Designing an Additively Manufactured Ti-Al-Fe Alloy with a Wide Process Window

Abstract

1. Introduction

2. Experimental

2.1. Composition Design

- (i)

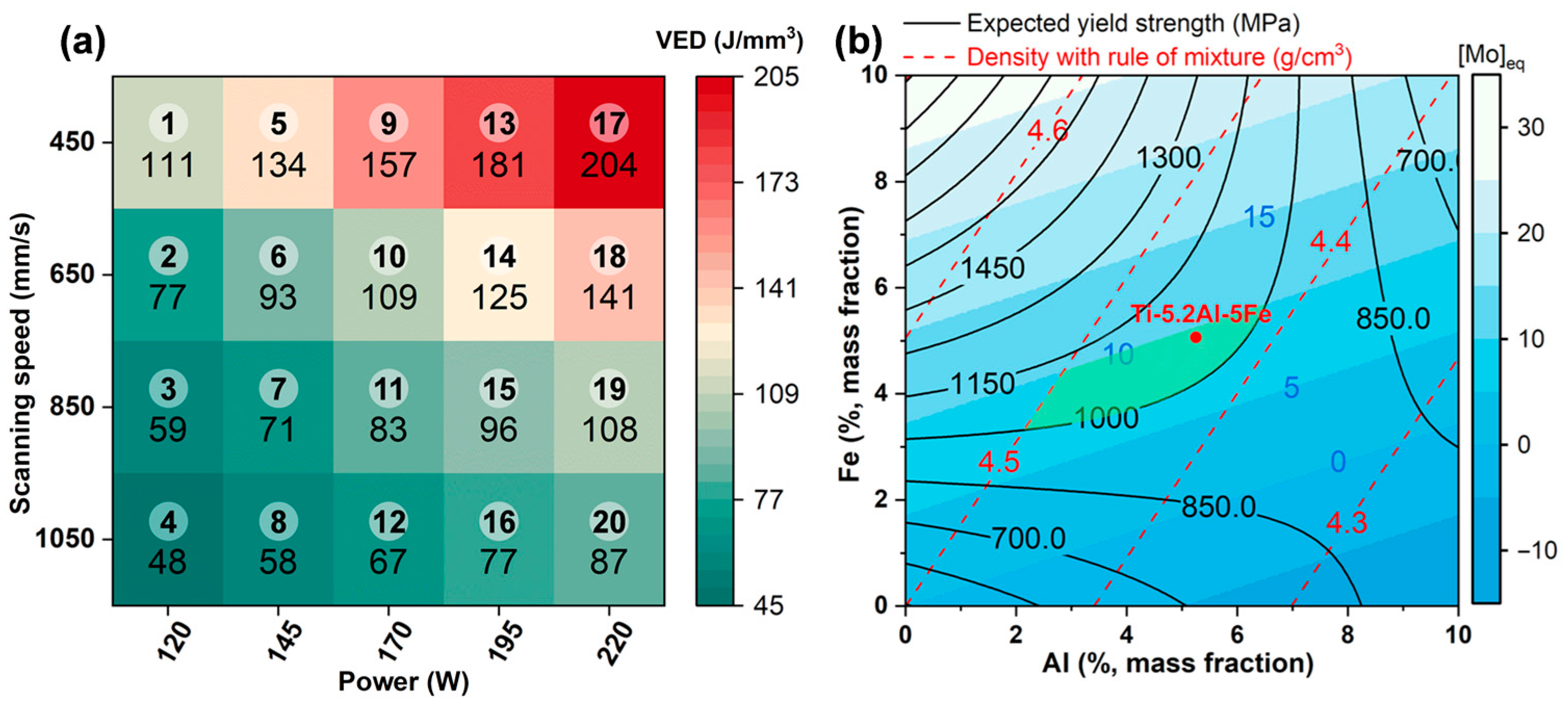

- Density minimization. The composition was selected based on the rule of mixtures [26] to achieve a theoretical density lower than that of pure Ti. In the contour map used for composition screening (Figure 1b), the red contour lines represent the theoretical density calculated according to the rule of mixtures.

- (ii)

- Yield strength optimization. Solid-solution strengthening is a core mechanism determining yield strength. This study utilized the yield strength prediction model proposed by Liang et al. [27]. Due to insufficient mechanical test data for Ti-Al-Fe alloys fabricated by additive manufacturing, the model used yield strength data from cast-formed alloys, which is a net-shape manufacturing process similar to AM. This model comprehensively considers the contributions of individual elements and their interactions, expressed as: , where M and N represent the elements in the alloy, represents the yield strength of the corresponding pure metal, represents the mole fraction of the element in the alloy, and represents the interaction parameter between the two elements in a binary alloy. Alloy compositions with a predicted yield strength greater than 1000 MPa were selected. In the composition diagram, the black contour lines intuitively illustrate the distribution of yield strength predicted based on this solid-solution-strengthening model.

- (iii)

- β-phase stability. To obtain a dual-phase titanium alloy, compositions with a Mo equivalent [Mo]eq slightly below the lower stability limit for the β phase (10 wt.%) [28] were selected. The varying shades of blue background in the composition diagram directly correspond to the values of the molybdenum equivalent, which is used to evaluate the stability of the β phase.

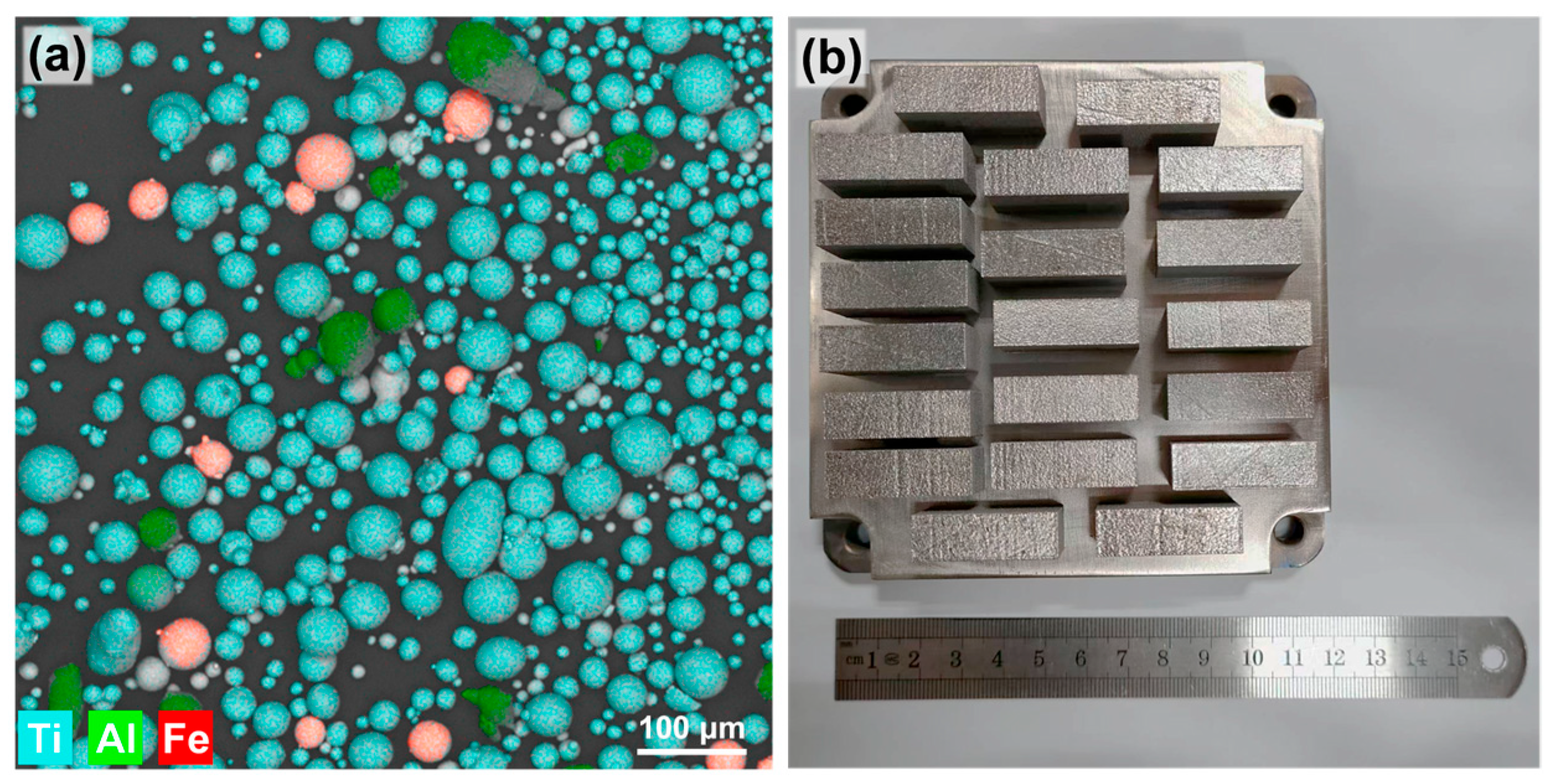

2.2. Materials Processing

2.3. Microstructural Characterization

2.4. Porosity Analysis

2.5. Mechanical Testing

3. Results and Discussion

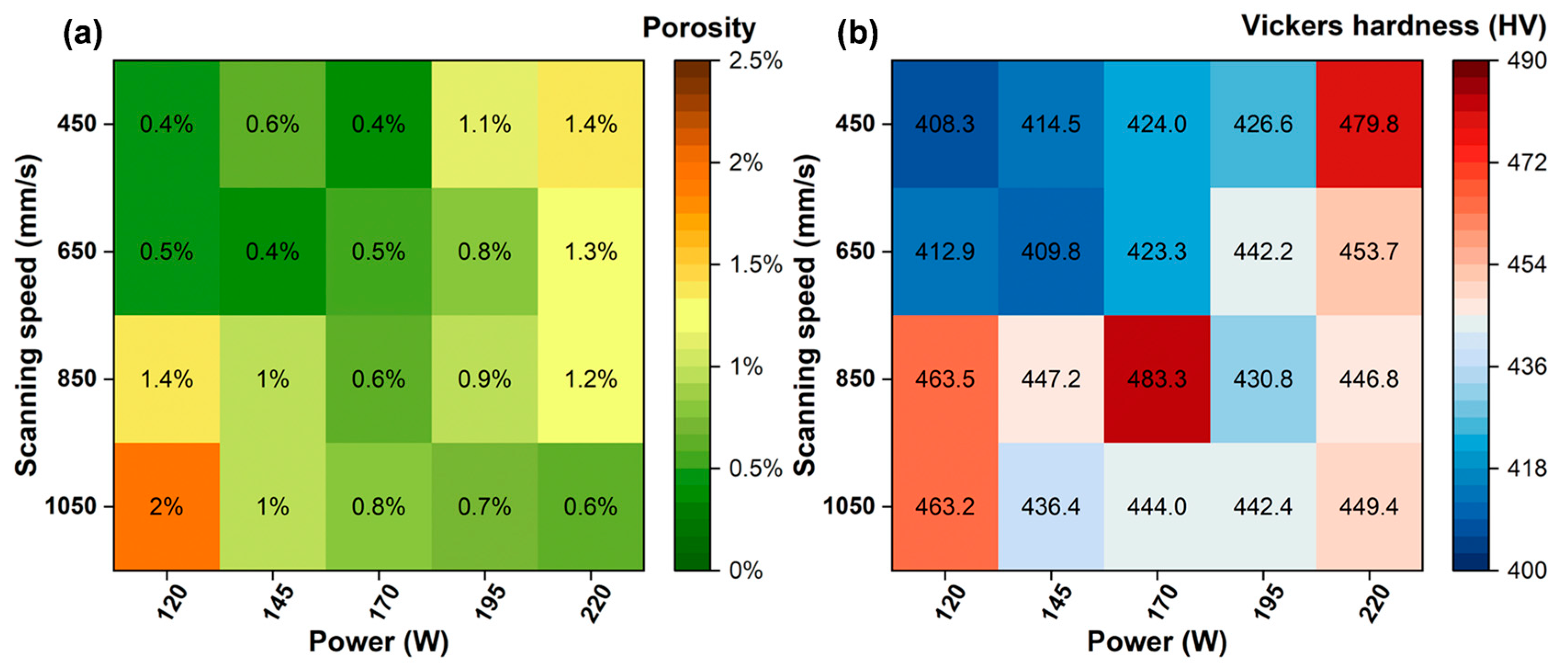

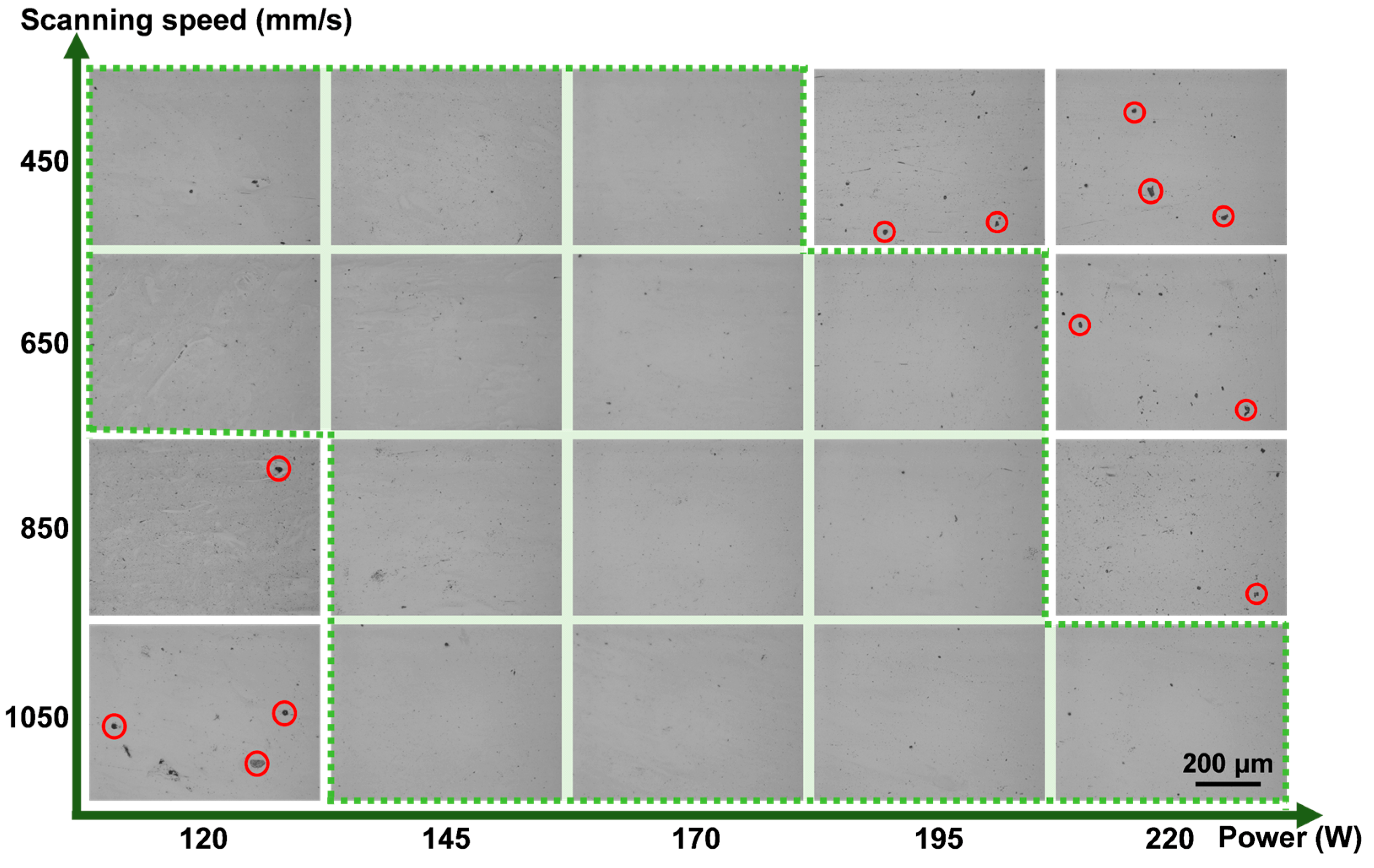

3.1. Formability of LPBF-Fabricated Ti-Al-Fe Alloy

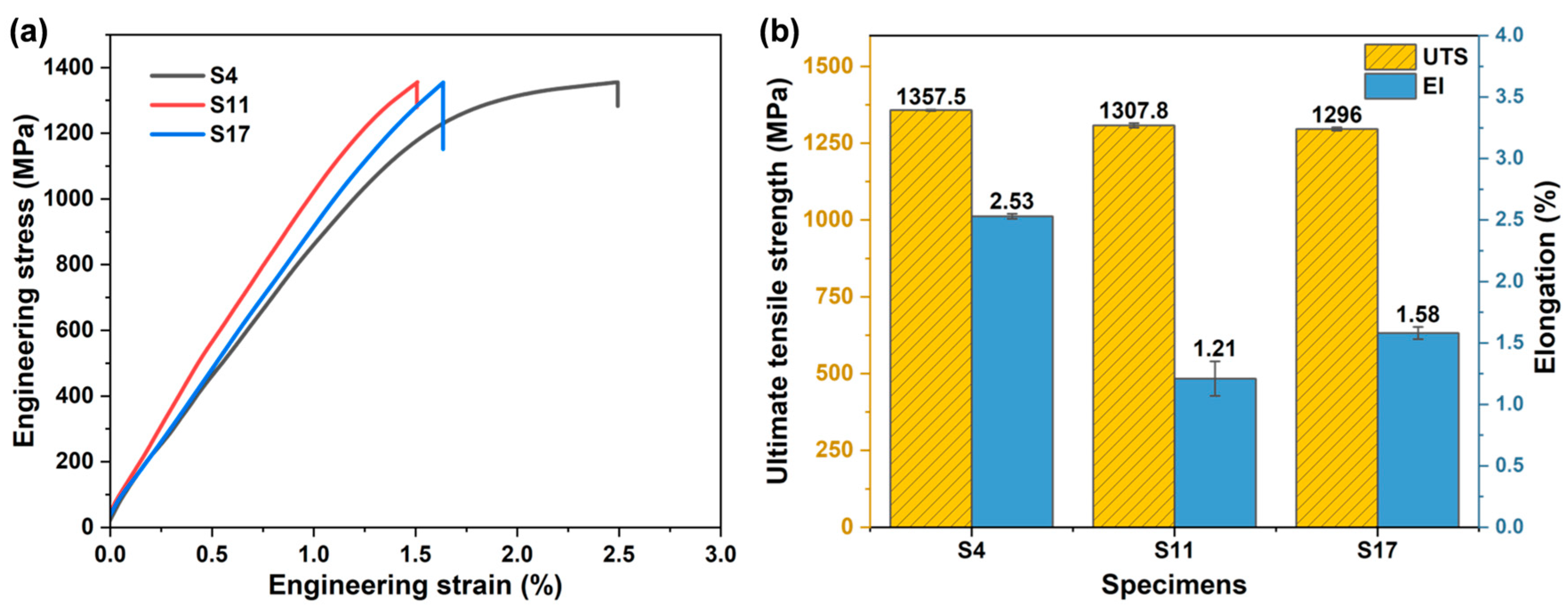

3.2. Tensile Properties of LPBF-Fabricated Ti-Al-Fe Alloy

3.3. Effect of Volumetric Energy Density on Microstructure

4. Conclusions

- (1)

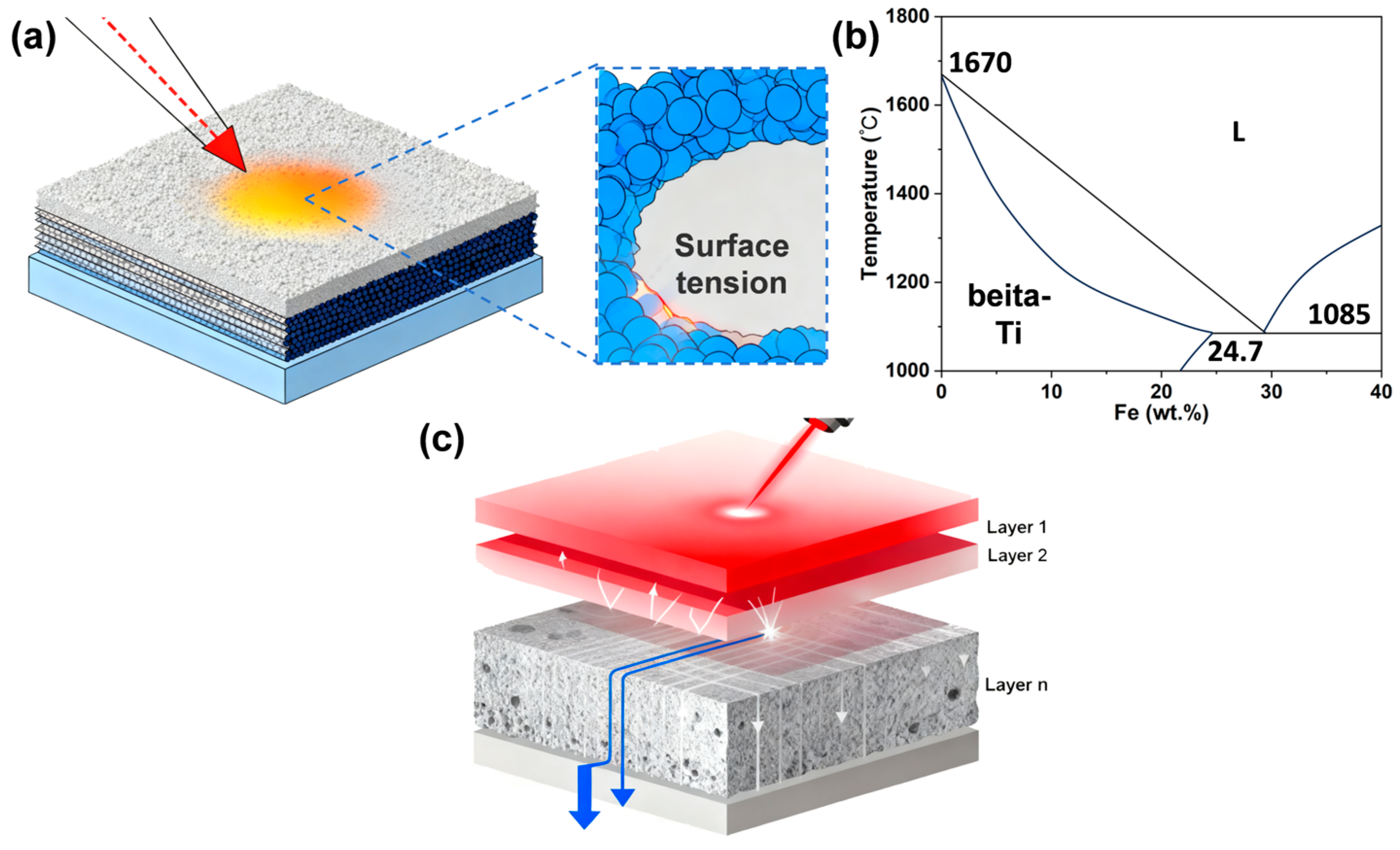

- The Ti-5.2Al-5Fe alloy, designed based on criteria of density, strength, and β-phase stability, achieved high densification (porosity generally ≤ 2%) across a wide energy density range of 48–204 J/mm3. The synergistic effects of Al (improving melt pool wettability) and Fe (lowering the liquidus temperature) collaboratively broadened the process window.

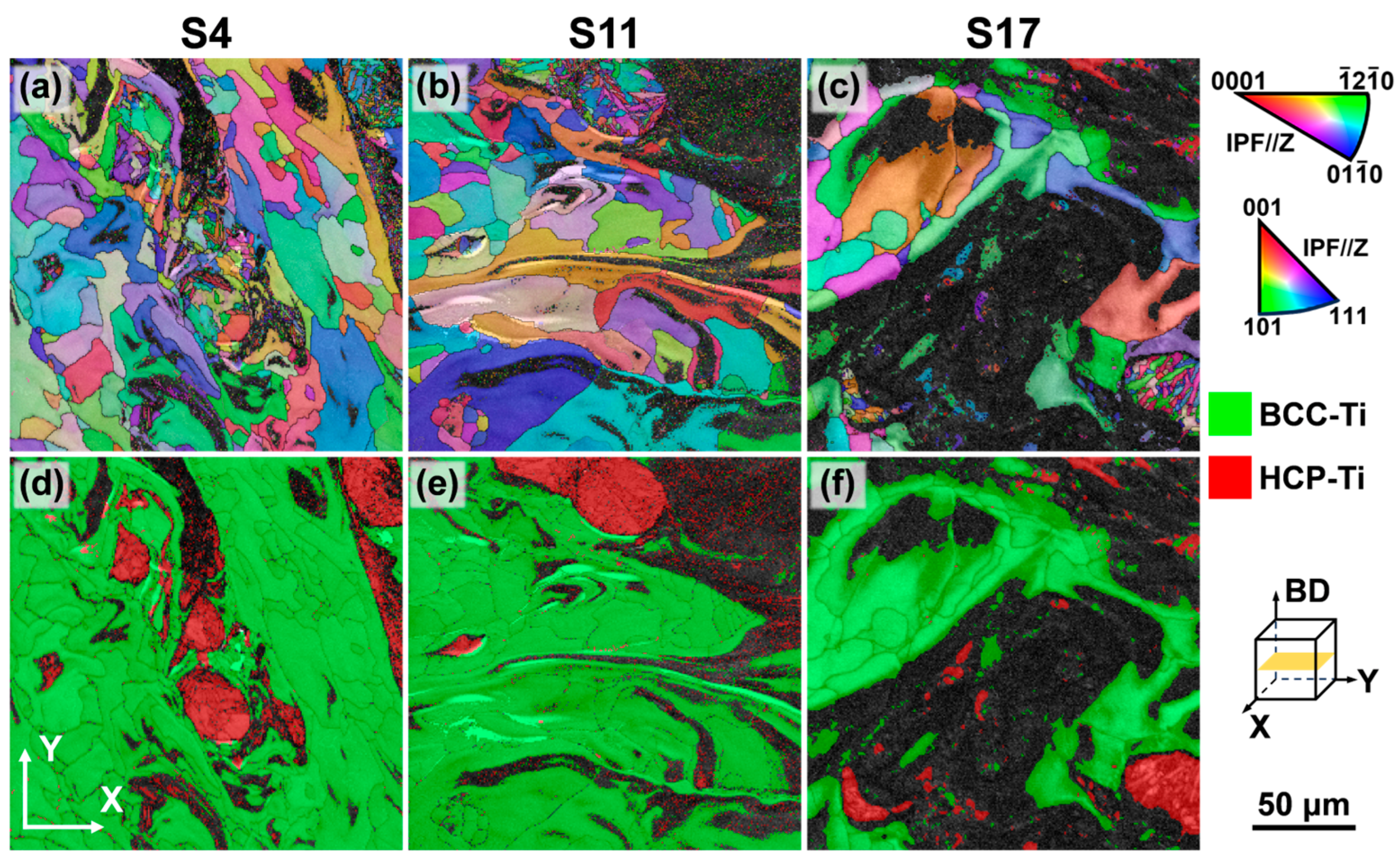

- (2)

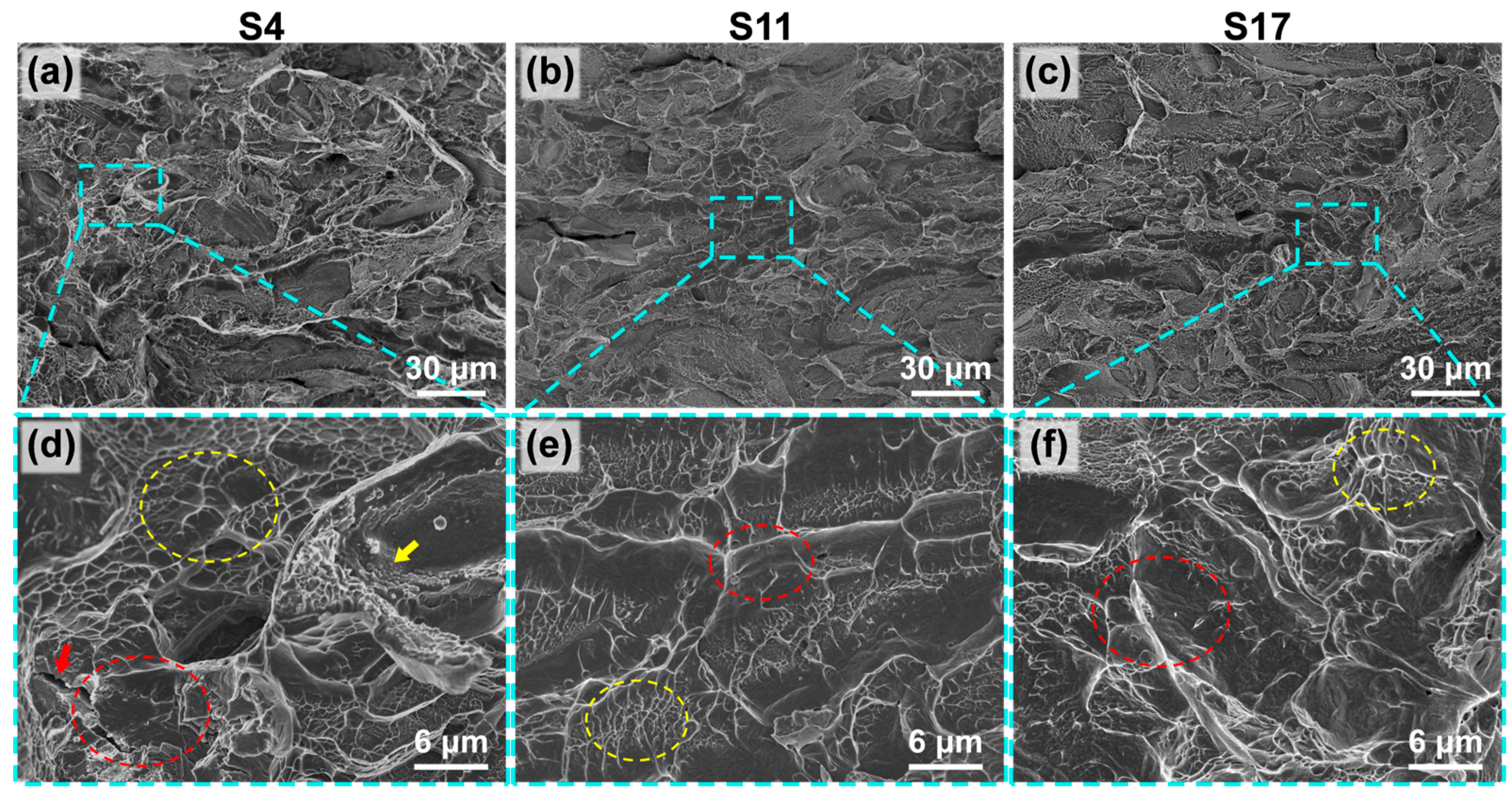

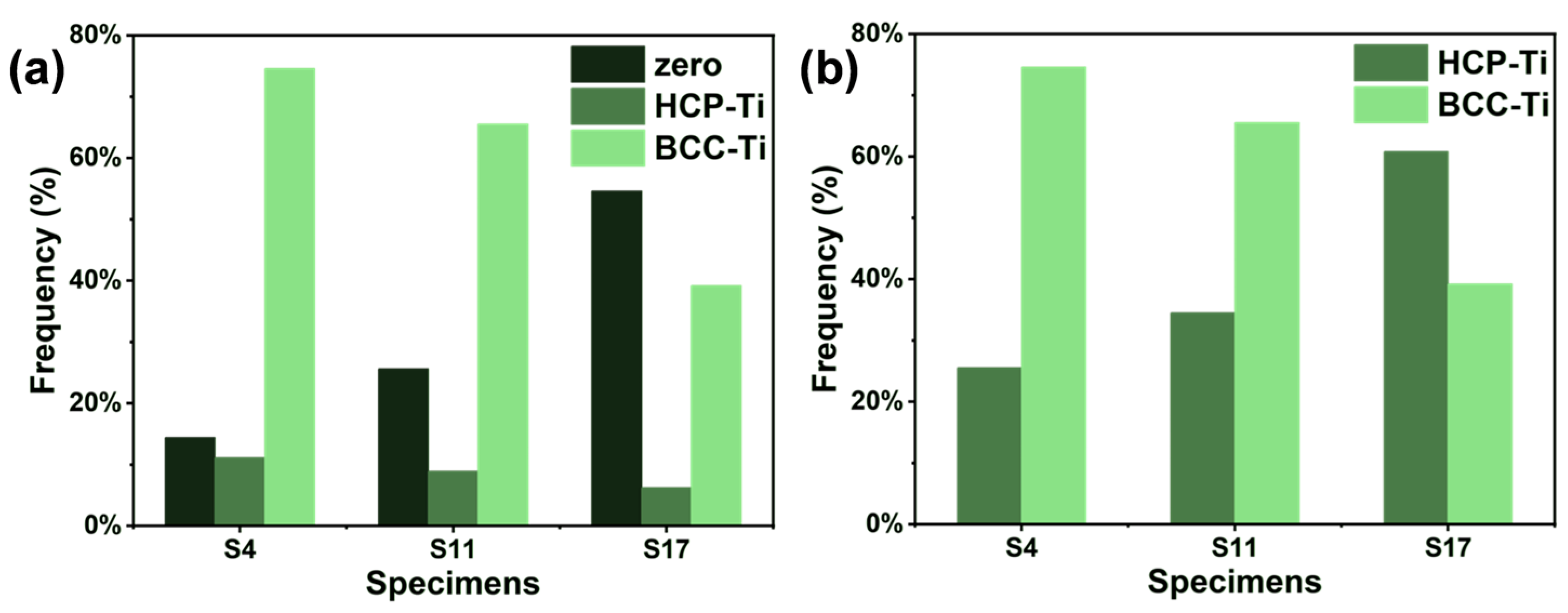

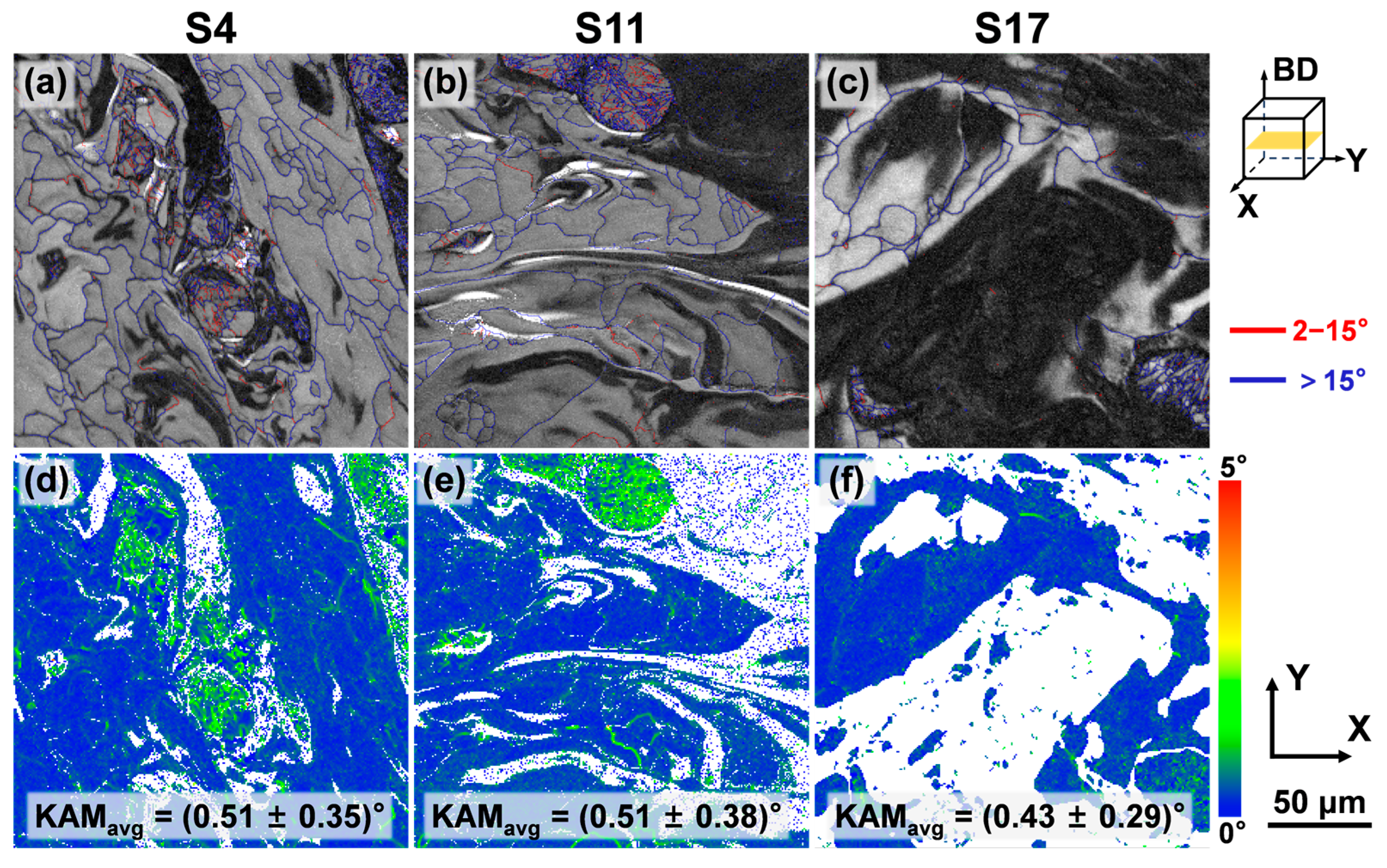

- The as-deposited microstructure consisted of α + β dual phases, with the α-phase content increasing from 25.4% to 60.8% as the energy density rose. EBSD analysis revealed that the α-phase acts as the primary carrier of micro-residual stress, as evidenced by a high fraction of “zero-solution” points, a high density of low-angle grain boundaries, and elevated KAM values, all indicating significant lattice distortion within the α-phase.

- (3)

- The alloy exhibited high strength but low ductility in the as-deposited state, with tensile strength exceeding 1290 MPa but elongation generally below 2.6%. The high strength originated from heterogeneous structures and solid-solution strengthening, while the limited ductility was primarily attributed to residual stress concentration in the α-phase regions.

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhang, D.; Qiu, D.; Gibson, M.A.; Zheng, Y.; Fraser, H.L.; StJohn, D.H.; Easton, M.A. Additive Manufacturing of Ultrafine-Grained High-Strength Titanium Alloys. Nature 2019, 576, 91–95. [Google Scholar] [CrossRef] [PubMed]

- Agbedor, S.-O.; Wu, H.; Ren, Y.; Liang, L.; Yang, D.; Liu, B.; Liu, Y.; Baker, I. A Two-Decade Odyssey in Fusion-Based Additive Manufacturing of Titanium Alloys and Composites. Appl. Mater. Today 2024, 39, 102242. [Google Scholar] [CrossRef]

- Wang, Q.; Xu, F.; Liu, X.; Ren, Y.; Song, M.; Liu, S.; Baker, I.; Zhou, K.; Wu, H. Effect of Fe Content on Tensile Properties of TA15 Alloy with Equiaxed Microstructure Produced by Laser Directed Energy Deposition. Virtual Phys. Prototy. 2025, 20, e2499479. [Google Scholar] [CrossRef]

- Zhang, K.; Chen, Y.; Marussi, S.; Fan, X.; Fitzpatrick, M.; Bhagavath, S.; Majkut, M.; Lukic, B.; Jakata, K.; Rack, A.; et al. Pore Evolution Mechanisms during Directed Energy Deposition Additive Manufacturing. Nat. Commun. 2024, 15, 1715. [Google Scholar] [CrossRef]

- Yu, T.; Zhao, J. Quantifying the Mechanisms of Keyhole Pore Evolutions and the Role of Metal-Vapor Condensation in Laser Powder Bed Fusion. Addit. Manuf. 2023, 72, 103642. [Google Scholar] [CrossRef]

- Cai, L.; Ren, Y.; Liu, X.; Song, M.; Baker, I.; Wu, H. Achieving Uniform Hardness in Additively Manufactured TA15 Alloy via Ni or Cu Additions. Mater. Res. Lett. 2024, 13, 9–16. [Google Scholar] [CrossRef]

- Du, J.; Ren, Y.; Liu, X.; Xu, F.; Wang, X.; Zhou, R.; Baker, I.; Wu, H. Microstructural Evolution, Mechanical Properties and Tribological Behavior of B4C-Reinforced Ti in Situ Composites Produced by Laser Powder Bed Fusion. Materials 2023, 16, 4890. [Google Scholar] [CrossRef]

- Wang, Q.; Liu, X.; Ren, Y.; Song, M.; Baker, I.; Wu, H. Microstructural Evolution and Cryogenic and Ambient Temperature Deformation Behavior of the Near-α Titanium Alloy TA15 Fabricated by Laser Powder Bed Fusion. J. Alloys Compd. 2024, 1001, 175075. [Google Scholar] [CrossRef]

- Zhang, C.; Bao, X.; Hao, M.; Chen, W.; Zhang, D.; Wang, D.; Zhang, J.; Liu, G.; Sun, J. Hierarchical Nano-Martensite-Engineered a Low-Cost Ultra-Strong and Ductile Titanium Alloy. Nat. Commun. 2022, 13, 5966. [Google Scholar] [CrossRef]

- Cao, L. Mesoscopic-Scale Numerical Investigation Including the Inuence of Process Parameters on LPBFMulti-Layer Multi-Path Formation. Cmes-Comp. Model. Eng. 2021, 126, 5–23. [Google Scholar] [CrossRef]

- Ren, Y.; Han, B.; Wu, H.; Wang, J.; Liu, B.; Wei, B.; Jiao, Z.; Baker, I. Copper Segregation-Mediated Formation of Nanotwins and 9R Phase in Titanium Alloys Produced by Laser Powder Bed Fusion. Scripta Mater. 2023, 224, 115115. [Google Scholar] [CrossRef]

- Liang, Q.; Cai, L.; Wang, Q.; Wang, Y.; Liang, X.; Shan, Q.; Wu, H. Laser Directed Energy Deposition of TA15/TiAl Bimetallic Structure: Laser Power Optimization, Microstructure Evolution and Mechanical Performance. Smart Mate Manuf. 2025, 3, 100087. [Google Scholar] [CrossRef]

- Ren, Y.; Li, Z.; Wang, Q.; Liu, J.; Zhang, L.; Song, M.; Liu, S.; Guo, S.; Jiao, Z.; Baker, I.; et al. Effect of Nb Content on Microstructural Evolution, Mechanical and Tribological Properties of in Situ Alloyed Copper-Modified Titanium Produced Using Laser Powder Bed Fusion. J. Mater. Sci. Technol. 2025, 219, 257–270. [Google Scholar] [CrossRef]

- Zhu, Y.; Wu, X. Heterostructured Materials. Prog. Mater. Sci. 2023, 131, 101019. [Google Scholar] [CrossRef]

- Song, T.; Chen, Z.; Cui, X.; Lu, S.; Chen, H.; Wang, H.; Dong, T.; Qin, B.; Chan, K.C.; Brandt, M.; et al. Strong and Ductile Titanium–Oxygen–Iron Alloys by Additive Manufacturing. Nature 2023, 618, 63–68. [Google Scholar] [CrossRef]

- Takeda, O.; Ouchi, T.; Okabe, T.H. Recent Progress in Titanium Extraction and Recycling. Metall. Mater. Trans. B 2020, 51, 1315–1328. [Google Scholar] [CrossRef]

- Fu, Y.; Xiao, W.; Zhao, S.; Ren, L.; Wang, J.; Rong, J.; Li, J.; Zhao, X.; Ma, C. Substantially Strengthening a Dual-Phase Titanium Alloy by Moderate Oxygen Doping. Scripta Mater. 2023, 226, 115236. [Google Scholar] [CrossRef]

- Ding, W.; Tao, Q.; Liu, C.; Chen, G.; Yoo, S.; Cai, W.; Cao, P.; Jia, B.; Wu, H.; Zhang, D.; et al. Lean Design of a Strong and Ductile Dual-Phase Titanium–Oxygen Alloy. Nat. Mater. 2025, 24, 506–512. [Google Scholar] [CrossRef]

- Chen, Z.; Li, H.; Wang, Z.; Xu, C.; Zhang, X.; Cheng, J.; Fan, J.; Kong, J.; Wang, K.; Peng, Y. A Novel High-Strength and High-Toughness Dual-Phase Titanium Alloy Fabricated by CMT-DED. Virtual Phys. Prototy. 2025, 20, e2476009. [Google Scholar] [CrossRef]

- Wu, Z.; Turner, R.; Qi, M.; Shi, L.; Wang, M.; Wang, F.; Gao, Z.; Chiu, Y.; Zhang, Z. Effect of Phase Boundary on the Critical Resolved Shear Stress and Dislocation Behavior of Dual-Phase Titanium Alloy. Acta Mater. 2024, 275, 120051. [Google Scholar] [CrossRef]

- Chong, Y.; Gholizadeh, R.; Tsuru, T.; Zhang, R.; Inoue, K.; Gao, W.; Godfrey, A.; Mitsuhara, M.; Morris, J.W.; Minor, A.M.; et al. Grain Refinement in Titanium Prevents Low Temperature Oxygen Embrittlement. Nat. Commun. 2023, 14, 404. [Google Scholar] [CrossRef] [PubMed]

- Chong, Y.; Zhang, R.; Hooshmand, M.S.; Zhao, S.; Chrzan, D.C.; Asta, M.; Morris, J.W.; Minor, A.M. Elimination of Oxygen Sensitivity in α-Titanium by Substitutional Alloying with Al. Nat. Commun. 2021, 12, 6158. [Google Scholar] [CrossRef]

- Huang, K.; Xu, F.; Liu, X.; Liu, S.; Wang, Q.; Baker, I.; Song, M.; Wu, H. Microstructure, Mechanical, and Tribological Properties of Nb-Doped TiAl Alloys Fabricated via Laser Metal Deposition. Materials 2024, 17, 4260. [Google Scholar] [CrossRef]

- Bermingham, M.J.; McDonald, S.D.; StJohn, D.H.; Dargusch, M.S. Beryllium as a Grain Refiner in Titanium Alloys. J. Alloy Compd. 2009, 481, L20–L23. [Google Scholar] [CrossRef]

- Zhang, T.; Huang, Z.; Yang, T.; Kong, H.; Luan, J.; Wang, A.; Wang, D.; Kuo, W.; Wang, Y.; Liu, C.-T. In Situ Design of Advanced Titanium Alloy with Concentration Modulations by Additive Manufacturing. Science 2021, 374, 478–482. [Google Scholar] [CrossRef]

- Cai, C.; Wang, B.; Yin, W.; Xu, Z.; Wang, R.; He, X. A New Algorithm to Generate Non-Uniformly Dispersed Representative Volume Elements of Composite Materials with High Volume Fractions. Mater. Design 2022, 219, 110750. [Google Scholar] [CrossRef]

- Liang, Z.; Kattner, U.; Campbell, C. Design Strategy for Additive Manufacturing Ti-Al-Fe Alloys with Calculation of Phase Diagram Method. Integr. Mater. Manuf. Innov. 2021, 10, 588–596. [Google Scholar] [CrossRef] [PubMed]

- Banerjee, D.; Williams, J.C. Perspectives on Titanium Science and Technology. Acta Mater. 2013, 61, 844–879. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials—Tensile Testing—Part 1: Method of Test at Room Temperature. Standard Press of China: Beijing, China, 2021.

- Egry, I.; Ricci, E.; Novakovic, R.; Ozawa, S. Surface Tension of Liquid Metals and Alloys—Recent Developments. Adv. Colloid. Interfac. 2010, 159, 198–212. [Google Scholar] [CrossRef]

- Wessing, J.J.; Brillo, J. Density, Molar Volume, and Surface Tension of Liquid Al-Ti. Metall. Mater. Trans. A 2017, 48, 868–882. [Google Scholar] [CrossRef]

- Min, J.; Guo, Y.; Niu, J.; Cao, J.; Sun, Z.; Chang, H. The Characteristic of Fe as a β-Ti Stabilizer in Ti Alloys. Materials 2021, 14, 7516. [Google Scholar] [CrossRef]

- Cacciamani, G.; De Keyzer, J.; Ferro, R.; Klotz, U.E.; Lacaze, J.; Wollants, P. Critical Evaluation of the Fe–Ni, Fe–Ti and Fe–Ni–Ti Alloy Systems. Intermetallics 2006, 14, 1312–1325. [Google Scholar] [CrossRef]

- Cook, P.S.; Murphy, A.B. Simulation of Melt Pool Behaviour during Additive Manufacturing: Underlying Physics and Progress. Addit. Manuf. 2020, 31, 100909. [Google Scholar] [CrossRef]

- Fang, Q.; Zhao, P.; Li, J.; Wu, H.; Peng, J. Unveiling Temperature Distribution and Residual Stress Evolution of Additively Manufactured Ti6Al4V Alloy: A Thermomechanical Finite Element Simulation. Metals 2025, 15, 83. [Google Scholar] [CrossRef]

- Gong, D.L.; Wang, H.L.; Obbard, E.G.; Li, S.J.; Yang, R.; Hao, Y.L. Tuning Thermal Expansion by a Continuing Atomic Rearrangement Mechanism in a Multifunctional Titanium Alloy. J. Mater. Sci. Technol. 2021, 80, 234–243. [Google Scholar] [CrossRef]

- Zheng, D.; Li, Z.; Jiang, Y.; Li, R.; Wu, Y.; Tu, Y.; Cheng, X.; Fu, P.; Peng, L.; Tang, H. Effect of Multiple Thermal Cycles on the Microstructure Evolution of GA151K Alloy Fabricated by Laser-Directed Energy Deposition. Addit. Manuf. 2022, 57, 102957. [Google Scholar] [CrossRef]

- Fan, J.; Wang, W.; Zhu, Y.; Godfrey, A.; Che, H.; Huang, X. Depth-Dependent Microstructural Observations Reveal the Role of Thermal Cycling on the Formation of a Hierarchical Dislocation Cell Structure during Selective Laser Melting of 316L Stainless Steel. Acta Mater. 2025, 296, 121271. [Google Scholar] [CrossRef]

- Keist, J.S.; Palmer, T.A. Development of Strength-Hardness Relationships in Additively Manufactured Titanium Alloys. Mat. Sci. Eng. A-Struct. 2017, 693, 214–224. [Google Scholar] [CrossRef]

- Chen, S.; Gao, H.; Zhang, Y.; Wu, Q.; Gao, Z.; Zhou, X. Review on Residual Stresses in Metal Additive Manufacturing: Formation Mechanisms, Parameter Dependencies, Prediction and Control Approaches. J. Mater. Res. Technol. 2022, 17, 2950–2974. [Google Scholar] [CrossRef]

- Ahmadikia, B.; Arul Kumar, M.; Beyerlein, I.J. Effect of Neighboring Grain Orientation on Strain Localization in Slip Bands in HCP Materials. Int. J. Plast. 2021, 144, 103026. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, K.; Qi, X.; Liu, H.; Li, A.; Ding, H.; Fujii, H.; Liu, W. Superplastic Behavior of a Metastable β-Type Ti Alloy Governed by Grain Size: Microstructure Evolution and Underlying Deformation Mechanism. Mat. Sci. Eng. A-Struct. 2024, 915, 147212. [Google Scholar] [CrossRef]

- Beladi, H.; Chao, Q.; Rohrer, G.S. Variant Selection and Intervariant Crystallographic Planes Distribution in Martensite in a Ti–6Al–4V Alloy. Acta Mater. 2014, 80, 478–489. [Google Scholar] [CrossRef]

- Shi, Q.; Zhong, H.; Loisnard, D.; Nowell, M.; Mollens, M.; Chen, Z.; Wang, H.; Roux, S. Towards Measuring Absolute Residual Stress by HR-EBSD with Simulated Reference Patterns. Mater. Charact. 2024, 218, 114508. [Google Scholar] [CrossRef]

- Chen, S.; Zhang, Y.; Wu, Q.; Gao, H.; Gao, Z.; Li, X. Effect of Solid-State Phase Transformation on Residual Stress of Selective Laser Melting Ti6Al4V. Mat. Sci. Eng. A-Struct. 2021, 819, 141299. [Google Scholar] [CrossRef]

- Liu, Q.; Fang, L.; Xiong, Z.; Yang, J.; Tan, Y.; Liu, Y.; Zhang, Y.; Tan, Q.; Hao, C.; Cao, L.; et al. The Response of Dislocations, Low Angle Grain Boundaries and High Angle Grain Boundaries at High Strain Rates. Mat. Sci. Eng. A-Struct. 2021, 822, 141704. [Google Scholar] [CrossRef]

- Mironov, S.; Ozerov, M.; Kalinenko, A.; Stepanov, N.; Plekhov, O.; Sikhamov, R.; Ventzke, V.; Kashaev, N.; Salishchev, G.; Semiatin, L.; et al. On the Relationship between Microstructure and Residual Stress in Laser-Shock-Peened Ti-6Al-4V. J. Alloys Compd. 2022, 900, 163383. [Google Scholar] [CrossRef]

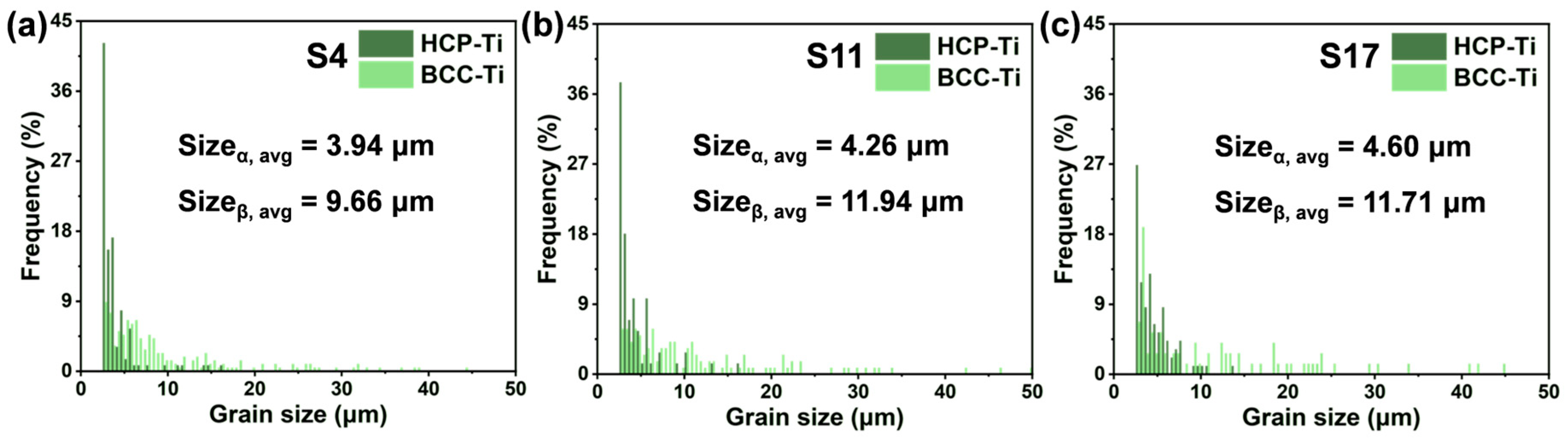

| Parameters | S4 | S11 | S17 | ||||||

|---|---|---|---|---|---|---|---|---|---|

| α | β | Entirety | α | β | Entirety | α | β | Entirety | |

| Fraction of area (%) | 25.4 | 74.6 | - | 34.5 | 65.5 | - | 60.8 | 39.2 | - |

| Average grain size (μm) | 3.94 | 9.66 | - | 4.26 | 11.94 | - | 4.60 | 11.71 | - |

| Fraction of LAGBs (%) | - | - | 14.4 | - | - | 16.0 | - | - | 7.5 |

| KAM value (°) | 0.80 | 0.46 | 0.51 | 0.78 | 0.48 | 0.51 | 0.57 | 0.42 | 0.43 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cai, L.; Hong, Z.; Xu, F.; Liu, X.; Zhao, Z.; Peng, J.; Fang, Q.; Wu, H. Designing an Additively Manufactured Ti-Al-Fe Alloy with a Wide Process Window. Materials 2025, 18, 4986. https://doi.org/10.3390/ma18214986

Cai L, Hong Z, Xu F, Liu X, Zhao Z, Peng J, Fang Q, Wu H. Designing an Additively Manufactured Ti-Al-Fe Alloy with a Wide Process Window. Materials. 2025; 18(21):4986. https://doi.org/10.3390/ma18214986

Chicago/Turabian StyleCai, Leyu, Zixuan Hong, Feng Xu, Xinyan Liu, Ziyuan Zhao, Jing Peng, Qihong Fang, and Hong Wu. 2025. "Designing an Additively Manufactured Ti-Al-Fe Alloy with a Wide Process Window" Materials 18, no. 21: 4986. https://doi.org/10.3390/ma18214986

APA StyleCai, L., Hong, Z., Xu, F., Liu, X., Zhao, Z., Peng, J., Fang, Q., & Wu, H. (2025). Designing an Additively Manufactured Ti-Al-Fe Alloy with a Wide Process Window. Materials, 18(21), 4986. https://doi.org/10.3390/ma18214986