Monocrystalline Sapphire Stress Field Analysis with Orthorhombic Crystal Orientation Under Vickers Indentation

Abstract

1. Introduction

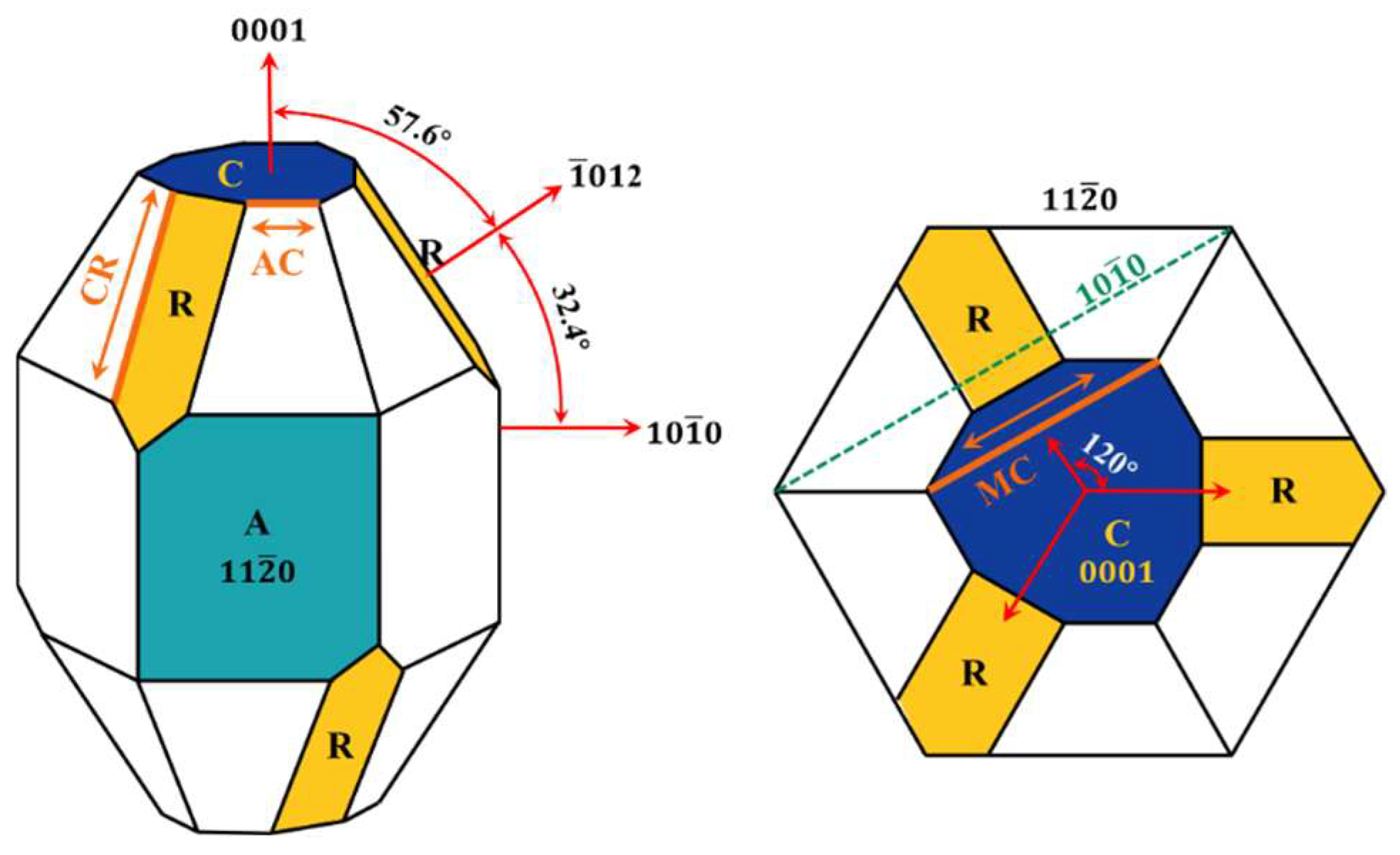

2. Experiments and Simulation

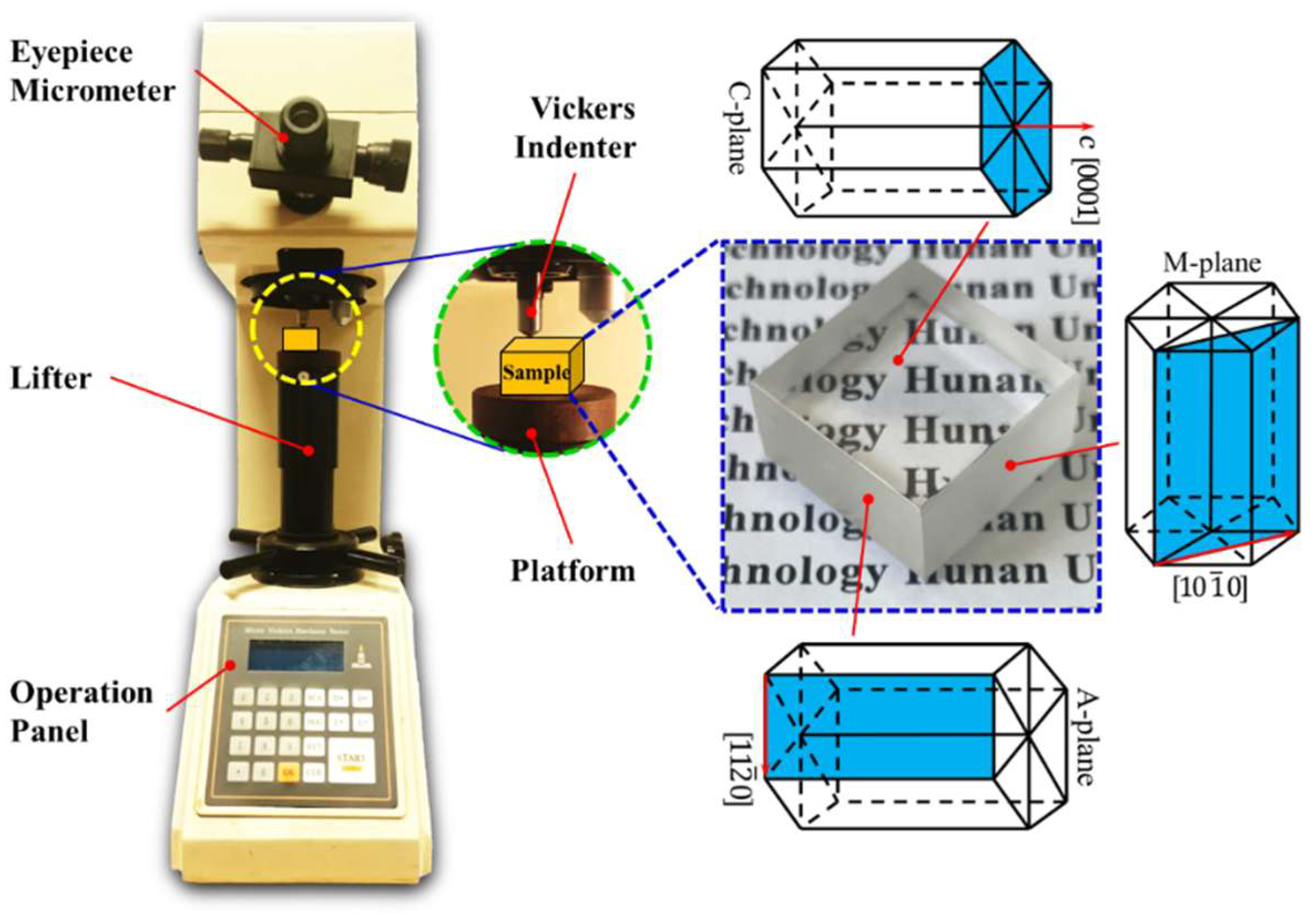

2.1. Experiment Set Up

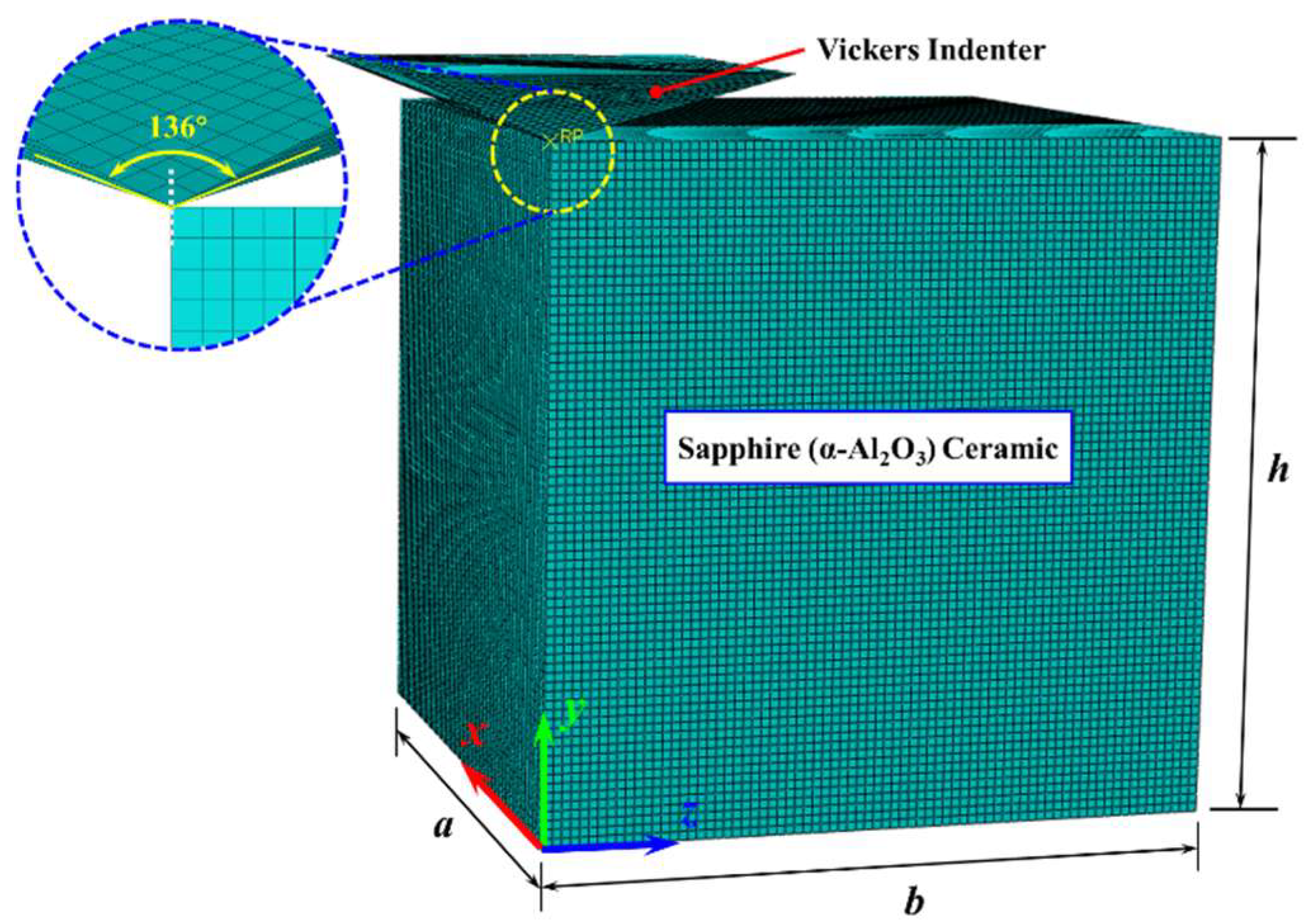

2.2. Simulation Modeling

3. Results and Discussion

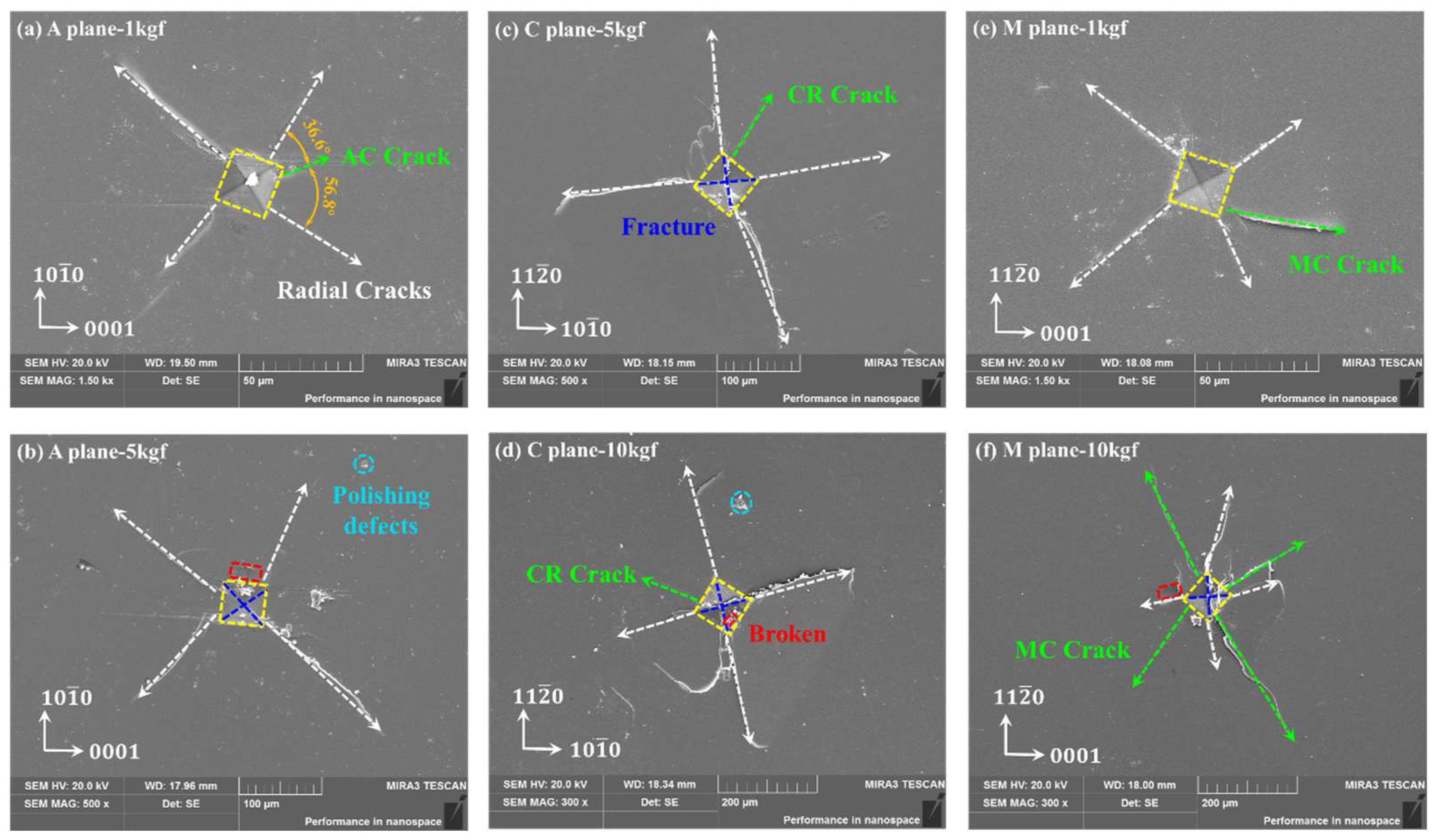

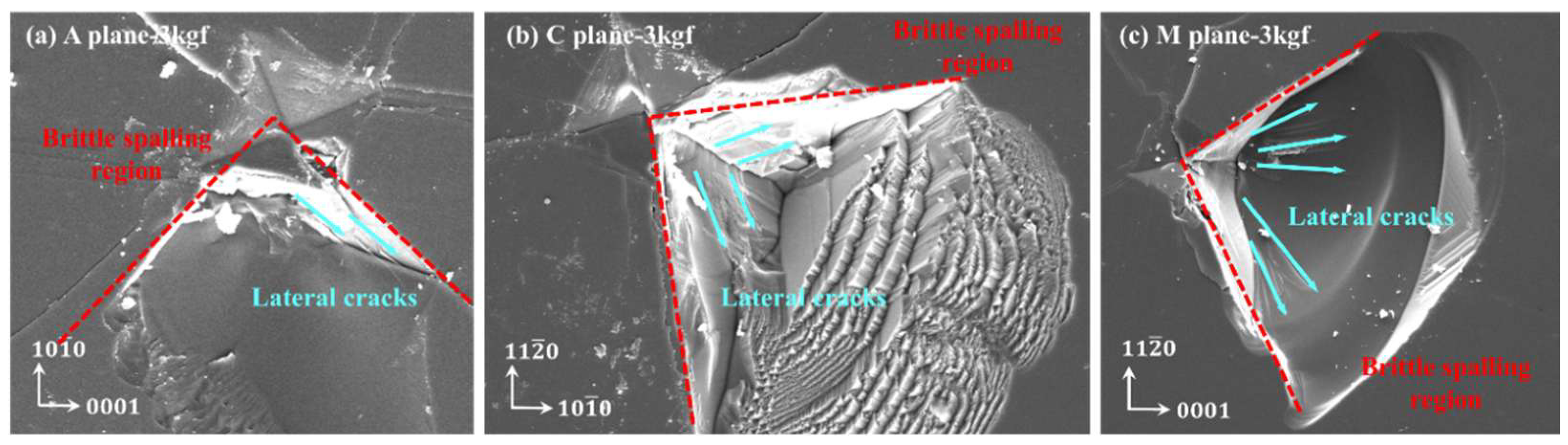

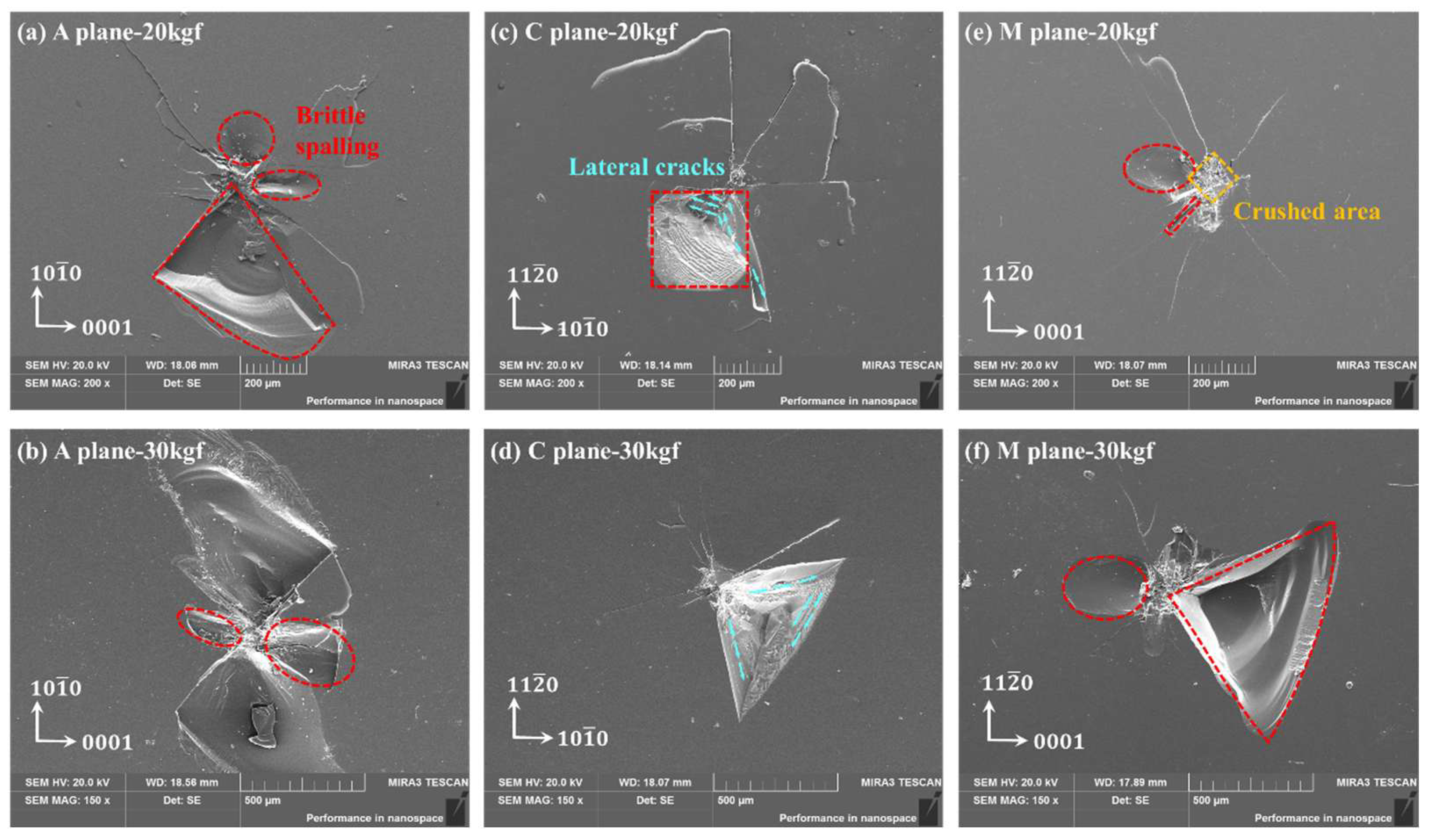

3.1. Indentation Surface Morphology

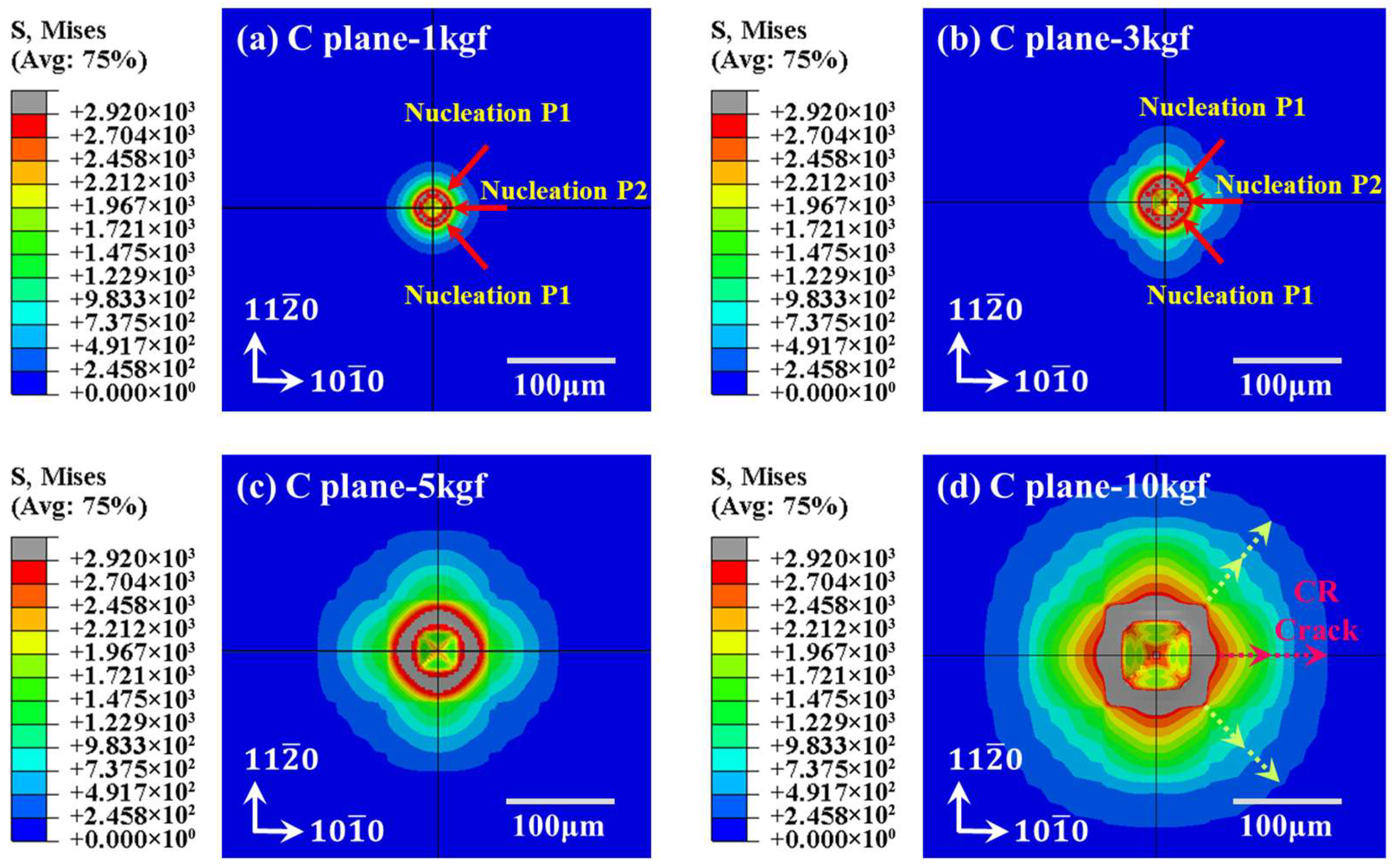

3.2. Finite Element Simulation Analysis

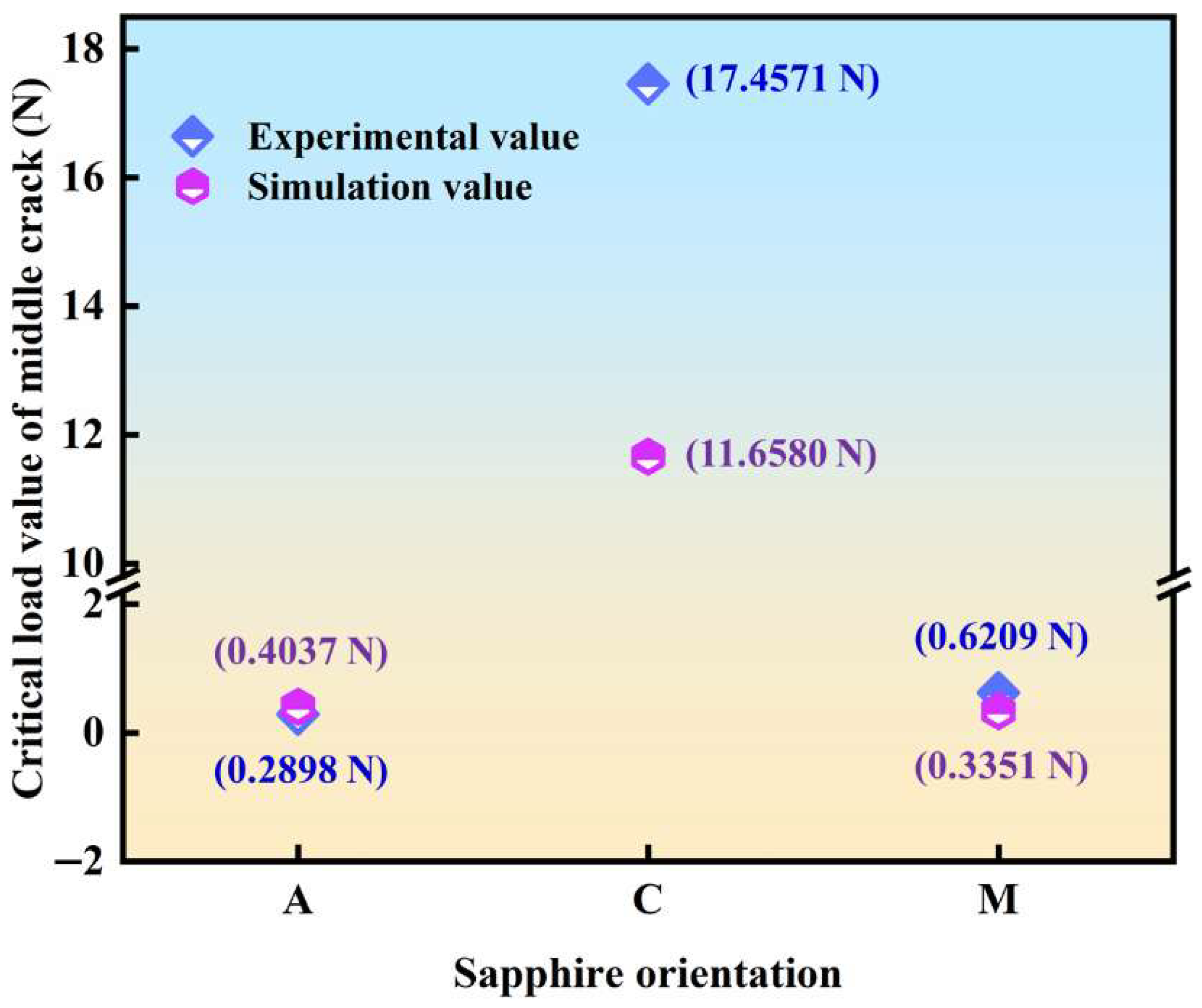

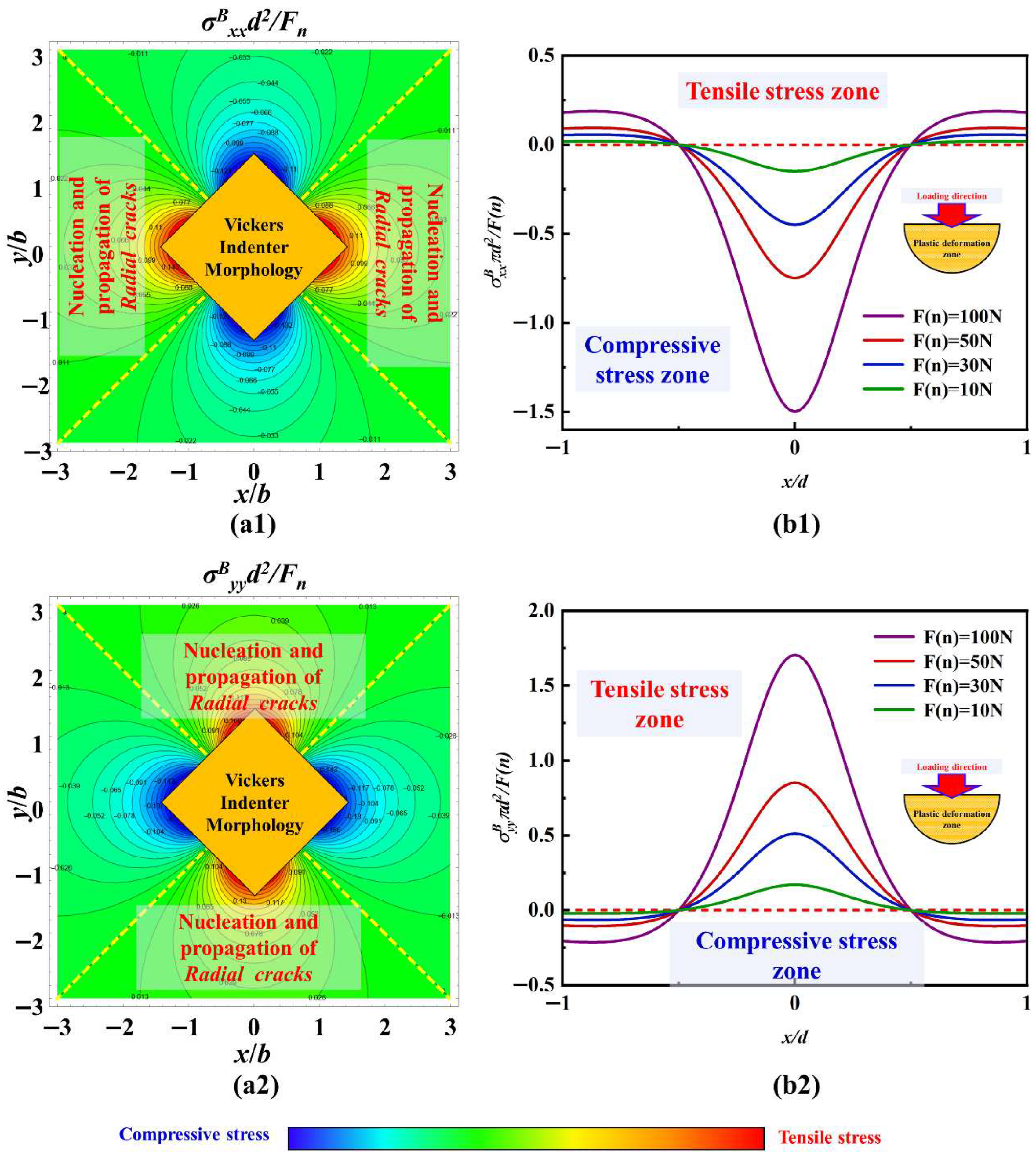

3.3. Judgment of Indentation Cracks

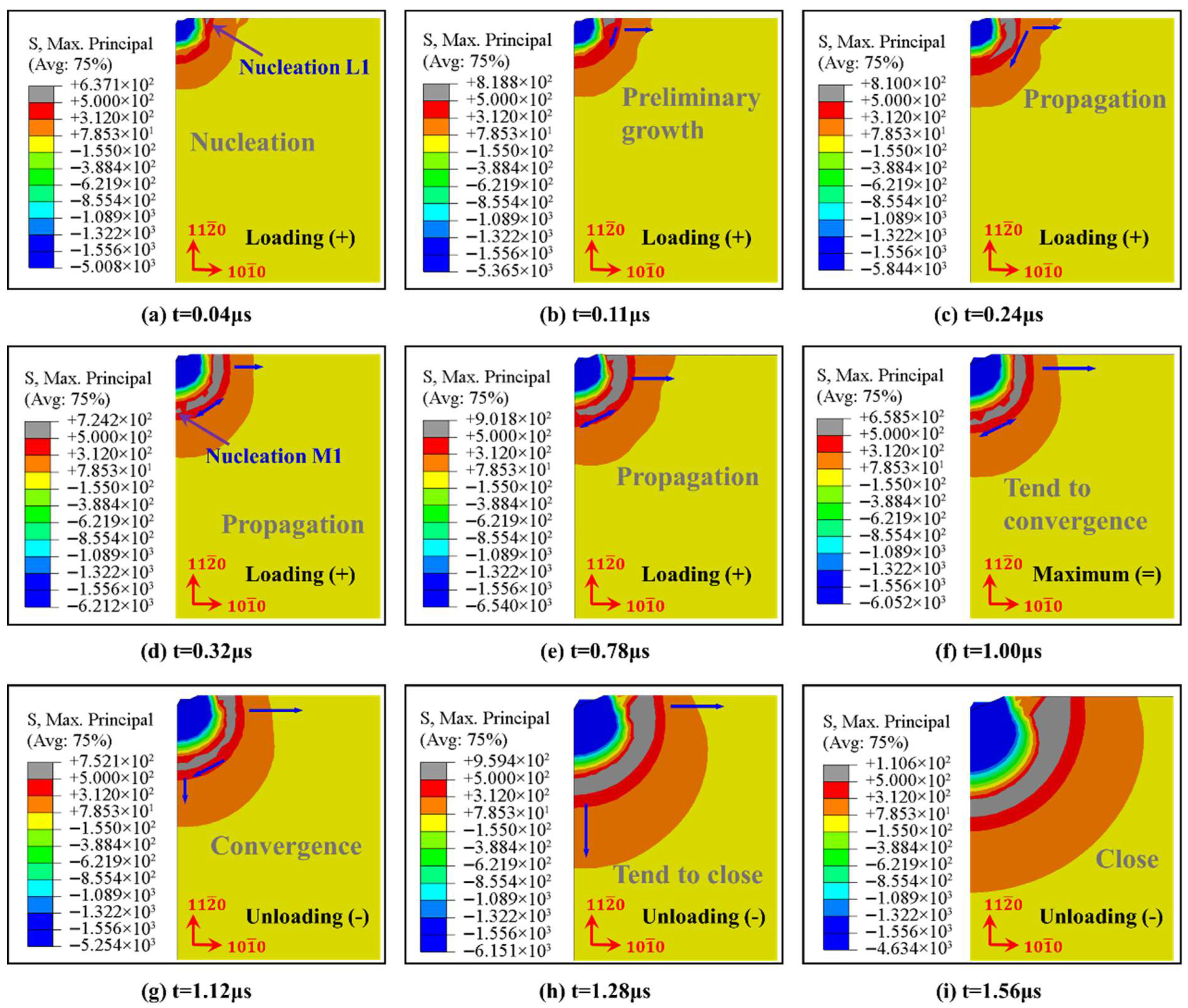

3.4. Indentation Cracks Propagation Process

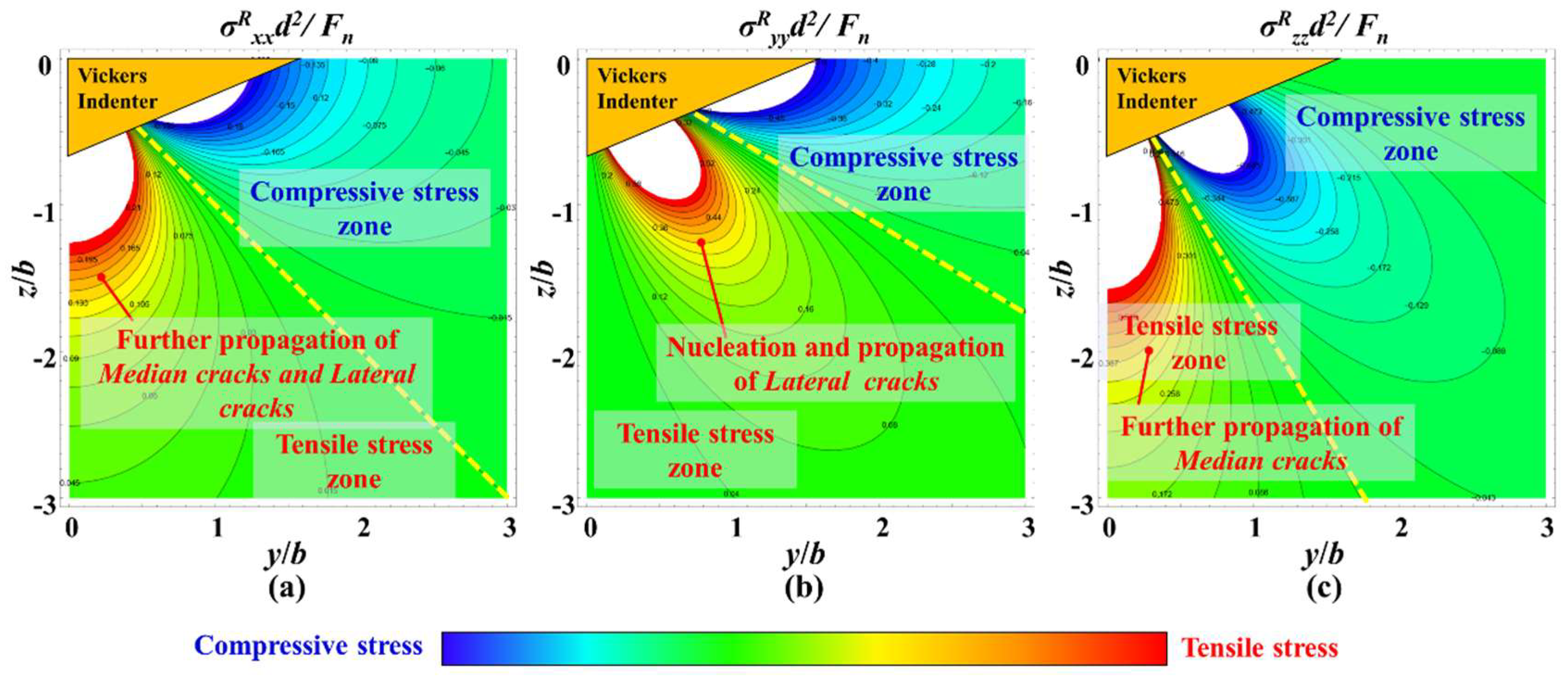

- (i)

- One is caused by the applied indentation pressing load, which will be entirely recovered after the indentation is completed.

- (ii)

- The other is caused by plastic deformation during indentation. Due to the irreversibility of plastic deformation, this stress field will continue to act on the inside of the sapphire after indentation.

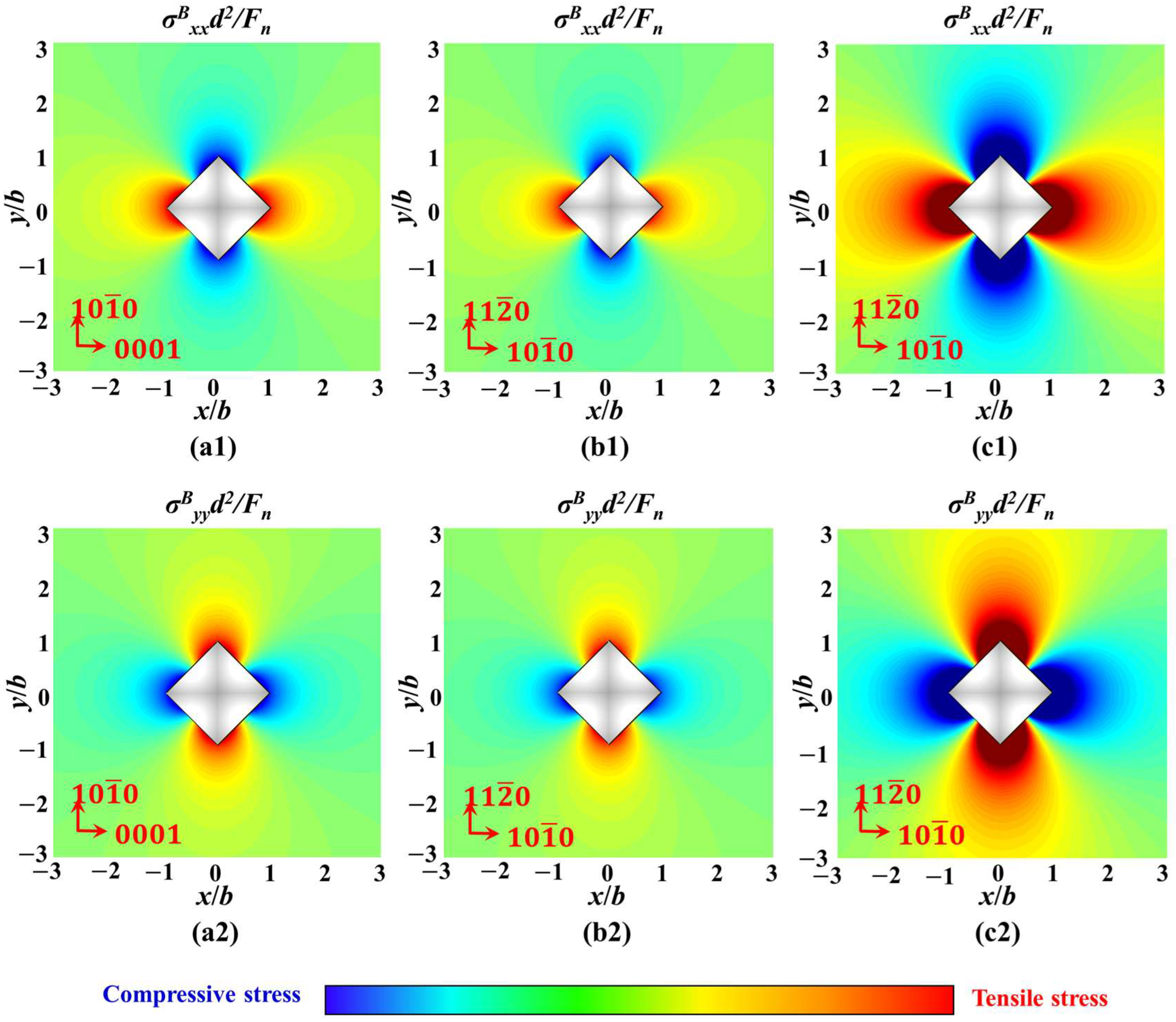

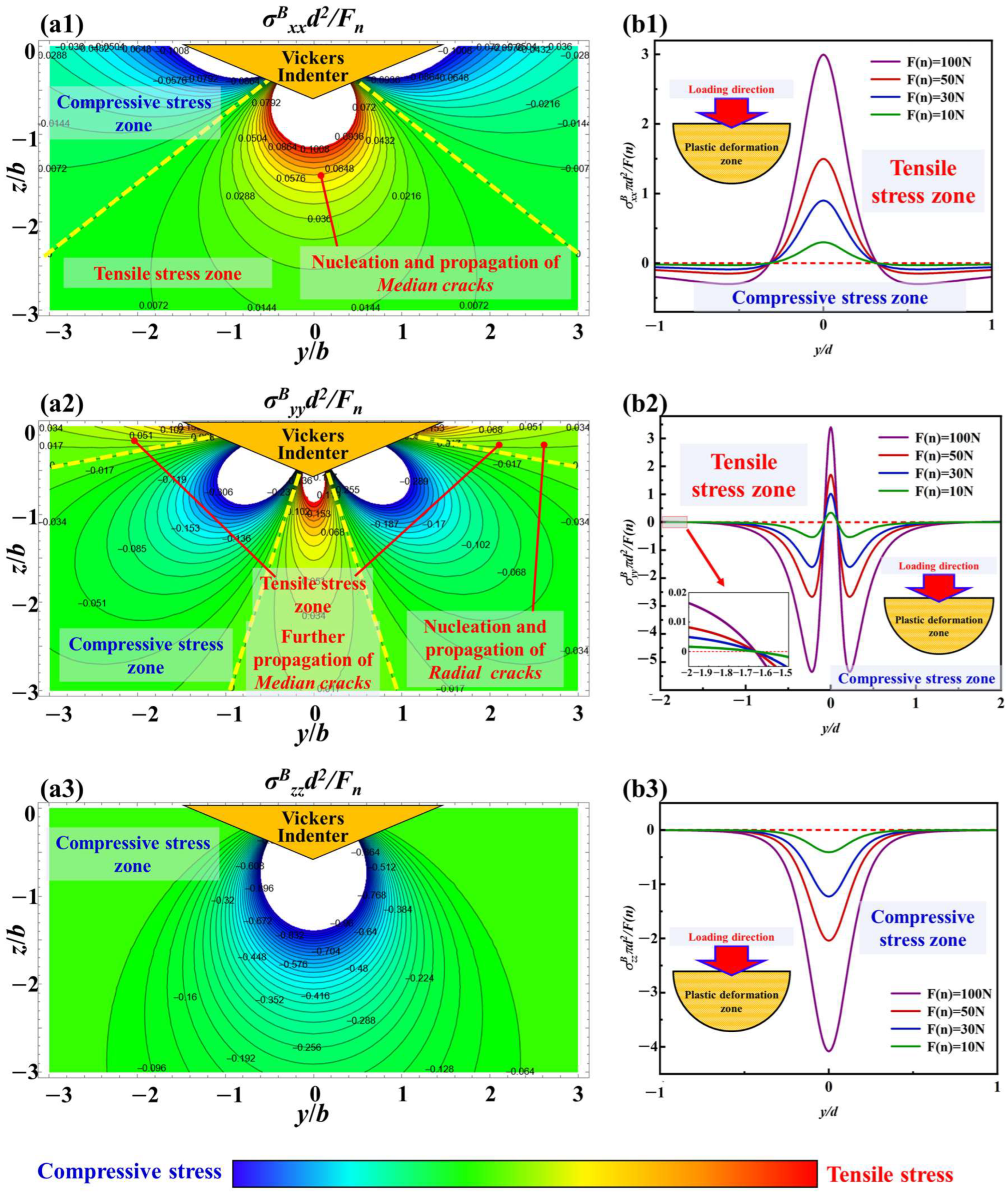

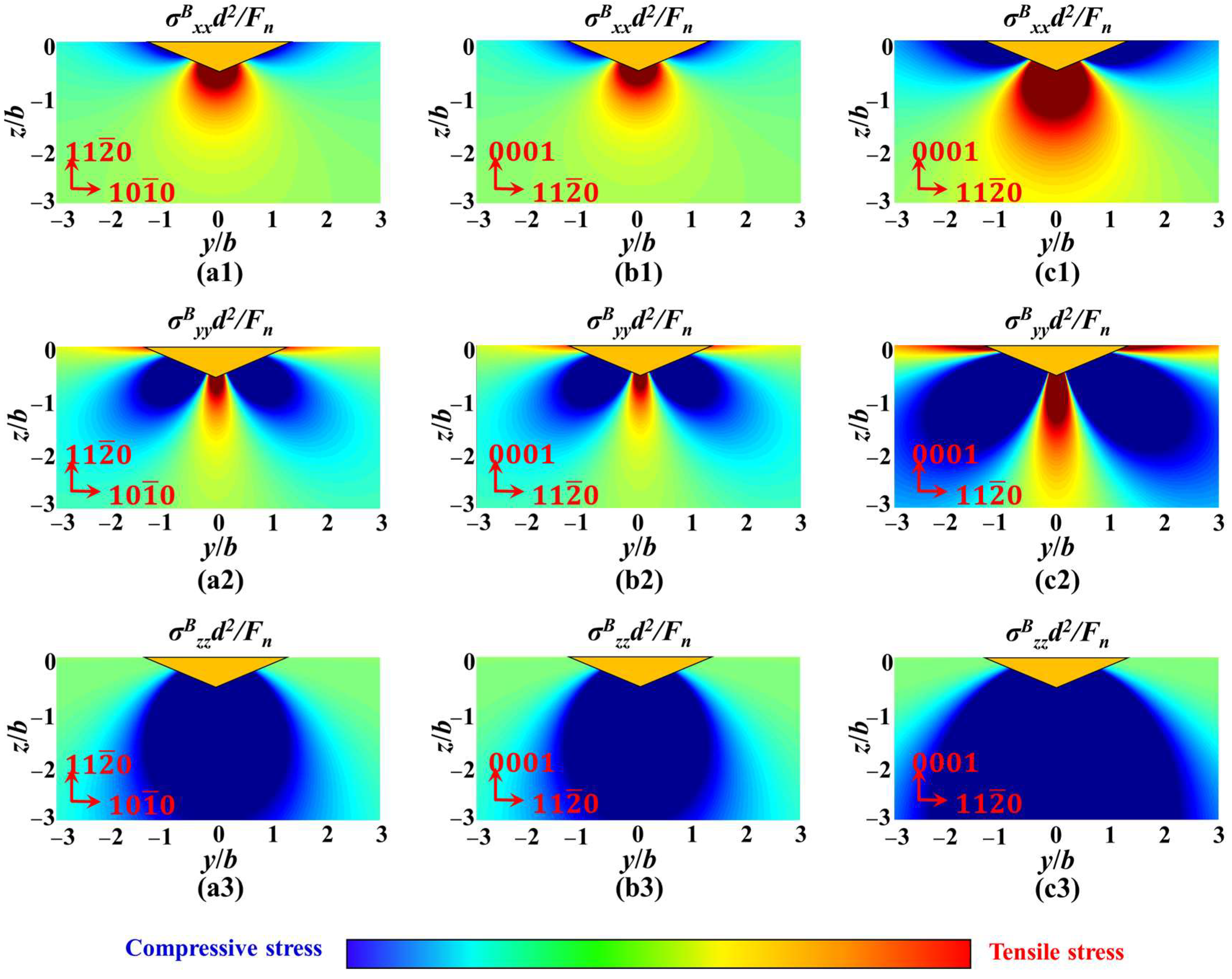

3.5. Stress Field Analysis

4. Conclusions

- (1)

- From experimental results, A-plane sapphire generated AC-orientation cracks, C-plane sapphire generated CR-direction cracks, and M-plane sapphire generated MC-orientation cracks. The indentation diagonal half-length relative errors of a-orientation (1 kgf), c-orientation (3 kgf), and m-orientation (10 kgf) are 4.81%, 6.79% and 17.94%, respectively; the crack length relative errors are 2.96%, 6.1%, and 12.3% and the maximum indentation depth relative errors are 10.8%, 8.86% and 5.59%.

- (2)

- The critical load value of the median crack of sapphire in both A- and M-planes is less than 0.1 kgf experimentally and simulatively, while C-plane sapphire is between 1 kgf and 2 kgf. Hence, as the load of C-plane sapphire is 1 kgf, the nucleation of radial crack occurred slowly, while the nucleation of median crack did not. However, the nucleation of both radial and median cracks occurred in A- and M-plane sapphire under the load of this paper’s experiment.

- (3)

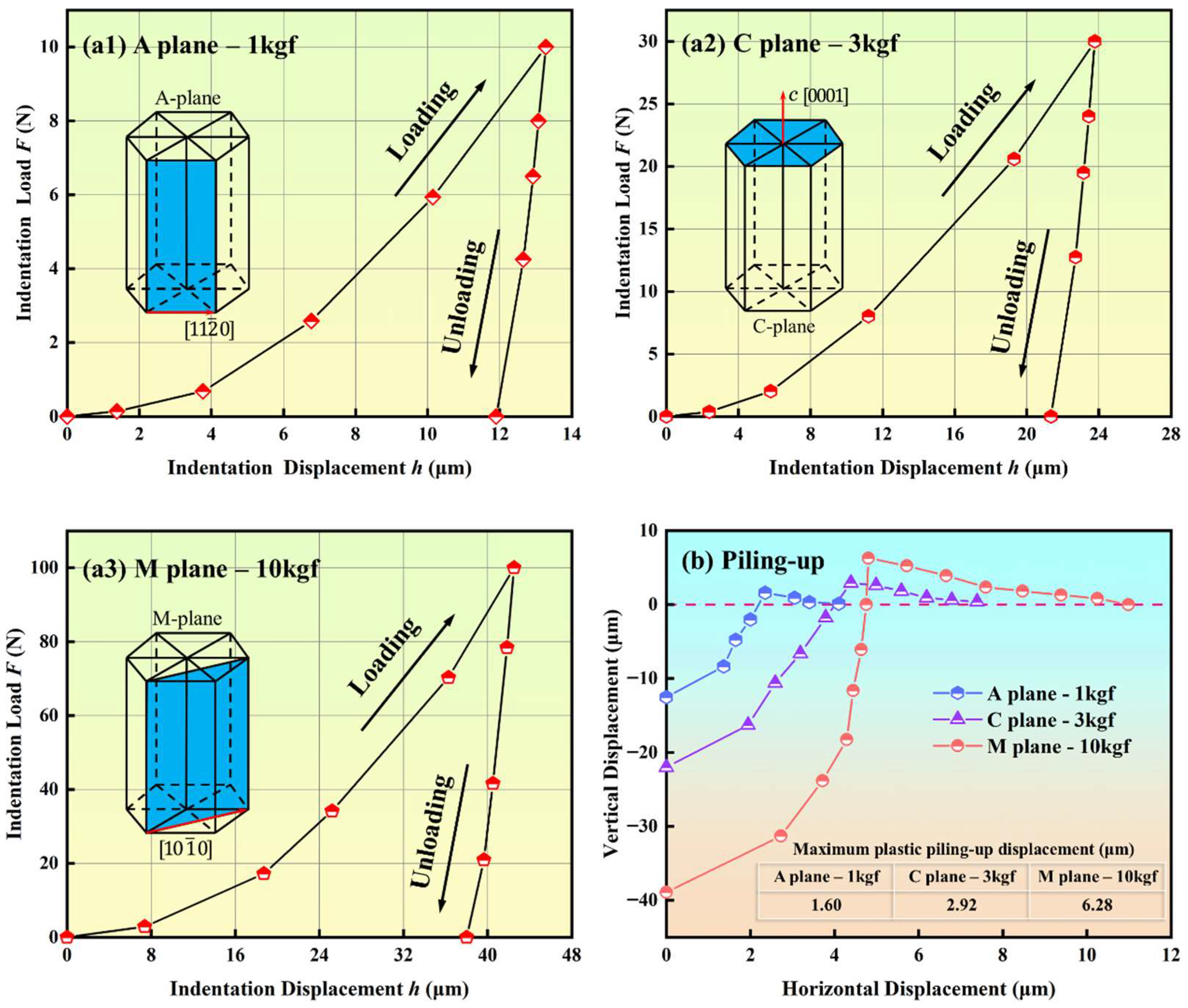

- From simulation results, the maximum depth of Vickers indentation of a-orientation (1 kgf), c-orientation (3 kgf), and m-orientation (10 kgf) are 13.279 μm, 23.775 μm, and 42.507 μm, respectively, and the corresponding linear elastic recovery rates are 10.5%, 7.42%, and 8.44%. The maximum plastic piling-up displacement of a-orientation (1 kgf), c-orientation (3 kgf), and m-orientation (10 kgf) are 1.60 μm, 2.92 μm, and 6.28 μm.

- (4)

- The radial cracks, which commenced earlier than the median crack, nucleate immediately at the initial contact, and then begin to propagate along the horizontal direction (priority at the crystal boundary) and along the elastic–plastic boundary direction. In the unloading stage, the radial crack has further propagation, and the median crack will propagate towards the free surface with large tensile stress and converge with the radial crack to form a median/radial crack system. The generation of lateral cracks will occur during the process of unloading, even at the end. Under the load of 20 kgf, the surface of Vickers indentations with three crystal orientations appeared brittle spalling or even cracking, owing to abundant lateral cracks, nucleated and propagated.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, Y.; Lu, J.; Xu, X.; Chen, C.-C.A.; Lin, Y. Study on high efficient sapphire wafer processing by coupling SG-mechanical polishing and GLA-CMP. Int. J. Mach. Tools Manuf. 2018, 130–131, 12–19. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, J.; Hu, W.; Zhang, L.; Xie, W.; Liao, L. Chemical mechanical polishing for sapphire wafers using a developed slurry. J. Manuf. Process. 2021, 62, 762–771. [Google Scholar] [CrossRef]

- Zhou, M.; Zhong, M.; Xu, W. Effects of ultrasonic amplitude on sapphire ultrasonic vibration assisted chemical mechanical polishing by experimental and CFD method. Mech. Adv. Mater. Struct. 2021, 29, 7086–7103. [Google Scholar] [CrossRef]

- Xu, W.; Sheng, C.; Zhong, M. Effects of ultrasonic vibration on sapphire polishing investigated by molecular dynamics. Tribol. Int. 2022, 176, 107911. [Google Scholar] [CrossRef]

- Xu, L.; Lei, H.; Wang, T.; Dong, Y.; Dai, S. Preparation of flower-shaped silica abrasives by double system template method and its effect on polishing performance of sapphire wafers. Ceram. Int. 2019, 45, 8471–8476. [Google Scholar] [CrossRef]

- Chen, Y.; Hu, Z.; Yu, Y.; Lai, Z.; Zhu, J.; Xu, X.; Peng, Q. Processing and machining mechanism of ultrasonic vibration-assisted grinding on sapphire. Mater. Sci. Semicond. Process. 2022, 142, 106470. [Google Scholar] [CrossRef]

- Deng, J.; Xiong, Q.; Nie, X.; Yan, Q.; Cao, J.; Lu, J. Optimisation of free-abrasive assisted lapping process with vitrified bonded diamond plates for sapphire substrates. Precis. Eng. 2024, 86, 183–194. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Z.; Hu, Y. Effects of polishing parameters on surface quality in sapphire double-sided CMP. Ceram. Int. 2020, 46, 13356–13364. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Z.; Ge, J.; Liu, T.; Wan, L. Experimental and theoretical analysis of single-sided and double-sided chemical mechanical polishing of sapphire wafers. Int. J. Adv. Manuf. Technol. 2022, 119, 5095–5106. [Google Scholar] [CrossRef]

- Li, Z.; Deng, Z.; Ge, J.; Zhuo, R.; Wan, L. Material Removal Rate Prediction for Sapphire Double-Sided CMP Based on RSM-SVM. ECS J. Solid State Sci. Technol. 2022, 11, 084002. [Google Scholar] [CrossRef]

- Chaslin, E.; Simon, Q.; Borroto, A.; Bruyère, S.; Migot, S.; Himdi, M.; Castel, X. Epitaxial cerium oxide films deposited on r-plane sapphire substrates: A comprehensive study of growth mechanisms. Appl. Surf. Sci. 2025, 696, 162917. [Google Scholar] [CrossRef]

- Huang, Y.; Song, Y.; Liu, Y.; Jia, H.; Wang, W.; Du, C.; Deng, Z.; Wang, Y.; Wang, X.; Sun, C.; et al. Direct epitaxy of high-quality a-plane GaN on r-plane sapphire substrate using patterned SiO2 mask. J. Alloys Compd. 2025, 1040, 183071. [Google Scholar] [CrossRef]

- Gong, S.; Zhu, X.; Sun, Y.; Tang, B.; Su, Z. Experimental research on surface characteristics and subsurface damage behavior of monocrystal sapphire induced by helical micro abrasive tools. Ceram. Int. 2022, 48, 21500–21513. [Google Scholar] [CrossRef]

- Luo, B.; Yan, Q.; Pan, J.; Lu, J.; Huang, Z. Influences of processing parameters on metal-bonded diamond wheel wear when grinding a sapphire wafer. Diam. Relat. Mater. 2021, 113, 108275. [Google Scholar] [CrossRef]

- Sun, Y.; Su, Z.P.; Gong, Y.D.; Jin, L.Y.; Wen, Q.; Qi, Y. An experimental and numerical study of micro-grinding force and performance of sapphire using novel structured micro abrasive tool. Int. J. Mech. Sci. 2020, 181, 105741. [Google Scholar] [CrossRef]

- Wang, L.; Hu, Z.; Chen, Y.; Yu, Y.; Xu, X. Material removal mechanism of sapphire substrates with four crystal orientations by double-sided planetary grinding. Ceram. Int. 2020, 46, 7813–7822. [Google Scholar] [CrossRef]

- Wang, S.; Zhao, Q.; Yang, X. Surface and subsurface microscopic characteristics in sapphire ultra-precision grinding. Tribol. Int. 2022, 174, 107710. [Google Scholar] [CrossRef]

- Geng, Y.; Sun, G.; Wang, S.; Zhao, Q. Fractal characterization of surface complexity and anisotropic scratch evolution in sapphire polishing. Tribol. Int. 2026, 214, 111149. [Google Scholar] [CrossRef]

- Wachtman, J.B.; Maxwell, L.H. Plastic deformation of ceramic-oxide single crystals, 2. J. Am. Ceram. Soc. 1957, 40, 377–385. [Google Scholar] [CrossRef]

- Kronberg, M.L. Plastic deformation of single crystals of sapphire—Basal slip and twinning. Acta Metall. 1957, 5, 507–524. [Google Scholar] [CrossRef]

- Hockey, B.J. Plastic deformation of aluminum oxide by indentation and abrasion. J. Am. Ceram. Soc. 1971, 54, 223–231. [Google Scholar] [CrossRef]

- Page, T.F.; Oliver, W.C.; McHargue, C.J. The deformation-behavior of ceramic crystals subjected to very low load (nano)indentations. J. Mater. Res. 1992, 7, 450–473. [Google Scholar] [CrossRef]

- Chan, H.M.; Lawn, B.R. Indentation deformation and fracture of sapphire. J. Am. Ceram. Soc. 1988, 71, 29–35. [Google Scholar] [CrossRef]

- Haney, E.J.; Subhash, G. Static and dynamic indentation response of basal and prism plane sapphire. J. Eur. Ceram. Soc. 2011, 31, 1713–1721. [Google Scholar] [CrossRef]

- Nowak, R.; Sekino, T.; Maruno, S.; Niihara, K. Deformation of sapphire induced by a spherical indentation on the (1010) plane. Appl. Phys. Lett. 1996, 68, 1063–1065. [Google Scholar] [CrossRef]

- Voloshin, A.V.; Dolzhenkova, E.F.; Litvinov, L.A. Anisotropy of deformation and fracture processes in sapphire surface. J. Superhard Mater. 2015, 37, 341–345. [Google Scholar] [CrossRef]

- Nowak, R.; Sekino, T.; Niihara, K. Non-linear surface deformation of the (1010) plane of sapphire: Identification of the linear features around spherical impressions. Acta Mater. 1999, 47, 4329–4338. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, F.; Li, Y.; Wang, N.; Hu, Z.; Yan, L.; Lu, J.; Wen, Q.; Lu, X. Prediction of pop-in load for sapphires with different crystal orientations. Ceram. Int. 2020, 46, 6682–6692. [Google Scholar] [CrossRef]

- Maas, P.; Mizumoto, Y.; Kakinuma, Y.; Min, S. Anisotropic brittle-ductile transition of monocrystalline sapphire during orthogonal cutting and nanoindentation experiments. Nanotechnol. Precis. Eng. 2018, 1, 157–171. [Google Scholar] [CrossRef]

- Zhang, Y.; Hu, Z.; Yu, Y.; Xu, X.; Cai, X.; Peng, Q.; Zeng, W.; Zhong, W.; Blunt, L.; Jiang, X. Anisotropic plastic deformation and damage evolution of sapphire under nanoindentation. Int. J. Mech. Sci. 2025, 307, 110769. [Google Scholar] [CrossRef]

- Yan, S.; Nawaz, A.; Islam, B.; Qin, Q.-H.; Mao, W.; Shen, Y.; Ahmad, I.; Hussain, I. Elastic-plastic deformation behavior of sapphire M-plane under static loading using nano-indentation. Ceram. Int. 2021, 47, 23528–23538. [Google Scholar] [CrossRef]

- Sheng, C.; Zhong, M.; Xu, W. A study on mechanism of sapphire polishing using the diamond abrasive by molecular dynamics. Mech. Adv. Mater. Struct. 2021, 30, 319–331. [Google Scholar] [CrossRef]

- Kim, W.K.; Xi, D.; Kim, B.H. Nanoscale indentation and scratching tests of single crystal sapphire using molecular dynamics simulation. Comput. Mater. Sci. 2019, 170, 109195. [Google Scholar] [CrossRef]

- Lin, J.; Jiang, F.; Xu, X.; Lu, J.; Tian, Z.; Wen, Q.; Lu, X. Molecular dynamics simulation of nanoindentation on c-plane sapphire. Mech. Mater. 2021, 154, 103716. [Google Scholar] [CrossRef]

- Jiang, F.; Luan, X.; Wang, N.; Xu, X.; Lu, X.; Wen, Q. Research on the dynamic mechanical properties of C-plane sapphire under impact loading. Ceram. Int. 2018, 44, 9839–9847. [Google Scholar] [CrossRef]

- Zhao, G.; Lin, Y.; Zheng, X.; Chen, B.; Wang, S.; Lin, Z.; Lu, Y.; Chen, Z.; Guo, W. Global context enhanced resolution networks for sapphire scratch detection and classification. Opt. Laser Technol. 2025, 184, 112522. [Google Scholar] [CrossRef]

- Luan, X.; Jiang, F.; Wang, N.; Xu, X.; Lu, X.; Wen, Q. The mechanical response characteristics of sapphire under dynamic and quasi-static indentation loading. Ceram. Int. 2018, 44, 15208–15218. [Google Scholar] [CrossRef]

- Wang, K.; Jiang, F.; Yan, L.; Xu, X.; Wang, N.; Zha, X.; Lu, X.; Wen, Q. Study on mechanism of crack propagation of sapphire single crystals of four different orientations under impact load and static load. Ceram. Int. 2019, 45, 7359–7375. [Google Scholar] [CrossRef]

- Wen, Q.; Chen, J.; Wei, X.; Lu, J.; Huang, H.; Cui, C.; Jiang, F. Crystal orientation-dependent scribing of A-, C-, and M-plane sapphires by an ultraviolet laser. Ceram. Int. 2022, 48, 18842–18854. [Google Scholar] [CrossRef]

- Zhao, W.; Wang, Y.; Liang, Z.; Zhou, T.; Wang, X.; Lin, H.; Zhong, J.; Luan, X. Research on ground surface characteristics of prism-plane sapphire under the orthogonal grinding direction. Appl. Surf. Sci. 2019, 489, 802–814. [Google Scholar] [CrossRef]

- Zhang, L.; Zhu, L.; Zhou, T.; Guo, P.; Wang, X.; Liu, P.; Shao, W. Study on the grinding characteristics of sapphire with the assistant of cerium oxide liquid. Mater. Des. 2022, 215, 110451. [Google Scholar] [CrossRef]

- Hyun, H.C.; Rickhey, F.; Lee, J.H.; Hahn, J.H.; Lee, H. Characteristics of indentation cracking using cohesive zone finite element techniques for pyramidal indenters. Int. J. Solids Struct. 2014, 51, 4327–4335. [Google Scholar] [CrossRef]

- Hyun, H.C.; Rickhey, F.; Lee, J.H.; Kim, M.; Lee, H. Evaluation of indentation fracture toughness for brittle materials based on the cohesive zone finite element method. Eng. Fract. Mech. 2015, 134, 304–316. [Google Scholar] [CrossRef]

- Deighton, M. Fracture of Brittle Solids. Phys. Bull. 1976, 27, 220–221. [Google Scholar] [CrossRef]

- Lawn, B.R.; Evans, A.G. Model for crack initiation in elastic-plastic indentation fields. J. Mater. Sci. 1977, 12, 2195–2199. [Google Scholar] [CrossRef]

- Lawn, B.R.; Evans, A.G.; Marshall, D.B. Elastic-plastic indentation damage in ceramics—The median-radial crack system. J. Am. Ceram. Soc. 1980, 63, 574–581. [Google Scholar] [CrossRef]

- Anstis, G.R.; Chantikul, P.; Lawn, B.R.; Marshall, D.B. A critical-evaluation of indentation techniques for measuring fracture-toughness, 1. direct crack measurements. J. Am. Ceram. Soc. 1981, 64, 533–538. [Google Scholar] [CrossRef]

- Lawn, B.R.; Marshall, D.B. Hardness, toughness, and brittleness—Indentation analysis. J. Am. Ceram. Soc. 1979, 62, 347–350. [Google Scholar] [CrossRef]

- Zhan, X.; Wu, J.; Wu, H.; Wang, M.; Hui, Y.; Shang, Q.; Ren, Y. A new modified ECM approach on the identification of plastic anisotropic properties by spherical indentation. Mater. Des. 2018, 139, 392–408. [Google Scholar] [CrossRef]

- Yoffe, E.H. Elastic stress fields caused by indenting brittle materials. Philos. Mag. A-Phys. Condens. Matter Struct. Defects Mech. Prop. 1982, 46, 617–628. [Google Scholar] [CrossRef]

- Lankford, J.; Davidson, D.L. Crack-initiation threshold in ceramic materials subject to elastic-plastic indentation. J. Mater. Sci. 1979, 14, 1662–1668. [Google Scholar] [CrossRef]

- Zhang, B.; Tokura, H.; Yoshikawa, M. Study on surface cracking of alumina scratched by single-point diamonds. J. Mater. Sci. 1988, 23, 3214–3224. [Google Scholar] [CrossRef]

| Materials | Density ρ (g/cm3) | Elastic Modulus E (MPa) | Yield Strength σ (MPa) | Shear Modulus γ (MPa) | Poisson’s Ratio ν |

|---|---|---|---|---|---|

| Sapphire-c [0001] | 3.98 | 456,490 | 2920 | 140,000 | 0.28 |

| Sapphire-a | 3.98 | 431,240 | 2920 | 140,000 | 0.25 |

| Sapphire-m | 3.98 | 411,570 | 2920 | 140,000 | 0.25 |

| Diamond | 3.5 | 1,140,000 | - | - | 0.07 |

| Crystal Orientations | Loads (kgf) | Experimental Value | Simulation Value | ||||

|---|---|---|---|---|---|---|---|

| (μm) | (μm) | (μm) | (μm) | (μm) | (μm) | ||

| a [ | 1 | 15.36 | 60.71 | 11.32 | 14.62 | 58.91 | 11.89 |

| c [0001] | 3 | 32.54 | 123.14 | 24.15 | 34.75 | 115.63 | 22.01 |

| m [ | 10 | 97.76 | 187.69 | 39.86 | 115.3 | 210.78 | 38.92 |

| A-Plane | C-Plane | M-Plane | |

|---|---|---|---|

| Experiment () | 2.43 | 6.77 | 2.94 |

| Simulation () | 2.64 | 6.12 | 2.52 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, Z.; Deng, Z.; Yang, W.; Ge, J. Monocrystalline Sapphire Stress Field Analysis with Orthorhombic Crystal Orientation Under Vickers Indentation. Materials 2025, 18, 5136. https://doi.org/10.3390/ma18225136

Li Z, Deng Z, Yang W, Ge J. Monocrystalline Sapphire Stress Field Analysis with Orthorhombic Crystal Orientation Under Vickers Indentation. Materials. 2025; 18(22):5136. https://doi.org/10.3390/ma18225136

Chicago/Turabian StyleLi, Zhongyang, Zhaohui Deng, Weiye Yang, and Jimin Ge. 2025. "Monocrystalline Sapphire Stress Field Analysis with Orthorhombic Crystal Orientation Under Vickers Indentation" Materials 18, no. 22: 5136. https://doi.org/10.3390/ma18225136

APA StyleLi, Z., Deng, Z., Yang, W., & Ge, J. (2025). Monocrystalline Sapphire Stress Field Analysis with Orthorhombic Crystal Orientation Under Vickers Indentation. Materials, 18(22), 5136. https://doi.org/10.3390/ma18225136