All-Solution-Processable Robust Carbon Nanotube Photo-Thermoelectric Devices for Multi-Modal Inspection Applications

Abstract

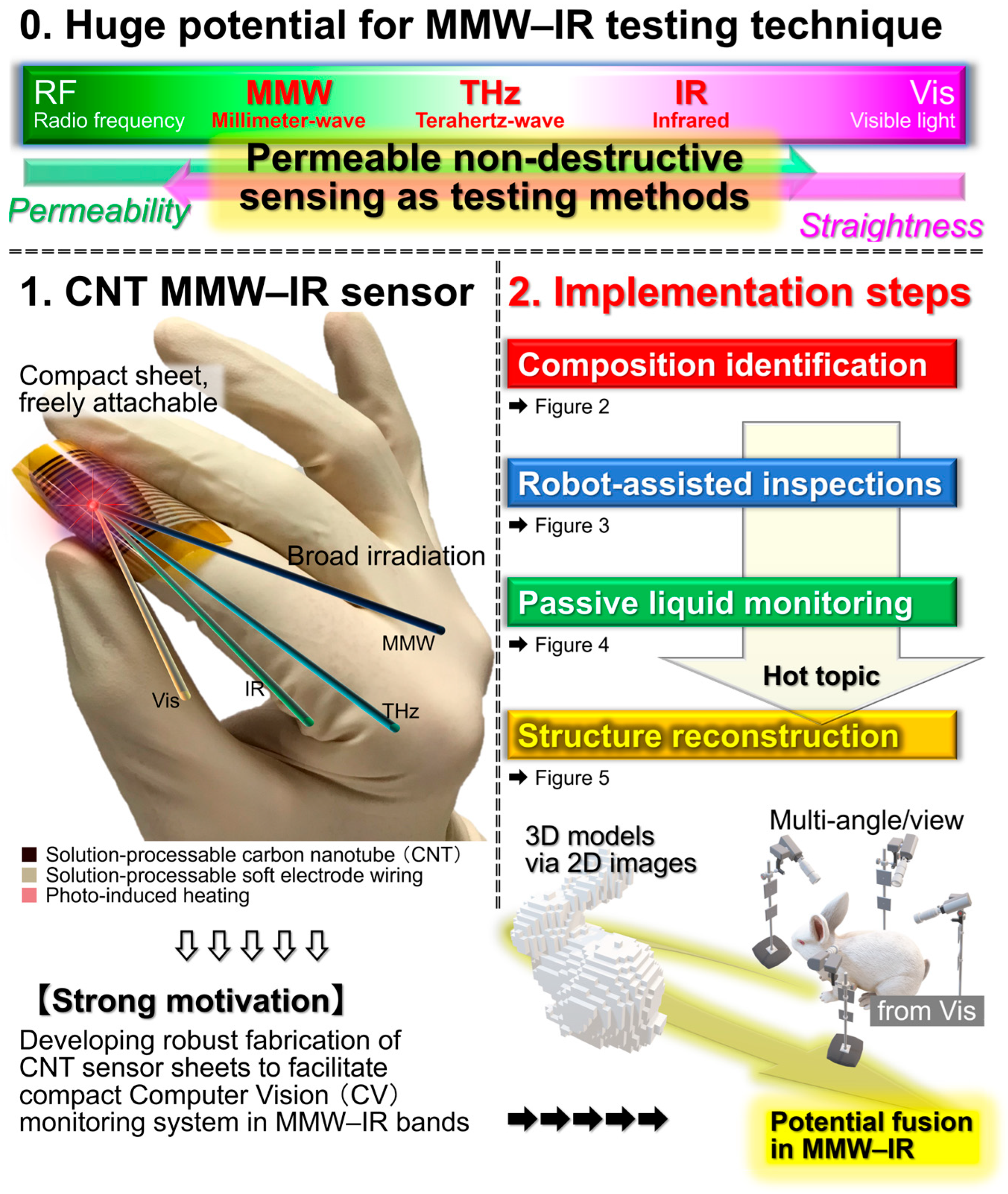

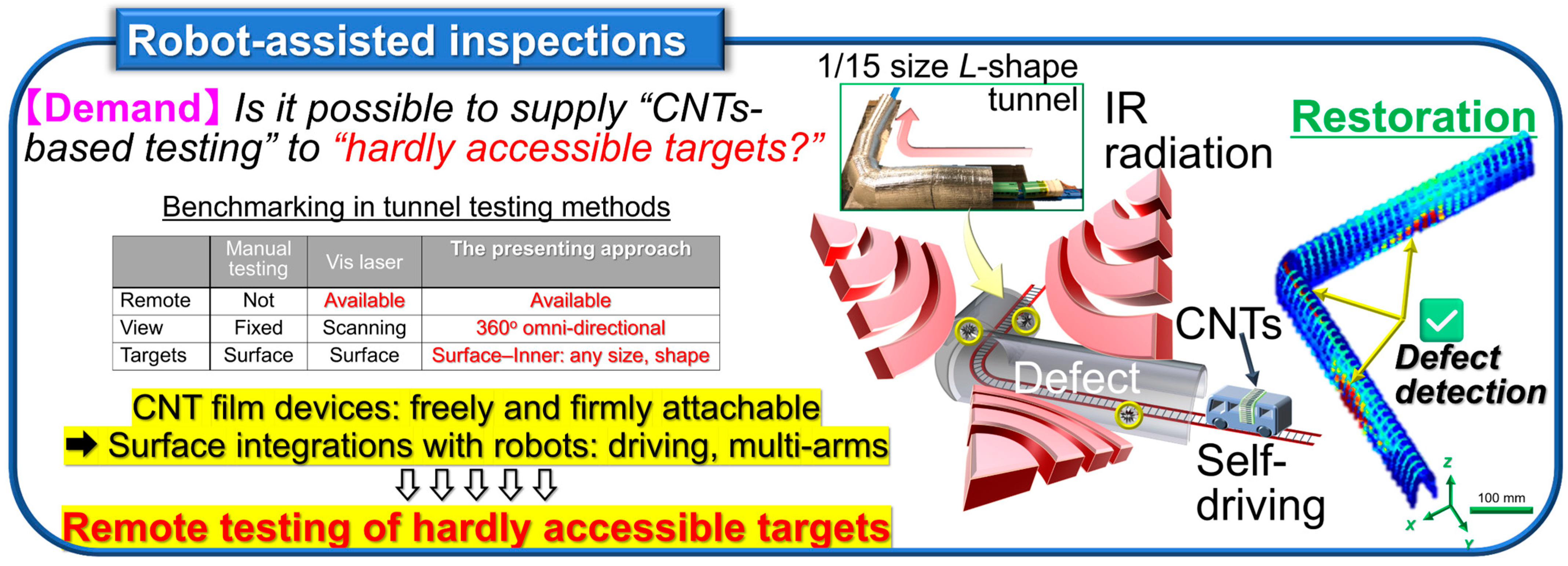

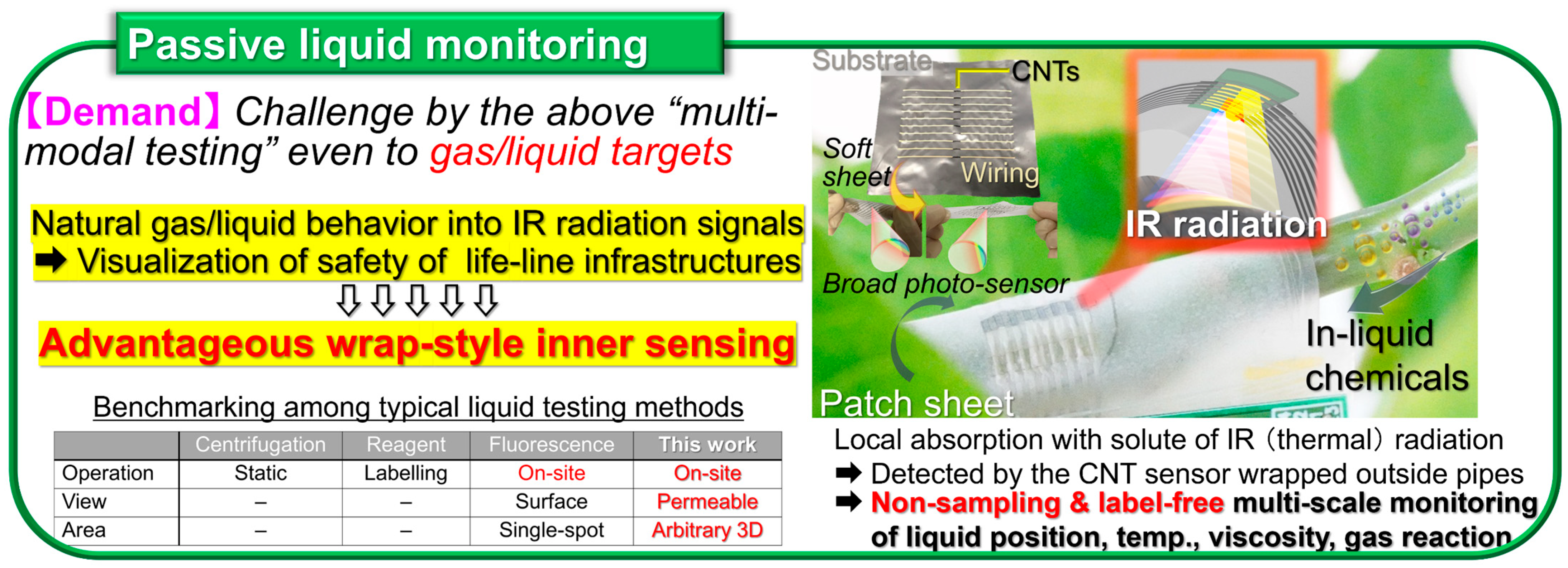

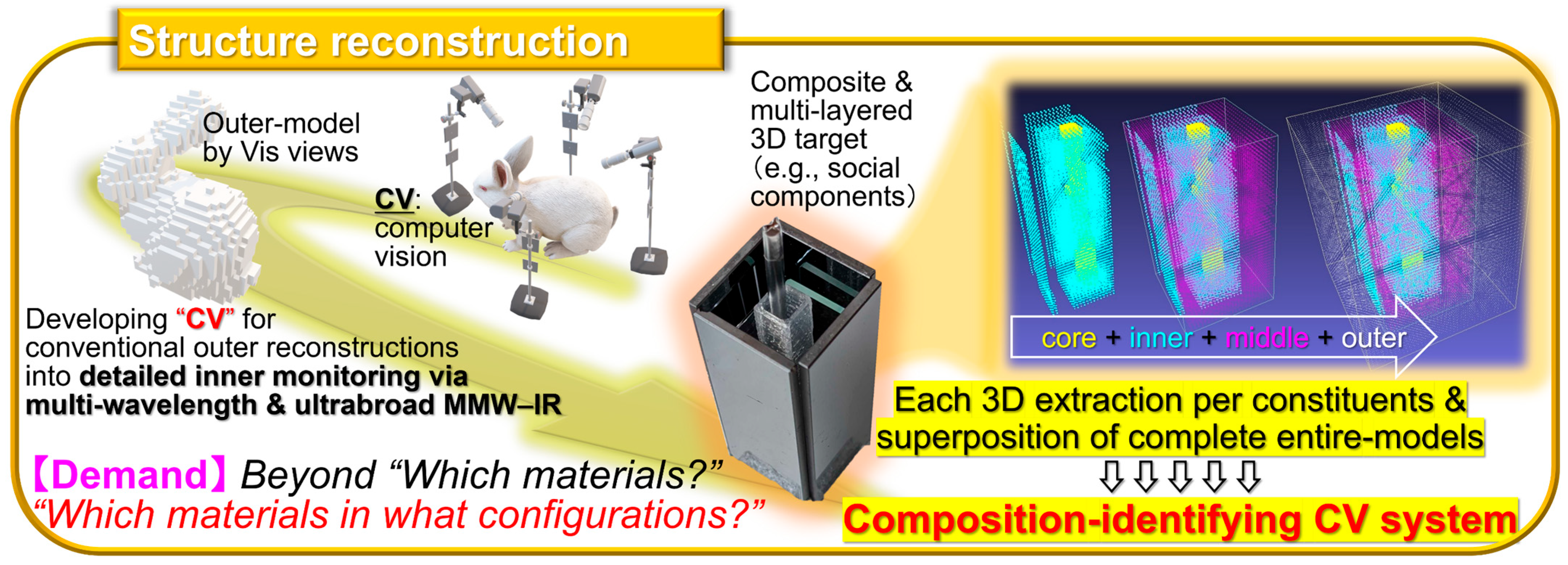

1. Introduction

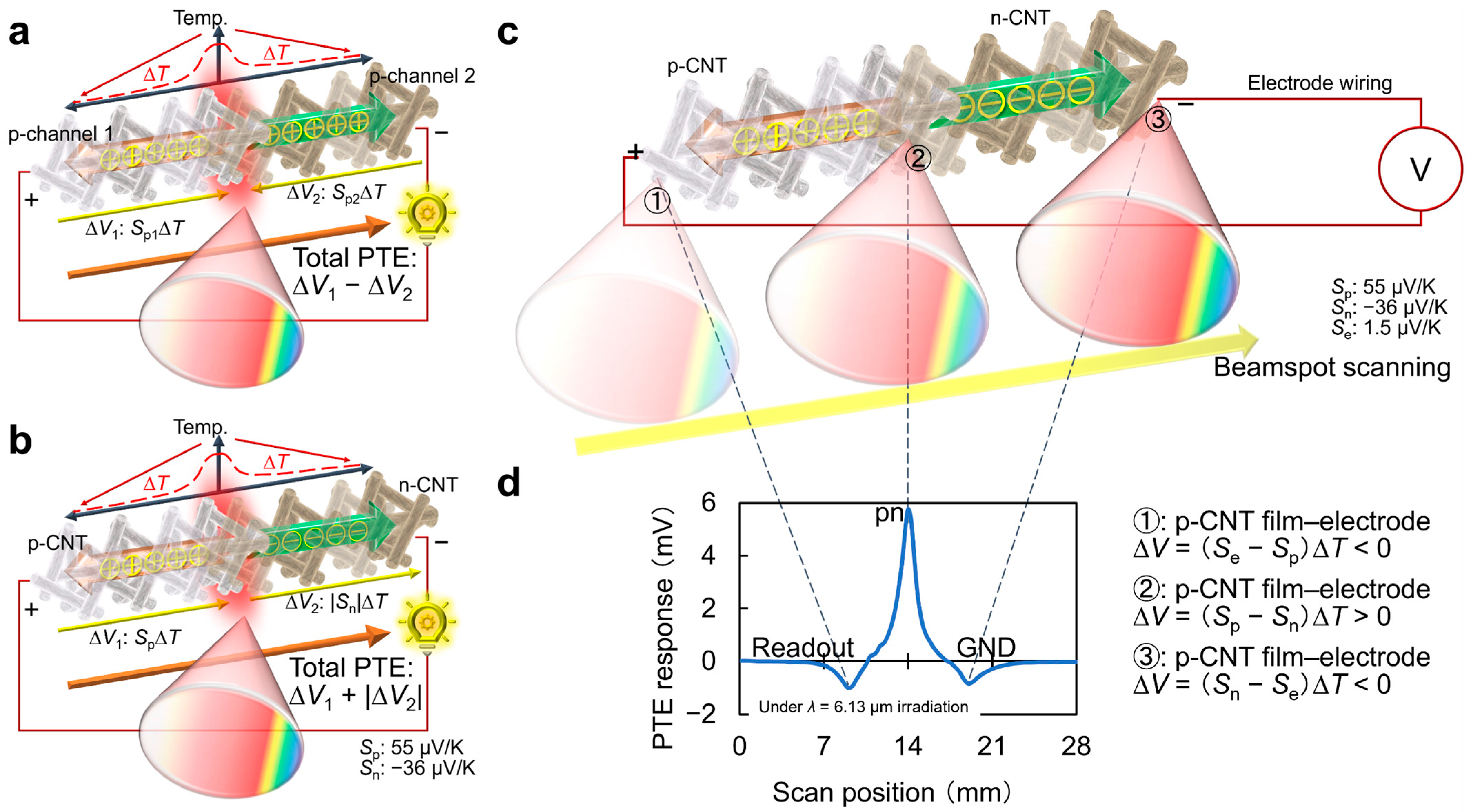

2. Device Mechanism

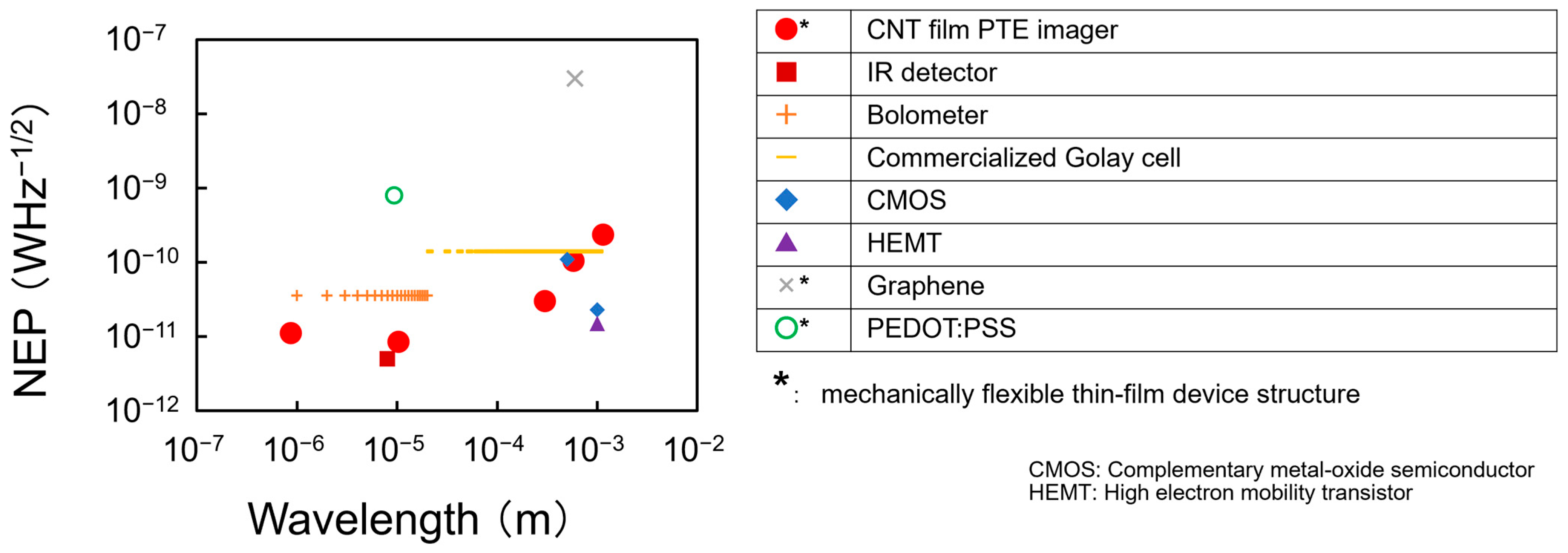

3. Results

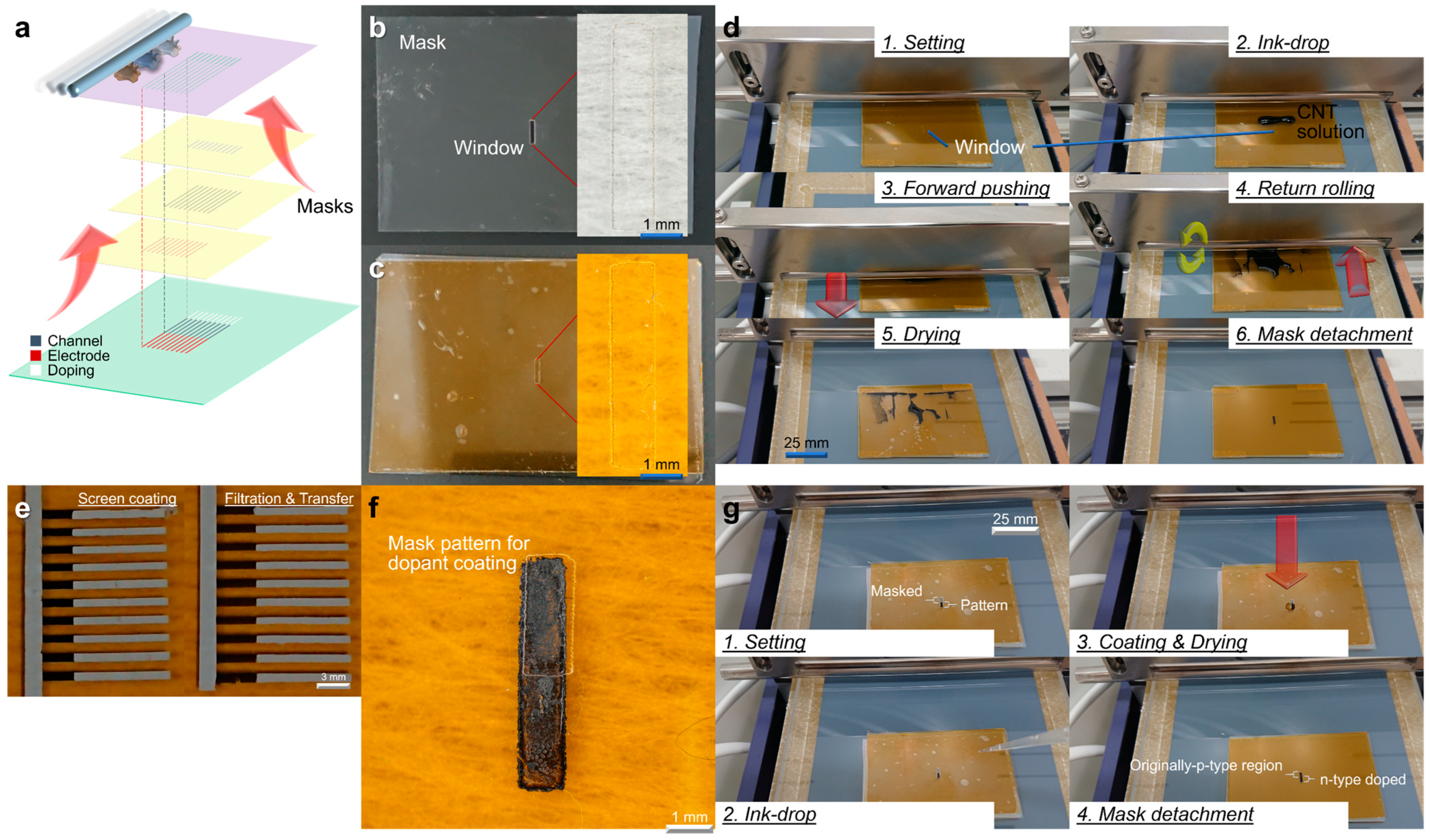

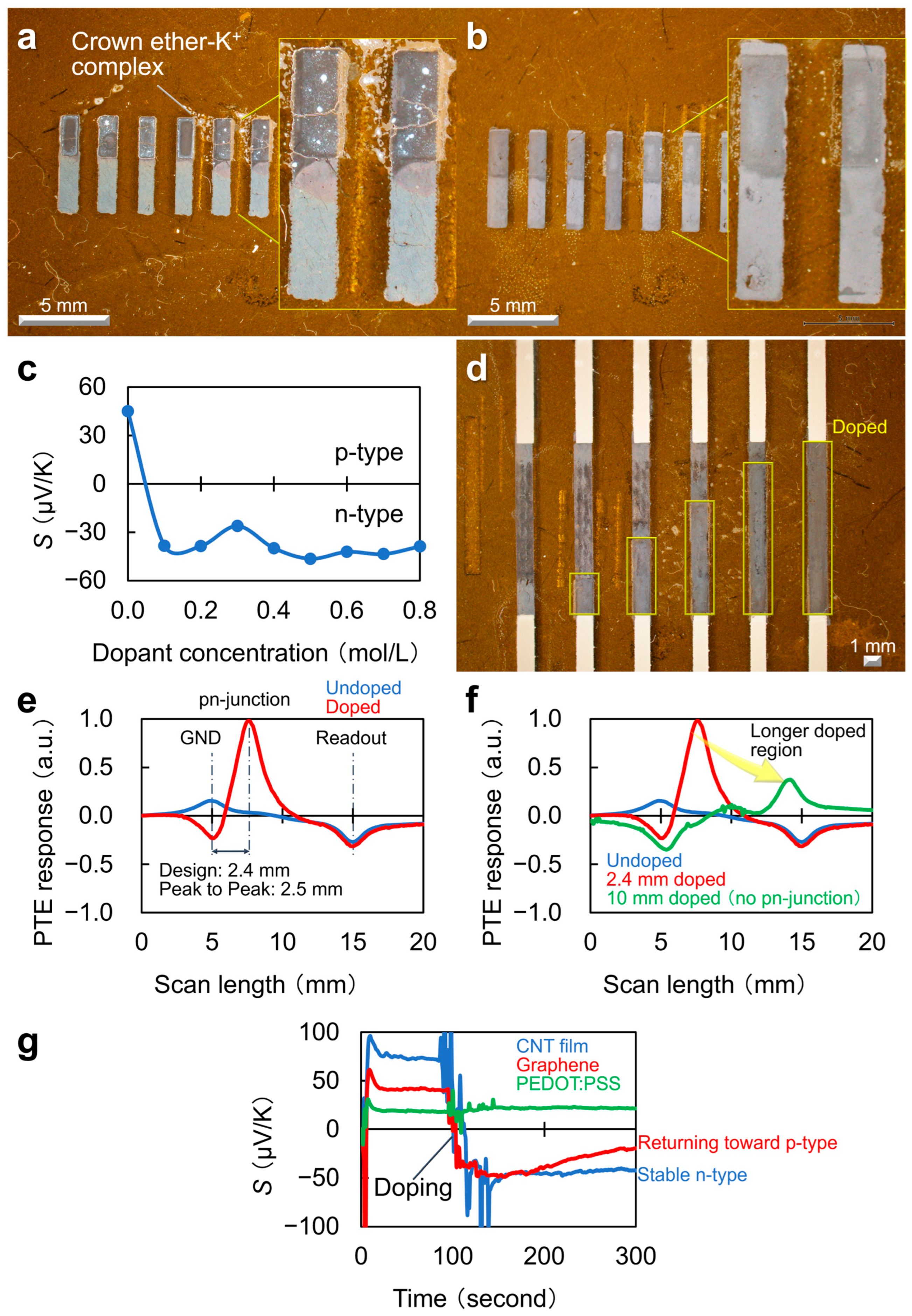

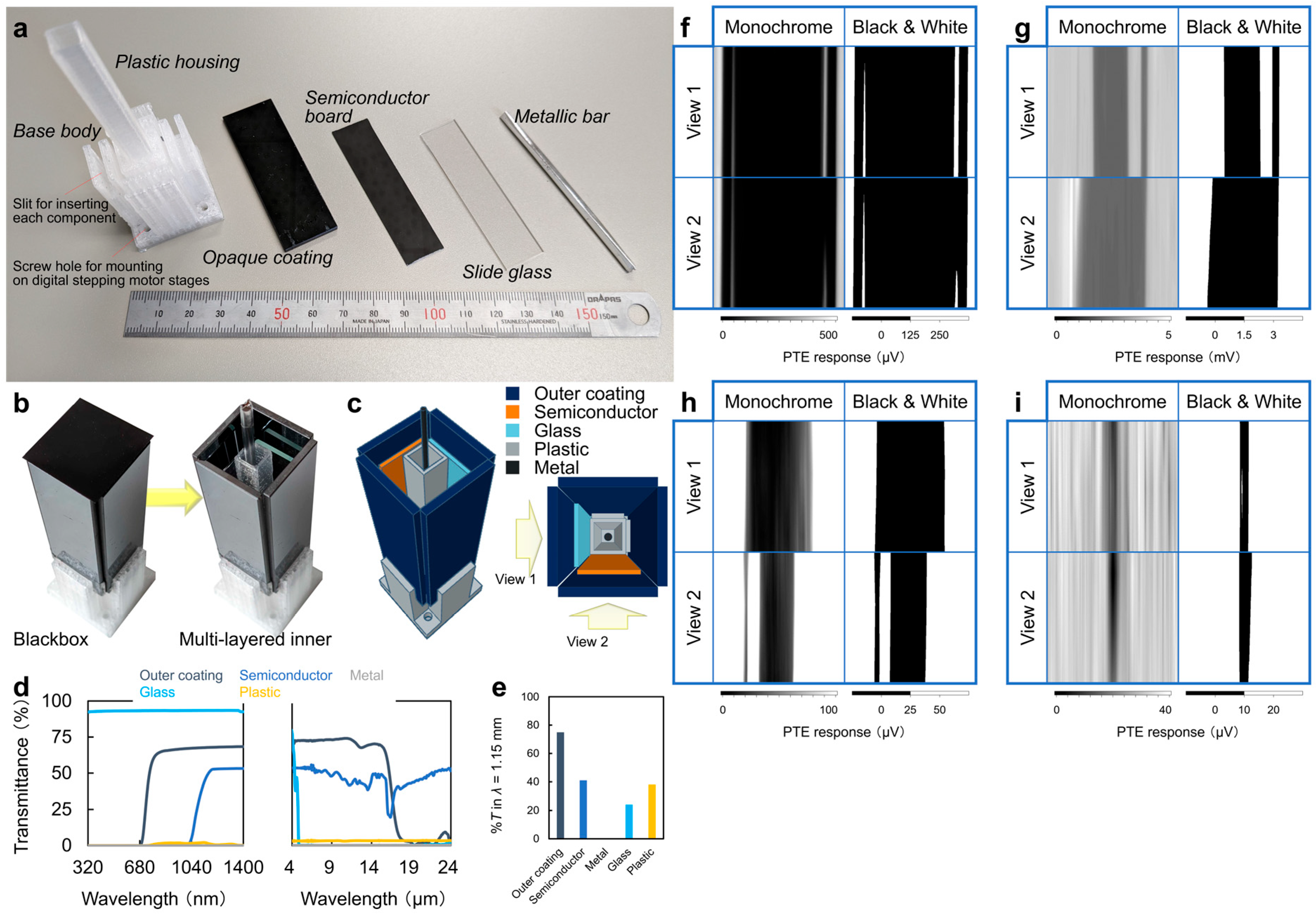

3.1. Screen-Printable CNT Film PTE Imager

3.1.1. Fabrication Process

3.1.2. Optical Property as Thin-Films

3.1.3. Stability and Robustness

3.1.4. Chemical-Type Electron Injection

3.2. Broadband Multi-Wavelength VH with the CNT Film PTE Imager

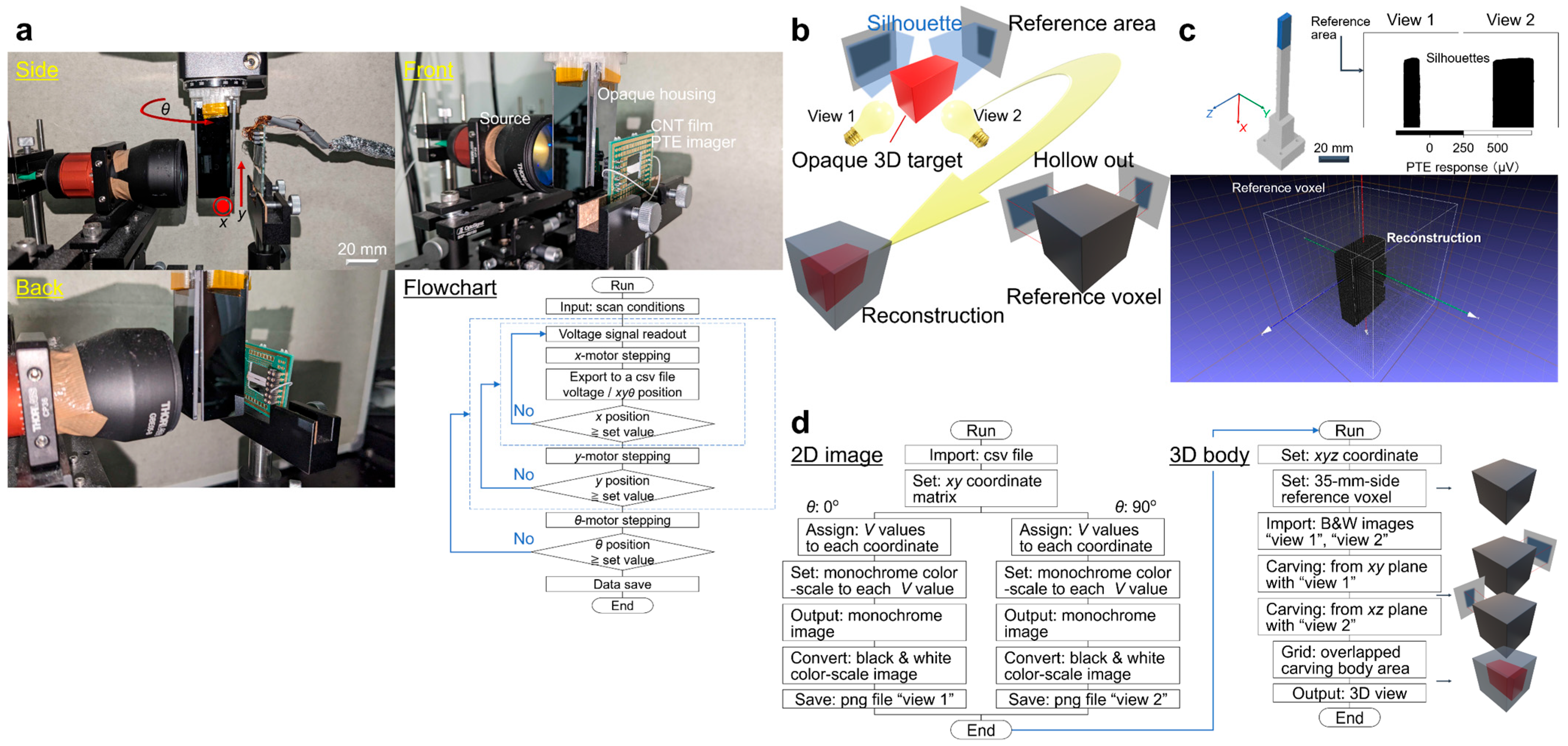

3.2.1. System Setup

3.2.2. Preparation of a Case Study Model

3.2.3. Non-Destructive Inspection Demonstration

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Lu, C.; Han, L.; Wang, J.; Wan, J.; Song, G.; Rao, J. Engineering of magnetic nanoparticles as magnetic particle imaging tracers. Chem. Soc. Rev. 2021, 50, 8102. [Google Scholar] [CrossRef]

- Sha, J.; Fan, M.; Cao, B.; Liu, B. Noncontact and nondestructive evaluation of heat-treated bearing rings using pulsed eddy current testing. J. Magn. Magn. Mater. 2021, 521, 167516. [Google Scholar] [CrossRef]

- Pradeep, A.D.; Rameshkumar, T. Review on centrifugal casting of functionally graded materials. Mater. Today Proc. 2021, 45, 729. [Google Scholar] [CrossRef]

- Gupta, M.; Khan, M.A.; Butola, R.; Singari, R.M. Advances in applications of Non-Destructive Testing (NDT): A review. Adv. Mater. Process. Technol. 2021, 8, 2286–2307. [Google Scholar] [CrossRef]

- Nooralishahi, P.; Ibarra-Castanedo, C.; Deane, S.; López, F.; Pant, S.; Genest, M.; Avdelidis, N.P.; Maldague, X.P.V. Drone-Based Non-Destructive Inspection of Industrial Sites: A Review and Case Studies. Drones 2021, 5, 106. [Google Scholar] [CrossRef]

- Goryanin, I.; Karbainov, S.; Shevelev, O.; Tarakanov, A.; Redpath, K.; Vesnin, S.; Ivanov, Y. Passive microwave radiometry in biomedical studies. Drug Discov. Today 2020, 25, 757. [Google Scholar] [CrossRef] [PubMed]

- Valušis, G.; Lisauskas, A.; Yuan, H.; Knap, W.; Roskos, H.G. Roadmap of terahertz imaging 2021. Sensors 2021, 21, 4092. [Google Scholar] [CrossRef]

- Martin, M.; Chong, A.; Biljecki, F.; Miller, C. Infrared thermography in the built environment: A multi-scale review. Renew. Sustain. Energy Rev. 2022, 165, 112540. [Google Scholar] [CrossRef]

- Koch, M.; Mittleman, D.M.; Ornik, J.; Castro-Camus, E. Terahertz time-domain spectroscopy. Nat. Rev. Methods Prim. 2023, 3, 48. [Google Scholar] [CrossRef]

- Nakatani, M.; Fukamachi, S.; Fernández, P.S.; Honda, S.; Kawahara, K.; Tsuji, Y.; Sumiya, Y.; Kuroki, M.; Li, K.; Liu, Q.; et al. Ready-to-transfer two-dimensional materials using tunable adhesive force tapes. Nat. Electron. 2024, 7, 119–130. [Google Scholar] [CrossRef]

- Tiernan, H.; Byrne, B.; Kazarian, S.G. ATR-FTIR spectroscopy and spectroscopic imaging for the analysis of biopharmaceuticals. Spectrochim. Acta Part A 2020, 241, 118636. [Google Scholar] [CrossRef] [PubMed]

- Baydin, A.; Makihara, T.; Peraca, N.M.; Kono, J. Time-domain terahertz spectroscopy in high magnetic fields. Front. Optoelectron. 2021, 14, 110. [Google Scholar] [CrossRef]

- Li, K.; Takahashi, N.; Togami, Y.; Koshimizu, R.; Izumi, N.; Hagiwara, N.; Sano, A.; Zhang, Q.; Jin, J.; Yamamoto, M.; et al. A chemically enriched, repeatedly deformable, and self-recoverable broadband wireless imager sheet. Commun. Mater. 2025, 6, 147. [Google Scholar] [CrossRef]

- Li, K.; Yuasa, R.; Utaki, R.; Sun, M.; Tokumoto, Y.; Suzuki, D.; Kawano, Y. Robot-assisted, source-camera-coupled multi-view broadband imagers for ubiquitous sensing platform. Nat. Commun. 2021, 12, 3009. [Google Scholar] [CrossRef]

- Li, K.; Suzuki, D.; Kawano, Y. Series photothermoelectric coupling between two composite materials for a freely attachable broadband imaging sheet. Adv. Photon. Res. 2021, 2, 2000095. [Google Scholar] [CrossRef]

- Hernández, A.; Kudriavtsev, Y.; Salinas-Fuentes, C.; Hernández-Gutierrez, C.; Asomoza, R. Optical Properties of Porous GaAs Formed by Low Energy Ion Implantation. Vacuum 2020, 171, 108976. [Google Scholar] [CrossRef]

- Moradi, T.; Hatef, A. Thermal Tracing of a Highly Reconfigurable and Wideband Infrared Heat Sensor Based on Vanadium Dioxide. J. Appl. Phys. 2020, 127, 243105. [Google Scholar] [CrossRef]

- Low, T.; Engel, M.; Steiner, M.; Avouris, P. Origin of Photoresponse in Black Phosphorus Phototransistors. Phys. Rev. B 2014, 90, 081408. [Google Scholar] [CrossRef]

- Oh, J.Y.; Lee, J.H.; Han, S.W.; Chae, S.S.; Bae, E.J.; Kang, Y.H.; Choi, W.J.; Cho, S.Y.; Lee, J.O.; Baik, H.K.; et al. Chemically Exfoliated Transition Metal Dichalcogenide Nanosheet-Based Wearable Thermoelectric Generators. Energy Environ. Sci. 2016, 9, 155–163. [Google Scholar] [CrossRef]

- Huang, J.; Lee, J.; Vollbrecht, J.; Brus, V.V.; Dixon, A.L.; Cao, D.X.; Zhu, Z.; Du, Z.; Wang, H.; Cho, K.; et al. A High-Performance Solution-Processed Organic Photodetector for Near-Infrared Sensing. Adv. Mater. 2020, 32, 1906027. [Google Scholar] [CrossRef]

- Li, S.; Yan, Z.; Liu, Z.; Chen, J.; Zhi, Y.; Guo, D.; Li, P.; Wu, Z.; Tang, W. A Self-Powered Solar-Blind Photodetector with Large Voc Enhancing Performance Based on the PEDOT:PSS/Ga2O3 Organic–Inorganic Hybrid Heterojunction. J. Mater. Chem. C 2020, 8, 1292–1300. [Google Scholar] [CrossRef]

- Li, Z.; Chen, S.; Nambiar, S.; Sun, Y.; Zhang, M.; Zheng, W.; Yeow, J.T.W. PMMA/MWCNT Nanocomposite for Proton Radiation Shielding Applications. Nanotechnology 2016, 27, 234001. [Google Scholar] [CrossRef]

- Chen, S.; Nambiar, S.; Li, Z.; Osei, E.; Darko, J.; Zheng, W.; Sun, Z.; Liu, P.; Yeow, J.T.W. Bismuth Oxide-Based Nanocomposite for High-Energy Electron Radiation Shielding. J. Mater. Sci. 2019, 54, 3023–3034. [Google Scholar] [CrossRef]

- Hata, K.; Futaba, D.N.; Mizuno, K.; Namai, T.; Yumura, M.; Iijima, S. Water-Assisted Highly Efficient Synthesis of Impurity-Free Single-Walled Carbon Nanotubes. Science 2004, 306, 1362–1364. [Google Scholar] [CrossRef]

- Saito, T.; Ohshima, S.; Okazaki, T.; Ohmori, S.; Yumura, M.; Iijima, S. Selective Diameter Control of Single-Walled Carbon Nanotubes in the Gas-Phase Synthesis. J. Nanosci. Nanotechnol. 2008, 8, 6153–6157. [Google Scholar] [CrossRef]

- Suzuki, D.; Li, K.; Ishibashi, K.; Kawano, Y. A Terahertz Video Camera Patch Sheet with an Adjustable Design Based on Self--Aligned, 2D, Suspended Sensor Array Patterning. Adv. Funct. Mater. 2021, 31, 2008931. [Google Scholar] [CrossRef]

- Wang, W.; Jiao, S.; Cao, J.; Naguib, H.E. Zinc oxide/carbon nanotube nanocomposite for high-performance flexible supercapacitor with sensing ability. Electrochim. Acta 2020, 350, 136353. [Google Scholar] [CrossRef]

- Cao, J.; Li, C.; Zhan, Y.; Sun, G.; Jiang, Y. Excitation and detection of Lamb waves based on a combined piezoelectric transducer and electromagnetic acoustic transducer. Sens. Actuators A 2012, 521, 126–133. [Google Scholar]

- Tanaka, T. Filtration characteristics of carbon nanotubes and preparation of buckypapers. Desalin. Water Treat. 2010, 17, 193–198. [Google Scholar] [CrossRef]

- Burdanova, M.G.; Tsapenko, A.P.; Kharlamova, M.V.; Kauppinen, E.I.; Gorshunov, B.P.; Kono, J.; Lloyd-Hughes, J. A Review of the Terahertz Conductivity and Photoconductivity of Carbon Nanotubes and Heteronanotubes. Adv. Opt. Mater. 2021, 9, 2101042. [Google Scholar] [CrossRef]

- Lu, X.; Sun, L.; Jiang, P.; Bao, X. Progress of Photodetectors Based on the Photothermoelectric Effect. Adv. Mater. 2019, 31, e1902044. [Google Scholar] [CrossRef]

- Zhang, Q.; Li, H.; Koshimizu, R.; Takahashi, N.; Kinoshita, Y.; Sano, A.; Jin, J.; Okawa, H.; Matsuzaki, Y.; Shikichi, D.; et al. Microwave Monitoring by Compact Carbon Nanotube Photo-Thermoelectric Sensors Beyond the Diffraction Limit Toward Ultrabroadband Non-Destructive Inspections. Adv. Sens. Res. 2025, 4, 2400159. [Google Scholar] [CrossRef]

- Araki, T.; Li, K.; Suzuki, D.; Abe, T.; Kawabata, R.; Uemura, T.; Izumi, S.; Tsuruta, S.; Terasaki, N.; Kawano, Y.; et al. Broadband Photodetectors and Imagers in Stretchable Electronics Packaging. Adv. Mater. 2024, 36, 202304048. [Google Scholar] [CrossRef] [PubMed]

- Li, K.; Kinoshita, Y.; Sakai, D.; Kawano, Y. Recent Progress in Development of Carbon-Nanotube-Based Photo-Thermoelectric Sensors and Their Applications in Ubiquitous Non-Destructive Inspections. Micromachines 2023, 14, 61. [Google Scholar] [CrossRef] [PubMed]

- Wang, J.; Xie, Z.; Liu, J.A.; Yeow, J.T.W. Design of Room-Temperature Infrared Photothermoelectric Detectors Based on CNT/PEDOT:PSS Composites. J. Mater. Chem. C 2022, 10, 15105–15113. [Google Scholar] [CrossRef]

- Li, K.; Araki, T.; Utaki, R.; Tokumoto, Y.; Sun, M.; Yasui, S.; Kurihira, N.; Kasai, Y.; Suzuki, D.; Marteijn, R.J.H.; et al. Stretchable broadband photo-sensor sheets for nonsampling, source-free, and label-free chemical monitoring by simple deformable wrapping. Sci. Adv. 2022, 8, eabm4349. [Google Scholar] [CrossRef]

- Zhang, M.; Ban, D.; Xu, C.; Yeow, J.T.W. Large-Area and Broadband Thermoelectric Infrared Detection. ACS Nano 2019, 13, 13285–13292. [Google Scholar] [CrossRef]

- Matsuzaki, Y.; Tadenuma, R.; Aoshima, Y.; Yamamoto, M.; Takai, L.; Kon, Y.; Sakai, D.; Takahashi, N.; Koshimizu, R.; Zhang, Q.; et al. All-Solution-Processable Hybrid Photothermoelectric Sensors with Carbon Nanotube Absorbers and Bismuth Composite Electrodes for Nondestructive Testing. Small Sci. 2025, 5, 2400448. [Google Scholar] [CrossRef]

- Li, K.; Kinoshita, Y.; Shikichi, D.; Kubota, M.; Takahashi, N.; Zhang, Q.; Koshimizu, R.; Tadenuma, R.; Yamamoto, M.; Takai, L.; et al. Simple Non-Destructive and 3D Multi-Layer Visual Hull Reconstruction with an Ultrabrandband Carbon Nanotubes Photo-Imager. Adv. Opt. Mater. 2024, 12, 2302847. [Google Scholar] [CrossRef]

- Wang, J.; Xie, Z.; Liu, J.A.; Yeow, J.T.W. System design of large-area vertical photothermoelectric detectors based on carbon nanotube forests with MXene electrodes. Nanoscale Adv. 2023, 5, 1133–1140. [Google Scholar] [CrossRef]

- Owens, C.E.; Headrick, R.J.; Williams, S.M.; Fike, A.J.; Pasquali, M.; McKinley, G.H.; Hart, A.J. Substrate-Versatile Direct-Write Printing of Carbon Nanotube-Based Flexible Conductors, Circuits, and Sensors. Adv. Funct. Mater. 2021, 31, 2100245. [Google Scholar] [CrossRef]

- Li, K.; Matsuzaki, Y.; Takahara, S.; Sakai, D.; Aoshima, Y.; Takahashi, N.; Yamamoto, M.; Kawano, Y. All-Screen-Coatable Photo-Thermoelectric Imagers for Physical and Thermal Durability Enhancement. Adv. Mater. Interfaces 2023, 35, 300528. [Google Scholar] [CrossRef]

- Kawabata, R.; Li, K.; Araki, T.; Akiyama, M.; Sugimachi, K.; Matsuoka, N.; Takahashi, N.; Sakai, D.; Matsuzaki, Y.; Koshimizu, R.; et al. Ultraflexible Wireless Imager Integrated with Organic Circuits for Broadband Infrared Thermal Analysis. Adv. Mater. 2024, 36, 202309864. [Google Scholar] [CrossRef]

- Kwon, K.; Rahman, M.K.; Phung, T.H.; Hoath, S.D.; Jeong, S.; Kim, J.S. Review of Digital Printing Technologies for Electronic Materials. Flex. Print. Electron. 2020, 5, 043003. [Google Scholar] [CrossRef]

- Xu, S.Y.; Wang, J.; Shou, W.C.; Ngo, T.; Sadick, A.M.; Wang, X.Y. Computer Vision Techniques in Construction: A Critical Revie. Arch. Comput. Methods Eng. 2021, 28, 3383. [Google Scholar] [CrossRef]

- Liao, M.H.; Zou, Z.S.; Wan, Z.Y.; Yao, C.; Bai, X. Real-Time Scene Text Detection with Differentiable Binarization and Adaptive Scale Fusion. IEEE Trans. Pattern Anal. Mach. Intell. 2023, 45, 1939. [Google Scholar] [CrossRef] [PubMed]

- Ikehata, S.; Yang, H.; Furukawa, Y. Structured Indoor Modeling. In Proceedings of the IEEE International Conference on Computer Vision (ICCM), Santiago, Chile, 11 December 2015. [Google Scholar]

- Lazebnik, S.; Furukawa, Y.; Ponce, J. Projective Visual Hulls. Int. J. Comput. Vis. 2007, 74, 137–165. [Google Scholar] [CrossRef]

- Shikichi, D.; Ota, R.; Kubota, M.; Kinoshita, Y.; Izumi, N.; Kosaka, M.; Nishi, T.; Sakai, D.; Matsuzaki, Y.; Takai, L.; et al. Multi Computer Vision-Driven Testing Platform: Structural Reconstruction and Material Identification with Ultrabroadband Carbon Nanotube Imagers. Adv. Mater. Technol. 2025, 10, 2401724. [Google Scholar] [CrossRef]

- Lin, L.; Hu, P.; Tong, X.; Na, S.; Cao, R.; Yuan, X.; Garrett, D.C.; Shi, J.; Maslov, K.; Wang, L.V. High-speed three-dimensional photoacoustic computed tomography for preclinical research and clinical translation. Nat. Commun. 2021, 12, 882. [Google Scholar] [CrossRef] [PubMed]

- Varpula, A.; Tappura, K.; Tiira, J.; Grigoras, K.; Kilpi, O.; Sovanto, K.; Ahopelto, J.; Prunnila, M. Nano-thermoelectric infrared bolometers. APL Photon. 2021, 6, 036111. [Google Scholar] [CrossRef]

- Huang, R.; Ji, X.; Liao, Y.; Peng, J.; Wang, K.; Xu, Y.; Yan, F. Dual-frequency CMOS terahertz detector with silicon-based plasmonic antenna. Opt. Express 2019, 27, 23250–23261. [Google Scholar] [CrossRef] [PubMed]

- Bauer, M.; Rämer, A.; Chevtchenko, S.A.; Osipov, K.Y.; Čibiraitė, D.; Pralgauskaitė, S. A High-Sensitivity AlGaN/GaN HEMT Terahertz Detector with Integrated Broadband Bow-Tie Antenna. IEEE Trans. Terahertz Sci. Technol. 2019, 9, 430–444. [Google Scholar] [CrossRef]

- Yang, X.; Vorobiev, A.; Generalov, A.; Andersson, M.A.; Stake, J. A flexible graphene terahertz detector. Appl. Phys. Lett. 2017, 111, 021102. [Google Scholar] [CrossRef]

- Xie, Z.; Wang, J.; Lu, G.; Yeow, J.T.W. Room-ambient operation of integrated and visualized photothermoelectric system with patterned Mo2C/PEDOT: PSS flexible devices. Mater. Des. 2023, 235, 112383. [Google Scholar] [CrossRef]

- Jung, S.H.; Lee, D.; Lee, H.G.; Park, J.; Kim, H.K. Self-Supervised Deep-Learning for Efficient Denoising of Terahertz Images. Exp. Therm. Fluid Sci. 2025, 148, 113634. [Google Scholar]

- Wang, L.V.; Gao, L. Photoacoustic Microscopy and Computed Tomography. Annu. Rev. Biomed. Eng. 2014, 16, 155–185. [Google Scholar] [CrossRef]

- Jewariya, M.; Abraham, E.; Kitaguchi, T.; Ohgi, Y.; Minami, M.; Araki, T.; Yasui, T. Fast three-dimensional terahertz computed tomography using real-time line projection of intense terahertz pulse. Opt. Express 2013, 21, 2423–2433. [Google Scholar] [CrossRef]

- Hong, J.; Jung, S.; Jung, C.; Jung, J.; Shim, D.H. A general-purpose task execution framework for manipulation mission of the 2017 Mohamed Bin Zayed International Robotics Challenge. J. Field Robot. 2019, 36, 149–169. [Google Scholar] [CrossRef]

- Tachella, J.; Altmann, Y.; Mellado, N.; McCarthy, A.; Tobin, R.; Buller, G.S.; Tourneret, J.; McLaughlin, S. Real-time 3D reconstruction from single-photon lidar data using plug-and-play point cloud denoisers. Nat. Commun. 2019, 10, 4984. [Google Scholar] [CrossRef]

- Hung, N.T.; Saito, R. The Origin of Quantum Effects in Low-Dimensional Thermoelectric Materials. Adv. Quantum Technol. 2021, 4, 2000115. [Google Scholar] [CrossRef]

- Sanchez–Valencia, J.R.; Dienel, T.; Groning, O.; Shorubalko, I.; Mueller, A.; Jansen, M.; Amsharov, K.; Ruffieux, P.; Fasel, R. Controlled synthesis of single-chirality carbon nanotubes. Nature 2014, 512, 61–64. [Google Scholar] [CrossRef]

- Yamaguchi, R.; Ishii, T.; Matsumoto, M.; Borah, A.; Tanaka, N.; Oba, K.; Tomita, M.; Watanabe, T.; Fujigaya, T. Thermal deposition method for p–n patterning of carbon nanotube sheets for planar-type thermoelectric generator. J. Mater. Chem. A 2021, 20, 12188–12195. [Google Scholar] [CrossRef]

- Krockel, C.; Preciado–Rivas, M.R.; Torres–Sanchez, V.A.; Chacon–Torres, J.C.; Hirch, A. Understanding the electron-doping mechanism in potassium-intercalated single-walled carbon nanotubes. J. Am. Chem. Soc. 2020, 142, 2327–2337. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Pham, P.H.Q.; Zhou, W.; Pham, T.D.; Burke, P.J. Carbon-nanotube–electrolyte interface: Quantum and electric double layer capacitance. ACS Nano 2018, 12, 9763–9774. [Google Scholar] [CrossRef]

- Yamamoto, M.; Sakai, D.; Matsuzaki, Y.; Takai, L.; Kon, Y.; Aoshima, Y.; Izumi, N.; Hagiwara, N.; Shikichi, D.; Jin, J.; et al. Mechanically alignable and all-dispenser-printable device design platform for carbon nanotube-based soft-deformable photo-thermoelectric broadband imager sheets. npj Flex. Electron. 2025, 9, 42. [Google Scholar] [CrossRef]

- Takai, L.; Kinoshita, Y.; Takahashi, N.; Yamamoto, M.; Shikichi, D.; Izumi, N.; Matsuzaki, Y.; Kon, Y.; Hagiwara, N.; Kawano, Y.; et al. n-type carbon nanotube inks for high-yield printing of ultrabroadband soft photo-imager thin sheets. FlexMat 2025, 2, 115–125. [Google Scholar] [CrossRef]

- Kim, J.; Kang, M.; Yoon, J.; Yang, J.; Jeong, Y.; Kim, H.; Lee, D.K.; Hong, Y. Improved uniformity and processability of inkjet-printed single-walled carbon nanotube thin-film transistor by introducing cellulose dispersant. ACS Appl. Mater. Interfaces 2025, 17, 9606–9616. [Google Scholar] [CrossRef]

- Nishinaka, M.; Jinno, H.; Jimbo, Y.; Lee, S.; Wang, J.; Lee, W.; Yokota, T.; Someya, T. High-transconductance organic electrochemical transistor fabricated on ultrathin films using spray coating. Small Struct. 2021, 2, 2000088. [Google Scholar] [CrossRef]

- Lemarchand, J.; Bridonneau, N.; Battaglini, N.; Carn, F.; Mattana, G.; Piro, B.; Zrig, S.; Noel, V. Challenges, prospects, and emerging applications of inkjet-printed electronics: A chemist’s point of view. Angew. Chem. Int. Ed. 2022, 61, e202200166. [Google Scholar] [CrossRef]

- Wakabayashi, S.; Arie, T.; Akita, S.; Nakajima, K.; Takei, K. A multitasking flexible sensor via reservoir computing. Adv. Mater. 2022, 34, 2201663. [Google Scholar] [CrossRef]

- Ham, J.; Han, A.K.; Cutkosky, M.R.; Bao, Z. UV-laser-machined stretchable multi-modal sensor network for soft robot interaction. npj Flex. Electron. 2022, 6, 94. [Google Scholar] [CrossRef]

- Homma, C.; Tsukiiwa, M.; Naguchi, H.; Tabaka, M.; Okochi, M.; Tomizawa, H.; Sugizaki, Y.; Isobayashi, A.; Hayamizu, Y. Designable peptides on graphene field-effect transistors for selective detection of odor molecules. Biosens. Bioelectron. 2023, 224, 115047. [Google Scholar] [CrossRef] [PubMed]

- Ansari, S.; Bianconi, S.; Kang, C.M.; Mohseni, H. From material to cameras: Low-dimensional photodetector arrays on CMOS. Small Methods 2024, 8, 2300595. [Google Scholar] [CrossRef] [PubMed]

- Kawakami, H.; Nagatake, K.; Ni, S.; Nakamura, F.; Takano, T.; Murakami, K.; Ohara, I.; Isano, Y.; Matsuda, R.; Suwa, H.; et al. R2R-based continuous production of patterned and multilayered elastic substrates with liquid metal wiring for stretchable electronics. Adv. Mater. Technol. 2024, 9, 2400487. [Google Scholar] [CrossRef]

- Rich, S.; Lee, S.; Fukuda, K.; Someya, T. Developing the Nondevelopable: Creating Curved-Surface Electronics from Nonstretchable Devices. Adv. Mater. 2021, 34, 2106683. [Google Scholar] [CrossRef] [PubMed]

- Rich, S.; Takakuwa, M.; Fukuda, K.; Someya, T. Simple Method for Creating Hydrophobic Ultraflexible Photovoltaics. ACS Appl. Mater. Interfaces 2023, 15, 12495–12501. [Google Scholar] [CrossRef] [PubMed]

- Karner-Petritz, E.; Petritz, A.; Uemura, T.; Namba, N.; Araki, T.; Sekitani, T.; Stadlober, B. Ultraflexible Organic Active Matrix Sensor Sheet for Tactile and Biosignal Monitoring. Adv. Electron. Mater. 2023, 9, 2201333. [Google Scholar] [CrossRef]

- Herban, S.; Costantino, D.; Alfio, V.S.; Pepe, M. Use of Low-Cost Spherical Cameras for the Digitisation of Cultural Heritage Structures into 3D Point Clouds. J. Imaging 2022, 8, 13. [Google Scholar] [CrossRef]

- Izuta, O.; Sato, T.; Kodama, S.; Koike, H. Bouncing Star project: Design and development of augmented sports application using a ball including electronic and wireless modules. In Proceedings of the 1st Augmented Human International Conference, Megève, France, 2–3 April 2010. [Google Scholar]

- Yoshioka, K. A Tutorial and Review of Automobile Direct ToF LiDAR SoCs: Evolution of Next-Generation LiDARs. IEICE Trans. Electron. 2022, 10, 534–543. [Google Scholar] [CrossRef]

- Niskanen, I.; Duan, G.; Vartiainen, E.; Immonen, M.; Hallman, L.; Kostamovaara, J.; Heikkilä, R. Enhancing Point Cloud Data Fusion through 2D Thermal Infrared Camera and 2D LiDAR Scanning. Infrared Phys. Technol. 2024, 141, 105432. [Google Scholar] [CrossRef]

- Shun, C.M.; Chan, P.W. Applications of an Infrared Doppler Lidar in Detection of Wind Shear. J. Atmos. Ocean. Technol. 2008, 25, 637–655. [Google Scholar] [CrossRef]

- Choi, J.D.; Kim, Y.M. A sensor fusion system with thermal infrared camera and LiDAR for autonomous vehicles and deep learning based object detection. ICT Express 2023, 9, 222–227. [Google Scholar] [CrossRef]

- Truong, V.; Bouchard, J.; Petkie, D. Multimodal sub-THz radar and LiDAR imaging for NDE Applications. In Proceedings of the 45th International Conference on Infrared, Millimeter, and Terahertz Waves (IRMMW-THz), Buffalo, NY, USA, 11 March 2021. [Google Scholar]

- Wang, W.; Tabata, S.; Xu, H.; Hu, Y.; Watanabe, Y.; Ishikawa, M. Dynamic depth-of-field projection mapping method based on a variable focus lens and visual feedback. Opt. Express. 2023, 31, 3945–3953. [Google Scholar] [CrossRef]

- Peng, H.; Sato, K.; Nakagawa, S.; Watanabe, Y. High-Speed Dynamic Projection Mapping onto Human Arm with Realistic Skin Deformation. Appl. Sci. 2021, 11, 3753. [Google Scholar] [CrossRef]

- Yasui, M.; Iwataki, R.; Ishikawa, M.; Watanabe, Y. Projection Mapping with a Brightly Lit Surrounding Using a Mixed Light Field Approach. IEEE Trans. Vis. Comput. Graph. 2024, 30, 2217–2227. [Google Scholar] [CrossRef]

- Ortega, M.; Ivorra, E.; Juan, A.; Venegas, P.; Martínez, J.; Alcañiz, M. MANTRA: An Effective System Based on Augmented Reality and Infrared Thermography for Industrial Maintenance. App. Sci. 2021, 11, 385. [Google Scholar] [CrossRef]

- Meier, E.L.; Tielemans, H.J.P.; Pronk, R.F.; Ulrich, D.J.O.; Hummelink, S. Projected augmented reality and dynamic infrared thermography enhances profunda artery perforator flap perforator mapping. Surg. Oncol. 2025, 62, 102274. [Google Scholar] [CrossRef] [PubMed]

- Yan, L.; Miah, M.A.R.; Zhou, J.; Zhang, Y.; Lo, Y.H. Room-Temperature Long-Wave Infrared Detector with Thin Double Layers of Amorphous Germanium and Amorphous Silicon. Opt. Express 2019, 27, 37056–37064. [Google Scholar]

- TYDEX LLC. Available online: https://www.tydexoptics.com/pdf/Golay_Detectors.pdf (accessed on 15 October 2025).

- Hong, G.; Lee, O. Three-dimensional reconstruction of skin disease using multi-view mobile images. Skin Res. Technol. 2019, 25, 434–439. [Google Scholar] [CrossRef] [PubMed]

- Wang, H. Deep Single-View 3D Object Reconstruction with Visual Shape Priors. AAAI Conf. Artif. Intell. 2019, 33, 4922. [Google Scholar]

- Hong, S.; Chung, D.; Kim, J.; Kim, Y.; Kim, A.; Yoon, H.K. In-water visual ship hull inspection using a hover-capable underwater vehicle with stereo vision. J. Field Robot. 2019, 36, 531–546. [Google Scholar] [CrossRef]

- Yang, M.D.; Su, T.C.; Lin, H. Fusion of Infrared Thermal Image and Visible Image for 3D Thermal Model Reconstruction Using Smartphone Sensors. Sensors 2018, 18, 2003. [Google Scholar] [CrossRef] [PubMed]

- Rawson, S.D.; Maksimcuka, J.; Withers, P.J.; Cartmell, S.H. X-ray computed tomography in life sciences. BMC Biol. 2020, 18, 21. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.X.; Ma, J.J.; Wang, J.M.; Cai, W.G.; Zheng, Z.; Huang, B.; Sun, M.Y.; Cheng, Q.Y.; Zhang, Z.L.; Pang, D.W.; et al. Ag2Te Quantum Dots as Contrast Agents for Near-Infrared Fluorescence and Computed Tomography Imaging. ACS Appl. Nano Mater. 2020, 3, 6071–6077. [Google Scholar] [CrossRef]

- Kubota, M.; Kinoshita, Y.; Hirokawa, S.; Shikichi, D.; Izumi, N.; Hagiwara, N.; Sakai, D.; Matsuzaki, Y.; Yamamoto, M.; Takai, L.; et al. In-line multi-wavelength non-destructive pharma quality monitoring with ultrabroadband carbon nanotubes photo-thermoelectric imaging scanners. Light Sci. Appl. 2025, 14, 306. [Google Scholar] [CrossRef] [PubMed]

| Specification | “CNT” | “Electrode” | “n-Dopant” |

|---|---|---|---|

| 1. Solute | Single-walled semiconducting-metallic unseparated CNT | Silver particle and acrylic resin | Crown-Ether and Potassium Hydroxide |

| 2. Solvent | Deionized water | Organic chemical | Deionized water |

| 3. Surfactant | Sodium linear-Alkylbenzenesulfonate | — | — |

| Mixture ratio of 1–3 | 1 (0.2 wt%), 2 (over 97 wt%), 3 (3 wt%) | 1 (71%) 2 (29%) | 1 (12%) 2 (88%) |

| Method | Wavelength Band | Accuracy and Resolution | Operation Time | System Size | Safety | System Cost | Operating Condition | Target & Use |

|---|---|---|---|---|---|---|---|---|

| MMW–IR–Vis VH [39] | 660 nm –1.15 mm | Within 2% error | 150 s per layer | Desktop | Non- invasive | 20 k$ | Indoor (ubiquitous) | Non-metallic outer–inner, Metallic inner |

| 650 µm | Material identification | |||||||

| Vis visual- Hull [95] | Vis | Within 3% error | 0.1 s per picture | Vehicle module | Non- invasive | Over 1 M$ | Outdoor | Construction |

| 54 cm | Outer-shape observation | |||||||

| LiDAR [60] | 1550 nm | N.A. | 20 milli s | Desktop | Non- invasive | 15 k$ | Outdoor | Human |

| 3.75 cm | Motion capture | |||||||

| sub-THz LiDAR [85] | 3 mm | N.A. | 130 s per picture | Meters-size desk | Non- invasive | 10 k$ | Indoor (in dried air) | Cardboards, metals |

| 1 cm | Identifying concealed metal cans | |||||||

| X-ray CT [97] | X-ray | Within 0.005% error | Several hours | Room-size | Invasive | Over 1 M$ | Shielded | Bio-samples, Non-metallic outer–inner, Metallic inner |

| 10 µm | Inner imaging, Bio-imaging | |||||||

| IR CT [98] | 1250 nm | N.A. | 0.2 s | Room-size | Non- invasive | Over 1 M$ | Shielded | Mice |

| 50 µm | Heart-shadow imaging | |||||||

| THz CT [58] | 150 µm | N.A. | 6 min | Meters-size desk | Non- invasive | 100 k$ | Indoor (in dried air) | Plastic |

| 1 mm | Inner metal imaging | |||||||

| Photo- acoustic [50] | Vis | Within 2% error | 10 s | Meters-size desk | Non- invasive | 100 k$ | Indoor (dark room) | Only bio-samples |

| 370 µm | Bio-imaging |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kon, Y.; Murakami, K.; Jin, J.; Kosaka, M.; Hamashima, H.; Kubota, M.; Takai, L.; Kawano, Y.; Li, K. All-Solution-Processable Robust Carbon Nanotube Photo-Thermoelectric Devices for Multi-Modal Inspection Applications. Materials 2025, 18, 4980. https://doi.org/10.3390/ma18214980

Kon Y, Murakami K, Jin J, Kosaka M, Hamashima H, Kubota M, Takai L, Kawano Y, Li K. All-Solution-Processable Robust Carbon Nanotube Photo-Thermoelectric Devices for Multi-Modal Inspection Applications. Materials. 2025; 18(21):4980. https://doi.org/10.3390/ma18214980

Chicago/Turabian StyleKon, Yukito, Kohei Murakami, Junyu Jin, Mitsuki Kosaka, Hayato Hamashima, Miki Kubota, Leo Takai, Yukio Kawano, and Kou Li. 2025. "All-Solution-Processable Robust Carbon Nanotube Photo-Thermoelectric Devices for Multi-Modal Inspection Applications" Materials 18, no. 21: 4980. https://doi.org/10.3390/ma18214980

APA StyleKon, Y., Murakami, K., Jin, J., Kosaka, M., Hamashima, H., Kubota, M., Takai, L., Kawano, Y., & Li, K. (2025). All-Solution-Processable Robust Carbon Nanotube Photo-Thermoelectric Devices for Multi-Modal Inspection Applications. Materials, 18(21), 4980. https://doi.org/10.3390/ma18214980