Long-Term Water Stability Analysis of Graphene-Composite-Modified Permeable Asphalt Mixture

Abstract

1. Introduction

2. Test Materials and Methods

2.1. Test Materials

2.2. Preparation of Modified Bitumen

2.3. Graphene-Composite-Modified Permeable Asphalt Mixture Mix Design

2.4. Test Methods

2.4.1. Thermal Oxygen Ageing Test

2.4.2. Freeze–ThawFreeze-Thaw Splitting Test

2.4.3. Cantabro Test

2.4.4. Multi-Factor Coupled Water Immersion Rutting Tests

2.4.5. Dynamic Shear Rheometer (DSR) Test

2.4.6. Raman Mapping Test

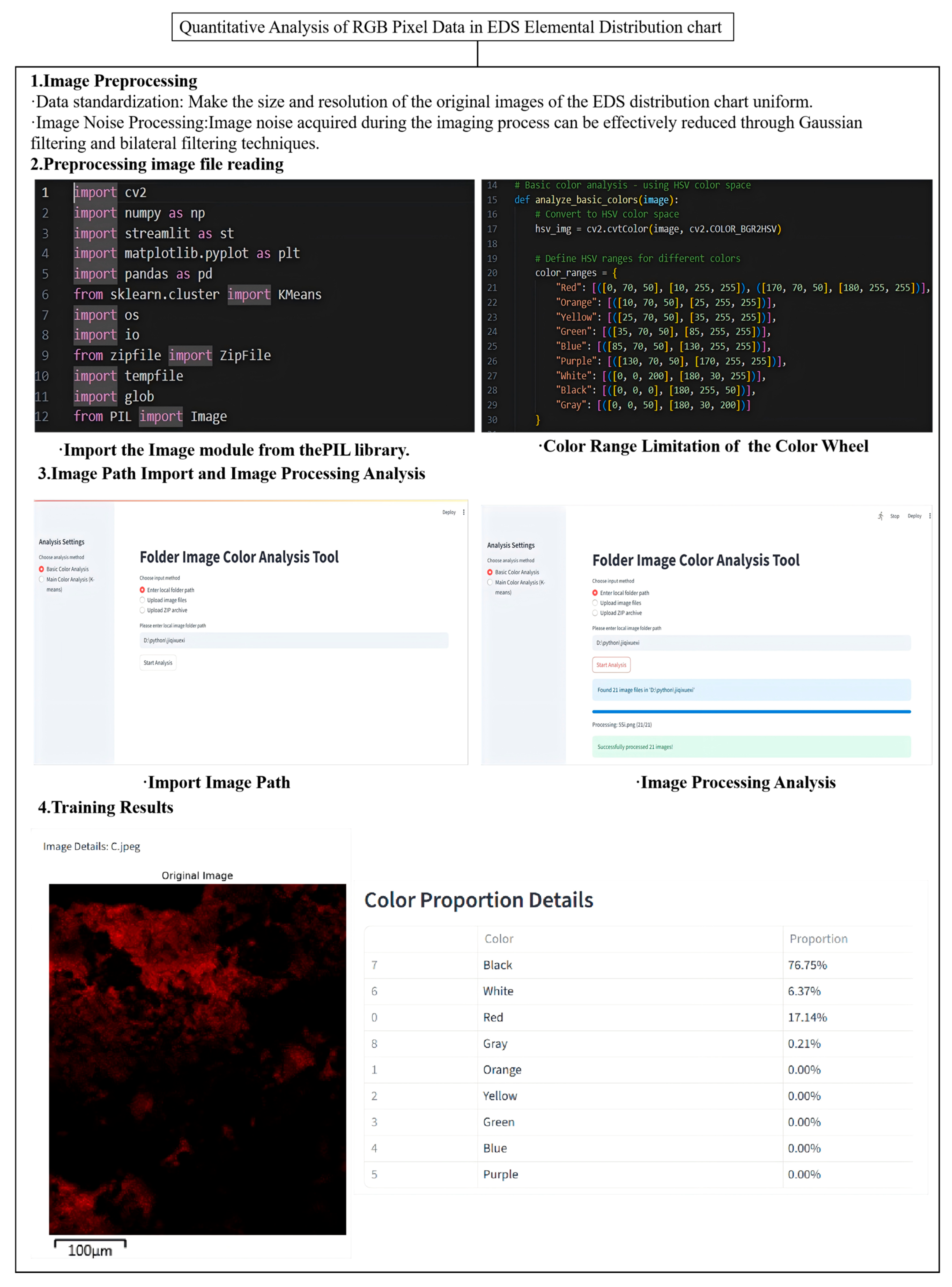

2.4.7. Energy Dispersive Spectrometer (EDS) Testing

3. Results and Discussion

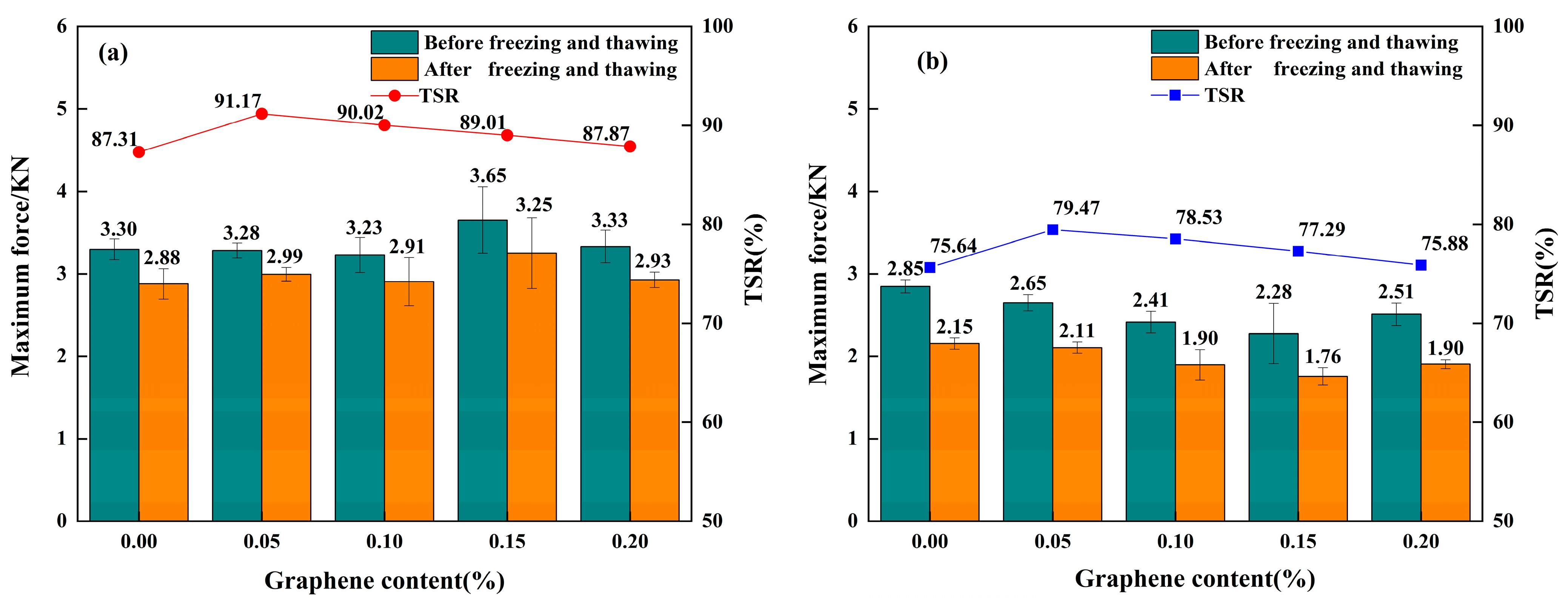

3.1. Water Stability Under Freeze–ThawFreeze-Thaw Action

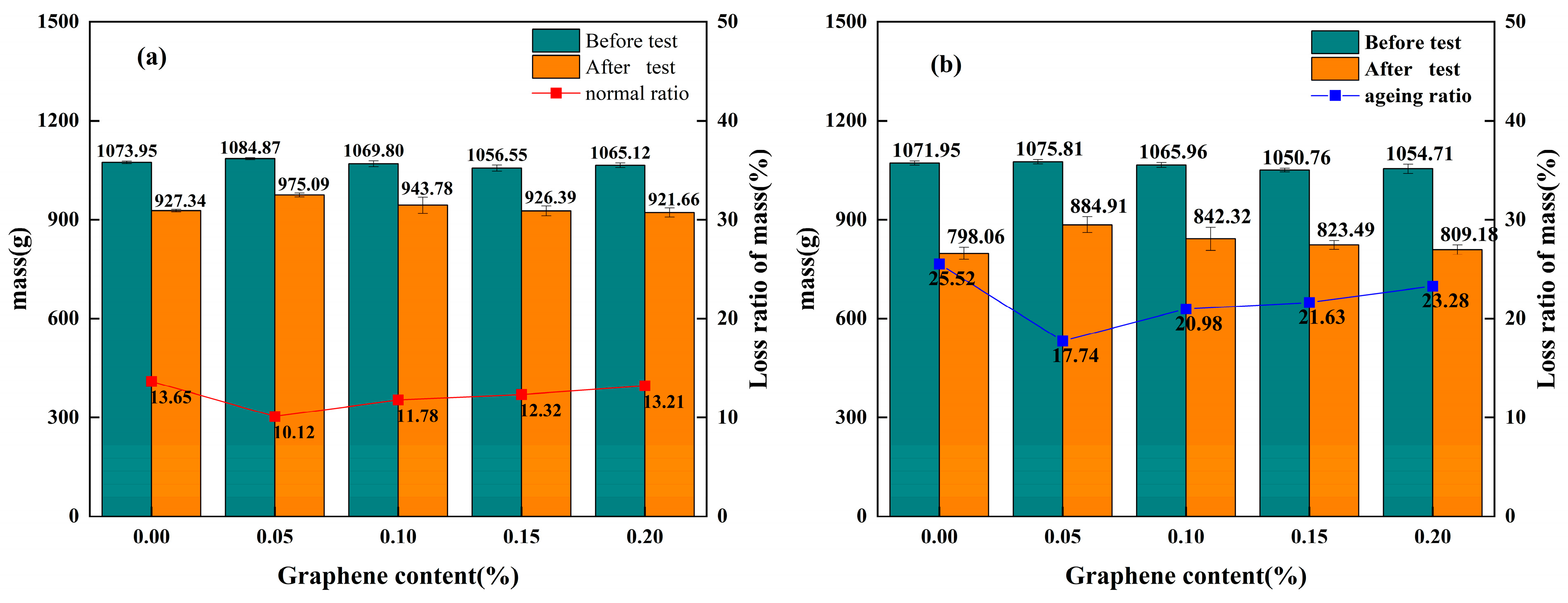

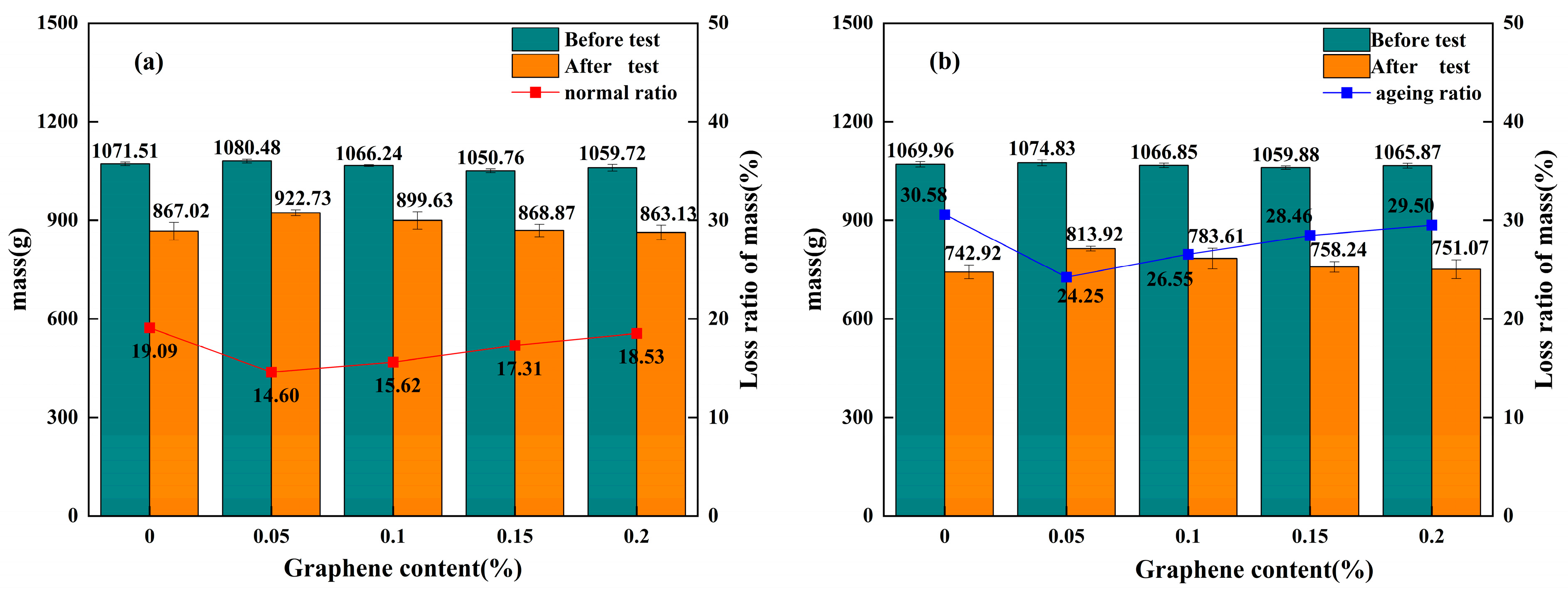

3.2. Water Stability Under Load

3.3. Water Stability Under Hydrothermal Conditions

3.4. Water Stability Under Load, Temperature, and Ageing Effects

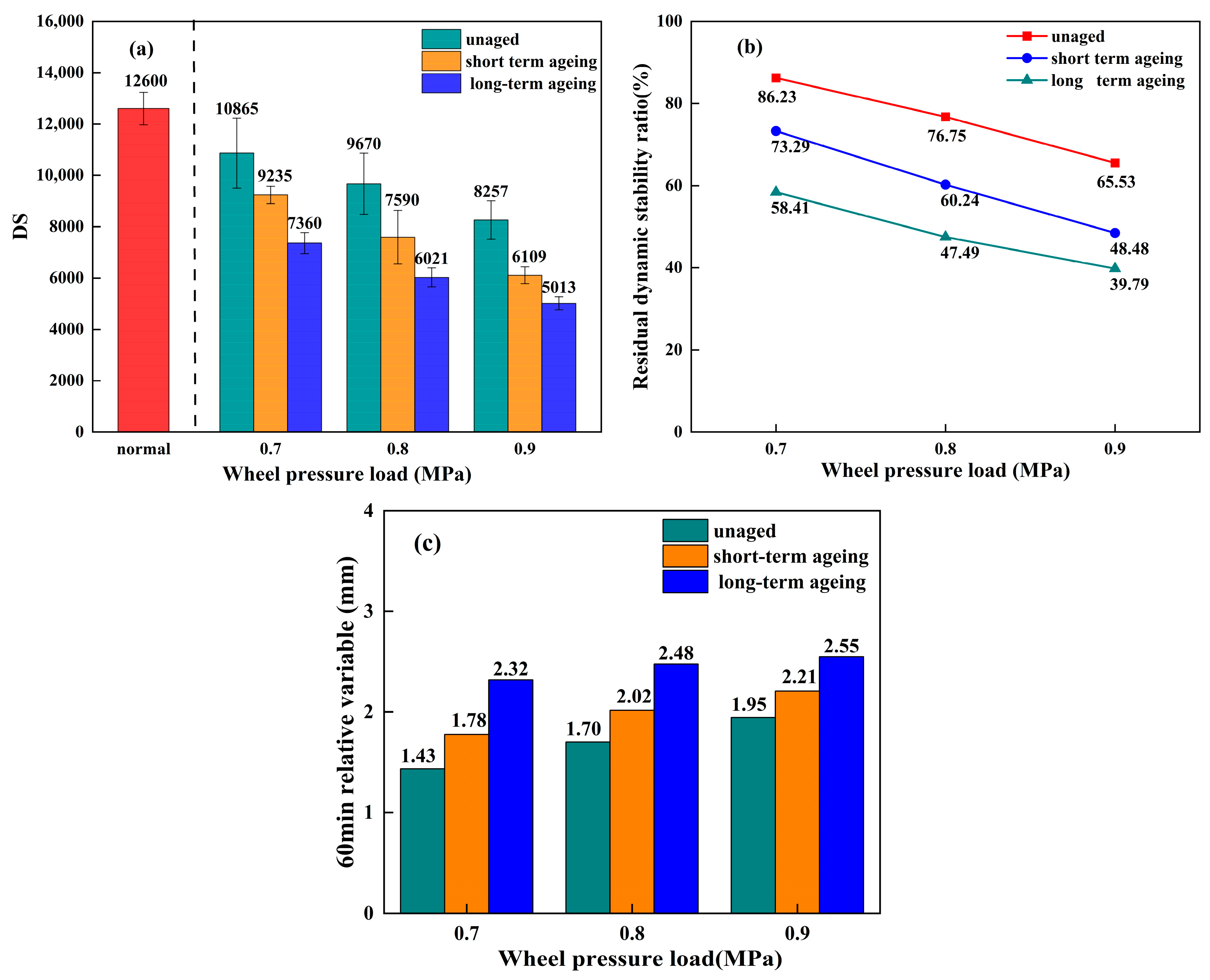

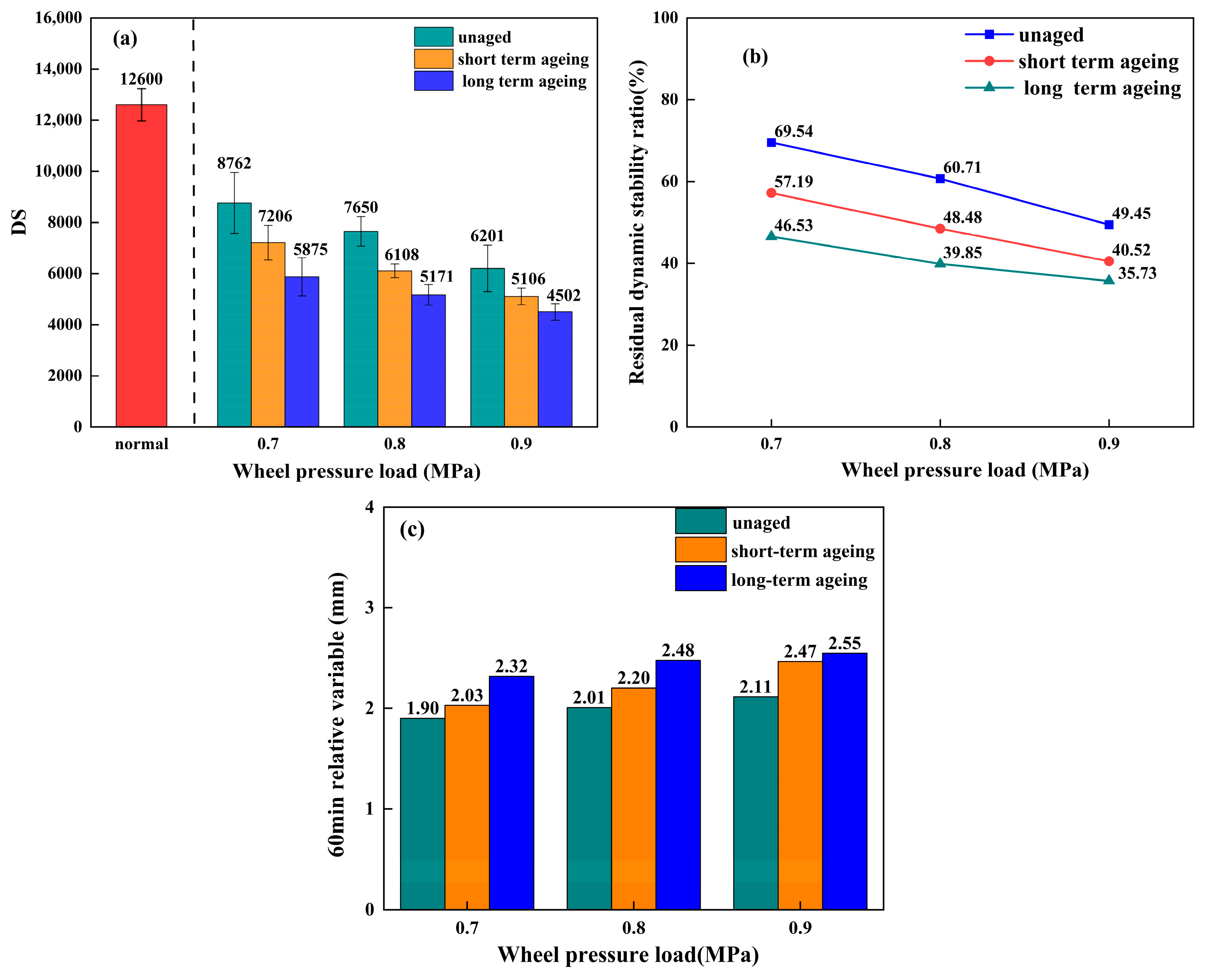

3.4.1. Water Stability Under Load, High Temperature, and Ageing Effects

3.4.2. Water Stability Under Load, Low Temperature, and Ageing Effects

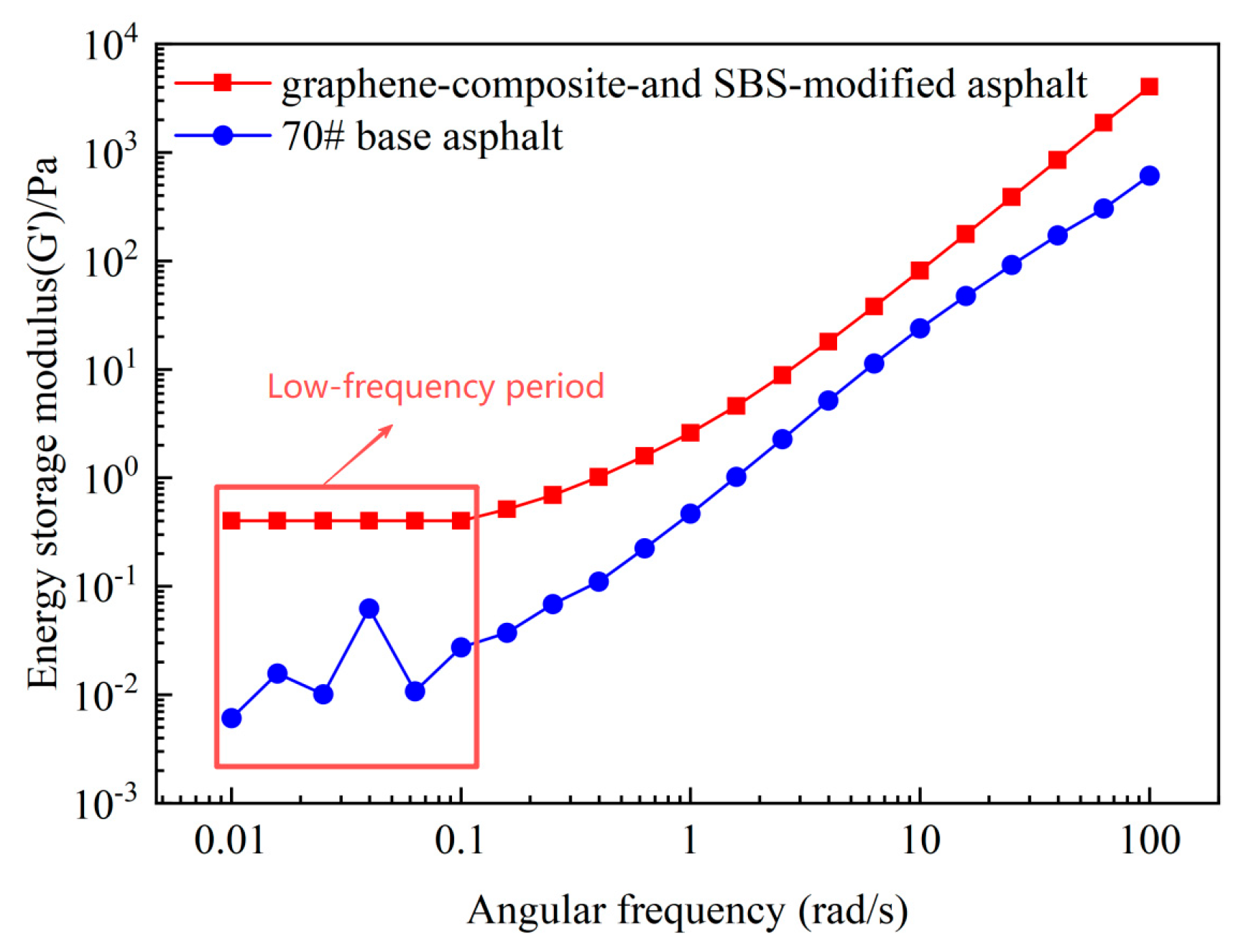

3.5. Analysis of Rheological Results

4. Microscopic Analysis of Graphene-Modified Permeable Asphalt Mixture

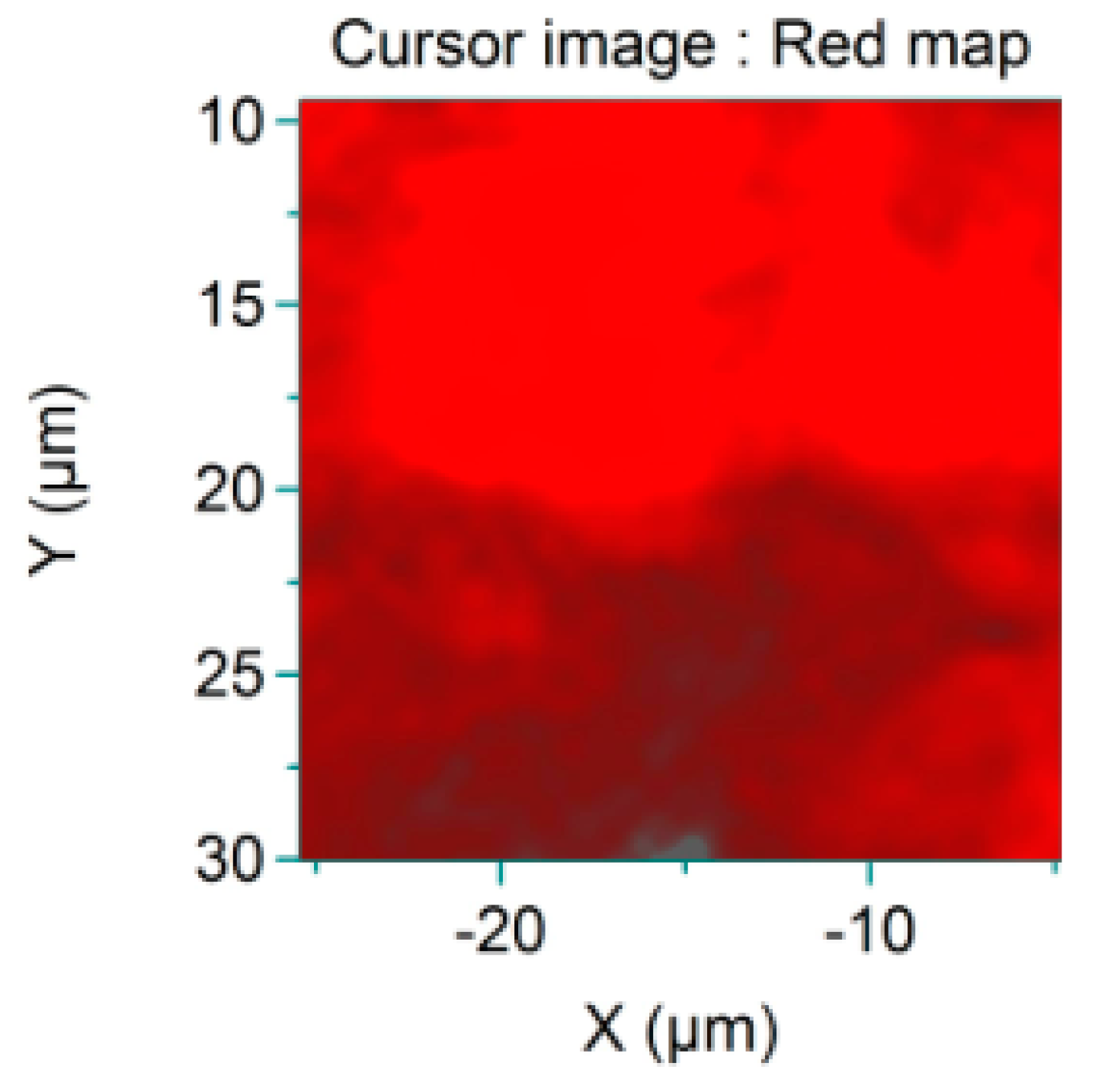

4.1. Analysis of the Uniformity of Graphene Dispersion

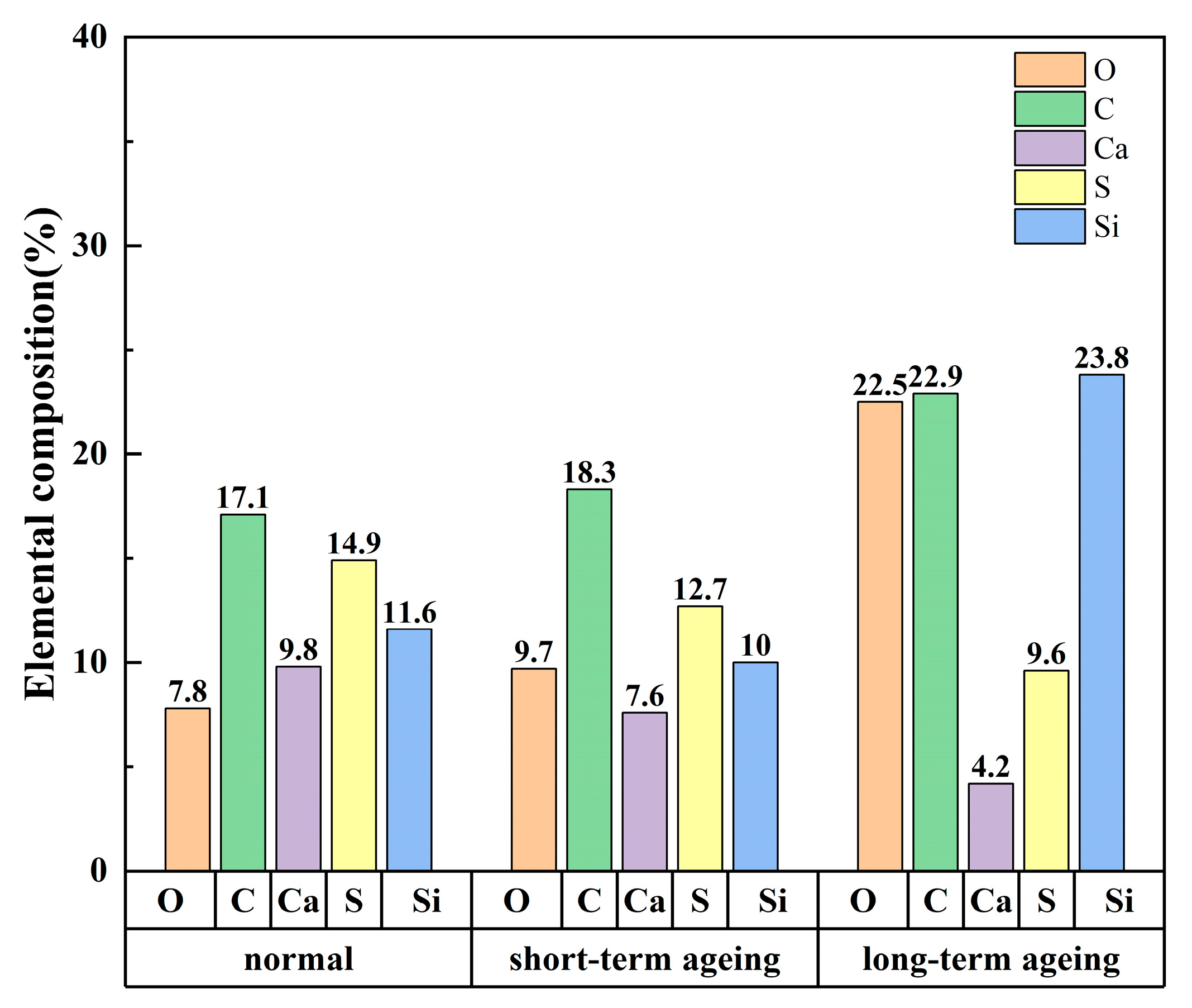

4.2. Distribution of Chemical Elements in Graphene-Modified Permeable Asphalt Mixtures at the Microscopic Level

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Geng, J.; Chen, M.; Shang, T.; Li, X.; Kim, Y.R.; Kuang, D. The Performance of Super Absorbent Polymer (SAP) Water-Retaining Asphalt Mixture. Materials 2019, 12, 1964. [Google Scholar] [CrossRef]

- Zhao, S.; Zhang, H.; Feng, Y.; Guo, Z.; Yang, H.; Li, Y. Effect of temperature and water conditioning on noise and skid resistance of dense-graded, open-graded and gap-graded asphalt mixes. Ain Shams Eng. J. 2024, 15, 102281. [Google Scholar] [CrossRef]

- Liu, H.; Xu, B.; Wang, H.; Gao, A.; Yu, X.; Ping, S.; Zhang, S. Drainage Performance of Long Longitudinal Slope and High Safety Permeable Asphalt Pavement. Buildings 2023, 13, 2955. [Google Scholar] [CrossRef]

- Cheng, Z.; Li, X.; Yang, Q.; Liang, N.; Chen, L.; Zheng, S.; Wang, D. Study on Compaction Properties and Skeleton Structural Characteristics of Porous Asphalt Mixture. Sustainability 2023, 15, 13911. [Google Scholar] [CrossRef]

- Gupta, A.; Lastra-Gonzalez, P.; Castro-Fresno, D.; Rodriguez-Hernandez, J. Laboratory Characterization of Porous Asphalt Mixtures with Aramid Fibers. Materials 2021, 14, 1935. [Google Scholar] [CrossRef]

- Eisa, M.S.; Mohamady, A.; Basiouny, M.E.; Abdulhamid, A.; Kim, J.R. Laboratory Evaluation of Mechanical Properties of Modified Asphalt and Mixture Using Graphene Platelets (GnPs). Materials 2021, 14, 5599. [Google Scholar] [CrossRef]

- Yu, J.; Ding, H.; Chen, B.; Sun, X.; Zhang, Y.; Zhou, Z. Changes in Current Transport and Regulation of the Microstructure of Graphene/Polyimide Films under Joule Heating Treatment. Materials 2024, 17, 2540. [Google Scholar] [CrossRef]

- Razaq, A.; Bibi, F.; Zheng, X.; Papadakis, R.; Jafri, S.H.; Li, H. Review on Graphene-, Graphene Oxide-, Reduced Graphene Oxide-Based Flexible Composites: From Fabrication to Applications. Materials 2022, 15, 1012. [Google Scholar] [CrossRef]

- Li, X.; Wang, Y.; Wu, Y.; Wang, H.; Wang, Q.; Zhu, X.; Liu, X.; Sun, H.; Fan, L. Effect of Graphene on Modified Asphalt Microstructures Based on Atomic Force Microscopy. Materials 2021, 14, 3677. [Google Scholar] [CrossRef] [PubMed]

- Wu, S.; Zhao, Z.; Li, Y.; Pang, L.; Amirkhanian, S.; Riara, M. Evaluation of Aging Resistance of Graphene Oxide Modified Asphalt. Appl. Sci. 2017, 7, 702. [Google Scholar] [CrossRef]

- Gao, Y.; Zou, F.; Wang, S.; Sui, H.; Yu, J.; Xu, B.; Chen, W.; Liu, Y. Redefining the cement substitution potential of recycled concrete powder using graphene oxide coating. Cem. Concr. Compos. 2025, 164, 106276. [Google Scholar] [CrossRef]

- Gao, Y.; Cheng, Z.; Yu, J.; Guo, X.; Liu, Y.; Chen, W. Mechanical performance enhancement of UHPC via ITZ improvement using graphene oxide-coated steel fibers. Cem. Concr. Compos. 2025, 157, 105931. [Google Scholar] [CrossRef]

- Gao, Y.; Zou, F.; Sui, H.; Xu, J.; Wang, S.; Lu, S.; Yu, J.; Chen, W.; Liu, Y.; Chen, J.; et al. Dispersion strategies development for high-performance carbon nanomaterials-reinforced cementitious composites–critical review on properties and future challenges. Mater. Des. 2025, 259, 114789. [Google Scholar] [CrossRef]

- Zhang, T.; Zhang, C.; Song, F.; Zou, J.; Gao, Y.; Yang, W. Breakage behavior of silica sands during high-pressure triaxial loading using X-ray microtomography. Acta Geotech. 2023, 18, 5195–5211. [Google Scholar] [CrossRef]

- Li, R.; Zhu, W.; Chen, H.; Li, X.; Sun, L.; Yue, J. Influence of Aging and Salt–Alkali Coupling on the Fatigue and Self-Healing Behavior of Graphene Oxide-Modified Asphalt. Materials 2025, 18, 1808. [Google Scholar] [CrossRef]

- Adnan, A.M.; Wang, J. Enhancement of rheological performance and compatibility of tire rubber-modified asphalt binder with the addition of graphene. Constr. Build. Mater. 2023, 402, 133038. [Google Scholar] [CrossRef]

- Zhao, Y.; Guo, R.; Li, J.; Wen, L. Research on preparation and road performance of graphene oxide framework modified asphalt and asphalt mixture based on micro-mechanism and grey correlation analysis. Constr. Build. Mater. 2025, 462, 139980. [Google Scholar] [CrossRef]

- Yong, P.; Tang, J.; Zhou, F.; Guo, R.; Yan, J.; Yang, T. Performance analysis of graphene modified asphalt and pavement performance of SMA mixture. PLoS ONE 2022, 17, e0267225. [Google Scholar] [CrossRef]

- Nguyen, T.H.; Ahn, J.; Lee, J.; Kim, J.-H. Dynamic Modulus of Porous Asphalt and the Effect of Moisture Conditioning. Materials 2019, 12, 1230. [Google Scholar] [CrossRef]

- Xu, B.; Wang, W.; Sun, Y.; Gong, M. Rheological Performance Analysis of Different Preventive Maintenance Materials in Porous High-Viscosity Asphalt Pavements. Materials 2024, 17, 1458. [Google Scholar] [CrossRef]

- Wang, B.; Zhang, Y.; Zhu, X.; Wei, D.; Wang, J. Experiment Investigation and Influence Evaluation of Permeability Ability Attenuation for Porous Asphalt Concrete under Repeated Clogging Conditions. Buildings 2023, 13, 2759. [Google Scholar] [CrossRef]

- Diao, H.; Ling, T.; Zhang, Z.; Peng, B.; Huang, Q. Multiscale Fatigue Performance Evaluation of Hydrated Lime and Basalt Fiber Modified Asphalt Mixture. Materials 2023, 16, 3608. [Google Scholar] [CrossRef]

- Zhen, T.; Kang, X.; Liu, J.; Zhang, B.; Si, W.; Ling, T. Multiscale Evaluation of Asphalt Aging Behaviour: A Review. Sustainability 2023, 15, 2953. [Google Scholar] [CrossRef]

- Shahnewaz, S.M.; Masri, K.A.; Ahmad Abdul Ghani, N.A.; Putra Jaya, R.; Siew Choo, C.; Giannakopoulou, P.P.; Rogkala, A.; Lampropoulou, P.; Petrounias, P. Porous asphalt mixtures enriched with bamboo fibers as a new approach for future sustainable construction. Constr. Build. Mater. 2023, 407, 133456. [Google Scholar] [CrossRef]

- Andrés-Valeri, V.C.; Muñoz-Cáceres, O.; Raposeiras, A.C.; Castro-Fresno, D.; Lagos-Varas, M.; Movilla-Quesada, D. Laboratory Evaluation of Porous Asphalt Mixtures with Cellulose Ash or Combustion Soot as a Filler Replacement. Sustainability 2023, 15, 15509. [Google Scholar] [CrossRef]

- Xiao, Y.; Wang, T.; Chen, Z.; Li, C.; Wang, F. Water Stability of Fibers-Enhanced Asphalt Mixtures under Static and Dynamic Damage Conditions. Materials 2024, 17, 1304. [Google Scholar] [CrossRef]

- Zhao, D.; Ma, X.; Wang, H.; Zhang, C. Investigation of the Wet and Thermal Conditions Effect on the Micro-Scale Characteristics of Interfacial Transition Zone of Porous Asphalt Mixture. Coatings 2023, 13, 566. [Google Scholar] [CrossRef]

- Tu, J.; Zhou, W.; Kiani, A.; Wolf, L.M.; Yan, M. Chemical Vapor Deposition of Monolayer Graphene on Centimeter-Sized Cu(111) for Nanoelectronics Applications. ACS Appl. Nano Mater. 2025, 8, 4926–4939. [Google Scholar] [CrossRef] [PubMed]

- Yadykova, A.Y.; Shariati, S.; Fini, E.H.; Ilyin, S.O. Novel Bio-Nanocomposite for Asphalt Pavements: Montmorillonite Intercalated with Castor Oil. ACS Sustain. Chem. Eng. 2024, 12, 13062–13079. [Google Scholar] [CrossRef]

- Gao, B.; Xu, H.; Wu, S.; Wang, H.; Yang, X.; Chen, P. Research on Improving Moisture Resistance of Asphalt Mixture with Compounded Recycled Metallurgical Slag Powders. Materials 2024, 17, 3499. [Google Scholar] [CrossRef]

- Cao, S.; Li, P.; Nan, X.; Yi, Z.; Sun, M. Optimization of Aggregate Characteristic Parameters for Asphalt Binder—Aggregate System under Moisture Susceptibility Condition Based on Random Forest Analysis Model. Appl. Sci. 2023, 13, 4732. [Google Scholar] [CrossRef]

- Dziadosz, S.; Słowik, M.; Niwczyk, F.; Bilski, M. Study on Styrene-Butadiene-Styrene Modified Asphalt Binders Relaxation at Low Temperature. Materials 2021, 14, 2888. [Google Scholar] [CrossRef]

- Liu, Z.; Liang, K.; Cao, X.; Chen, J.; Ji, S.; Shen, Q. Influence of graphene on the composite modified asphalt based on viscoelastic and elastic properties. Constr. Build. Mater. 2024, 443, 137671. [Google Scholar] [CrossRef]

- Chen, J.; Cheng, Y.; Liang, K.; Cao, X.; Wang, Y.; Shen, Q. A Study on the Low-Intensity Cracking Resistance of Drainage Asphalt Mixtures by Graphene/Rubber Powder Compound Modified Asphalt. Materials 2025, 18, 3451. [Google Scholar] [CrossRef] [PubMed]

- JTG F40-2004; The Provisions of the Technical Specification for Construction of Highway Asphalt Pavements. Ministry of Communications of the People’s Republic of China: Beijing, China, 2004.

- JTG E20-2011; Standard Test Methods of Asphalt and Asphalt Mixtures for Highway Engineering. Ministry of Transport of the People’s Republic of China: Beijing, China, 2011.

- Adolfo, F.R.; Claussen, L.E.; Cargnin, R.S.; Brudi, L.C.; Grasmann, C.S.; Nascimento, P.C.d.; Cravo, M.; Nascimento, L.A.; Alcantara, A.P.M.P.; Branco, V.T.F.C.; et al. Influence of thermal aging and long term-aging on Ni and V content in asphalt fractions and their determination in air particulate matter from asphalt mixing plants. Fuel 2022, 324, 124289. [Google Scholar] [CrossRef]

- Hamedi, G.H.; Ghahremani, H.; Saedi, D. Investigation the effect of short term aging on thermodynamic parameters and thermal cracking of asphalt mixtures modified with nanomaterials. Road Mater. Pavement Des. 2021, 22, 2838–2865. [Google Scholar] [CrossRef]

- Wang, X.; Fan, Z.; Li, L.; Wang, H.; Huang, M. Durability Evaluation Study for Crumb Rubber–Asphalt Pavement. Appl. Sci. 2019, 9, 3434. [Google Scholar] [CrossRef]

- Liu, Q.; Huang, L.; Bai, L. Delayed effects of large-scale cold surge on winter heavy rainfall in southern China. Atmos. Res. 2023, 285, 106632. [Google Scholar] [CrossRef]

- Huang, A.; Liu, G.; Mouillet, V.; Somé, S.C.; Cao, T.; Huang, H. Rheological and Chemical Evolution of HMA and WMA Binders Based on Ageing Kinetics. Materials 2022, 15, 679. [Google Scholar] [CrossRef]

- Abbas, Q.; Shinde, P.A.; Abdelkareem, M.A.; Alami, A.H.; Mirzaeian, M.; Yadav, A.; Olabi, A.G. Graphene Synthesis Techniques and Environmental Applications. Materials 2022, 15, 7804. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Qiu, Y.; Shi, J.; Zhang, B.; Meng, F.; Li, J.; Liu, C. Equilibrium Phase Relations of a SiO2–Al2O3–FeOx System with 10 wt % CaO Addition for the Production of Continuous Basalt Fibers. ACS Omega 2021, 6, 21465–21471. [Google Scholar] [CrossRef] [PubMed]

| Purity /% | Layer Size | Number of Layers | Oxygen Content /% | Sulphur Content /% | Specific Surface Area /m2/g |

|---|---|---|---|---|---|

| >95 | 5–50 | 6–10 | 0.5 | 0.5 | 100–300 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ji, S.; Li, Y.; Wu, X.; Liang, K.; Cao, X.; Yuan, X.; Shen, Q. Long-Term Water Stability Analysis of Graphene-Composite-Modified Permeable Asphalt Mixture. Materials 2025, 18, 5024. https://doi.org/10.3390/ma18215024

Ji S, Li Y, Wu X, Liang K, Cao X, Yuan X, Shen Q. Long-Term Water Stability Analysis of Graphene-Composite-Modified Permeable Asphalt Mixture. Materials. 2025; 18(21):5024. https://doi.org/10.3390/ma18215024

Chicago/Turabian StyleJi, Suzhan, Yu Li, Xu Wu, Ke Liang, Xiaojian Cao, Xiaoguang Yuan, and Qiangru Shen. 2025. "Long-Term Water Stability Analysis of Graphene-Composite-Modified Permeable Asphalt Mixture" Materials 18, no. 21: 5024. https://doi.org/10.3390/ma18215024

APA StyleJi, S., Li, Y., Wu, X., Liang, K., Cao, X., Yuan, X., & Shen, Q. (2025). Long-Term Water Stability Analysis of Graphene-Composite-Modified Permeable Asphalt Mixture. Materials, 18(21), 5024. https://doi.org/10.3390/ma18215024