Feasibility of Employing Semi-Hard Magnetic Materials for Hysteresis Magnetic Clutches in Railway Systems

Abstract

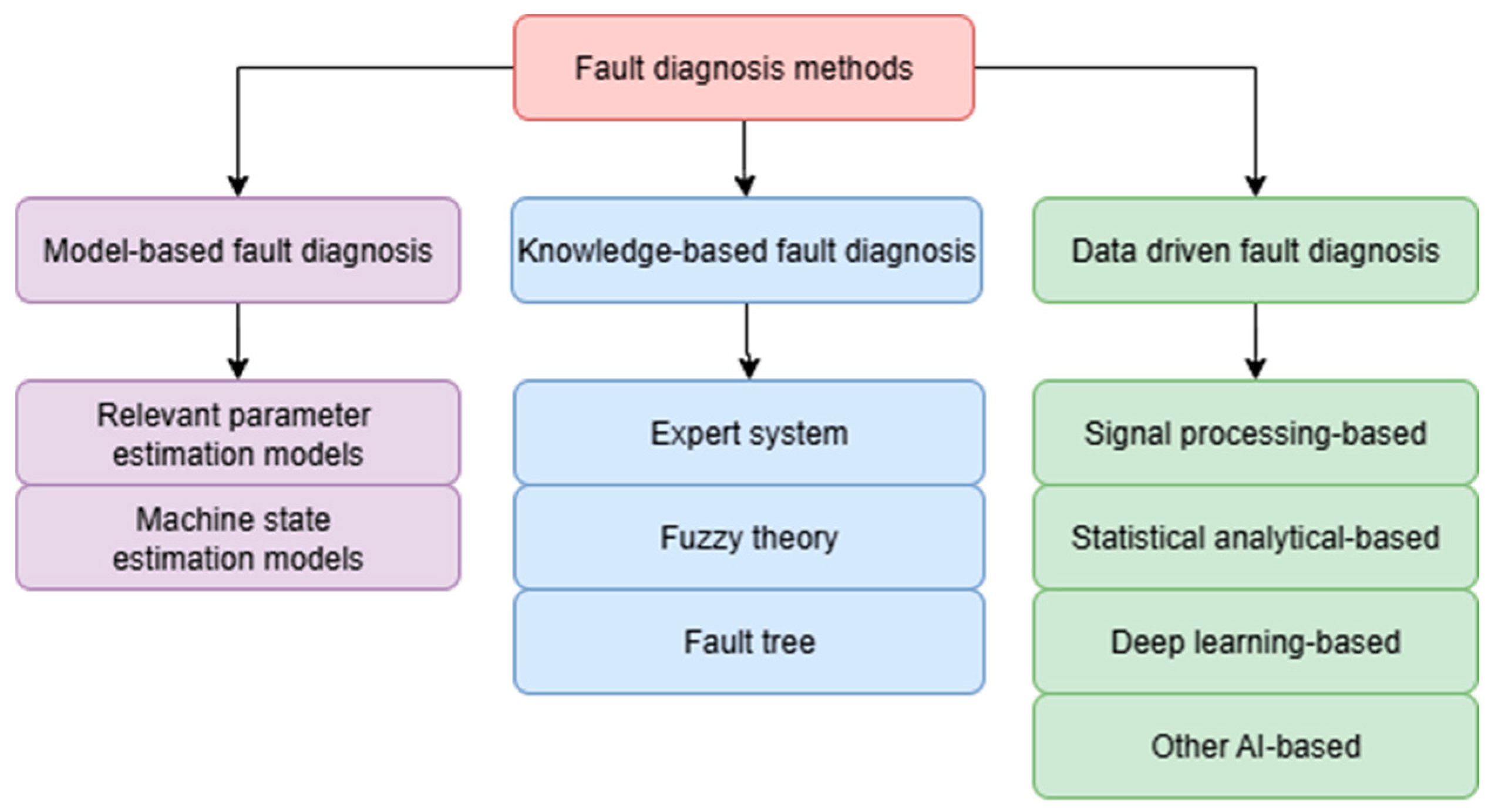

1. Introduction

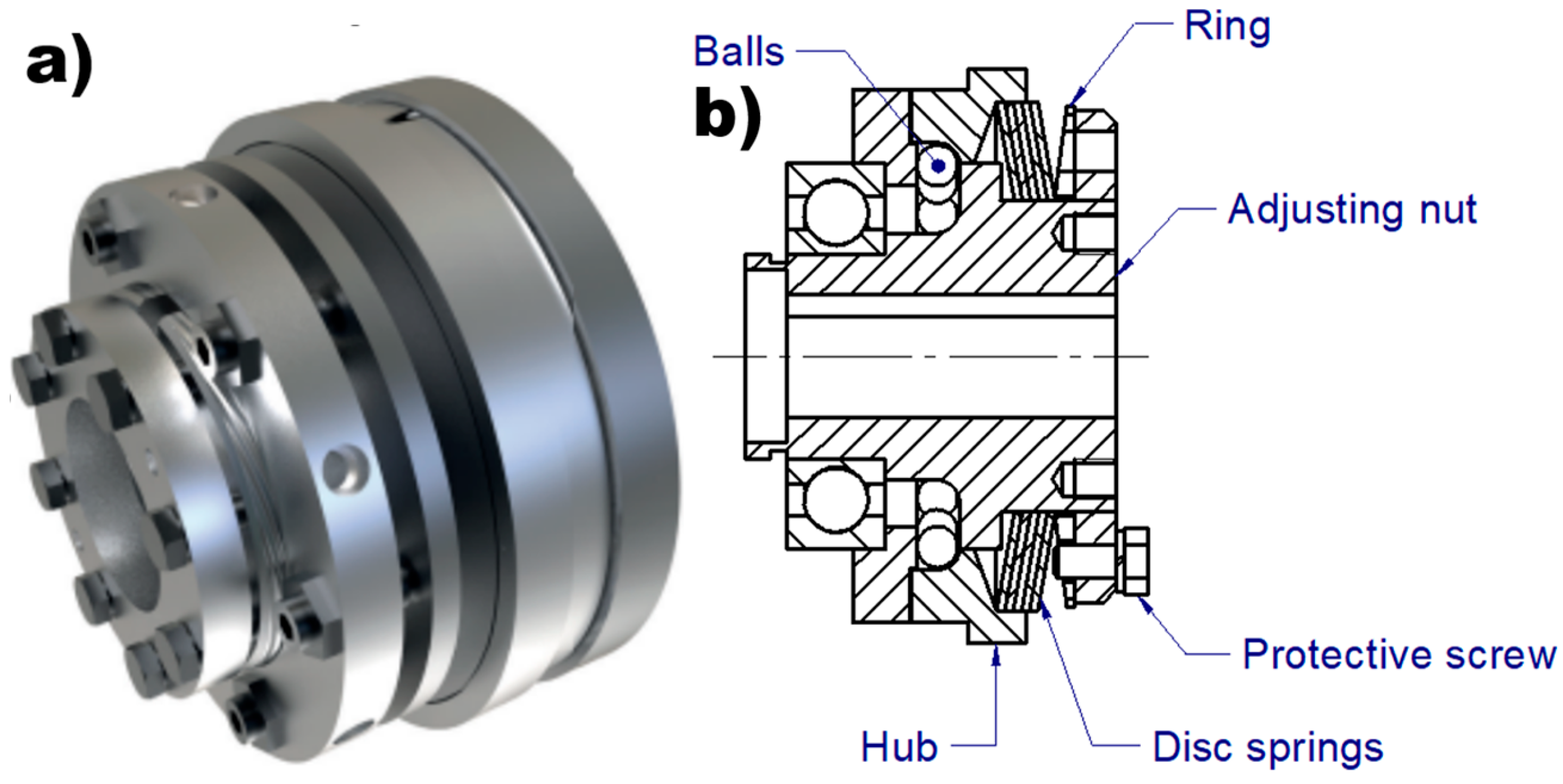

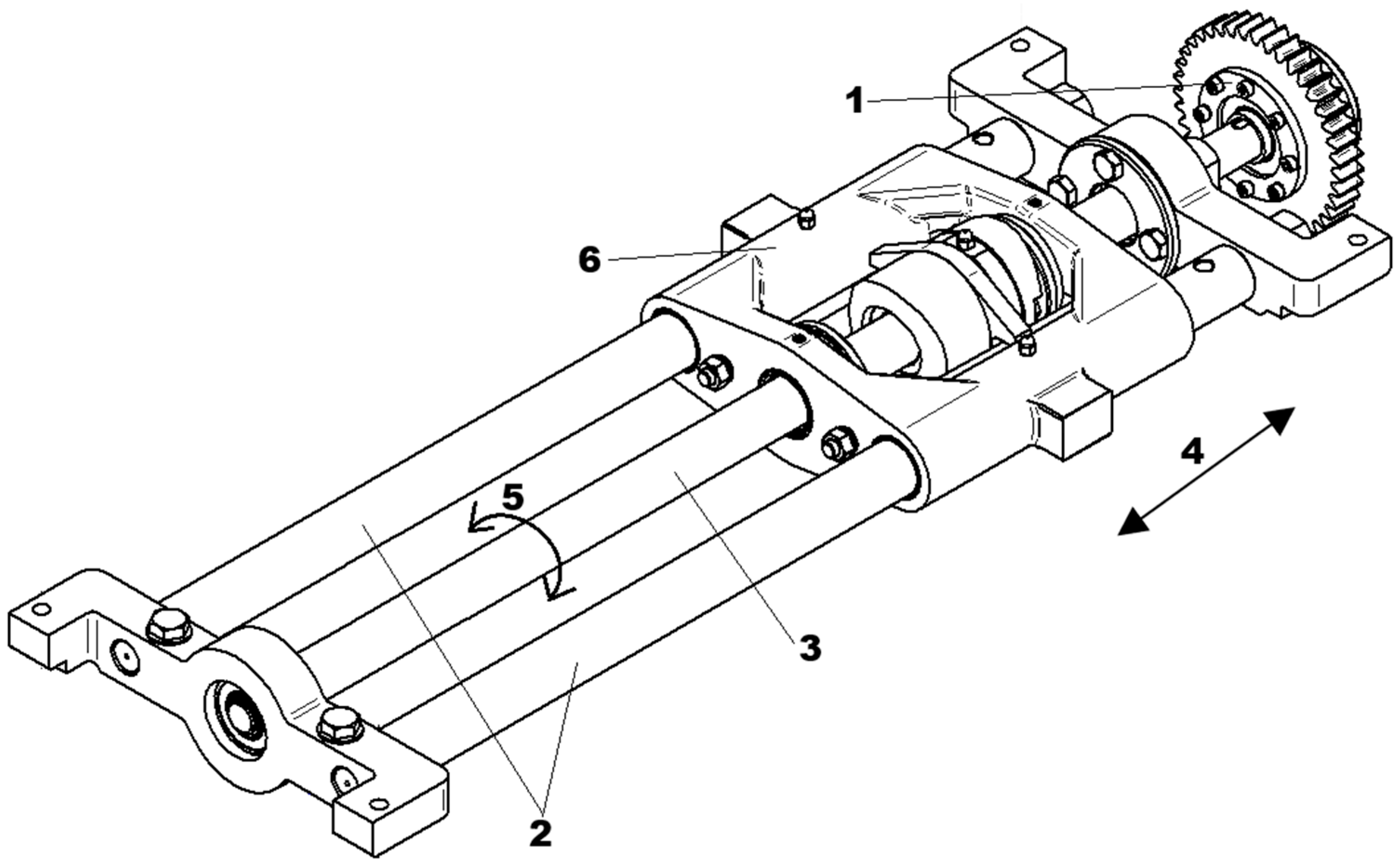

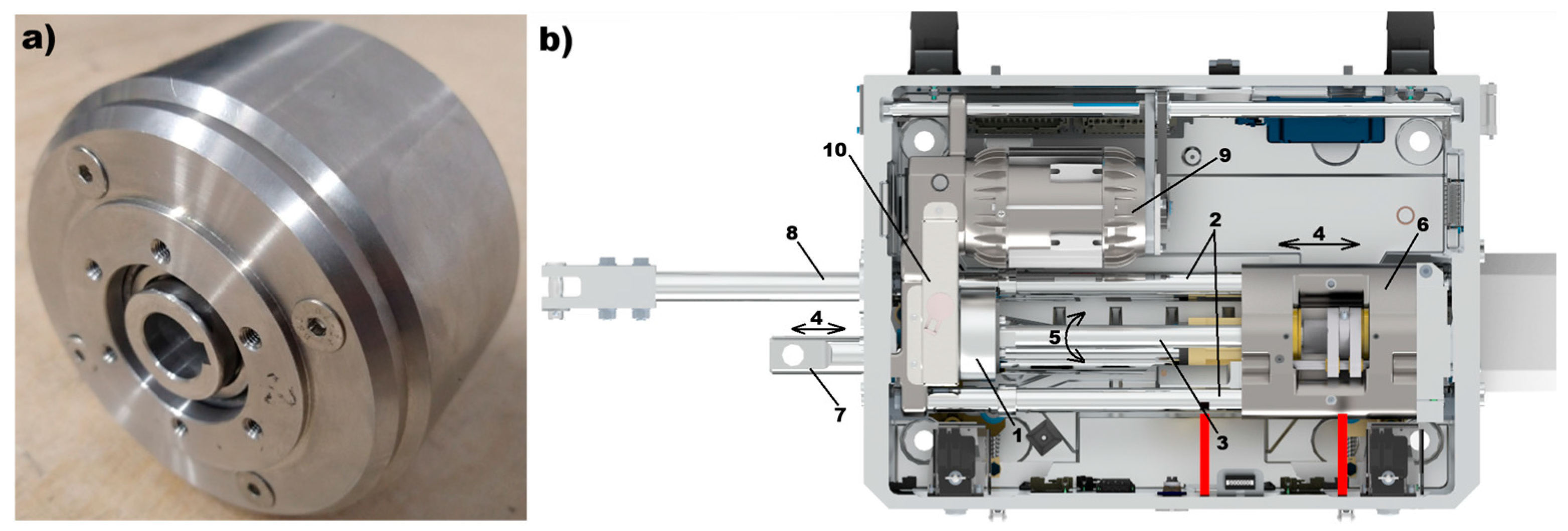

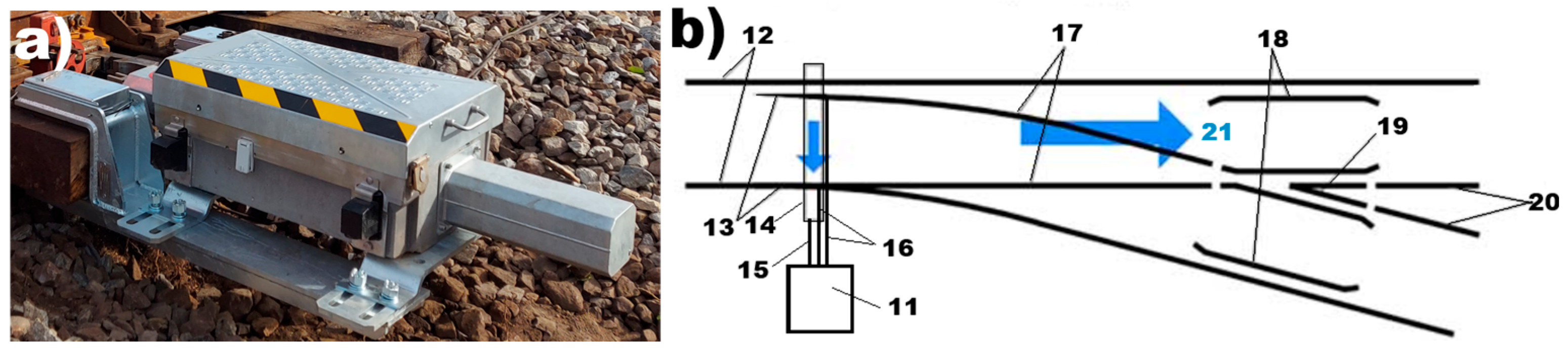

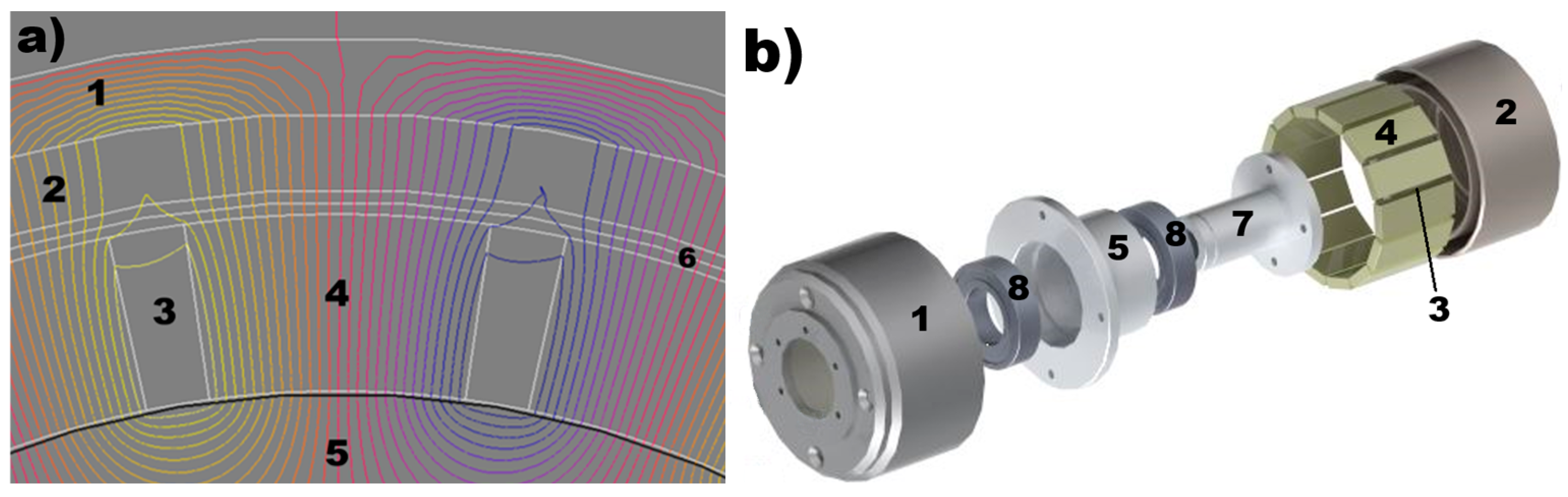

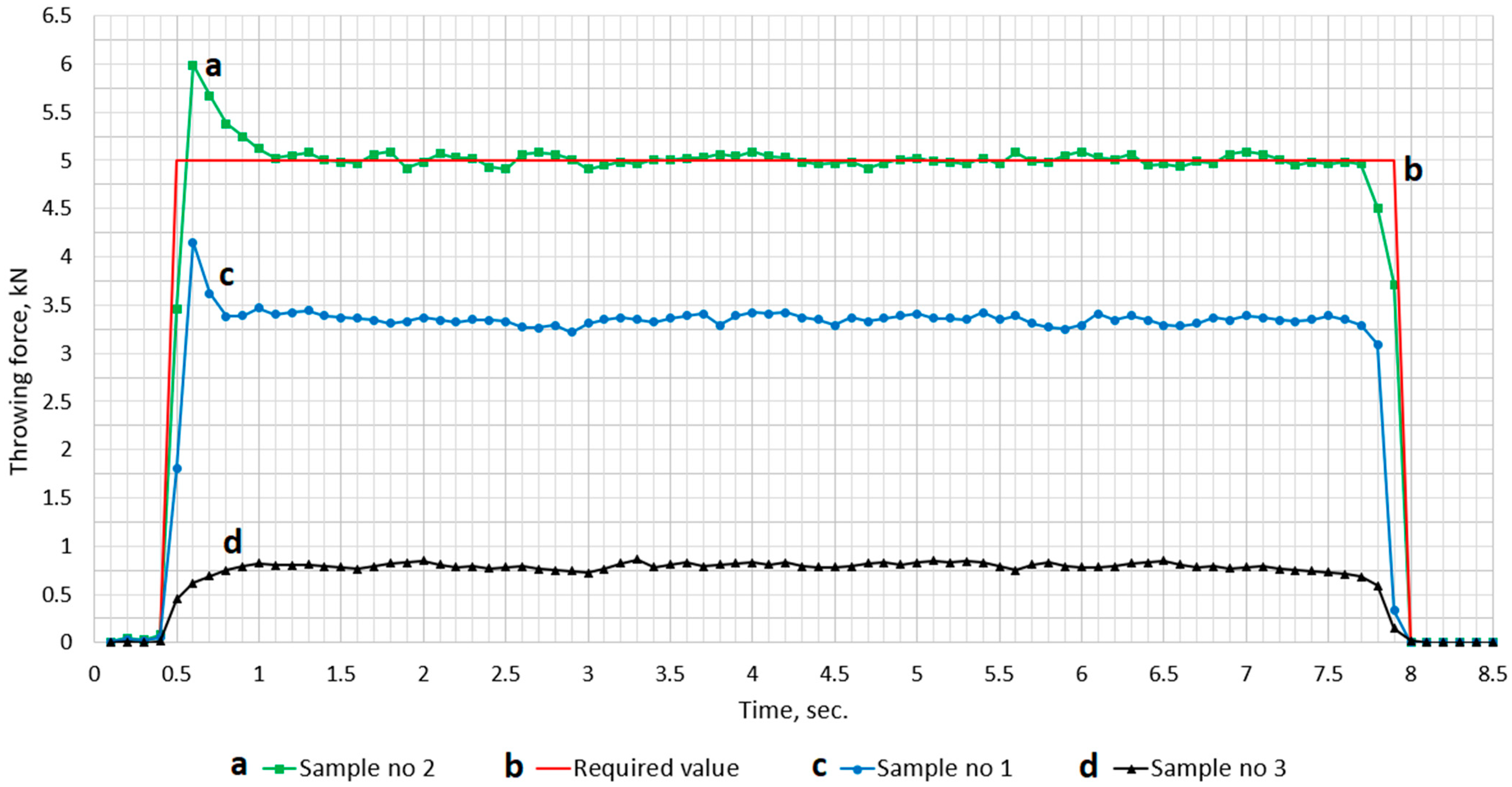

2. Operating Characteristics of Magnetic Clutch Intended for Railway Point Machine

3. Characteristics of Magnetic AlNiCoFe-Based Alloys

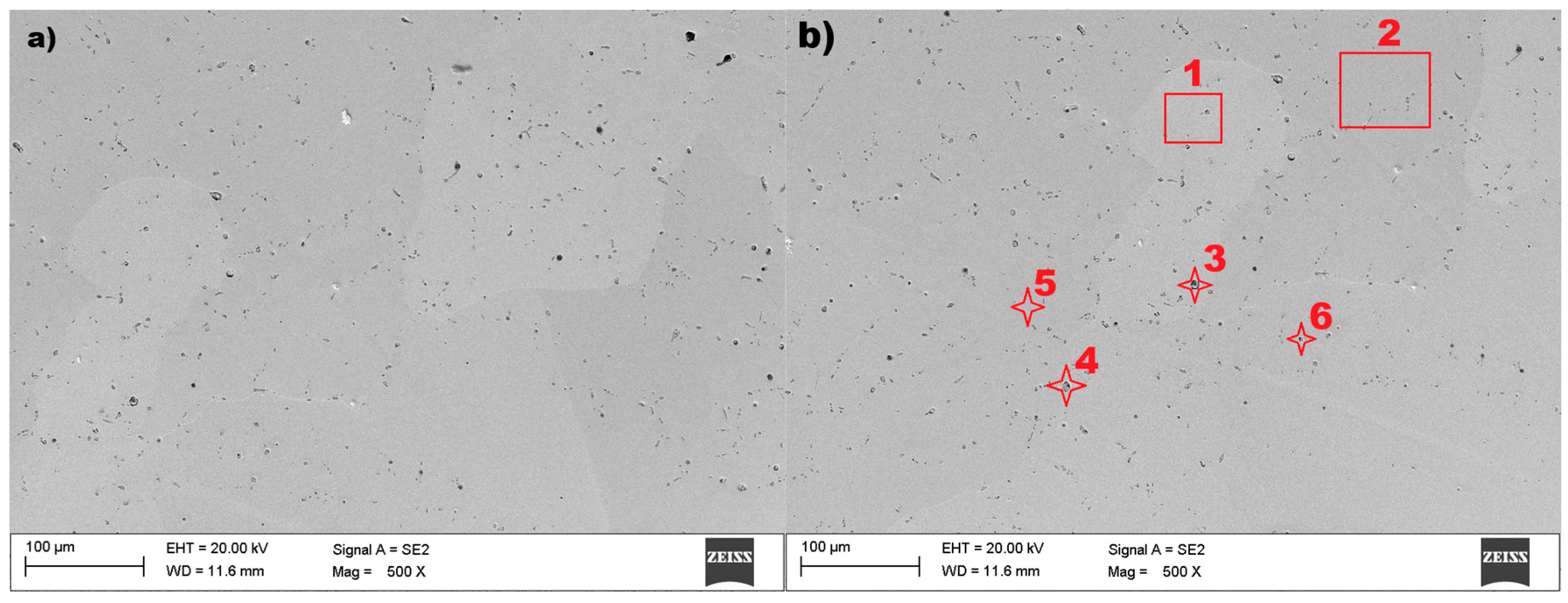

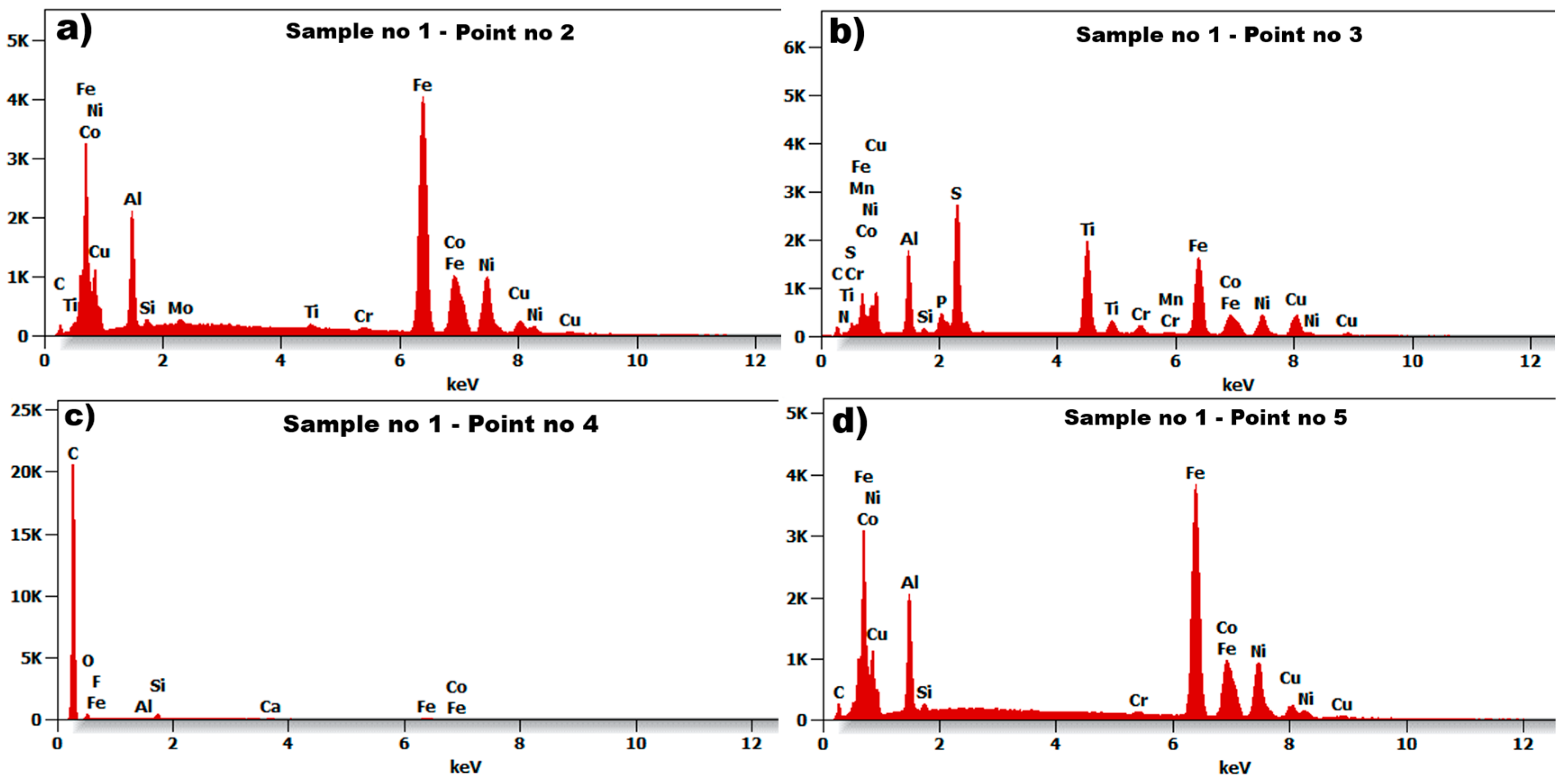

4. Microstructures and Diffractograms

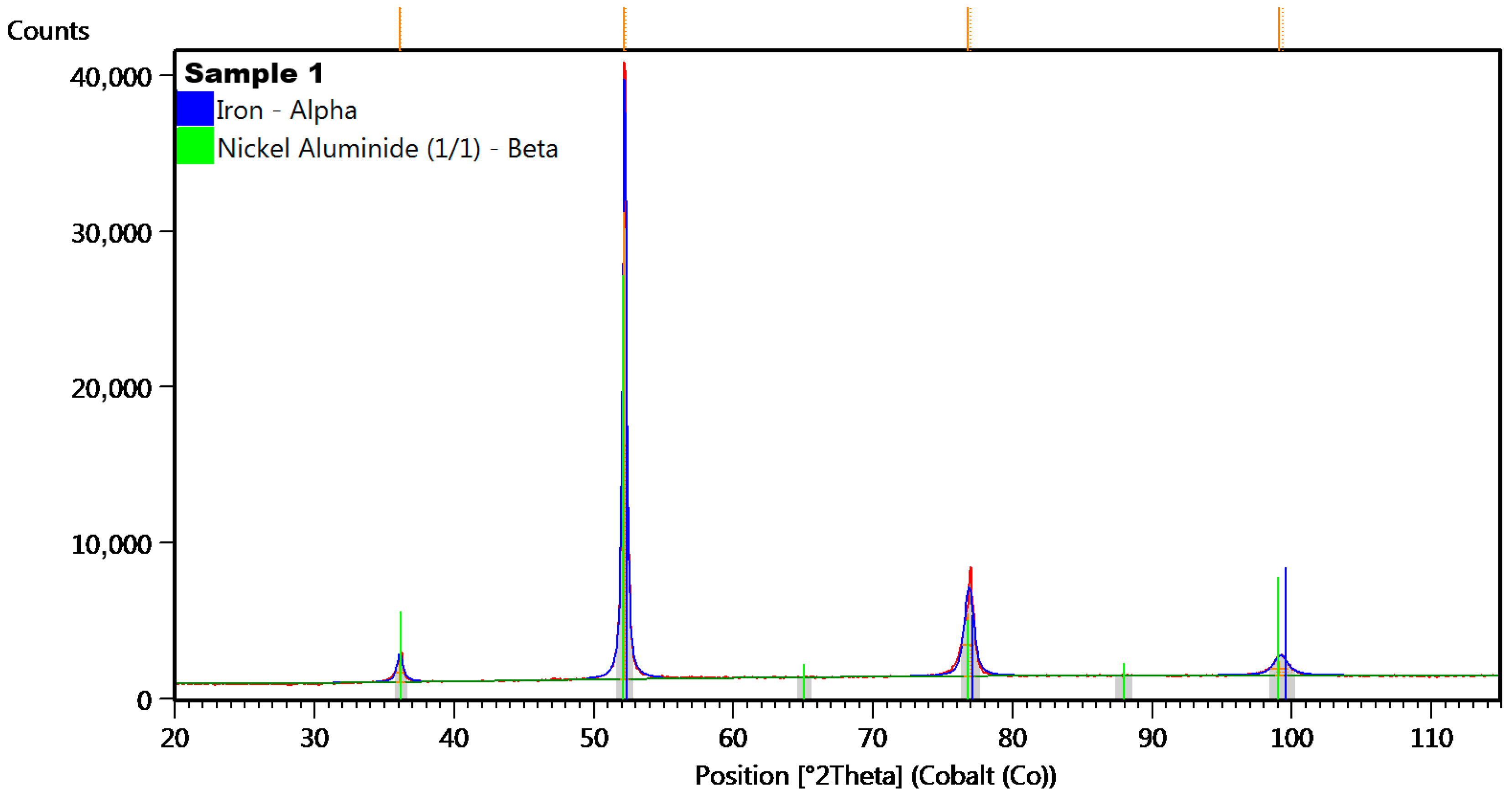

4.1. Sample No 1

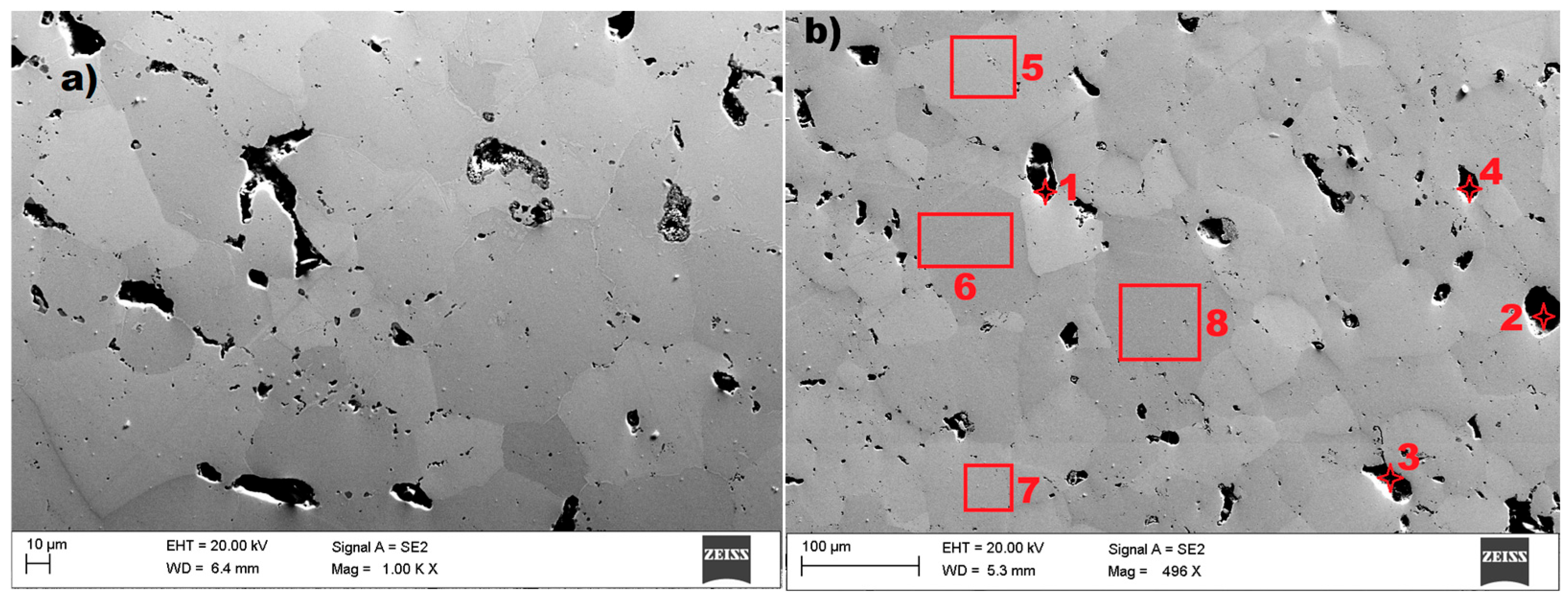

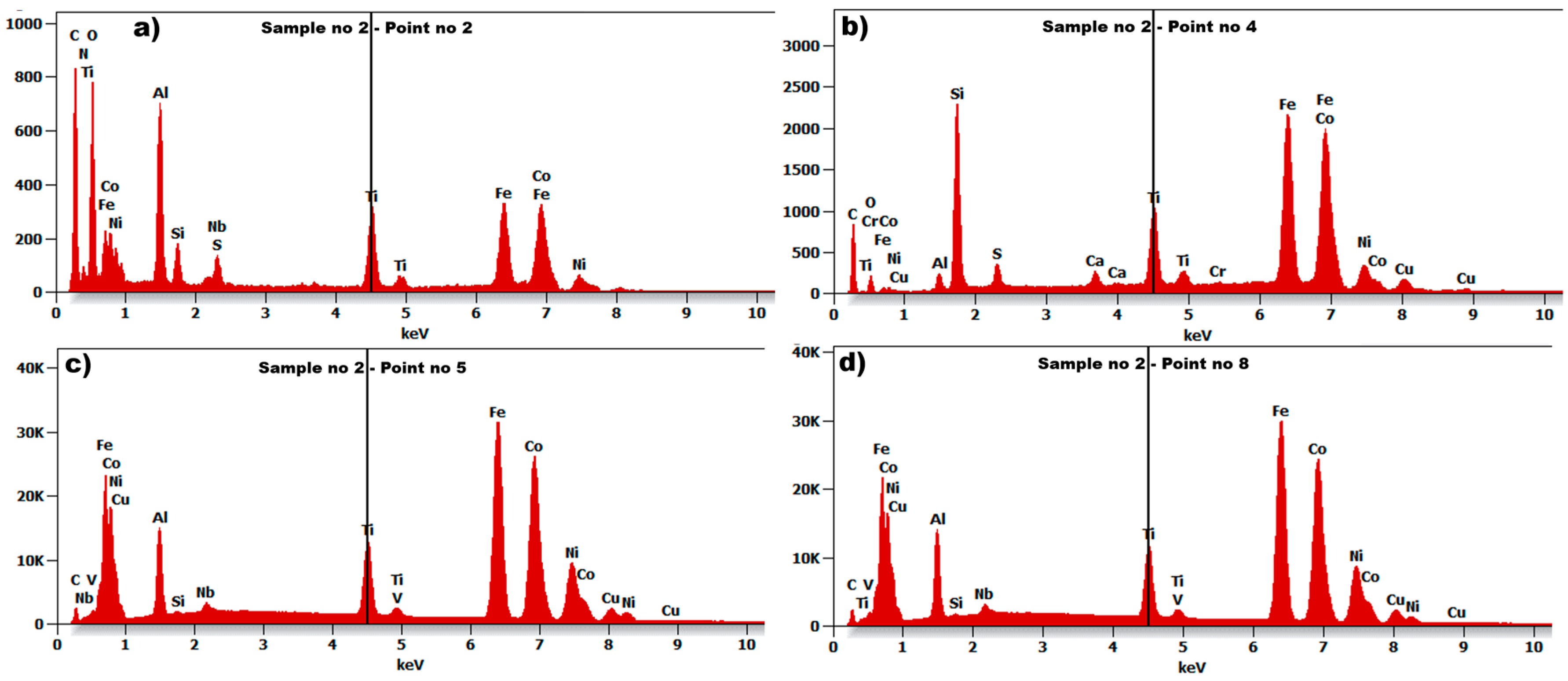

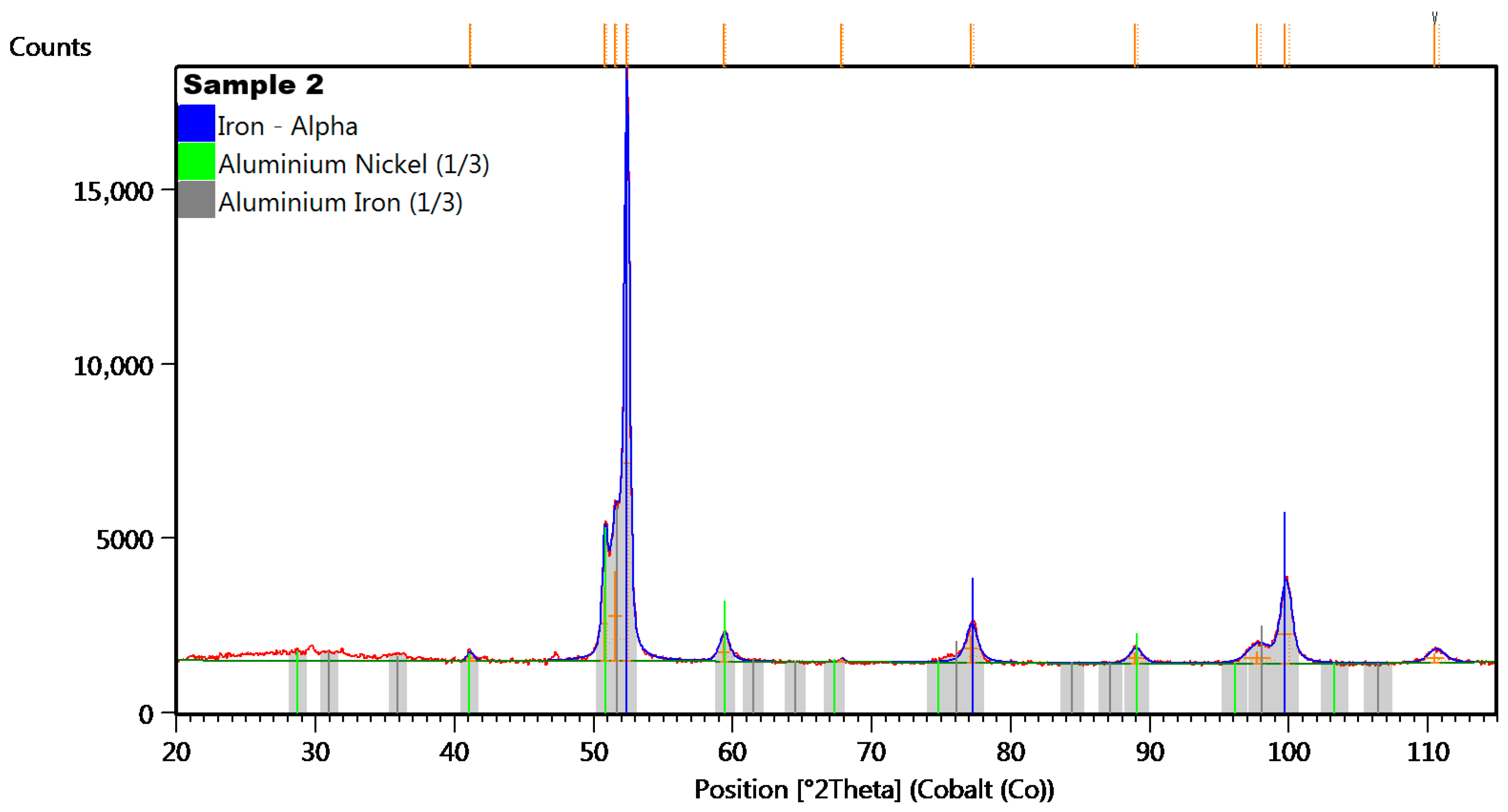

4.2. Sample No 2

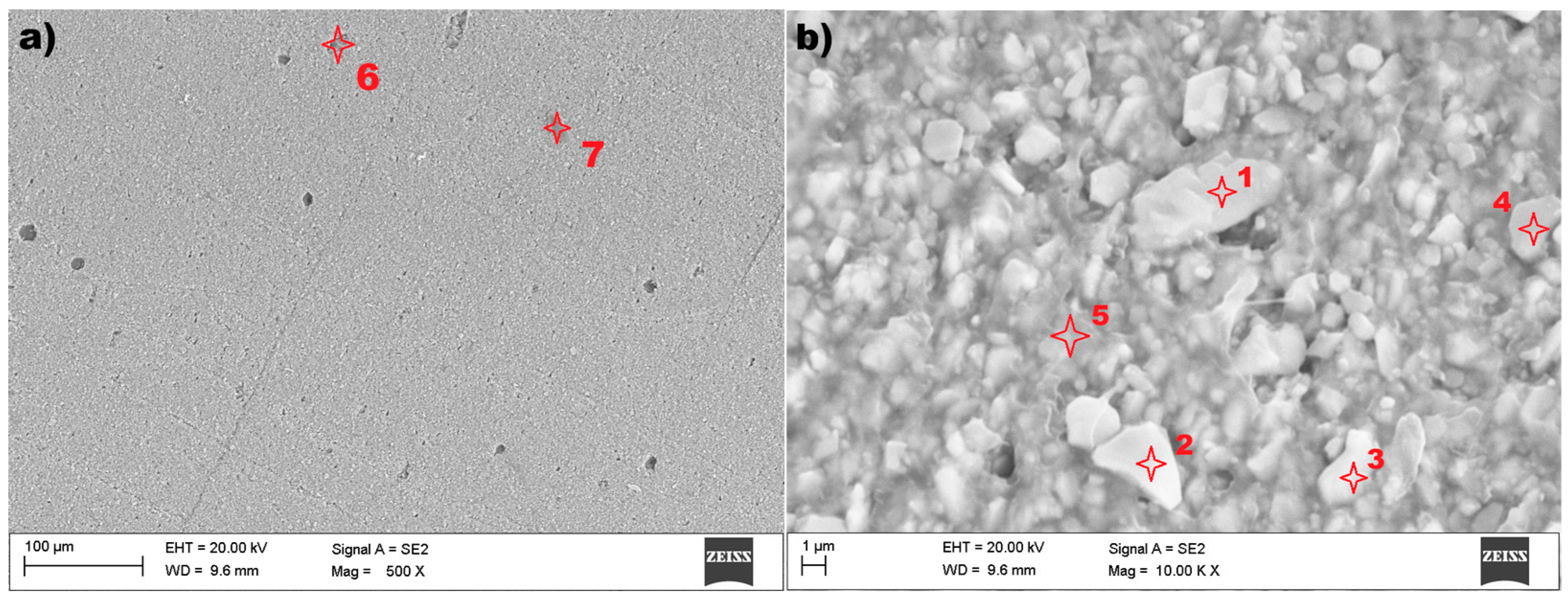

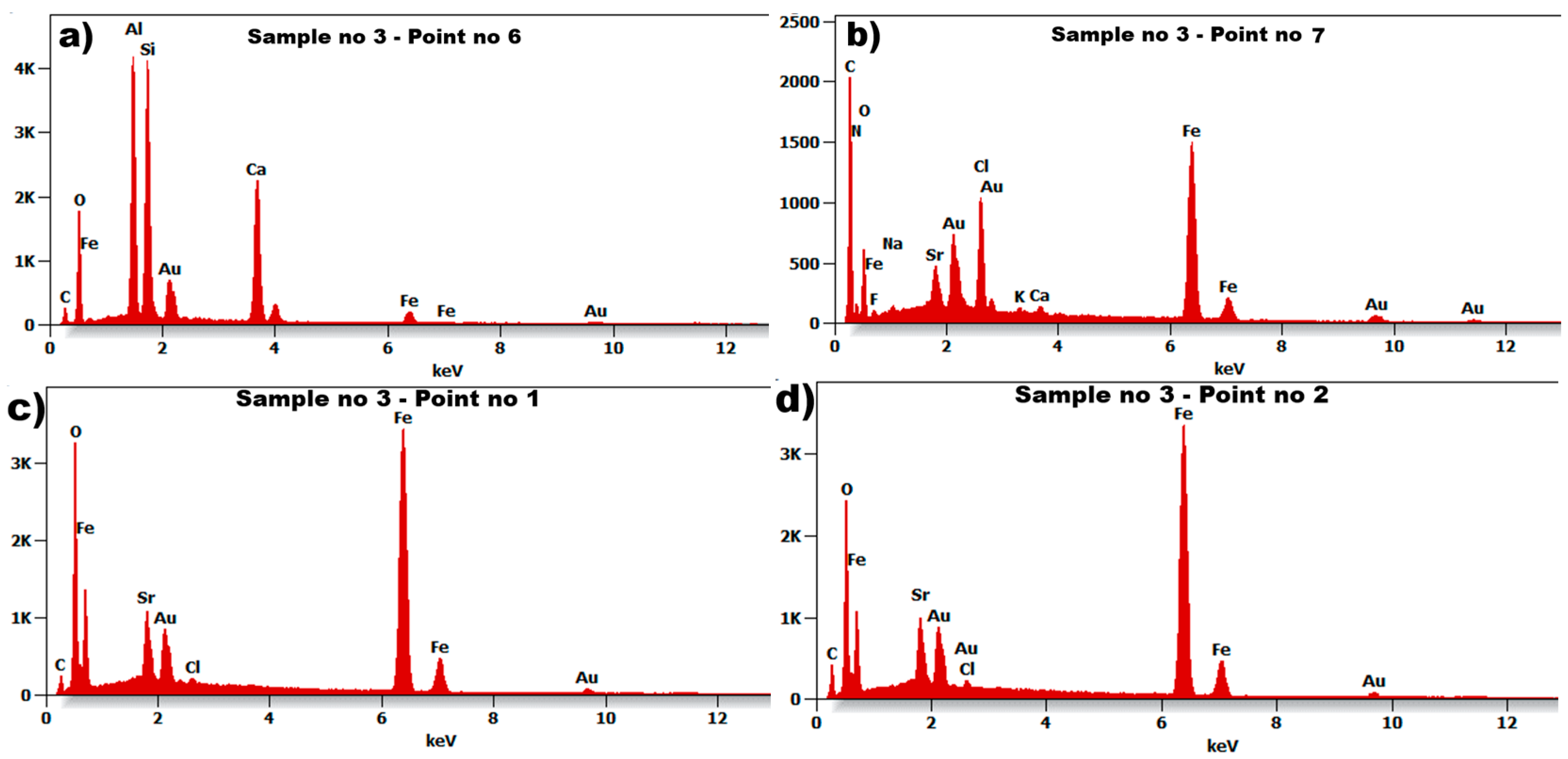

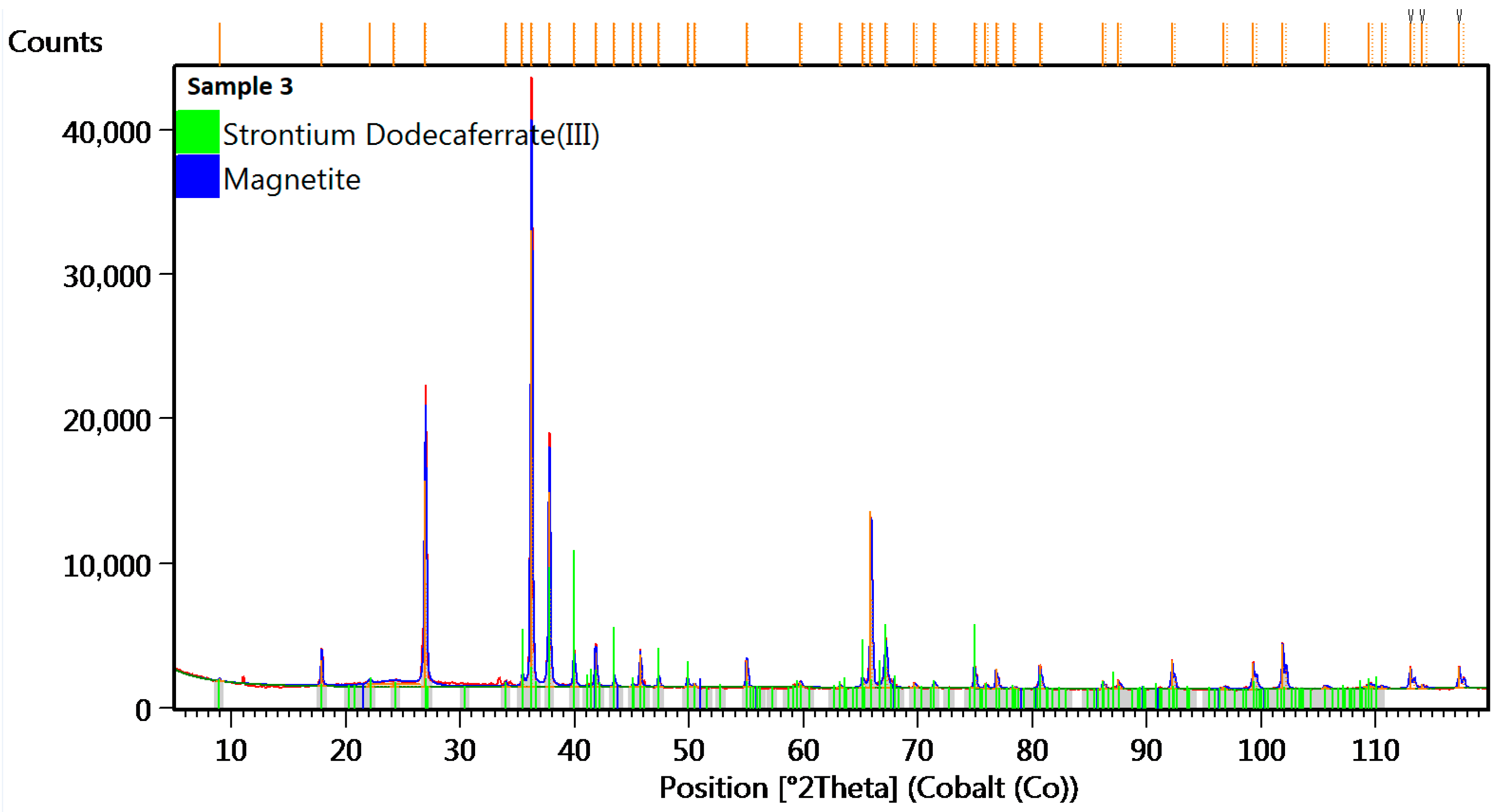

4.3. Sample No 3

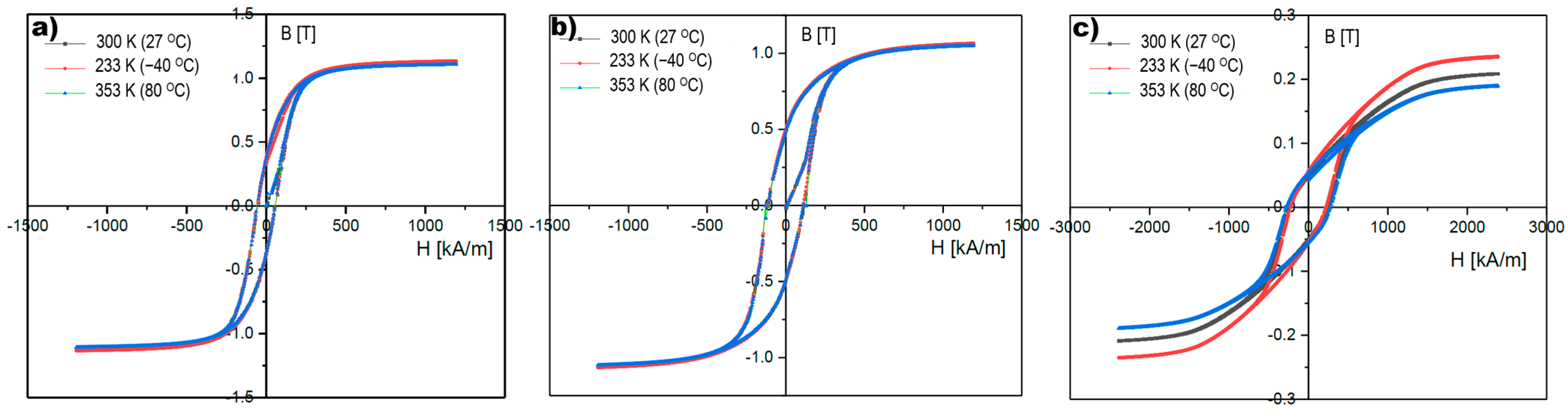

5. Hysteresis Loops

6. Discussion—Results Validation

7. Summary and Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| EDS | Energy Dispersive Spectroscopy |

| SEM | Scanning Electron Microscopy |

| XRD | X-Ray Diffraction |

| RPM | Railway Point Machine |

| VSM | Vibrating Sample Magnetometer method. |

| EMF | Electromotive Force |

| AlNiCoFe | Alloy with elements Al, Ni, Co, Fe |

References

- Fan, M.; Liu, Y.; Jha, R.; Dulikravich, G.S.; Schwartz, J.; Koch, C. On the evolution of Cu-Ni-rich bridges of Alnico alloys with tempering. J. Magn. Magn. Mater. 2016, 420, 296–302. [Google Scholar] [CrossRef]

- Rehman, S.U.; Jiang, Q.; He, L.; Ghazanfar, M.; Lei, W.; Hu, X.; Awan, S.U.; Ma, S.; Zhong, Z. Synthesis, microstructures, magnetic properties and thermal stabilities of isotropic alnico ribbons. J. Magn. Magn. Mater. 2018, 466, 277–282. [Google Scholar] [CrossRef]

- Zhou, L. Architecture and magnetism of AlNiCo. Acta Mater. 2014, 74, 224–233. [Google Scholar] [CrossRef]

- Lan, H.; Liu, Y.; Zhao, J.; Liu, L.; Yu, X.; Hu, T.; Sun, Y.; Ding, Y.; Yan, A. AlNiCo Magnet with NdFeB-Nanocrystalline Phase Prepared by Spark Plasma Sintering. Materials 2025, 18, 1847. [Google Scholar] [CrossRef] [PubMed]

- Feng, T.; Chen, W.; Qiu, J.; Hao, S. A New Kind of Absolute Magnetic Encoder. Sensors 2021, 21, 3095. [Google Scholar] [CrossRef]

- Wu, J.; Kong, W.; Liu, Y. Structural development of magnetorheological fluid brakes/clutches as typical transmission devices: A review. J. Magn. Magn. Mater. 2025, 614, 172697. [Google Scholar] [CrossRef]

- Cao, Z.; Yang, X.; Zhu, X.; Xia, Y. Optimal design and experimental study of comb-type disc magnetorheological brake. Measurement 2024, 229, 114458. [Google Scholar] [CrossRef]

- Hu, G. Spatially varying sparsity in dynamic regression models. Econom. Stat. 2021, 17, 23–34. [Google Scholar] [CrossRef]

- Singh, R.K.; Sarkar, C. Two-wheeler magnetorheological drum brake operating under hybrid mode for enhancing braking torque: Development and validation. Mechatronics 2023, 92, 102971. [Google Scholar] [CrossRef]

- Jeong, H.; Ji, H.; Choi, S.; Baek, J. Parametric Study of Eddy Current Brakes for Small-Scale Household Wind Turbine Systems. Energies 2021, 14, 6633. [Google Scholar] [CrossRef]

- Gulbahce, M.O. Neuromodel of an Eddy Current Brake for Load Emulation. Energies 2023, 16, 3649. [Google Scholar] [CrossRef]

- Gulbahce, M.O.; Nak, H.; Kocabas, D.A. Design of a mechanical load simulator having an excitation current controlled eddy current brake. In Proceedings of the 3rd International Conference on Electric Power and Energy Conversion Systems, Istanbul, Turkey, 2–4 October 2013; pp. 1–5. [Google Scholar]

- Gulbahce, M.O.; Kocabas, D.A.; Nayman, F. Investigation of the effect of pole shape on braking torque for a low power eddy current brake by finite elements method. In Proceedings of the 9th International Conference on Electrical and Electronics Engineering (ELECO), Bursa, Turkey, 26–28 November 2015; pp. 263–267. [Google Scholar]

- Xiang, C.; Chen, S.; Yao, M.; Gu, Y.; Yang, X. Optimization of Braking Force for Electromagnetic Track Brake Using Uniform Design. IEEE Access 2020, 8, 146065–146074. [Google Scholar] [CrossRef]

- Yang, Z.Q.; Kermani, M.R. A Computationally Efficient Hysteresis Model for Magneto-Rheological Clutches and Its Comparison with Other Models. Actuators 2023, 12, 190. [Google Scholar] [CrossRef]

- Gallicchio, G.; Palmieri, M.; Di Nardo, M.; Cupertino, F. Fast Torque Computation of Hysteresis Motors and Clutches Using Magneto-static Finite Element Simulation. Energies 2019, 12, 3311. [Google Scholar] [CrossRef]

- Feng, J.; Chen, S.; Qi, Z.; Zhong, J.; Liu, Z. Electromagnetic Hysteresis Based Dynamics Model of an Electromagnetically Controlled Torque Coupling. Processes 2019, 7, 557. [Google Scholar] [CrossRef]

- Sugiana, A.; Cahyadi, W.A.; Yusran, Y. Current-Signal-Based Fault Diagnosis of Railway Point Machines Using Machine Learning. Appl. Sci. 2024, 14, 267. [Google Scholar] [CrossRef]

- Zhang, S.; Dong, H.; Maschek, U.; Song, H. A digital-twin-assisted fault diagnosis of railway point machine. In Proceedings of the 2021 IEEE 1st International Conference on Digital Twins and Parallel Intelligence (DTPI), Beijing, China, 15 July–15 August 2021. [Google Scholar]

- Cao, Y.; Sun, Y.; Li, P.; Su, S. Vibration-Based Fault Diagnosis for Railway Point Machines Using Multi-Domain Features, Ensemble Feature Selection and SVM. IEEE Trans. Veh. Technol. 2024, 73, 176–184. [Google Scholar] [CrossRef]

- Cao, Y.; Sun, Y.; Xie, G.; Li, P. A Sound-Based Fault Diagnosis Method for Railway Point Machines Based on Two-Stage Feature Selection Strategy and Ensemble Classifier. IEEE Trans. Intell. Transp. Syst. 2022, 23, 12074–12083. [Google Scholar] [CrossRef]

- Wang, Y.; Miao, B.; Zhang, Y.; Huang, Z.; Xu, S. Review on Rail Damage Detection Technologies for High-Speed Trains. Appl. Sci. 2025, 15, 7725. [Google Scholar] [CrossRef]

- Garramiola, E.; Poza, J.; Madina, P.; del Olmo, J.; Almandoz, G.A. Review in Fault Diagnosis and Health Assessment for Railway Traction Drives. Appl. Sci. 2018, 8, 2475. [Google Scholar] [CrossRef]

- Hu, X.; Tang, T.; Tan, L.; Zhang, H. Fault Detection for Point Machines: A Review, Challenges, and Perspectives. Actuators 2023, 12, 391. [Google Scholar] [CrossRef]

- Sun, Y.; Cao, Y.; Liu, H.; Yang, W.; Su, S. Condition Monitoring and Fault Diagnosis Strategy of Railway Point Machines Using Vibration Signals. Transp. Saf. Environ. 2023, 5, tdac048. [Google Scholar] [CrossRef]

- Cao, Y.; Ji, Y.; Sun, Y.; Su, S. The Fault Diagnosis of a Switch Machine Based on Deep Random Forest Fusion. IEEE Intell. Transp. Syst. Mag. 2023, 15, 437–452. [Google Scholar] [CrossRef]

- Sun, Y.; Cao, Y.; Xie, G.; Wen, T. Condition Monitoring for Railway Point Machines Based on Sound Analysis and Support Vector Machine. Chin. J. Electron. 2020, 29, 786–792. [Google Scholar] [CrossRef]

- Lee, J.; Choi, H.; Park, D.; Chung, Y.; Kim, H.-Y.; Yoon, S. Fault Detection and Diagnosis of Railway Point Machines by Sound Analysis. Sensors 2016, 16, 549. [Google Scholar] [CrossRef]

- Yoon, S.; Sa, J.; Chung, Y.; Park, D.; Kim, H. Fault Diagnosis of Railway Point Machines Using Dynamic Time Warping. Electron. Lett. 2016, 52, 818–819. [Google Scholar] [CrossRef]

- Mo, X.M.; Fang, Y.; Yang, Y.G. Method on the Fault Detection and Diagnosis for the Railway Turnout Based on the Current Curve of Switch Machine. Appl. Mech. Mater. 2013, 427–429, 1022–1027. [Google Scholar] [CrossRef]

- Atamuradov, V.; Camci, F.; Baskan, S.; Şevkli, M. Failure Diagnostics for Railway Point Machines Using Expert Systems. In Proceedings of the IEEE International Symposium on Diagnostics for Electric Machines, Power Electronics and Drives (SDEMPED), Cargese, France, 31 August–3 September 2009. [Google Scholar]

- Zhang, Q.; Su, N.; Qin, B.; Sun, G.; Jing, X.; Hu, S.; Cai, Y.; Zhou, L. Fault Diagnosis for Rotating Machinery Based on Dimensionless Indices: Current Status, Development, Technologies, and Future Directions. Electronics 2024, 13, 4931. [Google Scholar] [CrossRef]

- Sa, J.; Choi, Y.; Chung, Y.; Kim, H.Y.; Park, D.; Yoon, S. Replacement Condition Detection of Railway Point Machines Using an Electric Current Sensor. Sensors 2017, 17, 263. [Google Scholar] [CrossRef] [PubMed]

- Eker, O.; Camci, F.; Kumar, U. SVM-Based Diagnostics on Railway Turnouts. Int. J. Perform. Eng. 2012, 8, 289–298. [Google Scholar]

- Bolbolamiri, N.; Sanai, M.; Mirabadi, A. Time-Domain Stator Current Condition Monitoring: Analyzing Point Failures Detection by Kolmogorov-Smirnov (K-S) Test. Int. J. Electr. Comput. Energetic Electron. Commun. Eng. 2012, 6, 587–592. [Google Scholar]

- Pourgol-Mohammad, M.; Hejazi, A.; Soleimani, M.; Ghasemi, P.; Ahmadi, A.; Jalali-Vahid, D. Design for Reliability of Automotive Systems; Case Study of Dry Friction Clutch. Int. J. Syst. Assur. Eng. Manag. 2017, 8, 572–583. [Google Scholar] [CrossRef]

- Liu, Y.G.; Qin, D.T.; Jiang, H.; Liu, C.; Zhang, Y. Clutch Torque Formulation and Calibration for Dry Dual Clutch Transmissions. Mech. Mach. Theory 2011, 46, 218–227. [Google Scholar] [CrossRef]

- Sun, Y. Clutch Structure Design and Automatic Control of Front and Rear Dual-Motor Driven Pure Electric Vehicles. IEEE Access 2025, 13, 99478. [Google Scholar] [CrossRef]

- MAYR Company. Dry Friction Clutches—Catalogue. Available online: https://www.mayr.com (accessed on 21 August 2025).

- AGICO GROUP. Railway Turnouts. Available online: http://www.railroadfastenings.com/blog/railway-turnout-types.html (accessed on 21 August 2025).

- Bańkowski, D.; Młynarczyk, P.; Spadło, S.; Sójka, R.; Klamczyński, K. Tomographic Testing of Alnico Alloys. In Proceedings of the 31st International Conference on Metallurgy and Materials, Brno, Czech Republic, 18–19 May 2022; Tanger Ltd.: Greensboro, NC, USA, 2022; pp. 675–681. [Google Scholar]

- Nieto, G.C.; Olvera, J.N.R.; Díaz de la Torre, S.; Febles, V.G.; Gómez, J.P.; Reyes, L.G.; Barriga Arceo, L.G.D. Microstructural and Morphological Properties of AlNiCo and CoNi Alloys: An In-Depth Study Based on Low-Energy Mechanical Alloying. Metals 2024, 14, 1307. [Google Scholar] [CrossRef]

- Dussa, S.; Joshi, S.S.; Sharma, S.; Krishna, K.V.M.; Radhakrishnan, M.; Dahotre, N.B. Additively Manufactured Alnico Permanent Magnet Materials—A Review. Magnetism 2024, 4, 125–156. [Google Scholar] [CrossRef]

- Liu, T.; Li, W.; Zhu, M.; Guo, Z.; Li, Y. Effect of Co on the Thermal Stability and Magnetic Properties of AlNiCo 8 Alloys. J. Appl. Phys. 2014, 115, 17A751. [Google Scholar] [CrossRef]

- Zhao, Z.; Zhao, J.; Wang, M.; Sun, Y.; Xia, W.; Chao, Z.; Li, S.; Chen, R.; Yan, A.; Jiang, L. Effect of Spinodal Decomposition Structure of AlNiCo Alloy on Magnetic Viscosity and Magnetization Reversal. J. Magn. Magn. Mater. 2023, 587, 171156. [Google Scholar] [CrossRef]

- Heidenreich, R.D.; Nesbitt, E.A. Physical Structure and Magnetic Anisotropy of Alnico 5. Part I. J. Appl. Phys. 1952, 23, 352–365. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, X.; Song, L.; Ran, L. Temperature Hysteresis Mechanism and Compensation of Quartz Flexible Accelerometer in Aerial Inertial Navigation System. Sensors 2021, 21, 294. [Google Scholar] [CrossRef]

- Liu, Y.; Zhao, J.; Zhao, Z.; Liu, L.; Huang, M.; Zhou, B.; Ding, Y.; Sun, Y.; Yan, A. Microstructure and Magnetic Properties of Dy-Added Alnico Alloys. J. Alloys Compd. 2024, 973, 172894. [Google Scholar] [CrossRef]

- Niazi, A.; Poddar, P.; Rastogi, A.K. A Precision, Low-Cost Vibrating Sample Magnetometer. Tech. Note Curr. Sci. 2000, 79, 99–109. [Google Scholar]

- Zhou, L.; White, E.; Ke, L.; Cullen, D.A.; Lu, P.; Constantinides, S.; McCallum, R.W.; Anderson, I.E.; Kramer, M.J. Microstructure and Coercivity in Alnico 9. J. Magn. Magn. Mater. 2018, 471, 142–147. [Google Scholar] [CrossRef]

- Mühl, T.; Elefant, D.; Koseva, R.; Mönch, I.; Leonhardt, A.; Rithchel, M.; Simon, P.; Zotova-Groudeva, S.; Graff, A.; Schneider, C.M. Magnetic Properties of Aligned Fe-Filled Carbon Nanotubes. J. Appl. Phys. 2003, 93, 7894. [Google Scholar] [CrossRef]

- Kurbatkina, V.V. Nickel Aluminides. In Concise Encyclopaedia of Self-Propagating High-Temperature Synthesis; Elsevier: Amsterdam, The Netherlands, 2017; pp. 212–213. [Google Scholar]

- Dey, G.K. Physical Metallurgy of Nickel Aluminides. Sadhana 2003, 28, 247–262. [Google Scholar] [CrossRef]

- Zagirov, N.N.; Loginov, Y.N.; Ivanov, E.V.; Galiev, R.I. Approval of a Method for Processing Aluminium Alloy Waste Cans Using a Combined Rolling and Pressing Method. Metall. J. 2022, 66, 343–348. [Google Scholar]

- Soto, T.E.; Alfonso, I.; González, F.; Aguilar, C.; Béjar, L.; Figueroa, I.A.; Vargas, J.; Abatal, M.; Samuel, F.H. An Overview on the Identification and Characterization of Cu-Rich Second Phases in Casting Al Alloys. Int. J. Met. 2023, 17, 1518–1534. [Google Scholar] [CrossRef]

- Lee, W.S.; Che, C.H.; Jhuo, Y.S.; Lien, H.L. Effect of Iron Content on Bimetallic Iron-Aluminium Particles for Dechlorination of Carbon Tetrachloride. J. Chin. Inst. Environ. Eng. 2006, 16, 159–166. [Google Scholar]

- Goto, K.; Ito, M.; Sakurai, T. Studies on Magnetic Domains of Small Particles of Barium Ferrite by Colloid-SEM Method. Jpn. J. Appl. Phys. 1980, 19, 1339. [Google Scholar] [CrossRef]

- Nowosielski, R.; Babilas, R.; Dercz, G.; Pająk, L.; Wrona, J. Structure and Properties of Barium Ferrite Powders Prepared by Milling and Annealing. Arch. Mater. Sci. Eng. 2007, 28, 735–742. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pistelok, P.; Adamiak, M. Feasibility of Employing Semi-Hard Magnetic Materials for Hysteresis Magnetic Clutches in Railway Systems. Materials 2025, 18, 5044. https://doi.org/10.3390/ma18215044

Pistelok P, Adamiak M. Feasibility of Employing Semi-Hard Magnetic Materials for Hysteresis Magnetic Clutches in Railway Systems. Materials. 2025; 18(21):5044. https://doi.org/10.3390/ma18215044

Chicago/Turabian StylePistelok, Paweł, and Marcin Adamiak. 2025. "Feasibility of Employing Semi-Hard Magnetic Materials for Hysteresis Magnetic Clutches in Railway Systems" Materials 18, no. 21: 5044. https://doi.org/10.3390/ma18215044

APA StylePistelok, P., & Adamiak, M. (2025). Feasibility of Employing Semi-Hard Magnetic Materials for Hysteresis Magnetic Clutches in Railway Systems. Materials, 18(21), 5044. https://doi.org/10.3390/ma18215044