Utilization of Brick Powder in Blended Cement Compositions: Rheological, Mechanical, and Microstructural Properties

Abstract

1. State of the Art

2. Materials and Experimental Program

2.1. Raw Materials and Mix Proportions

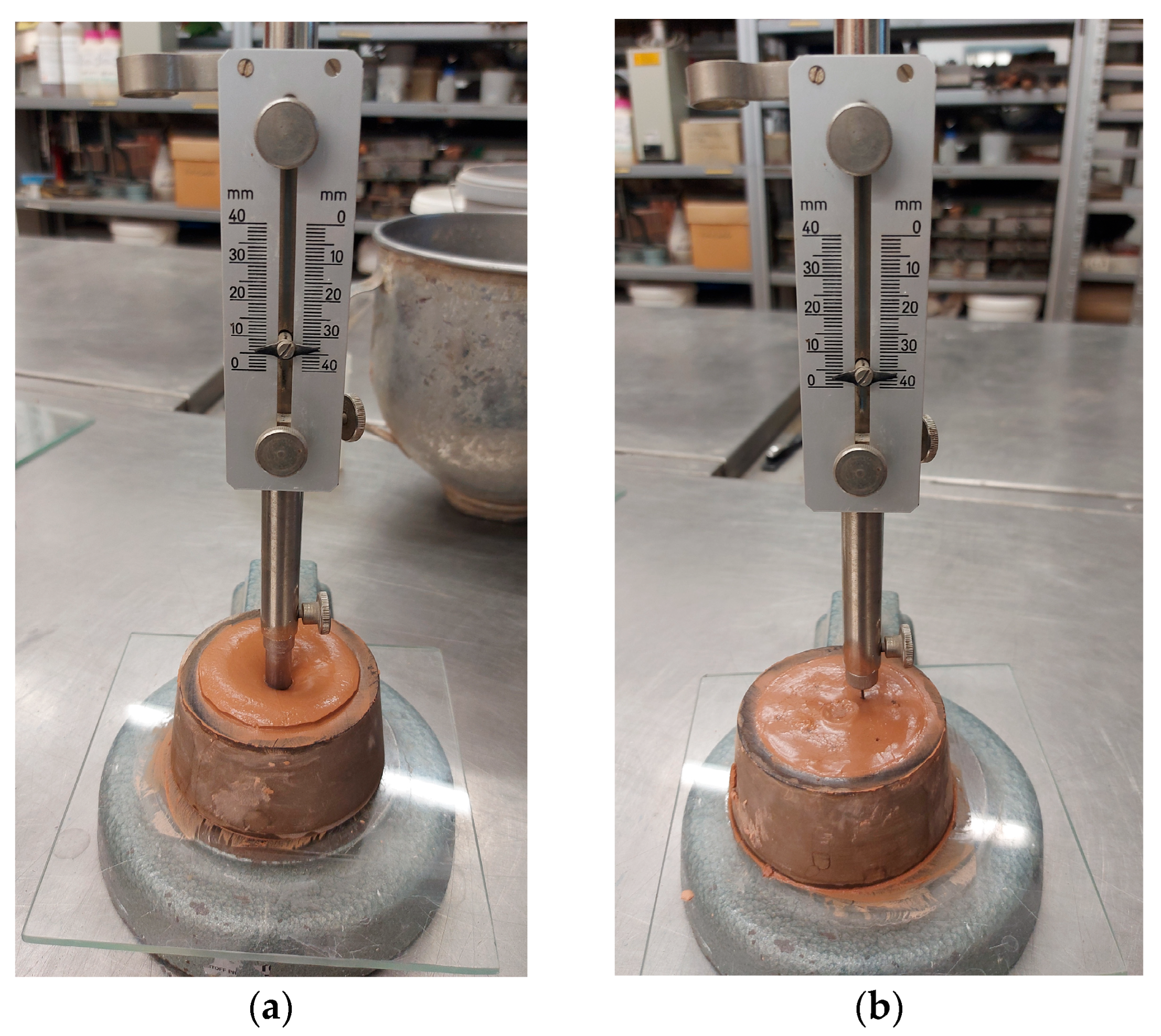

2.2. Standard Consistency and Setting Time

2.3. Workability

2.4. Water Absorption of Mineral Additives

2.5. Compressive and Flexural Strength

2.6. Strength Activity Index (SAI)

2.7. Microstructure Formation Analysis

2.7.1. Thermogravimetric Analysis (TGA)

2.7.2. Scanning Electron Microscopy Analysis (SEM)

2.7.3. Energy-Dispersive X-Ray Spectroscopy Analysis (EDX)

3. Test Results and Analysis

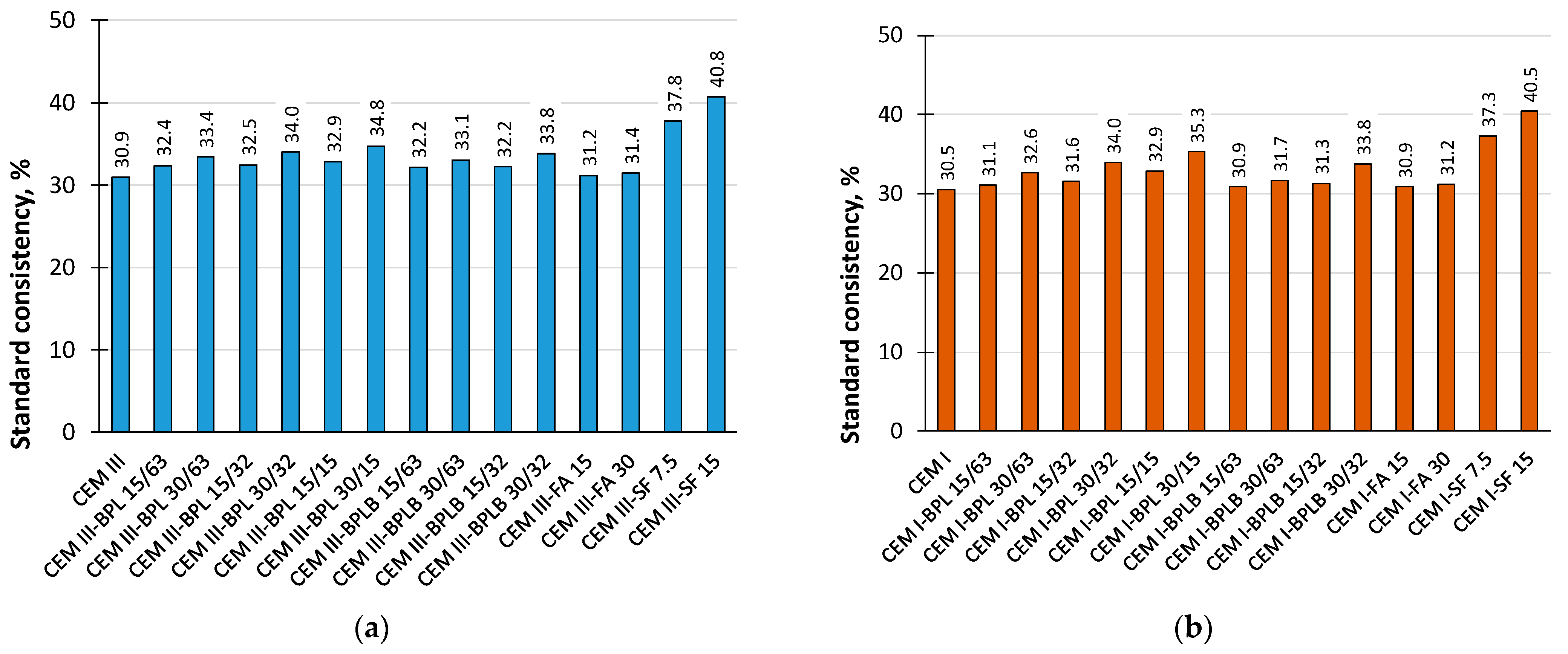

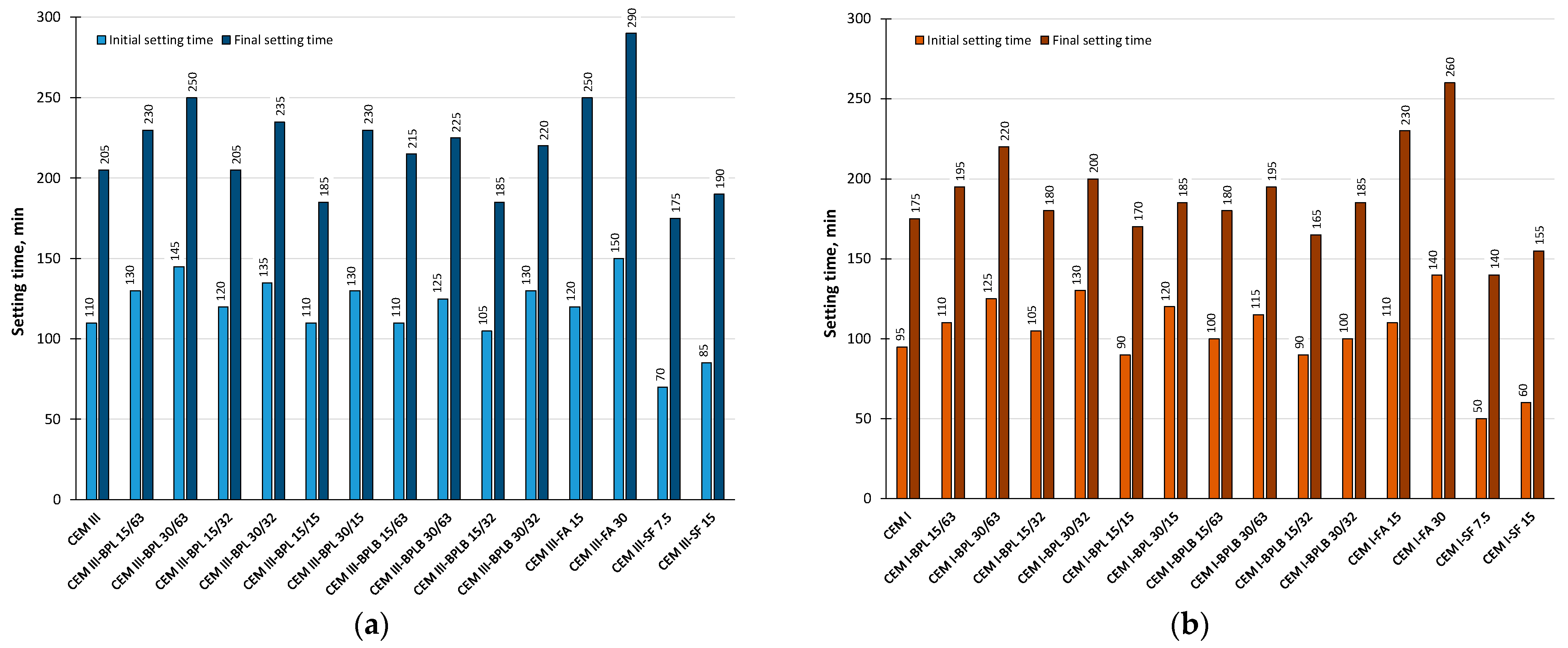

3.1. Standard Consistency and Setting Time

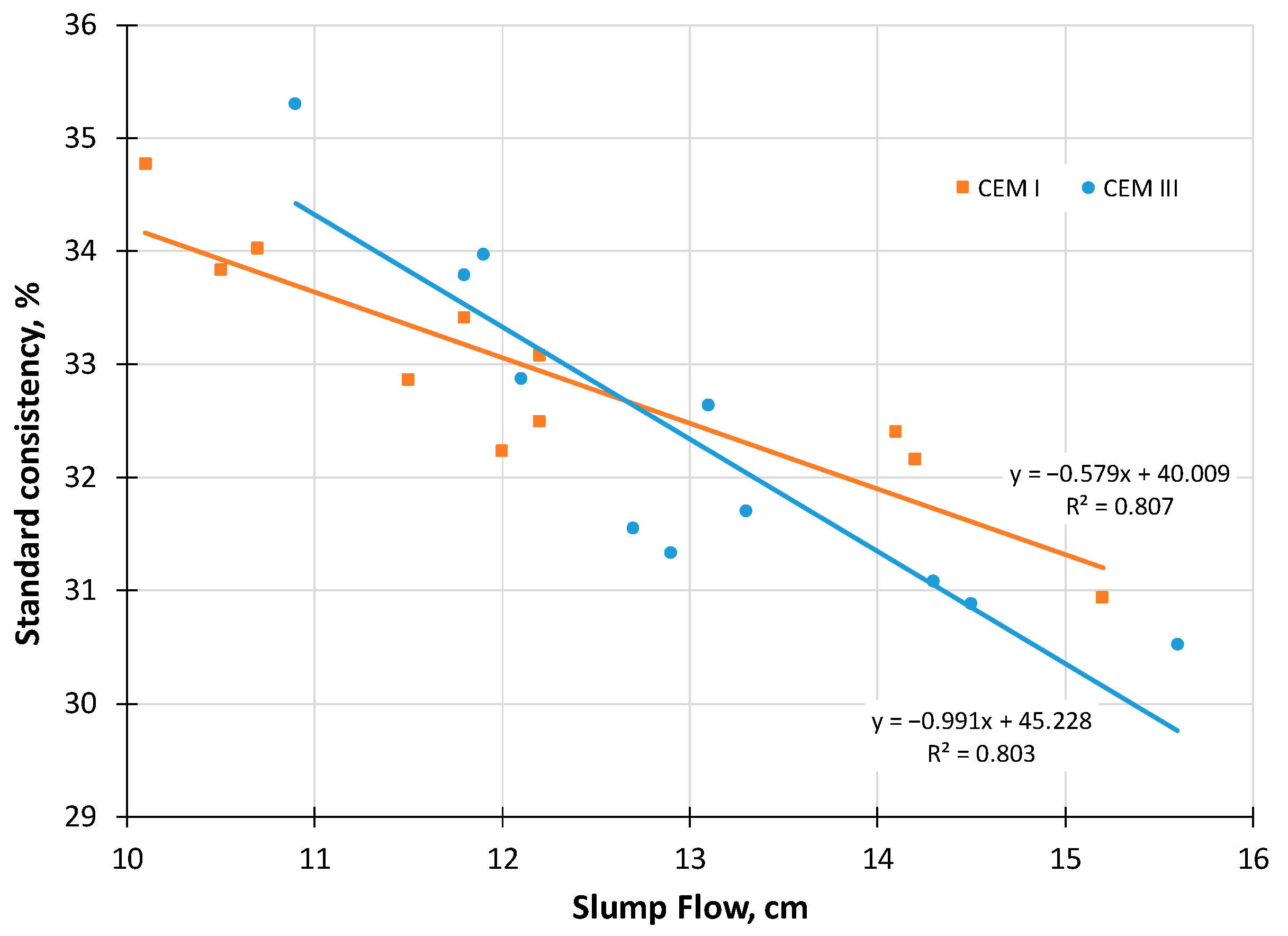

3.2. Workability

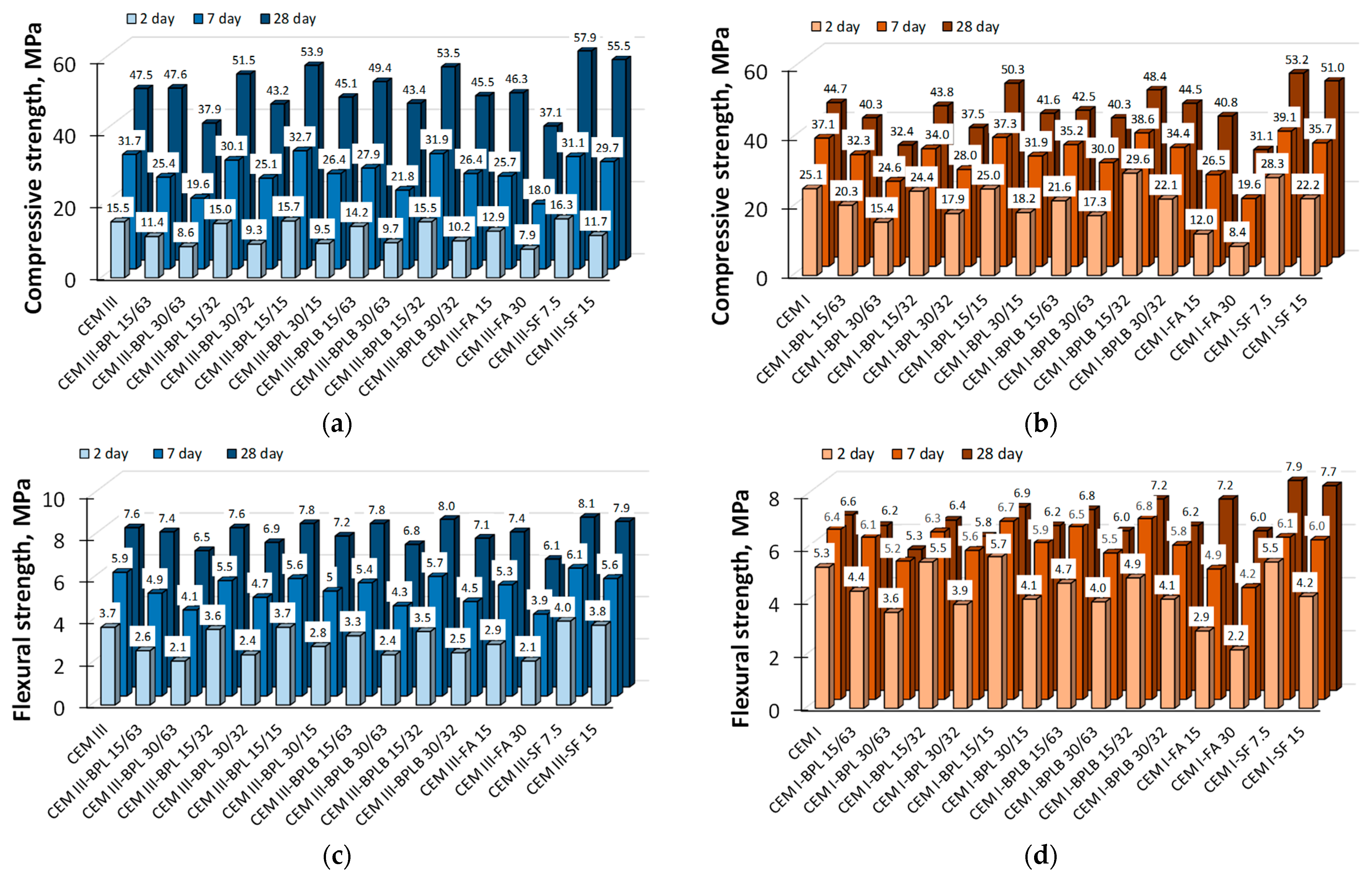

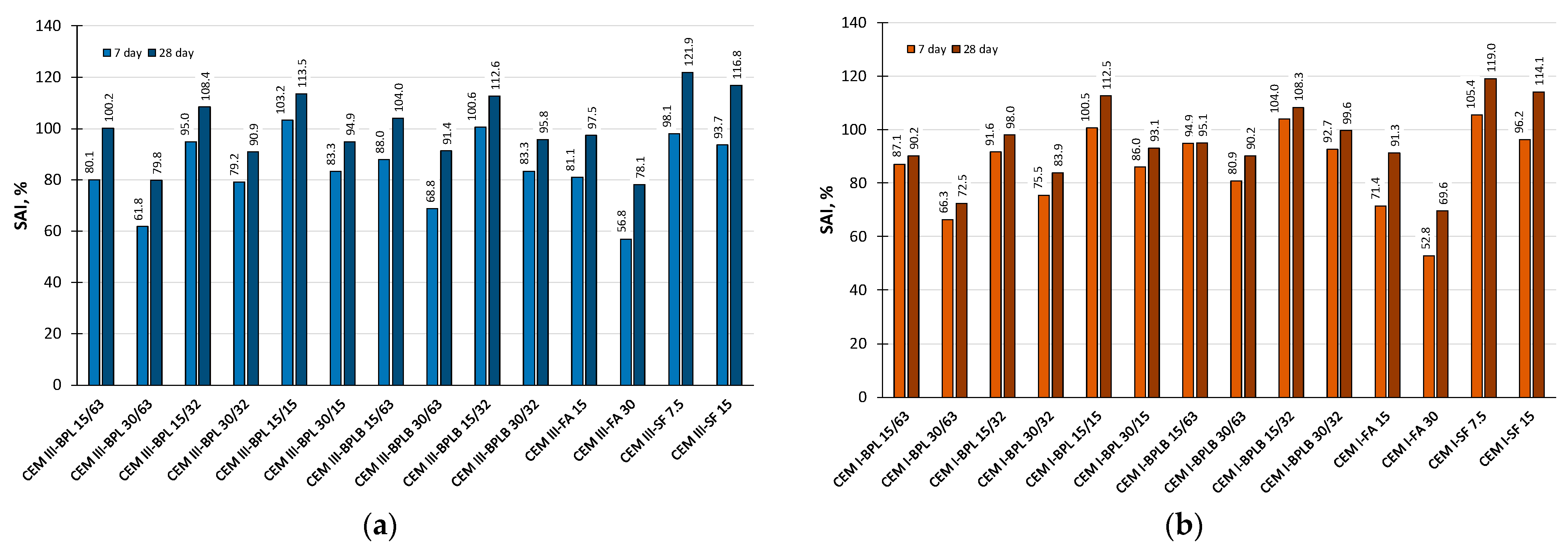

3.3. Compressive and Flexural Strength

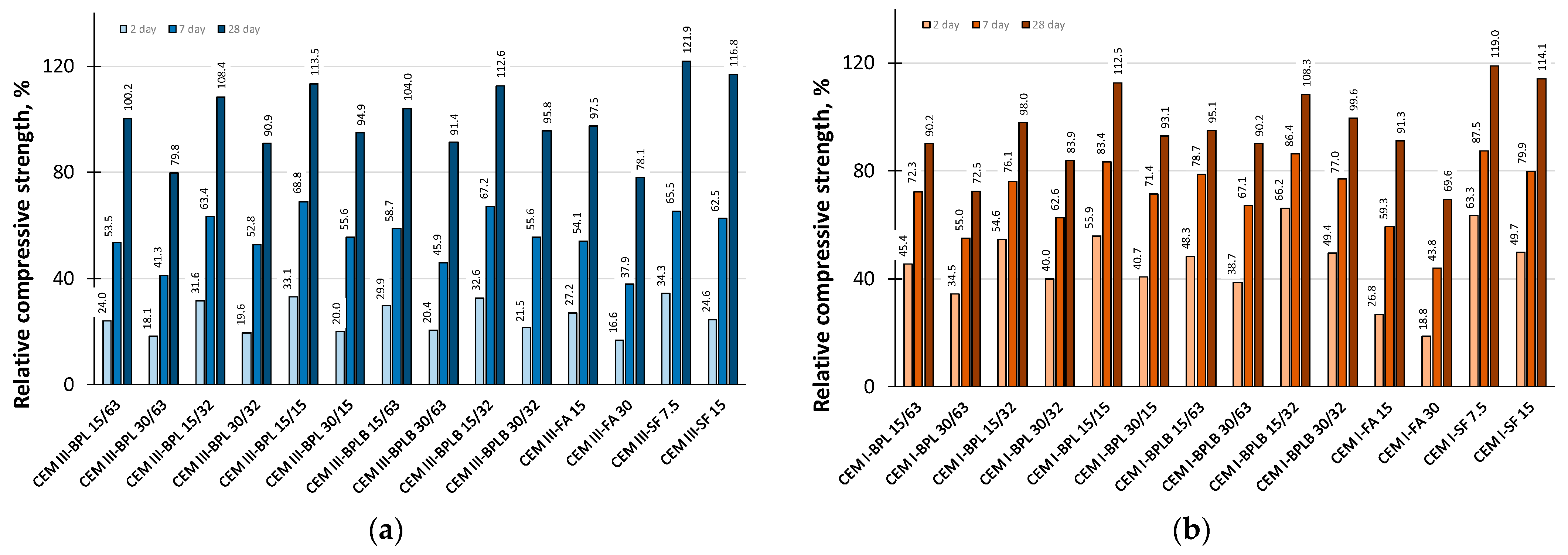

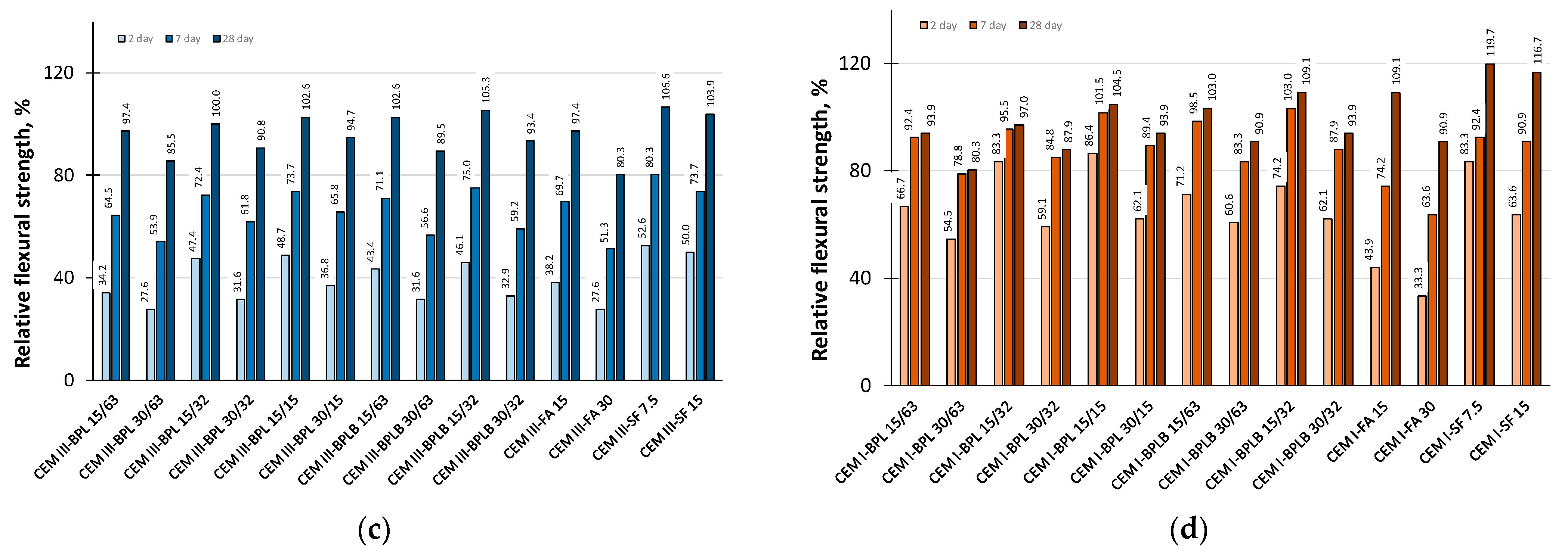

3.4. Strength Activity Index (SAI)

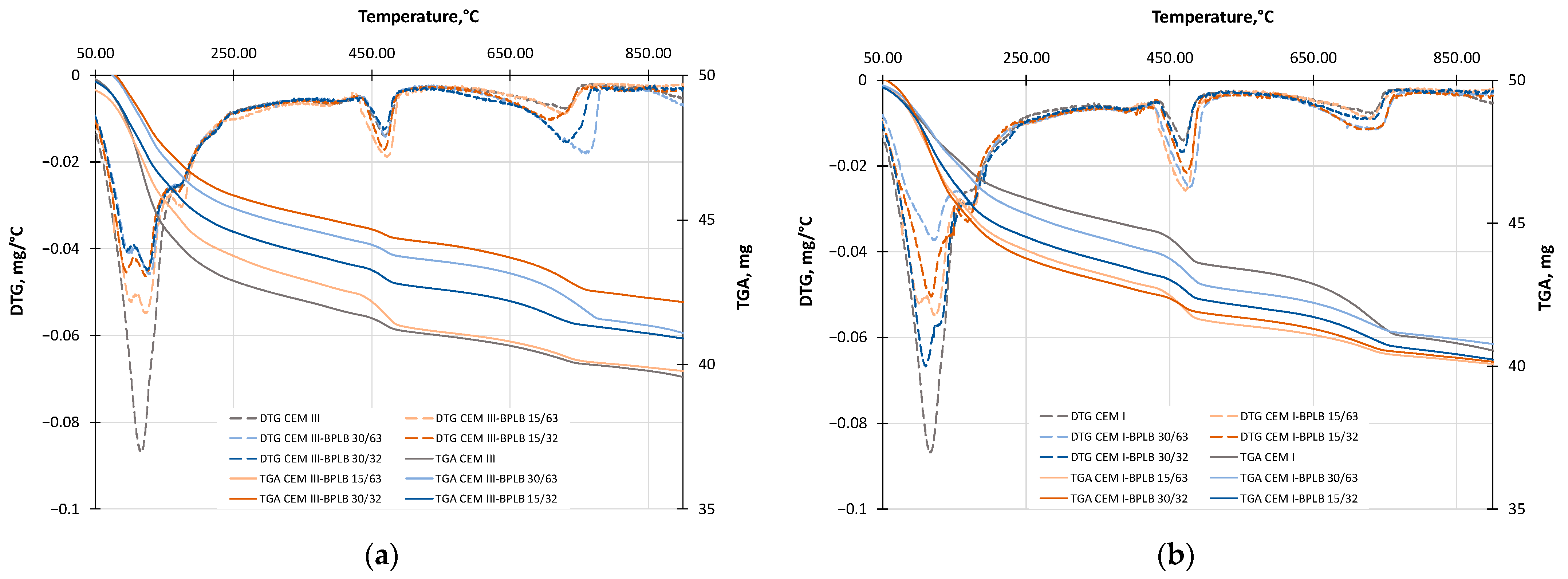

3.5. TGA

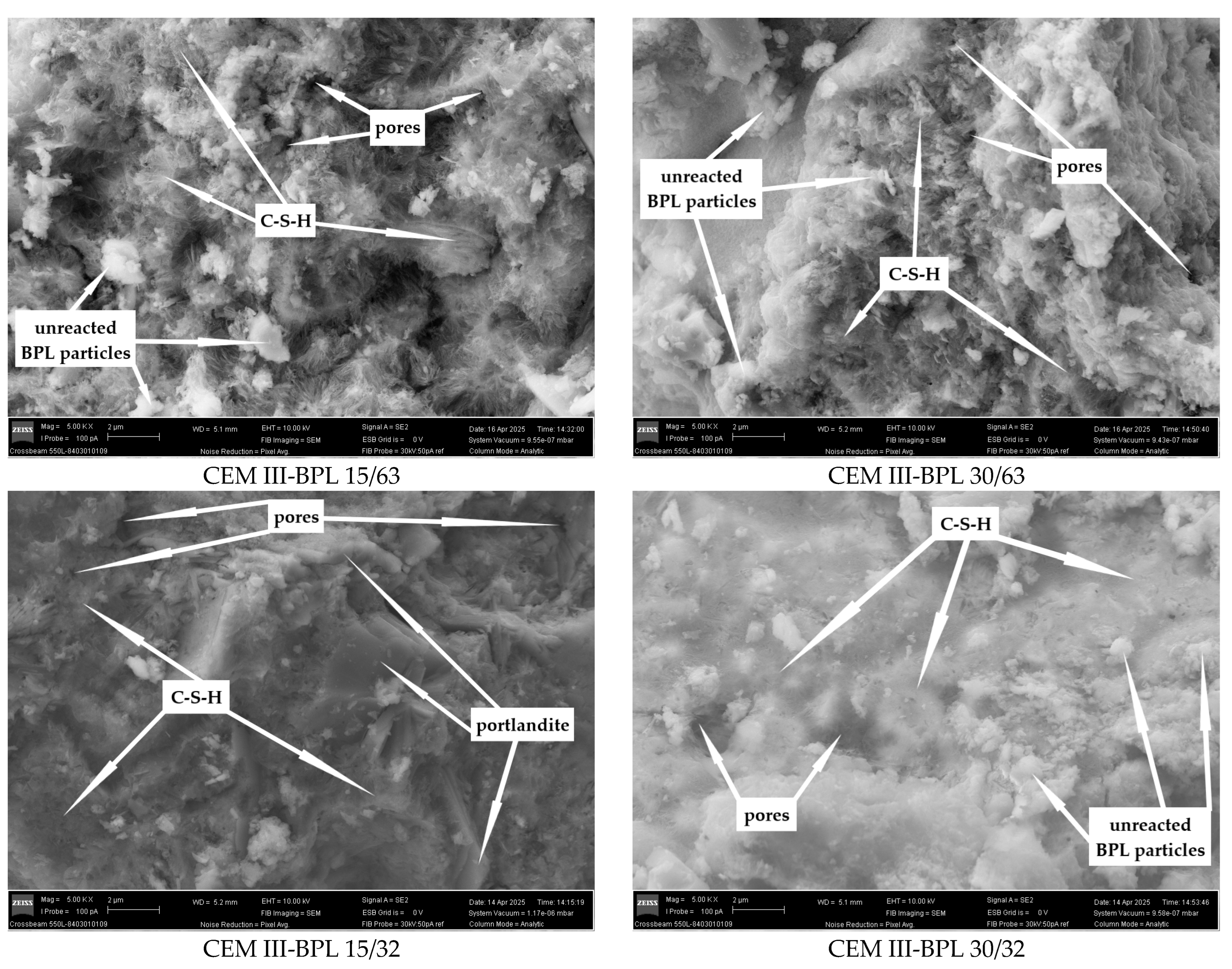

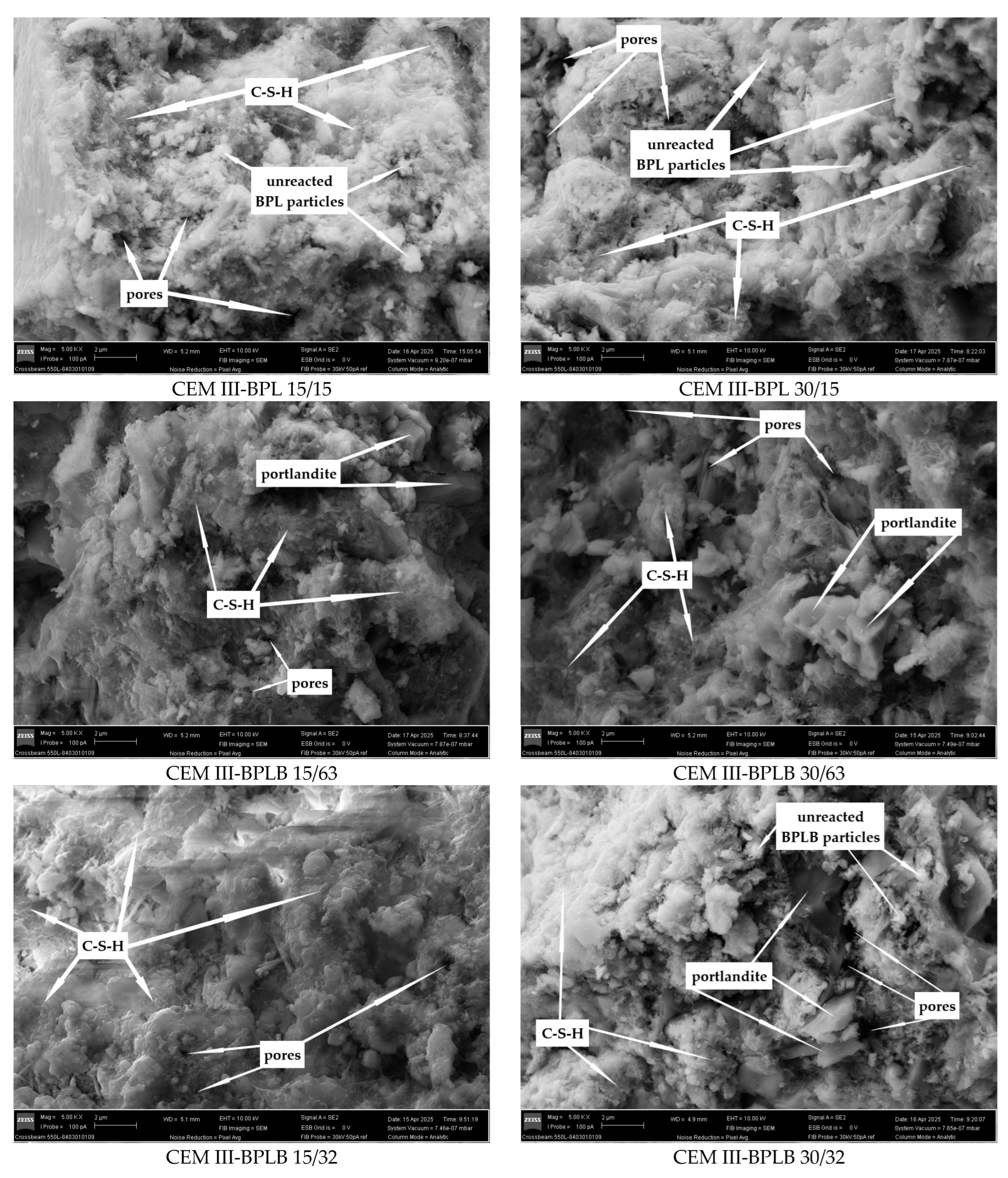

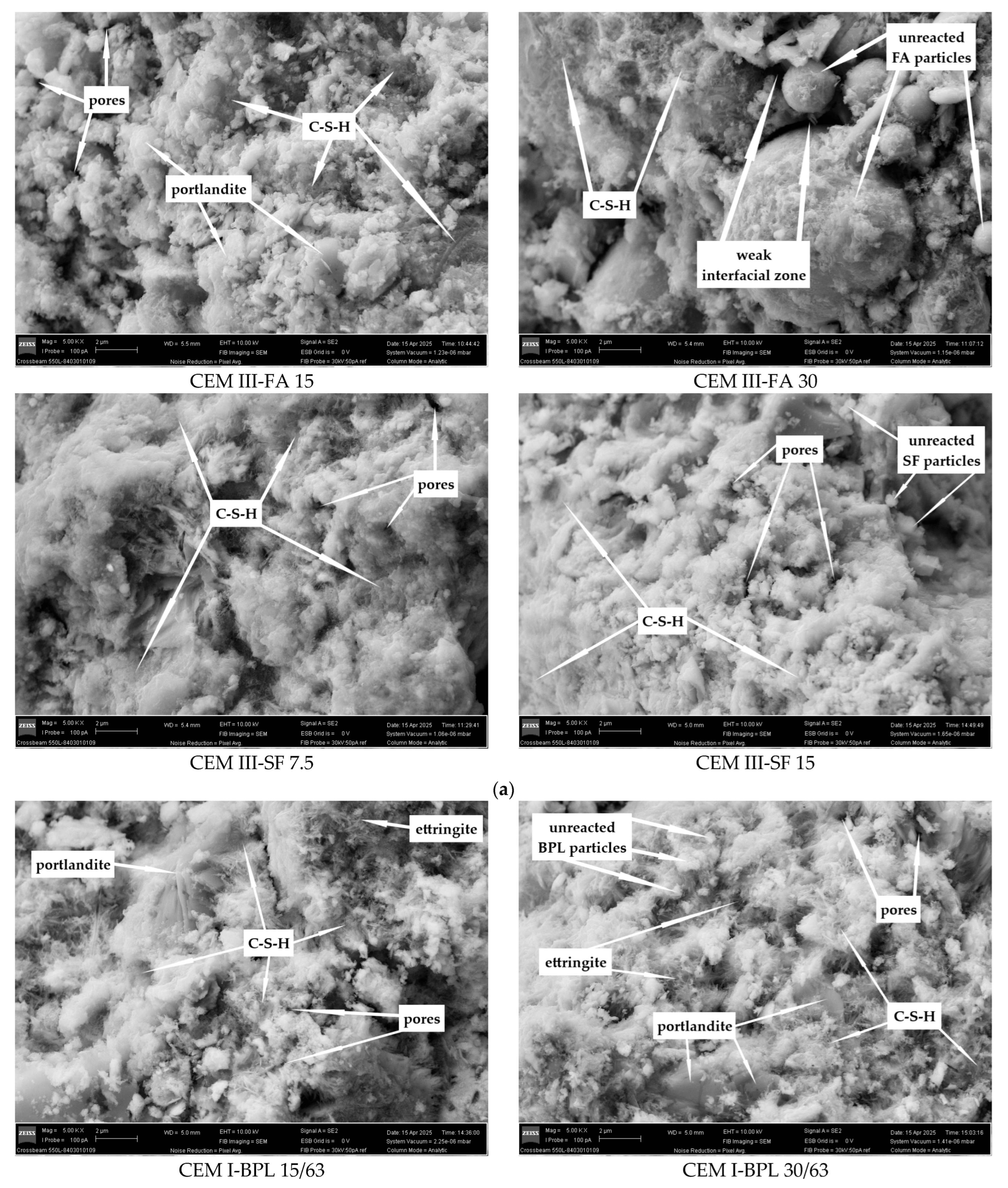

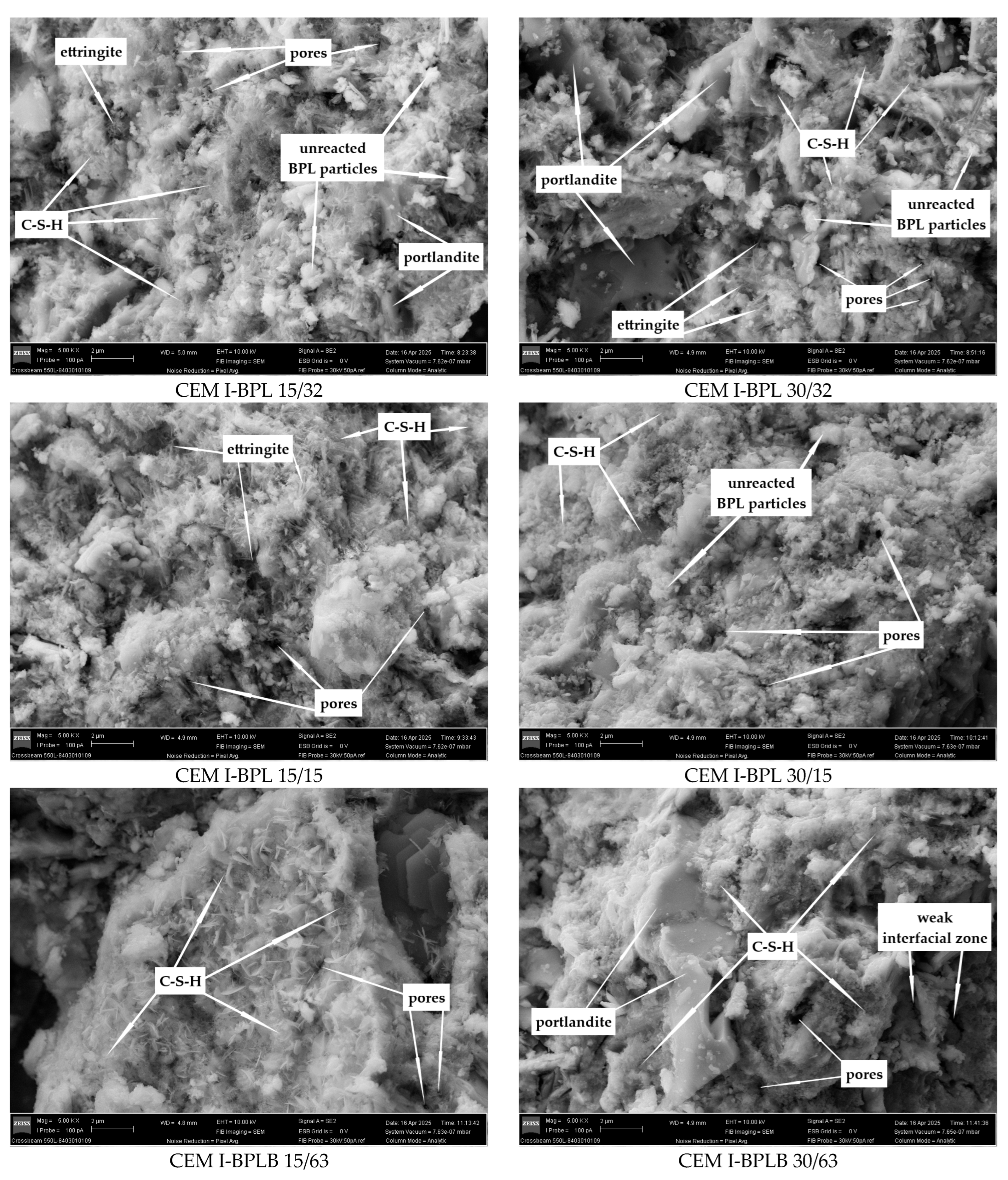

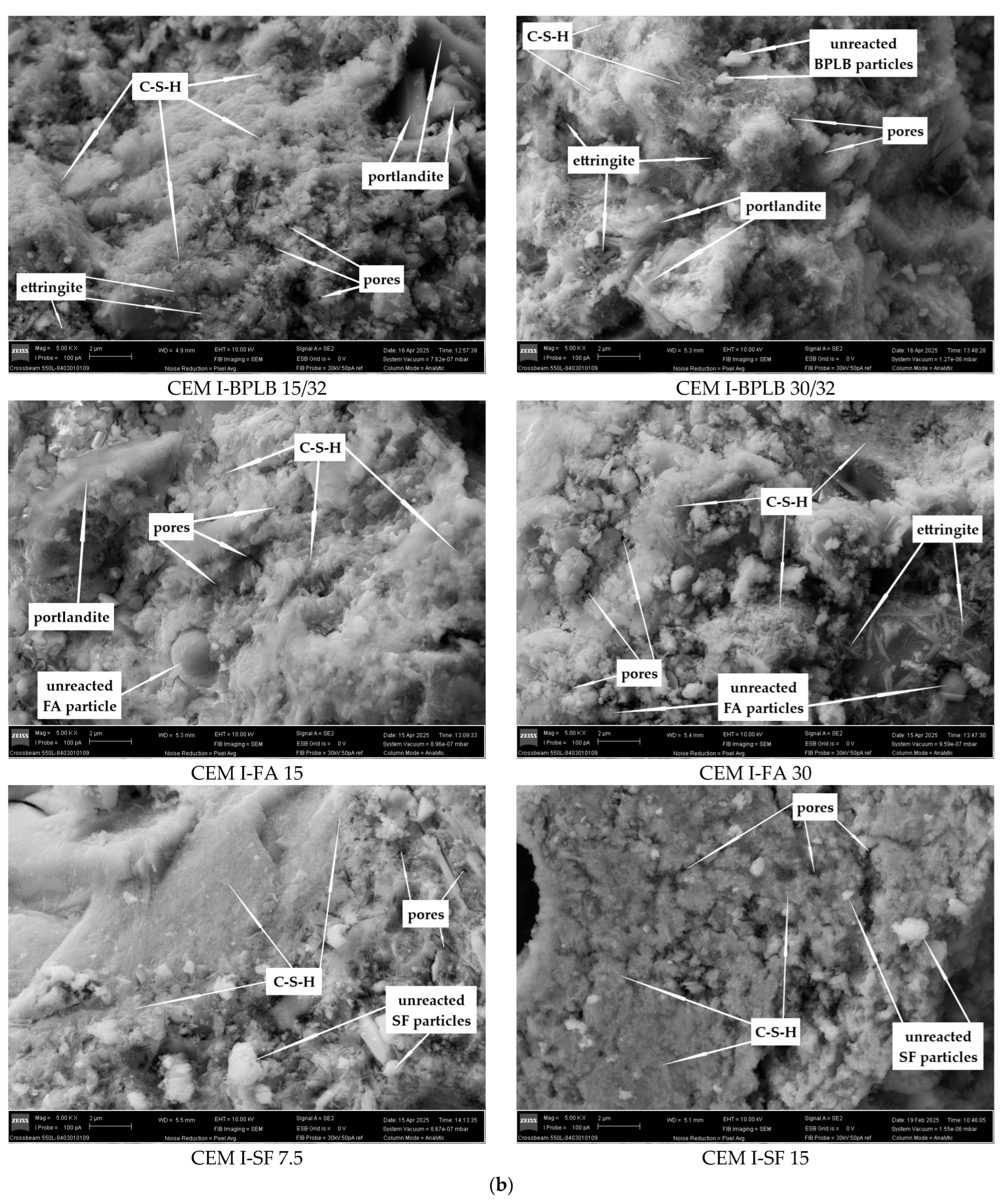

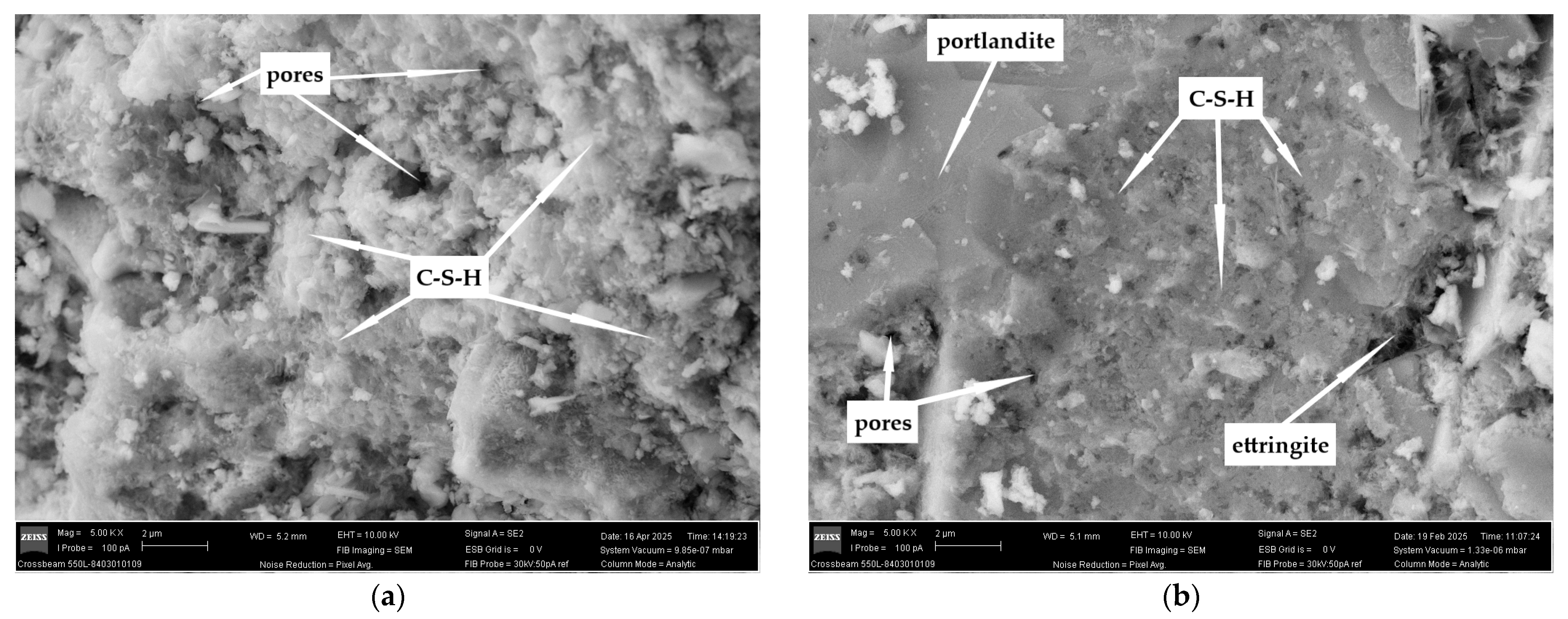

3.6. SEM

3.7. EDX

4. Conclusions

- -

- Increasing the dosage of cement replacement with brick powder, regardless of cement type, raises the water demand of cement pastes and consequently reduces the workability of cement–sand mortars based on them;

- -

- The setting times of cement pastes with both cement types decrease with reduced brick powder fineness. Despite nearly equal Al2O3 content, the amount of amorphous SiO2 in the powder plays a key role;

- -

- The highest strength values can be achieved by replacing slag cement or ordinary fast-hardening cement with up to 15% BPL powder, fineness 15 μm or up to 15% BPLB powder, fineness 32 μm. This is attributed to the chemical composition of the by-products used. Thus, it can be concluded that a SiO2 deficit exceeding 5% in brick powder cannot be compensated by further grinding;

- -

- Microstructural analysis using TGA/DTG, SEM, and EDX methods detailed the degree of hydrate phase formation after modifying blended cement composites. Specifically, the pozzolanic activity of the two brick powder types was confirmed, and the features of its chemical composition for the formation of low-basicity C-A-S-H gel in blended cement systems were established. The results demonstrate a strong correlation with strength indicators and the strength activity index.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

Appendix A.1. Supporting TGA Data

Appendix A.2. Supporting SEM Data

References

- Haist, M.; Bergmeister, K.; Curbach, M.; Forman, P.; Gaganelis, G.; Gerlach, J.; Mark, P.; Moffat, J.; Muller, C.; Muller, H.S.; et al. Nachhaltig konstruieren und bauen mit Beton (Sustainable Construction and Building with Concrete). In Beton Kalender 2022: Nachhaltigkeit, Digitalisierung, Instandhaltung; Wilhelm Ernst & Sohn: Berlin, Germany, 2022; pp. 421–531. [Google Scholar] [CrossRef]

- Bolte, G.; Zajac, M.; Skocek, J.; Haha, M.B. Development of Composite Cements Characterized by Low Environmental Footprint and Appreciable Performance. J. Clean. Prod. 2019, 226, 503–514. [Google Scholar] [CrossRef]

- Khaiyum, M.Z.; Sarker, S.; Kabir, G. Evaluation of Carbon Emission Factors in the Cement Industry: An Emerging Economy Context. Sustainability 2023, 15, 15407. [Google Scholar] [CrossRef]

- Winter, C.; Schröter, B.; Fidaschek, S. The German Cement Industry as a CO2 Source for Other Industries. Fuels 2022, 3, 342–352. [Google Scholar] [CrossRef]

- Kryzhanovskyi, V.; Avramidou, A.; Orlowsky, J.; Spyridis, P. Self-Compacting High-Strength Textile-Reinforced Concrete Using Sea Sand and Sea Water. Materials 2023, 16, 4934. [Google Scholar] [CrossRef] [PubMed]

- Lothenbach, B.; Scrivener, C.; Hooton, R.D. Supplementary Cementitious Materials. Cem. Concr. Res. 2011, 41, 1244–1256. [Google Scholar] [CrossRef]

- Dvorkin, L.; Zhitkovsky, V.; Sitarz, M.; Hager, I. Cement with Fly Ash and Metakaolin Blend—Drive towards a More Sustainable Construction. Energies 2022, 15, 3556. [Google Scholar] [CrossRef]

- Sanytsky, M.; Kropyvnytska, T.; Ivashchyshyn, H. Sustainable Modified Pozzolanic Supplementary Cementitious Materials based on Natural Zeolite, Fly Ash and Silica Fume. IOP Conf. Ser. Earth Environ. Sci. 2023, 1254, 012004. [Google Scholar] [CrossRef]

- Taylor, H. Cement Chemistry; Thomas Telford: London, UK, 1997; 459p. [Google Scholar]

- Mesecke, K.; Warr, L.N.; Malorny, W. Structure Modeling and Quantitative X-ray Diffraction of C-(A)-S-H. J. Appl. Crystallogr. 2022, 55, 133–143. [Google Scholar] [CrossRef]

- Lothenbach, B.; Nonat, A. Calcium Silicate Hydrates: Solid and Liquid Phase Composition. Cem. Concr. Res. 2015, 78, 57–70. [Google Scholar] [CrossRef]

- Kroviakov, S.; Zavoloka, M.; Dudnik, L.; Kryzhanovskyi, V. Comparison of Strength and Durability of Concretes Made with Sulfate-resistant Portland Cement and Portland Cement with Pozzolana Additive. Electron. J. Fac. Civ. Eng. Osijek-E-GFOS 2019, 10, 81–86. [Google Scholar] [CrossRef]

- Mishutin, A.; Kroviakov, S.; Kryzhanovskyi, V.; Chintea, L. Fiber-Reinforced Concrete for Rigid Road Pavements Modified with Polycarboxylate Admixture and Metakaolin. Electron. J. Fac. Civ. Eng. Osijek-E-GFOS 2021, 12, 1–10. [Google Scholar] [CrossRef]

- Liu, B.; Zhao, X.; Liu, X.; He, Z.; Cao, X.; Guan, B. Evaluation of Workability and Mechanical Properties in Cement Mortar after Compounding Igneous Rock Powder and Silica Fume. Buildings 2024, 14, 359. [Google Scholar] [CrossRef]

- Bahedh, M.A.; Jaafar, M.S. Ultra High-Performance Concrete Utilizing Fly Ash as Cement Replacement Under Autoclaving Technique. Case Stud. Constr. Mater. 2018, 9, e00202. [Google Scholar] [CrossRef]

- Tran, T.M.; Trinh Hoang, T.M.K.; Nguyen, D.; Tao, Q.; Mali, S.; Pham, T.M. Development of Sustainable Ultra-High-Performance Concrete Containing Ground Granulated Blast Furnace Slag and Glass Powder: Mix Design Investigation. Constr. Build. Mater. 2023, 397, 132358. [Google Scholar] [CrossRef]

- Vaičiukynienė, D.; Nizeviciene, D.; Kantautas, A.; Tamošaitis, G.; Villalon Fornes, I.; Kryvenko, P.; Boiko, O. Effect of Large Amounts of Supplementary Cementitious Material on the Hydration of Blended Cement. J. Mater. Civ. Eng. 2025, 37, 04025091. [Google Scholar] [CrossRef]

- Šoukal, F.; Bocian, L.; Novotný, R.; Dlabajová, L.; Šuleková, N.; Hajzler, J.; Koutný, O.; Drdlová, M. The Effects of Silica Fume and Superplasticizer Type on the Properties and Microstructure of Reactive Powder Concrete. Materials 2023, 16, 6670. [Google Scholar] [CrossRef]

- Hamada, H.M.; Abed, F.; Katman, H.Y.B.; Humada, A.M.; Al Jawahery, M.S.; Majdi, A.; Yousif, S.T.; Thomas, B.S. Effect of Silica Fume on the Properties of Sustainable Cement Concrete. J. Mater. Res. Technol. 2023, 24, 8887–8908. [Google Scholar] [CrossRef]

- Lewis, R.C. Silica Fume. In Properties of Fresh and Hardened Concrete Containing Supplementary Cementitious Materials; De Belie, N., Soutsos, M., Gruyaert, E., Eds.; RILEM State-of-the-Art Reports; Springer: Cham, Switzerland, 2018; Volume 25. [Google Scholar] [CrossRef]

- Chen, Z.; Li, M.; Guan, L. Safety and Effect of Fly Ash Content on Mechanical Properties and Microstructure of Green Low-Carbon Concrete. Appl. Sci. 2024, 14, 2796. [Google Scholar] [CrossRef]

- Alonso, J.D.; Gaviria, X.; López, J.E.; Saldarriaga, J.F. Estimation of the Addition of Fly Ash and its Environmental Impact in the Manufacture of Cement Pastes. Environ. Dev. Sustain. 2024, 26, 31677–31701. [Google Scholar] [CrossRef]

- Yehualaw, M.D.; Fentie, M.A.; Yifru, B.W. Effect of Partial Replacement of Cement by Metakaolin on Engineering Properties of Concrete. In Advancement of Science and Technology; Woldegiorgis, B.H., Mequanint, K., Getie, M.Z., Mulat, E.G., Alemayehu Assegie, A., Eds.; Green Energy and Technology; Springer: Cham, Switzerland, 2023; pp. 89–101. [Google Scholar] [CrossRef]

- Strybny, B.; Schack, T.; Link, J.; Haist, M. Calcined Clays as Concrete Additive in Structural Concrete: Workability, Mechanical Properties, Durability, and Sustainability Performance. Materials 2024, 17, 4517. [Google Scholar] [CrossRef]

- Panzer, M.; Scherb, S.; Beuntner, N.; Thienel, K.C. An Approach to Estimate the Strength Contribution of Calcined Clays in Blended Cements. Constr. Build. Mater. 2024, 447, 137800. [Google Scholar] [CrossRef]

- Ismail, A.A.M.; Rosdin, M.R.H.; Rozhan, A.N.; Purwanto, H.; Hamid, A.M.A.; Din, M.F.M.; Yason, M.F.M.; Ani, M.H. Blast Furnace Slag Cement Clinker Production Using Limestone-Hot Blast Furnace Slag Mixture. In Proceedings of the 5th International Conference on Advances in Manufacturing and Materials Engineering, Kuala Lumpur, Malaysia, 9—10 August 2022; Maleque, M.A., Ahmad Azhar, A.Z., Sarifuddin, N., Syed Shaharuddin, S.I., Mohd Ali, A., Abdul Halim, N.F.H., Eds.; Lecture Notes in Mechanical Engineering; Springer: Singapore, 2023; pp. 539–545. [Google Scholar] [CrossRef]

- Humad, A.M.; Habermehl-Cwirzen, K.; Cwirzen, A. Effects of Fineness and Chemical Composition of Blast Furnace Slag on Properties of Alkali-Activated Binder. Materials 2019, 12, 3447. [Google Scholar] [CrossRef]

- Zeraoui, A.; Maherzi, W.; Benzerzour, M.; Abriak, N.E.; Aouad, G. Development of Flash-Calcined Sediment and Blast Furnace Slag Ternary Binders. Buildings 2023, 13, 333. [Google Scholar] [CrossRef]

- Mohseni, E.; Tang, W.; Cui, H. Chloride Diffusion and Acid Resistance of Concrete Containing Zeolite and Tuff as Partial Replacements of Cement and Sand. Materials 2017, 10, 372. [Google Scholar] [CrossRef]

- Markiv, T.; Sobol, K.; Franus, M.; Franus, W. Mechanical and Durability Properties of Concretes Incorporating Natural Zeolite. Archiv. Civ. Mech. Eng. 2016, 16, 554–562. [Google Scholar] [CrossRef]

- Tran, Y.T.; Lee, J.; Kumar, P.; Kim, K.H.; Lee, S.S. Natural Zeolite and Its Application in Concrete Composite Production. Compos. Part B Eng. 2019, 165, 354–364. [Google Scholar] [CrossRef]

- Hasan, N.M.S.; Sobuz, M.H.R.; Khan, M.M.H.; Mim, N.J.; Meraz, M.M.; Datta, S.D.; Rana, M.J.; Saha, A.; Akid, A.S.M.; Mehedi, M.T.; et al. Integration of Rice Husk Ash as Supplementary Cementitious Material in the Production of Sustainable High-Strength Concrete. Materials 2022, 15, 8171. [Google Scholar] [CrossRef]

- Bheel, N.; Awoyera, P.; Shar, I.A.; Sohu, S.; Abbasi, S.A.; Prakash, A.K. Mechanical Properties of Concrete Incorporating Rice Husk Ash and Wheat Straw Ash as Ternary Cementitious Material. Adv. Civ. Eng. 2021, 2021, 2977428. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A. Rice Husk Ash. In Cement Replacement Materials; Springer Geochemistry/Mineralogy; Springer: Berlin/Heidelberg, Germany, 2014; pp. 257–298. [Google Scholar] [CrossRef]

- Zajac, M.; Song, J.; Ullrich, P.; Skocek, J.; Haha, M.B.; Skibsted, J. High Early Pozzolanic Reactivity of Alumina-Silica Gel: A Study of the Hydration of Composite Cements with Carbonated Recycled Concrete Paste. Cem. Concr. Res. 2024, 175, 107345. [Google Scholar] [CrossRef]

- Zajac, M.; Skocek, J.; Gołek, L.; Deja, J. Supplementary Cementitious Materials Based on Recycled Concrete Paste. J. Clean. Prod. 2023, 387, 135743. [Google Scholar] [CrossRef]

- Shao, J.; Gao, J.; Zhao, Y.; Chen, X. Study on the Pozzolanic Reaction of Clay Brick Powder in Blended Cement Pastes. Constr. Build. Mater. 2019, 213, 209–215. [Google Scholar] [CrossRef]

- Bertelsen, I.M.G.; Kahr, S.A.; Kunther, W.; Ottosen, L.M. Clay Brick Powder as Partial Cement Replacement. In International Rilem Conference on Synergising Expertise Towards Sustainability and Robustness of Cement-Based Materials and Concrete Structures; Springer: Cham, Switzerland, 2023; pp. 142–152. [Google Scholar] [CrossRef]

- Ruminski, P.; Szelag, M.; Matos, P. Evaluating the Feasibility of Using Brick Powder and Clay Powder in Cement Replacement. Materials 2022, 15, 8127. [Google Scholar] [CrossRef]

- Wu, H.; Chen, G.; Liu, C.; Gao, J. Understanding the Micro-Macro Properties of Sustainable Ultra-High Performance Concrete Incorporating High-Volume Recycled Brick Powder as Cement and Silica Fume Replacement. Constr. Build. Mater. 2024, 448, 138170. [Google Scholar] [CrossRef]

- Małek, M.; Smarzewski, P.; Kunikowski, M.; Kluczyński, J. Utilization of Brick Powder as a Sustainable Additive in Concrete: Optimization of Mechanical and Thermal Performance. Constr. Build. Mater. 2025, 492, 143092. [Google Scholar] [CrossRef]

- Kryzhanovskyi, V.; Orlowsky, J. Sustainable Alkali-Activated Self-Compacting Concrete for Precast Textile-Reinforced Concrete: Experimental–Statistical Modeling Approach. Materials 2024, 17, 6280. [Google Scholar] [CrossRef]

- Abbou, S.; Aalil, I.; Cherkaoui, K. The Impact of Brick Powder Specific Surface Area on Cement Replacement in Mortar Mixes: A Sustainable and Cost-effective Solution for the Construction Industry. Period. Polytech. Civ. Eng. 2023, 68, 141–154. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Liu, C.; Chen, X.; Xu, Z. The Particle-Size Effect of Waste Clay Brick Powder on its Pozzolanic Activity and Properties of Blended Cement. J. Clean. Prod. 2020, 242, 118521. [Google Scholar] [CrossRef]

- Ouyang, X.; Wang, L.; Fu, J.; Xu, S.; Ma, Y. Surface Properties of Clay Brick Powder and its Influence on Hydration and Strength Development of Cement Paste. Constr. Build. Mater. 2021, 300, 123958. [Google Scholar] [CrossRef]

- Xue, C.; Qiao, H.; Cao, H.; Feng, Q.; Li, Q. Analysis on the Strength of Cement Mortar Mixed with Construction Waste Brick Powder. Adv. Civ. Eng. 2021, 2021, 8871280. [Google Scholar] [CrossRef]

- Ma, Z.; Tang, Q.; Wu, H.; Xu, J.; Liang, C. Mechanical Properties and Water Absorption of Cement Composites with Various Fineness and Contents of Waste Brick Powder from C&D Waste. Cem. Concr. Compos. 2020, 114, 103758. [Google Scholar] [CrossRef]

- Müller, A.; Lipowsky, A.; Palzer, U. Brick Powders as Pozzolanic Additives in Cement Production. ZKG Int. 2020, 7–8, 38–45. [Google Scholar]

- Lliso-Ferrando, J.R.; Arenós-Barrachina, A.; Monzón-Bello, P.; Valcuende, M. Durability of Mortars with Partial Cement Replacement by Recycled Brick Powder. Appl. Sci. 2025, 15, 4133. [Google Scholar] [CrossRef]

- Palovčík, J.; Opravil, T.; Novonty, R.; Masilko, J. Application of Brick Grind Dust in Systems Based on Portland Cement. IOP Conf. Ser. Mater. Sci. Eng. 2018, 379, 012002. [Google Scholar] [CrossRef]

- Zou, Z.; Provoost, S.; Gruyaert, E. Utilization of Waste Brick Powder as a Partial Replacement of Portland Cement in Mortars. Sustainability 2024, 16, 624. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, J.; Xu, Z.; Li, S.; Luo, X.; Chen, G. Combined Effect of Slag and Clay Brick Powder on the Hydration of Blended Cement. Constr. Build. Mater. 2021, 299, 123996. [Google Scholar] [CrossRef]

- DIN EN 197-1:2011; Composition—Part 1: Specifications and Conformity Criteria for Common Cements. Deutsches Institut für Normung: Berlin, Germany, 2011.

- DIN EN 196-2:2013; Methods of Testing Cement—Part 2: Chemical Analysis of Cement. Deutsches Institut für Normung: Berlin, Germany, 2013.

- DIN EN 450-1:2012; Fly Ash for Concrete—Part 1: Definition, Specifications and Conformity Criteria. Deutsches Institut für Normung: Berlin, Germany, 2012.

- ASTM C 618-22; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2022.

- DIN EN 196-3:2017; Methods of Testing Cement—Part 3: Determination of Setting Times and Soundness. Deutsches Institut für Normung: Berlin, Germany, 2017.

- DIN EN 196-1:2017; Methods of Testing Cement—Part 1: Determination of Strength. Deutsches Institut für Normung: Berlin, Germany, 2017.

- DIN EN 13263-1:2009; Silica Fume for Concrete—Part 1: Definitions, Requirements and Conformity Criteria. Deutsches Institut für Normung: Berlin, Germany, 2013.

- ASTM C 1240-20; Standard Specification for Silica Fume Used in Cementitious Mixtures. ASTM International: West Conshohocken, PA, USA, 2020.

- Scriviner, K.; Snellings, R.; Lothenbach, B. A Practical Guide to Microstructural Analysis of Cementitious Materials; CRC Press: Boca Raton, FL, USA, 2016; 560p. [Google Scholar] [CrossRef]

- Irki, I.; Debieb, F.; Ouzadid, S.; Larouci Dilmi, H.; Settari, C.; Boukhelkhel, D. Effect of Blaine Fineness of Recycling Brick Powder Replacing Cementitious Materials in Self Compacting Mortar. J. Adhes. Sci. Technol. 2017, 32, 963–975. [Google Scholar] [CrossRef]

- Baran, S.; Baran, A.; Bıçakçı, S.; Turkmenoglu, H.; Atahan, H. Fresh, Setting, and Hardened Properties of Fly Ash Concrete with Nano-Silica. Arab. J. Sci. Eng. 2025, 50, 1683–1702. [Google Scholar] [CrossRef]

- Zhang, M.H.; Islam, J. Use of Nano-Silica to Reduce Setting Time and Increase Early Strength of Concretes with High Volumes of Fly Ash or Slag. Constr. Build. Mater. 2012, 29, 573–580. [Google Scholar] [CrossRef]

- Menéndez, E.; Sanjuán, M.Á.; Recino, H. Study of Microstructure, Crystallographic Phases and Setting Time Evolution over Time of Portland Cement, Coarse Silica Fume, and Limestone (PC-SF-LS) Ternary Portland Cements. Crystals 2023, 13, 1289. [Google Scholar] [CrossRef]

- Akbulut, Z.F.; Yavuz, D.; Tawfik, T.A.; Smarzewski, P.; Guler, S. Examining the Workability, Mechanical, and Thermal Characteristics of Eco-Friendly, Structural Self-Compacting Lightweight Concrete Enhanced with Fly Ash and Silica Fume. Materials 2024, 17, 3504. [Google Scholar] [CrossRef]

- Nayak, D.K.; Abhilash, P.P.; Singh, R.; Kumar, R.; Kumar, V. Fly Ash for Sustainable Construction: A Review of Fly Ash Concrete and Its Beneficial Use Case Studies. Clean. Mater. 2022, 6, 100143. [Google Scholar] [CrossRef]

- Rocha, J.H.A.; Ruiz, B.M.M.; Filho, R.D.T. Evaluating the Use of Recycled Brick Powder as a Partial Replacement for Portland Cement in Concrete. Ing. Investig. 2024, 44, e107462. [Google Scholar] [CrossRef]

- Giergiczny, Z. Fly Ash and Slag. Cem. Concr. Res. 2019, 124, 105826. [Google Scholar] [CrossRef]

- Rivera, R.A.; Sanjuán, M.Á.; Martin, D.A. Granulated Blast-Furnace Slag and Coal Fly Ash Ternary Portland Cements Optimization. Sustainability 2020, 12, 5783. [Google Scholar] [CrossRef]

- Moghaddam, F.; Sirivivatnanon, V.; Vessalas, K. The Effect of Fly Ash Fineness on Heat of Hydration, Microstructure, Flow and Compressive Strength of Blended Cement Pastes. Case Stud. Constr. Mater. 2019, 10, e00218. [Google Scholar] [CrossRef]

- Choi, Y.-C. Hydration and Mechanical Properties of High Volume Fly Ash Cement under Different Curing Temperatures. Materials 2024, 17, 4716. [Google Scholar] [CrossRef] [PubMed]

- Kuzielová, E.; Slaný, M.; Žemlička, M.; Másilko, J.; Palou, M.T. Phase Composition of Silica Fume—Portland Cement Systems Formed Under Hydrothermal Curing Evaluated by FTIR, XRD, and TGA. Materials 2021, 14, 2786. [Google Scholar] [CrossRef]

- Richardson, I.G. Model structures for C-(A)-S-H(I). Acta Crystallogr. B Struct. Sci. Cryst. Eng. Mater. 2014, 70, 903–923. [Google Scholar] [CrossRef]

- Li, J.; Geng, G.; Myers, R.; Yu, Y.S.; Shapiro, D.; Carraro, C.; Maboudian, R.; Monteiro, P.J.M. The Chemistry and Structure of Calcium (Alumino) Silicate Hydrate: A Study by XANES, Ptychographic Imaging, and Wide- and Small-Angle Scattering. Cem. Concr. Res. 2019, 115, 367–378. [Google Scholar] [CrossRef]

- Ngo, T.M.; Vo, D.H.; Phan, N.L.; Nguyen, H.A. Strength Development and Microstructure Evaluation of Cement Mortar Incorporating Various Waste Red Brick Powder. IOP Conf. Ser. Mater. Sci. Eng. 2023, 1289, 012066. [Google Scholar] [CrossRef]

- Ortega, J.M.; Letelier, V.; Solas, C.; Moriconi, G.; Climent, M.A.; Sánchez, I. Long-Term Effects of Waste Brick Powder Addition in the Microstructure and Service Properties of Mortars. Constr. Build. Mater. 2018, 182, 691–702. [Google Scholar] [CrossRef]

- Raini, I.; Mesrar, L.; Touache, A.; Raini, I.; Jabrane, R. Performance Evaluation of Cement Mortar Containing Construction and Demolition Waste as Supplementary Cement Materials. Ceram.-Silik. 2022, 66, 407–418. [Google Scholar] [CrossRef]

- Lothenbach, B.; Le Saout, G.; Haha, M.B.; Figi, R.; Wieland, E. Hydration of a Low-Alkali CEM III/B–SiO2 Cement (LAC). Cem. Concr. Res. 2012, 42, 410–423. [Google Scholar] [CrossRef]

- Yan, Y.; Bernard, E.; Miron, G.D.; Rentsch, D.; Ma, B.; Scrivener, K.; Lothenbach, B. Kinetics of Al Uptake in Synthetic Calcium Silicate Hydrate (C-S-H). Cem. Concr. Res. 2023, 172, 107250. [Google Scholar] [CrossRef]

- Hôpital, E.L.; Lothenbach, B.; Kulik, D.A.; Scrivener, K. Influence of Calcium to Silica Ratio on Aluminium Uptake in Calcium Silicate Hydrate. Cem. Concr. Res. 2016, 85, 111–121. [Google Scholar] [CrossRef]

- Yusuf, M.O. Characteristics of Silica Fume Nano Alumina Ternary Blended Mortar. Sustainability 2023, 15, 14615. [Google Scholar] [CrossRef]

| Oxide, % | CEM III | CEM I | BPL | BPLB | FA | SF |

|---|---|---|---|---|---|---|

| SiO2 | 27.04 | 20.41 | 56.68 | 63.06 | 51.71 | 97.14 |

| CaO | 52.35 | 62.14 | 8.33 | 6.56 | 4.25 | 0.30 |

| Al2O3 | 8.71 | 5.63 | 16.87 | 16.71 | 25.61 | 0.15 |

| Fe2O3 | 1.47 | 2.39 | 6.30 | 5.01 | 8.09 | 0.05 |

| TiO2 | 0.52 | 0.31 | 0.89 | 0.76 | 1.23 | - |

| MnO | 0.12 | 0.06 | 0.09 | 0.08 | 0.07 | - |

| MgO | 4.05 | 1.60 | 5.26 | 2.32 | 1.95 | 0.15 |

| K2O | 0.64 | 0.77 | 3.56 | 3.47 | 2.37 | 0.22 |

| Na2O | 0.15 | 0.14 | 0.59 | 0.13 | 0.60 | 0.12 |

| SO3 | 4.06 | 3.19 | 0.7 | 0.63 | 0.17 | - |

| P2O5 | 0.06 | 0.11 | 0.18 | 0.24 | 0.48 | 0.03 |

| LOI | 1.09 | 3.08 | 0.95 | 1.07 | 3.15 | 1.18 |

| Mixture ID * | CEM III, g | CEM I, g | BPL, g | BPLB, g | FA, g | SF, g | Sand, g | Water, g |

|---|---|---|---|---|---|---|---|---|

| CEM III | 450 | - | - | - | - | - | 1350 | 225 |

| CEM III-BPL 15/63 | 382.5 | - | 67.5 | - | - | - | ||

| CEM III-BPL 30/63 | 315 | - | 135 | - | - | - | ||

| CEM III-BPL 15/32 | 382.5 | - | 67.5 | - | - | - | ||

| CEM III-BPL 30/32 | 315 | - | 135 | - | - | - | ||

| CEM III-BPL 15/15 | 382.5 | - | 67.5 | - | - | - | ||

| CEM III-BPL 30/15 | 315 | - | 135 | - | - | - | ||

| CEM III-BPLB 15/63 | 382.5 | - | - | 67.5 | - | - | ||

| CEM III-BPLB 30/63 | 315 | - | - | 135 | - | - | ||

| CEM III-BPLB 15/32 | 382.5 | - | - | 67.5 | - | - | ||

| CEM III-BPLB 30/32 | 315 | - | - | 135 | - | - | ||

| CEM III-FA 15 | 382.5 | - | - | - | 67.5 | - | ||

| CEM III-FA 30 | 315 | - | - | - | 135 | - | ||

| CEM III-SF 7.5 | 416.25 | - | - | - | - | 33.75 | ||

| CEM III-SF 15 | 382.5 | - | - | - | - | 67.5 | ||

| CEM I | - | 450 | - | - | - | - | ||

| CEM I-BPL 15/63 | - | 382.5 | 67.5 | - | - | - | ||

| CEM I-BPL 30/63 | - | 315 | 135 | - | - | - | ||

| CEM I-BPL 15/32 | - | 382.5 | 67.5 | - | - | - | ||

| CEM I-BPL 30/32 | - | 315 | 135 | - | - | - | ||

| CEM I-BPL 15/15 | - | 382.5 | 67.5 | - | - | - | ||

| CEM I-BPL 30/15 | - | 315 | 135 | - | - | - | ||

| CEM I-BPLB 15/63 | - | 382.5 | - | 67.5 | - | - | ||

| CEM I-BPLB 30/63 | - | 315 | - | 135 | - | - | ||

| CEM I-BPLB 15/32 | - | 382.5 | - | 67.5 | - | - | ||

| CEM I-BPLB 30/32 | - | 315 | - | 135 | - | - | ||

| CEM I-FA 15 | - | 382.5 | - | - | 67.5 | - | ||

| CEM I-FA 30 | - | 315 | - | - | 135 | - | ||

| CEM I-SF 7.5 | - | 416.25 | - | - | - | 33.75 | ||

| CEM I-SF 15 | - | 382.5 | - | - | - | 67.5 |

| BPL 63 µm | BPL 32 µm | BPL 15 µm | BPLB 63 µm | BPLB 32 µm | FA | SF |

|---|---|---|---|---|---|---|

| 55.1 | 82.8 | 96.9 | 40.4 | 58.8 | 48.5 | 217.8 |

| Mixture ID | O, % | Ca, % | Si, % | Al, % | Mg, % | Fe, % | S, % | K, % | C, % |

|---|---|---|---|---|---|---|---|---|---|

| CEM III | 56.01 | 12.41 | 9.10 | 2.24 | 1.16 | 0.32 | 0.75 | 0.57 | 17.43 |

| CEM III-BPL 15/63 | 54.04 | 13.10 | 10.04 | 2.65 | 1.34 | 0.44 | 0.76 | 0.26 | 17.35 |

| CEM III-BPL 30/63 | 55.55 | 11.29 | 9.16 | 2.46 | 1.98 | 0.68 | 0.56 | 0.57 | 17.74 |

| CEM III-BPL 15/32 | 54.48 | 12.36 | 9.57 | 2.62 | 1.83 | 0.36 | 0.88 | 0.21 | 17.68 |

| CEM III-BPL 30/32 | 55.71 | 11.54 | 9.16 | 2.96 | 1.39 | 0.39 | 0.62 | 0.31 | 17.93 |

| CEM III-BPL 15/15 | 55.97 | 10.47 | 9.70 | 3.17 | 1.96 | 0.43 | 0.81 | 0.25 | 17.23 |

| CEM III-BPL 30/15 | 54.18 | 12.34 | 10.33 | 2.88 | 1.26 | 0.77 | 0.45 | 0.26 | 17.53 |

| CEM III-BPLB 15/63 | 57.07 | 11.61 | 9.07 | 2.75 | 0.83 | 0.47 | 0.88 | 0.62 | 16.70 |

| CEM III-BPLB 30/63 | 53.95 | 11.77 | 9.48 | 3.14 | 0.75 | 0.79 | 0.69 | 0.46 | 18.97 |

| CEM III-BPLB 15/32 | 55.60 | 10.84 | 9.84 | 2.67 | 1.07 | 0.65 | 0.87 | 0.61 | 17.84 |

| CEM III-BPLB 30/32 | 54.48 | 12.16 | 10.37 | 2.40 | 0.50 | 0.72 | 0.82 | 0.21 | 18.35 |

| CEM III-FA 15 | 55.52 | 12.02 | 9.62 | 3.54 | 0.67 | 0.91 | 0.38 | 0.26 | 17.09 |

| CEM III-FA 30 | 54.12 | 12.74 | 9.79 | 3.80 | 0.51 | 0.77 | 0.32 | 0.37 | 17.59 |

| CEM III-SF 7.5 | 54.73 | 11.52 | 12.51 | 1.64 | 0.99 | 0.25 | 0.38 | 0.26 | 17.72 |

| CEM III-SF 15 | 56.47 | 10.70 | 12.86 | 1.47 | 0.65 | 0.18 | 0.43 | 0.20 | 17.02 |

| CEM I | 57.79 | 13.26 | 8.41 | 2.11 | 1.00 | 0.77 | 0.64 | 0.26 | 15.77 |

| CEM I-BPL 15/63 | 57.34 | 12.72 | 8.60 | 1.97 | 1.01 | 1.32 | 0.64 | 0.21 | 16.19 |

| CEM I-BPL 30/63 | 56.31 | 13.30 | 9.49 | 2.14 | 1.19 | 0.85 | 0.71 | 0.37 | 15.65 |

| CEM I-BPL 15/32 | 56.61 | 12.21 | 8.53 | 2.20 | 1.18 | 1.47 | 0.77 | 0.31 | 16.71 |

| CEM I-BPL 30/32 | 55.48 | 12.74 | 9.38 | 2.82 | 0.85 | 1.14 | 0.71 | 0.42 | 16.46 |

| CEM I-BPL 15/15 | 54.95 | 13.33 | 9.81 | 2.17 | 0.94 | 1.53 | 0.72 | 0.37 | 16.17 |

| CEM I-BPL 30/15 | 57.50 | 11.62 | 8.84 | 2.87 | 0.92 | 1.17 | 0.70 | 0.47 | 15.92 |

| CEM I-BPLB 15/63 | 56.23 | 13.20 | 9.09 | 1.98 | 1.19 | 1.14 | 0.64 | 0.26 | 16.28 |

| CEM I-BPLB 30/63 | 54.96 | 13.11 | 9.20 | 3.14 | 0.60 | 1.22 | 0.65 | 0.42 | 16.70 |

| CEM I-BPLB 15/32 | 56.53 | 11.97 | 9.30 | 2.42 | 0.84 | 1.39 | 0.64 | 0.26 | 16.65 |

| CEM I-BPLB 30/32 | 56.20 | 12.49 | 9.57 | 2.97 | 0.59 | 1.07 | 0.90 | 0.16 | 16.06 |

| CEM I-FA 15 | 55.45 | 13.53 | 9.32 | 3.08 | 0.68 | 1.04 | 0.78 | 0.21 | 15.91 |

| CEM I-FA 30 | 56.01 | 12.87 | 9.14 | 2.82 | 0.59 | 1.07 | 0.71 | 0.37 | 16.42 |

| CEM I-SF 7.5 | 55.66 | 11.03 | 13.01 | 1.20 | 0.83 | 0.65 | 0.44 | 0.21 | 16.98 |

| CEM I-SF 15 | 54.98 | 11.20 | 13.59 | 1.43 | 0.75 | 0.55 | 0.51 | 0.26 | 16.74 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kryzhanovskyi, V.; Orlowsky, J.; Skocek, J.; Macias Barrientos, M. Utilization of Brick Powder in Blended Cement Compositions: Rheological, Mechanical, and Microstructural Properties. Materials 2025, 18, 5120. https://doi.org/10.3390/ma18225120

Kryzhanovskyi V, Orlowsky J, Skocek J, Macias Barrientos M. Utilization of Brick Powder in Blended Cement Compositions: Rheological, Mechanical, and Microstructural Properties. Materials. 2025; 18(22):5120. https://doi.org/10.3390/ma18225120

Chicago/Turabian StyleKryzhanovskyi, Vitalii, Jeanette Orlowsky, Jan Skocek, and Marina Macias Barrientos. 2025. "Utilization of Brick Powder in Blended Cement Compositions: Rheological, Mechanical, and Microstructural Properties" Materials 18, no. 22: 5120. https://doi.org/10.3390/ma18225120

APA StyleKryzhanovskyi, V., Orlowsky, J., Skocek, J., & Macias Barrientos, M. (2025). Utilization of Brick Powder in Blended Cement Compositions: Rheological, Mechanical, and Microstructural Properties. Materials, 18(22), 5120. https://doi.org/10.3390/ma18225120