Development and Implementation of a Defect Detection Model for Microstructures Using Image Processing Methods

Abstract

1. Introduction

- AI enables the automation of microstructure analysis processes with high accuracy and repeatability,

- Convolutional neural networks such as ResNet, UNet, and YOLO are used in image classification, as well as in the segmentation and detection of microstructural objects,

- Previous research has focused primarily on general phase analysis, pore detection, discontinuities, and the classification of correct/incorrect structures, while the issue of precise automatic martensite detection is relatively rare and remains a research challenge.

2. Materials and Methods

2.1. Methods

- ResNet (short for Residual Network) is one of the most influential deep neural network architectures, proposed [27]. This model significantly improved image classification performance in the ImageNet competition, and its main innovation was the introduction of so-called residual connections, which allow for training much deeper networks than previously possible [43]. In traditional deep neural networks, increasing the number of layers often led to the gradient vanishing problem—errors computed during backpropagation did not efficiently reach earlier layers, resulting in degraded training quality. ResNet addresses this problem by using residual blocks, which contain a direct connection (so-called skip connection) between the input and output of the block. This allows the model to learn the residual function F(x) = H(x) − x instead of the mapping H(x) directly, which significantly simplifies the optimization process [44]. Each residual block typically contains two or three convolutional layers and an addition operation that connects the original input with the output processed by the network layers. This structure allows for “shortcuts” in information flow, preserving the backscatter signal even with very deep architectures [44]. The original paper proposed several ResNet variants, differing in the number of layers: ResNet-18 and ResNet-34: networks with a shallow structure, with blocks containing two convolutional layers each; recommended for limited data or computational power. ResNet-50, ResNet-101, and ResNet-152: deeper versions that use so-called bottleneck blocks—three-layer blocks (1 × 1—3 × 3—1 × 1), allowing for a reduction in the number of parameters without sacrificing accuracy. In the context of this study, which aims to detect the presence of martensite in microscopic images, it was crucial to select a ResNet version that provides an appropriate compromise between depth, generalization ability, and computational cost. Using very deep variants, such as ResNet-101 or ResNet-152, could lead to overfitting due to the limited size and diversity of the available dataset [45]. On the other hand, too shallow networks (e.g., ResNet-18) may not be flexible enough to capture subtle structural differences between healthy microstructure and regions containing martensite. Therefore, we used ResNet50, an intermediate variant that provides a balance between architectural complexity and its generalization ability. This network contains 50 layers and uses classical residual blocks with two 3 × 3 convolutions, making it deep enough to detect complex patterns in image data, but not so complex that it requires a very large training set or hardware resources [45]. In the present study, ResNet was used to classify fragments of microscopic images as containing or not containing martensite. This architecture serves as a benchmark for more complex segmentation (UNet) and detection (YOLO) models, enabling comparison of results in terms of accuracy, precision, sensitivity, and inference time.

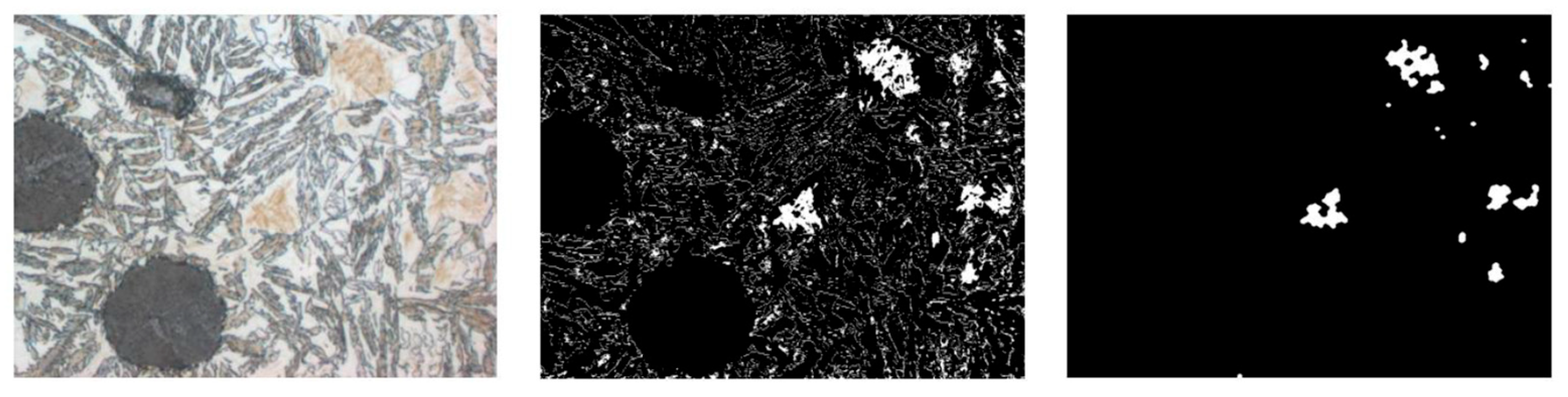

- UNet is a convolutional neural network architecture designed for precise semantic image segmentation, i.e., assigning a label to each input pixel. It was first presented in [23] as a tool for analyzing microscopic images in medicine [46]. Due to its versatility, efficiency, and ability to operate with limited datasets, UNet quickly found applications in many fields, including materials science [47]. The UNet architecture consists of two main parts: a contracting path and an expanding path. The contracting part operates analogously to classical convolutional networks—it consists of successive convolutional layers and pooling operations that reduce the image dimension while simultaneously increasing the network’s perceptual range. The goal of this part is to extract features with increasingly higher levels of abstraction. Then, in the expanding path, the image is successively restored to its original resolution using convolutional transposition operations (so-called upconvolution). At key points in the network, skip connections are used to copy feature maps from the corresponding levels of the shrinking path and connect them to the expansion layers. This allows UNet to combine global information (context) with local information (structure details), significantly improving segmentation quality, especially for fine, irregular structures [48]. UNet was designed for situations where small datasets are available, making it particularly attractive for materials science tasks, where labeled microscopic images are difficult and time-consuming to acquire [46]. The network can learn to effectively locate objects of interest even with a limited number of samples, as demonstrated in numerous publications on the segmentation of grains, pores, and non-metallic inclusions in metal microstructures [47]. In the context of this work, UNet was applied to segment areas containing martensite in microscopic images of ADI cast iron. This detection involves not only classifying the entire image but also pinpointing specific structural fragments where the defect is present. Thanks to its architecture, UNet is ideally suited for this task—it allows for high-precision marking of the contours and area occupied by the defect, even if its occurrence is irregular and localized. The advantage of using UNet is also the possibility of obtaining results in the form of segmentation masks, which can be subjected to further quantitative analysis—e.g., calculation of the area occupied by martensite, its shape, density or distribution relative to other phases. This type of data is extremely valuable in the context of quality control and prediction of mechanical properties of castings [47].

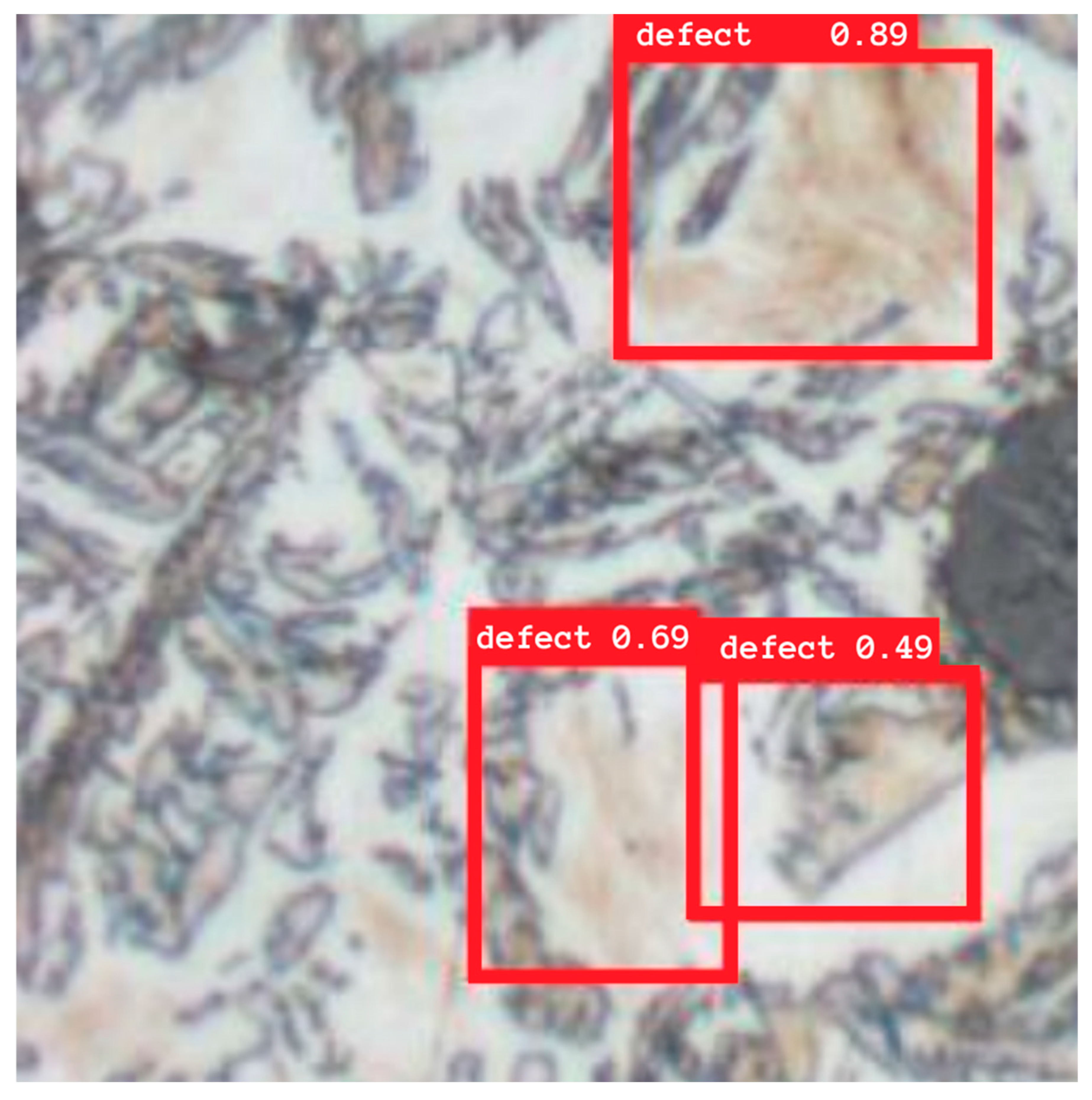

- YOLO (You Only Look Once) is a modern neural network architecture designed for fast object detection in images. Unlike classical approaches that analyze images in stages (e.g., region proposals, classification, localization), YOLO processes images end-to-end, performing detection and classification in a single pass through the network. This approach significantly increases performance and makes the model ideal for tasks requiring real-time operation, such as autonomous driving, monitoring, or industrial inspection [49].

- The coordinates of a bounding box;

- The probability of object occurrence;

- The object class [50].

- YOLOv1–v3: initial implementations, increasingly accurate and faster, but limited in localizing small objects.

- YOLOv4 (2020): significant improvement in accuracy thanks to the use of improved components such as CSPDarkNet53, PANet, and Spatial Pyramid Pooling.

- YOLOv5: not part of the official YOLO line, but one of the most commonly used in practice due to its availability, speed, and ease of implementation.

- YOLOv6–YOLOv8: versions based on newer network concepts and improved support for a variety of applications, including segmentation and classification in a single model [51].

2.2. Dataset

- Austenitizing at 820–950 °C;

- Isothermal hardening in the range of 250–400 °C for 0.5–4 h [1].

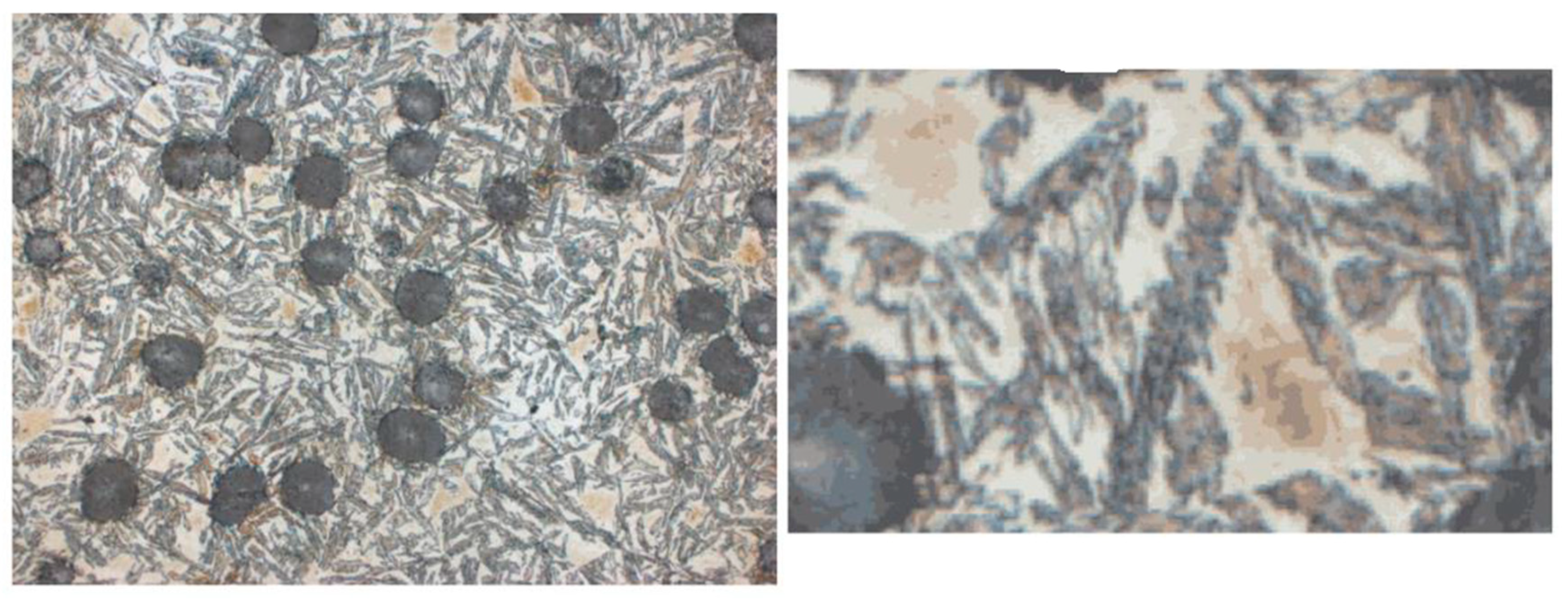

- Upper ausferrite (T > 350 °C): higher austenite content, feathery ferrite;

- Lower ausferrite (T < 350 °C): dominance of acicular ferrite, smaller austenite areas [1].

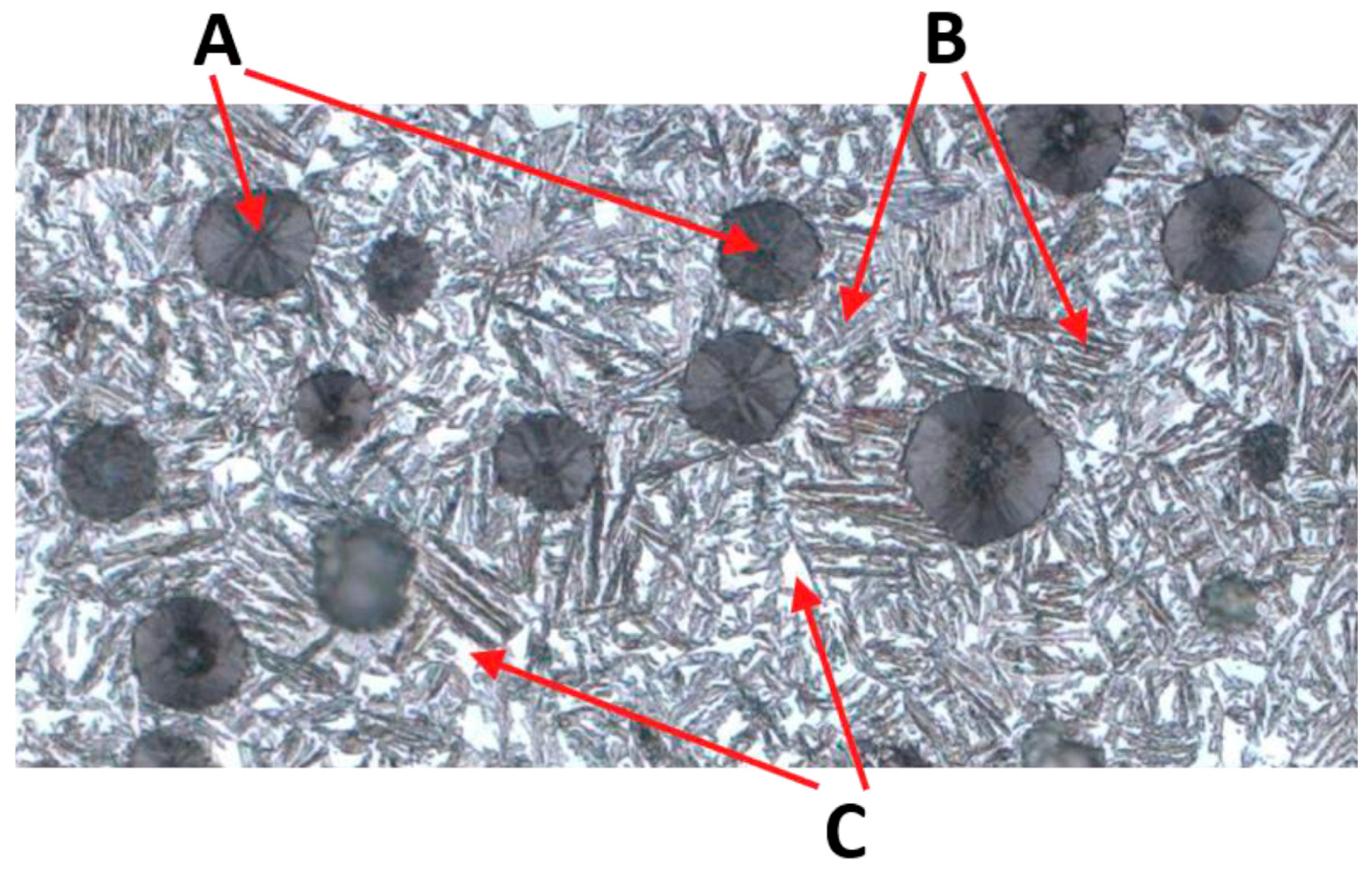

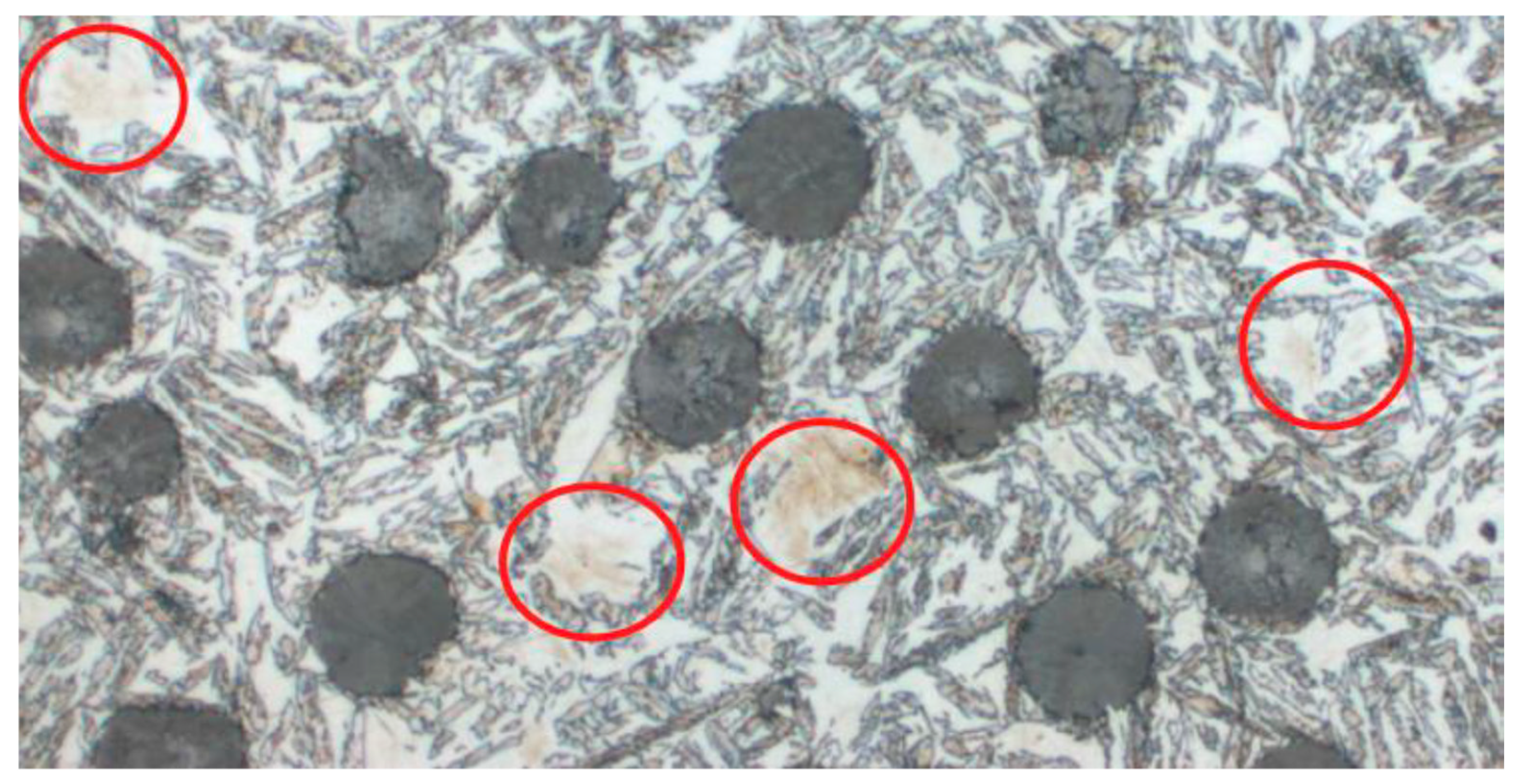

- It appears as sharply pointed needles or diamond-shaped precipitates, often forming distinct zigzag structures.

- Color: red, ash-gray, navy blue, or almost black.

- Distribution: It can be dispersed or form clusters within former austenite regions [2].

- It increases hardness at the expense of ductility.

- It causes brittleness and susceptibility to cracking.

2.3. Experiments

- ResNet—image classification (information about the presence or absence of a defect),

- UNet—semantic segmentation (precise delineation of defect areas),

- YOLO—object detection (localization of defects in the form of bounding boxes).

Experiment Preparation

- The training set included the majority of samples and was used to train the models;

- The validation set served as the basis for selecting hyperparameters and monitoring the learning process;

- The test set contained previously unused data and allowed for the final evaluation of model quality.

3. Results

3.1. ResNet Model Results

3.2. UNet Model Results

3.3. YOLO Model Results

3.4. Comparison of Model Results

4. Discussion

- ResNet is best suited for the quick classification of large image sets and filtering out defect-free fragments.

- UNet is effective in precise laboratory analysis, where accurate information about the defect’s shape and size is important.

- YOLO provides high-time efficiency and reliable defect localization, making it attractive for industrial applications.

5. Conclusions

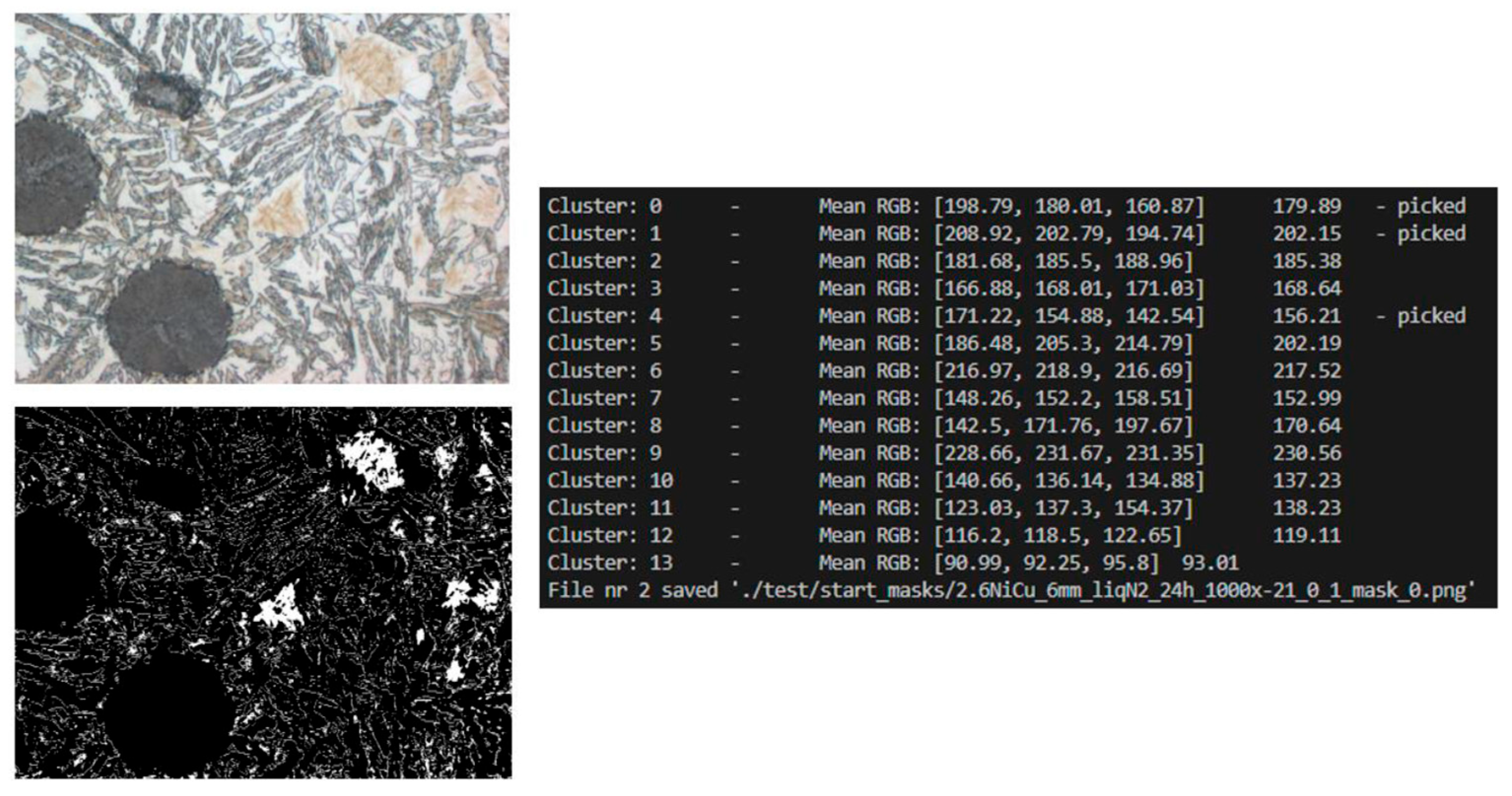

- The preparation of an original dataset including microstructure images along with their corresponding binary masks and detection labels. This process involved division of large images into smaller fragments, application of k-means clustering, morphological operations, and data augmentation, which ensured an adequate number and diversity of samples;

- The implementation of three neural network architectures adapted to the specifics of the task: ResNet as a binary classifier, UNet as a segmentator, and YOLO for the detection of rectangular bounding boxes;

- Conducting the full process of learning and validation using the Python environment and deep learning libraries, including hyperparameter selection, saving model checkpoints, and monitoring result quality in successive epochs;

- The qualitative and quantitative analysis of the obtained results based on a set of metrics (accuracy, precision, recall, F1-score, IoU, Dice, mAP), which allowed for a reliable comparison of the effectiveness of the individual approaches;

- The identification of potential practical applications: ResNet as a fast preliminary classifier, UNet as a tool for detailed laboratory analysis, and YOLO as a method for rapid detection in the context of industrial control.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Krawiec, H.; Lelito, J.; Mróz, M.; Radoń, M. Influence of Heat Treatment Parameters of Austempered Ductile Iron on the Microstructure, Corrosion and Tribological Properties. Materials 2023, 16, 4107. [Google Scholar] [CrossRef]

- Polishetty, A.; Pan, B.; Pasang, T.; Littlefair, G. Microstructural Study on Strain Induced Transformation in Austempered Ductile Iron Using Heat Tinting. In Proceedings of the ASME 2010 International Manufacturing Science and Engineering Conference, Erie, PA, USA, 12–15 October 2010; Volume 1, pp. 239–245. [Google Scholar] [CrossRef]

- Górny, M.; Tyrała, E. Effect of cooling rate on microstructure and mechanical properties of thin-walled ductile iron castings. J. Mater. Eng. Perform. 2013, 22, 300–305. [Google Scholar] [CrossRef]

- Silva, M.I.; Malitckii, E.; Santos, T.G.; Vilaça, P. Review of conventional and advanced non-destructive testing techniques for detection and characterization of small-scale defects. Prog. Mater. Sci. 2023, 138, 101155. [Google Scholar] [CrossRef]

- Jia, Y.; Chen, G.; Zhao, L. Defect detection of photovoltaic modules based on improved Varifocal Net. Sci. Rep. 2024, 14, 15170. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Zhang, C.; Ge, L.; Chen, Z.; Lu, K.; Wu, C. Joining Spatial Deformable Convolution and a Dense Feature Pyramid for Surface Defect Detection. IEEE Trans. Instrum. Meas. 2024, 73, 5012614. [Google Scholar] [CrossRef]

- Shao, R.; Zhou, M.; Li, M.; Han, D.; Li, G. TD-Net:tiny defect detection network for industrial products. Complex Intell. Syst. 2024, 10, 3943–3954. [Google Scholar] [CrossRef]

- Dehaerne, E.; Dey, B.; Blanco, V.; Davis, J. Scanning electron microscopy-based automatic defect inspection for semiconductor manufacturing: A systematic review. J. Micro/Nanopatterning Mater. Metrol. 2025, 24, 020901. [Google Scholar] [CrossRef]

- AI Image Evaluation, vs. Manual Microstructure Analysis—Advantages and Disadvantages. Available online: https://mivia.ai/en/2024/01/ki-bildauswertung-vs-manuelle-mikrostrukturanalyse-vor-und-nachteile/ (accessed on 23 October 2025).

- Campbell, A.; Murray, P.; Yakushina, E.; Marshall, S.; Ion, W. New methods for automatic quantification of microstructural features using digital image processing. Mater. Des. 2018, 141, 395–406. [Google Scholar] [CrossRef]

- Bai, J.; Wu, D.; Shelley, T.; Schubel, P.; Twine, D.; Russell, J.; Zeng, X.; Zhang, J. A Comprehensive Survey on Machine Learning Driven Material Defect Detection. ACM Comput. Surv. 2025, 57, 275. [Google Scholar] [CrossRef]

- Liu, Q.; Liu, M.; Wang, C.; Wu, Q.M.J. An efficient CNN-based detector for photovoltaic module cells defect detection in electroluminescence images. Sol. Energy 2024, 267, 112245. [Google Scholar] [CrossRef]

- Wang, Z.; Li, S.; Xuan, J.; Shi, T. Biologically inspired compound defect detection using a spiking neural network with continuous time–frequency gradients. Adv. Eng. Inform. 2025, 65, 103132. [Google Scholar] [CrossRef]

- Ferguson, M.; Ak, R.; Lee, Y.-T.T.; Law, K.H. Detection and Segmentation of Manufacturing Defects with Convolutional Neural Networks and Transfer Learning. Smart Sustain. Manuf. Syst. 2018, 2, 137–164. [Google Scholar] [CrossRef]

- Wang, Z.; Xuan, J.; Shi, T. An autonomous recognition framework based on reinforced adversarial open set algorithm for compound fault of mechanical equipment. Mech. Syst. Signal Process. 2024, 219, 111596. [Google Scholar] [CrossRef]

- Peng, C.; Peng, J.; Wang, Z.; Wang, Z.; Chen, J.; Xuan, J.; Shi, T. Adaptive fault diagnosis of railway vehicle on-board controller with large language models. Appl. Soft Comput. 2025, 16, 113919. [Google Scholar] [CrossRef]

- Nowroth, C.; Gu, T.; Grajczak, J.; Nothdurft, S.; Twiefel, J.; Hermsdorf, J.; Kaierle, S.; Wallaschek, J. Deep Learning-Based Weld Contour and Defect Detection from Micrographs of Laser Beam Welded Semi-Finished Products. Appl. Sci. 2022, 12, 4645. [Google Scholar] [CrossRef]

- Zhao, J.; Shen, C.; Huang, M.; Qi, Y.; Chai, Y.; Zheng, S. Deep learning accelerated micrograph-based porosity defect quantification in additively manufactured steels for uncovering a generic process-defect-properties relation. Mater. Charact. 2025, 225, 115094. [Google Scholar] [CrossRef]

- Nithin, A.M.; Perumal, M.; Davidson, M.J.; Srinivas, M.; Rao, C.S.P.; Harikrishna, K.; Jagtap, J.; Bhowmik, A.; Santhosh, A.J. Segmentation Studies on Al-Si-Mg Metallographic Images Using Various Different Deep Learning Algorithms and Loss Functions. Eng. Rep. 2025, 7, e70119. [Google Scholar] [CrossRef]

- Wang, Y.; Wei, X.; Wang, C.; Xu, W. Physical Metallurgy-Guided Machine Learning for Strength-Plasticity Optimization in Aluminum Alloys. Mater. Today Commun. 2025, 49, 113970. [Google Scholar] [CrossRef]

- Müller, M.; Stiefel, M.; Bachmann, B.-I.; Britz, D.; Mücklich, F. Overview: Machine Learning for Segmentation and Classification of Complex Steel Microstructures. Metals 2024, 14, 553. [Google Scholar] [CrossRef]

- DeCost, B.L.; Lei, B.; Francis, T.; Holm, E.A. High Throughput Quantitative Metallography for Complex Microstructures Using Deep Learning: A Case Study in Ultrahigh Carbon Steel. Microsc. Microanal. 2019, 25, 21–29. [Google Scholar] [CrossRef]

- Ronneberger, O.; Fischer, P.; Brox, T. U-Net: Convolutional Networks for Biomedical Image Segmentation. Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics). In Proceedings of the Medical Image Computing and Computer-Assisted Intervention, Munich, Germany, 5–9 October 2015; Volume 9351, pp. 234–241. [Google Scholar] [CrossRef]

- Liu, Y.; Liu, Y.; Guo, X.; Ling, X.; Geng, Q. Metal surface defect detection using SLF-YOLO enhanced YOLOv8 model. Sci. Rep. 2025, 15, 11105. [Google Scholar] [CrossRef]

- Biswas, M.; Pramanik, R.; Sen, S.; Sinitca, A.; Kaplun, D.; Sarkar, R. Microstructural segmentation using a union of attention guided U-Net models with different color transformed images. Sci. Rep. 2023, 13, 5737. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Computer Society Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 26 June–1 July 2016; pp. 770–778. [Google Scholar] [CrossRef]

- The Impact of AI on the Engineering Field|JHU EP. Available online: https://ep.jhu.edu/news/the-impact-of-ai-on-the-engineering-field/ (accessed on 23 October 2025).

- What Is Machine Learning? Definition, Types, Tools & More|DataCamp. Available online: https://www.datacamp.com/blog/what-is-machine-learning (accessed on 23 October 2025).

- An Overview of Deep Learning for Image Processing—Christian Garbin’s Personal Blog. Available online: https://cgarbin.github.io/deep-learning-for-image-processing-overview/ (accessed on 23 October 2025).

- Ge, M.; Su, F.; Zhao, Z.; Su, D. Deep learning analysis on microscopic imaging in materials science. Mater Today Nano 2020, 11, 100087. [Google Scholar] [CrossRef]

- Tu, S.; Vo, P. Microstructural Feature Extraction by a Convolutional Neural Network for Cold Spray of Aluminum Alloys. J. Therm. Spray Technol. 2024, 33, 540–550. [Google Scholar] [CrossRef]

- Gea, M.N.; Wanayumini, W.; Rosnelly, R. Impact of Hyperparameter Tuning on CNN-Based Algorithm for MRI Brain Tumor Classification. J. Tek. Inform. 2025, 18, 87–100. [Google Scholar] [CrossRef]

- Han, Y.; Li, R.; Yang, S.; Chen, Q.; Wang, B.; Liu, Y. Center-environment feature models for materials image segmentation based on machine learning. Sci. Rep. 2022, 12, 12960. [Google Scholar] [CrossRef]

- Wankhade, N.; Sale, V.; Yadav, R.; Jikar, P.; Gadgekar, S.; Dhokey, N. Metallurgical microstructure classification using CNN: A comprehensive study on heat treatment analysis for steel. Mater. Today Proc. 2024, in press. [Google Scholar] [CrossRef]

- Convolutional Neural Networks: A Complete Guide|Medium. Available online: https://medium.com/@alejandro.itoaramendia/convolutional-neural-networks-cnns-a-complete-guide-a803534a1930 (accessed on 23 October 2025).

- Convolutional Neural Networks (CNNs) and Layer Types—PyImageSearch. Available online: https://pyimagesearch.com/2021/05/14/convolutional-neural-networks-cnns-and-layer-types/ (accessed on 23 October 2025).

- Pehlivanoğlu, M.K.; İnCe, I.; Kından, B.A.; Eker, A.G.; Doğan, İ. Towards advanced brain tumor segmentation: A novel hybrid architecture integrating UNet, FCN, and YOLO models on the newly introduced BTS-DS 2024 dataset. Eur. Phys. J. Spec. Top. 2025, 234, 4421–4435. [Google Scholar] [CrossRef]

- Saxena, A. An Introduction to Convolutional Neural Networks. Int. J. Res. Appl. Sci. Eng. Technol. 2022, 10, 943–947. [Google Scholar] [CrossRef]

- Choudhary, K.; DeCost, B.; Chen, C.; Jain, A.; Tavazza, F.; Cohn, R.; Park, C.W.; Choudhary, A.; Agrawal, A.; Billinge, S.J.L.; et al. Recent advances and applications of deep learning methods in materials science. NPJ Comput. Mater. 2022, 8, 59. [Google Scholar] [CrossRef]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Identity mappings in deep residual networks. Lecture Notes in Computer Science (including subseries Lecture Notes in Artificial Intelligence and Lecture Notes in Bioinformatics). In Proceedings of the Computer Vision—ECCV 2016, Amsterdam, The Netherlands, 11–14 October 2016; 9908 LNCS. pp. 630–645. [Google Scholar] [CrossRef]

- Gebhardt, C.; Trimborn, T.; Weber, F.; Bezold, A.; Broeckmann, C.; Herty, M. Simplified ResNet approach for data driven prediction of microstructure-fatigue relationship. Mech. Mater. 2020, 151, 103625. [Google Scholar] [CrossRef]

- Medghalchi, S.; Kortmann, J.; Lee, S.-H.; Karimi, E.; Kerzel, U.; Korte-Kerzel, S. Automated segmentation of large image datasets using artificial intelligence for microstructure characterisation and damage analysis. Mater. Des. 2024, 243, 113031. [Google Scholar] [CrossRef]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. In Proceedings of the 2016 IEEE Conference on Computer Vision and Pattern Recognition (CVPR), Las Vegas, NV, USA, 27–30 June 2016; pp. 779–788. [Google Scholar] [CrossRef]

- Terven, J.; Córdova-Esparza, D.-M.; Romero-González, J.-A. A Comprehensive Review of YOLO Architectures in Computer Vision: From YOLOv1 to YOLOv8 and YOLO-NAS. Mach. Learn. Knowl. Extr. 2023, 5, 1680–1716. [Google Scholar] [CrossRef]

- Salvi, M.; Acharya, U.R.; Molinari, F.; Meiburger, K.M. The impact of pre- and post-image processing techniques on deep learning frameworks: A comprehensive review for digital pathology image analysis. Comput. Biol. Med. 2021, 128, 104129. [Google Scholar] [CrossRef]

- Luengo, J.; Moreno, R.; Sevillano, I.; Charte, D.; Peláez-Vegas, A.; Fernández-Moreno, M.; Mesejo, P.; Herrera, F. A tutorial on the segmentation of metallographic images: Taxonomy, new MetalDAM dataset, deep learning-based ensemble model, experimental analysis and challenges. Inf. Fusion 2022, 78, 232–253. [Google Scholar] [CrossRef]

- Dhanachandra, N.; Manglem, K.; Chanu, Y.J. Image Segmentation Using K -means Clustering Algorithm and Subtractive Clustering Algorithm. Procedia Comput. Sci. 2015, 54, 764–771. [Google Scholar] [CrossRef]

- Shi, C.; Wei, B.; Wei, S.; Wang, W.; Liu, H.; Liu, J. A quantitative discriminant method of elbow point for the optimal number of clusters in clustering algorithm. EURASIP J. Wirel. Commun. Netw. 2021, 2021, 31. [Google Scholar] [CrossRef]

- Goyal, M. Morphological image processing. Int. J. Comput. Sci. Technol. 2011, 2, 161–165. Available online: https://www.ijcst.com/vol24/1/megha.pdf (accessed on 10 September 2025).

- Webel, J.; Gola, J.; Britz, D.; Mücklich, F. A new analysis approach based on Haralick texture features for the characterization of microstructure on the example of low-alloy steels. Mater. Charact. 2018, 144, 584–596. [Google Scholar] [CrossRef]

- Feng, X.; Gao, X.; Luo, L. A ResNet50-Based Method for Classifying Surface Defects in Hot-Rolled Strip Steel. Mathematics 2021, 9, 2359. [Google Scholar] [CrossRef]

- Yang, D.; Cui, Y.; Yu, Z.; Yuan, H. Deep Learning Based Steel Pipe Weld Defect Detection. Appl. Artif. Intell. 2021, 35, 1237–1249. [Google Scholar] [CrossRef]

- Ma, B.; Wei, X.; Liu, C.; Ban, X.; Huang, H.; Wang, H.; Xue, W.; Wu, S.; Gao, M.; Shen, Q.; et al. Data augmentation in microscopic images for material data mining. NPJ Comput. Mater. 2020, 6, 125. [Google Scholar] [CrossRef]

- Ma, J.; Hu, C.; Zhou, P.; Jin, F.; Wang, X.; Huang, H. Review of Image Augmentation Used in Deep Learning-Based Material Microscopic Image Segmentation. Appl. Sci. 2023, 13, 6478. [Google Scholar] [CrossRef]

- Li, W.; Yang, L.; Peng, G.; Pang, G.; Yu, Z.; Zhu, X. An effective microscopic image augmentation approach. Sci. Rep. 2025, 15, 10247. [Google Scholar] [CrossRef]

- Şengöz, N.; Yïğ İt, T.; Özmen, Ö.; Isik, A.H. Importance of Preprocessing in Histopathology Image Classification Using Deep Convolutional Neural Network. Adv. Artif. Intell. Res. 2022, 2, 1–6. [Google Scholar] [CrossRef]

- Zhang, J.; Li, C.; Rahaman, M.; Yao, Y.; Ma, P.; Zhang, J.; Zhao, X.; Jiang, T.; Grzegorzek, M. A comprehensive review of image analysis methods for microorganism counting: From classical image processing to deep learning approaches. Artif. Intell. Rev. 2021, 55, 2875–2944. [Google Scholar] [CrossRef]

- Kato, S.; Hotta, K. Automatic Preprocessing and Ensemble Learning for Low Quality Cell Image Segmentation. arXiv 2021, arXiv:210813118. [Google Scholar]

| Model | Task | Metrics | Time | Advantages | Limitations |

|---|---|---|---|---|---|

| ResNet50 | Recognizing the presence of a defect in the image | Accuracy: 78% Precision: 72.5% Recall: 72.5% F1-score: 0.725 | 20 epochs (~13 h) | Speed of classification, simpler training data preparation | Lack of information about defect location and shape; predictions less certain (0.4–0.6) |

| UNet | Pixel-by-pixel segmentation of martensite areas | IoU: 0.66 Dice: 0.81 | 22 epochs (~19 h) | Very good segmentation precision for larger areas, detailed shape reproduction | Difficulties with fine, scattered islands; greater time requirements |

| YOLOv8 | Defect localization via bounding boxes | mAP: 0.83 Precision: 0.86 Recall: 0.74 F1-score: 0.79 | 80 epochs (~3 h) | Very fast prediction (0.02–0.03 s/image), effective detection of larger defects | Worse detection of the smallest structures, boxes do not accurately reflect shapes |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gajoch, S.; Wilk-Kołodziejczyk, D.; Marcjan, Ł.; Corizzo, R.; Bitka, A.; Małysza, M.; Skomin, G. Development and Implementation of a Defect Detection Model for Microstructures Using Image Processing Methods. Materials 2025, 18, 5207. https://doi.org/10.3390/ma18225207

Gajoch S, Wilk-Kołodziejczyk D, Marcjan Ł, Corizzo R, Bitka A, Małysza M, Skomin G. Development and Implementation of a Defect Detection Model for Microstructures Using Image Processing Methods. Materials. 2025; 18(22):5207. https://doi.org/10.3390/ma18225207

Chicago/Turabian StyleGajoch, Sandra, Dorota Wilk-Kołodziejczyk, Łukasz Marcjan, Roberto Corizzo, Adam Bitka, Marcin Małysza, and Gerard Skomin. 2025. "Development and Implementation of a Defect Detection Model for Microstructures Using Image Processing Methods" Materials 18, no. 22: 5207. https://doi.org/10.3390/ma18225207

APA StyleGajoch, S., Wilk-Kołodziejczyk, D., Marcjan, Ł., Corizzo, R., Bitka, A., Małysza, M., & Skomin, G. (2025). Development and Implementation of a Defect Detection Model for Microstructures Using Image Processing Methods. Materials, 18(22), 5207. https://doi.org/10.3390/ma18225207