The Role of Hollow Glass Microspheres as Functional Fillers in Fiber-Reinforced Polymer Composites: A Review

Abstract

1. Introduction

2. Hollow Glass Microspheres (HGMs)

2.1. Structure and Composition

2.2. Physical and Chemical Properties

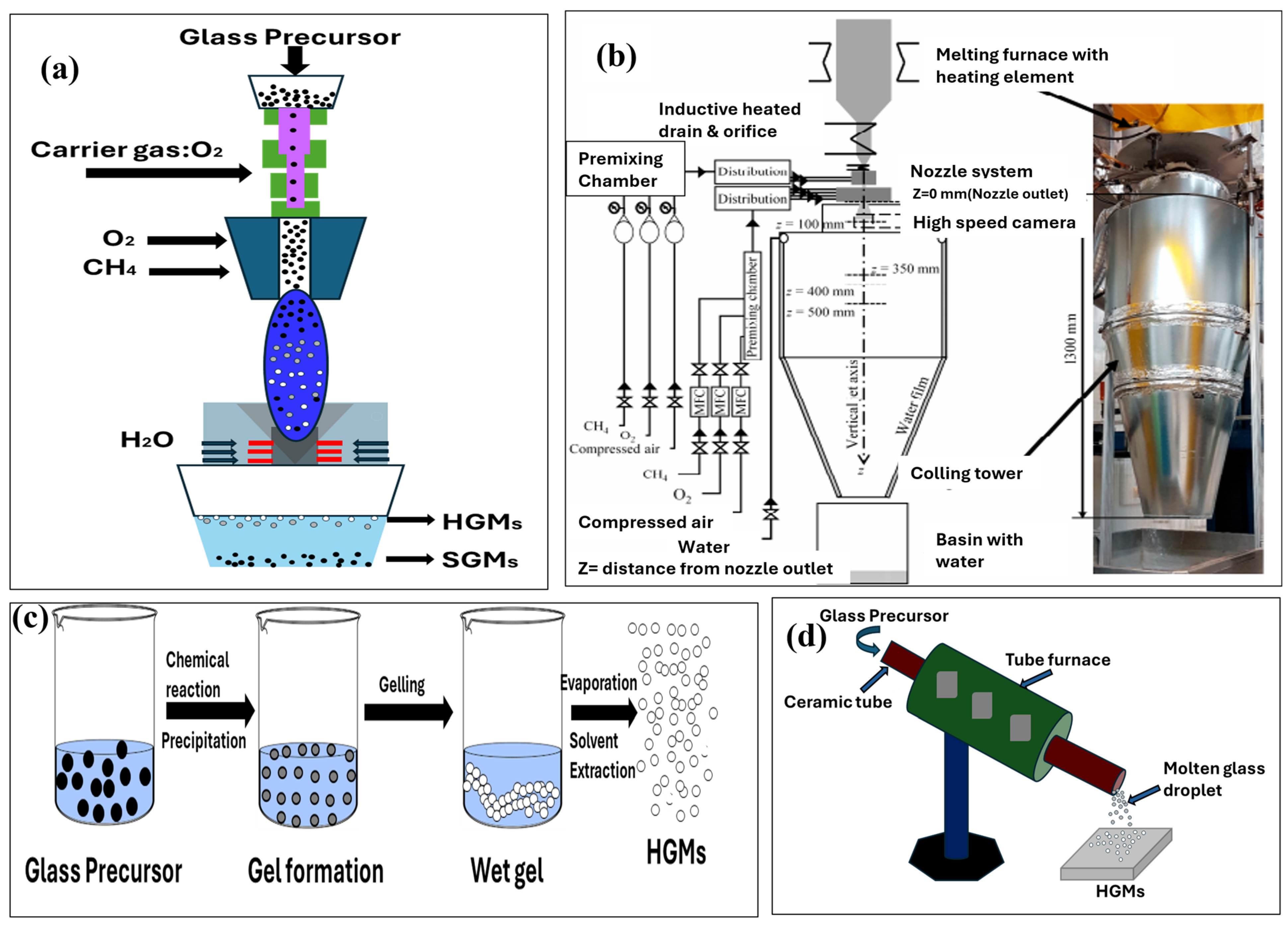

2.3. Synthesis and Manufacturing Techniques

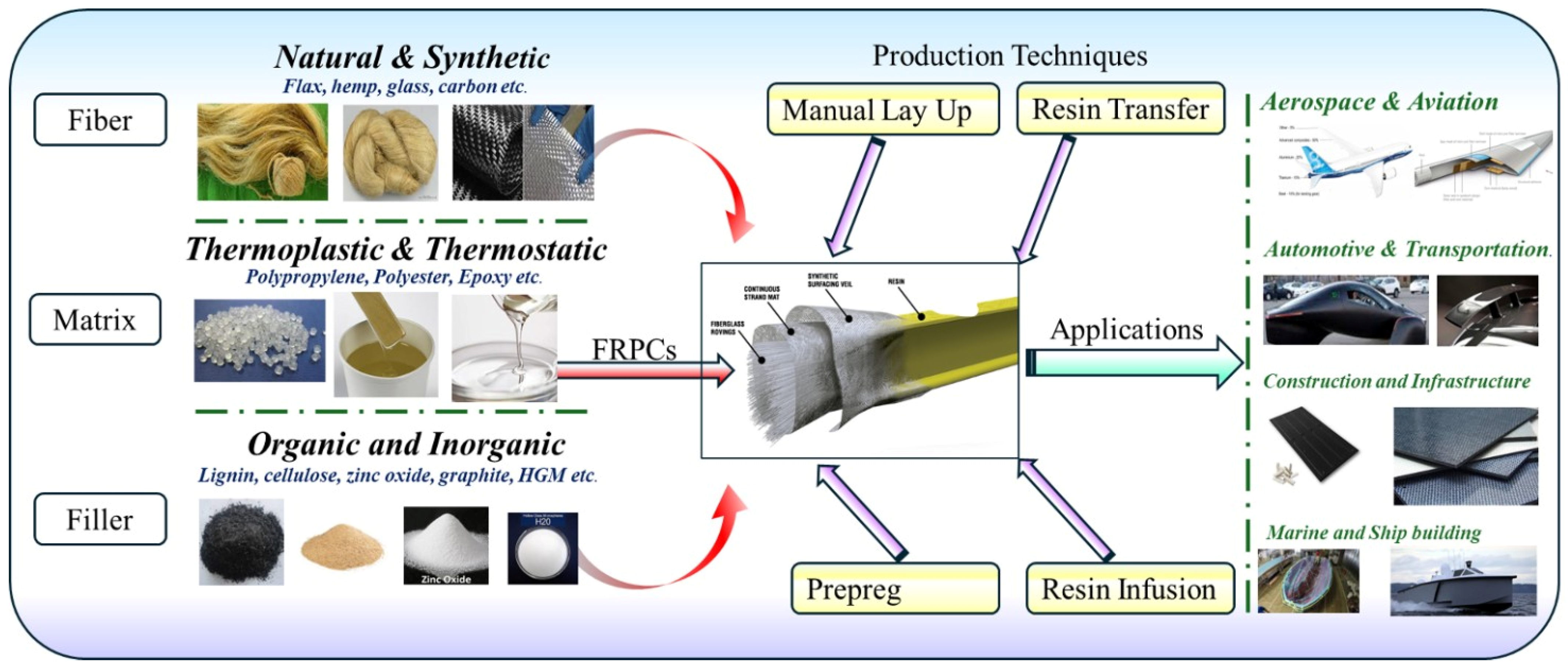

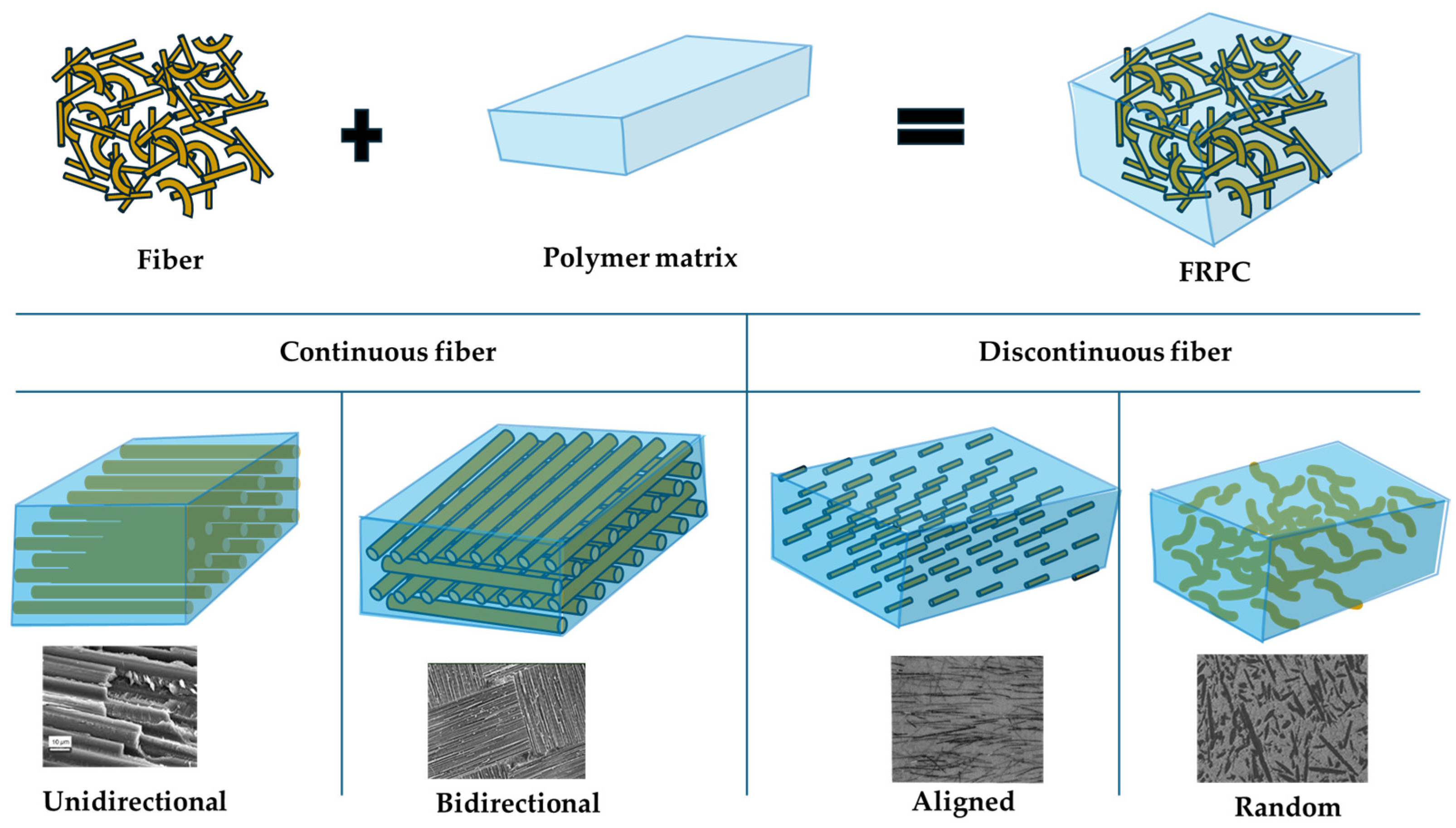

3. Overview of Fiber-Reinforced Polymer Composites (FRPCs)

3.1. Matrix and Fiber Types

3.2. Functional Requirements and Challenges

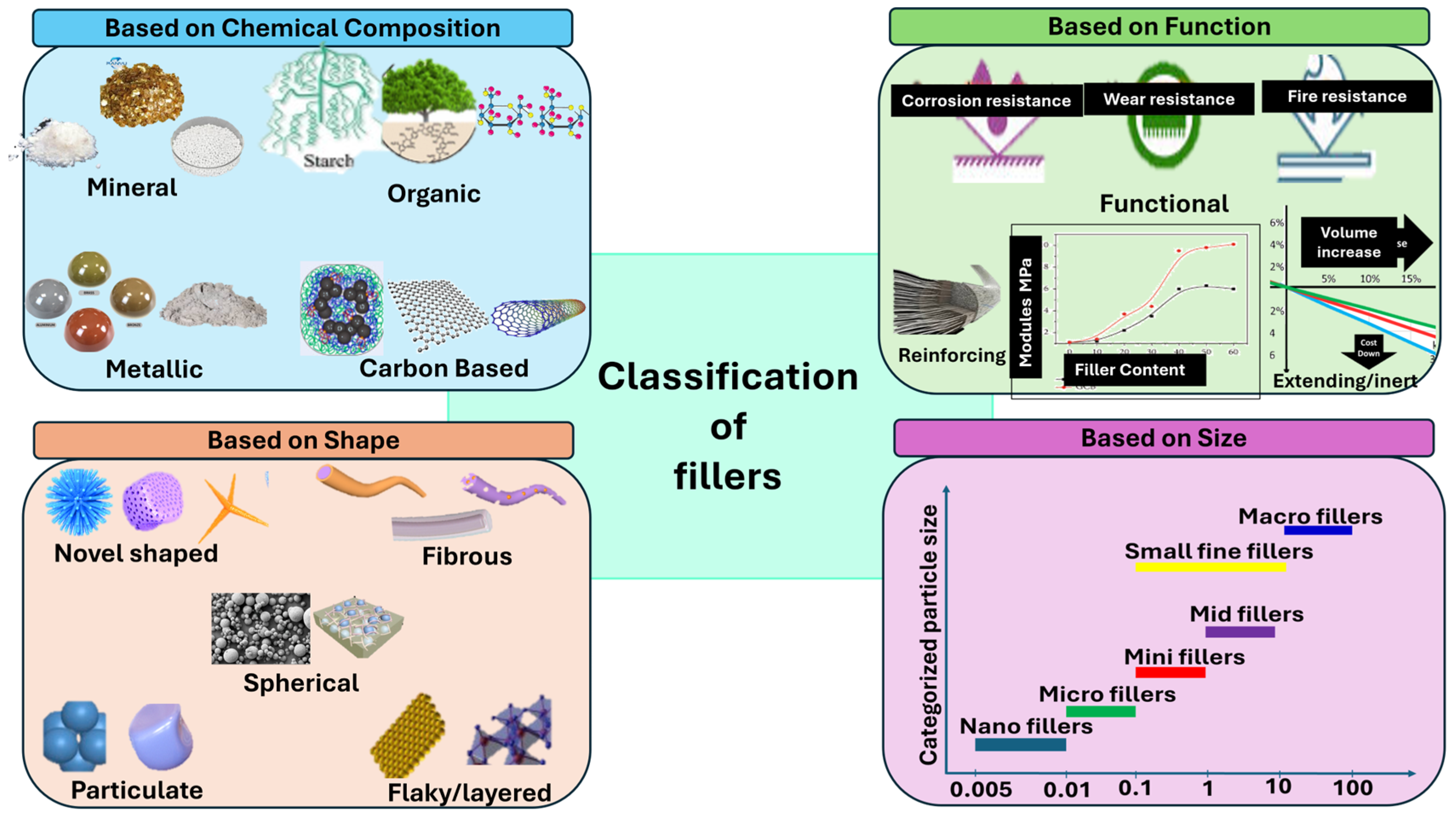

3.3. Role of Fillers in FRPCs

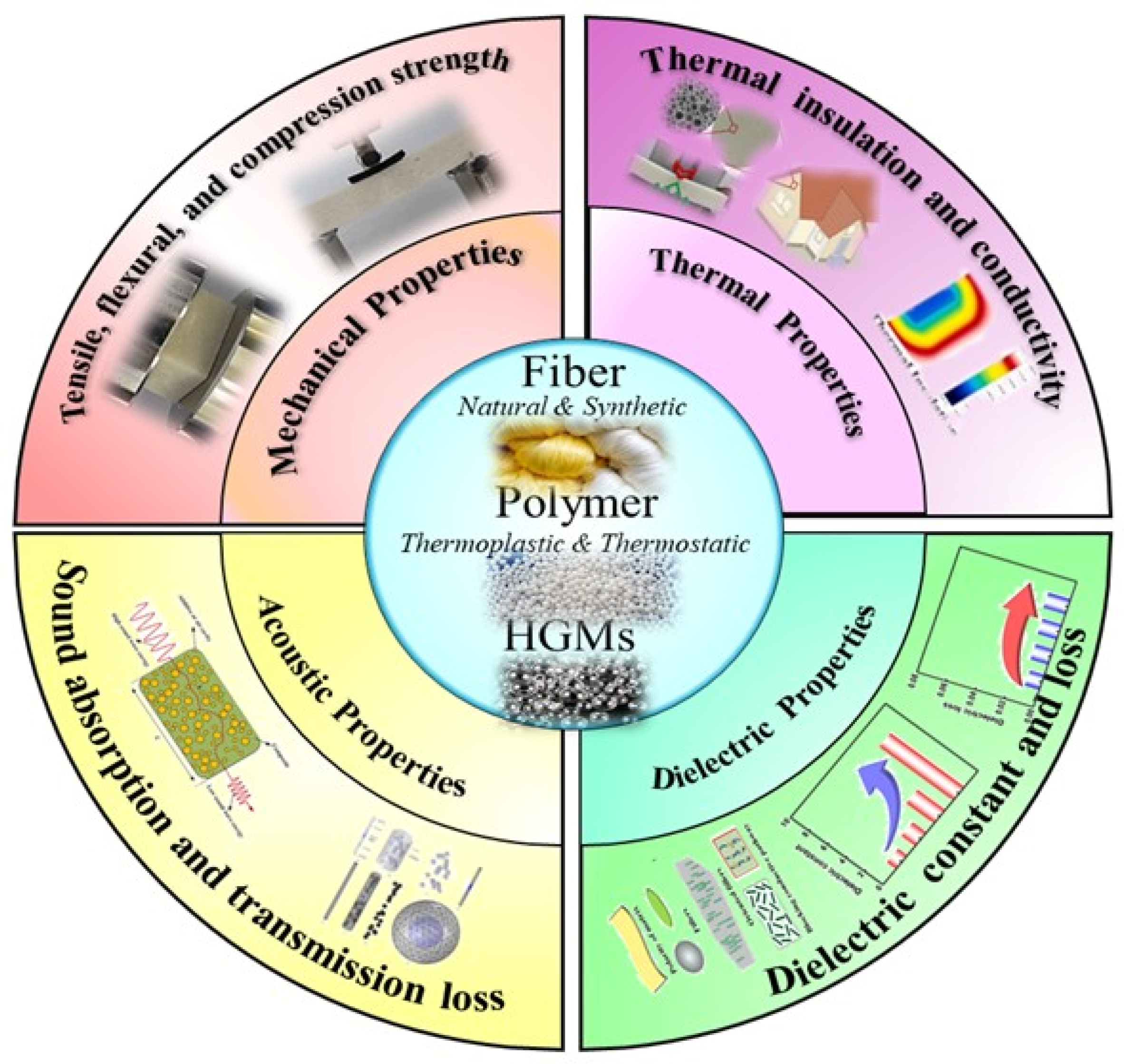

4. Functional Role of HGMs in FRPCs

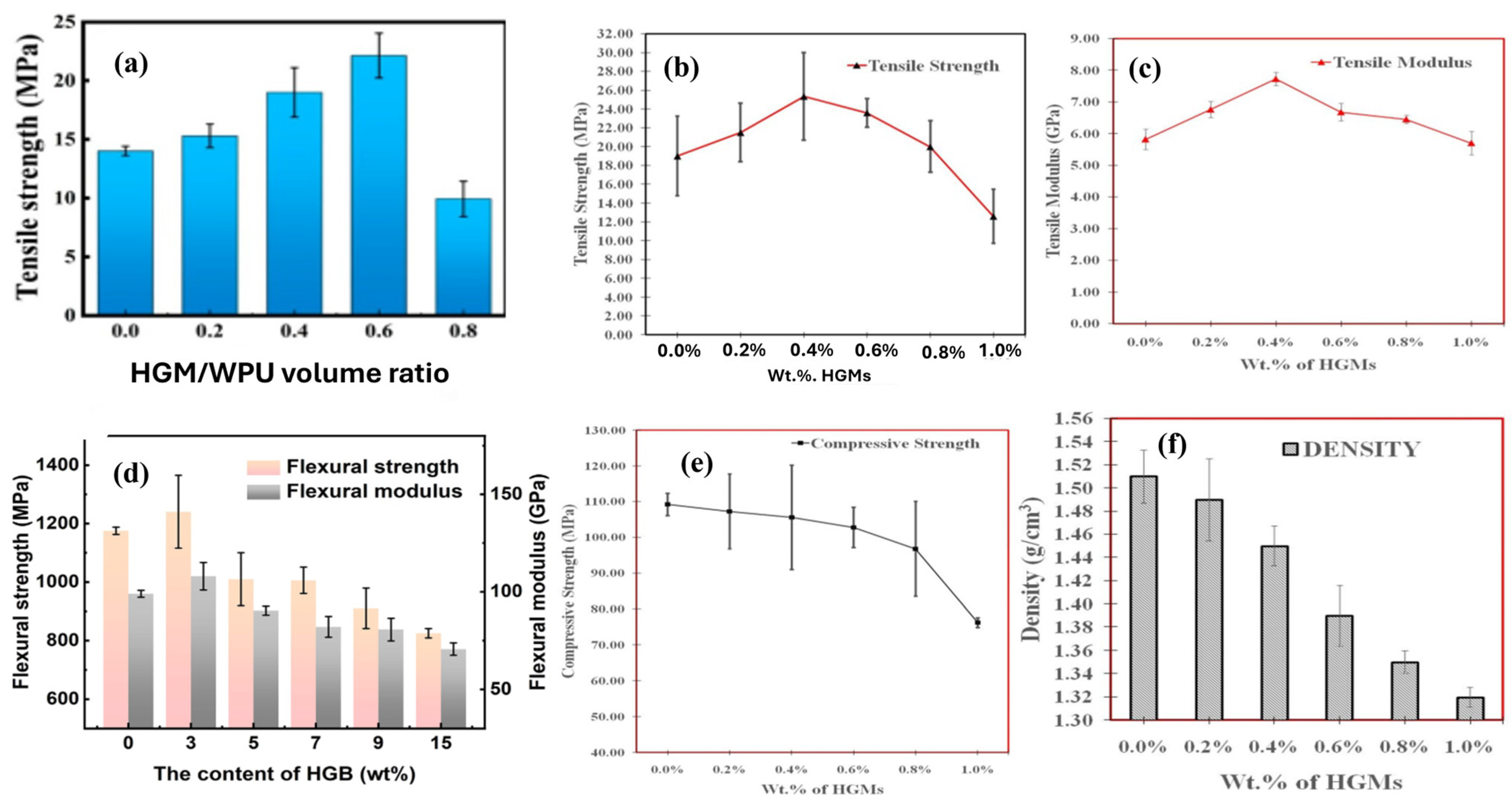

4.1. Mechanical Properties

4.2. Thermal Properties

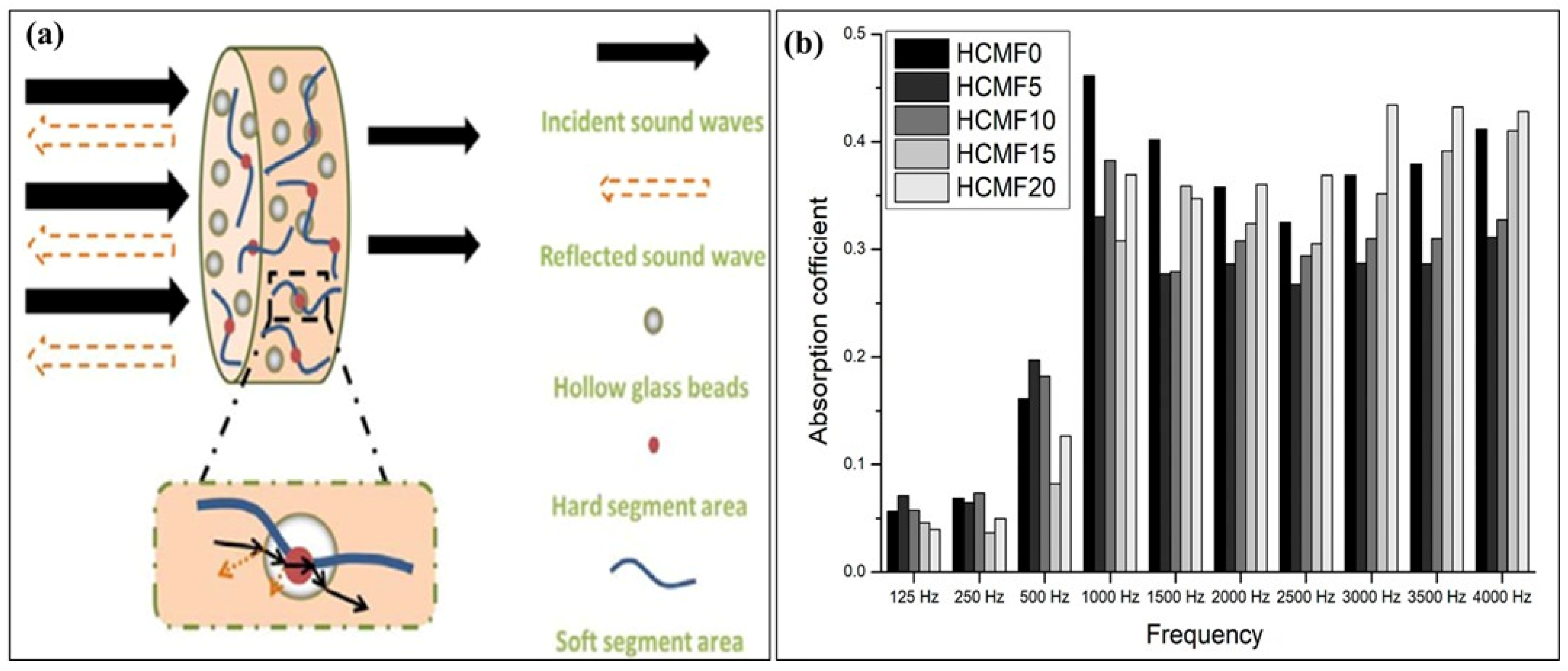

4.3. Acoustic Properties

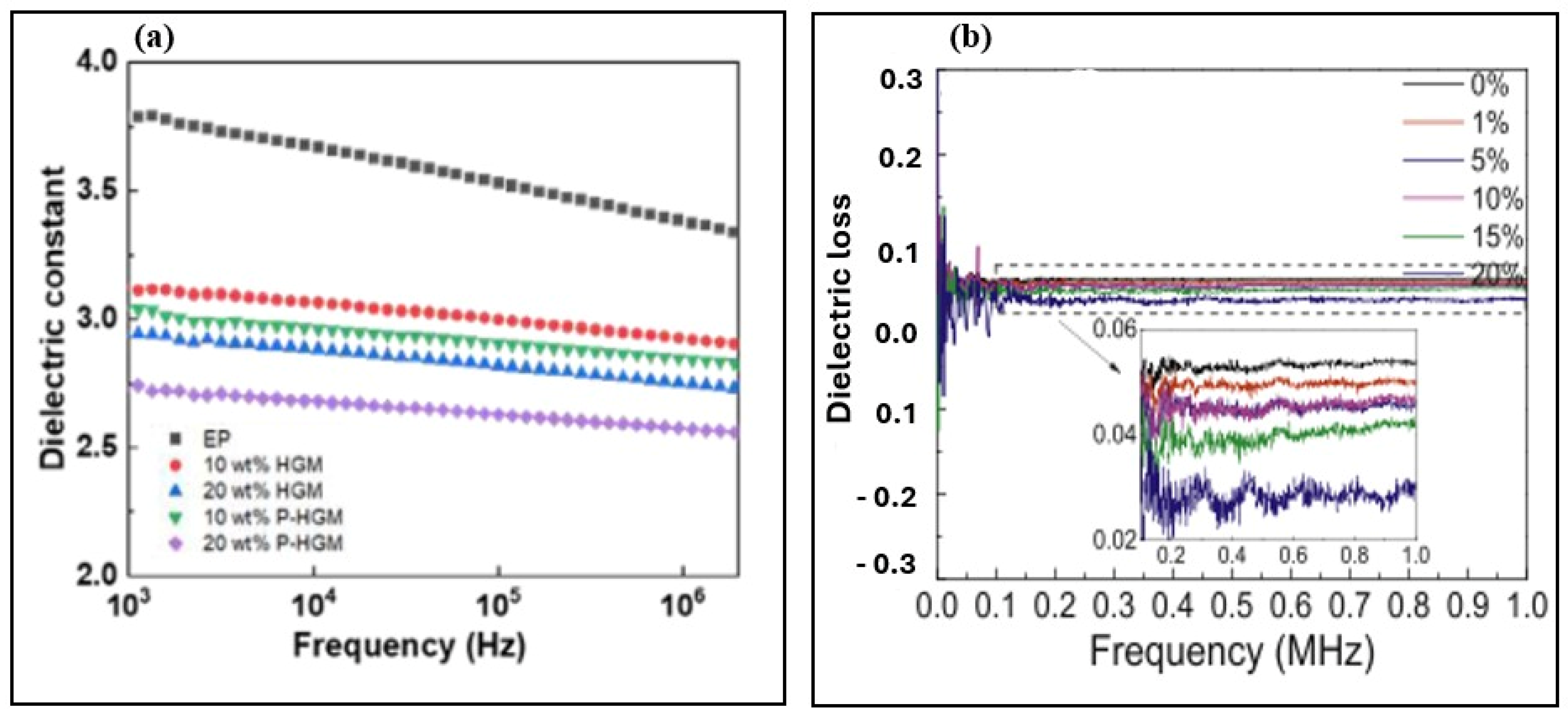

4.4. Dielectric Properties

5. Application Areas and Performance of HGMs-Filled FRPCs

6. Challenge and Future Prospects

7. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sharma, H.; Kumar, A.; Rana, S.; Sahoo, N.G.; Jamil, M.; Kumar, R.; Sharma, S.; Li, C.; Kumar, A.; Eldin, S.M. Critical review on advancements on the fiber-reinforced composites: Role of fiber/matrix modification on the performance of the fibrous composites. J. Mater. Res. Technol. 2023, 26, 2975–3002. [Google Scholar] [CrossRef]

- Fortune Business Insights. Fiber Reinforced Polymer Composites (FRP) Market. Available online: https://www.fortunebusinessinsights.com/fiber-reinforced-polymer-composites-frp-market-102905# (accessed on 2 August 2025).

- Jagadeesh, P.; Puttegowda, M.; Thyavihalli Girijappa, Y.G.; Rangappa, S.M.; Siengchin, S. Effect of natural filler materials on fiber reinforced hybrid polymer composites: An Overview. J. Nat. Fibers 2022, 19, 4132–4147. [Google Scholar] [CrossRef]

- Praveenkumara, J.; Madhu, P.; Yashas Gowda, T.; Sanjay, M.; Siengchin, S. A comprehensive review on the effect of synthetic filler materials on fiber-reinforced hybrid polymer composites. J. Text. Inst. 2022, 113, 1231–1239. [Google Scholar] [CrossRef]

- Somaiah, A.; Prasad, B.A.; Nath, N.K. A comprehensive review: Characterization of glass fiber reinforced polymer composites with fillers from a Thermo-mechanical perspective. Mater. Today Proc. 2022, 62, 3226–3232. [Google Scholar] [CrossRef]

- Feyzullahoğlu, E. Effect of different fillers on adhesive wear properties of glass fiber reinforced polyester composites. Tribol. Ind. 2017, 39, 482. [Google Scholar] [CrossRef]

- Arockiasamy, F.S.; Divakaran, D.; Kumar, S.G.; Raja, S.; Suyambulingam, I.; Rangappa, S.M.; Siengchin, S. Processing and application of bio-fillers/bio-plasticizers and their effects in polymeric composites. In Sustainable Fillers/Plasticizers for Polymer Composites; Elsevier: Amsterdam, The Netherlands, 2025; pp. 237–255. [Google Scholar]

- Xie, Z.; Liu, D.; Xiao, Y.; Wang, K.; Zhang, Q.; Wu, K.; Fu, Q. The effect of filler permittivity on the dielectric properties of polymer-based composites. Compos. Sci. Technol. 2022, 222, 109342. [Google Scholar] [CrossRef]

- Deeba, F.; Shrivastava, K.; Bafna, M.; Jain, A. Tuning of dielectric properties of polymers by composite formation: The effect of inorganic fillers addition. J. Compos. Sci. 2022, 6, 355. [Google Scholar] [CrossRef]

- Kiran, M.; Govindaraju, H.; Jayaraju, T.; Kumar, N. Effect of fillers on mechanical properties of polymer matrix composites. Mater. Today Proc. 2018, 5, 22421–22424. [Google Scholar] [CrossRef]

- Saravanakumaar, A.; Senthilkumar, A.; Muthu Chozha Rajan, B. Effect of fillers on natural fiber–Polymer composite: An overview of physical and mechanical properties. In Mechanical and Dynamic Properties of Biocomposites; Wiley: Hoboken, NJ, USA, 2021; pp. 207–233. [Google Scholar] [CrossRef]

- Gokulkumar, S.; Sathish, S.; Kumar, S.D.; Prabhu, L. Investigation and analysis of sound-absorbing properties of waste tea leaf fiber as fillers in pineapple leaf/glass fiber-reinforced composites. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2023, 237, 403–424. [Google Scholar] [CrossRef]

- Lee, O.H.; Kim, S.-S.; Lim, Y.-S. Conduction noise absorption by fiber-reinforced epoxy composites with carbon nanotubes. J. Magn. Magn. Mater. 2011, 323, 587–591. [Google Scholar] [CrossRef]

- Rybiński, P.; Mirkhodjaev, U.Z.; Żukowski, W.; Bradło, D.; Gawlik, A.; Zamachowski, J.; Marzec, A.; Szadkowski, B. The effect of the lignocellulosic filler on the reduction of fire hazard of styrene-butadiene rubber composites, including the reduction of smoke, PCDD/F, PAH emissions and toxicity during its thermal decomposition. Polym. Test. 2023, 118, 107900. [Google Scholar] [CrossRef]

- Rybiński, P.; Mirkhodjaev, U.Z.; Żukowski, W.; Bradło, D.; Gawlik, A.; Zamachowski, J.; Żelezik, M.; Masłowski, M.; Miedzianowska, J. Effect of hybrid filler, carbon black–lignocellulose, on fire hazard reduction, including PAHs and PCDDs/Fs of natural rubber composites. Polymers 2023, 15, 1975. [Google Scholar] [CrossRef]

- Antunes, P.; Ramalho, A.; Carrilho, E. Mechanical and wear behaviours of nano and microfilled polymeric composite: Effect of filler fraction and size. Mater. Des. 2014, 61, 50–60. [Google Scholar] [CrossRef]

- Rajak, D.K.; Pagar, D.D.; Menezes, P.L.; Linul, E. Fiber-reinforced polymer composites: Manufacturing, properties, and applications. Polymers 2019, 11, 1667. [Google Scholar] [CrossRef]

- Mazitova, A.K.; Zaripov, I.I.; Aminova, G.K.; Ovod, M.V.; Suntsova, N.L. Fillers for polymer composite materials. Nanotekhnologii V Stroit. 2022, 14, 294–299. [Google Scholar] [CrossRef]

- Xanthos, M. Functional Fillers for Plastics; John Wiley & Sons: Hoboken, NJ, USA, 2010. [Google Scholar]

- Friedrich, K.; Zhang, Z.; Schlarb, A.K. Effects of various fillers on the sliding wear of polymer composites. Compos. Sci. Technol. 2005, 65, 2329–2343. [Google Scholar] [CrossRef]

- Beck, W.R.; O’brien, D.L. Glass Bubbles Prepared by Reheating Solid Glass Partiles. U.S. Patent US3365315A, 23 August 1963. [Google Scholar]

- Karasu, B.; Demirel, İ.; Öztuvan, A.; Özdemir, B. Glass microspheres. El-Cezeri 2019, 6, 613–641. [Google Scholar] [CrossRef]

- Wang, Z.; Guo, Z.; Yan, Y.; Liu, Y.; Han, S.; Ji, P.; Yunusov, F.A.; Tolochko, O.V.; Yin, F. Preparation of lightweight glass microsphere/Al sandwich composites with high compressive properties. Mater. Lett. 2022, 308, 131220. [Google Scholar] [CrossRef]

- Mutua, F.N.; Lin, P.; Koech, J.K.; Wang, Y. Surface modification of hollow glass microspheres. Mater. Sci. Appl. 2012, 3, 856–860. [Google Scholar] [CrossRef]

- Wang, P.; Liao, B.; An, Z.; Yan, K.; Zhang, J. Measurement and calculation of cryogenic thermal conductivity of HGMs. Int. J. Heat Mass Transf. 2019, 129, 591–598. [Google Scholar] [CrossRef]

- Budov, V. Hollow glass microspheres. use, properties, and technology. Glass Ceram. 1994, 51, 230–235. [Google Scholar] [CrossRef]

- Yang, Y.; Yu, H.; Zhou, X.; Zhou, Z. Shallow porous microsphere carriers with core-shell structure based on glass beads cross-linking chitosan for immobilizing inulinase. Mol. Catal. 2020, 486, 110871. [Google Scholar] [CrossRef]

- Hong, W.; Guo, F.; Hu, L.; Wang, X.; Xing, C.; Tan, Y.; Zhao, X.; Xiao, P. A hierarchically porous bioactive glass-ceramic microsphere with enhanced bioactivity for bone tissue engineering. Ceram. Int. 2019, 45, 13579–13583. [Google Scholar] [CrossRef]

- Guillen, G.R.; Pan, Y.; Li, M.; Hoek, E.M. Preparation and characterization of membranes formed by nonsolvent induced phase separation: A review. Ind. Eng. Chem. Res. 2011, 50, 3798–3817. [Google Scholar] [CrossRef]

- Liu, B.; Wang, H.; Qin, Q.-H. Modelling and characterization of effective thermal conductivity of single hollow glass microsphere and its powder. Materials 2018, 11, 133. [Google Scholar] [CrossRef] [PubMed]

- Verweij, H.; De With, G.; Veeneman, D. Hollow glass microsphere composites: Preparation and properties. J. Mater. Sci. 1985, 20, 1069–1078. [Google Scholar] [CrossRef]

- Ren, S.; Liu, J.; Guo, A.; Zang, W.; Geng, H.; Tao, X.; Du, H. Mechanical properties and thermal conductivity of a temperature resistance hollow glass microspheres/borosilicate glass buoyance material. Mater. Sci. Eng. A 2016, 674, 604–614. [Google Scholar] [CrossRef]

- Amos, S.E.; Yalcin, B. Hollow Glass Microspheres for Plastics, Elastomers, and Adhesives Compounds; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Geng, H.; Liu, J.; Guo, A.; Ren, S.; Xu, X.; Liu, S. Fabrication of heat-resistant syntactic foams through binding hollow glass microspheres with phosphate adhesive. Mater. Des. 2016, 95, 32–38. [Google Scholar] [CrossRef]

- Wang, J.; Cui, W. A probability distribution model for the compressive strength of micro thin-walled hollow glass beads under uniform pressure. Heliyon 2023, 9, e21597. [Google Scholar] [CrossRef]

- Liang, J.; Li, F. Measurement of thermal conductivity of hollow glass-bead-filled polypropylene composites. Polym. Test. 2006, 25, 527–531. [Google Scholar] [CrossRef]

- Zhang, H.; Sun, J.; Shen, L. Electroless silver plating on hollow microsphere. Electroplat. Finish. 2007, 26, 26. [Google Scholar]

- Afolabi, O.A. Hybrid Syntactic Foam Core Cased Natural-Glass Fibre Sandwich Composite. Ph.D. Thesis, Durban University of Technology, Durban, South Africa, 2023. [Google Scholar]

- Wang, J.; Liang, G.; Yan, H.; He, S. Mechanical and dielectric properties of epoxy/dicyclopentadiene bisphenol cyanate ester/glass fabric composites. Express Polym. Lett. 2008, 2, 118–125. [Google Scholar] [CrossRef]

- Wu, B.; Liu, H.; Fu, R.; Song, X.; Su, X.; Liu, X. Epoxy-matrix composite with low dielectric constant and high thermal conductivity fabricated by HGMs/Al2O3 co-continuous skeleton. J. Alloys Compd. 2021, 869, 159332. [Google Scholar] [CrossRef]

- Hossain, K.M.Z.; Patel, U.; Kennedy, A.R.; Macri-Pellizzeri, L.; Sottile, V.; Grant, D.M.; Scammell, B.E.; Ahmed, I. Porous calcium phosphate glass microspheres for orthobiologic applications. Acta Biomater. 2018, 72, 396–406. [Google Scholar] [CrossRef] [PubMed]

- Kraxner, J.; Michalek, M.; Romero, A.R.; Elsayed, H.; Bernardo, E.; Boccaccini, A.R.; Galusek, D. Porous bioactive glass microspheres prepared by flame synthesis process. Mater. Lett. 2019, 256, 126625. [Google Scholar] [CrossRef]

- Nagrath, M.; Yazdi, A.R.; Rafferty, A.; Daly, D.; Rahman, S.U.; Gallant, R.C.; Ni, H.; Arany, P.R.; Towler, M.R. Tantalum-containing meso-porous glass fibres for hemostatic applications. Mater. Today Commun. 2021, 27, 102260. [Google Scholar] [CrossRef]

- Helling, T.; Reischl, F.; Rosin, A.; Gerdes, T.; Krenkel, W. Atomization of Borosilicate Glass Melts for the Fabrication of Hollow Glass Microspheres. Processes 2023, 11, 2559. [Google Scholar] [CrossRef]

- Lee, M.Y.; Tan, J.; Heng, J.Y.; Cheeseman, C. A comparative study of production of glass microspheres by using thermal process. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2017; p. 012022. [Google Scholar]

- Dalai, S.; Vijayalakshmi, S.; Shrivastava, P.; Sivam, S.P.; Sharma, P. Preparation and characterization of hollow glass microspheres (HGMs) for hydrogen storage using urea as a blowing agent. Microelectron. Eng. 2014, 126, 65–70. [Google Scholar] [CrossRef]

- Bobkova, N.; Savchin, V.; Trusova, E.; Pavlyukevich, Y.G. Rheological Basis of Hollow Glass Microsphere Production Based on Alkali-Borosilicate Systems. Glass Ceram. 2018, 75, 3–6. [Google Scholar] [CrossRef]

- Bobkova, N.M.; Trusova, E.; Savchin, V.; Sabadakha, E.; Pavlyukevich, Y.G. Obtaining hollow glass microspheres and their use in the production of water-dispersion coatings. Glass Ceram. 2020, 76, 401–405. [Google Scholar] [CrossRef]

- Schmitt, M.; Shelby, J.; Hall, M. Preparation of hollow glass microspheres from sol–gel derived glass for application in hydrogen gas storage. J. Non-Cryst. Solids 2006, 352, 626–631. [Google Scholar] [CrossRef]

- Ward, J.M.; Wu, Y.; Khalfi, K.; Chormaic, S.N. Short vertical tube furnace for the fabrication of doped glass microsphere lasers. Rev. Sci. Instrum. 2010, 81, 073106. [Google Scholar] [CrossRef]

- Bica, I. Iron micro-spheres generation in argon plasma jet. Mater. Sci. Eng. B 2002, 88, 107–109. [Google Scholar] [CrossRef]

- Mahmoud, M.; Kraxner, J.; Elsayed, H.; Bernardo, E.; Galusek, D. Fabrication and environmental applications of glass microspheres: A review. Ceram. Int. 2023, 49, 39745–39759. [Google Scholar] [CrossRef]

- Chukov, D.; Nematulloev, S.; Zadorozhnyy, M.; Tcherdyntsev, V.; Stepashkin, A.; Zherebtsov, D. Structure, mechanical and thermal properties of polyphenylene sulfide and polysulfone impregnated carbon fiber composites. Polymers 2019, 11, 684. [Google Scholar] [CrossRef] [PubMed]

- Yashas Gowda, T.; Sanjay, M.; Subrahmanya Bhat, K.; Madhu, P.; Senthamaraikannan, P.; Yogesha, B. Polymer matrix-natural fiber composites: An overview. Cogent Eng. 2018, 5, 1446667. [Google Scholar] [CrossRef]

- Sherif, G.; Chukov, D.; Tcherdyntsev, V.; Torokhov, V. Effect of formation route on the mechanical properties of the polyethersulfone composites reinforced with glass fibers. Polymers 2019, 11, 1364. [Google Scholar] [CrossRef] [PubMed]

- Neves Monteiro, S.; Salgado de Assis, F.; Ferreira, C.L.; Tonini Simonassi, N.; Pondé Weber, R.; Souza Oliveira, M.; Colorado, H.A.; Camposo Pereira, A. Fique fabric: A promising reinforcement for polymer composites. Polymers 2018, 10, 246. [Google Scholar] [CrossRef] [PubMed]

- Chukov, D.; Nematulloev, S.; Torokhov, V.; Stepashkin, A.; Sherif, G.; Tcherdyntsev, V. Effect of carbon fiber surface modification on their interfacial interaction with polysulfone. Results Phys. 2019, 15, 102634. [Google Scholar] [CrossRef]

- Naser, M.; Hawileh, R.; Abdalla, J. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Taj, S.; Munawar, M.A.; Khan, S. Natural fiber-reinforced polymer composites. Proc.-Pak. Acad. Sci. 2007, 44, 129. [Google Scholar]

- Neto, J.; Queiroz, H.; Aguiar, R.; Lima, R.; Cavalcanti, D.; Banea, M.D. A review of recent advances in hybrid natural fiber reinforced polymer composites. J. Renew. Mater. 2022, 10, 561. [Google Scholar] [CrossRef]

- Dhal, J.P.; Mishra, S.C. Processing and Properties of Natural Fiber-Reinforced Polymer Composite. J. Mater. 2013, 2013, 297213. [Google Scholar] [CrossRef]

- Maithil, P.; Gupta, P.; Chandravanshi, M. Study of mechanical properties of the natural-synthetic fiber reinforced polymer matrix composite. Mater. Today Proc. 2023, in press. [Google Scholar] [CrossRef]

- Ardanuy, M.; Claramunt, J.; Toledo Filho, R.D. Cellulosic fiber reinforced cement-based composites: A review of recent research. Constr. Build. Mater. 2015, 79, 115–128. [Google Scholar] [CrossRef]

- Balea, A.; Fuente, E.; Blanco, A.; Negro, C. Nanocelluloses: Natural-based materials for fiber-reinforced cement composites. A critical review. Polymers 2019, 11, 518. [Google Scholar] [CrossRef]

- Thomas, S.; Jose, S. Wool Fiber Reinforced Polymer Composites; Woodhead Publishing: London, UK, 2022. [Google Scholar]

- Begum, S.; Fawzia, S.; Hashmi, M. Polymer matrix composite with natural and synthetic fibres. Adv. Mater. Process. Technol. 2020, 6, 547–564. [Google Scholar] [CrossRef]

- Venkateshwaran, N.; ElayaPerumal, A.; Jagatheeshwaran, M. Effect of fiber length and fiber content on mechanical properties of banana fiber/epoxy composite. J. Reinf. Plast. Compos. 2011, 30, 1621–1627. [Google Scholar] [CrossRef]

- Wang, H.; Zhou, H.; Gui, L.; Ji, H.; Zhang, X. Analysis of effect of fiber orientation on Young’s modulus for unidirectional fiber reinforced composites. Compos. Part B Eng. 2014, 56, 733–739. [Google Scholar] [CrossRef]

- Asoodeh, F.; Aghvami-Panah, M.; Salimian, S.; Naeimirad, M.; Khoshnevis, H.; Zadhoush, A. The effect of fibers’ length distribution and concentration on rheological and mechanical properties of glass fiber–reinforced polypropylene composite. J. Ind. Text. 2022, 51 (Suppl. S5), 8452S–8471S. [Google Scholar] [CrossRef]

- Sharma, A.K.; Bhandari, R.; Aherwar, A.; Rimašauskienė, R. Matrix materials used in composites: A comprehensive study. Mater. Today Proc. 2020, 21, 1559–1562. [Google Scholar] [CrossRef]

- Laycock, B.; Pratt, S.; Halley, P. A perspective on biodegradable polymer biocomposites-from processing to degradation. Funct. Compos. Mater. 2023, 4, 10. [Google Scholar] [CrossRef]

- Kumar, N.V.; Krishna, B.S.; Chandrika, N.S. Evaluation of properties of glass-banana-fiber reinforced hybrid fiber polymer composite. Mater. Today Proc. 2019, 18, 2137–2141. [Google Scholar] [CrossRef]

- Alabtah, F.G.; Mahdi, E.; Eliyan, F.F.; Eltai, E.; Khraisheh, M. Towards the development of novel hybrid composite steel pipes: Electrochemical evaluation of fiber-reinforced polymer layered steel against corrosion. Polymers 2021, 13, 3805. [Google Scholar] [CrossRef]

- Uthaman, A.; Xian, G.; Thomas, S.; Wang, Y.; Zheng, Q.; Liu, X. Durability of an epoxy resin and its carbon fiber-reinforced polymer composite upon immersion in water, acidic, and alkaline solutions. Polymers 2020, 12, 614. [Google Scholar] [CrossRef] [PubMed]

- Boon, Y.D.; Joshi, S.C.; Bhudolia, S.K.; Gohel, G. Recent advances on the design automation for performance-optimized fiber reinforced polymer composite components. J. Compos. Sci. 2020, 4, 61. [Google Scholar] [CrossRef]

- Alarifi, I.M. Investigation into the morphological and mechanical properties of date palm fiber-reinforced epoxy structural composites. J. Vinyl Addit. Technol. 2021, 27, 77–88. [Google Scholar] [CrossRef]

- Jagadeesh, P.; Puttegowda, M.; Girijappa, Y.G.T.; Rangappa, S.M.; Gupta, M.K.; Siengchin, S. Mechanical, electrical and thermal behaviour of additively manufactured thermoplastic composites for high performance applications. In Additive and Subtractive Manufacturing of Composites; Springer: Berlin/Heidelberg, Germany, 2021; pp. 167–199. [Google Scholar]

- Senthilkumar, K.; Saba, N.; Rajini, N.; Chandrasekar, M.; Jawaid, M.; Siengchin, S.; Alotman, O.Y. Mechanical properties evaluation of sisal fibre reinforced polymer composites: A review. Constr. Build. Mater. 2018, 174, 713–729. [Google Scholar] [CrossRef]

- Lebreton, L.C.; Van Der Zwet, J.; Damsteeg, J.-W.; Slat, B.; Andrady, A.; Reisser, J. River plastic emissions to the world’s oceans. Nat. Commun. 2017, 8, 15611. [Google Scholar] [CrossRef]

- Venkatachalam, N.; Navaneethakrishnan, P.; Rajsekar, R.; Shankar, S. Effect of pretreatment methods on properties of natural fiber composites: A review. Polym. Polym. Compos. 2016, 24, 555–566. [Google Scholar] [CrossRef]

- Aniskevich, A.; Glaskova-Kuzmina, T. Effect of moisture on elastic and viscoelastic properties of fiber reinforced plastics: Retrospective and current trends. In Creep and Fatigue in Polymer Matrix Composites; Elsevier: Amsterdam, The Netherlands, 2019; pp. 83–120. [Google Scholar]

- Bachchan, A.A.; Das, P.P.; Chaudhary, V. Effect of moisture absorption on the properties of natural fiber reinforced polymer composites: A review. Mater. Today Proc. 2022, 49, 3403–3408. [Google Scholar] [CrossRef]

- Zhou, F.; Zhang, J.; Song, S.; Yang, D.; Wang, C. Effect of temperature on material properties of carbon fiber reinforced polymer (CFRP) tendons: Experiments and model assessment. Materials 2019, 12, 1025. [Google Scholar] [CrossRef]

- Li, Y.; Li, W.; Shao, J.; Deng, Y.; Kou, H.; Ma, J.; Zhang, X.; Zhang, X.; Chen, L.; Qu, Z. Modeling the effects of interfacial properties on the temperature dependent tensile strength of fiber reinforced polymer composites. Compos. Sci. Technol. 2019, 172, 74–80. [Google Scholar] [CrossRef]

- Hashim, U.R.; Jumahat, A.; Jawaid, M.; Dungani, R.; Alamery, S. Effects of accelerated weathering on degradation behavior of basalt fiber reinforced polymer nanocomposites. Polymers 2020, 12, 2621. [Google Scholar] [CrossRef]

- Gualberto, H.R.; dos Reis, J.M.L.; de Andrade, M.C.; Costa, H.R.M.; Amorim, F.d.C.; Hunt, J.D. Effect of exposure time to UV radiation on mechanical properties of glass/epoxy composites. Appl. Compos. Mater. 2024, 31, 447–465. [Google Scholar] [CrossRef]

- Wagmare, R.; Harshe, R.; Pednekar, J.; Patro, T.U. Additive manufacturing of continuous fiber-reinforced polymer composites: Current trend and future directions. Prog. Addit. Manuf. 2025, 10, 1973–2000. [Google Scholar] [CrossRef]

- Sztorch, B.; Brząkalski, D.; Pakuła, D.; Frydrych, M.; Špitalský, Z.; Przekop, R.E. Natural and synthetic polymer fillers for applications in 3D printing—FDM technology area. Solids 2022, 3, 508–548. [Google Scholar] [CrossRef]

- Golewski, G.L. Determination of fracture toughness in concretes containing siliceous fly ash during mode III loading. Struct. Eng. Mech 2017, 62, 1–9. [Google Scholar] [CrossRef]

- Golewski, G.L. Effect of fly ash addition on the fracture toughness of plain concrete at third model of fracture. J. Civ. Eng. Manag. 2017, 23, 613–620. [Google Scholar] [CrossRef]

- Das, S.C.; Nizam, M. Applications of fiber reinforced polymer composites (FRP) in civil engineering. Int. J. Adv. Struct. Geotech. Eng. 2014, 3, 299–309. [Google Scholar]

- Yim, D.; Park, J.; Jang, S.; Choi, J.; Park, N.-H. Fabrication and properties of glass fiber-reinforced composites using polyimide prepregs with inorganic nanofillers. Fibers Polym. 2021, 22, 804–810. [Google Scholar] [CrossRef]

- Singh, T.; Gangil, B.; Ranakoti, L.; Joshi, A. Effect of silica nanoparticles on physical, mechanical, and wear properties of natural fiber reinforced polymer composites. Polym. Compos. 2021, 42, 2396–2407. [Google Scholar] [CrossRef]

- Gapsari, F.; A, M.S.; Putri, T.M.; Juliano, H.; Djakfar, L.; Handajani, R.P.; Budio, S.P.; Juwono, P.T.; Jagadeesh, P.; Mavinkere Rangappa, S.; et al. Influence of calcium carbonate fillers on pine fiber reinforced polyester composites. Polym. Compos. 2022, 43, 4306–4317. [Google Scholar] [CrossRef]

- Mawardi, I.; Razak, H.; Akadir, Z.; Jaya, R.P. The effect of containing Al2O3 microparticles in different matrix polymers on properties of pineapple fiber-reinforced composites. Fract. Struct. Integr. 2024, 18, 94–107. [Google Scholar] [CrossRef]

- Thipperudrappa, S.; Ullal Kini, A.; Hiremath, A. Influence of zinc oxide nanoparticles on the mechanical and thermal responses of glass fiber-reinforced epoxy nanocomposites. Polym. Compos. 2020, 41, 174–181. [Google Scholar] [CrossRef]

- Ferreira, T.R.M.; Lechtman, M.d.A.; Dias, F.L.; Silva, A.B.d. Effect of hollow glass microspheres addition on density reduction and mechanical properties of PA6/glass fibers composites. Polímeros 2022, 32, e2022001. [Google Scholar] [CrossRef]

- Ajayi, A.A.; Krishnan, K.; Pandurangan, M.T. Effect of surface modification on mechanical properties of hollow glass microspheres (HGM)-filled epoxy foam composites. SPE Polym. 2025, 6, e70009. [Google Scholar] [CrossRef]

- Afolabi, O.A.; Mohan, T.P.; Kanny, K. Processing of low-density HGM-filled epoxy–syntactic foam composites with high specific properties for marine applications. Materials 2023, 16, 1732. [Google Scholar] [CrossRef]

- Berata, W.; Wijanarko, W.; Sidharta, I. Effect of volume fraction epoxy-hollow glass microspheres and curing temperature variation on compressive properties of composites. ARPN J. Eng. Appl. Sci. 2016, 11, 2729–2733. [Google Scholar]

- Ding, Y.; Dong, Z.; Xu, H.; Ma, Z.; Zhai, G. Influence of the Void Structure on Thermal Performance in HGM/ER Composites. Energies 2025, 18, 2073. [Google Scholar] [CrossRef]

- Tejasvi, K.; Ranga, K.V.; Gurusideswar, S.; Singh, P.S. Preparation and Characterization of Hollow Glass Microspheres Reinforced Carbon-Epoxy Composite; 0148-7191; SAE Technical Paper; SAE International: Warrendale, PA, USA, 2023. [Google Scholar]

- Qiao, Y.; Wang, X.; Zhang, X.; Xing, Z. Investigation of flexural properties of hollow glass microsphere filled resin-matrix composites. Pigment Resin Technol. 2016, 45, 426–430. [Google Scholar] [CrossRef]

- Bhatia, S.; Angra, S.; Khan, S. Mechanical and wear properties of epoxy matrix composite reinforced with varying ratios of solid glass microspheres. In Journal of Physics: Conference Series; IOP Publishing: Bristol, UK, 2019; p. 012080. [Google Scholar]

- Sethi, S.; Ray, B. An assessment of interfacial chemistry and character of fiber/polymer micro-composites. J. Polym. Compos. 2013, 1, 1–5. [Google Scholar]

- Bhatia, S.; Khan, M.; Sengar, H.; Bhatia, V. A review on the mechanical properties and environmental impact of hollow glass microsphere epoxy composites. IIOAB J. 2018, 9, 1–8. [Google Scholar]

- Awais, H.; Nawab, Y.; Anjang, A.; Akil, H.M.; Abidin, M.S.Z. Mechanical properties of continuous natural fibres (jute, hemp, flax) reinforced polypropylene composites modified with hollow glass microspheres. Fibers Polym. 2020, 21, 2076–2083. [Google Scholar] [CrossRef]

- Tejasvi, K.; Sharma, A.; Ranga, K.; Gurusideswar, S.; Sundar Singh, P. Effect of hollow glass microspheres on transverse properties of carbon fiber reinforced epoxy composites. Polym. Compos. 2024, 45, 15820–15831. [Google Scholar] [CrossRef]

- Gogoi, R.; Manik, G.; Arun, B. High specific strength hybrid polypropylene composites using carbon fibre and hollow glass microspheres: Development, characterization and comparison with empirical models. Compos. Part B Eng. 2019, 173, 106875. [Google Scholar] [CrossRef]

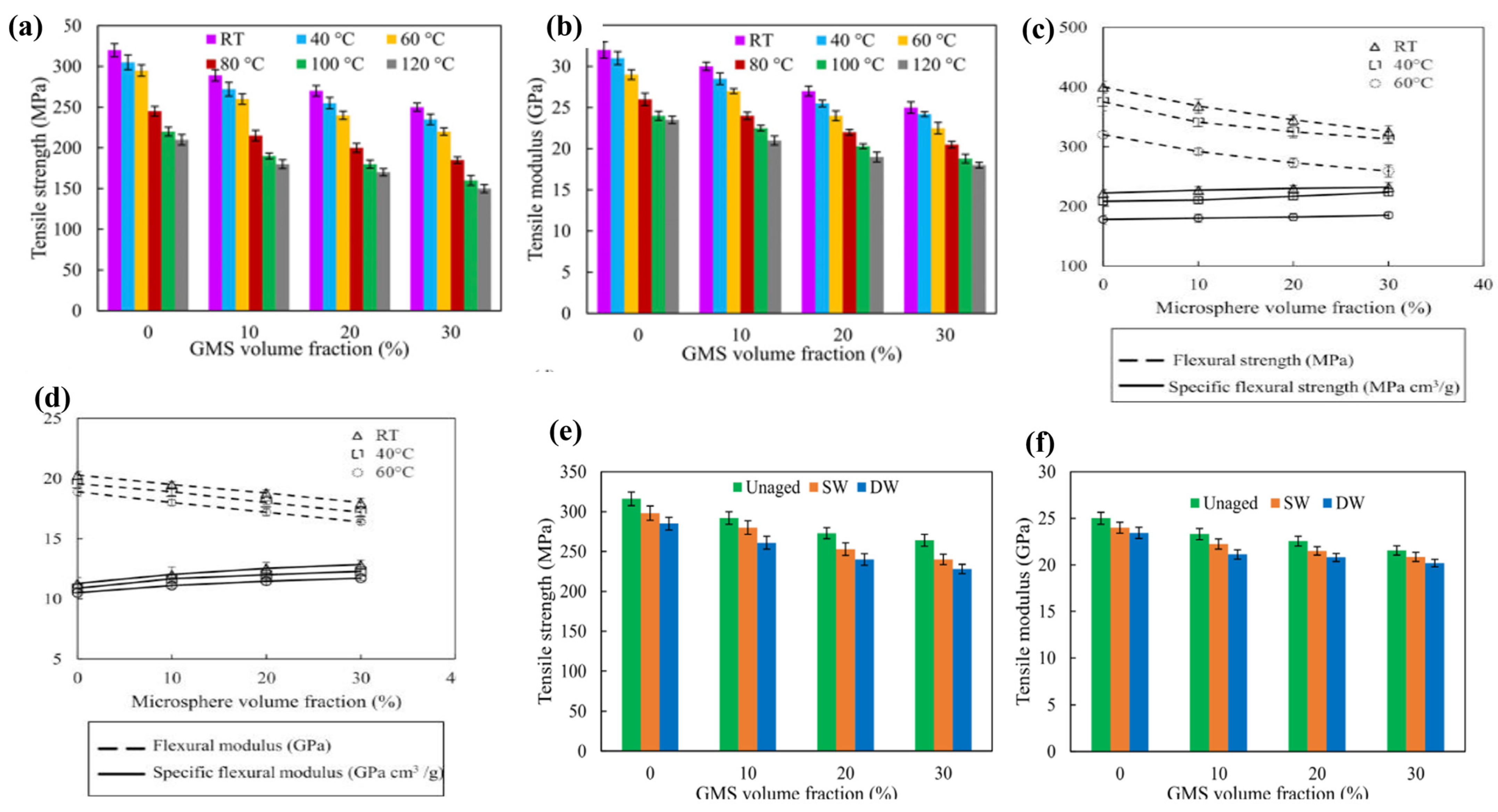

- Anandakumar, P.; Kanny, K.; Mohan, T.P.; Velmurugan, R. Effect of temperature on the mechanical behavior of glass fiber reinforced with hollow glass particle-filled epoxy composites. Mater. Today Proc. 2024, in press. [Google Scholar] [CrossRef]

- Anandakumar, P.; Kanny, K.; Mohan, T.P.; Velmurugan, R. Mechanical behavior of glass fiber-reinforced hollow glass particles filled epoxy composites under moisture environment. Polym. Compos. 2024, 45, 8613–8630. [Google Scholar] [CrossRef]

- Borges, T.E.; Almeida Jr, J.H.S.; Amico, S.C.; Amado, F.D. Hollow glass microspheres/piassava fiber-reinforced homo-and co-polypropylene composites: Preparation and properties. Polym. Bull. 2017, 74, 1979–1993. [Google Scholar] [CrossRef]

- Kumar, N.; Mireja, S.; Khandelwal, V.; Arun, B.; Manik, G. Light-weight high-strength hollow glass microspheres and bamboo fiber based hybrid polypropylene composite: A strength analysis and morphological study. Compos. Part B Eng. 2017, 109, 277–285. [Google Scholar] [CrossRef]

- Doumbia, A.S.; Bourmaud, A.; Jouannet, D.; Falher, T.; Orange, F.; Retoux, R.; Le Pluart, L.; Cauret, L. Hollow microspheres–poly-(propylene) blends: Relationship between microspheres degradation and composite properties. Polym. Degrad. Stab. 2015, 114, 146–153. [Google Scholar] [CrossRef]

- Liang, J.-Z. Tensile and flexural properties of hollow glass bead-filled ABS composites. J. Elastomers Plast. 2005, 37, 361–370. [Google Scholar] [CrossRef]

- Gupta, N.; Ye, R.; Porfiri, M. Comparison of tensile and compressive characteristics of vinyl ester/glass microballoon syntactic foams. Compos. Part B Eng. 2010, 41, 236–245. [Google Scholar] [CrossRef]

- Singh, A.; Trivedi, A.K.; Gupta, M.; Singh, H. Static, dynamic mechanical, and thermal analysis of coir/epoxy composites: Effect of hollow glass microspheres reinforcement. Polym. Compos. 2023, 44, 8529–8540. [Google Scholar] [CrossRef]

- Li, J.; Luo, X.; Lin, X. Preparation and characterization of hollow glass microsphere reinforced poly (butylene succinate) composites. Mater. Des. 2013, 46, 902–909. [Google Scholar] [CrossRef]

- Chattopadhyay, S.K.; Khandal, R.; Uppaluri, R.; Ghoshal, A.K. Bamboo fiber reinforced polypropylene composites and their mechanical, thermal, and morphological properties. J. Appl. Polym. Sci. 2011, 119, 1619–1626. [Google Scholar] [CrossRef]

- Afolabi, O.A.; Kanny, K.; Mohan, T.P. Analysis of particle variation effect on flexural properties of hollow glass microsphere filled epoxy matrix syntactic foam composites. Polymers 2022, 14, 4848. [Google Scholar] [CrossRef]

- Sun, J.; Cai, F.; Tao, D.; Ni, Q.; Fu, Y. Enhanced thermal insulation of the hollow glass microsphere/glass fiber fabric textile composite material. Polymers 2021, 13, 505. [Google Scholar] [CrossRef] [PubMed]

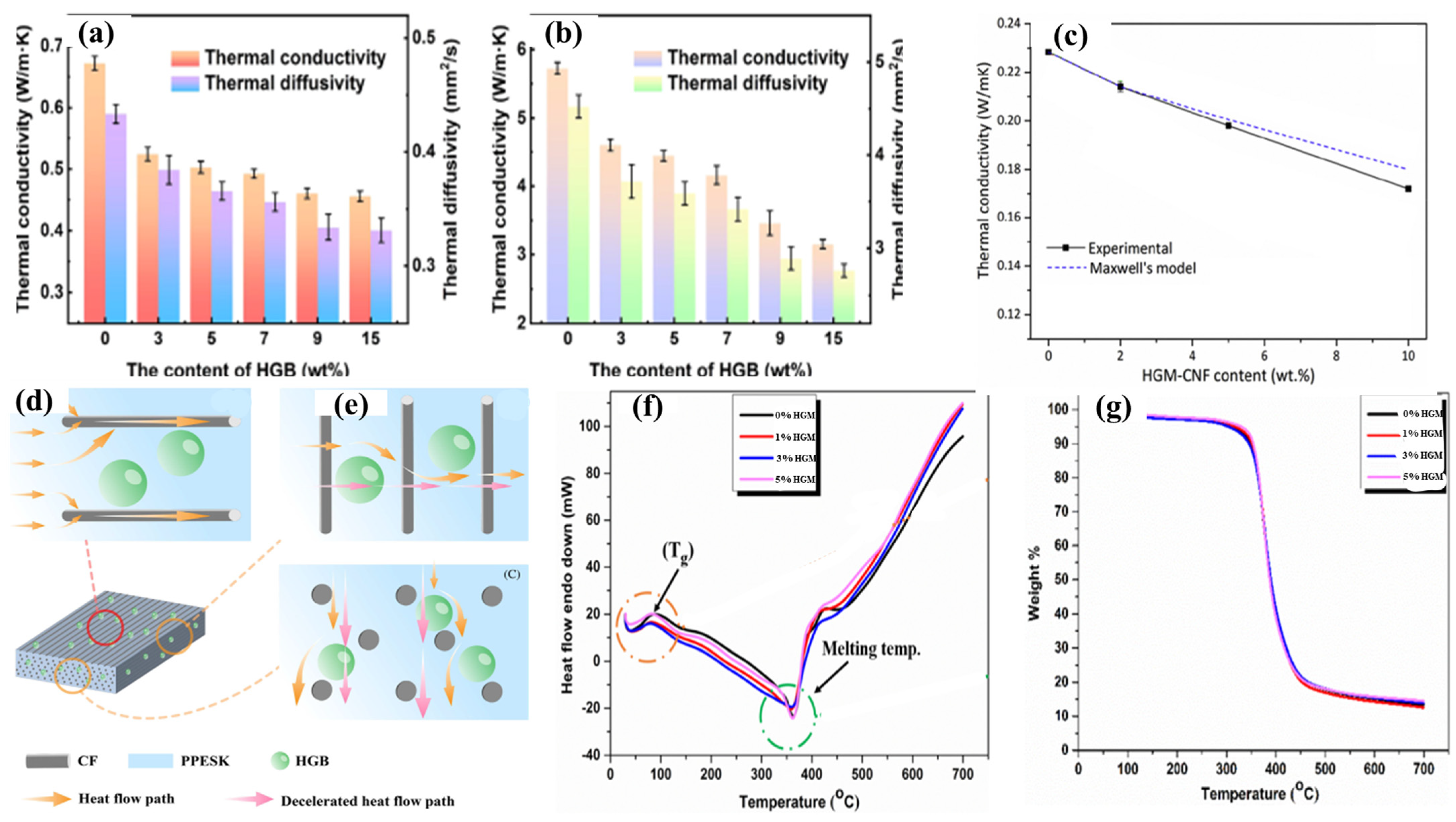

- Feng, J.; Li, N.; Wang, B.; Cheng, S.; Bao, Q.; Wang, H.; Jian, X. Thermal insulation and mechanical properties of carbon fiber-reinforced thermoplastic polyphthalazine ether sulfone ketone composites reinforced by hollow glass beads. Polym. Compos. 2023, 44, 7941–7952. [Google Scholar] [CrossRef]

- Nimbagal, V.; Banapurmath, N.; Umarfarooq, M.; Revankar, S.; Sajjan, A.M.; Soudagar, M.E.M.; Shahapurkar, K.; Alamir, M.A.; Alarifi, I.M.; Elfasakhany, A. Mechanical and fracture properties of carbon nano fibers/short carbon fiber epoxy composites. Polym. Compos. 2023, 44, 3977–3989. [Google Scholar] [CrossRef]

- Paramasivam, A.; Kanny, K.; Turup Pandurangan, M.; Ramachandran, V. Mechanical behavior of glass fiber-reinforced hollow glass particles filled epoxy composites under thermal loading. J. Compos. Mater. 2024, 58, 2027–2044. [Google Scholar] [CrossRef]

- Dagar, A.; Narula, A. Fabrication of thermoplastic composites using fly-ash a coal and hollow glass beads to study their mechanical, thermal, rheological, morphological and flame retradency properties. Russ. J. Appl. Chem. 2017, 90, 1494–1503. [Google Scholar] [CrossRef]

- Liang, J.-Z. Estimation of thermal conductivity for polypropylene/hollow glass bead composites. Compos. Part B Eng. 2014, 56, 431–434. [Google Scholar] [CrossRef]

- Yağci, Ö.; Eker Gümüş, B.; Taşdemir, M. Thermal, structural and dynamical mechanical properties of hollow glass sphere-reinforced polypropylene composites. Polym. Bull. 2021, 78, 3089–3101. [Google Scholar] [CrossRef]

- Imran, M.; Rahaman, A.; Pal, S. Effect of low concentration hollow glass microspheres on mechanical and thermomechanical properties of epoxy composites. Polym. Compos. 2019, 40, 3493–3499. [Google Scholar] [CrossRef]

- Hu, Y.; Mei, R.; An, Z.; Zhang, J. Silicon rubber/hollow glass microsphere composites: Influence of broken hollow glass microsphere on mechanical and thermal insulation property. Compos. Sci. Technol. 2013, 79, 64–69. [Google Scholar] [CrossRef]

- Patankar, S.; Kranov, Y. Hollow glass microsphere HDPE composites for low energy sustainability. Mater. Sci. Eng. A 2010, 527, 1361–1366. [Google Scholar] [CrossRef]

- Li, Q.; Pan, Z. Present status of research on lightweight thermal insulating materials and its developing trend. Bull. Chin. Ceram. Soc. 2011, 30, 379–386. [Google Scholar]

- Wang, J.; Tian, Y.; Zhang, J. Thermal insulating epoxy composite coatings containing sepiolite/hollow glass microspheres as binary fillers: Morphology, simulation and application. Sci. Eng. Compos. Mater. 2017, 24, 379–386. [Google Scholar] [CrossRef]

- Herrera-Ramirez, L.C.; Cano, M.; de Villoria, R.G. Low thermal and high electrical conductivity in hollow glass microspheres covered with carbon nanofiber–polymer composites. Compos. Sci. Technol. 2017, 151, 211–218. [Google Scholar] [CrossRef]

- Gong, F.; Duong, H.M.; Papavassiliou, D.V. Inter-carbon nanotube contact and thermal resistances in heat transport of three-phase composites. J. Phys. Chem. C 2015, 119, 7614–7620. [Google Scholar] [CrossRef]

- Gong, F.; Bui, K.; Papavassiliou, D.V.; Duong, H.M. Thermal transport phenomena and limitations in heterogeneous polymer composites containing carbon nanotubes and inorganic nanoparticles. Carbon 2014, 78, 305–316. [Google Scholar] [CrossRef]

- Cosse, R.L.; Araujo, F.H.; Pinto, F.A.; de Carvalho, L.H.; de Morais, A.C.L.; Barbosa, R.; Alves, T.S. Effects of the type of processing on thermal, morphological and acoustic properties of syntactic foams. Compos. Part B Eng. 2019, 173, 106933. [Google Scholar] [CrossRef]

- HM, K.; Bavan, S.; B, Y.; MR, S.; Siengchin, S.; Gorbatyuk, S. Effect of coir fiber and inorganic filler on physical and mechanical properties of epoxy based hybrid composites. Polym. Compos. 2021, 42, 3911–3921. [Google Scholar] [CrossRef]

- Vlassov, S.; Oras, S.; Timusk, M.; Zadin, V.; Tiirats, T.; Sosnin, I.M.; Lõhmus, R.; Linarts, A.; Kyritsakis, A.; Dorogin, L.M. Thermal, mechanical, and acoustic properties of polydimethylsiloxane filled with hollow glass microspheres. Materials 2022, 15, 1652. [Google Scholar] [CrossRef]

- Pakdel, E.; Naebe, M.; Kashi, S.; Cai, Z.; Xie, W.; Yuen, A.C.Y.; Montazer, M.; Sun, L.; Wang, X. Functional cotton fabric using hollow glass microspheres: Focus on thermal insulation, flame retardancy, UV-protection and acoustic performance. Prog. Org. Coat. 2020, 141, 105553. [Google Scholar] [CrossRef]

- Yu, Z.; Du, X.; Zhu, P.; Zhao, T.; Sun, R.; Chen, J.; Wang, N.; Li, W. Surface modified hollow glass microspheres-epoxy composites with enhanced thermal insulation and reduced dielectric constant. Mater. Today Commun. 2022, 32, 104046. [Google Scholar] [CrossRef]

- Sathishkumar, G. Structural Analysis and Mechanical Properties of Lignite Fly-Ash/Hollow Glass Microsphere/Acacia Nilotica Incorporated-Jute-Epoxy Polymer Matrix Composite. Ph.D. Thesis, Anna University, Chennai, India, 2021. [Google Scholar]

- Altay, P.; Uçar, N. Improvement of insulation properties of glass fiber fabric/epoxy composites modified by polymeric and inorganic fillers. Polym. Compos. 2022, 43, 225–238. [Google Scholar] [CrossRef]

- Wang, H.; Yan, R.; Cheng, H.; Zou, M.; Wang, H.; Zheng, K. Hollow glass microspheres/phenolic syntactic foams with excellent mechanical and thermal insulate performance. Front. Chem. 2023, 11, 1216706. [Google Scholar] [CrossRef]

- Dhilipkumar, T.; Vasumathi, M.; Begum, S.R.; Sathyaseelan, P.; Gnanavel, B.; Ghfar, A.A. Evaluation of acoustic and structural behavior of banana fiber reinforced polymer composites. Fibers Polym. 2024, 25, 2303–2314. [Google Scholar] [CrossRef]

- Dev, B.; Rahman, M.A.; Repon, M.R.; Rahman, M.M.; Haji, A.; Nawab, Y. Recent progress in thermal and acoustic properties of natural fiber reinforced polymer composites: Preparation, characterization, and data analysis. Polym. Compos. 2023, 44, 7235–7297. [Google Scholar] [CrossRef]

- Jayamani, E.; Hamdan, S. Sound absorption coefficients natural fibre reinforced composites. Adv. Mater. Res. 2013, 701, 53–58. [Google Scholar] [CrossRef]

- Dhandapani, N.; Megalingam, A. Mechanical and sound absorption behavior of sisal and palm fiber reinforced hybrid composites. J. Nat. Fibers 2022, 19, 4530–4543. [Google Scholar] [CrossRef]

- Chen, D.; Li, J.; Ren, J. Study on sound absorption property of ramie fiber reinforced poly (l-lactic acid) composites: Morphology and properties. Compos. Part A Appl. Sci. Manuf. 2010, 41, 1012–1018. [Google Scholar] [CrossRef]

- Samaei, S.E.; Mahabadi, H.A.; Mousavi, S.M.; Khavanin, A.; Faridan, M.; Taban, E. The influence of alkaline treatment on acoustical, morphological, tensile and thermal properties of Kenaf natural fibers. J. Ind. Text. 2022, 51, 8601S–8625S. [Google Scholar] [CrossRef]

- Mehdi Jalili, M.; Yahya Mousavi, S.; Pirayeshfar, A.S. Investigating the acoustical properties of carbon fiber-, glass fiber-, and hemp fiber-reinforced polyester composites. Polym. Compos. 2014, 35, 2103–2111. [Google Scholar] [CrossRef]

- Shin, P.-S.; Kim, J.-H.; DeVries, K.L.; Park, J.-M. Manufacturing and qualitative properties of glass fiber/epoxy composite boards with added air bubbles for airborne and solid-borne sound insulation. Compos. Sci. Technol. 2020, 194, 108166. [Google Scholar] [CrossRef]

- Hopkins, C. Sound Insulation; Routledge: Oxfordshire, UK, 2012. [Google Scholar]

- Shi, X.; Wu, J.; Wang, X.; Zhou, X.; Xie, X.; Xue, Z. Novel sound insulation materials based on epoxy/hollow silica nanotubes composites. Compos. Part B Eng. 2017, 131, 125–133. [Google Scholar] [CrossRef]

- Zhang, Z.; Jiang, H.; Li, R.; Gao, S.; Wang, Q.; Wang, G.; Ouyang, X.; Wei, H. High-damping polyurethane/hollow glass microspheres sound insulation materials: Preparation and characterization. J. Appl. Polym. Sci. 2021, 138, 49970. [Google Scholar] [CrossRef]

- Yang, X.; Tang, S.; Shen, X.; Peng, W. Research on the sound insulation performance of composite rubber reinforced with hollow glass microsphere based on acoustic finite element simulation. Polymers 2023, 15, 611. [Google Scholar] [CrossRef]

- Lin, J.-H.; Hsu, P.-Y.; Huang, C.-H.; Lai, M.-F.; Shiu, B.-C.; Lou, C.-W. Functional hollow ceramic microsphere/flexible polyurethane foam composites with a cell structure: Mechanical property and sound absorptivity. Polymers 2022, 14, 913. [Google Scholar] [CrossRef]

- George, M.; Mohanty, A. Study on the thermal, dielectric, and dynamic mechanical properties of graphene decorated with graphene quantum dots (GDGQD) reinforced epoxy nanocomposites. Mater. Res. Express 2019, 6, 125336. [Google Scholar] [CrossRef]

- Singha, A.; Rana, A.K.; Jarial, R. Mechanical, dielectric and thermal properties of Grewia optiva fibers reinforced unsaturated polyester matrix based composites. Mater. Des. 2013, 51, 924–934. [Google Scholar] [CrossRef]

- Qiu, J.; Gu, Q.; Sha, Y.; Huang, Y.; Zhang, M.; Luo, Z. Preparation and application of dielectric polymers with high permittivity and low energy loss: A mini review. J. Appl. Polym. Sci. 2022, 139, 52367. [Google Scholar] [CrossRef]

- Zha, J.-W.; Zheng, M.-S.; Fan, B.-H.; Dang, Z.-M. Polymer-based dielectrics with high permittivity for electric energy storage: A review. Nano Energy 2021, 89, 106438. [Google Scholar] [CrossRef]

- Tomppo, L.; Tiitta, M.; Lappalainen, R. The effect of moisture content on electrical impedance spectroscopy response of natural fibre-polymer composite granules. J. Thermoplast. Compos. Mater. 2019, 32, 216–227. [Google Scholar] [CrossRef]

- Das, P.P.; Vadlamudi, V.; Raihan, R. Dielectric state variables as qualitative indicators of moisture absorption-caused mechanical property degradation in GFRP composite structures. Compos. Part C Open Access 2022, 9, 100295. [Google Scholar] [CrossRef]

- Bhuvaneswari, H.; Reddy, N. A review on dielectric properties of biofiber-based composites. Adv. Compos. Hybrid Mater. 2018, 1, 635–648. [Google Scholar] [CrossRef]

- Zhou, J.; Li, Y.; Cheng, L.; Hao, X. Dielectric properties of continuous fiber reinforced polymer composites: Modeling, validation, and application. Polym. Compos. 2018, 39, 4646–4655. [Google Scholar] [CrossRef]

- Dewangan, H.C.; Thakur, M.; Patel, B.; Ramteke, P.M.; Hirwani, C.K.; Panda, S.K. Dynamic deflection responses of glass/epoxy hybrid composite structure filled with hollow-glass microbeads. Eur. Phys. J. Plus 2021, 136, 722. [Google Scholar] [CrossRef]

- Hsieh, T.-H.; Shen, M.-Y.; Huang, Y.-S.; He, Q.-Q.; Chen, H.-C. Mechanical properties of glass bead-modified polymer composite. Polym. Polym. Compos. 2018, 26, 35–44. [Google Scholar] [CrossRef]

- Afolabi, O.A.; Kanny, K.; Mohan, T. Processing of hollow glass microspheres (HGM) filled epoxy syntactic foam composites with improved structural characteristics. Sci. Eng. Compos. Mater. 2021, 28, 116–127. [Google Scholar] [CrossRef]

- Zhu, B.; Ma, J.; Wang, J.; Wu, J.; Peng, D. Thermal, dielectric and compressive properties of hollow glass microsphere filled epoxy-matrix composites. J. Reinf. Plast. Compos. 2012, 31, 1311–1326. [Google Scholar] [CrossRef]

- Zhang, X.; Liu, M.; Chen, Y.; He, J.; Wang, X.; Xie, J.; Li, Z.; Chen, Z.; Fu, Y.; Xiong, C. Epoxy resin/hollow glass microspheres composite materials with low dielectric constant and excellent mechanical performance. J. Appl. Polym. Sci. 2022, 139, e52787. [Google Scholar] [CrossRef]

- Liu, L.; Yuan, Y.; Huang, Y.; Yu, H.; Yang, J. A new mechanism for the low dielectric property of POSS nanocomposites: The key role of interfacial effect. Phys. Chem. Chem. Phys. 2017, 19, 14503–14511. [Google Scholar] [CrossRef]

- Gao, G.; Hu, Y.; Jia, H.; Liu, P.; Du, P.; Xu, D. Acoustic and dielectric properties of epoxy resin/hollow glass microsphere composite acoustic materials. J. Phys. Chem. Solids 2019, 135, 109105. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, S.; Zhang, L.; Wang, C.; Min, C. Preparation and properties of hollow glass microspheres/dicyclopentadiene phenol epoxy resin composite materials. Materials 2023, 16, 3768. [Google Scholar] [CrossRef]

- Ren, T.; Wang, R.; Zhang, Y.; Nie, S.; Guo, S.; Zhang, X. Hollow glass microsphere/polybutadiene composites with low dielectric constant and ultralow dielectric loss in high-frequency. J. Appl. Polym. Sci. 2025, 142, e56351. [Google Scholar] [CrossRef]

- Zhu, B.; Wang, J.; Zheng, H.; Ma, J.; Wu, J.; Wu, R. Investigation of thermal conductivity and dielectric properties of LDPE-matrix composites filled with hybrid filler of hollow glass microspheres and nitride particles. Compos. Part B Eng. 2015, 69, 496–506. [Google Scholar] [CrossRef]

- Jeong, A.; Son, S.M.; Lee, S.; Seong, D.G. Hollow glass microsphere/polydopamine/glass fiber reinforced composites with high thermal insulation performance by inhibiting conductive and radiative heat transfer. Compos. Part A Appl. Sci. Manuf. 2024, 179, 108041. [Google Scholar] [CrossRef]

- Wang, P.; Zhong, S.; Yan, K.; Liao, B.; Zhang, J. Influence of a batch of hollow glass microspheres with different strength grades on the compression strength of syntactic foam. Compos. Sci. Technol. 2022, 223, 109442. [Google Scholar] [CrossRef]

- Ajayi, A.A.; Pandurangan, M.T.; Krishnan, K. Development of epoxy-based sandwich composite panel with hollow glass microspheres/clay hybrid core and banana fiber facesheet for structural applications. Heliyon 2024, 10, e30428. [Google Scholar] [CrossRef] [PubMed]

| Types of Fiber and Polymer Matrix | HGMs Volume Fraction | Maximum Value of | Reference | |||

|---|---|---|---|---|---|---|

| Tensile Strength | Tensile Modulus | Flexural Strength | Compression Strength | |||

| Jute, hemp, flax/Polypropylene | 0.0–3.0% | 40.7 MPa flax at 1.5% HGM | 8.6% flax at 1.5% HGM | 19% Jute at 1.5% HGM | - | [107] |

| Carbon fiber/epoxy resin | 0.0–1.0% | 25.4 MPa at 0.4% | 7.4% at 0.4% | - | High at 0% HGMs | [108] |

| Carbon fiber/polypropylene | 0.0–40% | 85.03% MPa at 10%HGMs with 8% fiber | 6.72%, at 40% HGMs with 8% fiber | 87.2MPa at 10% HGMs with 8% fiber | - | [109] |

| Glass fiber/epoxy under high temperature (RT-60 °C) | 0.0–30% | Declined by 8% from RT | Declined by 6% from RT | Decrease of 24% from RT | [110] | |

| Glass fiber/epoxy under moisture (sea water SW and distilled water DW) | 0.0–30% | Reduction 13% DW and 9% SW | - | Reduction 24% DW and 11% SW | - | [111] |

| piassava fiber/polypropylene | 0.0–5% | 33.29 MPa at 0% | 2055.3 MPa at 5% | 59.22 MPa at 0% | [112] | |

| Bamboo fiber/polypropylene | 10 wt% | Enhanced by 14.38% from base matrix at 20 wt% fiber | Enhanced by 65.55% from base matrix at 20 wt% fiber | Increases by 18.4% from base matrix at 20 wt% fiber | Increases by 39.2% from base matrix at 20 wt% fiber | [113] |

| Types of Fiber and Polymer Matrix | HGM Volume Fraction | Acoustic Properties | Thermal Properties | References | |

|---|---|---|---|---|---|

| Thermal Conductivity | Thermal Insulation | ||||

| PDMS (Polydimethylsiloxane) + HGMs | 0–17 wt% | Decrease from −29 dB (pure PDMS) to −26 dB (at 17 wt% HGMs) | Reduced by 31% (from ~0.2 W/mK) | Significantly improved | [138] |

| Glass fiber fabric/Waterborne PU | 0–0.8 HGMs/WPU (volume ratio) | Not studied | A 45.2% reduction was observed, decreasing from 0.21 at 0% HGM to 0.1154 W/(m·K) at a 0.8 HGMs ratio | A 17.74 °C temperature difference (25.3% insulation) was achieved at 70 °C (ratio 0.8) | [121] |

| Cotton Fabric/Acrylic Binder Composite | 20 wt% | Excellent absorption noise reduction coefficient (0.303) across frequency (0–3500 Hz). | Attributed to a considerably low value because of the hollow structure | Remarkable 78% enhancement in thermal resistance; acts as an effective heat barrier. | [139] |

| Surface-modified HGMs (KH560)/Epoxy Resin | 67 vol% | Exceptionally low permittivity (Dk = 2.3) at 110 MHz | Reduced to 0.14 W·m−1·K−1 (from 0.24 for neat epoxy) due to hollow, gas-filled microspheres acting as thermal barriers | Excellent (42% reduction) in conductivity compared to neat epoxy, making it suitable for electronic packaging. | [140] |

| Alkali-treated Jute/Epoxy | 2.5 vol.% | - | Decreased (Low thermal conductivity confirmed) | Improved (Stable up to 540.0 K/266.9 °C) | [141] |

| Glass fiber fabric/Epoxy | 7% by weight | Max absorption coefficient of 0.18 at 6300 Hz, showing no improvement over the reference value of 0.1 | Slightly higher than the reference value, 0.484 ± 0.005 W/mK compared to 0.480 W/mK | No improvement, as agglomeration limited HGMs’ contribution to thermal insulation | [142] |

| Phenolic Resin/HGMS | 20 wt% | - | Reduced at 0.129 W·m−1·K−1, lower than neat resin due to porosity; higher loadings increased from microsphere crushing | Excellent (~46.7% lower than neat resin) | [143] |

| HDPE/Hollow Glass Microspheres (HGMs) | 1 wt%, 5 wt% | Increased absorption coefficient, best for Internal Mixer (IM1) at 1% HGMs (0.85 at 1250 Hz). | Reduction in thermal conductivity for similar systems | Improved thermal stability with higher decomposition temp than neat HDPE; best at 5% HGMs. | [136] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tassaw, D.F.; Barburski, M.; Kassie, B.B. The Role of Hollow Glass Microspheres as Functional Fillers in Fiber-Reinforced Polymer Composites: A Review. Materials 2025, 18, 4974. https://doi.org/10.3390/ma18214974

Tassaw DF, Barburski M, Kassie BB. The Role of Hollow Glass Microspheres as Functional Fillers in Fiber-Reinforced Polymer Composites: A Review. Materials. 2025; 18(21):4974. https://doi.org/10.3390/ma18214974

Chicago/Turabian StyleTassaw, Dehenenet Flatie, Marcin Barburski, and Bantamlak Birlie Kassie. 2025. "The Role of Hollow Glass Microspheres as Functional Fillers in Fiber-Reinforced Polymer Composites: A Review" Materials 18, no. 21: 4974. https://doi.org/10.3390/ma18214974

APA StyleTassaw, D. F., Barburski, M., & Kassie, B. B. (2025). The Role of Hollow Glass Microspheres as Functional Fillers in Fiber-Reinforced Polymer Composites: A Review. Materials, 18(21), 4974. https://doi.org/10.3390/ma18214974