Analysis of a Two-Stage Magnetic Precession Gear Exploiting 3D Finite Element Method

Abstract

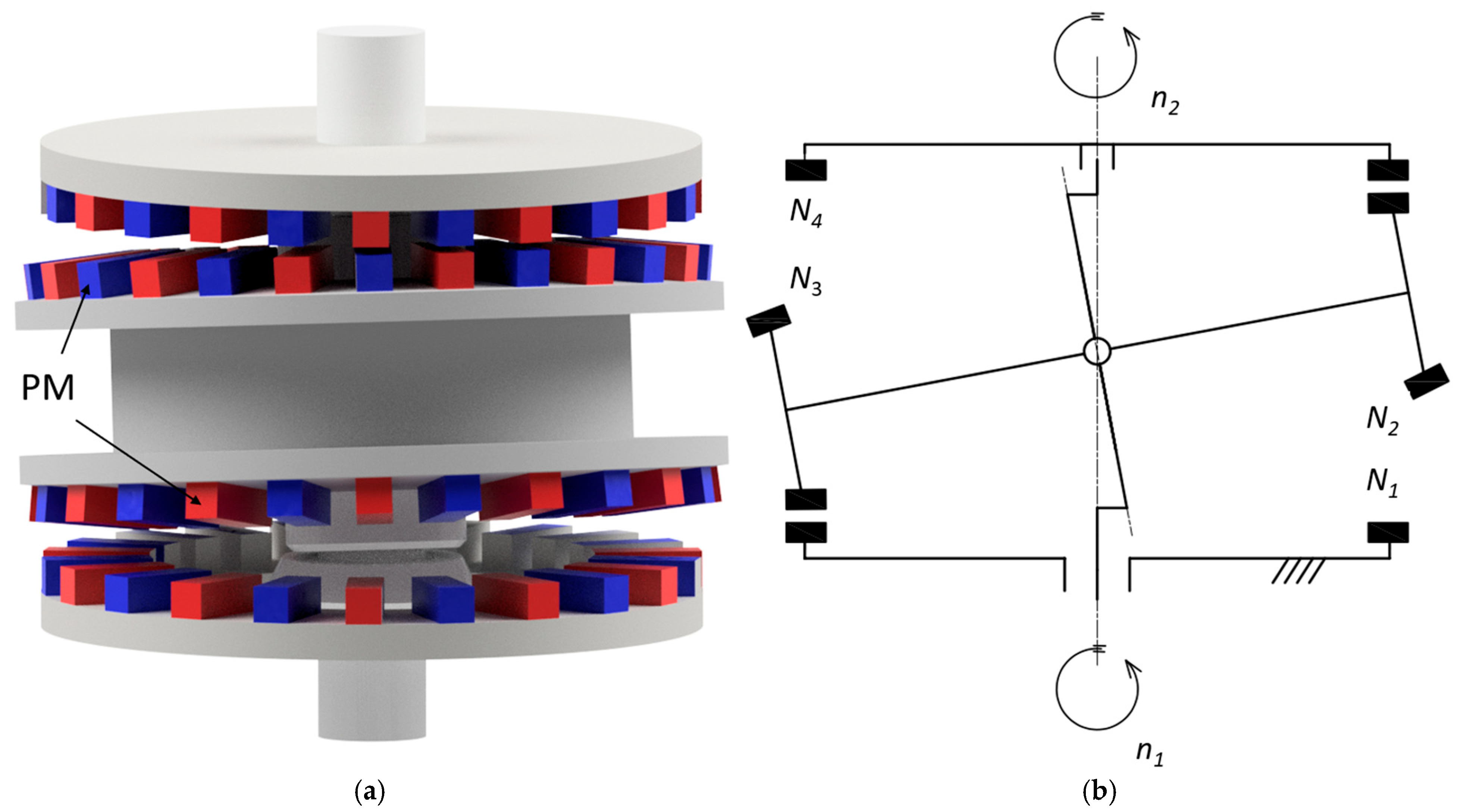

1. Introduction

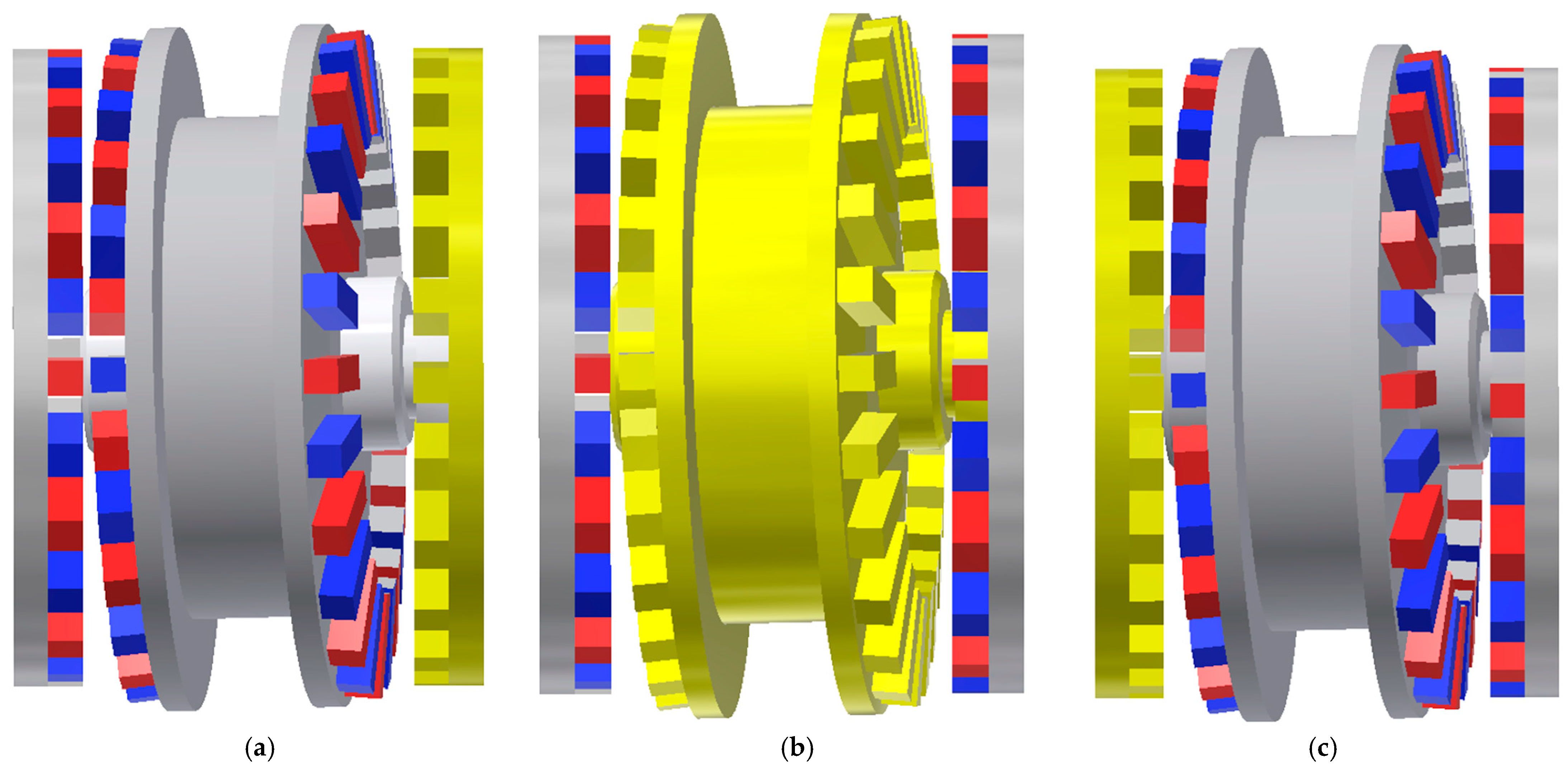

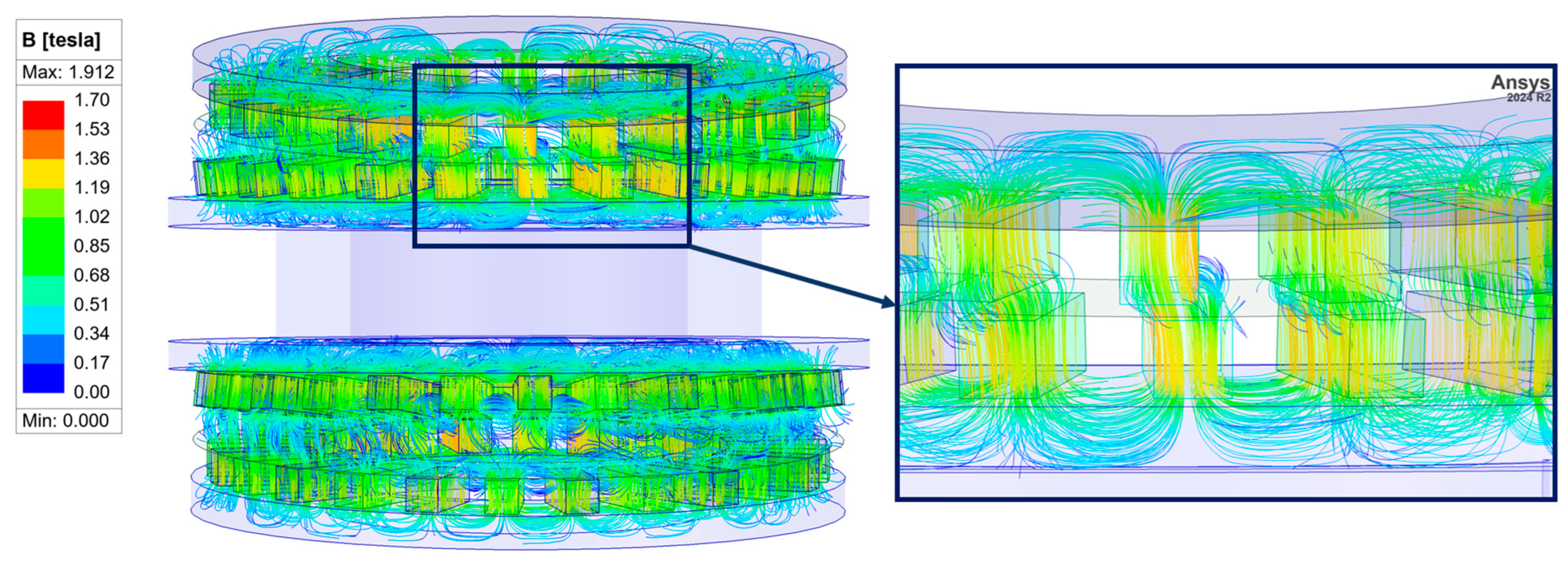

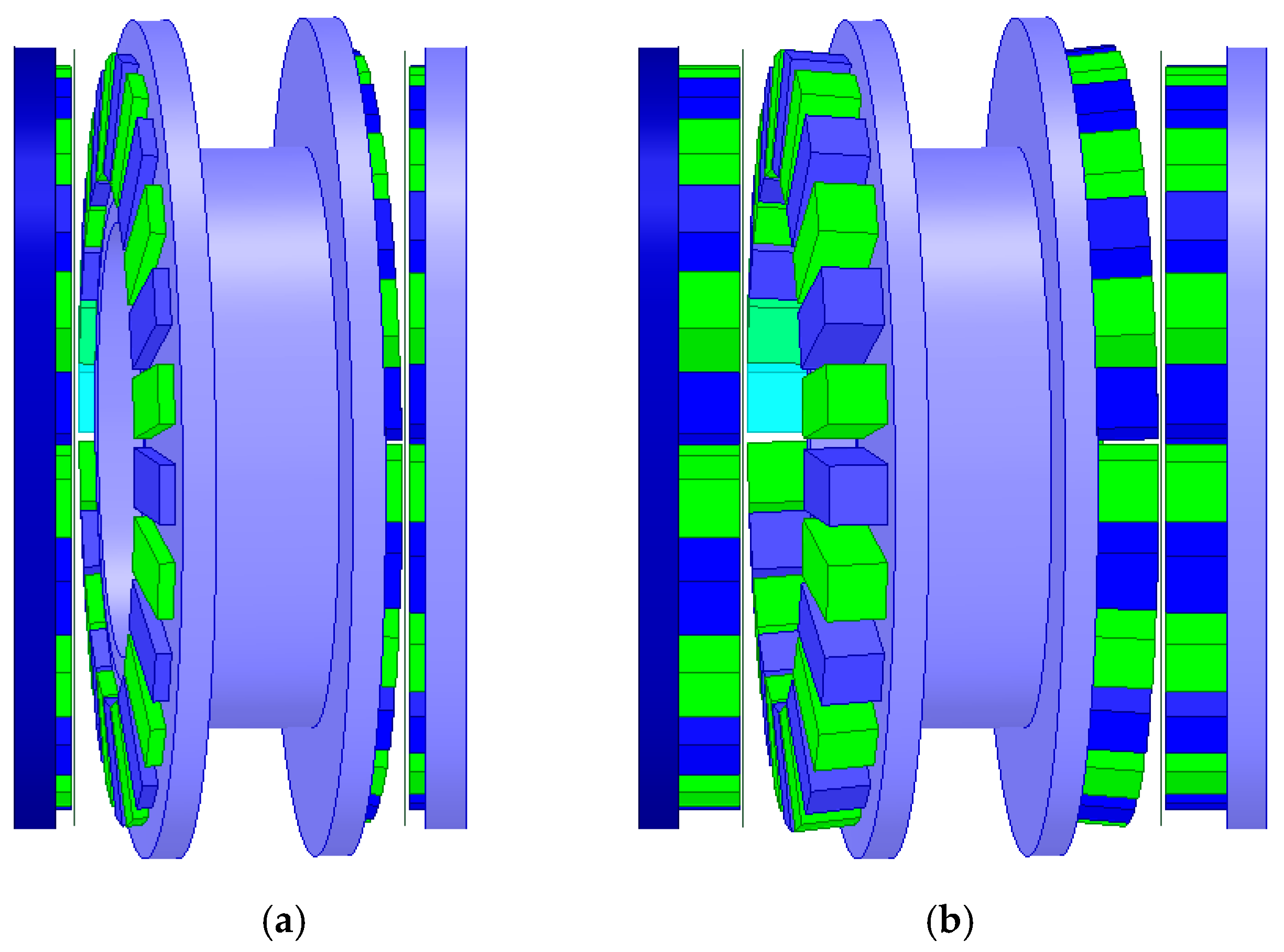

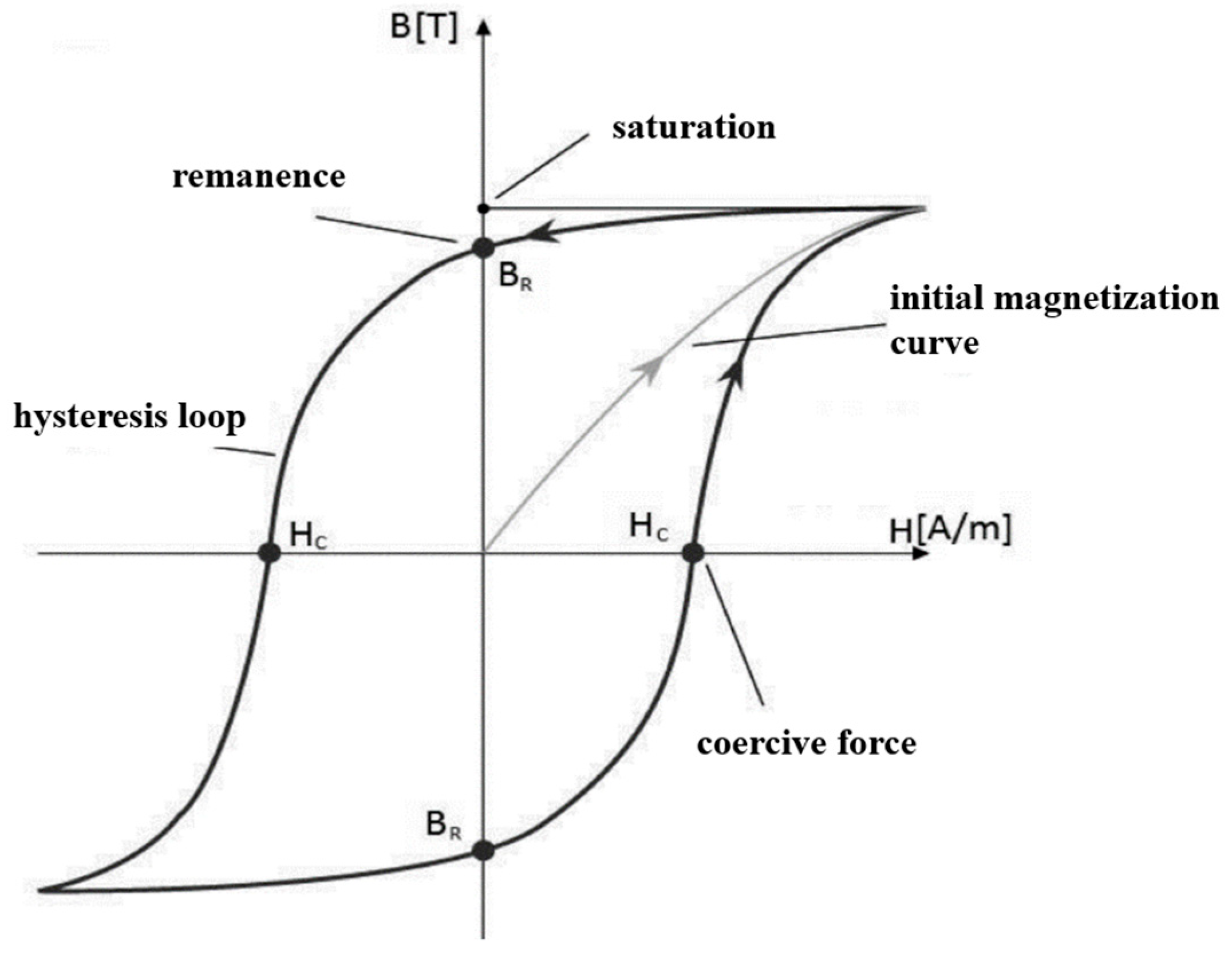

2. Materials and Methods

3. Results and Discussion

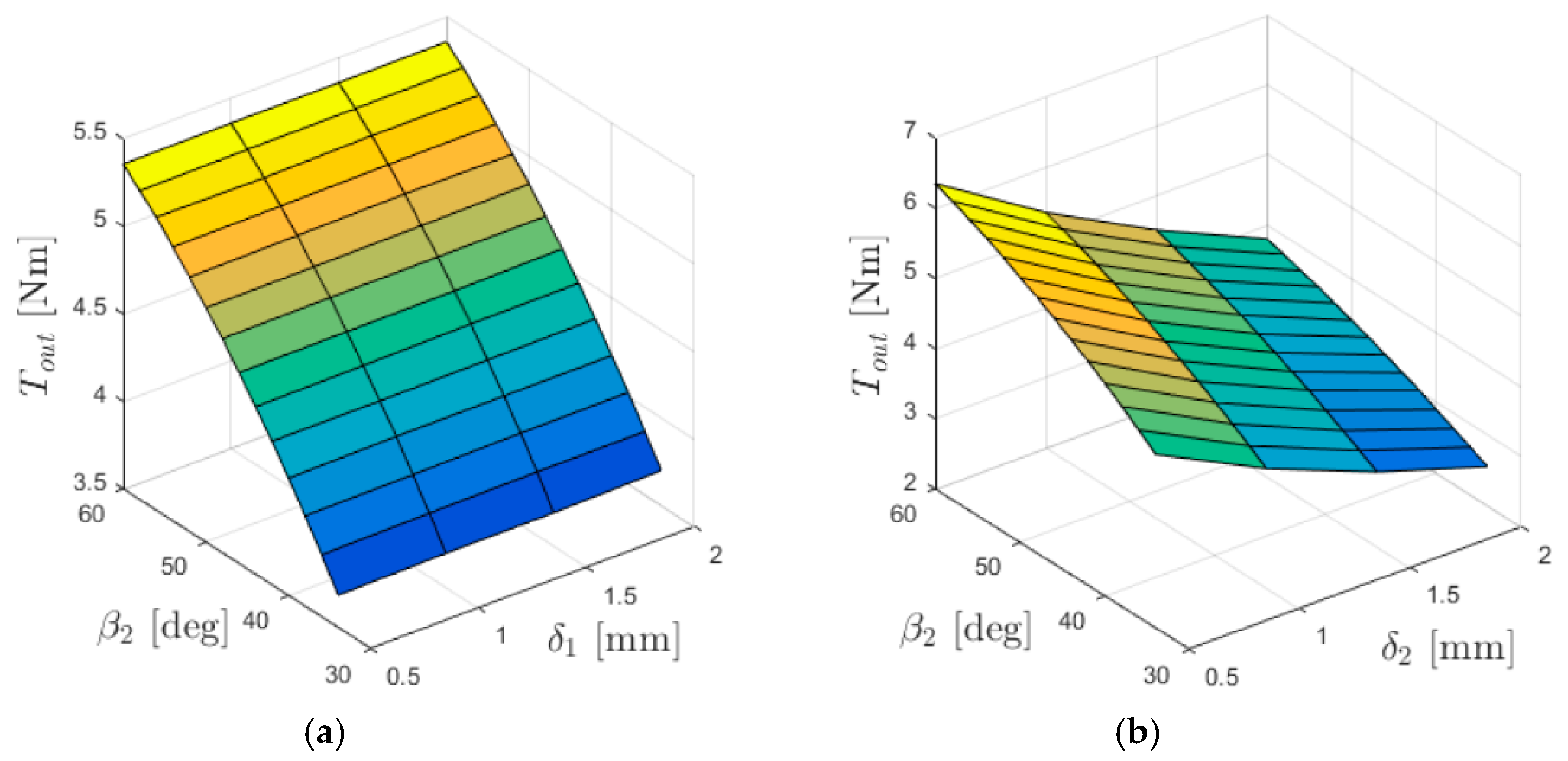

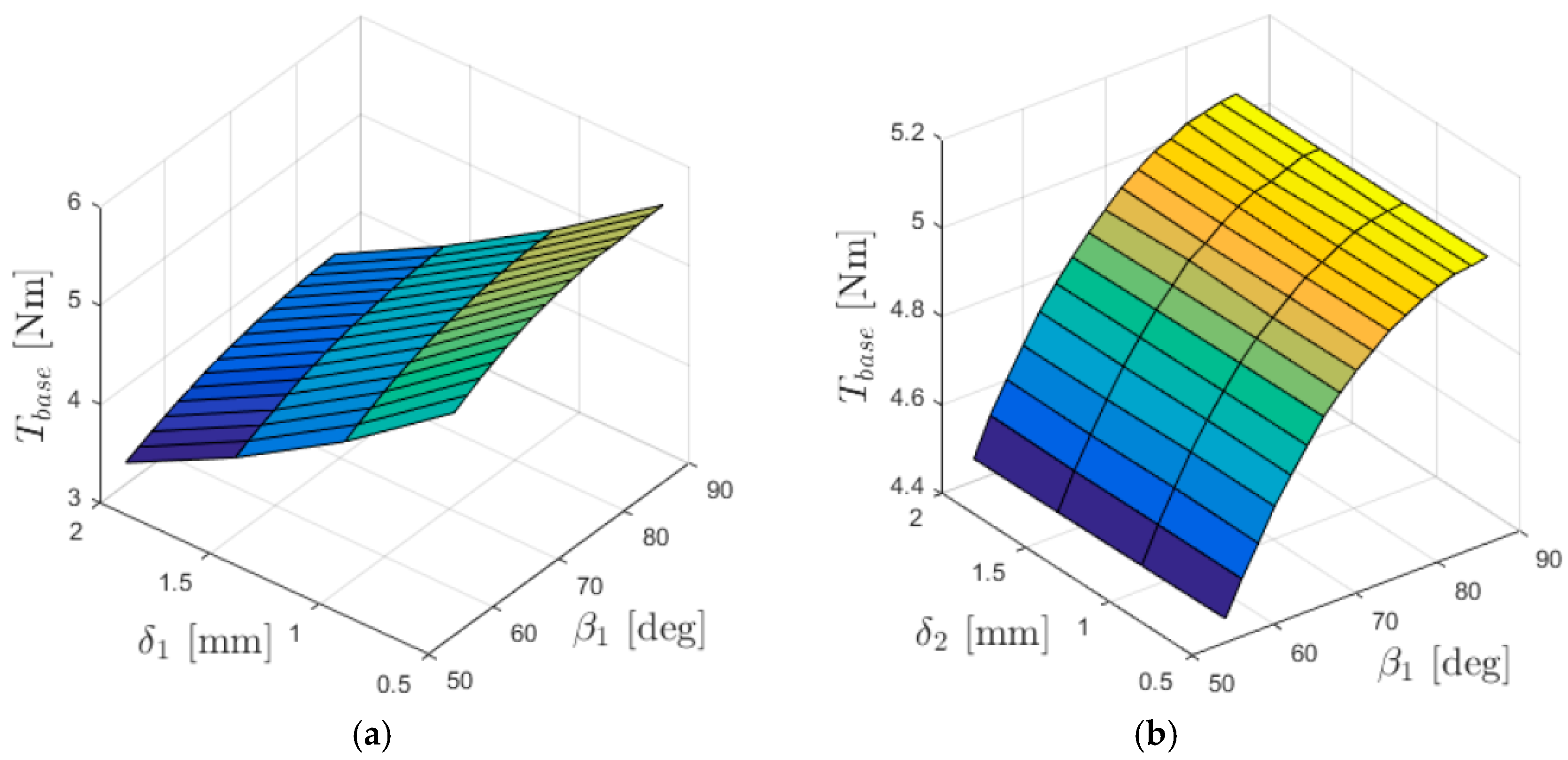

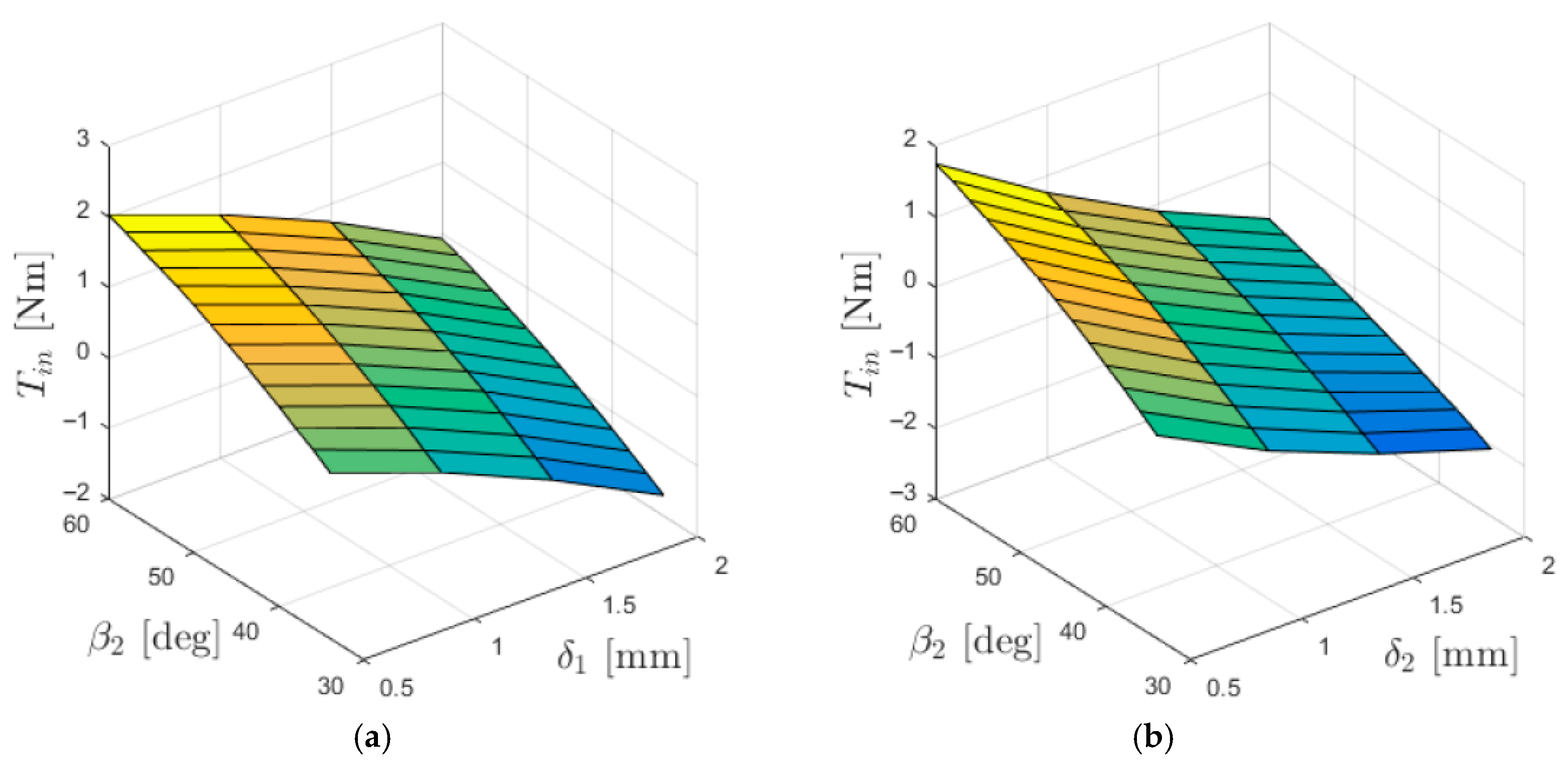

3.1. Examination of the Influence of Air Gap Lengths

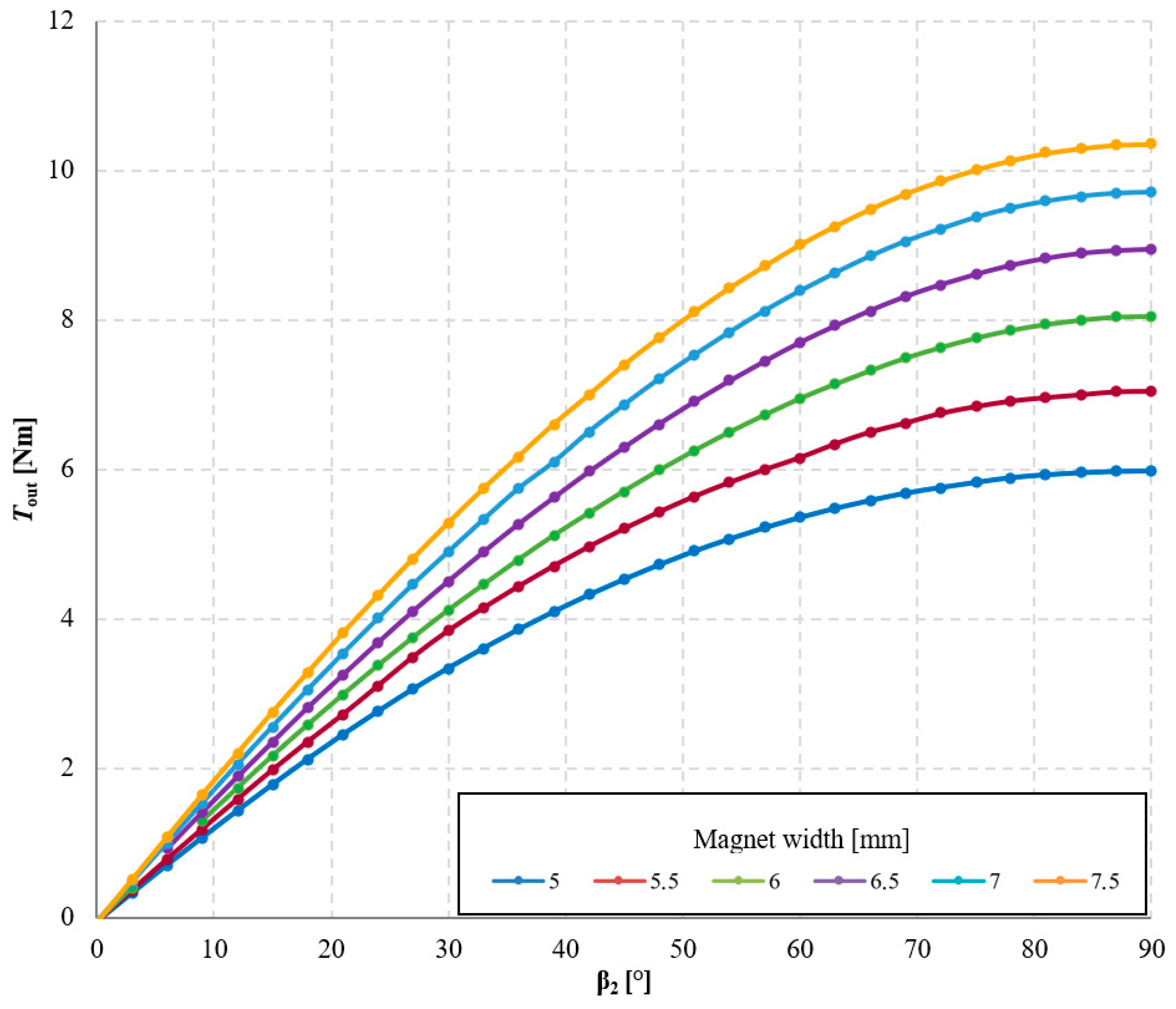

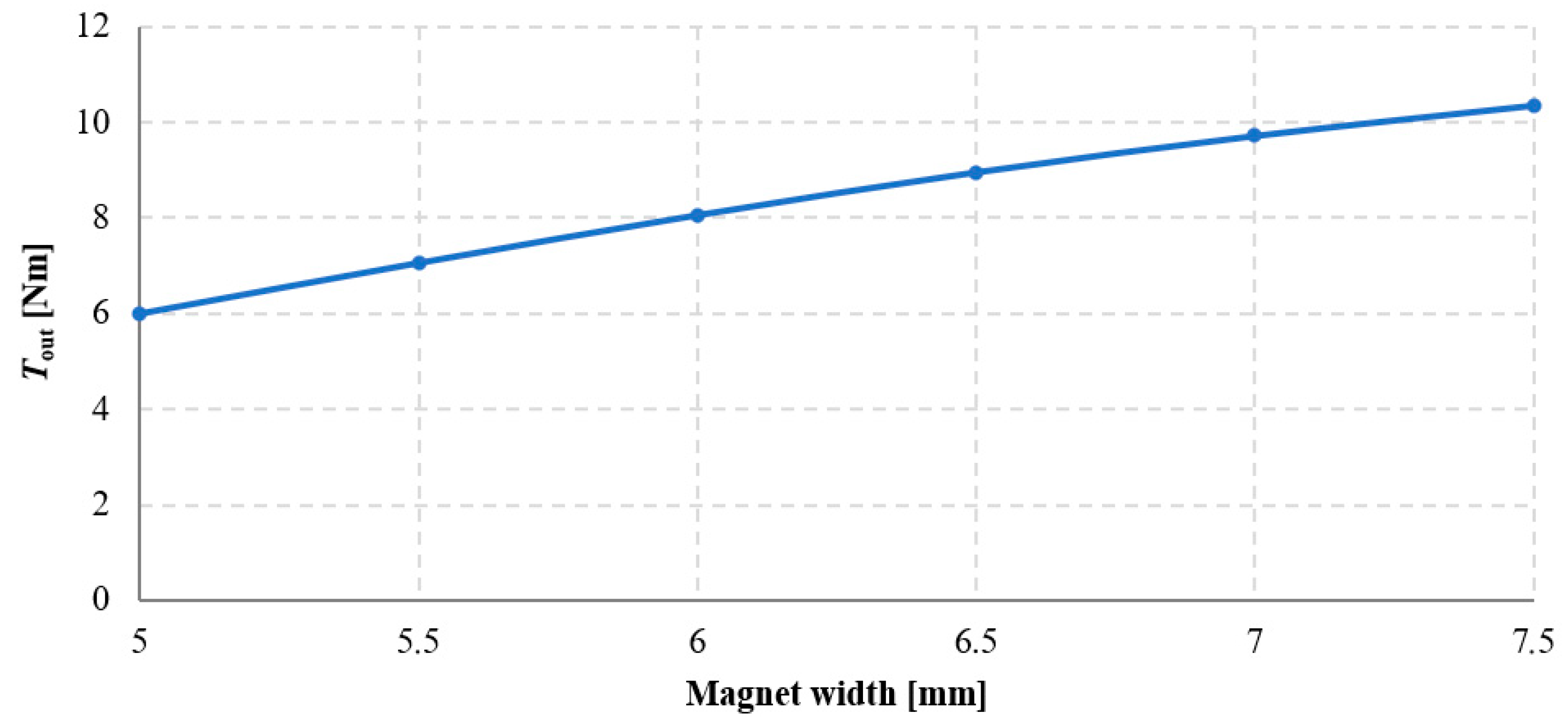

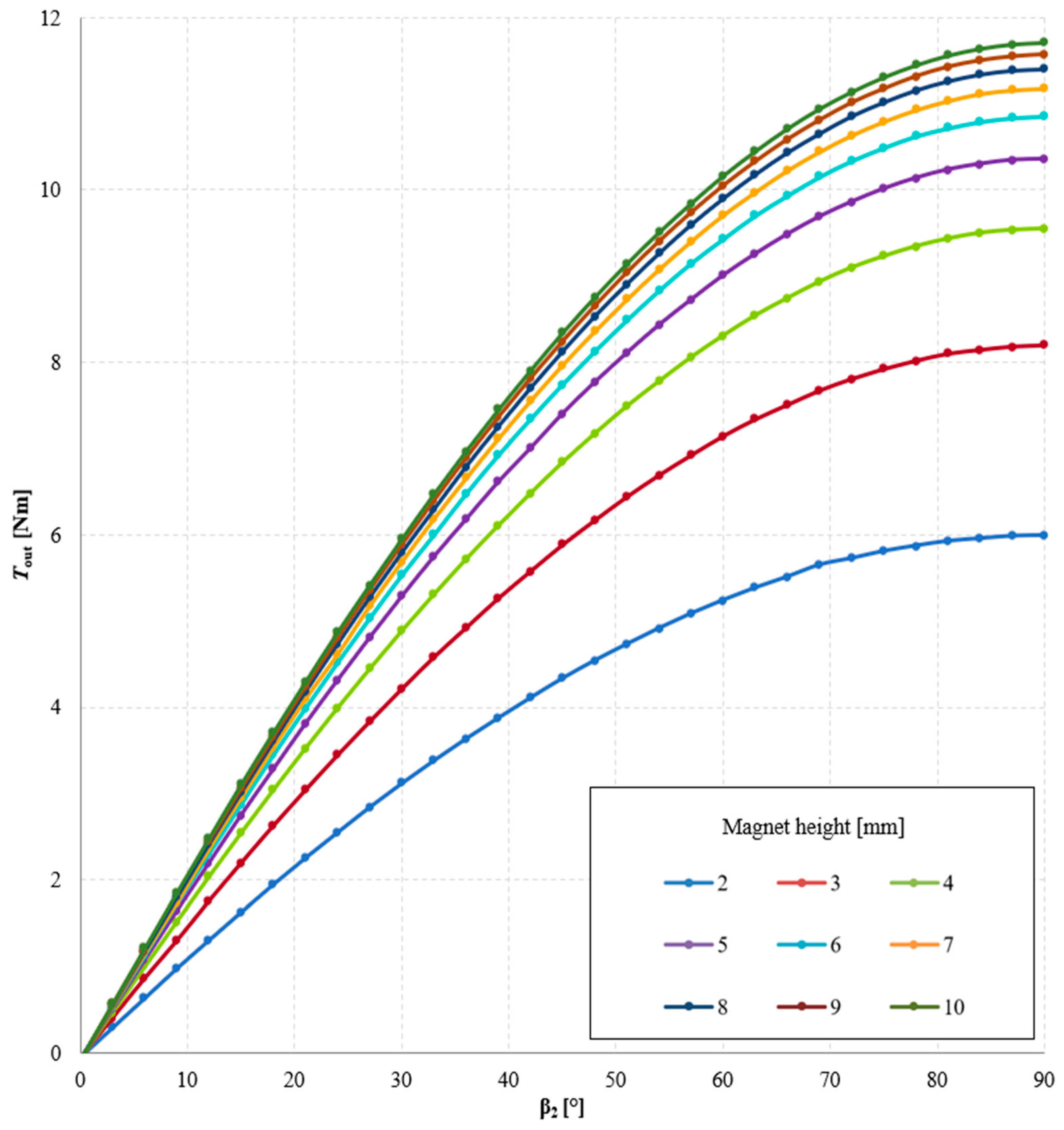

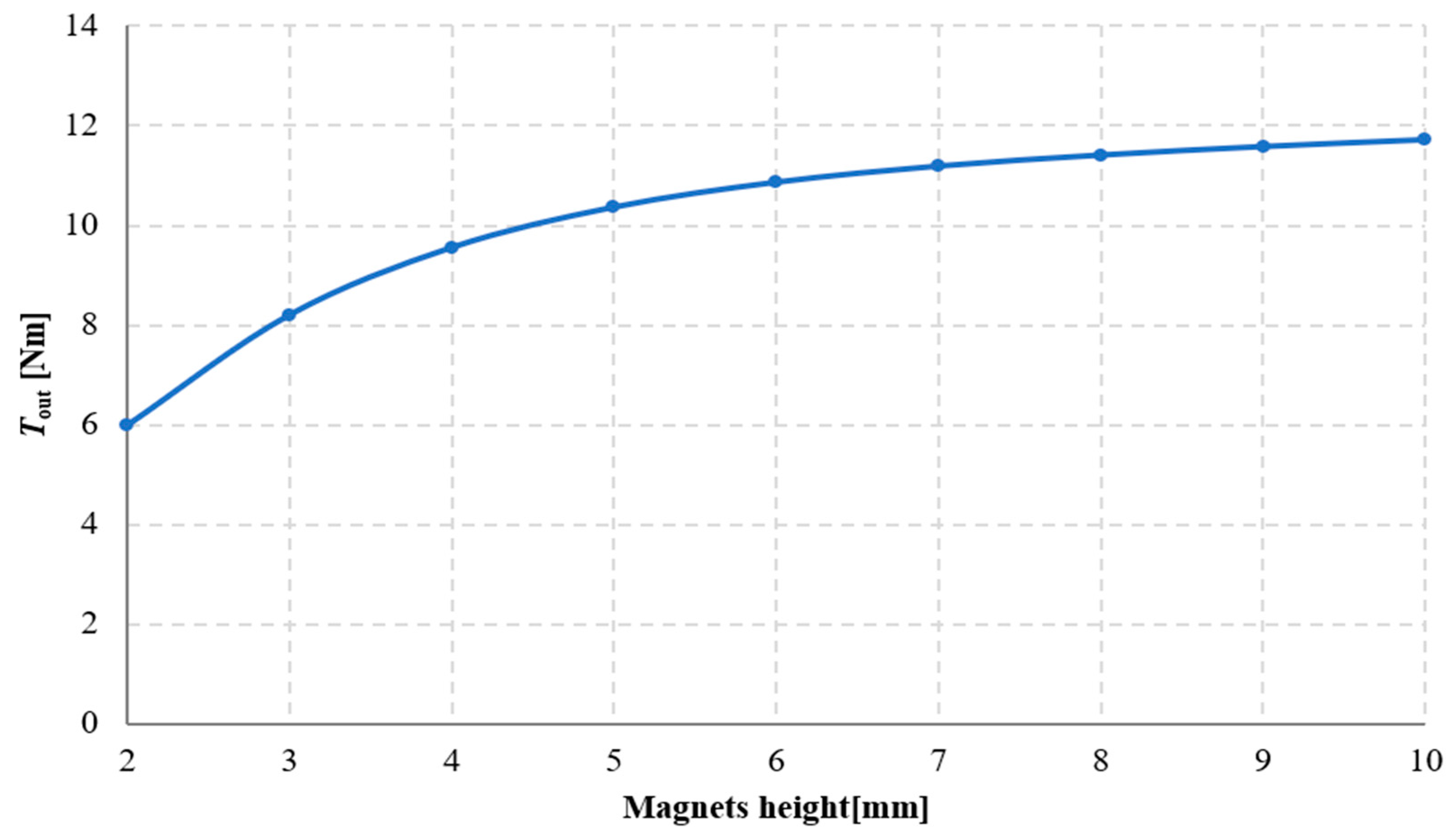

3.2. Investigation of the Influence of Magnet Dimensions

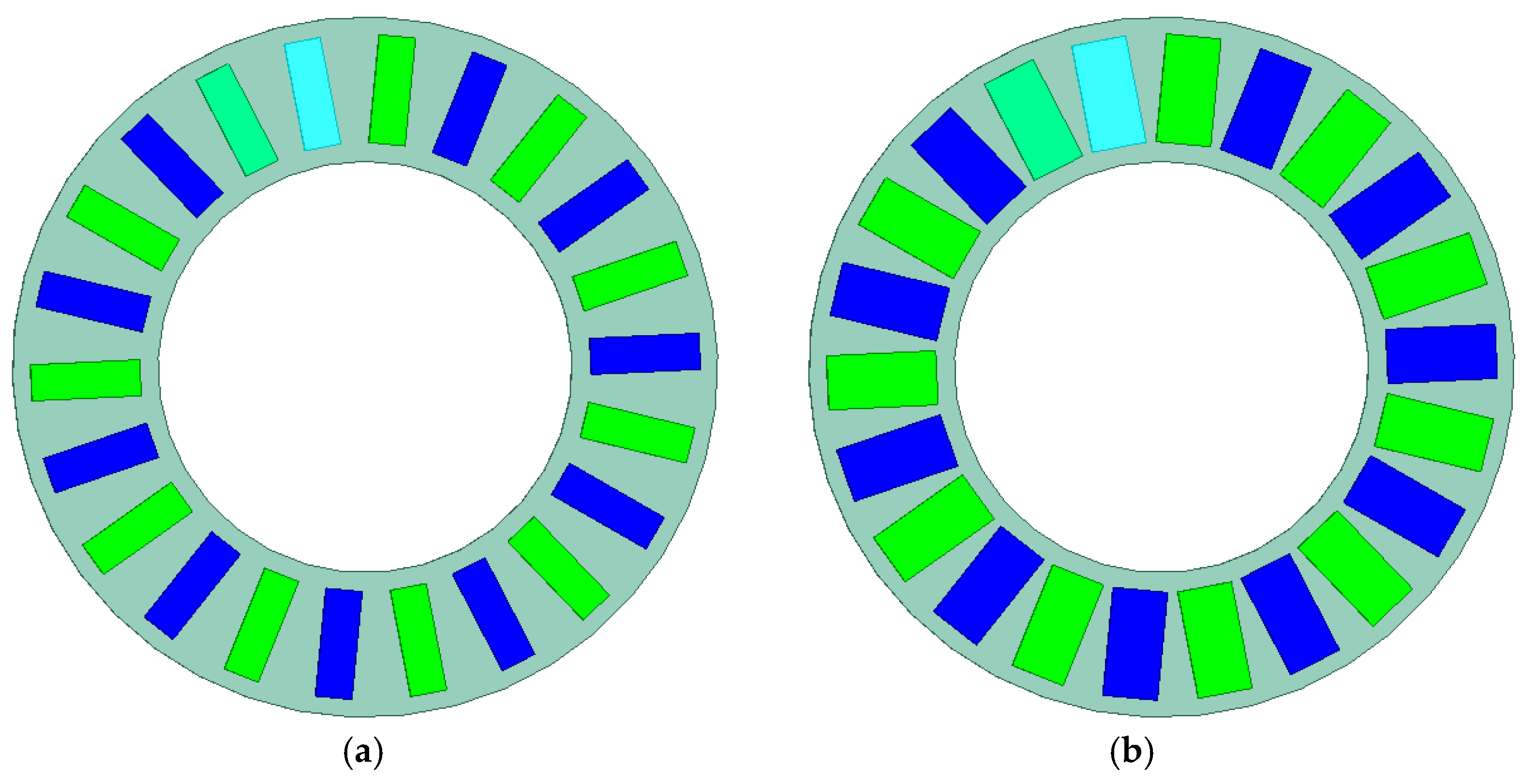

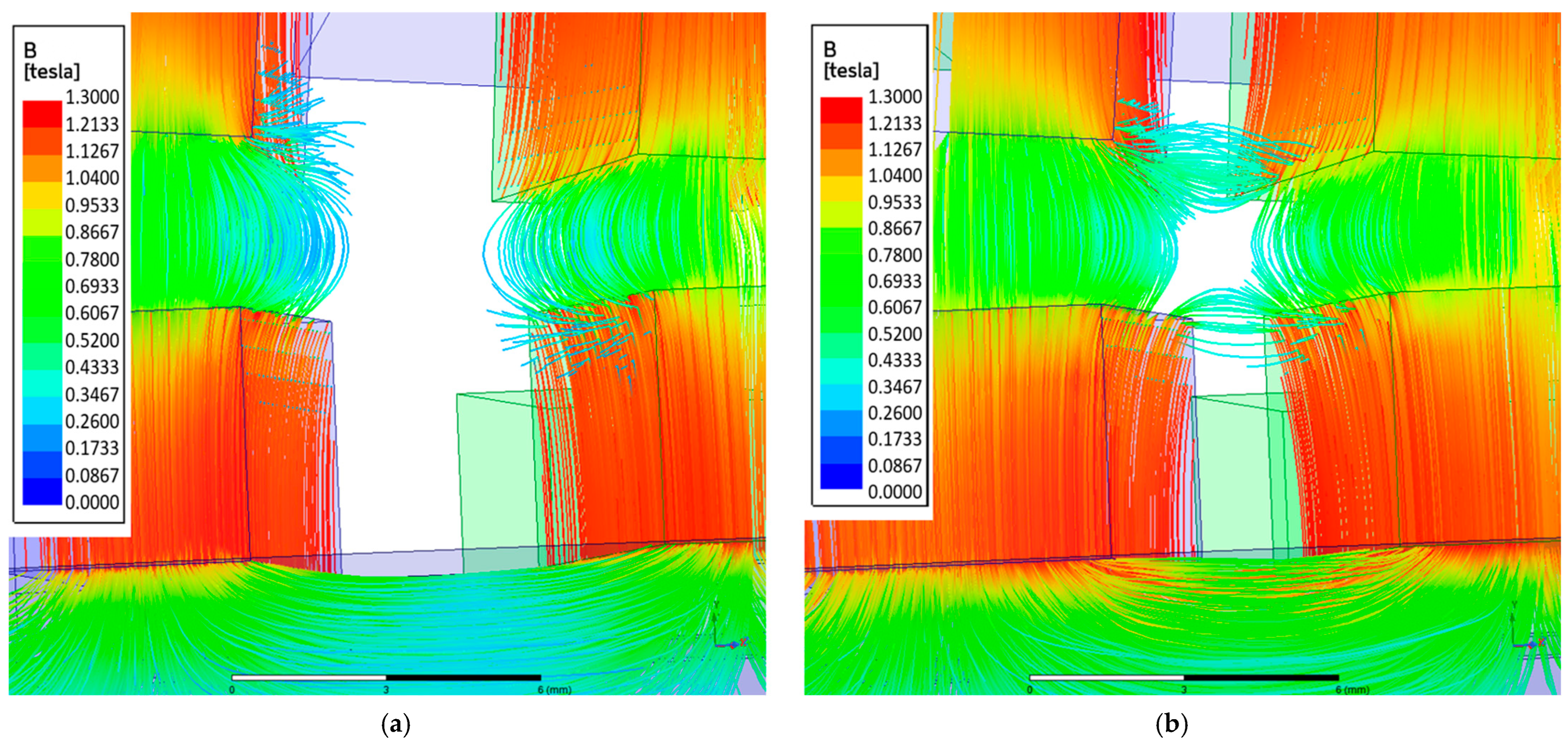

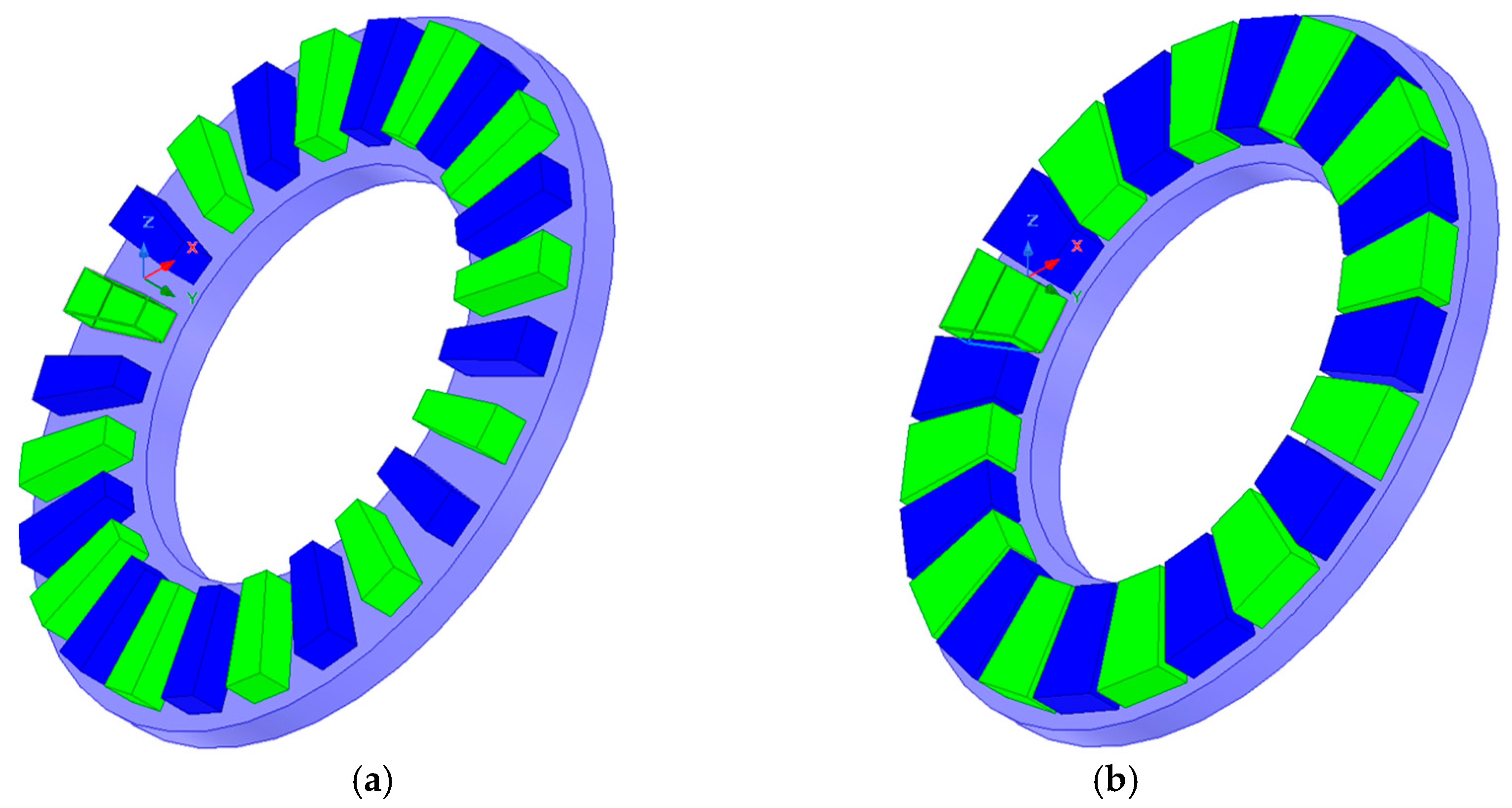

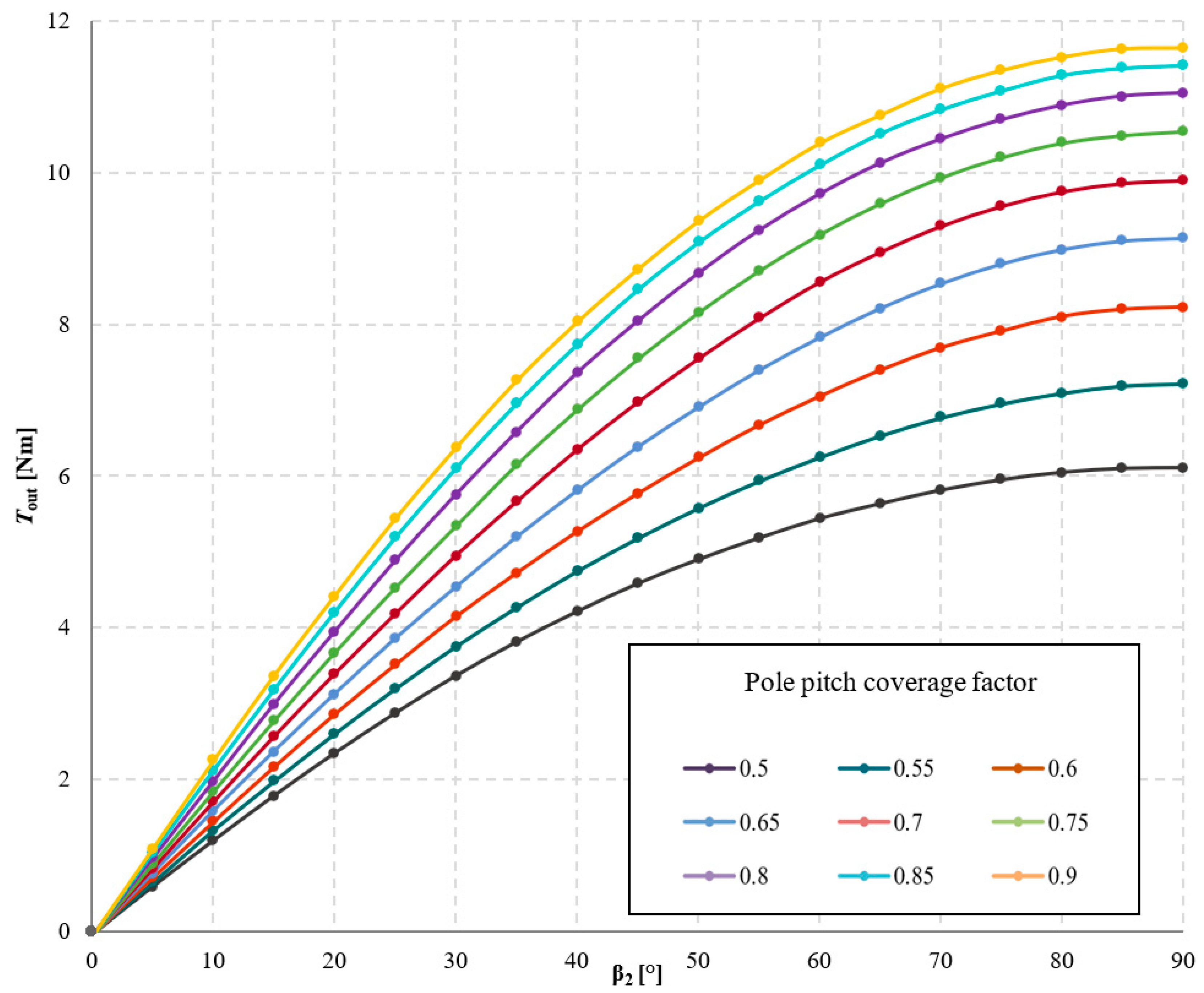

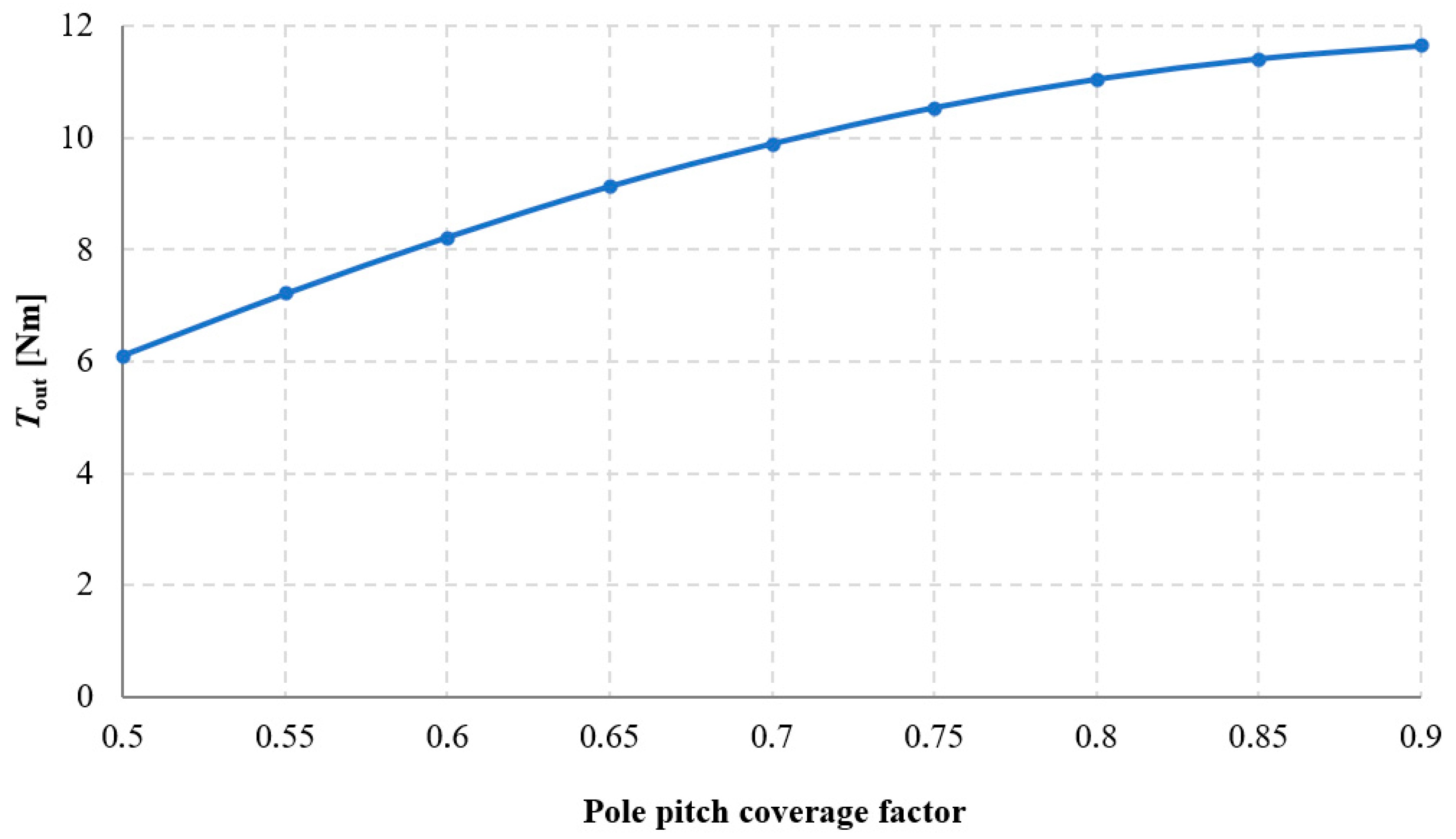

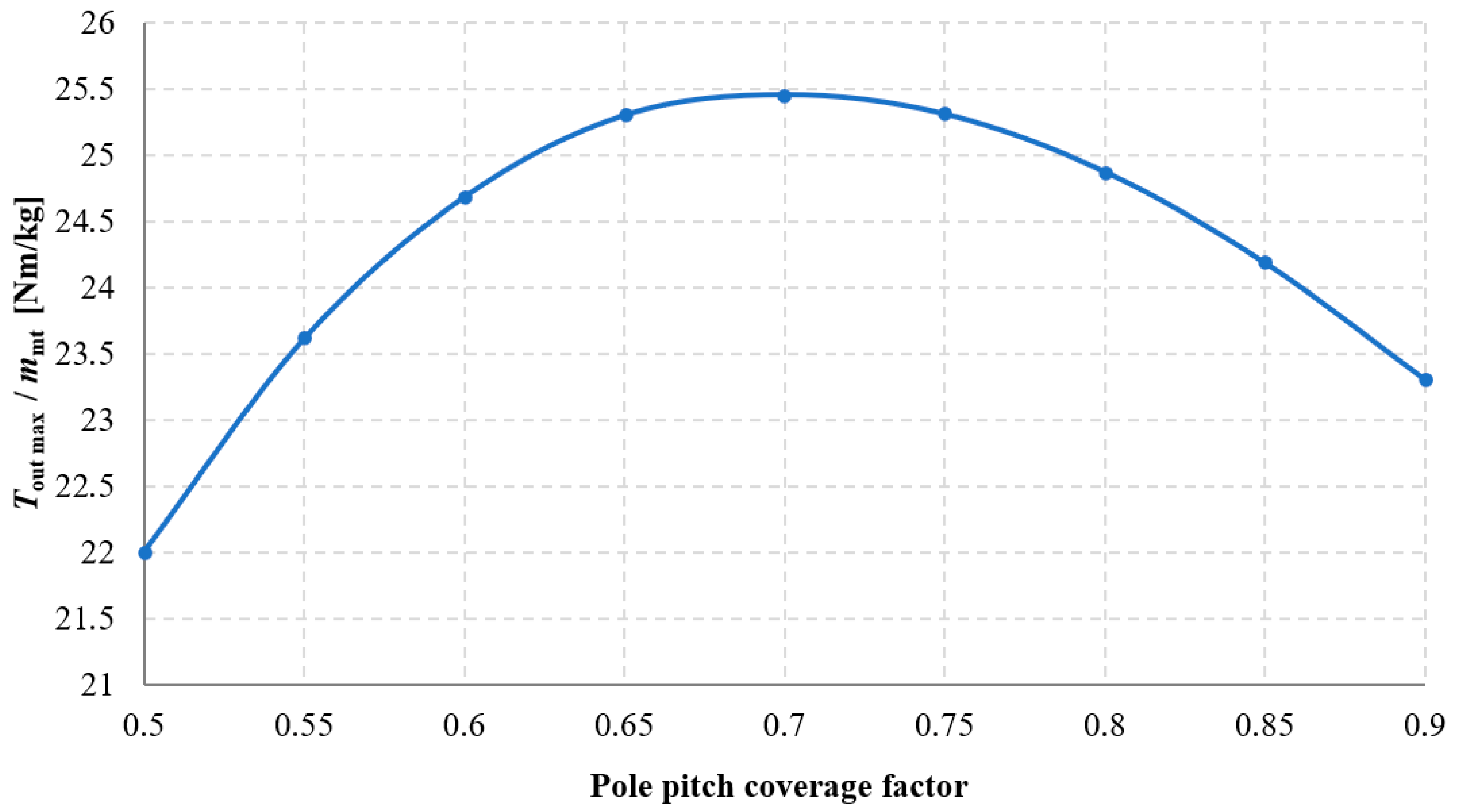

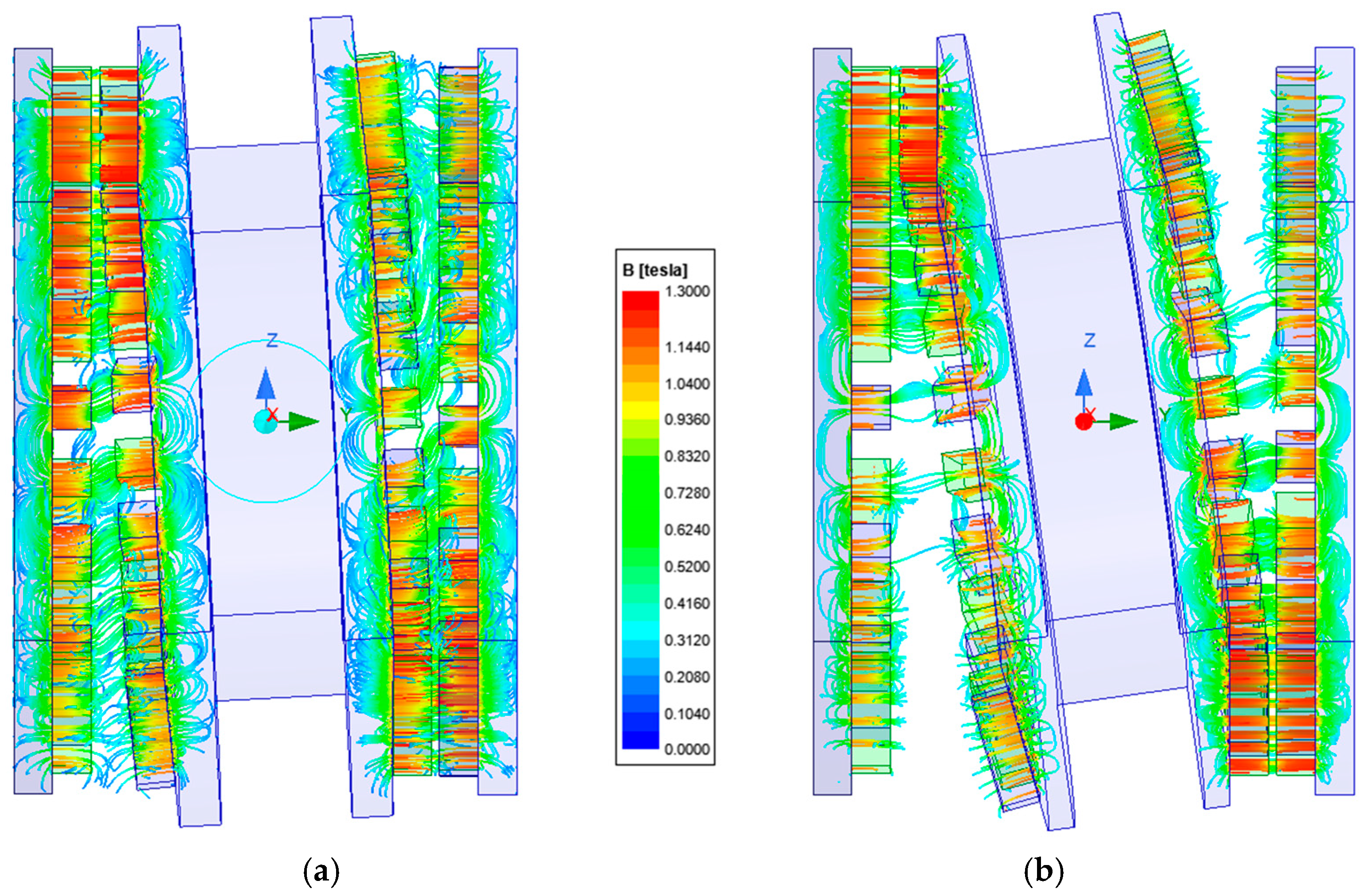

3.3. Investigation of the Influence of Magnets Shape

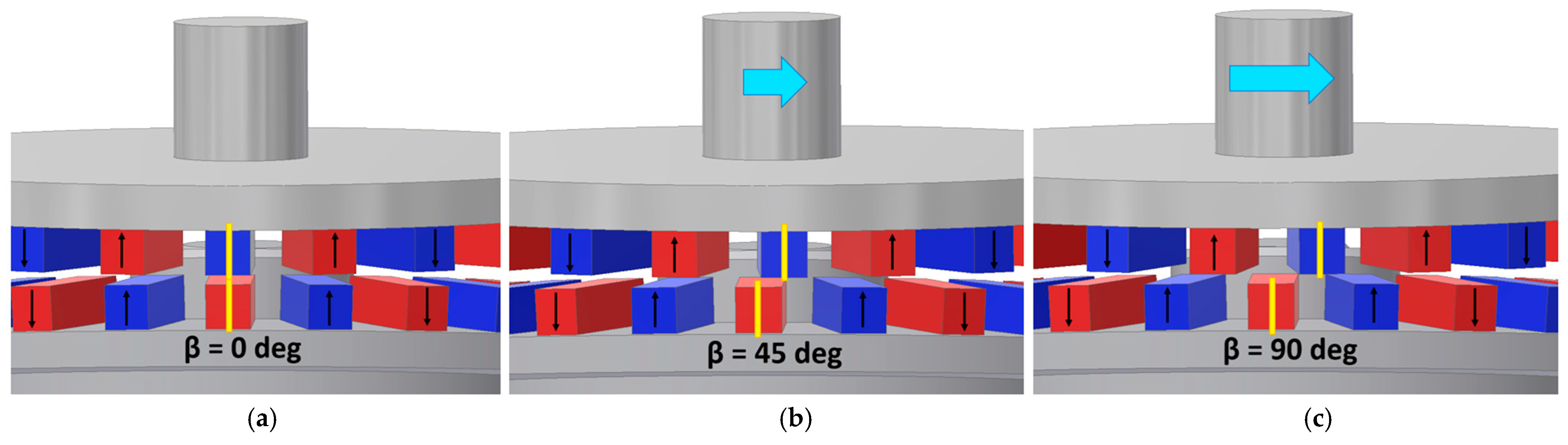

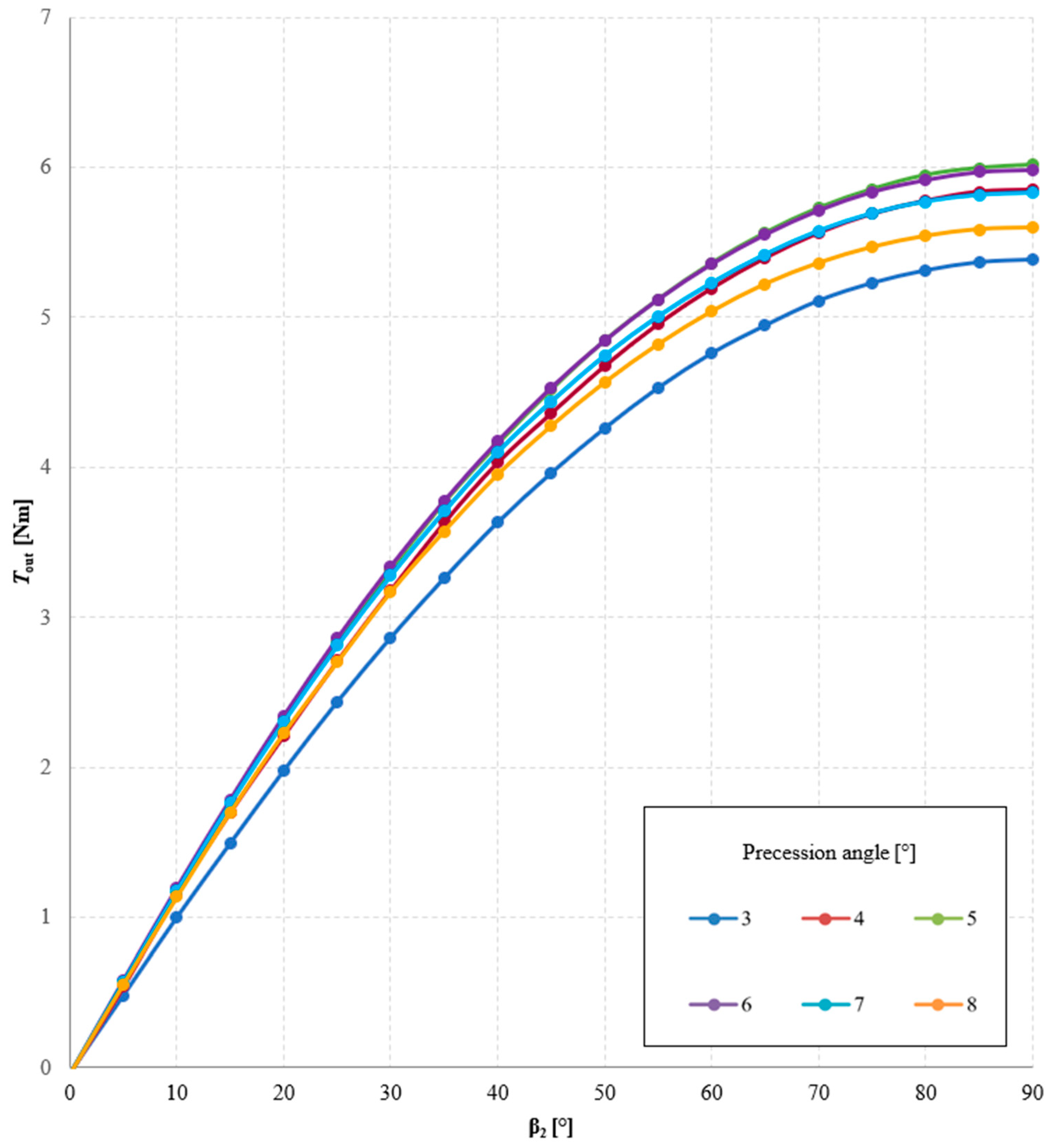

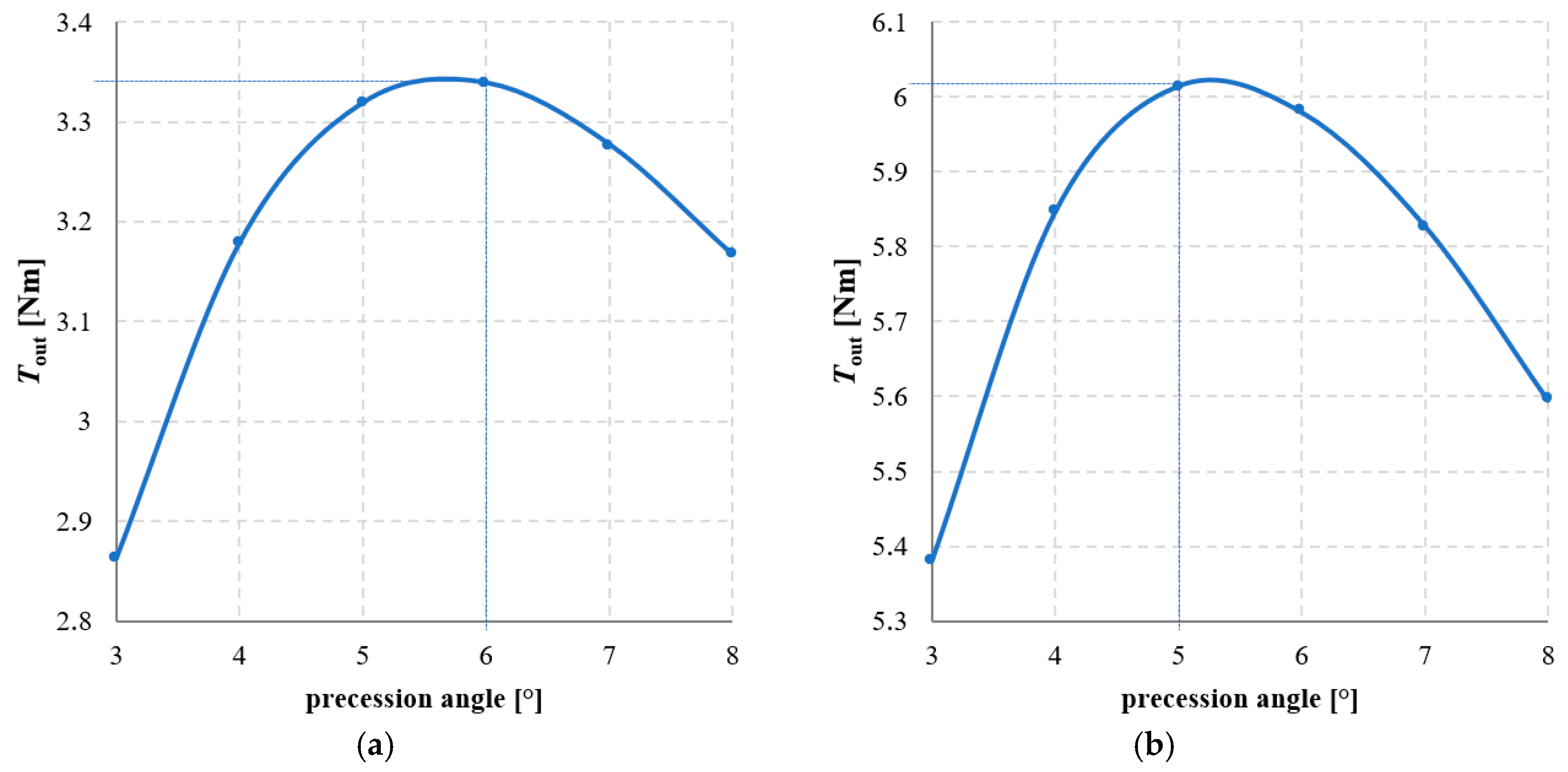

3.4. Investigation of the Influence of Precession Angle

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| FEM | Finite Element Method |

| MG | Magnetic gear |

| MPG | Magnetic precession gear |

References

- Crider, J.M.; Scott, D.S. An Inner Rotor Flux-Modulated Permanent Magnet Synchronous Machine for Low-Speed High-Torque Applications. IEEE Trans. Energy Convers. 2015, 30, 1247–1254. [Google Scholar] [CrossRef]

- Wang, Z.; Fu, W.; Song, J.; Chen, P.; Qiao, Z.; Bi, Y. Optimization of Gear Ratio and Torque Density of Magnetic Gears Based on Genetic Algorithm. In Proceedings of the 10th Frontier Academic Forum of Electrical Engineering (FAFEE2022), Xi’an, China, 25 August 2022; Dong, X., Yang, Q., Ma, W., Eds.; Springer Nature: Singapore, 2023; pp. 27–36. [Google Scholar]

- Molokanov, O.; Dergachev, P.; Kiruhin, V.; Kurbatov, P. Analyses and Experimental Validation of Coaxial Magnetic Planetary Gear. In Proceedings of the International Symposium on Electrical Apparatus and Technologies, SIELA—Proc., Bourgas, Bulgaria, 12–15 June 2024; IEEE Computer Society: Washington, DC, USA, 2014. [Google Scholar]

- Kucuk, F.; Mousavi, S. Development of a Novel Coaxial Magnetic Gear. In Proceedings of the International Conference Electrrical Machine, Drives Power Systems ELMA—Proc., Bourgas, Bulgaria, 3–6 June 2020; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2017; pp. 22–25. [Google Scholar]

- Jian, L.; Chau, K.T.; Gong, Y.; Jiang, J.Z.; Yu, C.; Li, W. Comparison of Coaxial Magnetic Gears with Different Topologies. IEEE Trans. Magn. 2009, 45, 4526–4529. [Google Scholar] [CrossRef]

- Khan, S.A.; Afsari, P.; Gardner, M.C. Comparison between Flux Angle Mapping and Cycloidal Magnetic Gears for High Gear Ratio Applications. In Proceedings of the IEEE Energy Conversion Conference and Expo ECCE—Proc., Phoenix, AZ, USA, 20–24 October 2024; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2024; pp. 5337–5342. [Google Scholar]

- Kołodziej, J.; Gabor, R.; Kowol, M.; Łukaniszyn, M. Theoretical and Experimental Comparison of Gear Systems: Planetary Mechanical Transmission and Coaxial Magnetic Gear. Bull. Pol. Acad. Sci. Tech. Sci. 2024, 72, 150334. [Google Scholar] [CrossRef]

- Nicolas, W. Frank; Siavash Pakdelian; Hamid, A. Toliyat Passive Suppression of Transient Oscillations in the Concentric Planetary Magnetic Gear. IEEE Trans. Energy Convers. 2011, 26, 933–939. [Google Scholar] [CrossRef]

- Frank, N.W.; Pakdelian, S.; Toliyat, H.A. A Magnetic Gear with Passive Transient Suppression Capability. In Proceedings of the IEEE Electric Ship Technologies Symposium, Alexandria, VA, USA, 10–13 April 2011; ESTS: Exeter, UK, 2011; pp. 326–329. [Google Scholar]

- Pakdelian, S.; Frank, N.W.; Toliyat, H.A. Damper Windings for the Magnetic Gear. In Proceedings of the IEEE Energy Conversion Congress and Exposition: Energy Conversion Innovation Clean Energy Future, ECCE, Proc., Phoenix, AZ, USA, 7–22 September 2011; pp. 3974–3981. [Google Scholar]

- Bai, J.; Liu, Y.; Lin, J.; Song, Z.; Wang, W. Analysis of Torque Characteristics of Magnetic Gears. In Proceedings of the International Conference on Electrical Machines and Systems, ICEMS, Berlin, Germany, 2–5 September 2014; Institute of Electrical and Electronics Engineers Inc.: New York, NY, USA, 2014; pp. 2164–2169. [Google Scholar]

- Hao, X.; Hao, W.; Wang, Q.; Pan, D. Free Vibration of Magnetic Gear with Intersecting Axes. Prog. Electromagn. Res. C 2020, 104, 187–199. [Google Scholar] [CrossRef]

- Macyszyn, L.; Jedryczka, C.; Mysinski, M. Analysis of a Two-Stage Magnetic Precession Gear Dynamics. Energies 2023, 16, 4484. [Google Scholar] [CrossRef]

- Macyszyn, Ł.; Myszkowski, A.; Staniek, R.; Pabiszczak, S. Two-Stage Precession Type Gear: Design, Geometric and Kinematic Analysis; American Society of Mechanical Engineers: Washington, DC, USA, 2018. [Google Scholar]

- Macyszyn, Ł.; Jedryczka, C.; Staniek, R. Design and Finite Element Analysis of Novel Two-Stage Magnetic Precession Gear. Int. J. Simul. Model. 2019, 18, 586–595. [Google Scholar] [CrossRef] [PubMed]

- Coulomb, J. A Methodology for the Determination of Global Electromechanical Quantities from a Finite Element Analysis and Its Application to the Evaluation of Magnetic Forces, Torques and Stiffness. IEEE Trans. Magn. 1983, 19, 2514–2519. [Google Scholar] [CrossRef]

- Macyszyn, L.; Jedryczka, C.; Myszkowski, A. Simulation and Experimental Investigation of a Two-Stage Magnetic Precession Gear. Energies 2021, 14, 1838. [Google Scholar] [CrossRef]

- Ionel, D.M.; Eastham, J.F.; Miller, T.J.E.; Demeter, E. Design Considerations for Permanent Magnet Synchronous Motors for Flux Weakening Applications. IEE Proc. -Electr. Power Appl. 1998, 145, 435–440. [Google Scholar] [CrossRef]

- Huang, W.; Bettayeb, A.; Kaczmarek, R.; Vannier, J. Optimization of Magnet Segmentation for Reduction of Eddy-Current Losses in Permanent Magnet Synchronous Machine. IEEE Trans. Energy Convers. 2010, 25, 381–387. [Google Scholar] [CrossRef]

- Knypiński, Ł. Optymalizacja Silników O Magnesach Trwałych Na Podstawie Polowoobwodowego Modelu Zjawisk Elektomagnetycznych; Rozprawa Doktorska, Politechnika Poznańska: Poznań, Poland, 2016. [Google Scholar]

- Korta, J.; Giergiel, M.; Uhl, T. Koncepcja Koła Magnetycznego. Model. Inż. 2011, 41, 173–180. [Google Scholar]

- Bolkowski, S. Elektrotechnika 4. Podręcznik; Wydawnictwa Szkolne i Pedagogiczne: Warsaw, Poland, 1995; ISBN 83-02-05981-1. [Google Scholar]

- Gieras, J.; Frydrychowicz, G.; Józefowicz, W. Projektowanie Silników Prądu Stałego Małej Mocy o Magnesach Trwałych Wspomagane Maszyną Cyfrową. Przegląd Elektrotechniczny 1978, 4, 152–156. [Google Scholar]

- Pyrhönen, J.; Jokinen, T.; Hrabovcova, V. Design of Rotating Electrical Machines; Wiley: Hoboken, NJ, USA, 2008; ISBN 978-0-470-69516-6. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Macyszyn, L.; Jedryczka, C.; Mysinski, M. Analysis of a Two-Stage Magnetic Precession Gear Exploiting 3D Finite Element Method. Materials 2025, 18, 5277. https://doi.org/10.3390/ma18235277

Macyszyn L, Jedryczka C, Mysinski M. Analysis of a Two-Stage Magnetic Precession Gear Exploiting 3D Finite Element Method. Materials. 2025; 18(23):5277. https://doi.org/10.3390/ma18235277

Chicago/Turabian StyleMacyszyn, Lukasz, Cezary Jedryczka, and Michal Mysinski. 2025. "Analysis of a Two-Stage Magnetic Precession Gear Exploiting 3D Finite Element Method" Materials 18, no. 23: 5277. https://doi.org/10.3390/ma18235277

APA StyleMacyszyn, L., Jedryczka, C., & Mysinski, M. (2025). Analysis of a Two-Stage Magnetic Precession Gear Exploiting 3D Finite Element Method. Materials, 18(23), 5277. https://doi.org/10.3390/ma18235277