1. Introduction

Flooring is the top layer of the floor and its outermost finishing coat. Concrete flooring is often used as a floor structure in industrial facilities, warehouses, commercial buildings, and garages [

1,

2,

3,

4,

5]. Standard concrete floorings wear quickly due to frequent use and external loads, which results in surface degradation and excessive dusting. Various treatments, including but not limited to modifying the concrete’s composition by adding high-quality fibres and aggregates, are used to enhance the strength characteristics of floors and improve their abrasion resistance [

6,

7,

8,

9,

10,

11,

12,

13]. Surface treatment with dedicated materials composed of cement, sand, and admixtures or additives which create a hard and robust coating resistant to wear, impact, and mechanical damage is the most effective solution [

14,

15,

16,

17,

18,

19,

20,

21].

Dry Shake Topping (DST), which involves hardening the flooring surface with dry, cementitious toppings, is one of the most-used methods for finishing concrete flooring. Concrete industrial floorings with dry mineral toppings are most common in industrial buildings [

22]. The DST consists of high-performance cements (class 52.5), which ensure the strength and durability of the layers, along with abrasion-resistant aggregates. Incorporating the topping at the wrong time can result in delamination or poor abrasion properties of the floor. Calcium aluminate cement (CAC) and Portland cement are used in DST floors [

23]; these cements have increased resistance to abrasion, and the timing of installation is crucial for the quality of the floor. The final quality of industrial floorings with dry mineral toppings depends largely on the quantity of mineral topping used during the production process. This directly influences the floor’s abrasion resistance, which is crucial for the actual flooring’s durability and service performance. Additionally, the bond between the mineral topping layer and the concrete substrate is another critical factor. In brief, the execution of such floorings involves the following steps: concrete mix spreading, compacting with a vibrating float, smoothing the concrete mix and layer of water spontaneously released from the concrete (if applicable), waiting for the concrete mix setting to start, and spreading and floating the hardening topping [

24,

25].

Using the DST surface hardening method to finish the flooring provides unique characteristics by hardening the surface, reducing the risk of abrasion and mechanical damage, and creating a smooth and shiny top surface with a homogeneous colour [

15,

21,

23,

26]. However, it is challenging to fabricate surface-hardened floors. The critical parameter is to determine the starting time of the spreading and floating of the cementitious topping on the concrete mix surface. The time depends on several factors, including the concrete mix composition, consistency, gain rate of the concrete mix strength, ambient temperature, and humidity [

27,

28,

29,

30,

31,

32,

33,

34]. If the initiation time of floating the hardening topping is incorrectly determined, the procedure can start too soon or too late. Such timing errors can result in future defects in concrete flooring, including cracking of the hardened layer, delamination, colour differences, and non-uniform characteristics on the flooring surface, all of which can significantly affect the floor’s performance and durability [

21,

35,

36]. Concrete flooring is susceptible to shrinkage and must be properly cured to prevent cracking and development of desired mechanical properties [

22,

23,

37].

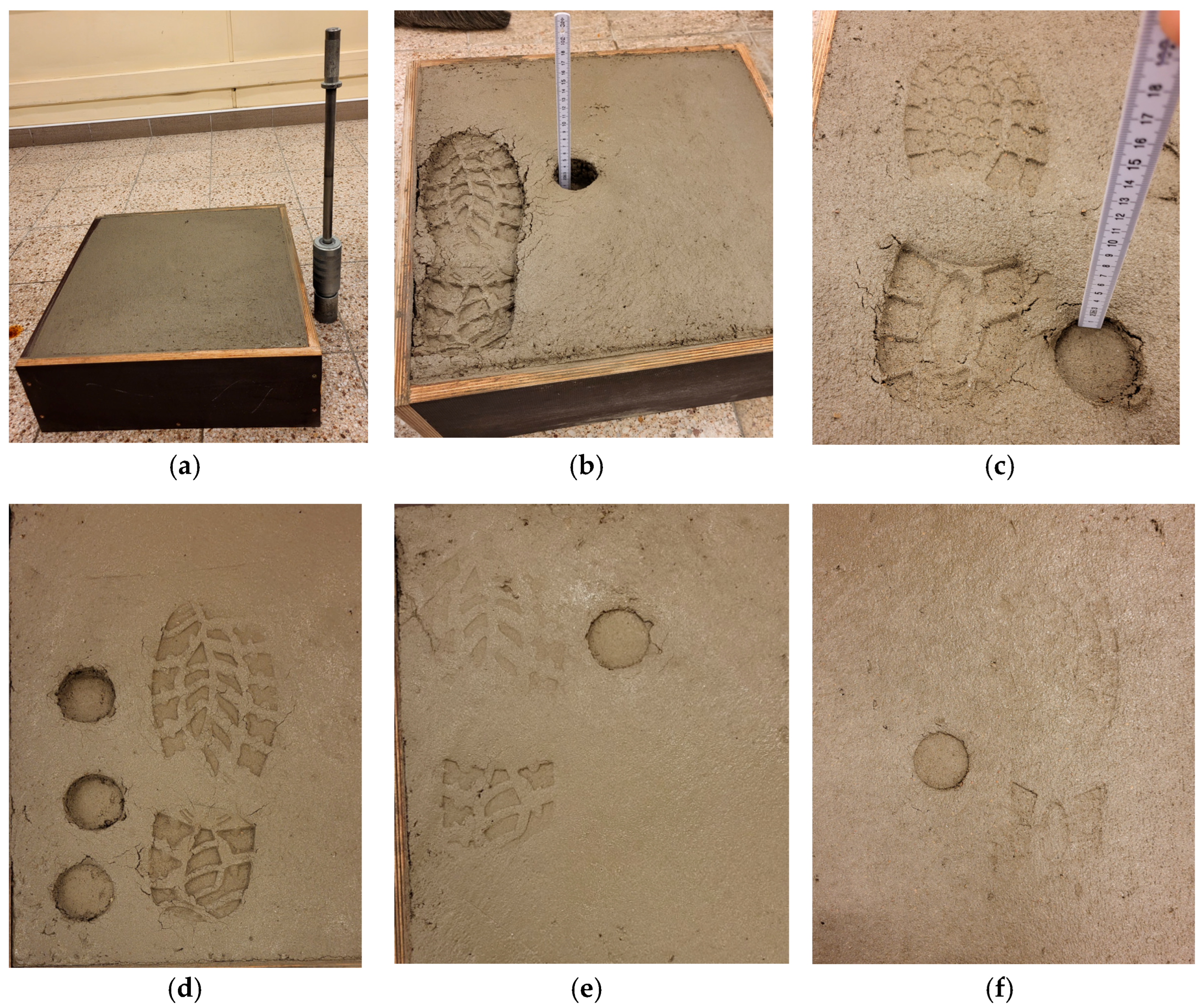

At present, no universally accepted technical test methods are available to determine the optimal initiation time for applying hardening topping during on-site floating and subsequent surface finishing using the DST method. The flooring contractors check the time using a technique that measures the shoeprint penetration depth, which should not exceed 3–5 mm upon stepping onto the concrete mix. Identifying the right moment depends on the flooring contractor’s experience as well as their weight or shoe size. However, this method is imprecise and may lead to execution difficulties, potentially resulting in improper floating of the hardening topping and subsequent flooring defects.

A literature review revealed publications on the test method for determining the initiation time of floating hardening topping [

8,

23,

35,

38,

39,

40]. A Dutch document, NEN 2743:2003 [

38], describes the probe time method. The test shall be performed indoors at a temperature of 20 °C ± 2 °C. The method involves the following parameters: pouring the concrete mix into a ten-litre container using a probe with a right hammer, the total length of the probe should be 480 mm, the hammer’s weight should be 400 g, the diameter of the hammer base should be 200 mm, and the hammer drop height should be 250 mm. This method is used to determine the time after which the penetration depth of the twenty-five hammer drops at a single point in the concrete mix reaches 35 mm. The time refers to the moment when the floating of the hardening topping on the concrete flooring should begin. The test should be repeated three times for one concrete container. The result should be quoted as the mean of three measurements, with an accuracy of up to 1 mm. It also requires the repetition of the test every thirty minutes, or more often, and stopping the measurement when the penetration depth is less than 20 mm. The results should be presented in a graphic form as a diagram of the probe penetration depth (mm) versus time (h). The right initiation time of floating is then interpolated from the diagram.

The analysed Dutch method has some limitations: one should have the proper probe described in the document, the test is carried out under laboratory conditions, and the concrete mix is tested in plastic containers. All the aforementioned parameters do not adequately represent the actual performance of concrete flooring in situ. There are some doubts concerning the fact that the tests are performed under different conditions of concrete flooring setting (in a laboratory). In practice, floors are typically made at temperatures ranging from +5 °C to +30 °C, which may lead to substantial discrepancies between laboratory results and actual field performance.

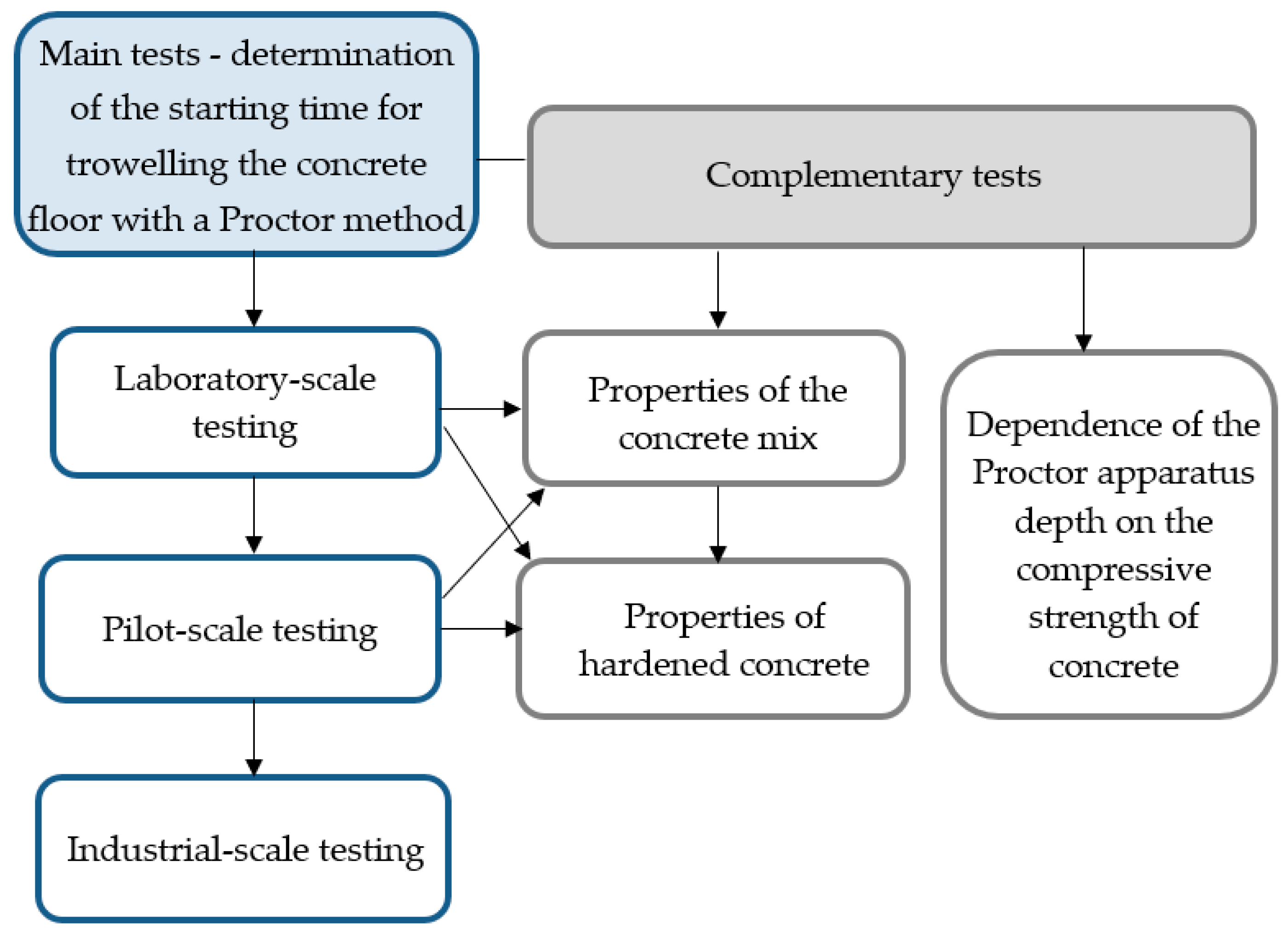

Thus, the following scientific and research problem is addressed in this article: there is currently no universal testing method using measurement equipment to determine the optimal starting/initiation time for concrete flooring hardening using the Dry Shake Topping (DST) mechanical floating method. In practice, the concrete setting rate is determined by the person making the flooring, who checks the shoeprint penetration depth to ca. 3–5 mm. The concrete mix should be sufficiently set and strong to be stepped onto with the hardening topping floating equipment. On the other hand, it must not be fully set (hardened) as it would prevent the successful floating of the hardening topping. This is the only way to ensure adequate blending of the hardening layer with the fresh concrete. It affects the flooring’s final strength, durability, and visual characteristics and eliminates the risk of cracking and delamination of the hardening flooring layer. Although the literature describes the method for determining probe time [

38], these approaches are not widely used due to equipment limitations, the method’s performance conditions, and the complexity of result interpretation. Therefore, a simple and rapid method for assessing the setting rate of fresh concrete to initiating the floating of the hardening topping is essential for the effective mechanical hardening of concrete floors using the DST method. Such a method should be universally applicable for any concrete formula.

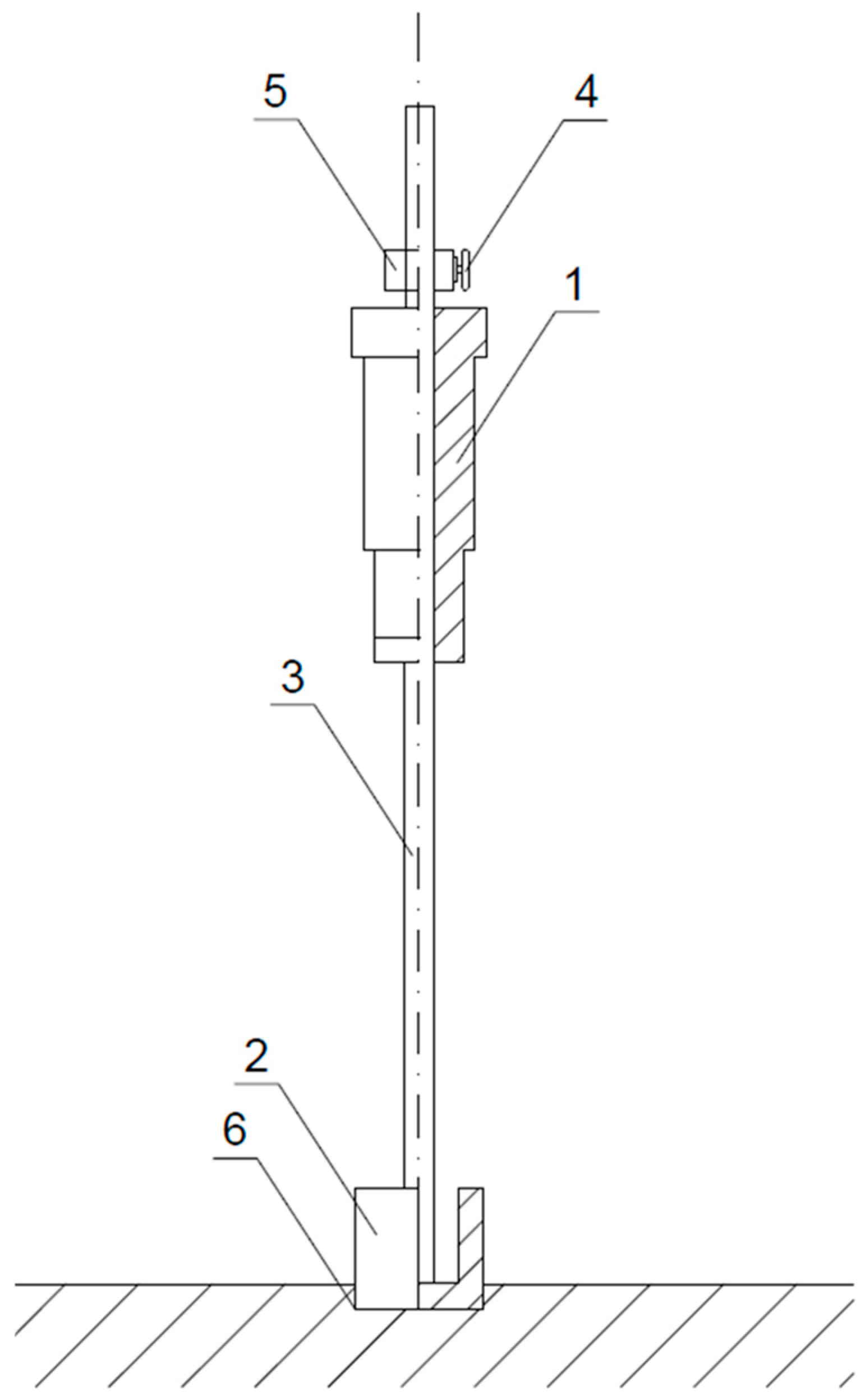

Moreover, it is essential to determine the concrete’s actual compressive strength upon starting the hardening topping floating. New flooring concrete shall be strong enough to be stepped onto with a topping floating machine, yet sufficiently fresh to ensure effective and durable binding of the topping with the concrete. The compressive strength is determined based on the Proctor Compaction Test Apparatus drop depth, which complements the developed method.

The aim of the research is to define the simple and rapid method for determining the initiation time of concrete flooring floating using the Proctor Compaction Test Apparatus. The method builds upon existing practices by utilising a well-known, manual, and portable apparatus. It can be used in situ during the construction of mechanically floated floorings, which is the innovative aspect of the study. Using the Proctor Compaction Test Apparatus with the proposed method eliminates the need for low-precision shoeprint penetration testing, regardless of the concrete mix used for flooring applications. In practice, this will result in fewer incorrectly hardened floorings, where the topping floating was performed too soon or too late, leading to numerous surface defects in concrete floorings, such as microcracking or delamination of the layer. The developed method enables the use of the Proctor Compaction Test Apparatus, allowing for measurements on real floorings under any temperature conditions and providing quick and straightforward reading of the results, with no need for correlation.

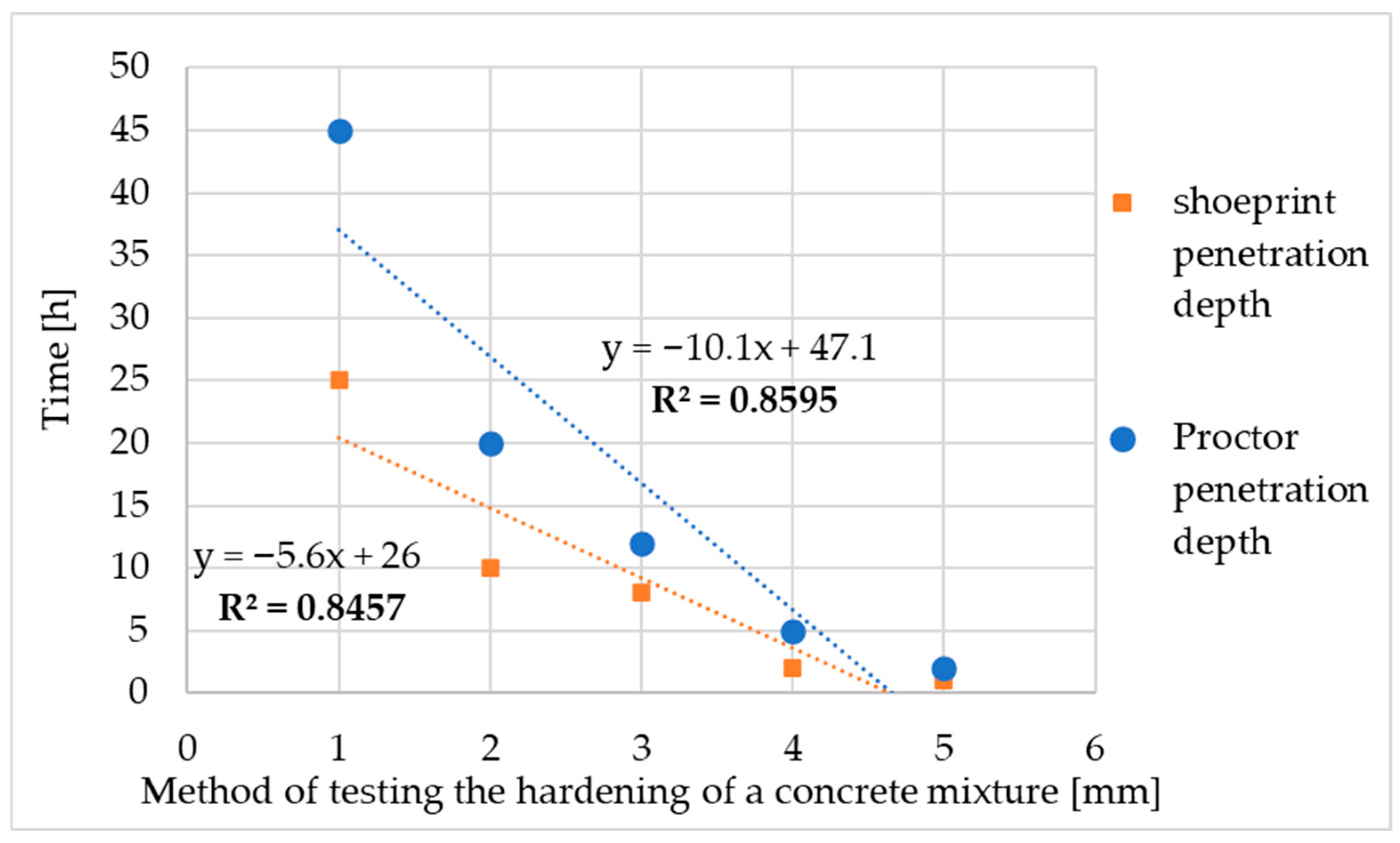

The article presents the test results on the correlation between penetration depth measured with the Proctor Compaction Test Apparatus and the actual compressive strength of fresh concrete. The tests contributed to determine the strength level of the concrete mix at the initiation of the trowelling process for the hardening topping on the concrete surface. This testing approach represents a novel aspect, as no similar results were found in the reviewed literature.

4. Discussion

Concrete floorings with surfaces hardened with the DST method are the most common finishing type of flooring surface due to their smoothness, high strength, abrasion resistance, and surface tightness. Determining the optimal starting time for surface hardening is crucial to achieving the required flooring performance parameters. Therefore, there is a need for a universal, practical, and repeatable in situ testing method that utilises commercially available equipment.

In current practice, the shoeprint method is routinely used to assess the setting of the concrete mix. However, this method is imprecise and prone to numerous errors, as it depends on various factors such as the tester’s body weight and shoe size. For example, the shoeprint penetration depth differs between individuals weighing 80 kg and 100 kg or wearing shoes with different sizes. Such variability can lead to inaccurate assessments resulting in flooring defects or subsequent complaints.

The literature describes a standardised procedure for determining the optimal starting time for concrete floor hardening in the Dutch standard NEN 2743:2003 [

38], which outlines the probe time method. However, this method is complex and has several limitations. It requires laboratory conditions (20 ± 2 °C) and testing of the concrete mix in ten-litre containers. Additionally, the probe used in this method has a diameter of 200 mm (probe weight: 400 g, drop height: 250 mm, length: 480 mm), which is insufficient for concrete mixes containing aggregates with a maximum size of 16 or 32 mm. There is also the risk when the probe hits the aggregate grain, which can affect measurement accuracy. In the probe time method [

30], the time is determined after which the depth of the twenty-five hammer drops in one measurement point amounts to 35 mm. The test shall be repeated three times per container with concrete, with the result quoted as a mean of three measurements with an accuracy of up to 1 mm. The test should be repeated every thirty minutes, requiring a high number of containers with concrete mix. The measurement can be stopped when the penetration depth is less than 20 mm. The results should be presented in a graphic form, as a diagram of the penetration depth (mm) versus time (h). The end time is extrapolated from the diagram. In practice, a quick method for investigating the setting rate of concrete mix is expected so as not to miss the moment when surface hardening with topping should start. These factors make this method difficult to apply in practice, leading to its infrequent use.

To address these issues, a new approach was developed based on numerous validation tests conducted under laboratory conditions, followed by pilot- and industrial-scale trials. This method determines the setting rate of concrete mixes to establish the appropriate time for commencing surface hardening with a topping. It employs the Proctor Compaction Test Apparatus, a device commonly used in construction for soil compaction.

This proposed method offers several advantages, such as a diameter of probe suitable for testing concrete mixes (50 mm in diameter, hammer weight: 4.5 kg, drop height: 457 mm, length: 610 mm), and it uses a mobile construction device, allowing for easy on-site use. Results are obtained immediately, and the method does not require complex laboratory procedures. The depth obtained in the Proctor method is identified when one hammer drop is 4–7 mm in depth. The result is quoted as the mean of three measurement points, positioned at least 50 mm apart, with an accuracy of up to 1 mm. Initially, the test is repeated every thirty minutes. When the mix starts curing, it is repeated every 15–20 min. The results are obtained in situ, which is a significant improvement over the Dutch method. Moreover, the Proctor method can be applied to different concrete mixture compositions, regardless of ingredients or concrete mix characteristics, and under various environmental conditions (e.g., different temperatures and humidity levels). Additionally, this research involves the determination of the early strength of fresh, setting concrete when the hardening topping is floated, which was not previously addressed in the literature. The test results on the Proctor apparatus penetration depth and simultaneous compressive strength tests reveal that floating of the hardening mix with floats and discs on the flooring surface with the DST method can start when the concrete’s compressive strength falls within the 0.2–0.3 MPa range.

The obtained results indicated that the procedure of spreading the hardening topping on the concrete mix surface and its subsequent floating can begin when the mean penetration depth of three Proctor apparatus measurements falls between 4 and 7 mm.

This method provides a technical and reliable alternative to the traditional shoeprint approach, effectively eliminating the uncertainties associated with manual assessment.

The presented Proctor Compaction Test Apparatus penetration method has several advantages: it utilises known mobile equipment commonly used in construction, the results are instantly available, and the tests can cover various concrete mixes, allowing for performance under different environmental conditions. Moreover, the work determined the actual compressive strength at the moment of starting to trowel the hardening powder onto the floor surface, which is a novelty in this article.

The method is certainly limited by the use of dense reinforcement concrete. Furthermore, application limitations include errors in the concrete mix composition, such as excessively fluid consistency, mix segregation, or high fly ash content. Assuming the concrete mix has the appropriate composition and properties, the method is effective.

—the correlated starting time of floating is highlighted in grey.

—the correlated starting time of floating is highlighted in grey. —the correlated time of starting the floating is highlighted in grey.

—the correlated time of starting the floating is highlighted in grey. —the determined time of starting the floating with the Proctor method is highlighted in grey.

—the determined time of starting the floating with the Proctor method is highlighted in grey.