Effect of TiB2 Content on Microstructure and Mechanical Properties of TiB2/Al-Zn-Mg-Cu Composites with High Zn Content

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

3.1. Microstructures Evolution

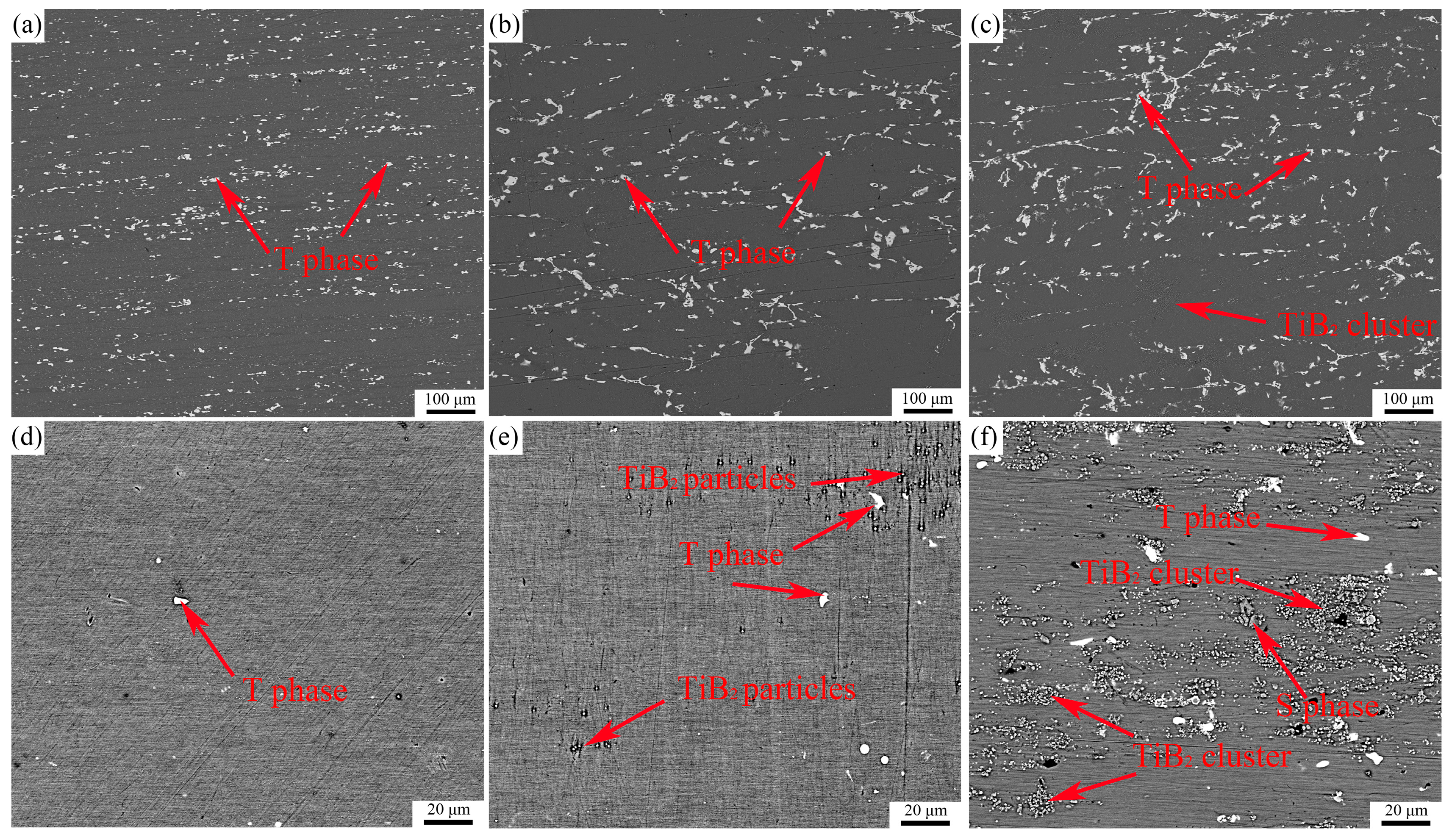

3.1.1. Microstructures and Phases

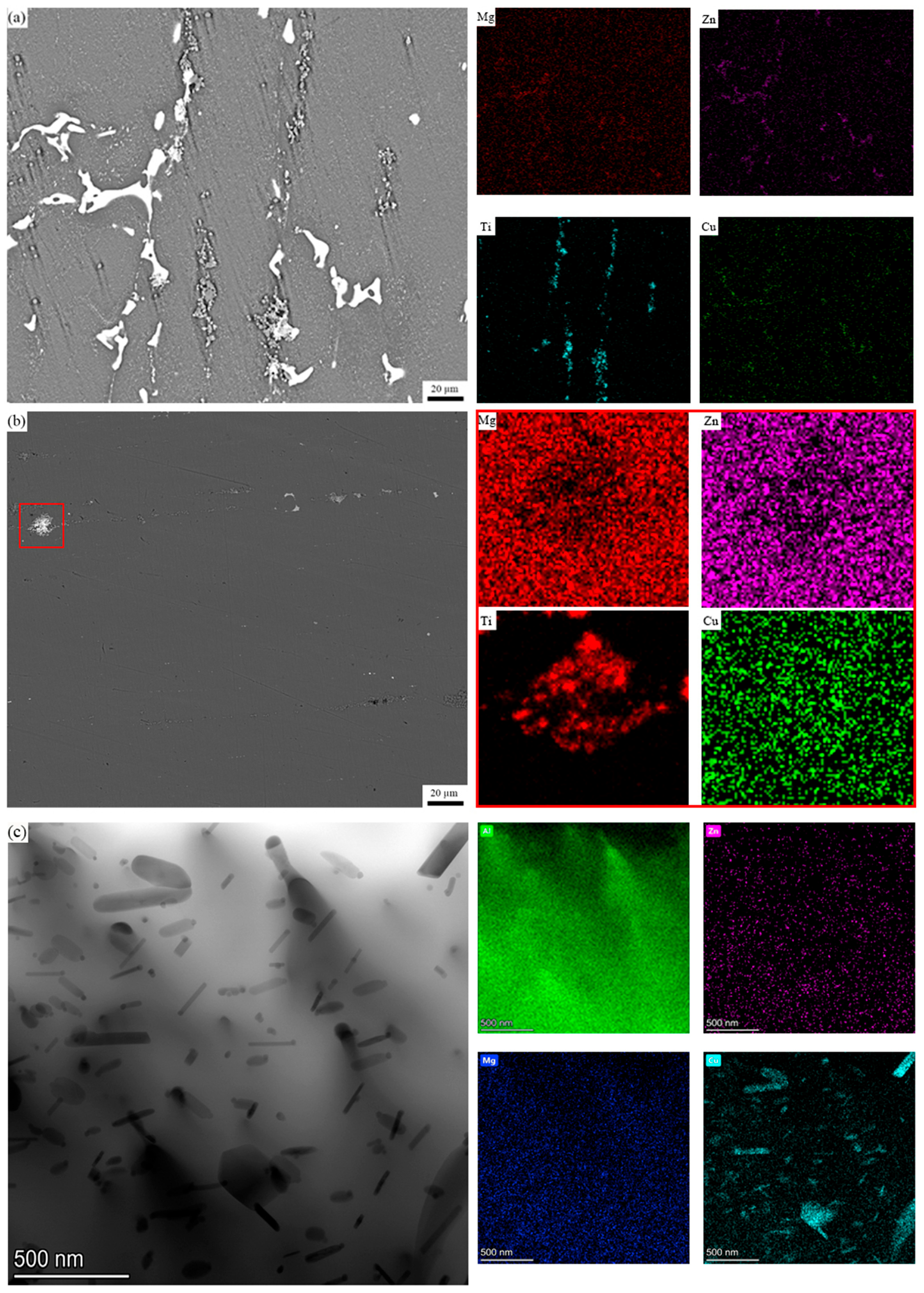

3.1.2. Effect of TiB2 on the Second Phase

3.1.3. Effect of TiB2 Particles on Precipitation Kinetics

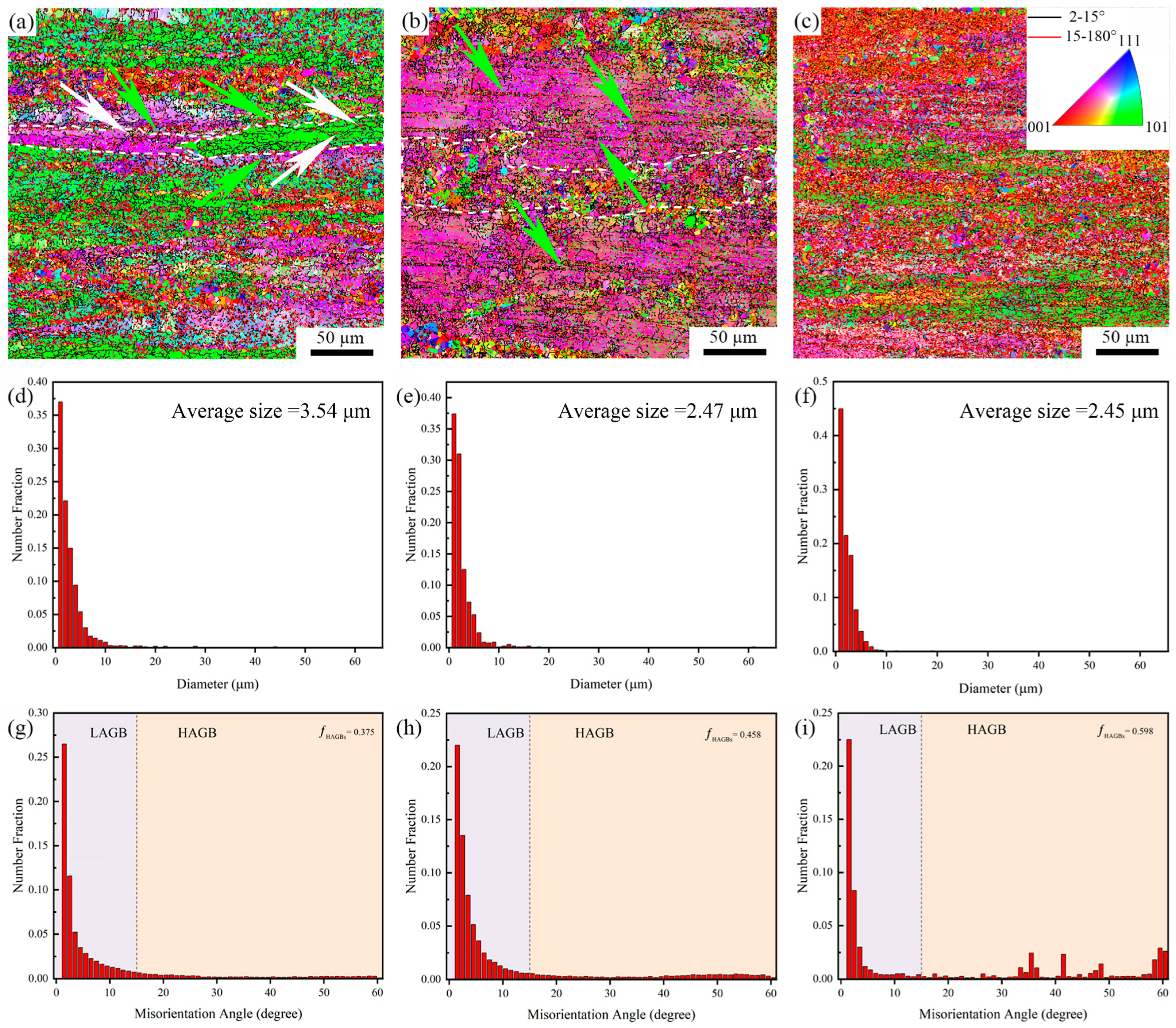

3.2. Orientation Relationship

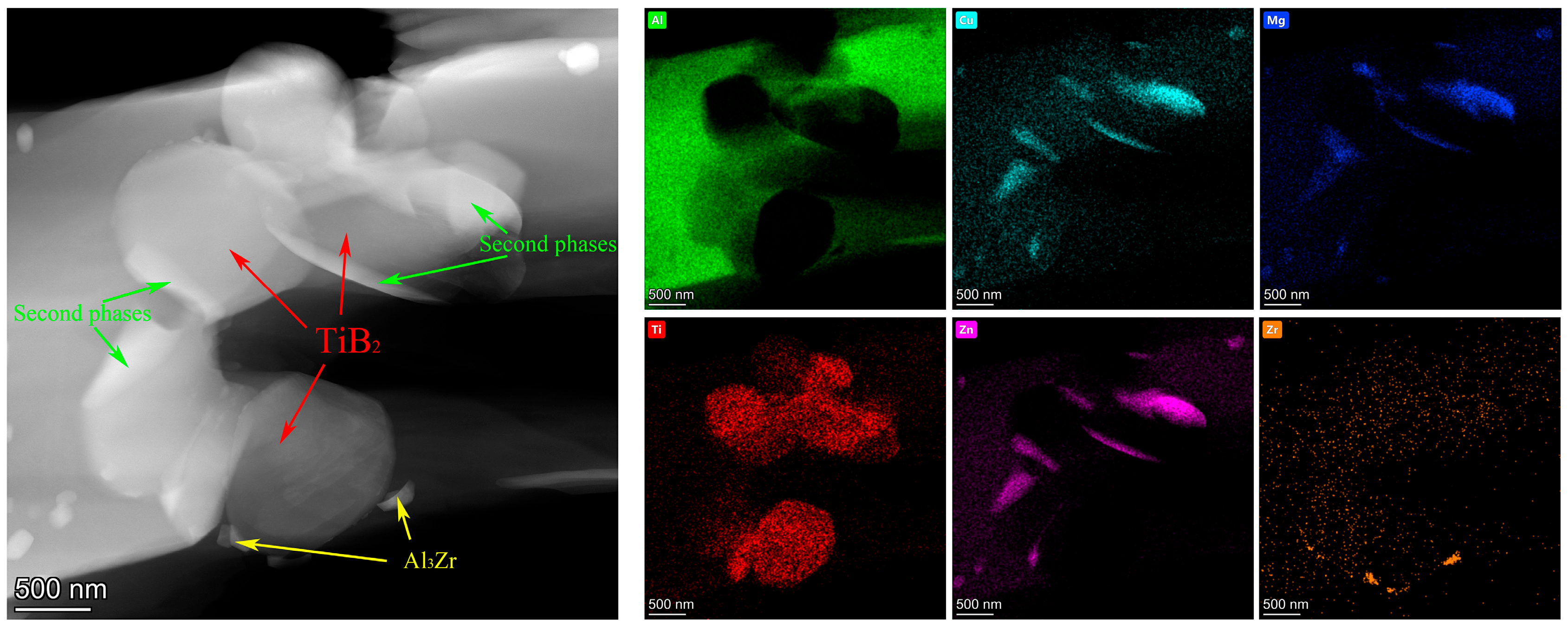

3.2.1. The Interface Relationship Between TiB2 Particles and Al-Matrix

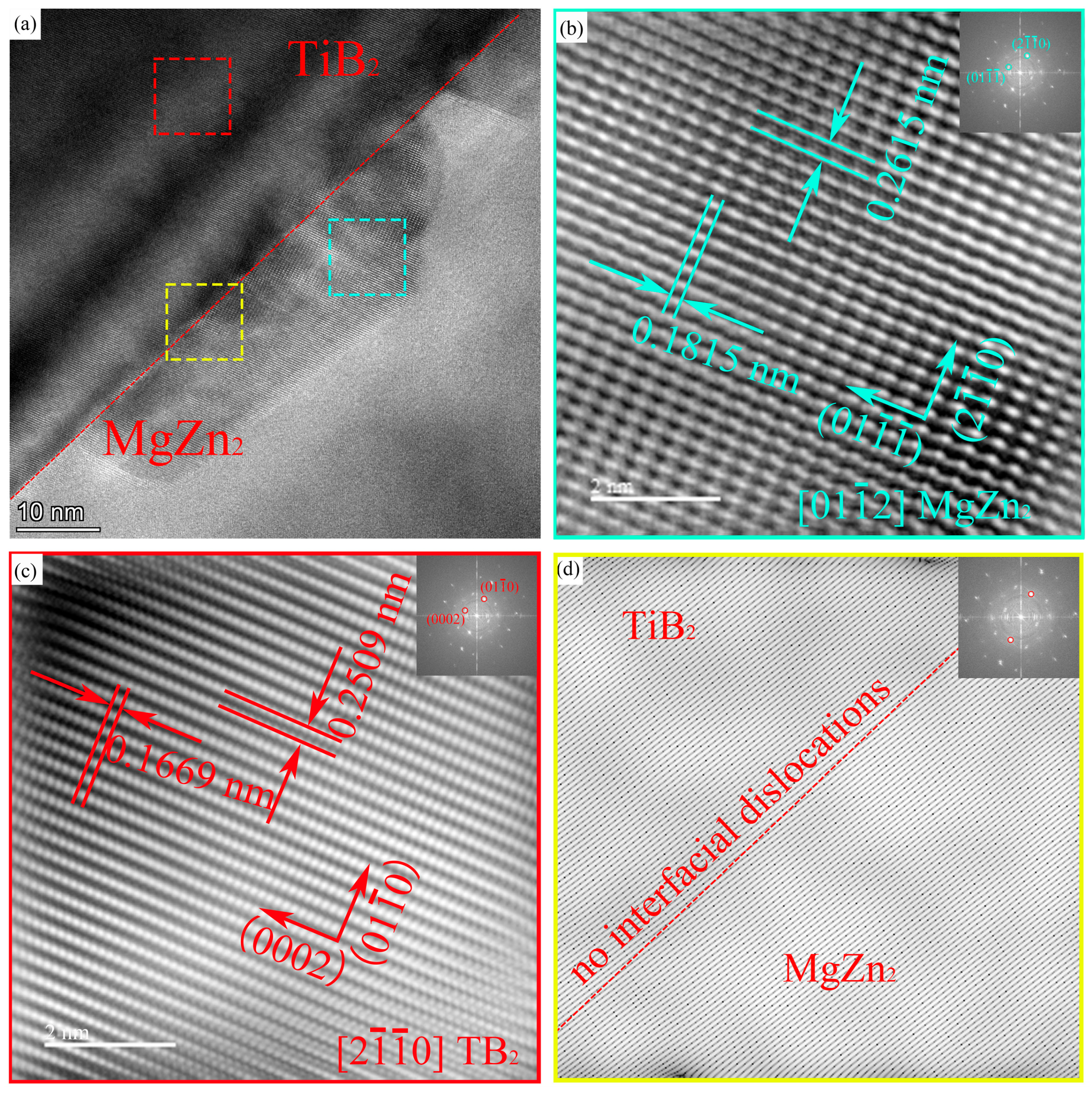

3.2.2. The Interface Relationship Between TiB2 Particles and MgZn2 Phase

3.3. Mechanical Properties

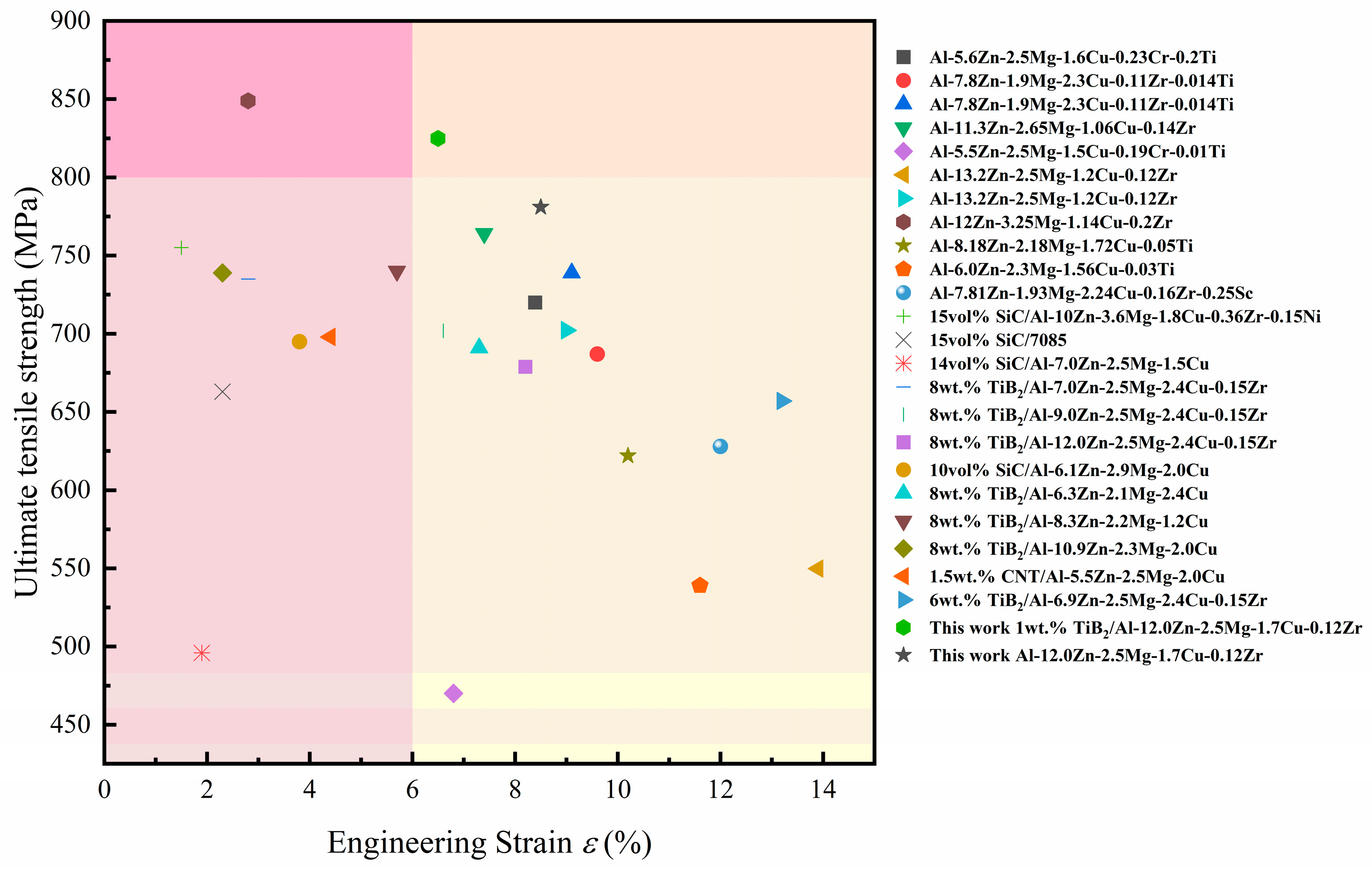

3.3.1. Hardness and Tensile Properties

3.3.2. Tensile Properties and Work Hardening Rate Curves

3.3.3. Strengthening Mechanism

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Fang, H.C.; Luo, F.H.; Chen, K.H. Effect of intermetallic phases and recrystallization on the corrosion and fracture behavior of an Al-Zn-Mg-Cu-Zr-Yb-Cr alloy. Mater. Sci. Eng. A 2017, 684, 480–490. [Google Scholar] [CrossRef]

- Carvalho, A.L.M.; Renaudin, L.B.; Zara, A.J.; Martins, J.P. Microstructure analysis of 7050 aluminum alloy processed by multistage aging treatments. J. Alloys Compd. 2022, 907, 164400. [Google Scholar] [CrossRef]

- Rotpai, U.; Arlai, T.; Nusen, S.; Juijerm, P. Novel flow stress prediction and work hardening behavior of aluminium alloy AA7075 at room and elevated temperatures. J. Alloys Compd. 2022, 891, 162013. [Google Scholar] [CrossRef]

- Jiang, H.; Xing, H.; Xu, Z.; Yang, B.; Liang, E.; Zhang, J.; Sun, B. Effect of Zn content and Sc、Zr addition on microstructure and mechanical properties of Al-Zn-Mg-Cu alloys. J. Alloys Compd. 2023, 947, 169246. [Google Scholar] [CrossRef]

- Wang, M.; Wang, Y.; Liu, J.; Chen, Z.; Chen, H.; Wu, Y.; Zhang, F.; Wang, H. Effects of Zn content on microstructures and mechanical properties of in-situ TiB2/Al-Zn-Mg-Cu composites subjected to hot extrusion. Mater. Sci. Eng. A 2019, 742, 364–372. [Google Scholar] [CrossRef]

- Tang, J.; Wang, J.; Teng, J.; Wang, G.; Fu, D.; Zhang, H.; Jiang, F. Effect of Zn content on the dynamic softening of Al–Zn–Mg–Cu alloys during hot compression deformation. Vacuum 2021, 184, 109941. [Google Scholar] [CrossRef]

- Liu, J.-T.; Zhang, Y.-A.; Li, X.-W.; Li, Z.-H.; Xiong, B.-Q.; Zhang, J.-S. Phases and microstructures of high Zn-containing Al–Zn–Mg–Cu alloys. Rare Met. 2014, 35, 380–384. [Google Scholar] [CrossRef]

- Peng, Y.-H.; Liu, C.-Y.; Wei, L.-L.; Jiang, H.-J.; Ge, Z.-J. Quench sensitivity and microstructures of high-Zn-content Al−Zn−Mg−Cu alloys with different Cu contents and Sc addition. Trans. Nonferrous Met. Soc. China 2021, 31, 24–35. [Google Scholar] [CrossRef]

- Al-Furjan, M.S.H.; Hajmohammad, M.H.; Shen, X.; Rajak, D.K.; Kolahchi, R. Evaluation of tensile strength and elastic modulus of 7075-T6 aluminum alloy by adding SiC reinforcing particles using vortex casting method. J. Alloys Compd. 2021, 886, 161262. [Google Scholar] [CrossRef]

- Ma, G.N.; Wang, D.; Liu, Z.Y.; Xiao, B.L.; Ma, Z.Y. An investigation on particle weakening in T6-treated SiC/Al–Zn–Mg–Cu composites. Mater. Charact. 2019, 158, 109966. [Google Scholar] [CrossRef]

- Ceschini, L.; Boromei, I.; Minak, G.; Morri, A.; Tarterini, F. Microstructure, tensile and fatigue properties of AA6061/20vol.%Al2O3p friction stir welded joints. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1200–1210. [Google Scholar] [CrossRef]

- Xiao, H.-Y.; Li, Y.-G.; Geng, J.-W.; Li, H.-P.; Wang, M.-L.; Chen, D.; Li, Z.-G.; Wang, H.-W. Effects of nano-sized TiB2 particles and Al3Zr dispersoids on microstructure and mechanical properties of Al–Zn–Mg–Cu based materials. Trans. Nonferrous Met. Soc. China 2021, 31, 2189–2207. [Google Scholar] [CrossRef]

- Ma, Y.; Addad, A.; Ji, G.; Zhang, M.-X.; Lefebvre, W.; Chen, Z.; Ji, V. Atomic-scale investigation of the interface precipitation in a TiB2 nanoparticles reinforced Al–Zn–Mg–Cu matrix composite. Acta Mater. 2020, 185, 287–299. [Google Scholar] [CrossRef]

- Yang, Q.; Shen, Y.; Liu, J.; Wang, L.; Chen, Z.; Wang, M.L.; Zhong, S.Y.; Wu, Y.; Wang, H.W. Microstructure and mechanical response of TiB2/Al–Zn–Mg–Cu composites with more addition of Zn. J. Alloys Compd. 2020, 816, 152584. [Google Scholar] [CrossRef]

- Krstić, J.; Jovanović, J.; Gajević, S.; Miladinović, S.; Vaxevanidis, N.M.; Kiss, I.; Stojanović, B. Application of metal matrix nanocomposites in engineering. Adv. Eng. Lett. 2024, 3, 180–190. [Google Scholar] [CrossRef]

- Angirekula, R.; Manickam, S.; Ravindra Babu, P. Optimizing process parameters for enhancing mechanical properties of aa6061 composites reinforced with walnut shell ash and silicon carbide. Appl. Eng. Lett. J. Eng. Appl. Sci. 2024, 9, 232–246. [Google Scholar] [CrossRef]

- Guerini, S.; Piquini, P. Theoretical investigation of TiB2 nanotubes. Microelectron. J. 2003, 34, 495–497. [Google Scholar] [CrossRef]

- Youssef, Y.M.; Dashwood, R.J.; Lee, P.D. Effect of clustering on particle pushing and solidification behaviour in TiB2 reinforced aluminium PMMCs. Compos. Part A Appl. Sci. Manuf. 2005, 36, 747–763. [Google Scholar] [CrossRef]

- Hamilton, R.W.; Forster, M.F.; Dashwood, R.J.; Lee, P.D. Application of X-ray tomography to quantify the distribution of TiB2 particulate in aluminium. Scr. Mater. 2002, 46, 25–29. [Google Scholar] [CrossRef]

- Geng, J.; Hong, T.; Ma, Y.; Wang, M.; Chen, D.; Ma, N.; Wang, H. The solution treatment of in-situ sub-micron TiB2/2024 Al composite. Mater. Des. 2016, 98, 186–193. [Google Scholar] [CrossRef]

- Robson, J.D.; Henry, D.T.; Davis, B. Particle effects on recrystallization in magnesium–manganese alloys: Particle-stimulated nucleation. Acta Mater. 2009, 57, 2739–2747. [Google Scholar] [CrossRef]

- Sidor, J.J.; Petrov, R.H.; Kestens, L.A.I. Microstructural and texture changes in severely deformed aluminum alloys. Mater. Charact. 2011, 62, 228–236. [Google Scholar] [CrossRef]

- Chung, T.-F.; Yeh, C.-W.; Liaw, Y.-S.; Lin, J.-R.; Ho, P.-L.; Hsiao, C.-N.; Tsao, C.-S.; Chou, C.-M.; Yang, Y.-L.; Yang, J.-R.; et al. Grain structure and co-precipitation behavior of high-Zn containing Al–Zn–Mg–Cu aluminium alloys during deformation via high-temperature upsetting-extrusion. J. Alloys Compd. 2023, 968, 171871. [Google Scholar] [CrossRef]

- Chung, T.-F.; Yang, Y.-L.; Huang, B.-M.; Shi, Z.; Lin, J.; Ohmura, T.; Yang, J.-R. Transmission electron microscopy investigation of separated nucleation and in-situ nucleation in AA7050 aluminium alloy. Acta Mater. 2018, 149, 377–387. [Google Scholar] [CrossRef]

- Tham, L.M.; Gupta, M.; Cheng, L. Effect of limited matrix–reinforcement interfacial reaction on enhancing the mechanical properties of aluminium–silicon carbide composites. Acta Mater. 2001, 49, 3243–3253. [Google Scholar] [CrossRef]

- Wu, Y.; Liu, B.; Kang, H.; Guo, E.; Li, J.; Du, G.; Chen, Z.; Wang, T. Ultrasound-assisted dispersion of TiB2 nanoparticles in 7075 matrix hybrid composites. Mater. Sci. Eng. A 2022, 840, 142958. [Google Scholar] [CrossRef]

- Raja, N.; Kumar, N.; Gautam, G. Microstructural and mechanical properties of in-situ ZrB2/Al7068 nanocomposites synthesized by ultrasonic-assisted stir casting technique. Int. J. Met. 2023, 18, 431–444. [Google Scholar] [CrossRef]

- Wu, C.; Ma, K.; Zhang, D.; Wu, J.; Xiong, S.; Luo, G.; Zhang, J.; Chen, F.; Shen, Q.; Zhang, L.; et al. Precipitation phenomena in Al-Zn-Mg alloy matrix composites reinforced with B4C particles. Sci. Rep. 2017, 7, 9589–9599. [Google Scholar] [CrossRef]

- Mandal, A.; Maiti, R.; Chakraborty, M.; Murty, B.S. Effect of TiB2 particles on aging response of Al–4Cu alloy. Mater. Sci. Eng. A 2004, 386, 296–300. [Google Scholar] [CrossRef]

- Cui, Y.; Jin, T.; Cao, L.; Liu, F. Aging behavior of high volume fraction SiCp/Al composites fabricated by pressureless infiltration. J. Alloys Compd. 2016, 681, 233–239. [Google Scholar] [CrossRef]

- Chen, Z.; Li, J.; Borbely, A.; Ji, G.; Zhong, S.Y.; Wu, Y.; Wang, M.L.; Wang, H.W. The effects of nanosized particles on microstructural evolution of an in-situ TiB2/6063Al composite produced by friction stir processing. Mater. Des. 2015, 88, 999–1007. [Google Scholar] [CrossRef]

- Li, H.; Wang, X.; Chai, L.; Wang, H.; Chen, Z.; Xiang, Z.; Jin, T. Microstructure and mechanical properties of an in-situ TiB2/Al-Zn-Mg-Cu-Zr composite fabricated by Melt-SHS process. Mater. Sci. Eng. A 2018, 720, 60–68. [Google Scholar] [CrossRef]

- Liu, T.; Jiang, H.; Sun, H.; Wang, Y.; Dong, Q.; Zeng, J.; Bian, F.; Zhang, J.; Chen, F.; Sun, B. Effects of rolling deformation on precipitation behavior and mechanical properties of Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2022, 847, 143342. [Google Scholar] [CrossRef]

- Liang, H.; Chen, S.L.; Chang, Y.A. A Thermodynamic Description of the Al-Mg-Zn System. Metall. Mater. Trans. A 1997, 28, 1725–1734. [Google Scholar] [CrossRef]

- Chen, Z.; Mo, Y.; Nie, Z. Effect of Zn Content on the Microstructure and Properties of Super-High Strength Al-Zn-Mg-Cu Alloys. Metall. Mater. Trans. A 2013, 44, 3910–3920. [Google Scholar] [CrossRef]

- Styles, M.J.; Hutchinson, C.R.; Chen, Y.; Deschamps, A.; Bastow, T.J. The coexistence of two S (Al2CuMg) phases in Al–Cu–Mg alloys. Acta Mater. 2012, 60, 6940–6951. [Google Scholar] [CrossRef]

- Maloney, S.K.; Hono, K.; Polmear, I.J.; Ringer, S.P. The Chemistry of Precipitates in An Aged Al-2.1Zn-1.7Mg at.% Alloy. Acta Metall. 1999, 41, 1031–1038. [Google Scholar] [CrossRef]

- Wang, J.; Bai, Y.; Wu, B.; Jin, W.; Xu, Z.; Kang, H. Effects of Cu concentration on microstructure and tensile properties of high-Zn-content Al–Zn–Mg–Cu alloys. J. Alloys Compd. 2024, 988, 174208. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, Y.; Huang, S.; Mao, X.; He, H.; Tang, J.; Guo, W.; Dong, F. Dynamic recrystallization mechanisms of 2195 aluminum alloy during medium/high temperature compression deformation. Mater. Sci. Eng. A 2021, 804, 140650. [Google Scholar] [CrossRef]

- Ma, H.; Zeng, W.; Kou, Y.; Zhang, P.; Zhang, F.; Liang, X. Formation mechanism of Cube texture components ({001}<100>) associated with dynamic recrystallization during compression in the single BCC phase region of Ti-22Al-25Nb alloy. J. Alloys Compd. 2023, 966, 171563. [Google Scholar]

- Duan, M.-g.; Li, Y.; Yang, X.; Qian, X.; Liu, K.; Zhao, H.; Li, B. Mechanical responses of in-situ TiB2/7050 composite subjected to monotonic and cyclic loadings: A comparative study with 7050-Al. Int. J. Fatigue 2022, 163, 107102. [Google Scholar] [CrossRef]

- Calcagnotto, M.; Ponge, D.; Demir, E.; Raabe, D. Orientation gradients and geometrically necessary dislocations in ultrafine grained dual-phase steels studied by 2D and 3D EBSD. Mater. Sci. Eng. A 2010, 527, 2738–2746. [Google Scholar] [CrossRef]

- Lang, Y.; Cai, Y.; Cui, H.; Zhang, J. Effect of strain-induced precipitation on the low angle grain boundary in AA7050 aluminum alloy. Mater. Des. 2011, 32, 4241–4246. [Google Scholar] [CrossRef]

- Lang, Y.; Zhou, G.; Hou, L.; Zhang, J.; Zhuang, L. Significantly enhanced the ductility of the fine-grained Al–Zn–Mg–Cu alloy by strain-induced precipitation. Mater. Des. 2015, 88, 625–631. [Google Scholar] [CrossRef]

- Sha, G.; Cerezo, A. Early-stage precipitation in Al–Zn–Mg–Cu alloy (7050). Acta Mater. 2004, 52, 4503–4516. [Google Scholar] [CrossRef]

- Ren, X.; Jiang, X.; Yuan, T.; Zhao, X.; Chen, S. Microstructure and properties research of Al-Zn-Mg-Cu alloy with high strength and high elongation fabricated by wire arc additive manufacturing. J. Mater. Process. Technol. 2022, 307, 117665. [Google Scholar] [CrossRef]

- Schaffer, P.L.; Miller, D.N.; Dahle, A.K. Crystallography of engulfed and pushed TiB2 particles in aluminium. Scr. Mater. 2007, 57, 1129–1132. [Google Scholar] [CrossRef]

- Xiao, H.; Geng, J.; Li, Y.; Wang, Z.; Yang, Q.; Li, H.; Wang, M.; Chen, D.; Li, Z.; Wang, H. Improved microstructures and mechanical properties for 7085Al alloy subjected to slow quenching by aging treatment. Mater. Sci. Eng. A 2021, 827, 142068. [Google Scholar] [CrossRef]

- Huang, J.; Xiang, Z.; Li, J.; Ma, X.; Yang, Z.; Shen, G.; Wang, Z.; Chen, Z. Effect on microstructure and mechanical properties of in situ 6 wt%TiB2/Al–Zn–Mg–Cu composite subjected by two-step orthogonal deformation process. J. Mater. Res. 2021, 36, 4426–4437. [Google Scholar] [CrossRef]

- Yao, Y.; Euesden, R.; Burnett, T.L.; Shanthraj, P.; Prangnell, P.B. Effect of Cooling Rate on Quench-Induced Grain Boundary η-Phase Precipitation in 7xxx Aluminium Alloys. Metall. Mater. Trans. A 2025, 56, 1230–1251. [Google Scholar] [CrossRef]

- Wang, Y.; Toda, H.; Fujihara, H.; Shimizu, K.; Hirayama, K.; Takeuchi, A.; Uesugi, M. Role of retrogression and reaging in suppressing hydrogen-induced transgranular cracking in 7xxx Al alloys. Scr. Mater. 2025, 255, 116383. [Google Scholar] [CrossRef]

- Huang, J.; Xiang, Z.; Tang, Y.; Li, J.; Shen, G.; Shi, G.; Ma, X.; Chen, Y.; Chen, Z. Interfacial precipitation of the in-situ TiB2-reinforced Al–Zn–Mg–Cu–Zr composite. Mater. Chem. Phys. 2023, 301, 127561. [Google Scholar] [CrossRef]

- Li, C.; Wu, S.; Lü, S.; Li, J.; Liu, L.; Xia, L. Effects of Excessive Zr Content and Ultrasonic Treatment on Microstructure and Mechanical Properties of Al-Zn-Mg-Cu Alloy. Metals 2021, 11, 632. [Google Scholar] [CrossRef]

- Dutta, I.; Allen, S.M.; Hafley, J.L. Effect of reinforcement on the aging response of cast 6061 Al-Al2O3 particulate composites. Metall. Trans. A 1991, 22, 2553–2563. [Google Scholar] [CrossRef]

- Dutta, I.; Harper, C.P.; Dutta, G. Role of Al2O3 particulate reinforcements on precipitation in 2014 Al-matrix composites. Metall. Mater. Trans. A 1994, 25, 1591–1602. [Google Scholar] [CrossRef]

- Wang, M.; Chen, D.; Chen, Z.; Wu, Y.; Wang, F.; Ma, N.; Wang, H. Mechanical properties of in-situ TiB2/A356 composites. Mater. Sci. Eng. A 2014, 590, 246–254. [Google Scholar] [CrossRef]

- Dunand, D.C.; Mortensen, A. On plastic relaxation of thermal stresses in reinforced metals. Acta Metall. 1991, 39, 127–139. [Google Scholar] [CrossRef]

- Song, M.; Wen, J.F.; Jiao, Z.; Was, G.S. Elastic strain energy control of the precipitate free zone around primary carbides in nickel base alloy 725. Acta Mater. 2016, 120, 138–149. [Google Scholar] [CrossRef]

- Ma, K.; Wen, H.; Hu, T.; Topping, T.D.; Isheim, D.; Seidman, D.N.; Lavernia, E.J.; Schoenung, J.M. Mechanical behavior and strengthening mechanisms in ultrafine grain precipitation-strengthened aluminum alloy. Acta Mater. 2014, 62, 141–155. [Google Scholar] [CrossRef]

- Angella, G.; Zanardi, F.; Donnini, R. On the significance to use dislocation-density-related constitutive equations to correlate strain hardening with microstructure of metallic alloys: The case of conventional and austempered ductile irons. J. Alloys Compd. 2016, 669, 262–271. [Google Scholar] [CrossRef]

- Ditta, A.; Wei, L.; Xu, Y.; Wu, S. Microstructural characteristics and properties of spray formed Zn-rich Al-Zn-Mg-Cu alloy under various aging conditions. Mater. Charact. 2020, 161, 110133. [Google Scholar] [CrossRef]

- Seyed Ebrahimi, S.H.; Emamy, M.; Pourkia, N.; Lashgari, H.R. The microstructure, hardness and tensile properties of a new super high strength aluminum alloy with Zr addition. Mater. Des. 2010, 31, 4450–4456. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, H.; Cui, Z.; Chen, D.; Chen, Z. Strength and ductility improvement of an in-situ TiB2/Al–Zn–Mg–Cu composite by elliptical cross-section torsion extrusion. Compos. Part B Eng. 2021, 216, 108843. [Google Scholar] [CrossRef]

- Xu, R.; Tan, Z.; Fan, G.; Ji, G.; Xiong, D.-B.; Guo, Q.; Su, Y.; Li, Z.; Zhang, D. High-strength CNT/Al-Zn-Mg-Cu composites with improved ductility achieved by flake powder metallurgy via elemental alloying. Compos. Part A Appl. Sci. Manuf. 2018, 111, 1–11. [Google Scholar] [CrossRef]

- Lee, S.-H.; Jung, J.-G.; Baik, S.-I.; Seidman, D.N.; Kim, M.-S.; Lee, Y.-K.; Euh, K. Precipitation strengthening in naturally aged Al–Zn–Mg–Cu alloy. Mater. Sci. Eng. A 2021, 803, 140719. [Google Scholar] [CrossRef]

- Han, T.; Li, J.; Zhao, N.; He, C. Microstructure and properties of copper coated graphene nanoplates reinforced Al matrix composites developed by low temperature ball milling. Carbon 2020, 159, 311–323. [Google Scholar] [CrossRef]

| Alloy | Zn (wt.%) | Mg (wt.%) | Cu (wt.%) | Zr (wt.%) | Ti (wt.%) | B (wt.%) | Al (wt.%) |

|---|---|---|---|---|---|---|---|

| A | 12.29 | 2.72 | 1.75 | 0.112 | 0 | 0 | Bal. |

| B | 12.69 | 2.81 | 1.69 | 0.102 | 0.48 | 0.4 | Bal. |

| C | 12.35 | 2.69 | 1.68 | 0.121 | 1.61 | 0.82 | Bal. |

| Alloy | σ0.2 (MPa) | σb (MPa) | At (%) | E (GPa) | n |

|---|---|---|---|---|---|

| A | 743 ± 2 | 781 ± 3 | 8.5 ± 0.5 | 74 ± 1 | 0.081 |

| B | 801 ± 3 | 831 ± 5 | 6.7 ± 0.3 | 75 ± 2 | 0.058 |

| C | 759 ± 2 | 788 ± 4 | 2.9 ± 0.4 | 78 ± 2 | 0.044 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, W.; Xiang, Z.; Li, J.; Yang, Z.; Han, Y.; Chen, Z. Effect of TiB2 Content on Microstructure and Mechanical Properties of TiB2/Al-Zn-Mg-Cu Composites with High Zn Content. Materials 2025, 18, 5191. https://doi.org/10.3390/ma18225191

Sun W, Xiang Z, Li J, Yang Z, Han Y, Chen Z. Effect of TiB2 Content on Microstructure and Mechanical Properties of TiB2/Al-Zn-Mg-Cu Composites with High Zn Content. Materials. 2025; 18(22):5191. https://doi.org/10.3390/ma18225191

Chicago/Turabian StyleSun, Wenchao, Zhilei Xiang, Jihao Li, Zian Yang, Yang Han, and Ziyong Chen. 2025. "Effect of TiB2 Content on Microstructure and Mechanical Properties of TiB2/Al-Zn-Mg-Cu Composites with High Zn Content" Materials 18, no. 22: 5191. https://doi.org/10.3390/ma18225191

APA StyleSun, W., Xiang, Z., Li, J., Yang, Z., Han, Y., & Chen, Z. (2025). Effect of TiB2 Content on Microstructure and Mechanical Properties of TiB2/Al-Zn-Mg-Cu Composites with High Zn Content. Materials, 18(22), 5191. https://doi.org/10.3390/ma18225191