Analysis of Microstructure and Pore Formation Mechanism in Magnetic Pulse-Assisted Semi-Solid Brazed Joints of Cu/Al Tubes

Abstract

1. Introduction

2. Materials and Method

2.1. Materials

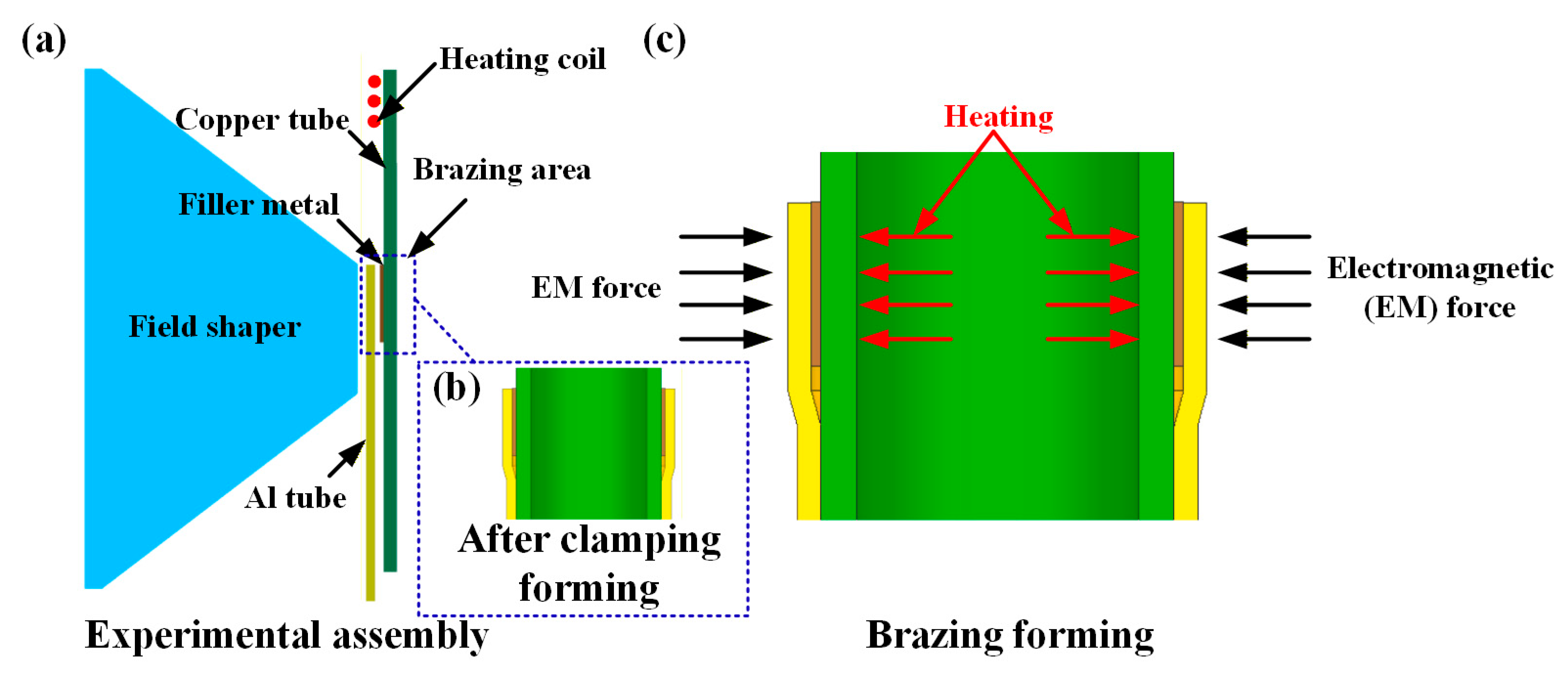

2.2. Experimental Methods

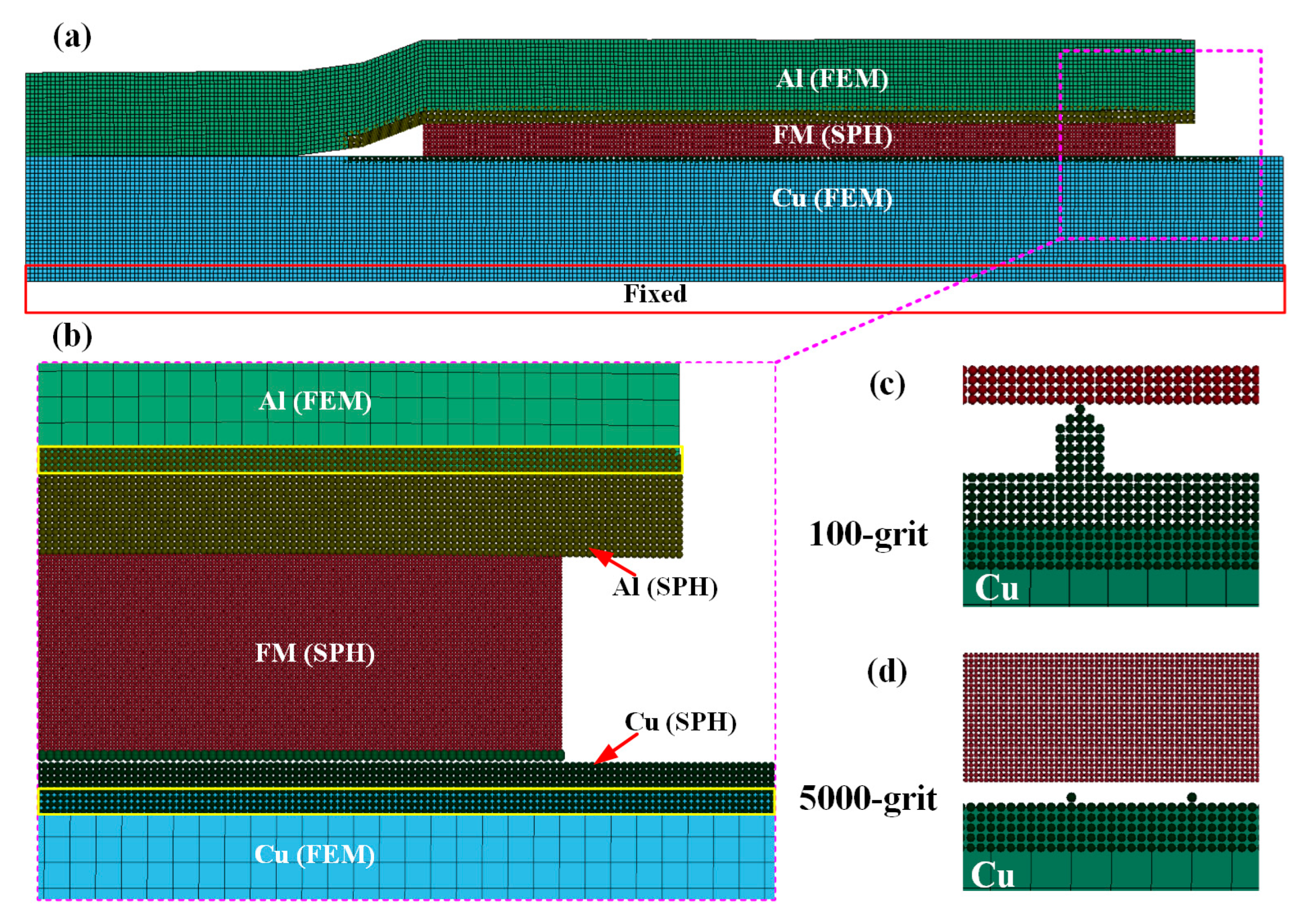

2.3. Simulation Analysis

3. Results

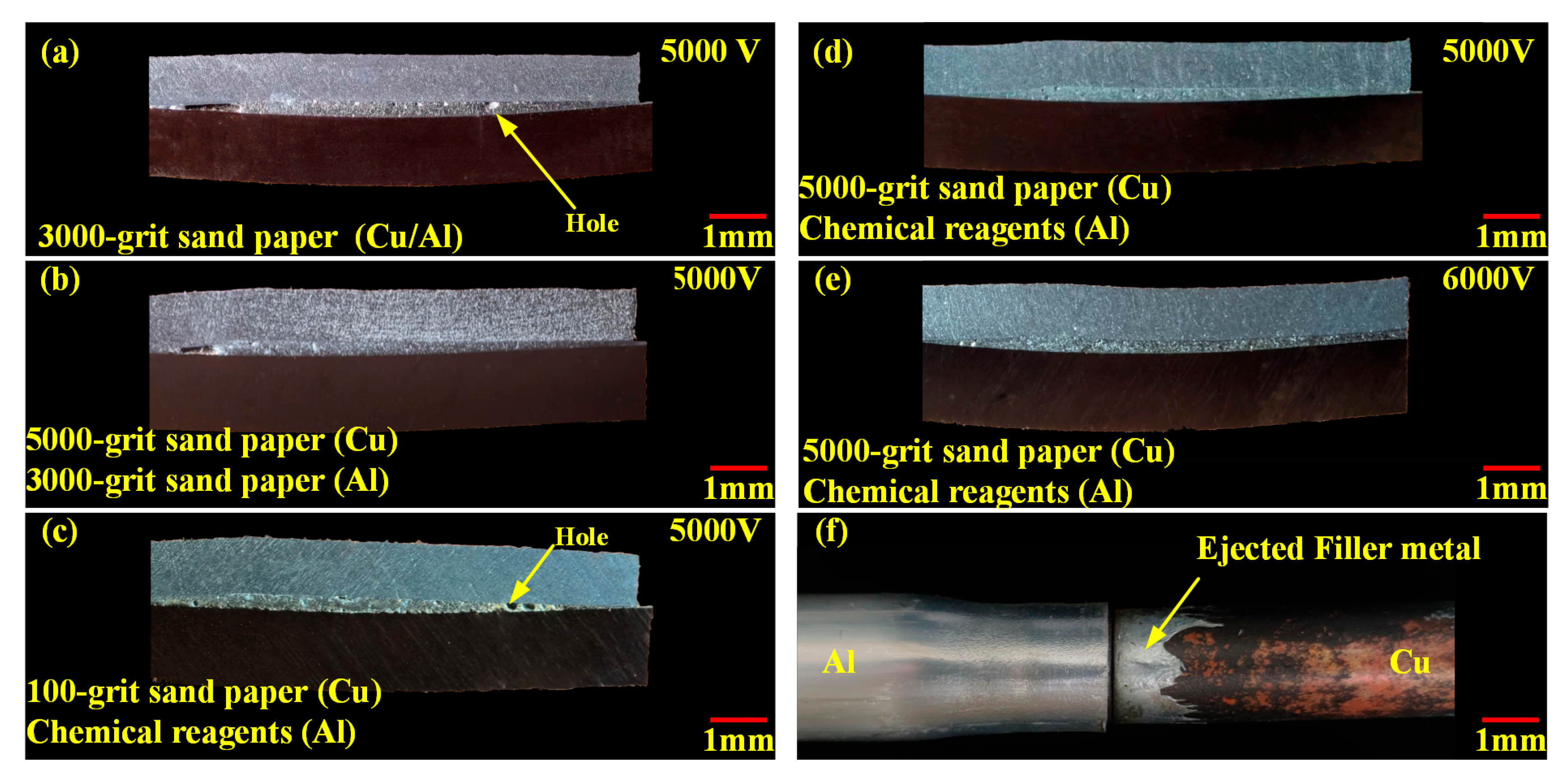

3.1. Analysis of Joint Macromorphology

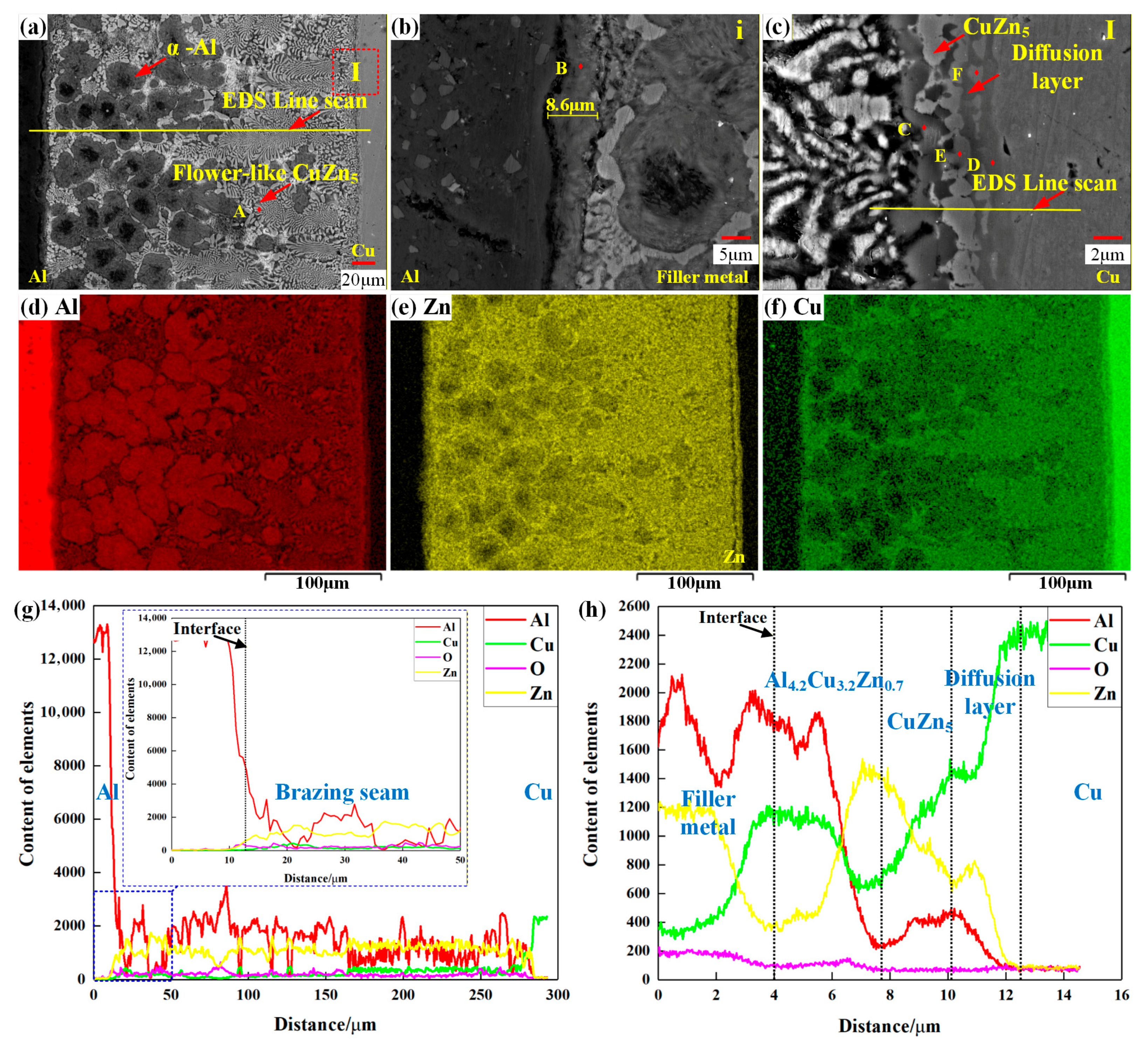

3.2. Analysis of Microstructure of Typical Joints

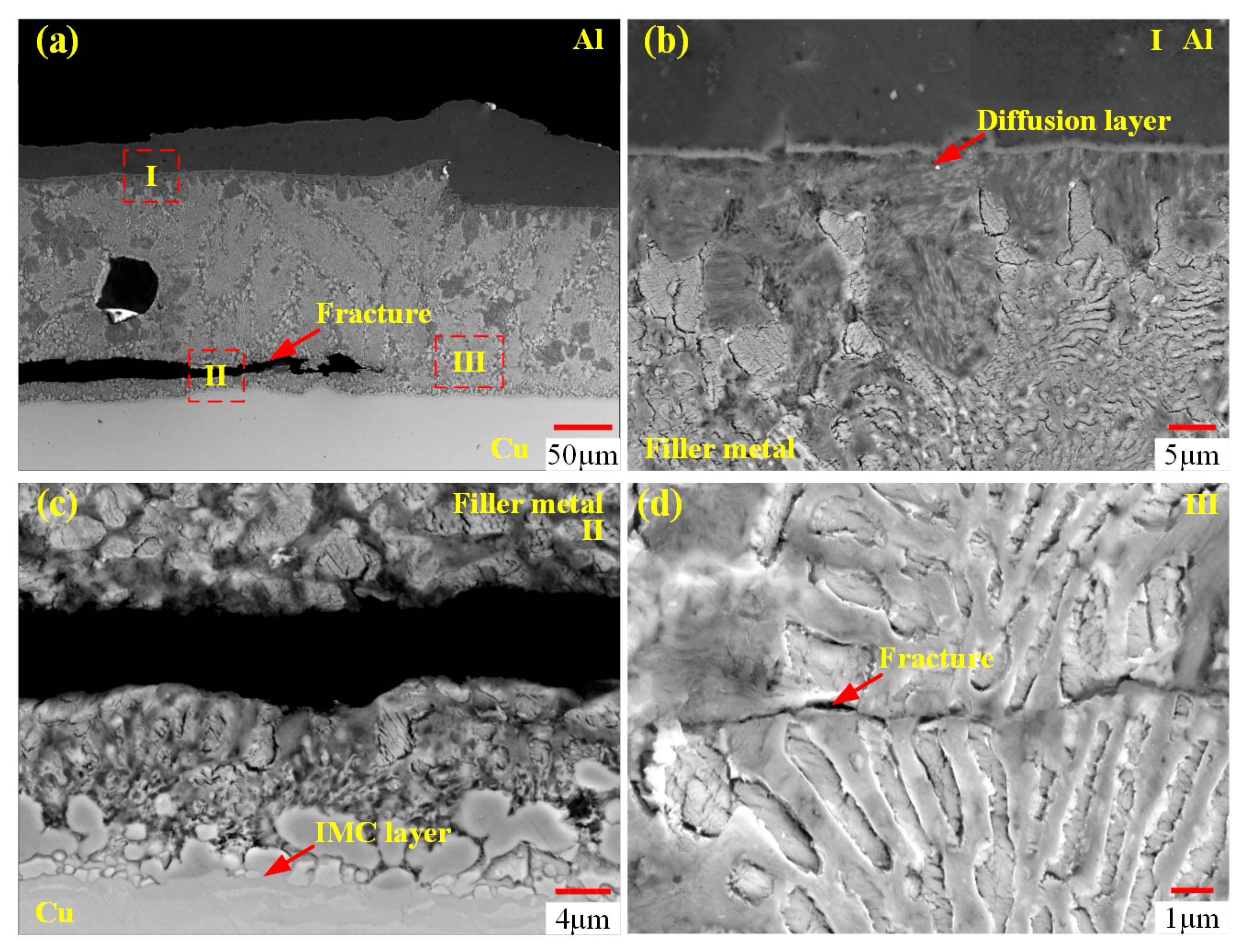

3.3. Analysis of Pore Formation Mechanism Under Solid–Liquid Interface Interaction

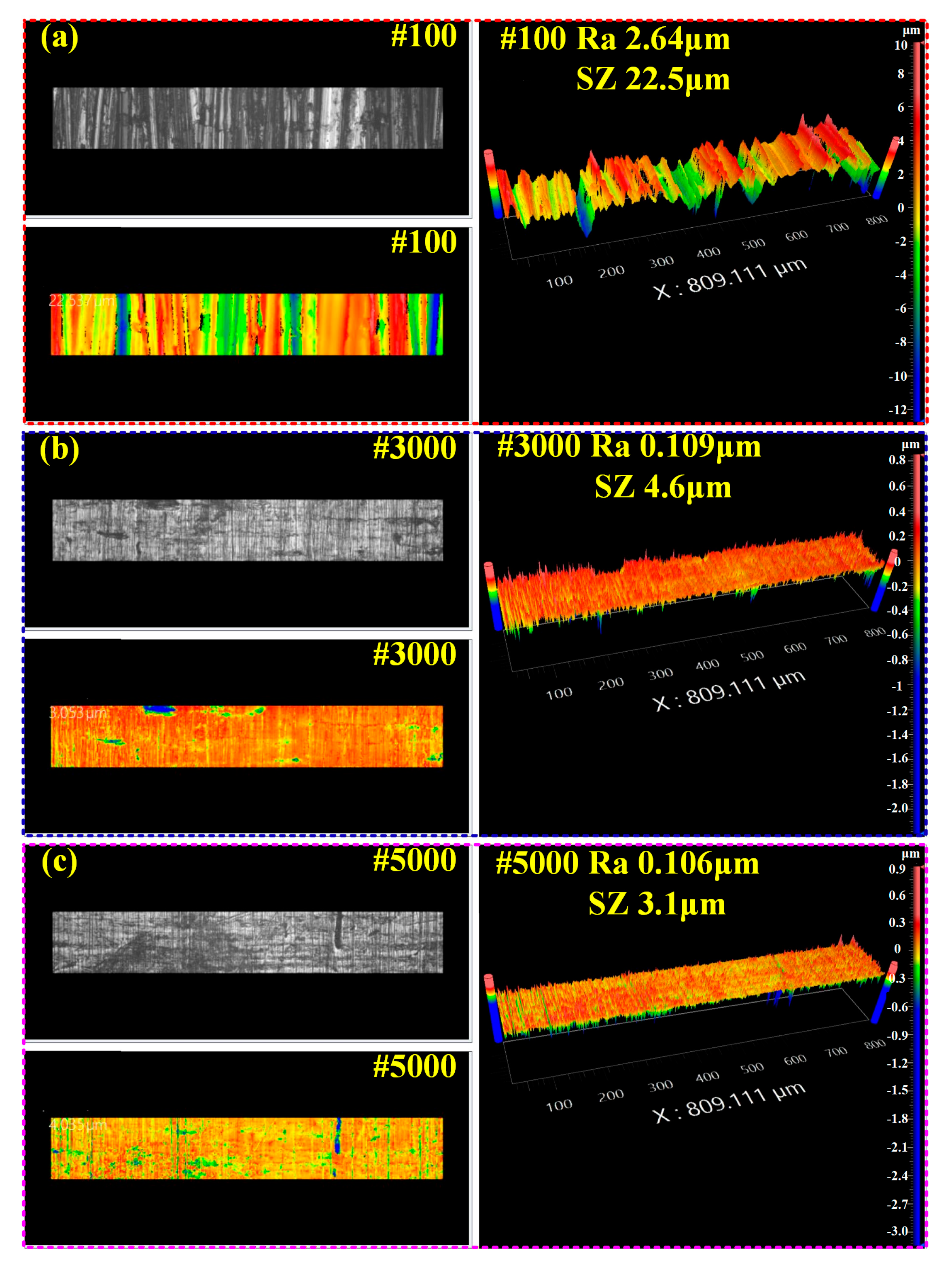

3.3.1. Analysis of Copper Tube Surface Roughness

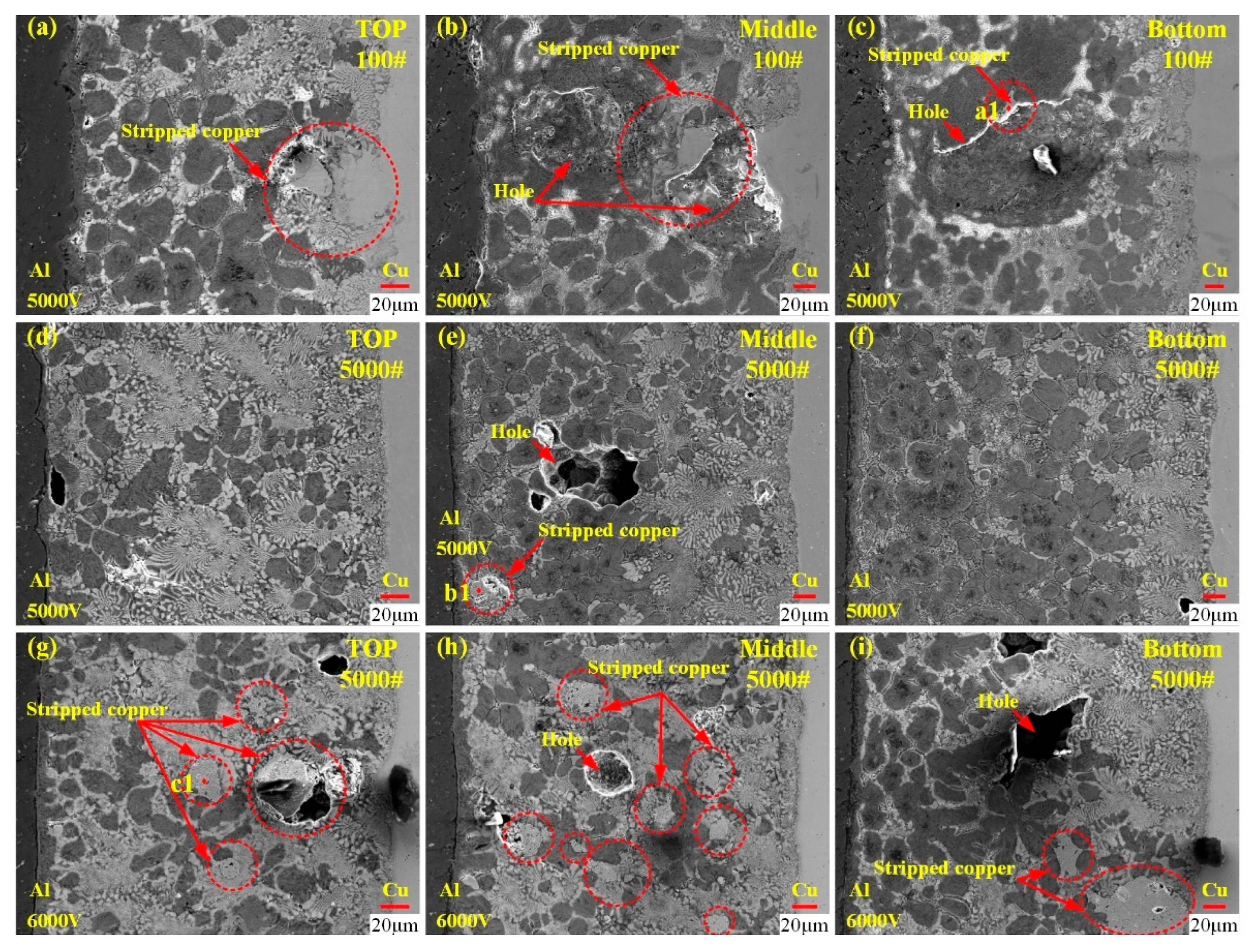

3.3.2. Effect of Copper Tube Surface Roughness on Joint Microstructure

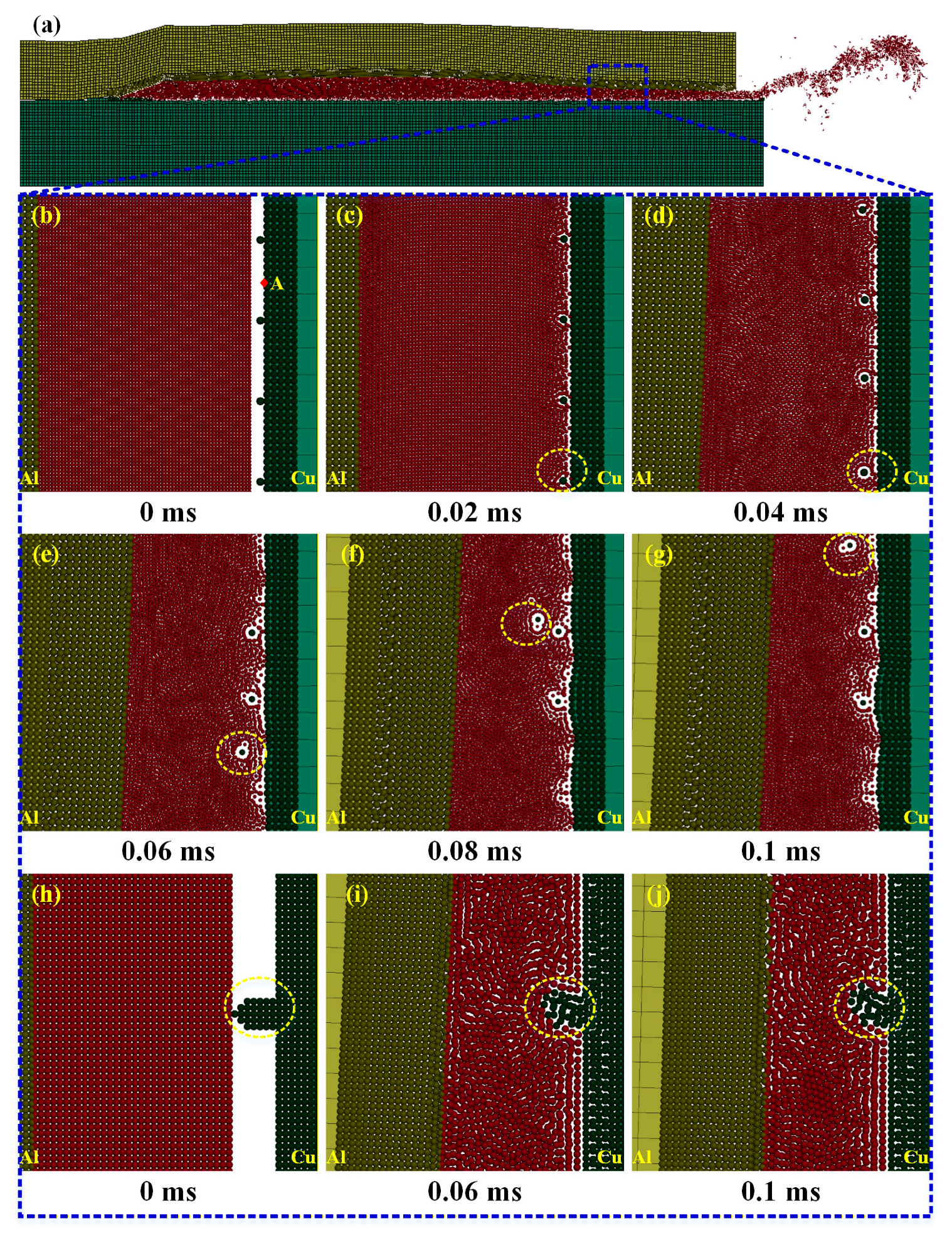

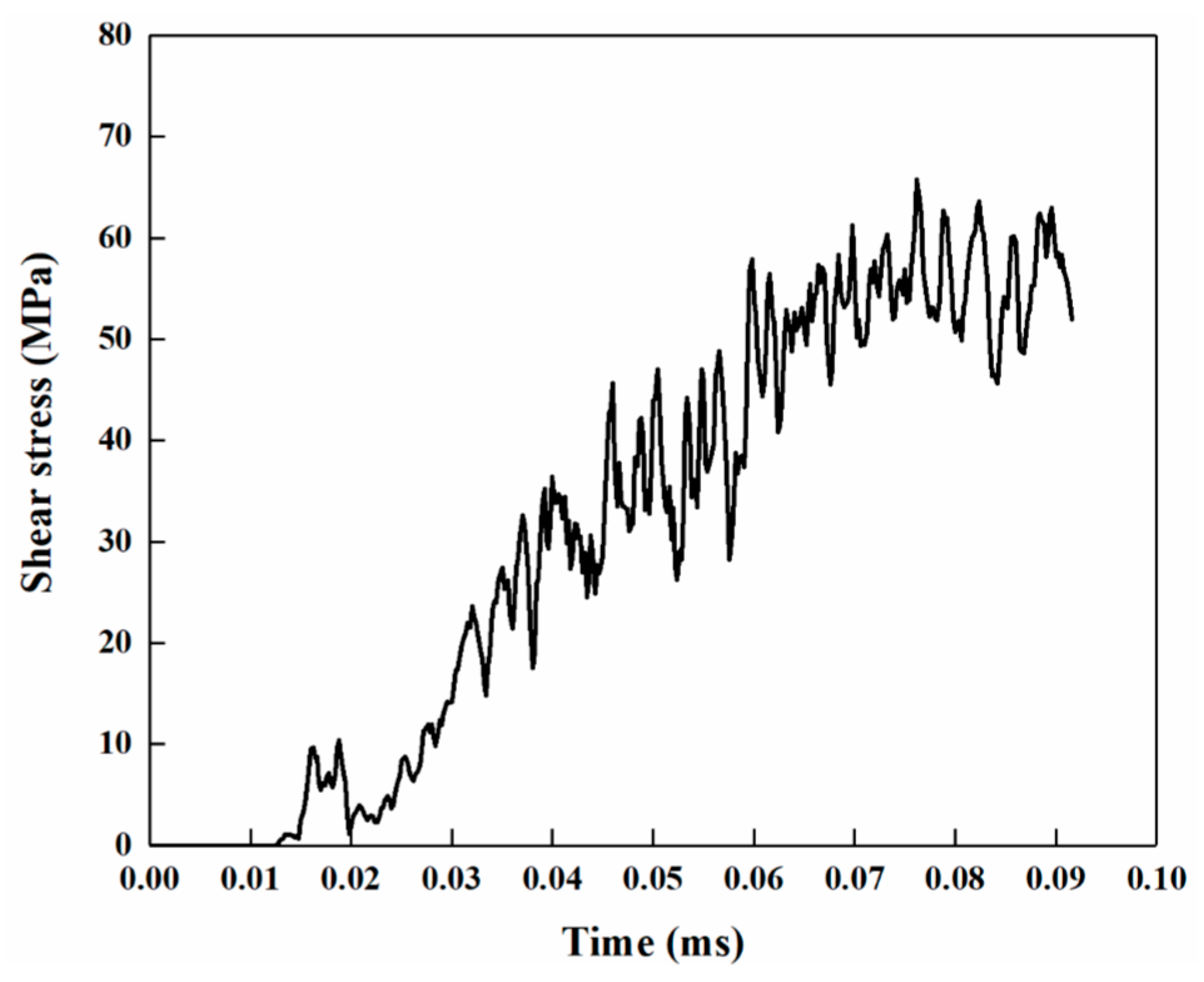

3.3.3. FEM-SPH Simulation

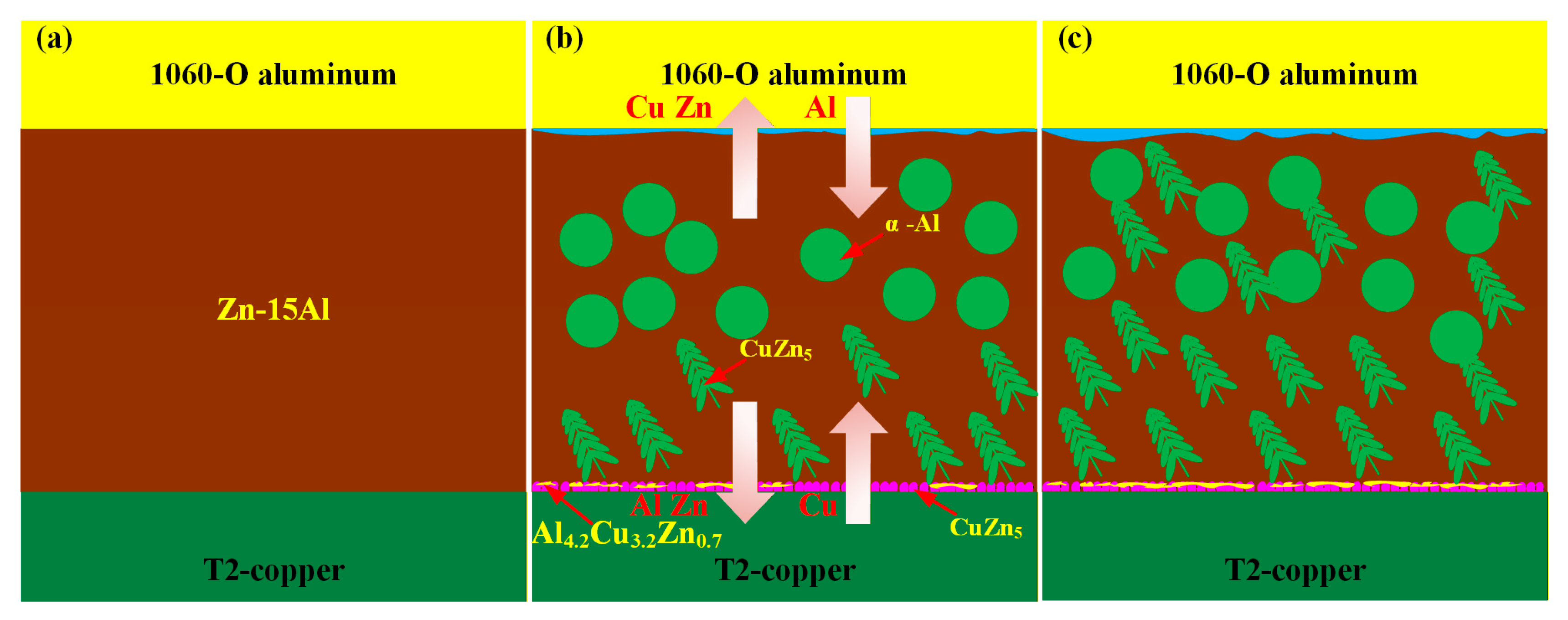

3.4. Analysis of Joint Microstructure Evolution Mechanism

3.5. Mechanical Properties of Joints

4. Conclusions

- (1)

- The MPASSB method enables the fabrication of Cu/Al tube joints with excellent metallurgical bonding at a low brazing temperature (390 °C). A diffusion layer is formed at the aluminum–side interface of the joint, while the copper–side interface consists of CuZn5 and Al4.2Cu3.7Zn0.7 phases. No brittle IMCs are detected in the joint.

- (2)

- The joints exhibit good mechanical properties, with a shear strength of 63.3 MPa and fractures occurring in the brazing seam area adjacent to the copper–side interface.

- (3)

- The FEM-SPH approach is well-suited for the simulation of solid–liquid coupling interactions. The solid–liquid interface interaction and the surface roughness of the tubes are the key factors influencing pore formation in the joint. Under the premise of ensuring effective joint bonding, the brazing forming voltage and the surface roughness of the tubes should be minimized as much as possible.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Beygi, R.; Carbas, R.J.C.; Marques, E.A.S.; Barbosa, A.Q.; Kasaei, M.; da Silva, L. Mechanism of toughness enhancement of brittle fracture by intermittent η-intermetallic in Al/Cu joint made by FSW. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2024, 890, 16. [Google Scholar] [CrossRef]

- Cai, H.; Yang, S.; Wang, Q.; Zhao, Y.; Jia, Q.; Ebrahimi, M.; Liu, L.; Guo, F.; Shang, Z. Interfacial Shear Fracture Behavior of C18150Cu/1060Al/C18150Cu Trilayered Composite at Different Temperatures. Materials 2025, 18, 559. [Google Scholar] [CrossRef] [PubMed]

- Paidar, M.; Mohanavel, V.; Ojo, O.O.; Mehrez, S.; Rajkumar, S.; Ravichandran, M. Dieless friction stir extrusion-brazing (DFSE-B) of AA2024-T3 aluminum alloy to copper with Zn interlayer. Results Phys. 2021, 24, 10. [Google Scholar] [CrossRef]

- Hou, W.T.; Shen, Z.K.; Huda, N.; Oheil, M.; Shen, Y.F.; Jahed, H.; Gerlich, A.P. Enhancing metallurgical and mechanical properties of friction stir butt welded joints of Al-Cu via cold sprayed Ni interlayer. Mater. Sci. Eng. A-Struct. Mater. Prop. Microstruct. Process. 2021, 809, 10. [Google Scholar] [CrossRef]

- Hu, T.; Li, B.; Wu, T.; Pan, H.; Ding, K.; Gao, Y. Characterization of the Microstructure and Interfacial Morphology of Magnetic Pulse Welded Steel/Al Tubes. Materials 2025, 18, 757. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Yang, D.; Yang, W.; Wu, Z.; Liu, C. Effect of Annealing Temperature on Microstructure and Properties of Al/Mg Magnetic Pulse Welding Joints. Materials 2022, 15, 5519. [Google Scholar] [CrossRef] [PubMed]

- Pourabbas, M.; Abdollah-Zadeh, A.; Sarvari, M.; Movassagh-Alanagh, F.; Pouranvari, M. Role of collision angle during dissimilar Al/Cu magnetic pulse welding. Sci. Technol. Weld. Join. 2020, 25, 549–555. [Google Scholar] [CrossRef]

- Yan, S.H.; Shi, Y. Influence of laser power on microstructure and mechanical property of laser-welded Al/Cu dissimilar lap joints. J. Manuf. Process. 2019, 45, 312–321. [Google Scholar] [CrossRef]

- Zhao, D.; Li, D.; Xiao, Y.; Li, M.Y.; Chen, W. Acoustic cavitation-induced microstructure evolution in ultrasonically brazed Al/Cu joints using Zn-Al alloy fillers. Ultrason. Sonochem. 2024, 109, 107001. [Google Scholar] [CrossRef] [PubMed]

- Huang, S.Y.; Rui, Z.L.; Xie, Z.P. Mechanism of oxide film removal and analysis of diffusion behavior of interfacial elements during magnetic pulse-assisted semi-solid brazing. J. Mater. Process. Technol. 2023, 318, 15. [Google Scholar] [CrossRef]

- Rui, Z.L.; Huang, S.Y.; Wang, H.J. Magnetic pulse-assisted semi-solid brazing of Cu/Al tubes: Finite element simulation and experimental analysis. Int. J. Adv. Manuf. Technol. 2025, 139, 6089–6106. [Google Scholar] [CrossRef]

- Rui, Z.; Huang, S.; Wang, H.; Meng, Z. The Influence of temperature on the microstructure and properties of Cu/Al tube joints in magnetic pulse-assisted semi-solid brazing. J. Adv. Join. Process. 2025, 11, 100313. [Google Scholar] [CrossRef]

- Xiong, Q.; Yang, M.; Liu, X.; Song, X.Q.; Qiu, L.; Jiang, J.B.; Yu, K. A Dual-Coil Method for Electromagnetic Attraction Forming of Sheet Metals. IEEE Access 2020, 8, 92708–92717. [Google Scholar] [CrossRef]

- Zhou, L.; Luo, L.Y.; Tan, C.W.; Li, Z.Y.; Song, X.G.; Zhao, H.Y.; Huang, Y.X.; Feng, J.C. Effect of welding speed on microstructural evolution and mechanical properties of laser welded-brazed Al/brass dissimilar joints. Opt. Laser Technol. 2018, 98, 234–246. [Google Scholar] [CrossRef]

- Liu, L.; Chen, Z.W.; Zhou, Z.X.; Chen, G.; Wu, F.S.; Liu, C.Q. Diffusion barrier property of electroless Ni-W-P coating in high temperature Zn-5Al/Cu solder interconnects. J. Alloy. Compd. 2017, 722, 746–752. [Google Scholar] [CrossRef]

- Gancarz, T.; Pstrus, J.; Mosinska, S.; Pawlak, S. Effect of Cu Addition to Zn-12Al Alloy on Thermal Properties and Wettability on Cu and Al Substrates. Metall. Mater. Trans. A-Phys. Metall. Mater. Sci. 2016, 47A, 368–377. [Google Scholar] [CrossRef]

- Zhang, H.; Liu, X.; Zhang, B.; Guo, Y. Enhancing the mechanical performances of friction stir lap welded Al-Zn-Mg-Cu alloy joint by promoting diffusion of alloying element Zn toward the pre-positioned Cu interlayer. Mater. Sci. Eng. A 2022, 832, 142467. [Google Scholar] [CrossRef]

- Niu, Z.; Ye, Z.; Huang, J.; Yang, H.; Yang, J.; Chen, S. Interfacial structure and properties of Cu/Al joints brazed with Zn-Al filler metals. Mater. Charact. 2018, 138, 78–88. [Google Scholar] [CrossRef]

- Xiao, Y.; Ji, H.J.; Li, M.Y.; Kim, J. Ultrasound-assisted brazing of Cu/Al dissimilar metals using a Zn-3Al filler metal. Mater. Des. 2013, 52, 740–747. [Google Scholar] [CrossRef]

- Yan, F.; Xu, D.R.; Wu, S.C.; Sun, Q.D.; Wang, C.M.; Wang, Y.J. Microstructure and phase constitution near the interface of Cu/3003 torch brazing using Al-Si-La-Sr filler. J. Mech. Sci. Technol. 2012, 26, 4089–4096. [Google Scholar] [CrossRef]

| Clamping Forming Voltage (V) | Brazing Forming Voltage (V) | Surface Cleaning (Sandpaper) | ||

|---|---|---|---|---|

| Cu | Al | |||

| 1 | 5000 | 5000 | 3000-grit | 3000-grit |

| 2 | 5000 | 5000 | 5000-grit | 3000-grit |

| 3 | 5000 | 5000 | 100-grit | chemical reagents |

| 4 | 5000 | 5000 | 5000-grit | chemical reagents |

| 5 | 5000 | 6000 | 5000-grit | chemical reagents |

| Point | At% | Possible Phase | |||

|---|---|---|---|---|---|

| Al | Cu | Zn | O | ||

| A | 2.8 | 15.2 | 66.8 | 15.1 | CuZn5 |

| B | 68.45 | 0.75 | 19.3 | 11.5 | Diffusion layer |

| C | 51.2 | 29.4 | 12.5 | 6.9 | Al4.2Cu3.2Zn0.7 |

| D | 19.3 | 48.5 | 27.6 | 4.6 | Diffusion layer |

| E | 12.0 | 26.5 | 60.6 | 0.9 | CuZn5 |

| F | 9.6 | 41.1 | 47.1 | 2.3 | Cu5Zn8 |

| Ra μm | SZ μm | |

|---|---|---|

| 100-grit | 0.045 | 22.5 |

| 3000-grit | 0.78 | 4.6 |

| 5000-grit | 2.22 | 3.1 |

| Analysis Point | At.% | Possible Phase | |||

|---|---|---|---|---|---|

| Al | Cu | Zn | O | ||

| a1 | 0.3 | 90.2 | 6.6 | 2.9 | Cu |

| b1 | 13.1 | 70.8 | 15.8 | 0.3 | Cu |

| c1 | 7.8 | 82.3 | 6.7 | 3.2 | Cu |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rui, Z.; Huang, S.; Wang, H. Analysis of Microstructure and Pore Formation Mechanism in Magnetic Pulse-Assisted Semi-Solid Brazed Joints of Cu/Al Tubes. Materials 2025, 18, 5121. https://doi.org/10.3390/ma18225121

Rui Z, Huang S, Wang H. Analysis of Microstructure and Pore Formation Mechanism in Magnetic Pulse-Assisted Semi-Solid Brazed Joints of Cu/Al Tubes. Materials. 2025; 18(22):5121. https://doi.org/10.3390/ma18225121

Chicago/Turabian StyleRui, Zhenglei, Shangyu Huang, and Huajun Wang. 2025. "Analysis of Microstructure and Pore Formation Mechanism in Magnetic Pulse-Assisted Semi-Solid Brazed Joints of Cu/Al Tubes" Materials 18, no. 22: 5121. https://doi.org/10.3390/ma18225121

APA StyleRui, Z., Huang, S., & Wang, H. (2025). Analysis of Microstructure and Pore Formation Mechanism in Magnetic Pulse-Assisted Semi-Solid Brazed Joints of Cu/Al Tubes. Materials, 18(22), 5121. https://doi.org/10.3390/ma18225121