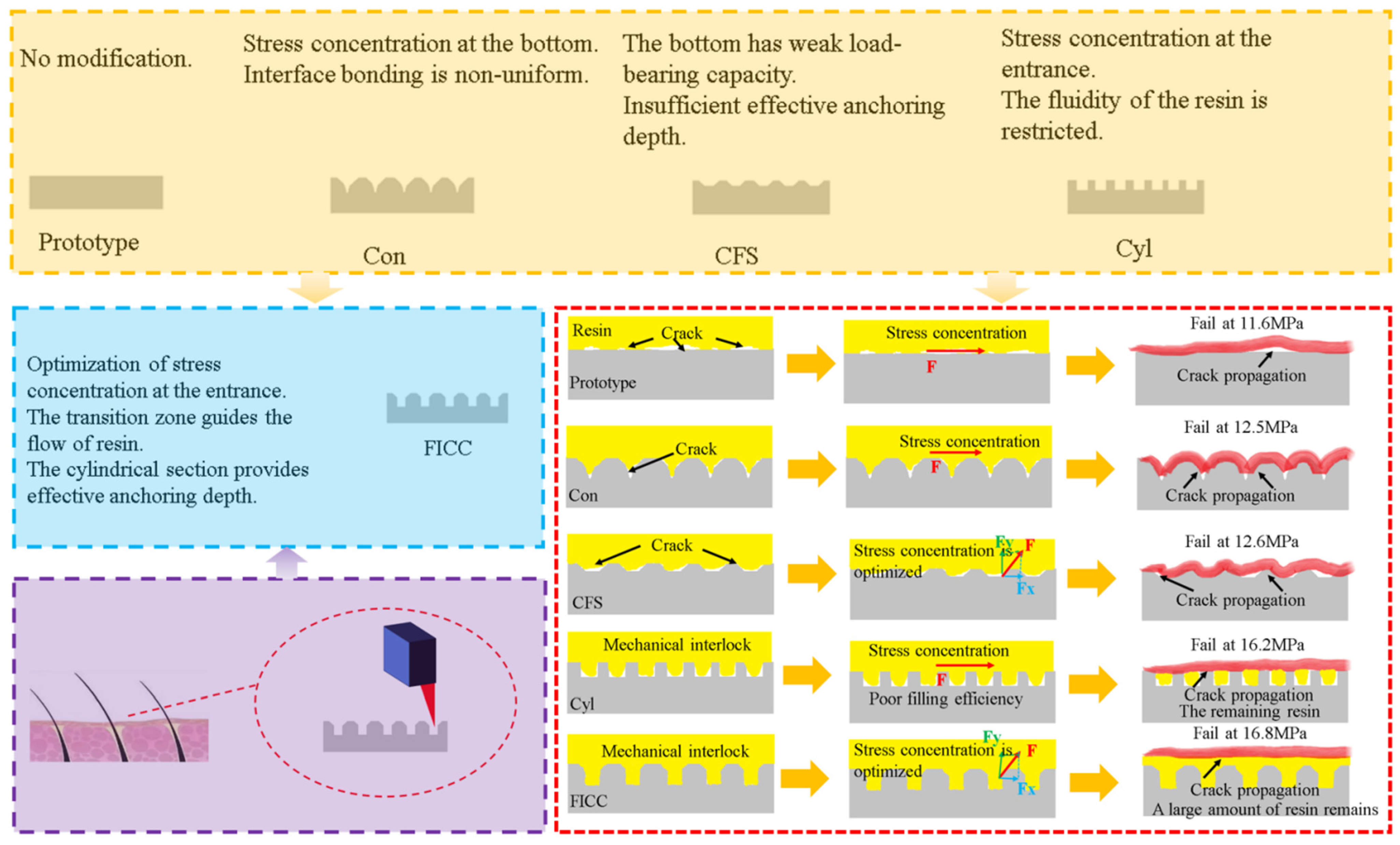

2.1. Materials

2.2. Surface Treatments of Fe Sheets

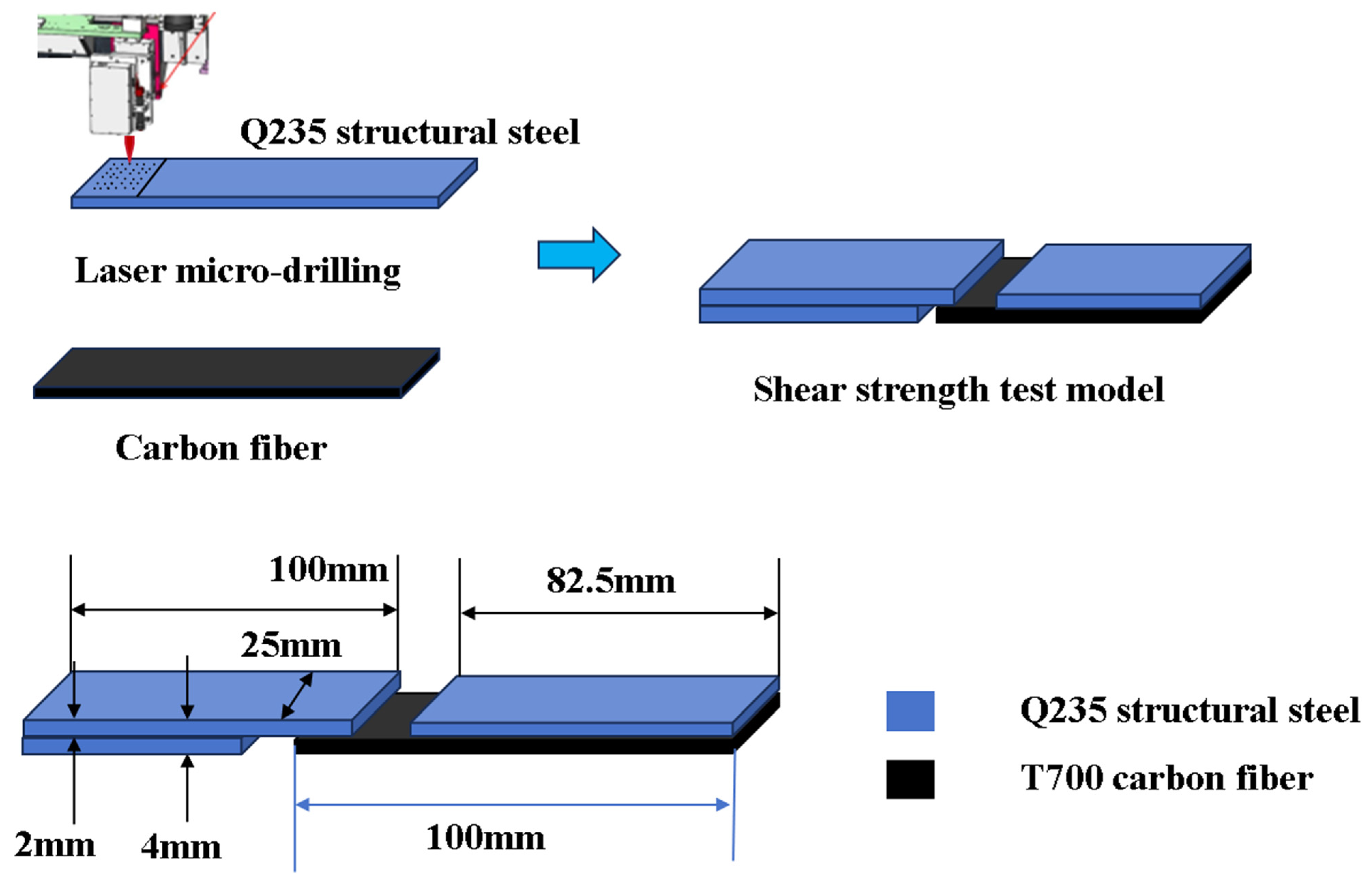

2.3. Preparation of Fe-CFRP Hybrid Laminates

2.4. Characterizations

2.4.1. Microscopic Analysis

2.4.2. Single-Lap Shear Test

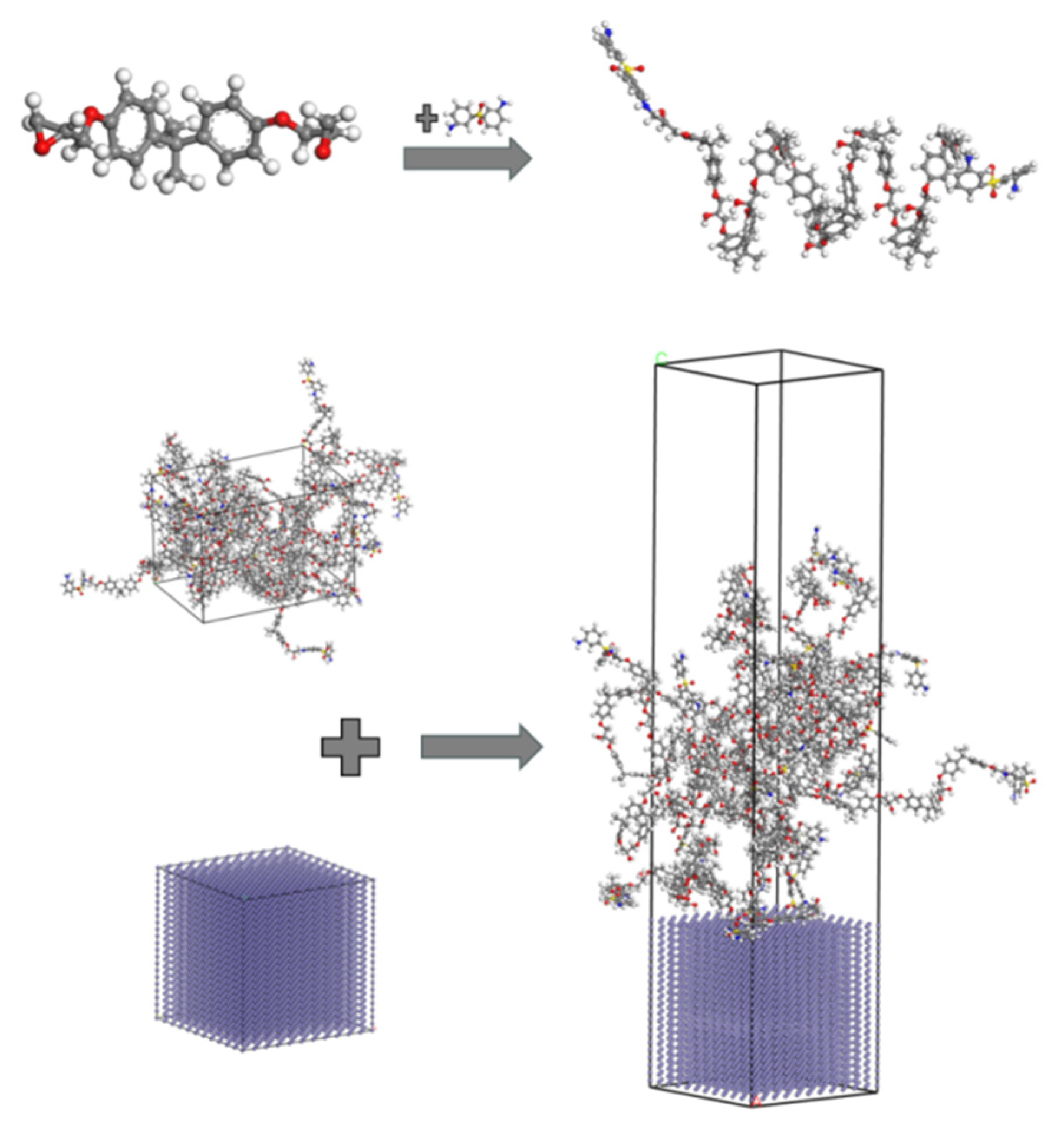

3. Molecular Dynamics Analysis

3.1. Molecular Dynamics Models

3.2. Equations of Energy

4. Results and Discussion

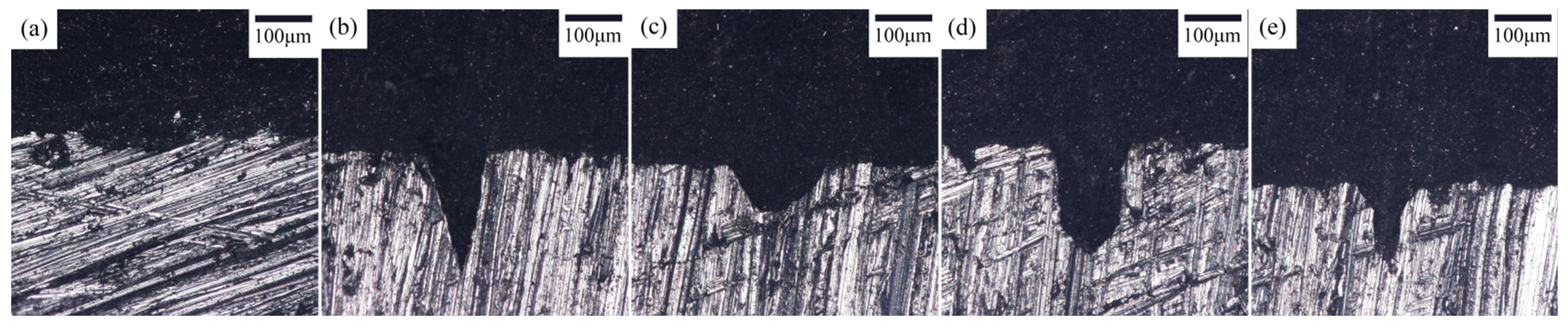

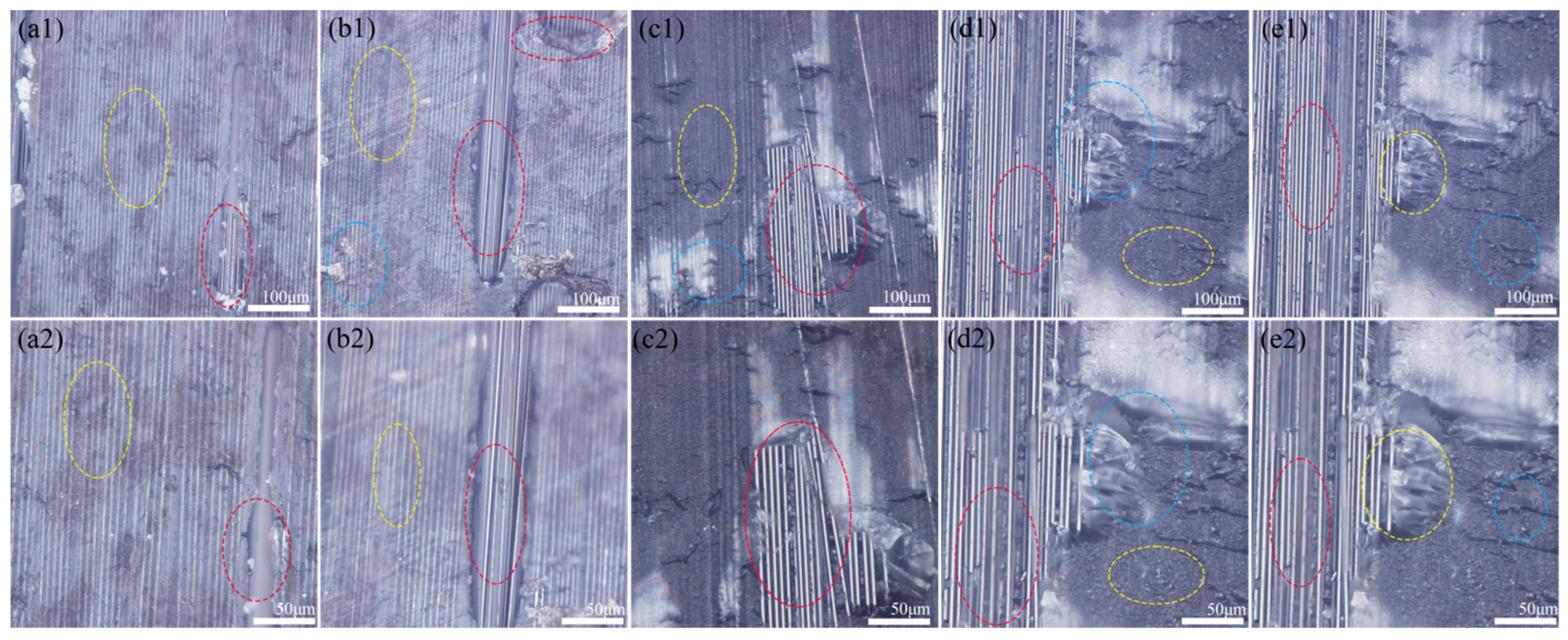

4.1. Microstructure Analysis

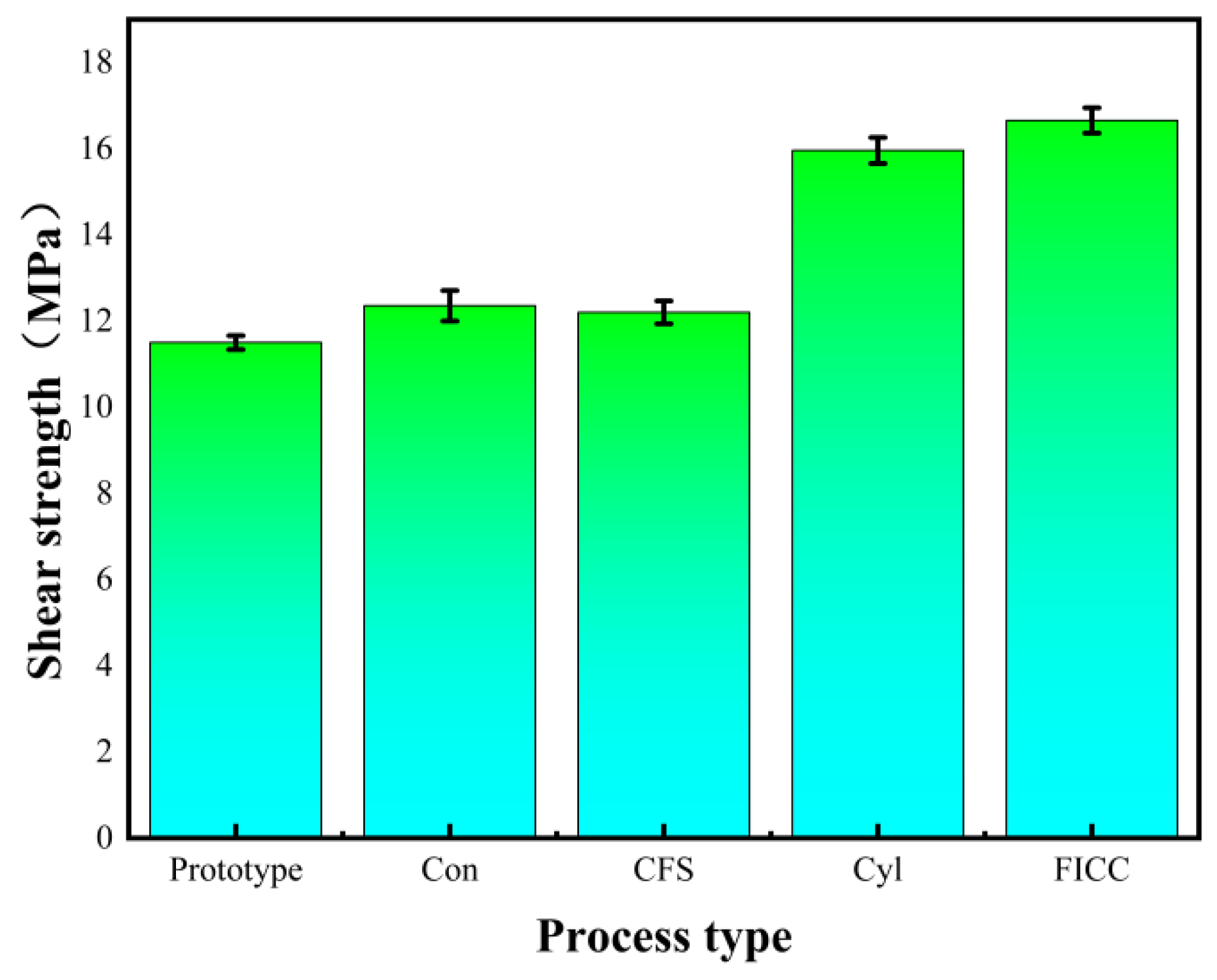

4.2. Interlaminar Shear Properties of Fe-CFRP Hybrid Laminates

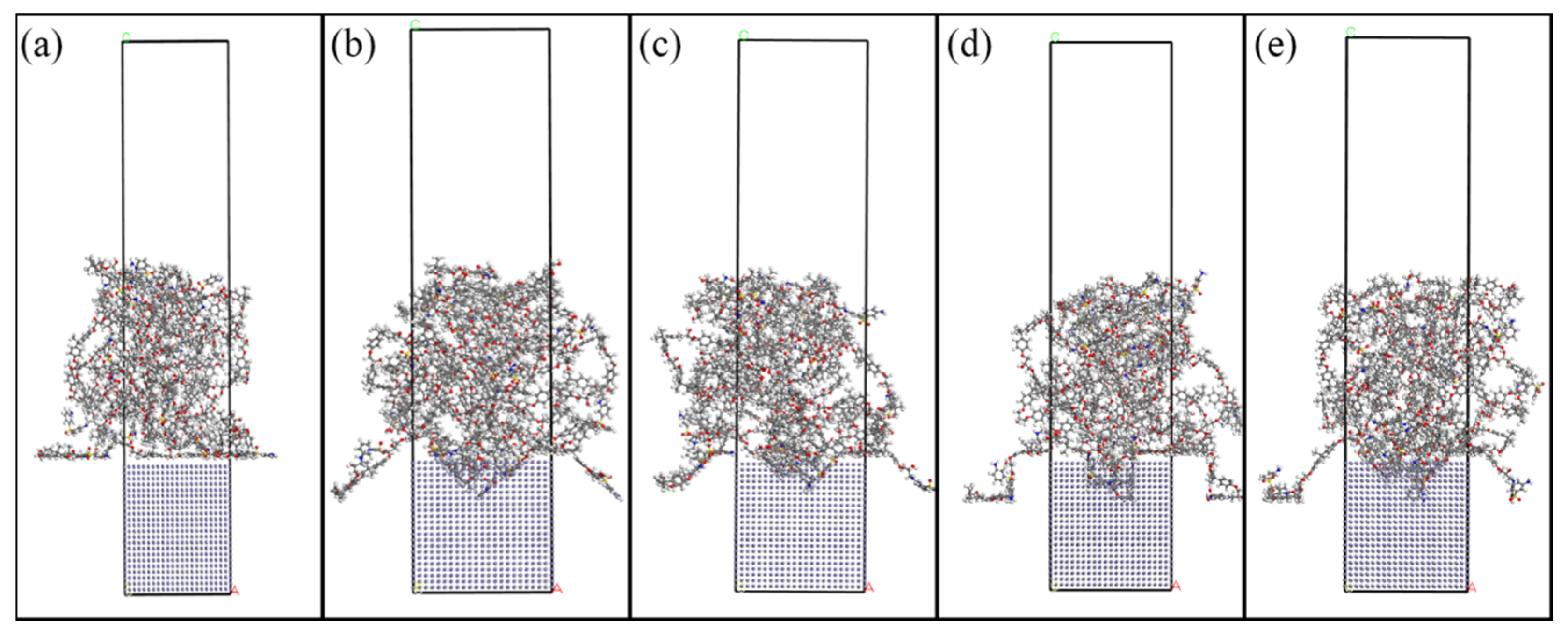

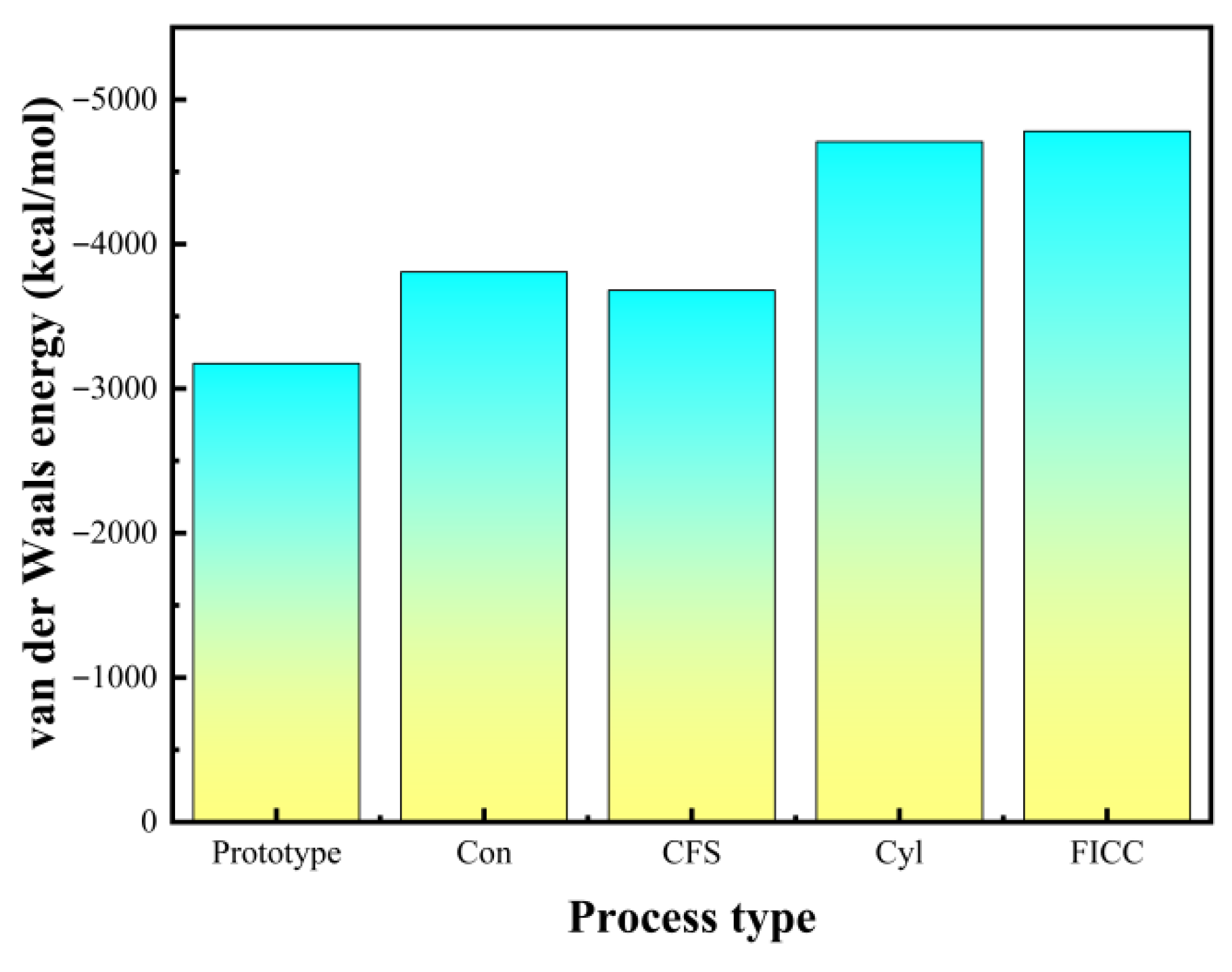

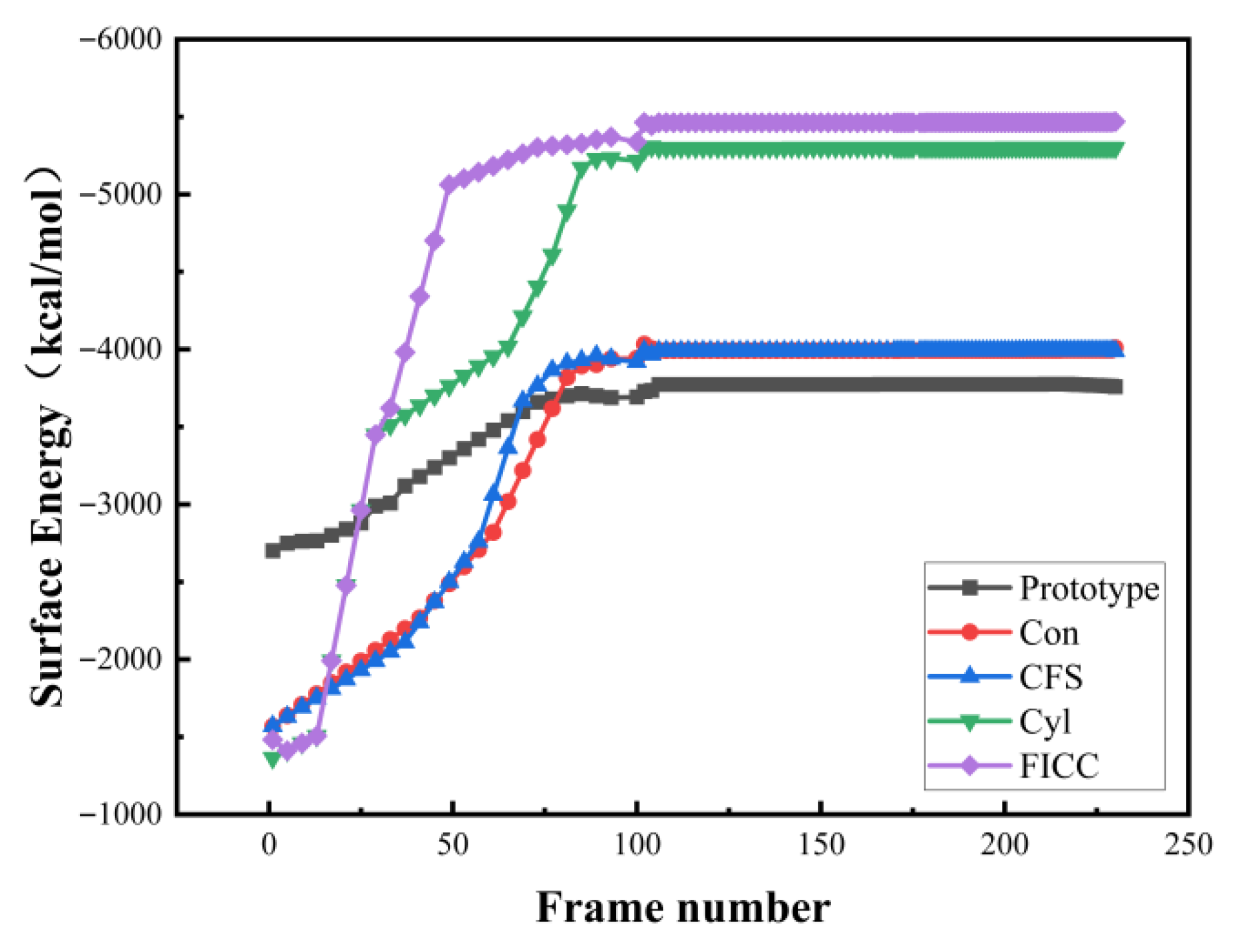

4.3. Molecular Dynamics Simulation Results

4.4. Mechanism of Surface Drilling Treatment on Interface Strengthening

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- O’Donnell, J.; Chalivendra, V. Multi-functional glass/carbon fibers hybrid inter/intra laminated composites. Compos. Part C Open Access 2021, 4, 100121. [Google Scholar] [CrossRef]

- Han, M.; Silberschmidt, V.V. Theoretical analysis on needle-punched carbon/carbon composites. Appl. Compos. Mater. 2019, 26, 805–816. [Google Scholar] [CrossRef]

- Almuhammadi, K.; Yudhanto, A.; Lubineau, G. Real-time electrical impedance monitoring of carbon fiber-reinforced polymer laminates undergoing quasi-static indentation. Compos. Struct. 2019, 207, 255–263. [Google Scholar] [CrossRef]

- Rubino, F.; Nisticò, A.; Tucci, F.; Carlone, P. Marine application of fiber reinforced composites: A review. J. Mar. Sci. Eng. 2020, 8, 26. [Google Scholar] [CrossRef]

- Ahmad, H.; Markina, A.A.; Porotnikov, M.V.; Ahmad, F. A review of carbon fiber materials in automotive industry. IOP Conf. Ser. Mater. Sci. Eng. 2020, 971, 032011. [Google Scholar]

- Aamir, M.; Tolouei-Rad, M.; Giasin, K.; Nosrati, A. Recent advances in drilling of carbon fiber–reinforced polymers for aerospace applications: A review. Int. J. Adv. Manuf. Technol. 2019, 105, 2289–2308. [Google Scholar] [CrossRef]

- Li, Y.; Yu, C.; Wang, W.; Li, H.; Jiang, X. A review on structural failure of composite pressure hulls in deep sea. J. Mar. Sci. Eng. 2022, 10, 1456. [Google Scholar] [CrossRef]

- Al-Fatlawi, A.; Jármai, K.; Kovács, G. Optimal design of a fiber-reinforced plastic composite sandwich structure for the base plate of aircraft pallets in order to reduce weight. Polymers 2021, 13, 834. [Google Scholar] [CrossRef]

- Soutis, C. Carbon fiber reinforced plastics in aircraft construction. Mater. Sci. Eng. A 2005, 412, 171–176. [Google Scholar] [CrossRef]

- Wong, R. Design, Build and Certification of Composite Airplane Structure. In CANCOM 2001 Proceedings of the 3rd Canadian International Conference on Composites; CRC Press: Boca Raton, FL, USA, 2020; pp. 717–725. [Google Scholar]

- Zhang, R.; Li, Z.; Sun, Q.; Yu, G.; Wang, X.; Wu, L. Design and characterization of the carbon fiber tube reinforced polymer composite for full ocean depth submersibles. Compos. Sci. Technol. 2022, 217, 109074. [Google Scholar] [CrossRef]

- Mathai, A.; Subramanian, S.; John, G.P. Analytic investigations of carbon fiber reinforced polymer stiffened cylindrical submarine hull. Int. J. Eng. Sci. Technol. 2013, 5, 1553. [Google Scholar]

- Palmer, C. Like the Titanic. Flawed Engineering—And Hubris—Doomed the Titan. Engineering 2024, 32, 1–3. [Google Scholar] [CrossRef]

- Nakazawa, M. Mechanism of adhesion of epoxy resin to steel surface; Tekko hyomen to epoxy jushino secchaku mechanism. Shinnittetsu Giho 1994, 16–21. Available online: https://www.osti.gov/etdeweb/biblio/34109 (accessed on 16 September 2025).

- Xie, G.H.; You, Y.; Tao, Z.A.; Li, S.Q. Experimental and theoretical study on mechanical behaviors of CFRP–steel interface. Thin-Walled Struct. 2023, 182, 110208. [Google Scholar] [CrossRef]

- Li, C.; Ke, L.; He, J.; Chen, Z.; Jiao, Y. Effects of mechanical properties of adhesive and CFRP on the bond behavior in CFRP-strengthened steel structures. Compos. Struct. 2019, 211, 163–174. [Google Scholar] [CrossRef]

- Cao, M.; Wang, S.; Zang, J.; Liu, M.; Qian, C.; Zhang, Y.; Na, D. Experimental and simulation analysis of the effect of GNPs on the mechanical and interfacial properties of CF/PEEK-Ti fiber metal laminates. Compos. Sci. Technol. 2024, 246, 110387. [Google Scholar] [CrossRef]

- Jin, K.; Wang, H.; Tao, J.; Zhang, X. Interface strengthening mechanisms of Ti/CFRP fiber metal laminate after adding MWCNTs to resin matrix. Compos. Part B Eng. 2019, 171, 254–263. [Google Scholar] [CrossRef]

- Zhuang, J.; Lin, Y.; An, G.; Liu, X. Steady superlubricity achieved by epoxy resin composite coatings containing polydimethylsiloxane. Prog. Org. Coat. 2023, 175, 107361. [Google Scholar] [CrossRef]

- Wan, H.; Teng, H.; Lv, F.; Lin, J.; Min, J. Interface wetting driven by Laplace pressure on multiscale topographies and its application to performance enhancement of metal-composite hybrid structure. ACS Appl. Mater. Interfaces 2023, 15, 18427–18439. [Google Scholar] [CrossRef]

- Harris, A.F.; Beevers, A. The effects of grit-blasting on surface properties for adhesion. Int. J. Adhes. Adhes. 1999, 19, 445–452. [Google Scholar] [CrossRef]

- Xu, Y.; Li, H.; Shen, Y.; Liu, S.; Wang, W.; Tao, J. Improvement of adhesion performance between aluminum alloy sheet and epoxy based on anodizing technique. Int. J. Adhes. Adhes. 2016, 70, 74–80. [Google Scholar] [CrossRef]

- Liang, C.S.; Lv, Z.F.; Bo, Y.; Cui, J.Y.; Xu, S.A. Effect of modified polypropylene on the interfacial bonding of polymer–aluminum laminated films. Mater. Des. 2015, 81, 141–148. [Google Scholar] [CrossRef]

- He, P.; Chen, K.; Yang, J. Surface modifications of Ti alloy with tunable hierarchical structures and chemistry for improved metal–polymer interface used in deepwater composite riser. Appl. Surf. Sci. 2015, 328, 614–622. [Google Scholar] [CrossRef]

- Zhu, D.; Zuo, P.; Li, F.; Tian, H.; Liu, T.; Hu, L.; Huang, H.; Liu, J.; Qian, X. Fabrication and applications of surface micro/nanostructures by femtosecond laser. Colloid Interface Sci. Commun. 2024, 59, 100770. [Google Scholar] [CrossRef]

- Tang, Z.-Q.; Li, Y.-F.; Wang, G.; Yu, Y.; Cao, H.; Li, L.-F.; Jin, Z.-S.; Wang, Y.-L.; Lu, Z. Research advances of femtosecond laser drilling microholes in hard and brittle materials. Opt. Laser Technol. 2025, 185, 112572. [Google Scholar] [CrossRef]

- Tam, L.H.; Zhou, A.; Yu, Z.; Qiu, Q.; Lau, D. Understanding the effect of temperature on the interfacial behavior of CFRP-wood composite via molecular dynamics simulations. Compos. Part B Eng. 2017, 109, 227–237. [Google Scholar] [CrossRef]

- Elkhateeb, M.G.; Shin, Y.C. Molecular dynamics-based cohesive zone representation of Ti6Al4V/TiC composite interface. Mater. Des. 2018, 155, 161–169. [Google Scholar] [CrossRef]

- Li, Y.; Wang, S.; Arash, B.; Wang, Q. A study on tribology of nitrile-butadiene rubber composites by incorporation of carbon nanotubes: Molecular dynamics simulations. Carbon 2016, 100, 145–150. [Google Scholar] [CrossRef]

- Li, Y.; Hu, N.; Yamamoto, G.; Wang, Z.; Hashida, T.; Asanuma, H.; Dong, C.; Okabe, T.; Arai, M.; Fukunaga, H. Molecular mechanics simulation of the sliding behavior between nested walls in a multi-walled carbon nanotube. Carbon 2010, 48, 2934–2940. [Google Scholar] [CrossRef]

- Zhang, H.; Gn, S.W.; An, J.; Xiang, Y.; Yang, J.L. Impact behaviour of GLAREs with MWCNT modified epoxy resins. Exp. Mech. 2014, 54, 83–93. [Google Scholar] [CrossRef]

- ASTM D5868-01; Standard Test Method for Lap Shear Adhesion for Fiber Reinforced Plastic (FRP) Bonding. ASTM International: West Conshohocken, PA, USA, 2014.

- Arab, B.; Shokuhfar, A. Molecular dynamics simulation of cross-linked epoxy polymers: The effect of force field on the estimation of properties. Nano-Electron. Phys. 2013, 5, 01013. [Google Scholar]

- Liu, F.; Wang, S.; Zhang, W.; Ding, X.; Ferraris, E.; Ivens, J. Mechanical and interfacial analysis of 3D-printed two-matrix continuous carbon fibre composites for enhanced structural performance. Compos. Part A Appl. Sci. Manuf. 2024, 180, 108105. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, L.; Wang, L.; Cui, G.; Zhang, W.; Chen, M.; Hou, J.; Cui, C. Bioinspired Microcavities Enhancing the Interface of Fe–Carbon Fiber-Reinforced Polymer. Materials 2025, 18, 5444. https://doi.org/10.3390/ma18235444

He L, Wang L, Cui G, Zhang W, Chen M, Hou J, Cui C. Bioinspired Microcavities Enhancing the Interface of Fe–Carbon Fiber-Reinforced Polymer. Materials. 2025; 18(23):5444. https://doi.org/10.3390/ma18235444

Chicago/Turabian StyleHe, Longfei, Lianhai Wang, Guorong Cui, Wencong Zhang, Mengkai Chen, Jiabin Hou, and Chao Cui. 2025. "Bioinspired Microcavities Enhancing the Interface of Fe–Carbon Fiber-Reinforced Polymer" Materials 18, no. 23: 5444. https://doi.org/10.3390/ma18235444

APA StyleHe, L., Wang, L., Cui, G., Zhang, W., Chen, M., Hou, J., & Cui, C. (2025). Bioinspired Microcavities Enhancing the Interface of Fe–Carbon Fiber-Reinforced Polymer. Materials, 18(23), 5444. https://doi.org/10.3390/ma18235444