Effects of Equal Channel Angular Pressing on the Microstructure and Mechanical Properties of Explosion-Welded Al-Cu Bimetallic Plates

Abstract

1. Introduction

2. Materials and Methods

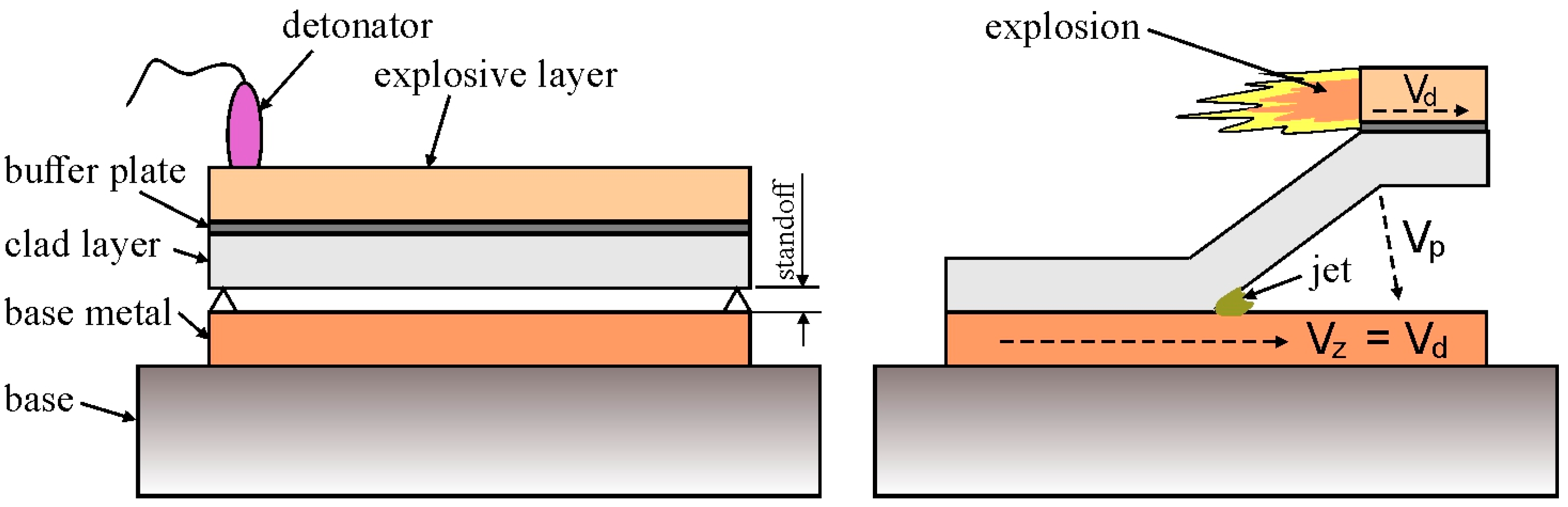

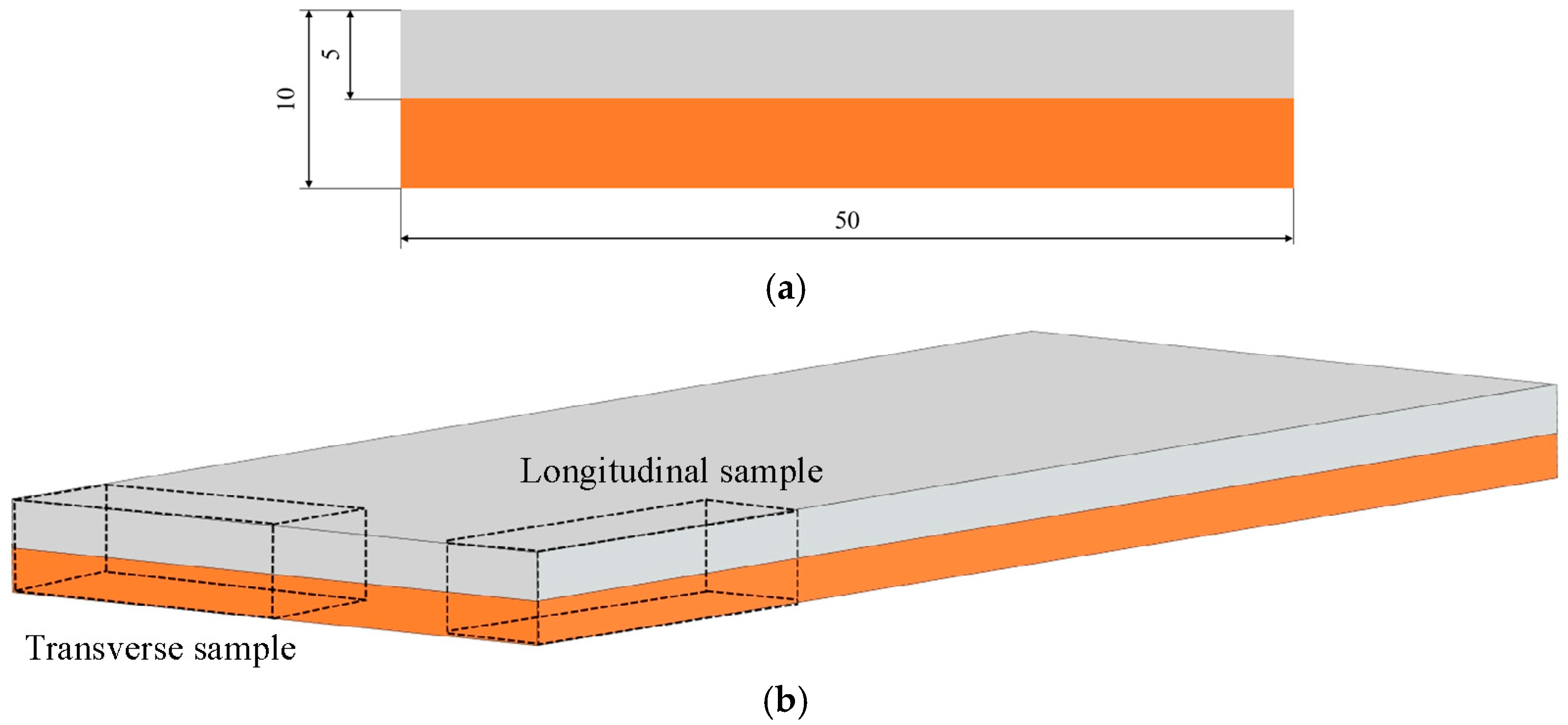

2.1. Test Material

2.2. Experimental Procedure

2.2.1. Equal Channel Angular Pressing

2.2.2. Scanning Electron Microscopy

2.2.3. Hardness

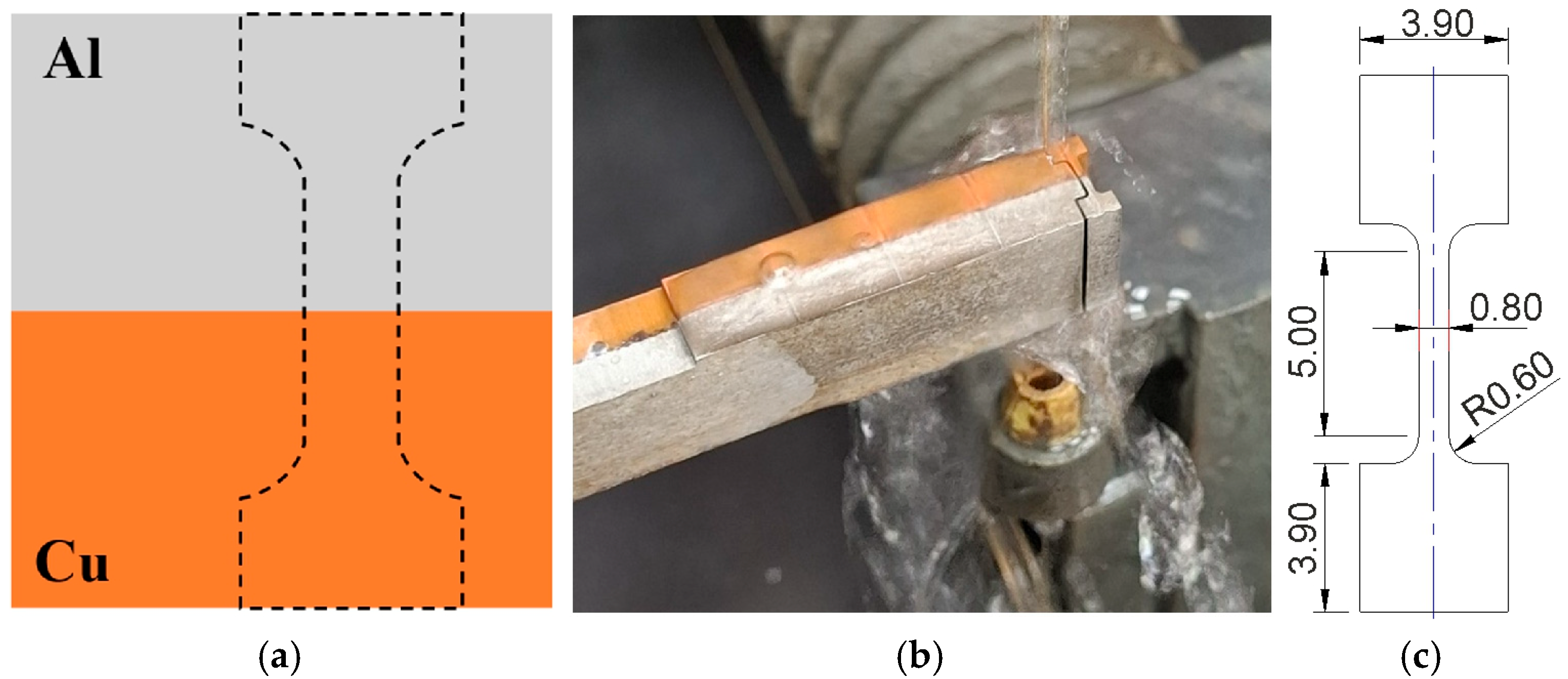

2.2.4. Uniaxial Tensile Test

3. Results and Discussion

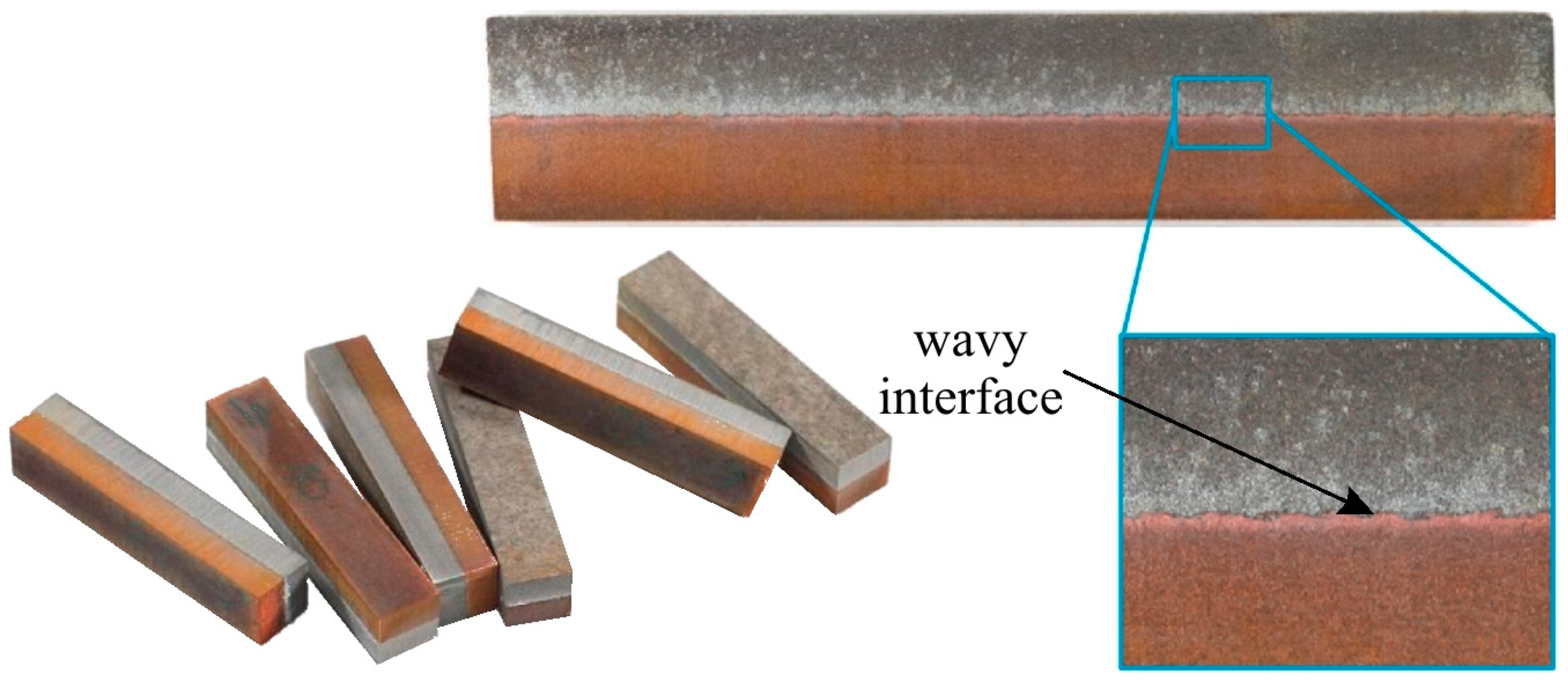

3.1. Base Bimetallic Material

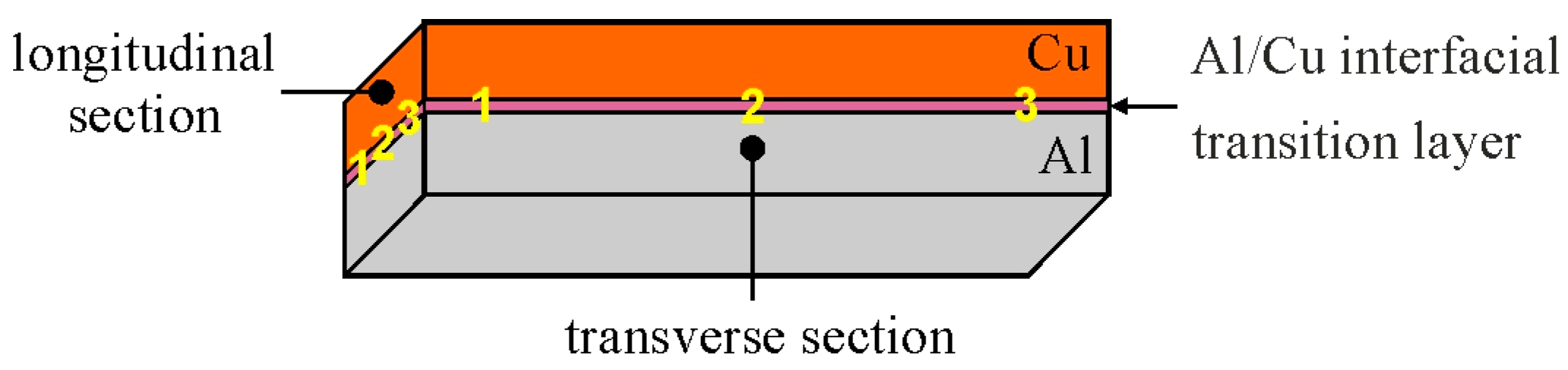

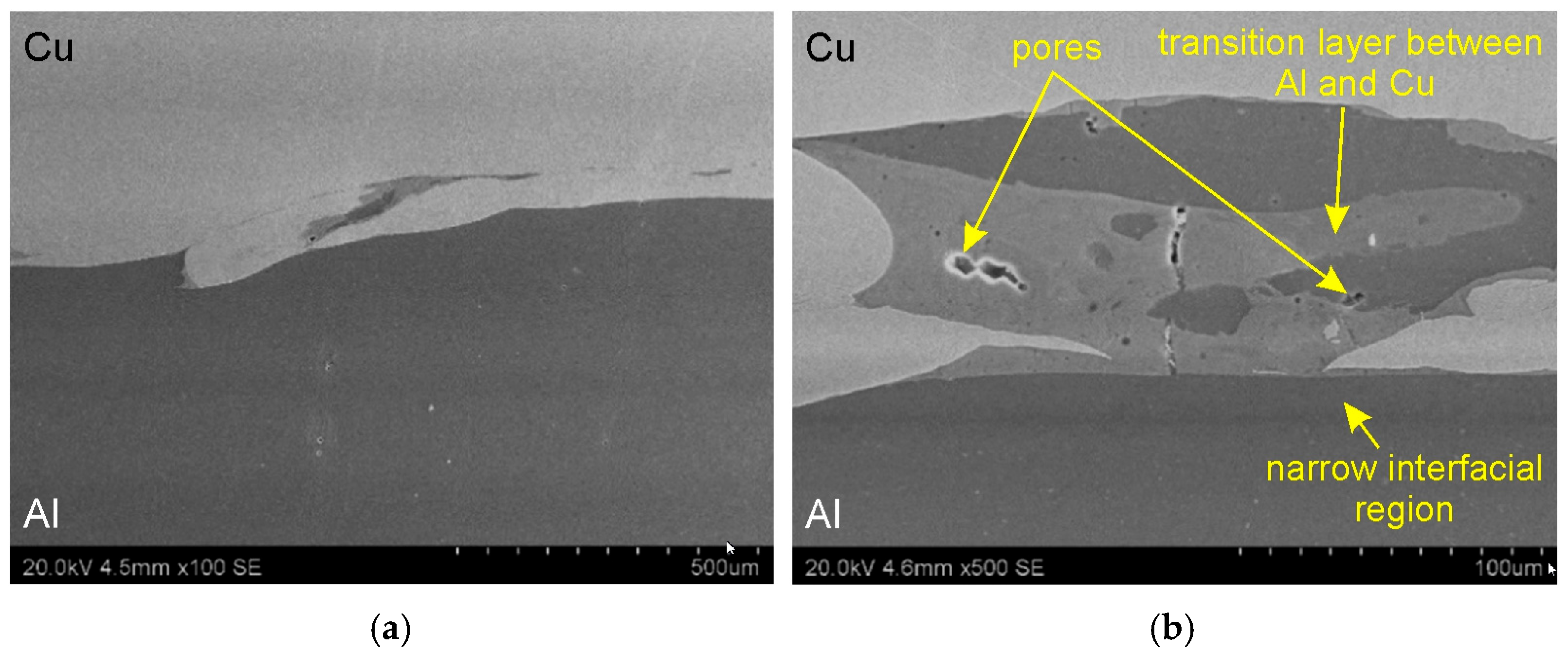

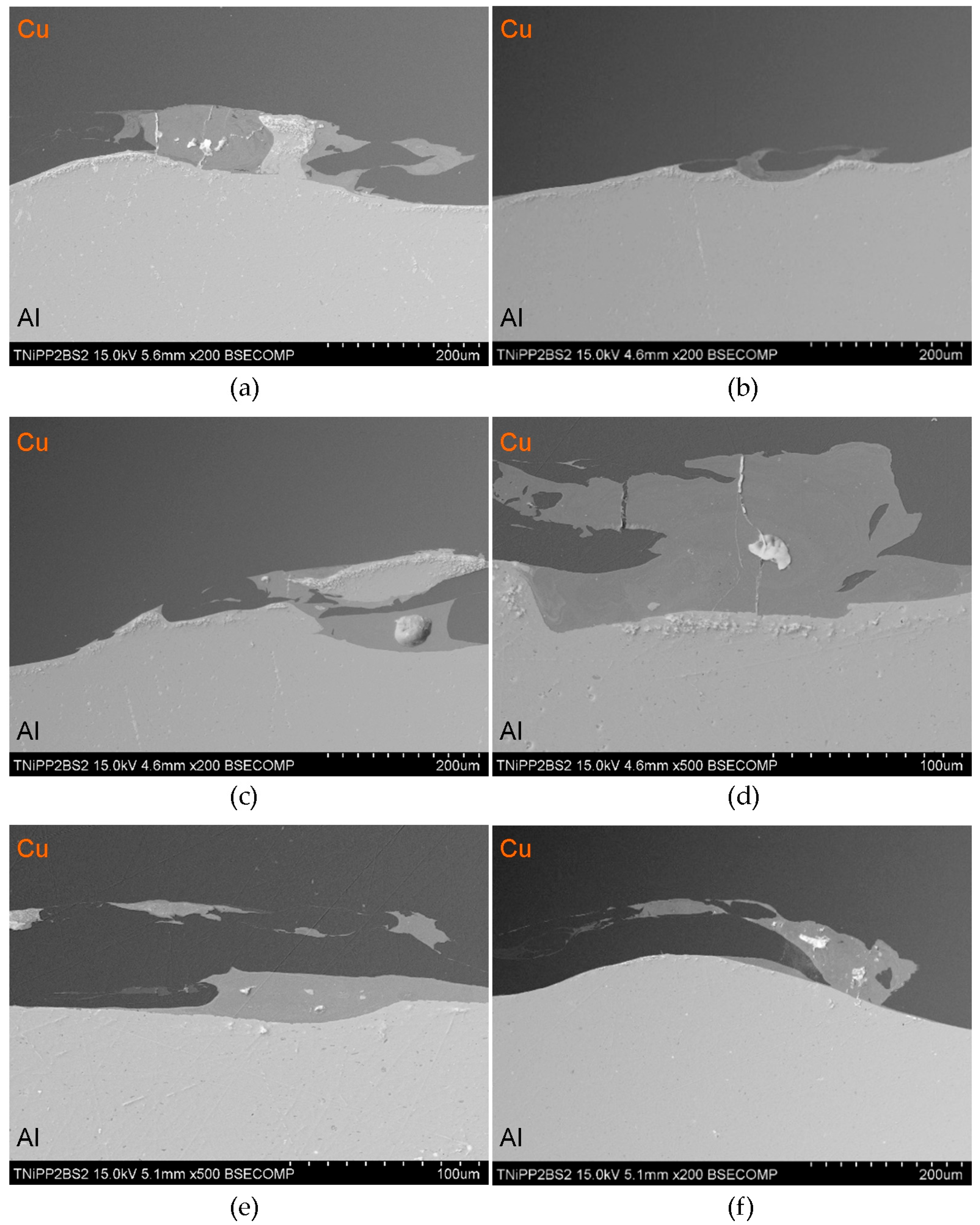

3.1.1. Interface Microstructure

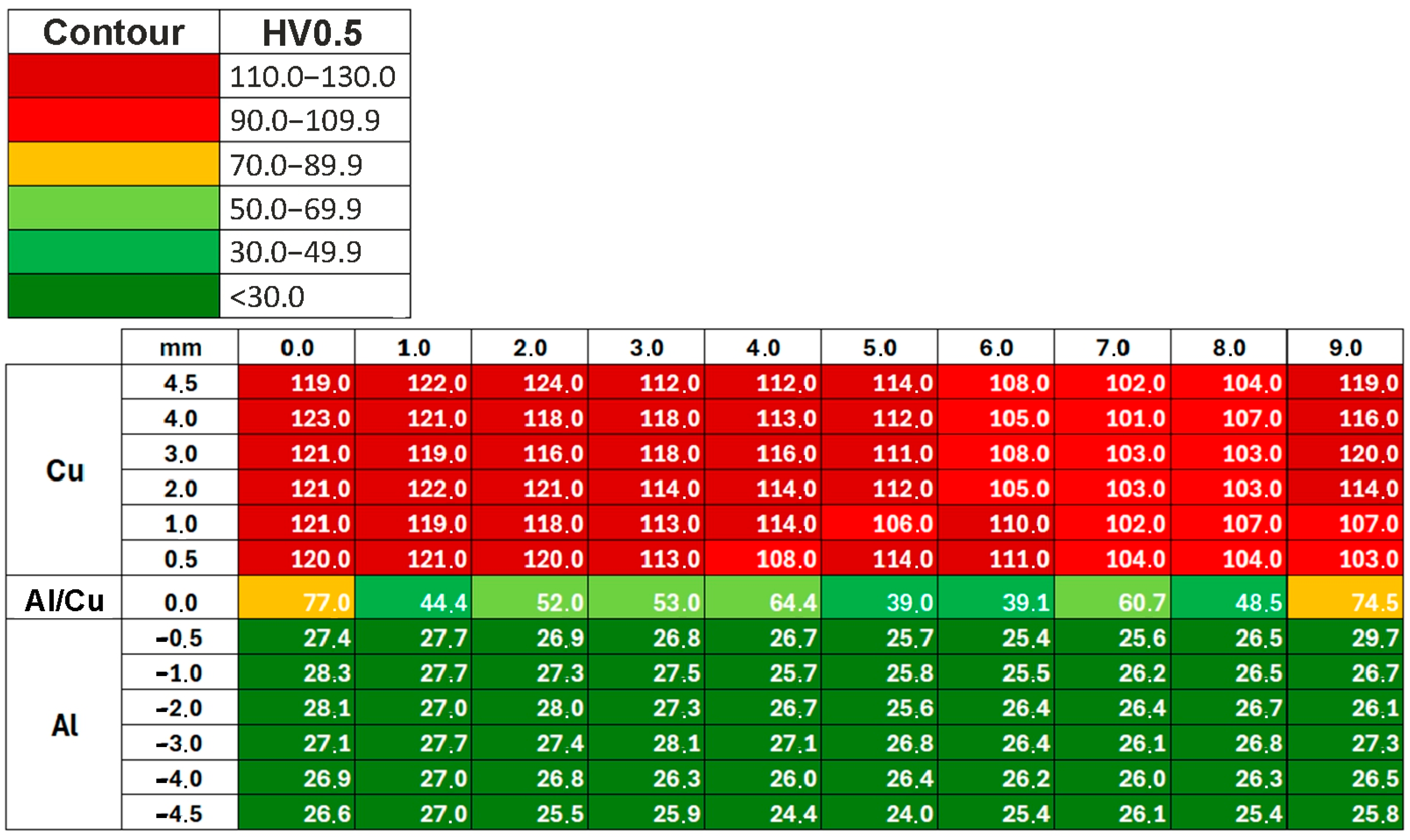

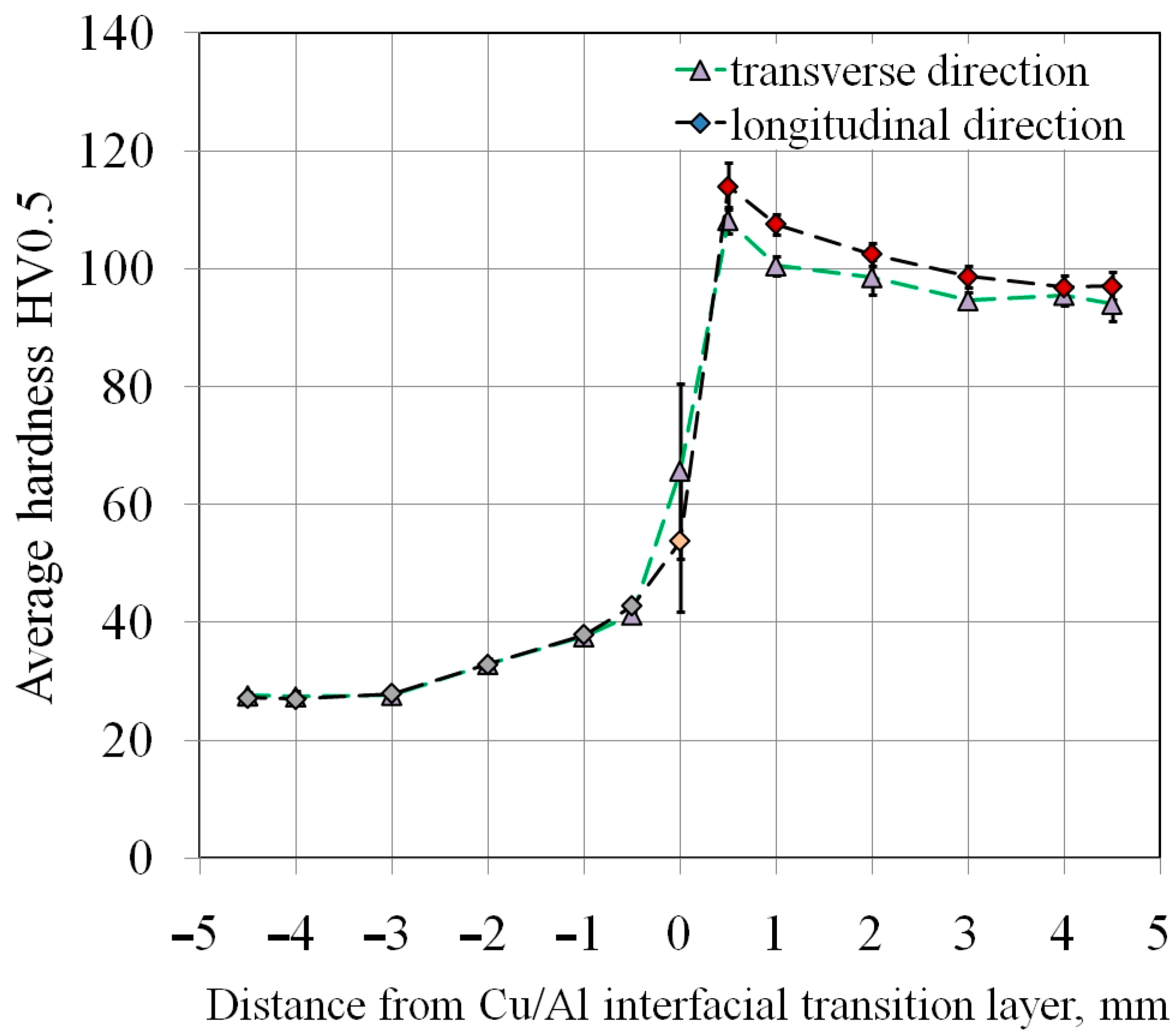

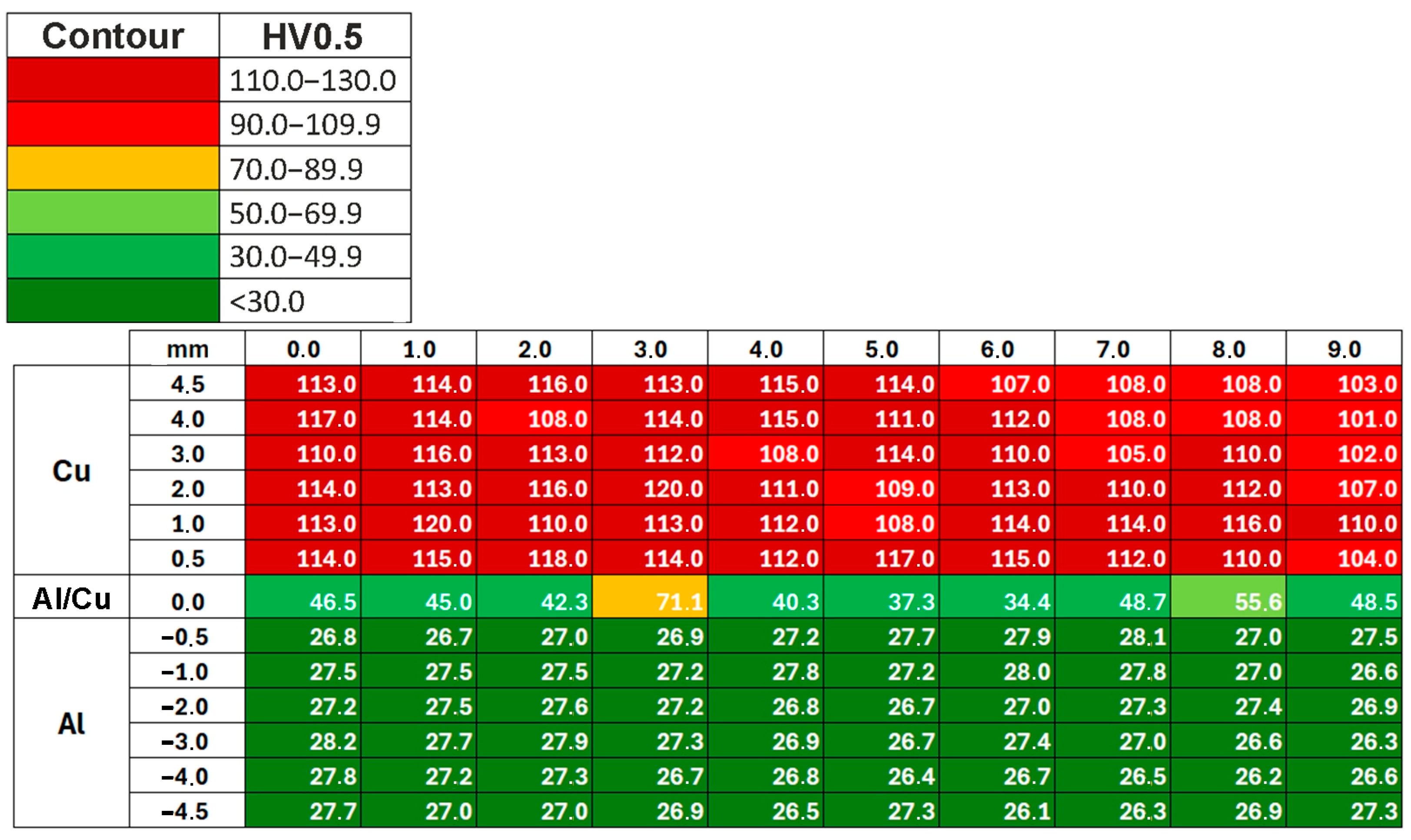

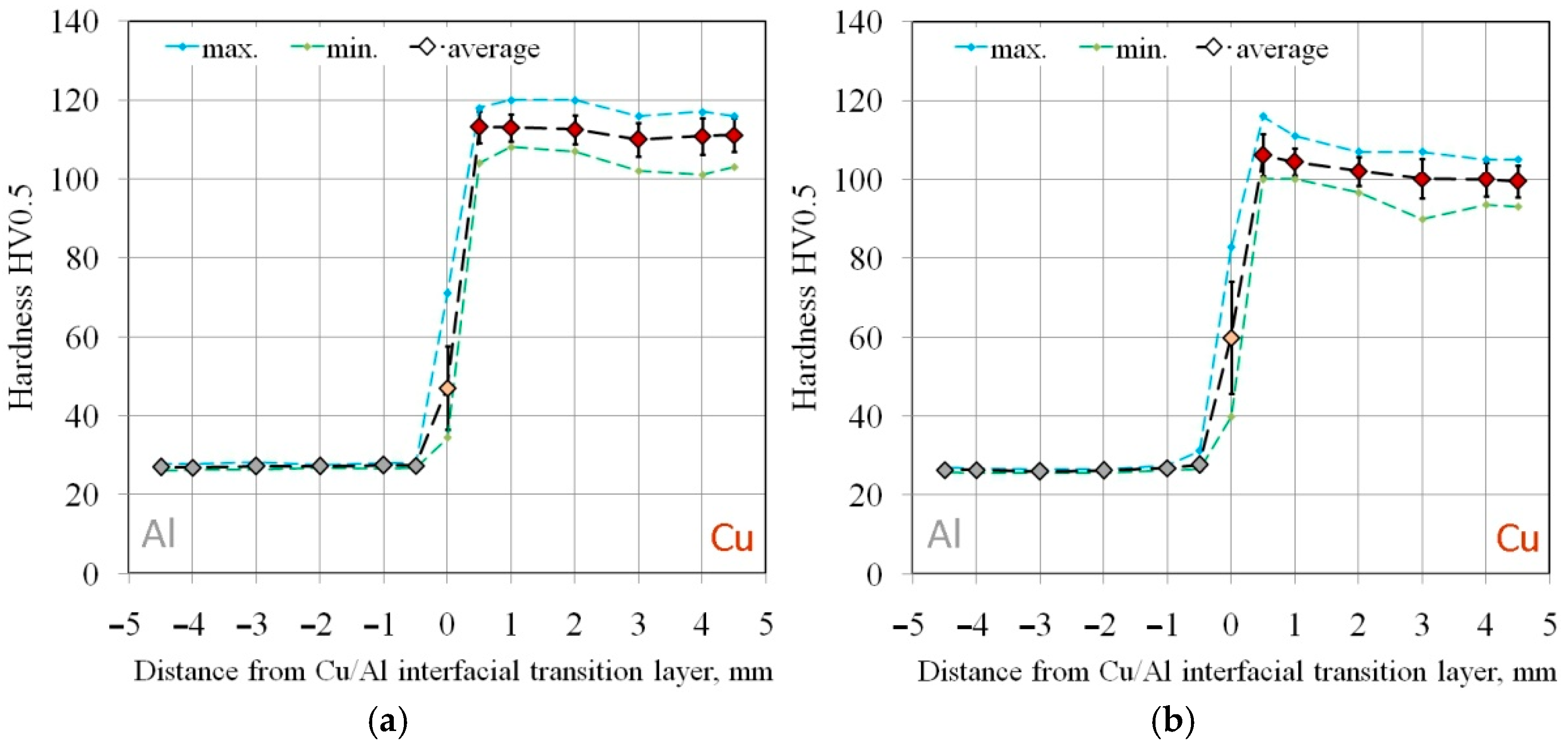

3.1.2. Vickers Hardness

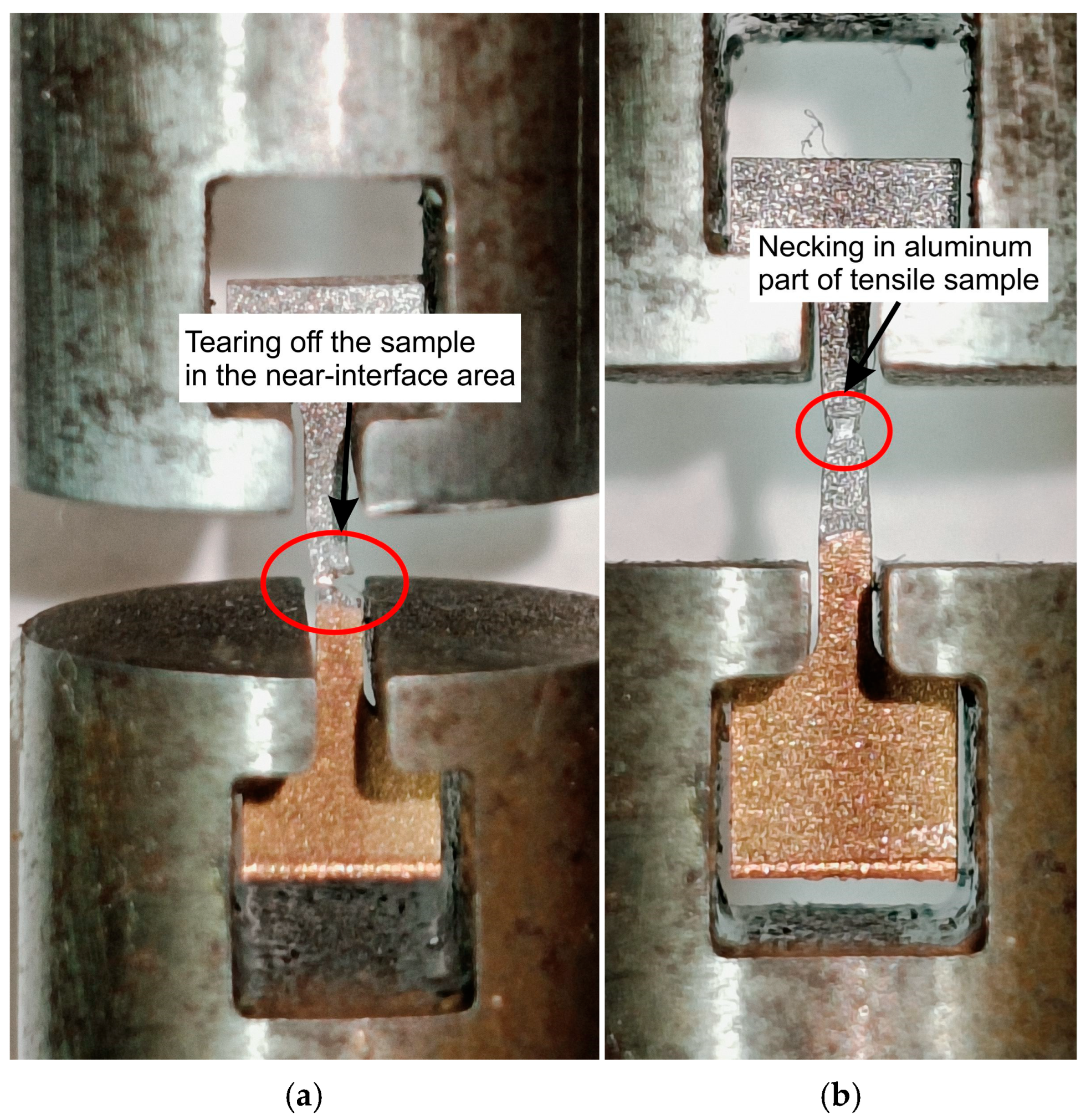

3.1.3. Mechanical Properties

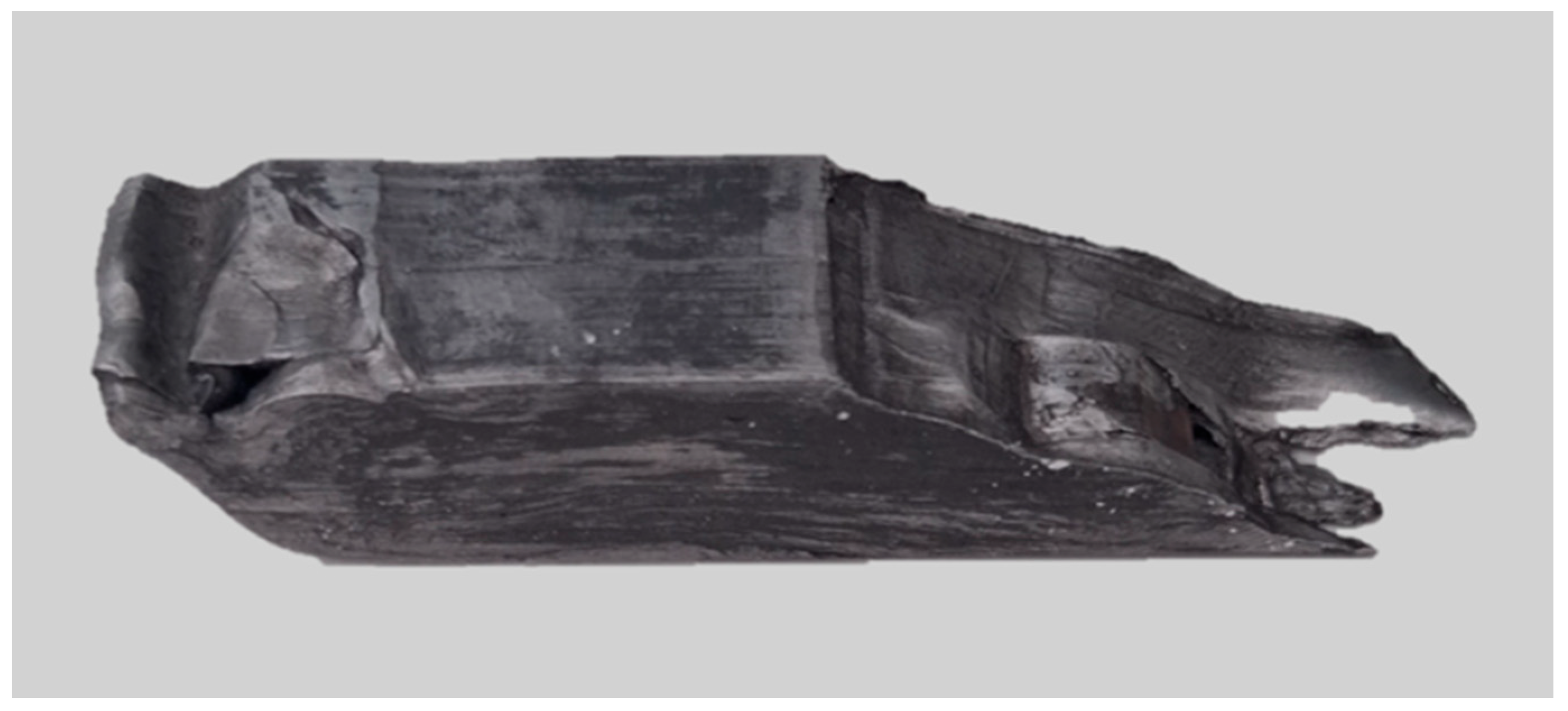

3.2. Equal Channel Angular Pressed Samples

3.2.1. Mechanical Properties After ECAP

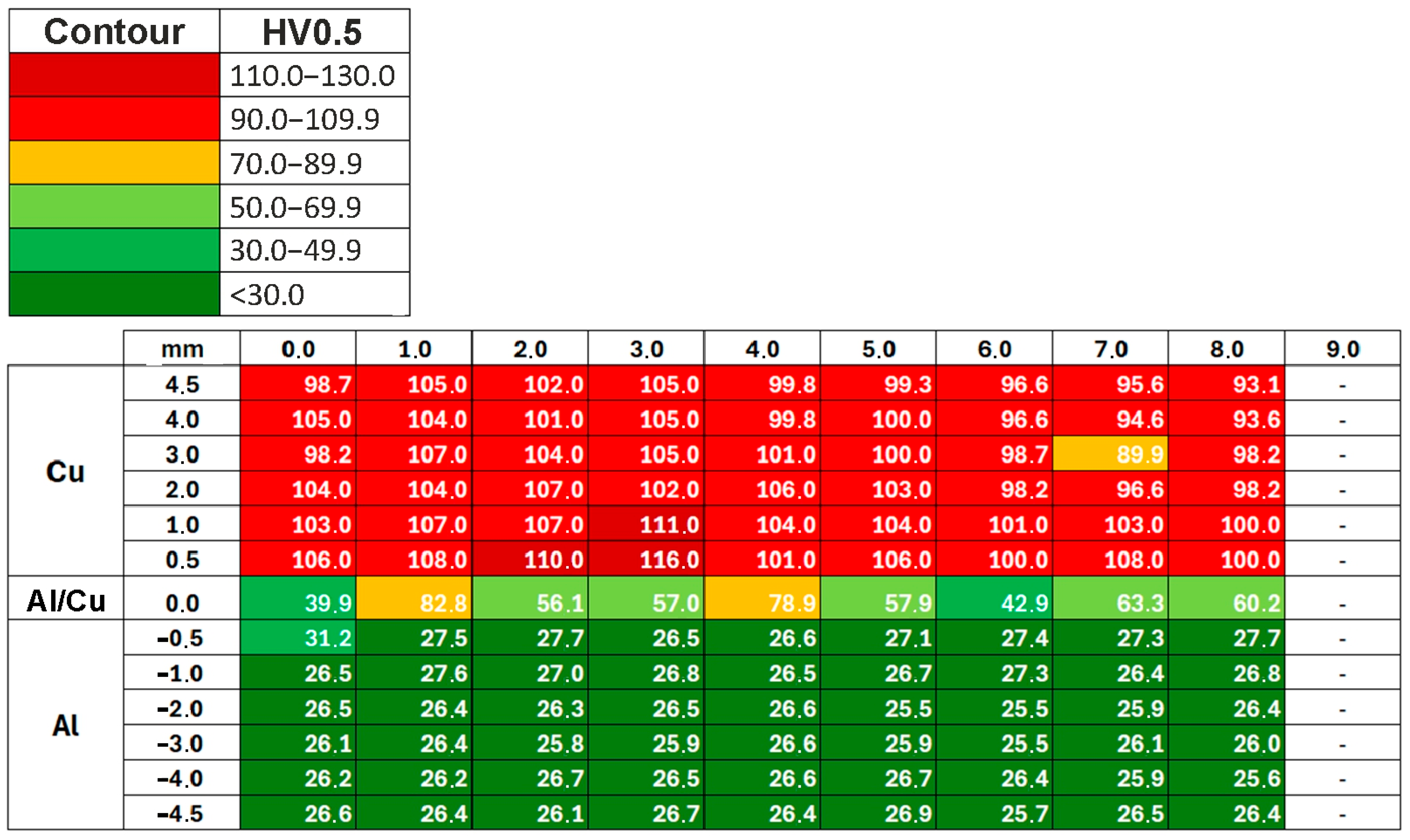

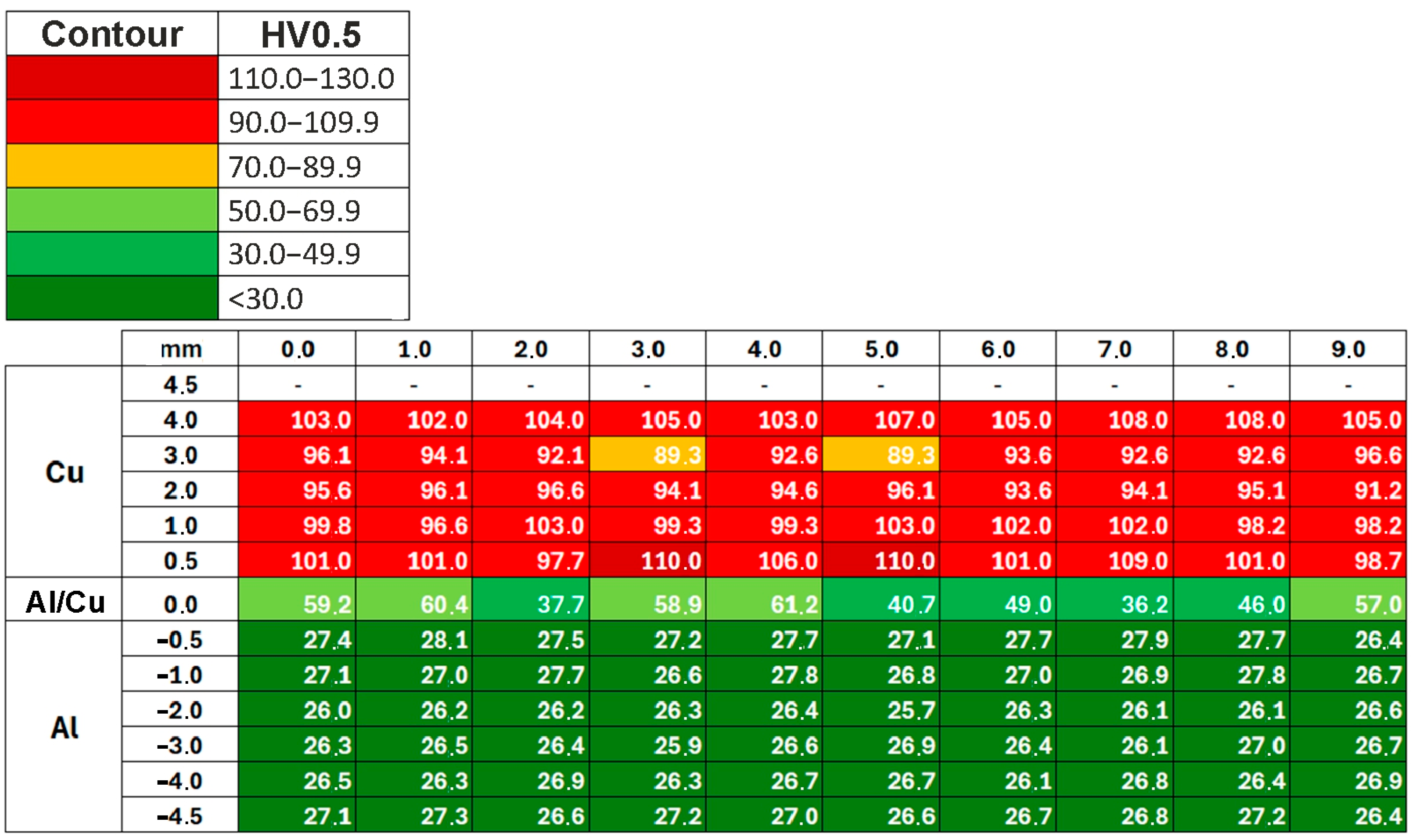

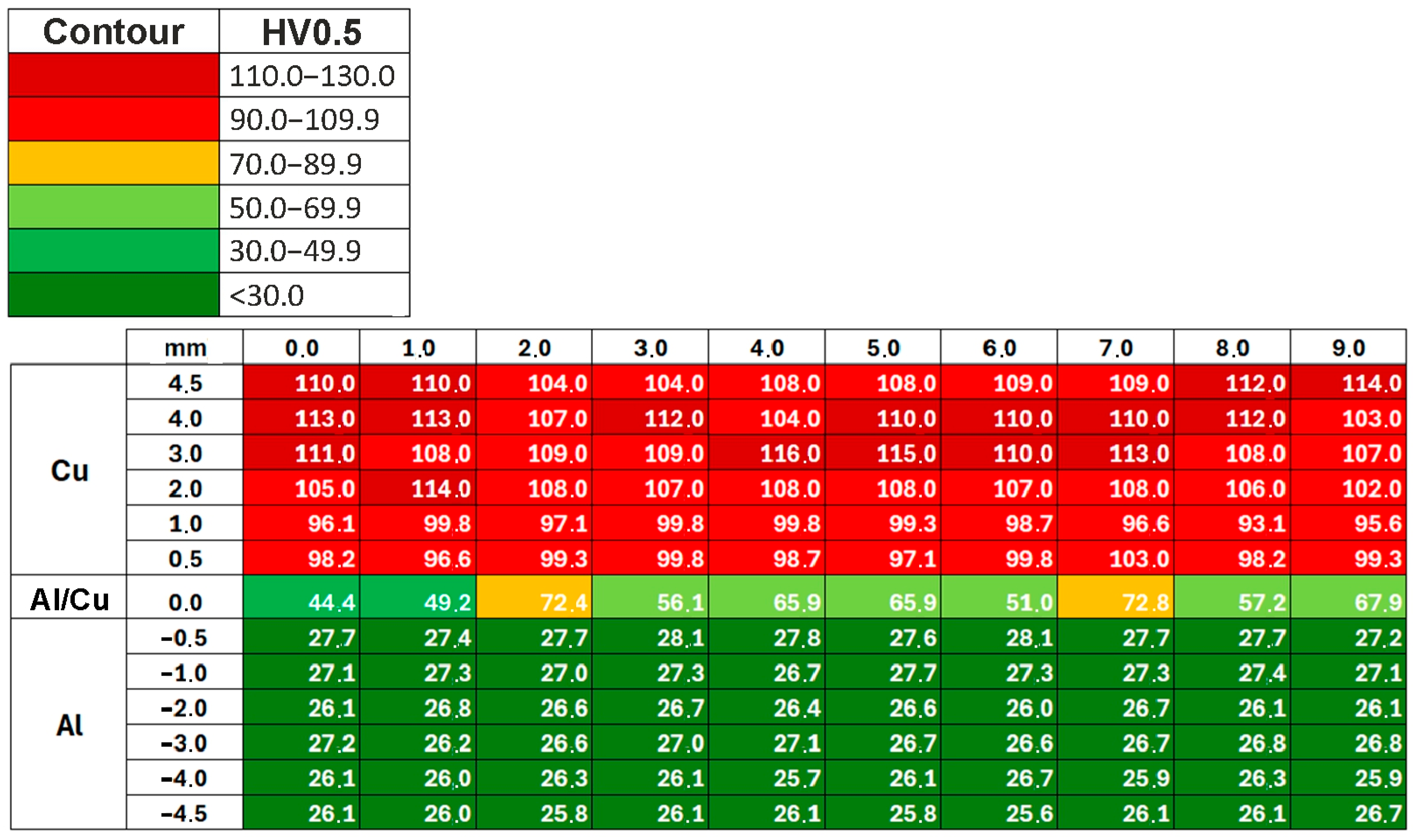

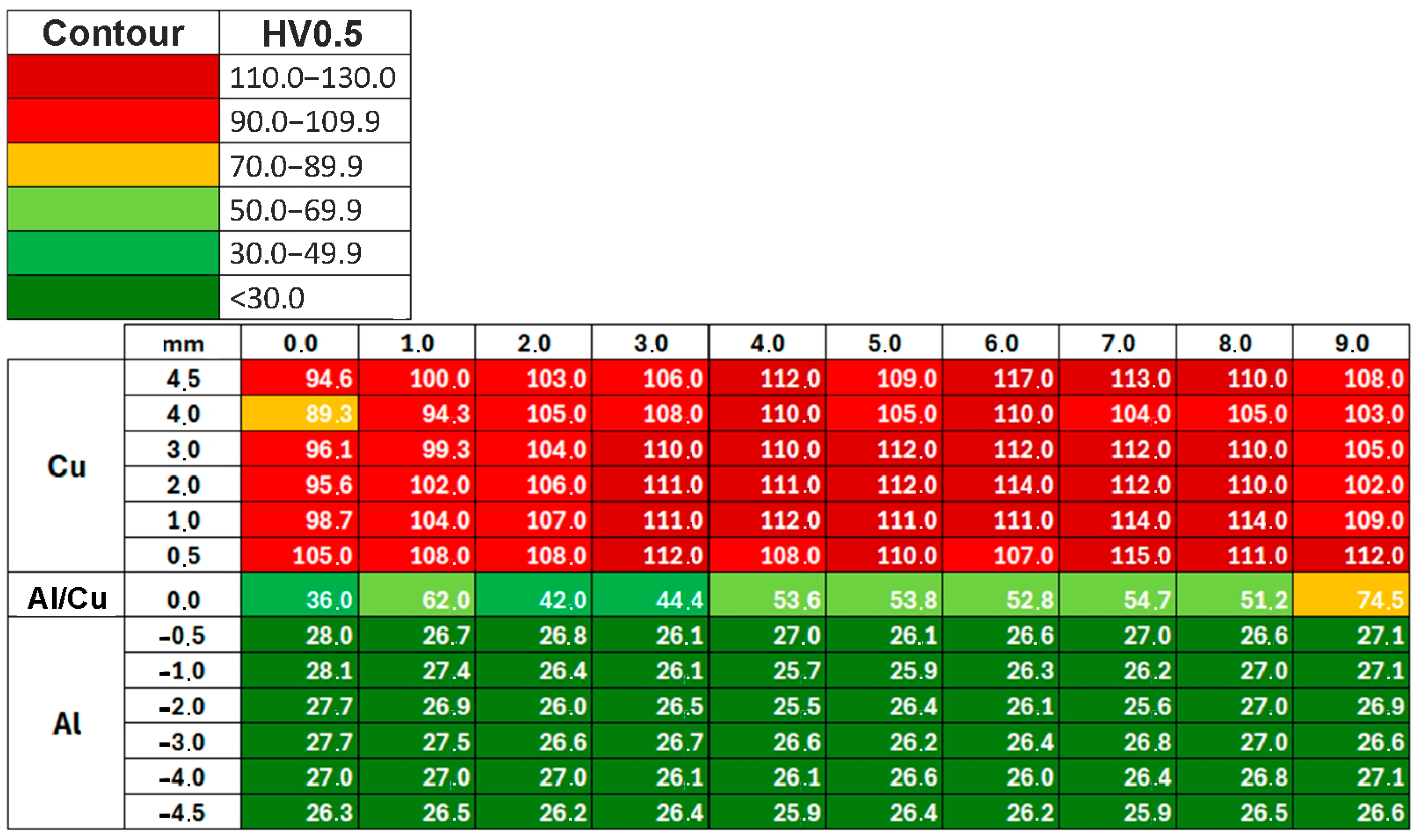

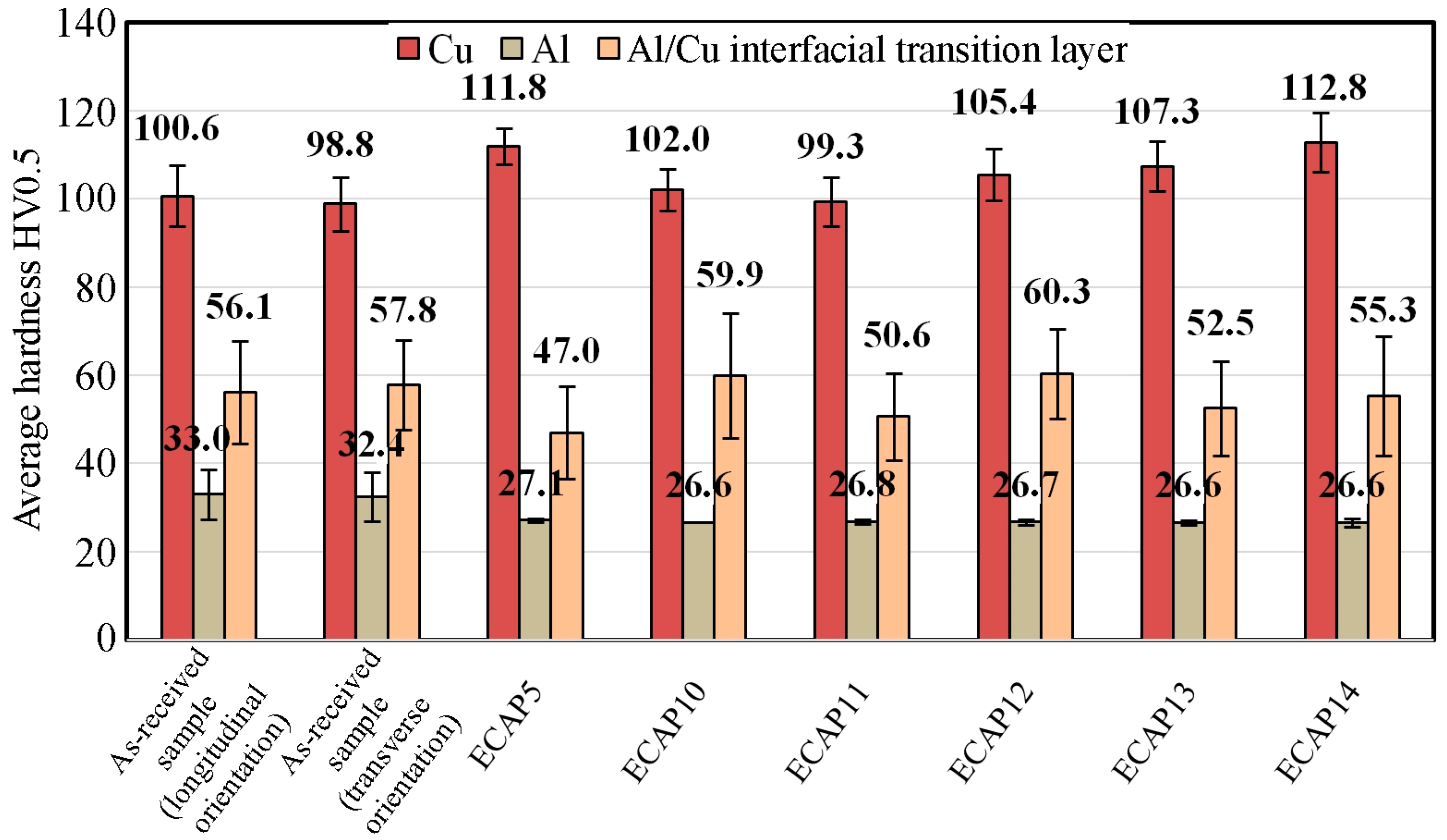

3.2.2. Vickers Hardness After ECAP

3.2.3. Microstructure After ECAP

4. Conclusions

- Chemical composition

- -

- Isolated pores and transition regions were present near the Al/Cu interfacial transition layer, resulting from local phase fusion during the welding process. The plane of sample cutting relative to the Al/Cu interfacial transition layer had no effect on the microstructure of the resulting bimetallic plate, which was homogeneous in all three locations of the base material. Sample orientation with respect to the Al/Cu interface had no effect on the microstructure of the base plates.

- -

- Each subsequent pass in the ECAP process led to a gradual, severe change in the morphology of the Al/Cu interfacial transition layer. As a result of explosive welding, intermetallic compounds were formed only in the Al/Cu interfacial transition layer. As the distance from the Al/Cu interfacial transition layer increased, the foreign phase content in the base material layer decreased.

- Hardness

- -

- The highest hardness values were obtained in the vicinity of the Al/Cu interfacial transition layer of the base materials. Areas closer to the outer surfaces of the samples had the lowest hardness values.

- -

- The orientation of the cutting plane of the samples from the base bimetallic material was shown to have no effect on its hardness.

- -

- Vickers hardness tests of ECAP-processed samples revealed a more uniform hardness distribution compared to the base material. The orientation of the Al/Cu plate layers in the die channel clearly determined the character of the hardness distribution.

- -

- After ECAP processing, the hardness in the Cu layer increased in all samples as a result of plastic deformation. Regardless of the sample orientation in the die entry and the number of passes, the hardness values in the Al plate of all ECAP-processed samples were very similar and lower than those measured in the base material.

- Tensile properties

- -

- In its as-received state, the fabricated Al/Cu bimetallic plate was characterized by the highest tensile strength. After the ECAP processing, the tensile strength of all analyzed samples decreased by approximately 15%.

- -

- During the static tensile test, no material fracture occurred in the Al/Cu interfacial transition layer.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

References

- Giudice, F.; Missori, S.; Scolaro, C.; Sili, A. A Review on Metallurgical Issues in the Production and Welding Processes of Clad Steels. Materials 2024, 17, 4420. [Google Scholar] [CrossRef]

- Xu, J.; Liu, Q.; Xu, Y.; Xiao, R.; Hou, Z.; Chen, S. Review on the Application of the Attention Mechanism in Sensing Information Processing for Dynamic Welding Processes. J. Manuf. Mater. Process. 2024, 8, 22. [Google Scholar] [CrossRef]

- Chen, H.; Zhu, Z.; Zhu, Y.; Sun, L.; Guo, Y. Solid-State Welding of Aluminum to Magnesium Alloys: A Review. Metals 2023, 13, 1410. [Google Scholar] [CrossRef]

- Joshi, G.R.; Badheka, V.J.; Darji, R.S.; Oza, A.D.; Pathak, V.J.; Burduhos-Nergis, D.D.; Burduhos-Nergis, D.P.; Narwade, G.; Thirunavukarasu, G. The Joining of Copper to Stainless Steel by Solid-State Welding Processes: A Review. Materials 2022, 15, 7234. [Google Scholar] [CrossRef]

- Feng, R.; Liu, D.; Zhang, C.; Pan, Y.; Wang, Y.; Chen, J.; Ye, X.; Lei, M.; Li, Y. Effect of Solid-State Phase Transformation and Transverse Restraint on Residual Stress Distribution in Laser–Arc Hybrid Welding Joint of Q345 Steel. Materials 2024, 17, 2632. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Dengm, Y.; Chen, F.; Luo, Y.; Xiao, X.; Lu, N.; Liu, Y.; Deng, Y. Fatigue life prediction for orthotropic steel bridge decks welds using a Gaussian variational bayes network and small sample experimental data. Reliab. Eng. Syst. Saf. 2025, 264, 111406. [Google Scholar] [CrossRef]

- Klimpel, A. Welding, Welding, and Cutting Metals; Technologies; Wydawnictwa Naukowo-Techniczne: Warsaw, Poland, 1999. [Google Scholar]

- Opiekun, Z.A. Welding of Metallic Materials; Wydawnictwo i Handel Książkami KaBe: Krosno, Poland, 2022. [Google Scholar]

- Akca, E.; Gursel, A. Solid State Welding and Application in Aeronautical Industry. Period. Eng. Nat. Sci. 2016, 4, 1–8. [Google Scholar] [CrossRef]

- Gadakh, V.S.; Badheka, V.J.; Mulay, A.S. Solid-state joining of aluminum to titanium: A review. Mater. Des. Appl. 2021, 235, 1757–1799. [Google Scholar] [CrossRef]

- An Introduction to Forge Welding. Available online: https://vernlewis.com/forge-welding/ (accessed on 12 September 2024).

- Zhao, D.; Jiang, C.; Zhao, K. Ultrasonic welding of AZ31B magnesium alloy and pure copper: Microstructure, mechanical properties and finite element analysis. J. Mater. Res. Technol. 2023, 23, 1273–1284. [Google Scholar] [CrossRef]

- Kaya, Y. Investigation of Copper-Aluminium Composite Materials Produced by Explosive Welding. Metals 2018, 8, 780. [Google Scholar] [CrossRef]

- Szachogłuchowicz, I.; Śnieżek, L.; Ślęzak, T. Mechanical Properties Analysis of Explosive Welded Sheet of AA2519-Ti6Al4V with Interlayer of AA1050 Subjected to Heat-Treatment. Materials 2022, 15, 4023. [Google Scholar] [CrossRef]

- Inao, D.; Mori, A.; Tanaka, S.; Hokamoto, K. Explosive Welding of Thin Aluminum Plate onto Magnesium Alloy Plate Using a Gelatin Layer as a Pressure-Transmitting Medium. Metals 2020, 10, 106. [Google Scholar] [CrossRef]

- Sherpa, B.B.; Rani, R. Advancements in explosive welding process for bimetallic material joining: A review. J. Alloys Metall. Syst. 2024, 6, 100078. [Google Scholar] [CrossRef]

- Gulenc, B. Investigation of interface properties and weldability of aluminum and copper plates by explosive welding method. Mater. Des. 2008, 29, 275–278. [Google Scholar] [CrossRef]

- Lysak, V.I.; Kuzmin, S.V. Lower boundary in metal explosive welding. Evolution of ideas. J. Mater. Process. Technol. 2012, 212, 150–156. [Google Scholar] [CrossRef]

- Kwiecienńn, M.; Majta, J.; Dziedzic, D. Shear deformation and failure of explosive welded Inconel-microalloyed steels bimetals. Arch. Civ. Mech. Eng. 2014, 14, 32–39. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Attarilar, S.; Gode, C.; Kandavalli, S.R.; Shamsborhan, M.; Wang, Q. Conceptual Analysis on Severe Plastic Deformation Processes of Shape Memory Alloys: Mechanical Properties and Microstructure Characterization. Metals 2023, 13, 447. [Google Scholar] [CrossRef]

- Mavlyutov, A.; Evstifeev, A.; Volosevich, D.; Gushchina, M.; Voropaev, A.; Zotov, O.; Klimova-Korsmik, O. The Effect of Severe Plastic Deformation on the Microstructure and Mechanical Properties of Composite from 5056 and 1580 Aluminum Alloys Produced with Wire Arc Additive Manufacturing. Metals 2023, 13, 1281. [Google Scholar] [CrossRef]

- Snopinski, P.; Tanski, T.; Labisz, K.; Rusz, S.; Jonsta, P.; Krol, M. Wrought Aluminum-Magnesium Alloys Subjected to SPD Processing. Int. J. Mater. Res. 2016, 107, 637–645. [Google Scholar] [CrossRef]

- Medeiros, M.P.; Lopes, D.R.; Kawasaki, M.; Langdon, T.G.; Figueiredo, R.B. An Overview on the Effect of Severe Plastic Deformation on the Performance of Magnesium for Biomedical Applications. Materials 2023, 16, 2401. [Google Scholar] [CrossRef]

- Kowalczyk, K.; Jablonska, M.; Rusz, S.; Bednarczyk, I. Influence of the DRECE Process of Severe Plastic Deformation on the Mechanical Properties of the Ultra-Low Carbon Interstitial Free Steel. Arch. Metall. Mater. 2018, 63, 2095–2100. [Google Scholar] [CrossRef]

- Rusz, S.; Malanik, K.; Dutkiewicz, J.; Cizek, L.; Donic, T.; Kedron, J.; Tylsar, S. New Design of the Forming Equipment DRECE for Obtaining UFG Structure in Strip of Sheet. Arch. Mater. Sci. Eng. 2010, 42, 111–118. [Google Scholar]

- Rusz, S.; Hilser, O.; Ochodek, V.; Cada, R.; Svec, J.; Szkandera, P. Influence of SPD Process on Low-Carbon Steel Mechanical Properties. MM Sci. J. 2019, 12, 2910–2914. [Google Scholar] [CrossRef]

- Carvalho, G.H.S.F.L.; Galvão, I.; Mendes, R.; Leal, R.M.; Loureiro, A. Weldability of aluminium-copper in explosive welding. Int. J. Adv. Manuf. Technol. 2019, 103, 3211–3221. [Google Scholar] [CrossRef]

- EN 1652; Copper and Copper Alloys—Plate, Sheet, Strip and Circles for General Purposes. European Committee for Standardization (CEN): Brussels, Belgium, 1997.

- EN 573-1; Aluminium and Aluminium Alloys—Chemical Composition and form of Wrought Products—Part 1: Numerical Designation System. European Committee for Standardization (CEN): Brussels, Belgium, 2004.

- Shan, S.; Liu, Y.; Zhang, J.; Fan, X.; Jiao, K. Explosion welding research on large-size ultra thick copper-steel composites: A review. J. Mater. Res. Technol. 2023, 24, 4130–4142. [Google Scholar] [CrossRef]

- Koujalagi, M.B.; Siddesha, H.S. ECAP of titanium alloy by sever plastic deformation: A review. Mater. Today Proc. 2021, 45, 71–77. [Google Scholar] [CrossRef]

- Shaeri, M.H.; Shaeri, M.; Salehi, M.T.; Seyyedein, S.H.; Abutalebi, M.R. Effect of equal channel angular pressing on aging treatment of Al-7075 alloy. Prog. Nat. Sci. Mater. Int. 2015, 25, 159–168. [Google Scholar] [CrossRef]

- Valiev, R.Z.; Langdon, T.G. Principles of equal-channel angular pressing as a processing tool for grain refinement. Prog. Mater. Sci. 2006, 51, 881–981. [Google Scholar] [CrossRef]

- Bataev, I.A.; Riabinkina, P.A.; Emurlaev, K.I.; Golovin, E.D.; Lazarenko, D.V.; Chen, P.; Bataeva, Z.B.; Ogneva, T.S.; Nasennik, I.E.; Bataev, A.A. Uncovering the influence of mechanical properties on wave formation during high-velocity impact welding by numerical simulation. J. Mater. Process. Technol. 2024, 332, 118532. [Google Scholar] [CrossRef]

- Mendes, R.; Ribeiro, J.B.; Loureiro, A. Effect of explosive characteristics on the explosive welding of stainless steel to carbon steel in cylindrical configuration. Mater. Des. 2013, 51, 182–192. [Google Scholar] [CrossRef]

- Carton, E.P. Wave Forming Mechanisms in Explosive Welding. Mater. Sci. Forum 2004, 465–466, 219–224. [Google Scholar] [CrossRef]

- Bahrani, A.S.; Black, T.J.; Crossland, B. The Mechanics of Wave Formation in Explosive Welding. Proc. R. Soc. London Ser. A Math. Phys. Sci. 1967, 296, 123–136. [Google Scholar]

- Ben-Artzy, A.; Stern, A.; Frage, N.; Shribman, V.; Sadot, O. Wave formation mechanism in magnetic pulse welding. Int. J. Impact Eng. 2010, 37, 397–404. [Google Scholar] [CrossRef]

- Plaksin, I.; Campos, J.; Ribeiro, J.; Mendes, R.; Direito, J.; Braga, D.; Pruemmer, R. Novelties in physics of explosive welding and powder compaction. J. Phys. IV 2003, 110, 797–802. [Google Scholar] [CrossRef]

- Wang, K.; Kuroda, M.; Chen, X.; Hokamoto, K.; Li, X.; Zeng, X.; Nie, S.; Wang, Y. Mechanical Properties of Explosion-Welded Titanium/Duplex Stainless Steel under Different Energetic Conditions. Metals 2022, 12, 1354. [Google Scholar] [CrossRef]

- Sun, Y.; Yu, S.; Wang, B.; Liu, L.; Liu, E.; Feng, T. Interface Microstructure and Mechanical Properties of Nickel/Steel Bimetal Composite Pipe Fabricated by Explosive Welding. Metals 2024, 14, 1253. [Google Scholar] [CrossRef]

- Kaya, Y. Microstructural, Mechanical and Corrosion Investigations of Ship Steel-Aluminum Bimetal Composites Produced by Explosive Welding. Metals 2018, 8, 544. [Google Scholar] [CrossRef]

- Żaba, K.; Puchlerska, S.; Kuczek, Ł.; Trzepieciński, T.; Maj, P. Effect of Step Size on the Formability of Al/Cu Bimetallic Sheets in Single Point Incremental Sheet Forming. Materials 2023, 16, 367. [Google Scholar] [CrossRef]

- Figueiredo, R.B.; Cetlin, P.R.; Langdon, T.G. The processing of difficult-to-work alloys by ECAP with an emphasis on magnesium alloys. Acta Mater. 2007, 55, 4769–4779. [Google Scholar] [CrossRef]

- Stepanov, N.D.; Kuznetsov, A.V.; Salischev, G.A.; Raab, G.I.; Valiev, R.Z. Effect of Cold Rolling on Structure and Mechanical Properties of Copper Subjected to Different Numbers of Passes of ECAP. Mater. Sci. Forum 2011, 667–669, 295–300. [Google Scholar] [CrossRef]

- de Faria, C.G.; Almeida, N.G.S.; Balzuweit, K.; Aguilar, M.T.P.; Cetlin, P.R. The effect of initial strain in the severe plastic deformation of aluminum on the subsequent work hardening regeneration through low strain amplitude multi-directional forging. Mater. Lett. 2021, 290, 129462. [Google Scholar] [CrossRef]

- Eivani, A.R.; Mirzakoochakshirazi, H.R.; Jafarian, H.R. Investigation of joint interface and cracking mechanism of thick cladding of copper on aluminum by equal channel angular pressing (ECAP). J. Mater. Res. Technol. 2020, 9, 3394–3405. [Google Scholar] [CrossRef]

- Volokitina, I.; Sapargaliyeva, B.; Agabekova, A.; Syrlybekkyzy, S.; Volokitin, A.; Nurshakhanova, L.; Nurbaeva, F.; Kolesnikov, A.; Sabyrbayeva, S.; Iabassar, A.; et al. Increasing strength and performance properties of bimetallic rods during severe plastic deformation. Case Stud. Constr. Mater. 2023, 19, e02256. [Google Scholar] [CrossRef]

- Yu, T. Deformation Microstructure and Recovery. In Recrystallization: Types, Techniques and Applications; Huang, K., Ed.; Nova Science Publishers: Hauppauge, NY, USA, 2020; pp. 1–44. [Google Scholar]

- Loureiro, A.; Mendes, R.; Ribeiro, J.B.; Leal, R.M.; Galvão, I. Effect of explosive mixture on quality of explosive welds of copper to aluminium. Mater. Des. 2016, 95, 256–267. [Google Scholar] [CrossRef]

- Bakhtiari, H.; Abbasi, H.; Sabet, H.; Khanzadeh, M.R.; Farvizi, M. Investigation on the Effects of Explosive Welding Parameters on the Mechanical Properties and Electrical Conductivity of Al-Cu Bimetal. J. Environ. Friendly Mater. 2022, 6, 31–37. [Google Scholar]

- Amani, H.; Soltanieh, M. Intermetallic Phase Formation in Explosively Welded Al/Cu Bimetals. The Minerals, Metals & Materials Society and ASM International 2016. Metall. Mater. Trans. B 2016, 47, 2524–2534. [Google Scholar]

- Paul, H.; Lityńska-Dobrzyńska, L.; Prażmowski, M. Microstructure and Phase Constitution Near the Interface of Explosively Welded Aluminum/Copper Plates. Metall. Mater. Trans. A 2013, 44, 3836–3851. [Google Scholar] [CrossRef]

- Medvedev, A.E.; Lapovok, R.; Koch, E.; Höppel, H.W.; Göken, M. Optimisation of interface formation by shear inclination: Example of aluminium-cooper hybrid produced by ECAP with back-pressure. Mater. Des. 2018, 146, 142–151. [Google Scholar] [CrossRef]

- Azizi, A.; Abedi, H.R.; Saboori, A. Work hardening behavior and substructure evolution of a low-density steel during compressive deformation. J. Mater. Res. Technol. 2022, 21, 4200–4211. [Google Scholar] [CrossRef]

| Bi | O | Pb | Others | Cu |

|---|---|---|---|---|

| ≤0.0005 | ≤0.04 | ≤0.005 | ≤0.03 | ≥99.90 |

| Zn | Si | Mg | Fe | Ti | Cu | Mn | Others | Al |

|---|---|---|---|---|---|---|---|---|

| ≤0.07 | ≤0.25 | ≤0.05 | ≤0.40 | ≤0.05 | ≤0.05 | ≤0.05 | ≤0.03 | ≥99.50 |

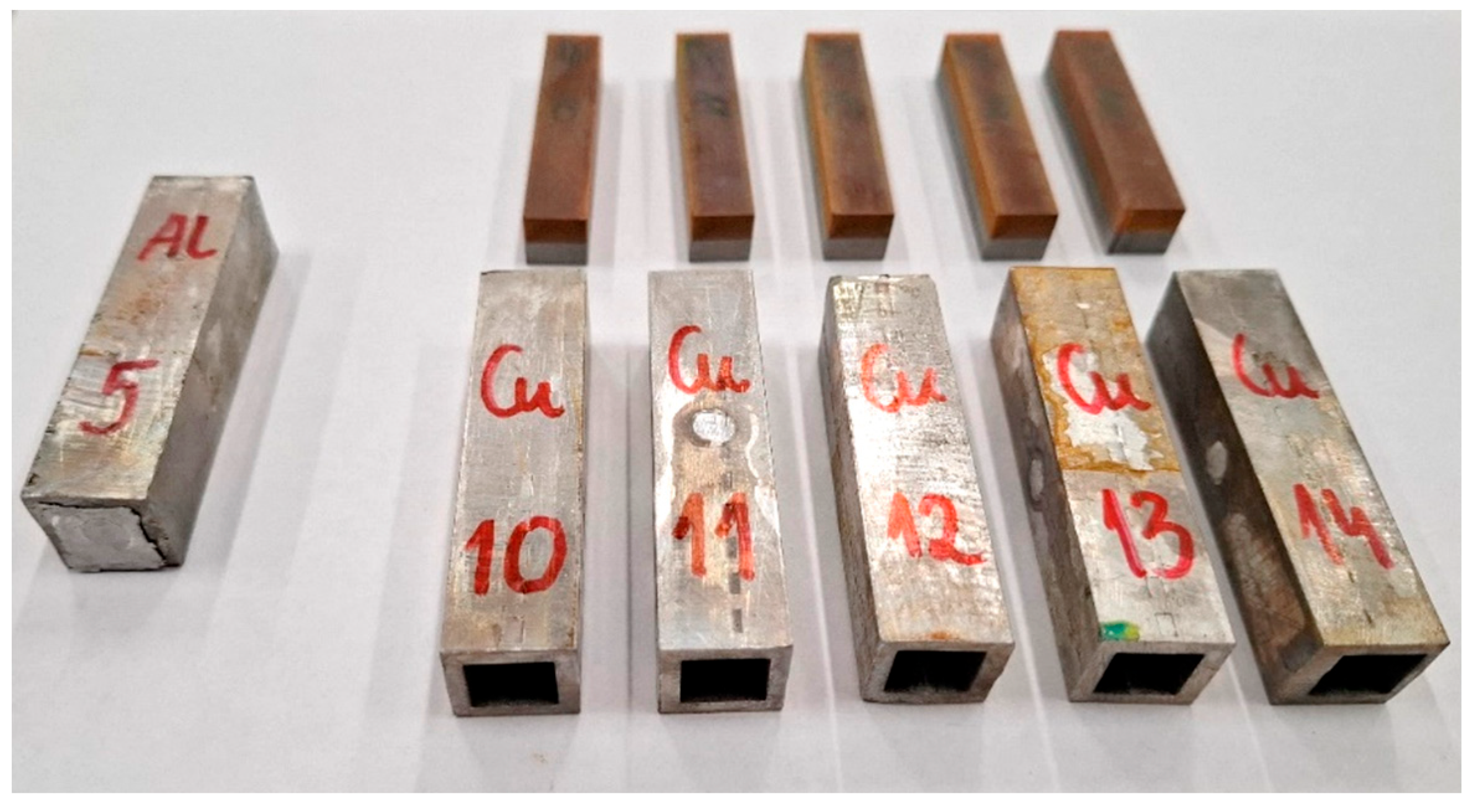

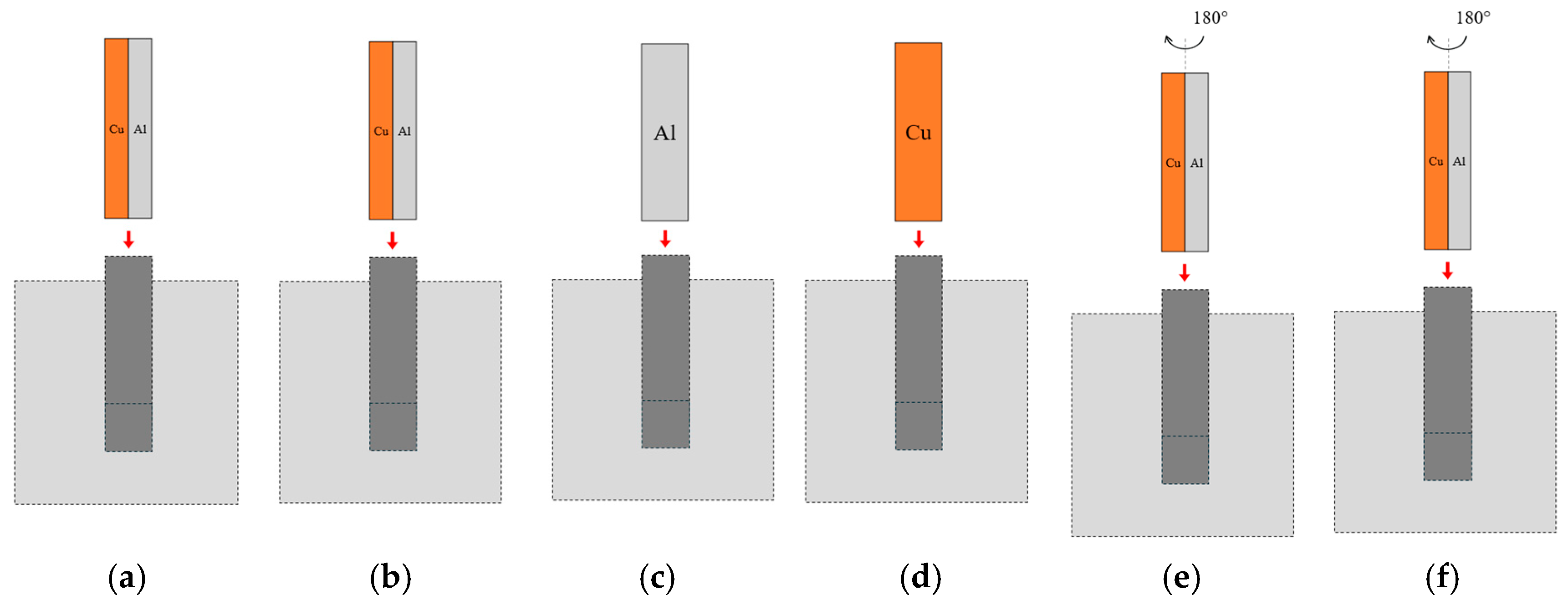

| Sample Denotation | Sample Type | Number of Passes | Sample Orientation at the Entrance to the Die Channel in the First Pass | Processing Method |

|---|---|---|---|---|

| ECAP5 | transverse | 1 | Al/Cu plate | no sample rotation |

| ECAP10 | longitudinal | 1 | Al/Cu plate | no sample rotation |

| ECAP11 | longitudinal | 1 | Al | no sample rotation |

| ECAP12 | longitudinal | 1 | Cu | no sample rotation |

| ECAP13 | longitudinal | 2 | Al/Cu plate | 180° rotation between successive passes |

| ECAP14 | longitudinal | 3 | Al/Cu plate | 180° rotation between successive passes |

| Section Orientation | Measurement Number | Average Hardness HV0.5 | Standard Deviation HV0.5 | ||||

|---|---|---|---|---|---|---|---|

| Cu | Al | Al/Cu Interfacial Transition Layer | Cu | Al | Al/Cu Interfacial Transition Layer | ||

| longitudinal | L1 | 102.8 | 32.6 | 53.8 | 6.7 | 6.1 | 12.0 |

| L2 | 97.9 | 32.9 | 49.0 | 6.9 | 5.1 | 13.9 | |

| L3 | 101.1 | 33.5 | 65.6 | 7.2 | 5.6 | 9.0 | |

| average | 100.6 | 33.0 | 56.1 | 6.9 | 5.6 | 11.7 | |

| transverse | T1 | 98.6 | 32.4 | 65.7 | 5.4 | 5.6 | 14.9 |

| T2 | 98.1 | 32.5 | 53.3 | 6.8 | 5.6 | 12.4 | |

| T3 | 99.8 | 32.3 | 54.4 | 6.2 | 5.2 | 3.3 | |

| average | 98.8 | 32.4 | 57.8 | 6.1 | 5.5 | 10.2 | |

| Parameter | Sample | Average Value | Standard Deviation | ||

| P1 | P2 | P3 | |||

| Rp0.2, MPa | 90.5 | 73.7 | 73.2 | 59.4 | 9.8 |

| Rm, MPa | 92.8 | 74.7 | 73.5 | 80.3 | 10.8 |

| A, % | 15.4 | 14.3 | 14.4 | 14.7 | 0.6 |

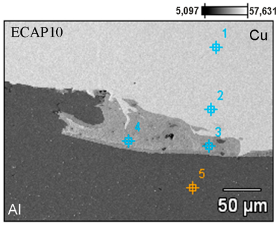

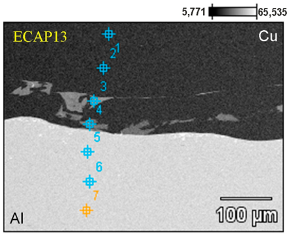

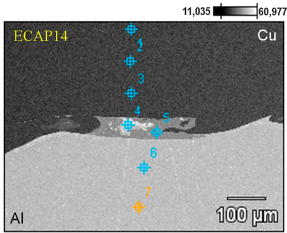

| Sample | Point | Wt.% | At.% | Al-Cu Phase | ||

| Al-K | Cu-K | Al-K | Cu-K | |||

| 1 | 0.30 | 99.70 | 0.70 | 99.30 | Cu |

| 2 | 0.11 | 99.89 | 0.25 | 99.75 | Cu | |

| 3 | 45.34 | 54.66 | 66.14 | 33.86 | Al2Cu | |

| 4 | 39.68 | 60.32 | 60.77 | 39.23 | Al2Cu | |

| 5 | 98.90 | 1.10 | 99.53 | 0.47 | Al | |

| 1 | 0.63 | 99.37 | 1.47 | 98.53 | Cu |

| 2 | 0.53 | 99.47 | 1.24 | 98.76 | Cu | |

| 3 | 49.81 | 50.19 | 70.03 | 29.97 | Al/Al2Cu | |

| 4 | 40.58 | 59.42 | 61.67 | 38.33 | AlCu or Al2Cu | |

| 5 | 98.48 | 1.52 | 99.35 | 0.65 | Al | |

| 6 | 98.05 | 1.95 | 99.16 | 0.84 | Al | |

| 7 | 98.81 | 1.19 | 99.49 | 0.51 | Al | |

| 1 | 0.25 | 99.75 | 0.59 | 99.41 | Cu |

| 2 | 0.55 | 99.45 | 1.28 | 98.72 | Cu | |

| 3 | 0.25 | 99.75 | 0.58 | 99.42 | Cu | |

| 4 | 97.84 | 2.16 | 99.07 | 0.93 | Al | |

| 5 | 59.10 | 40.90 | 77.29 | 22.71 | Al/Al2Cu | |

| 6 | 98.98 | 1.02 | 99.57 | 0.43 | Al | |

| 7 | 98.84 | 1.16 | 99.50 | 0.50 | Al | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Żaba, K.; Ortyl, K.; Hilšer, O.; Pastrnak, M.; Kuczek, Ł.; Różycka, I.; Pałka, P.; Gałka, A.; Trzepieciński, T. Effects of Equal Channel Angular Pressing on the Microstructure and Mechanical Properties of Explosion-Welded Al-Cu Bimetallic Plates. Materials 2025, 18, 5080. https://doi.org/10.3390/ma18225080

Żaba K, Ortyl K, Hilšer O, Pastrnak M, Kuczek Ł, Różycka I, Pałka P, Gałka A, Trzepieciński T. Effects of Equal Channel Angular Pressing on the Microstructure and Mechanical Properties of Explosion-Welded Al-Cu Bimetallic Plates. Materials. 2025; 18(22):5080. https://doi.org/10.3390/ma18225080

Chicago/Turabian StyleŻaba, Krzysztof, Kinga Ortyl, Ondřej Hilšer, Martin Pastrnak, Łukasz Kuczek, Ilona Różycka, Paweł Pałka, Aleksander Gałka, and Tomasz Trzepieciński. 2025. "Effects of Equal Channel Angular Pressing on the Microstructure and Mechanical Properties of Explosion-Welded Al-Cu Bimetallic Plates" Materials 18, no. 22: 5080. https://doi.org/10.3390/ma18225080

APA StyleŻaba, K., Ortyl, K., Hilšer, O., Pastrnak, M., Kuczek, Ł., Różycka, I., Pałka, P., Gałka, A., & Trzepieciński, T. (2025). Effects of Equal Channel Angular Pressing on the Microstructure and Mechanical Properties of Explosion-Welded Al-Cu Bimetallic Plates. Materials, 18(22), 5080. https://doi.org/10.3390/ma18225080