Strength, Microstructural, and Environmental Performance of Phosphogypsum–GGBS–Carbide Slag Ternary Blended Cement

Abstract

1. Introduction

2. Materials and Methods

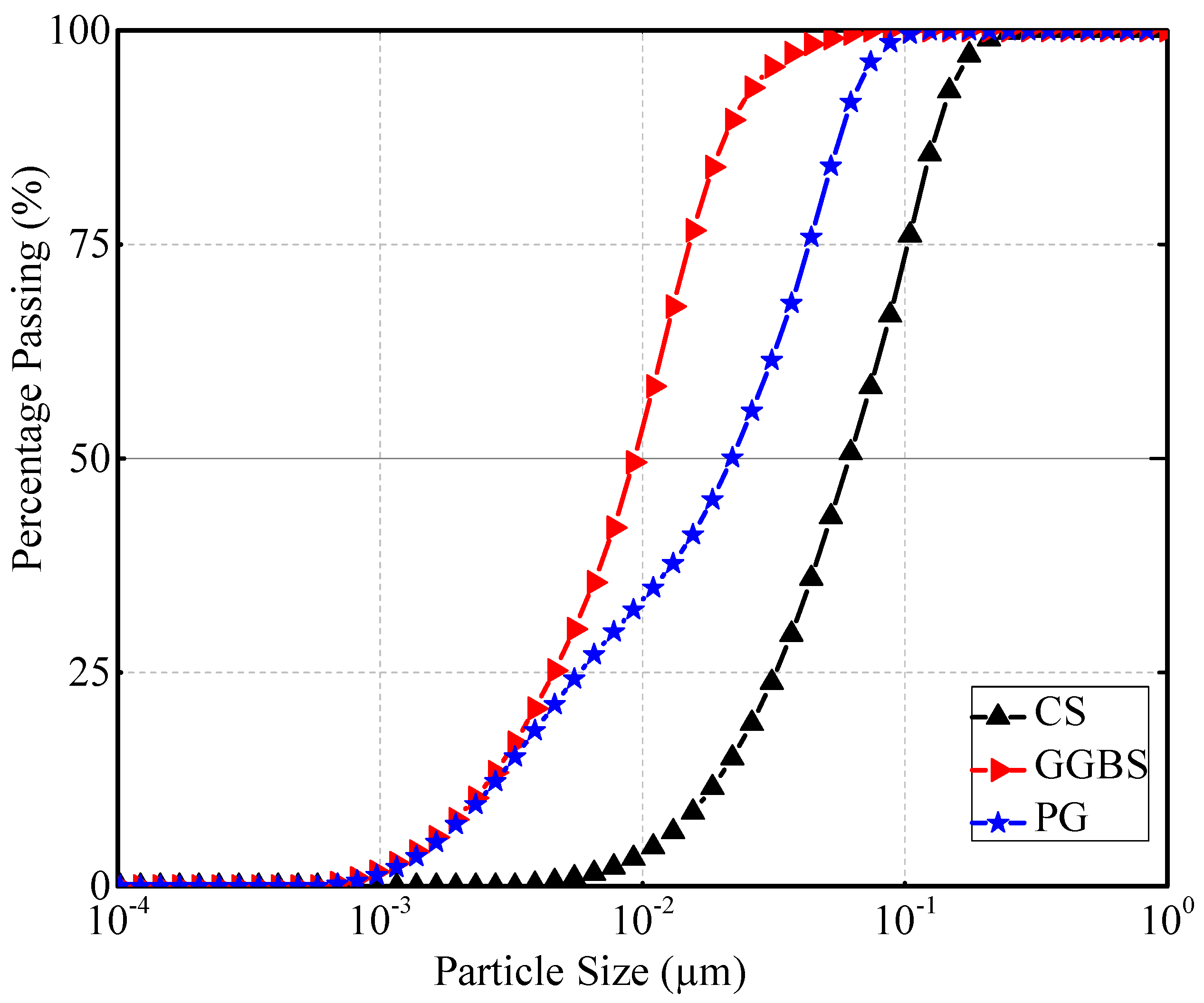

2.1. Materials

2.2. Sample Paste Preparation

3. Methods

3.1. Unconfined Compressive Strength (UCS) Test

3.2. Microstructural Characterizations

4. Results and Analysis

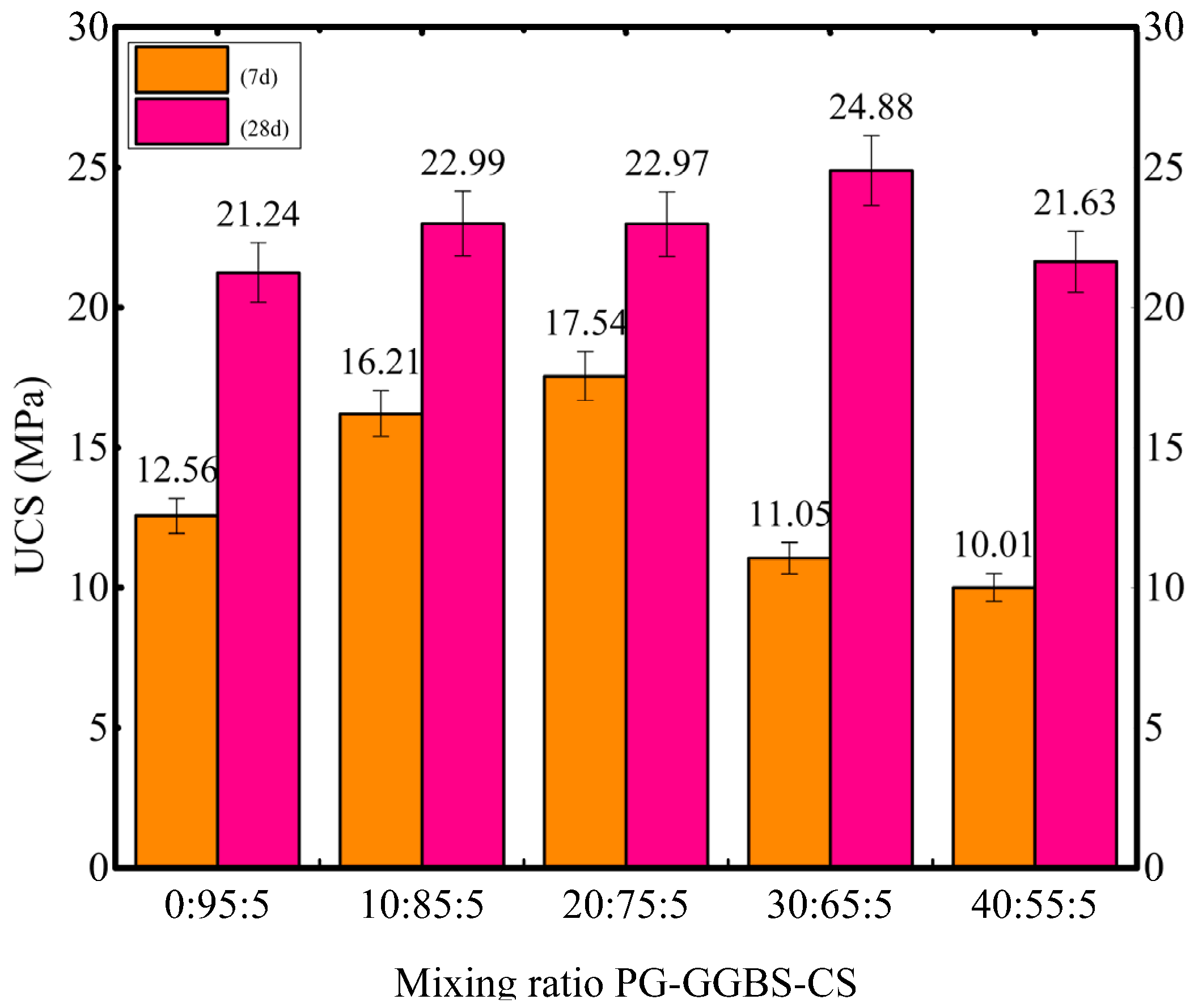

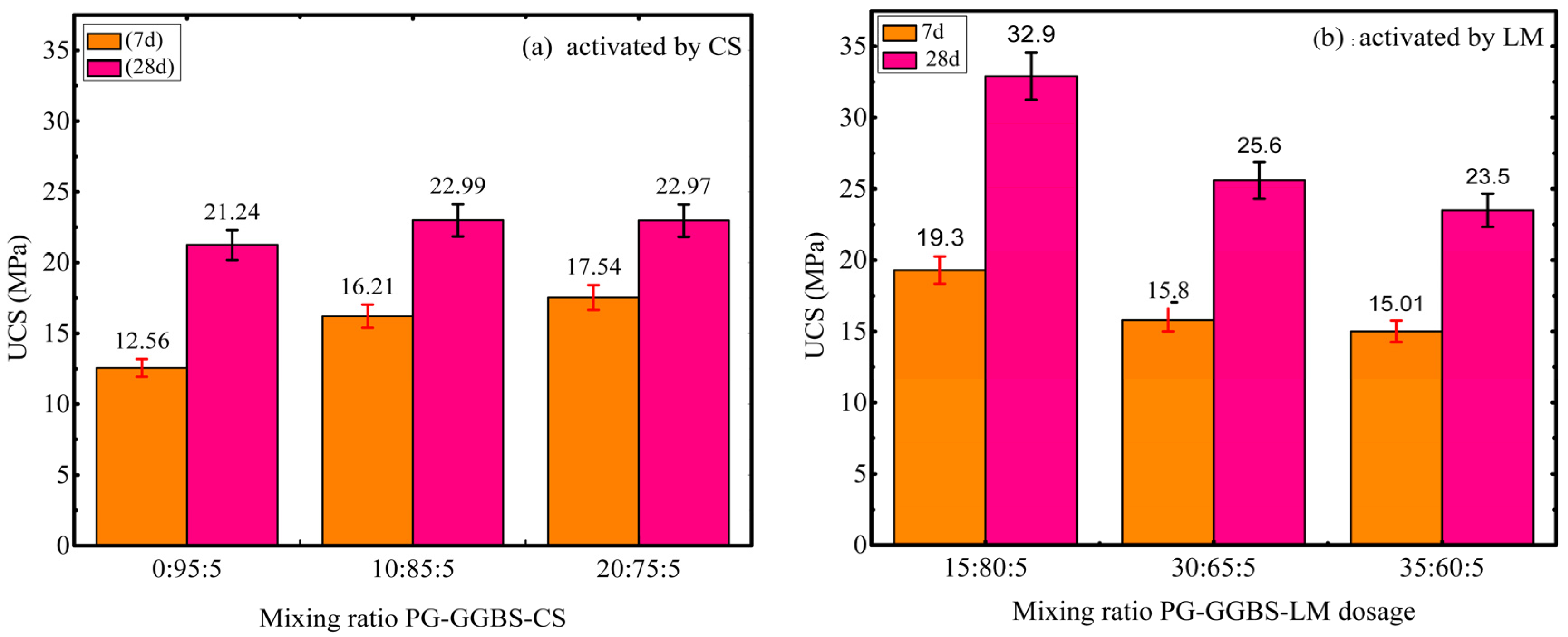

4.1. UCS Analysis

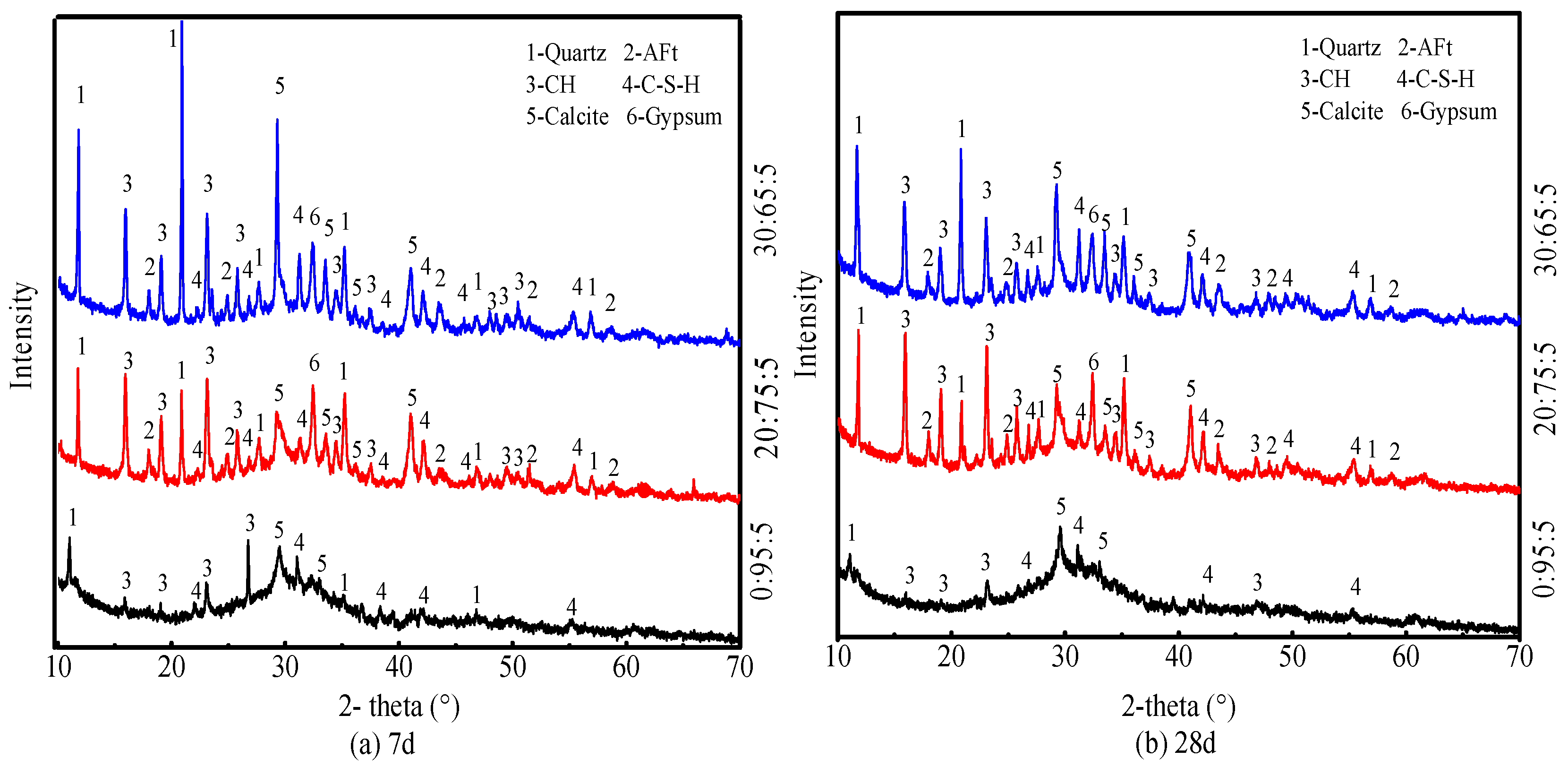

4.2. XRD Analysis

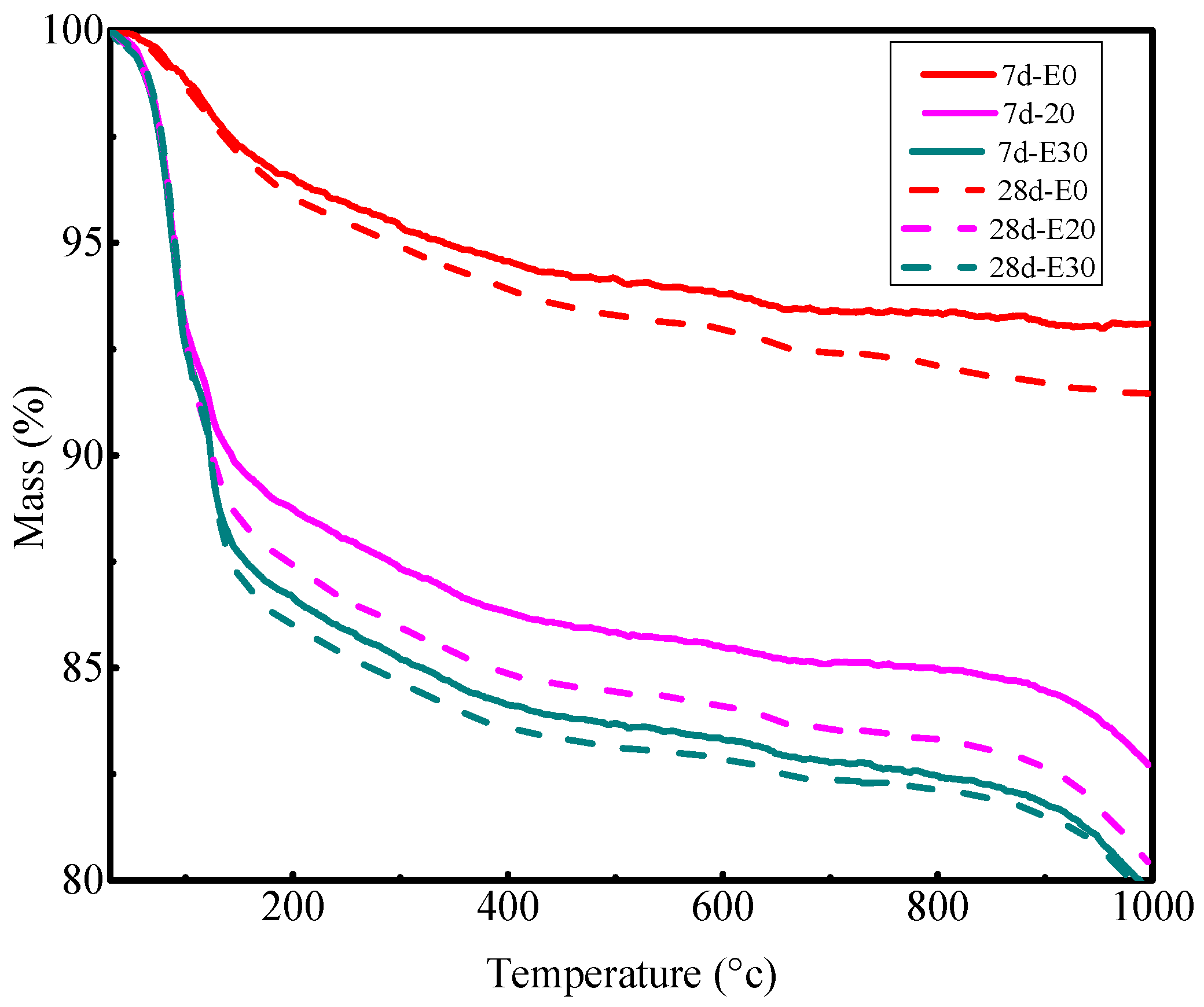

4.3. DTG-DSC Analysis

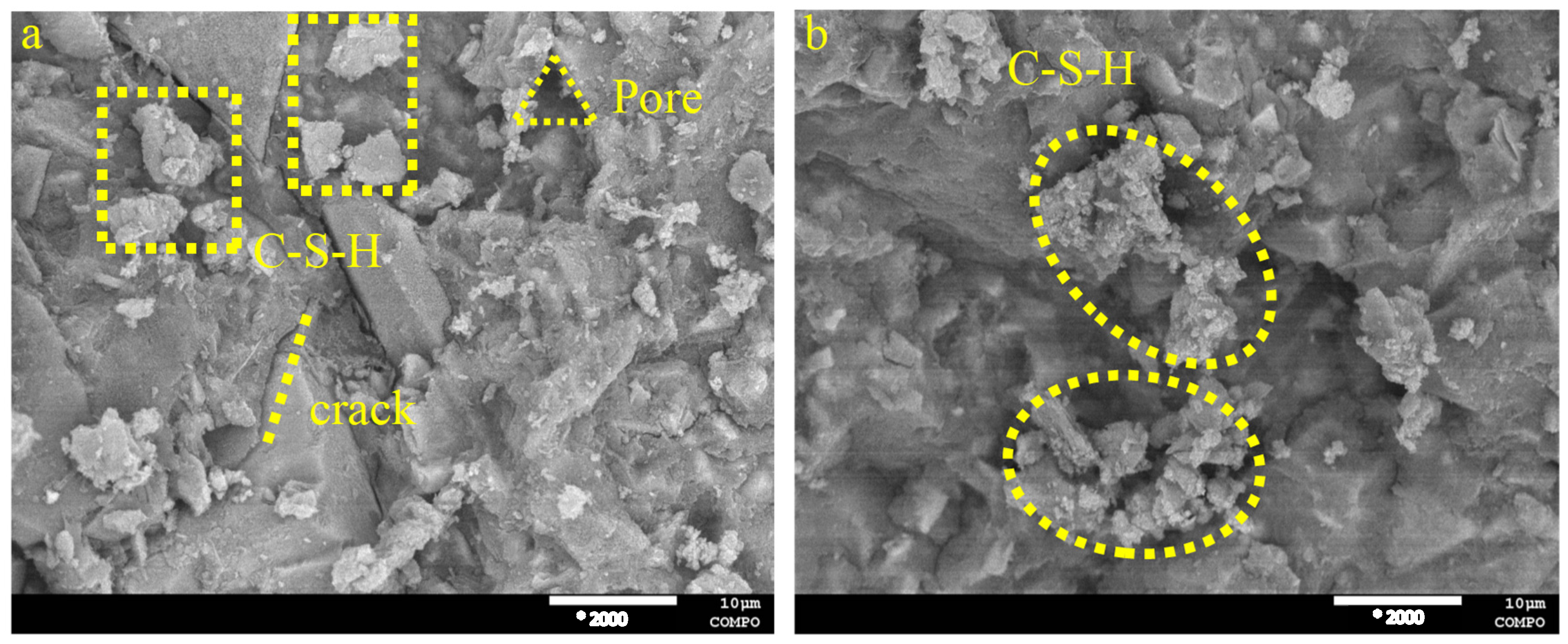

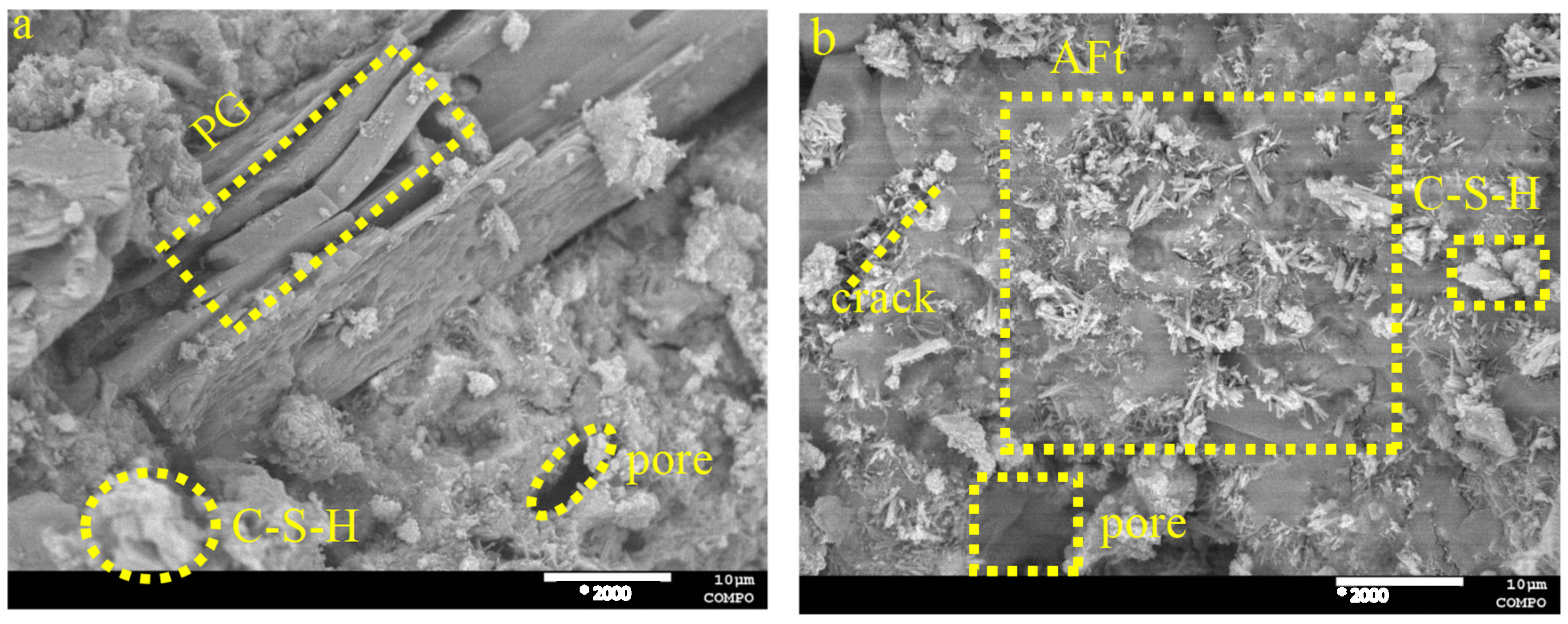

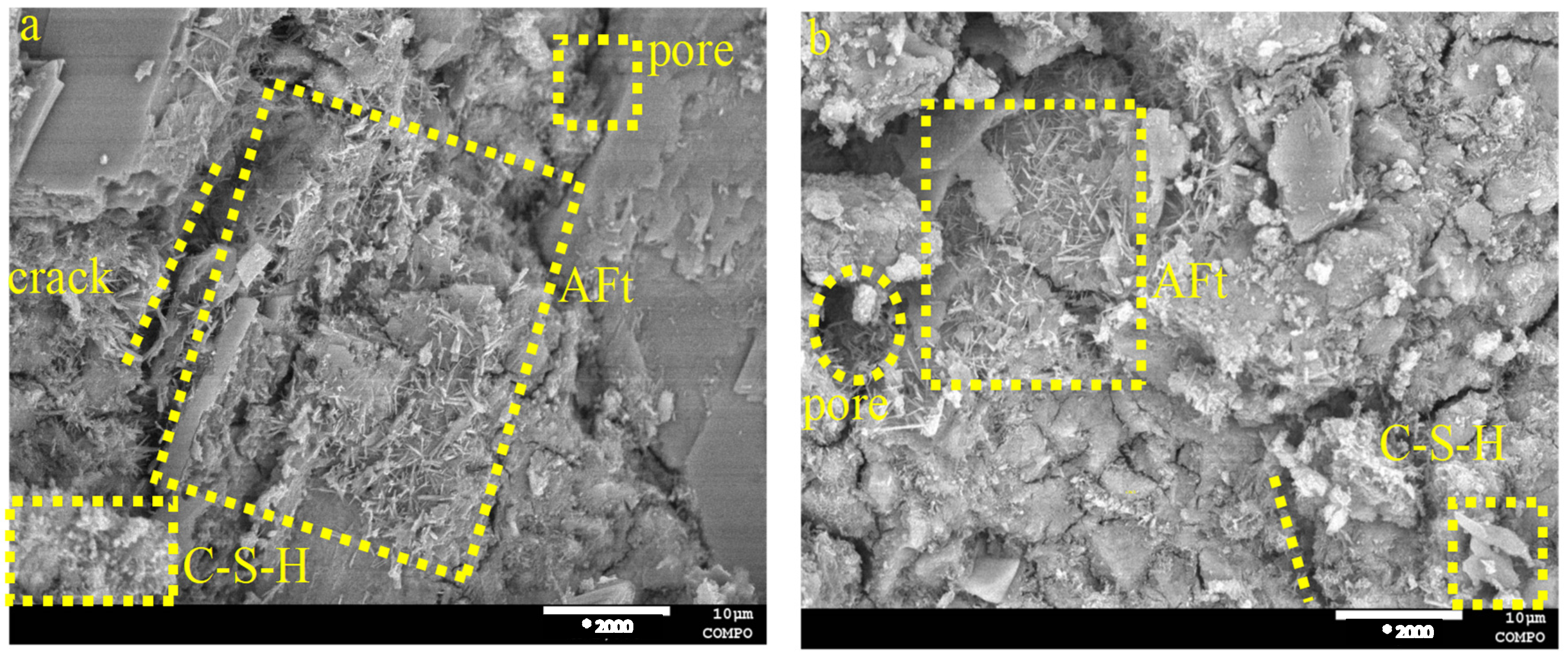

4.4. SEM Analysis

5. Discussion

Mechanical Behavior of PG-GGBS-CS and PG-GGBS-LM

| Specimens | Reference | Electricity Production (kWh/t) | 28 d UCS (MPa) | CO2 Emissions (kg/t) | Cost (RMB/t) | MSI (×10−5) |

|---|---|---|---|---|---|---|

| PG | [48,49] | 14.65 | 0.364 | 50 | ||

| GGBS | 59.4 | 0.037 | 400 | |||

| CS | 0 | 0.004 | 150 | |||

| LM | 0.933 | 0.021 | 500 | |||

| Portland Cement | 84.75 | 42.5 | 0.74 | 600 | 0.74 | |

| PG-GGBS-CS | 38.61 | 24.88 | 4.480 | 282.5 | 1.96 | |

| PG-GGBS-LM | 40.21 | 25.26 | 4.630 | 300 | 1.82 | |

| PG-GGBS-OPC | 53.96 | 32.9 | 5.396 | 305 | 1.99 |

6. Conclusions

- (1)

- UCS of PG-GGBS-CS ternary cements shows a nonlinear evolution with PG content, peaking at 30% PG before declining. Without PG, ternary cements yield weak microstructures that do not form AFt. At 20–30% PG, sulfates from PG enable AFt formation while CS maintains alkalinity for C-S-H production, creating optimal densification. Beyond 30%, excess AFt may weaken the matrix. This highlights the critical balance between PG-CS and mechanical performance.

- (2)

- XRD, TG-DTG, and SEM analyses revealed that hydration products increase with PG content (0–30%) after long-term curing, resulting in a denser microstructure. XRD confirmed the progressive formation of both crystalline (AFt, residual gypsum) and amorphous phases (C-S-H gels). TG-DTG highlighted the decomposition of hydrated phases (water loss from C-S-H/AFt) and gypsum (50–200 °C), with maximum hydration product mass at 30% PG. SEM showed reduced porosity and improved phase connectivity, explaining the densification.

- (3)

- PG–GGBS–CS binders achieved mechanical performance statistically comparable to PG–GGBS–LM systems at higher PG contents, confirming that CS can effectively substitute lime while reducing carbon emissions by approximately 3.2%. This validates the research hypothesis that CS provides sufficient alkalinity and calcium to sustain efficient hydration and strength gain.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| CS | Carbide Slag |

| GGBS | Ground granulated blast furnace slag |

| PG | Phosphogypsum |

| SEM | Scanning electron microscopy |

| UCS | Unconfined compressive strength |

| XRF | X-ray fluorescence spectroscopy |

| XRD | X-ray diffraction |

| TGA | Thermogravimetric analysis |

| AFt | Ettringite |

| CH | Portlandite |

| C-S-H | Calcium silicate hydrate |

| DTG-DSC | Derivative Thermogravimetry-Differential Scanning Calorimetry |

| PG-GGBS-LM | Phosphogypsum, ground granulated blast-furnace slag, and lime ternary stabilizer lime ternary stabilizer |

| PG-GGBS-CS | Phosphogypsum, ground granulated blast-furnace slag, and carbide slag ternary stabilizer |

References

- Wei, C.; Lu, Y.; Liu, X.; Zhang, Z.; Wu, P.; Gu, J. Harmless disposal of phosphogypsum synergized red mud: Harmful element control and material utilization. J. Environ. Chem. Eng. 2024, 12, 113660. [Google Scholar] [CrossRef]

- Zha, F.; Liu, R.; Kang, B.; Qin, L.; Tao, S.; Tao, W. Engineering Properties and Environmental Effects of Phosphogypsum Modified Expansive Soil. J. Environ. Eng. 2025, 151, 04024072. [Google Scholar] [CrossRef]

- Parreira, A.B.; Kobayashi, A.R.K.; Silvestre, O.B. Influence of Portland Cement Type on Unconfined Compressive Strength and Linear Expansion of Cement-Stabilized Phosphogypsum. J. Environ. Eng. 2003, 129, 956–960. [Google Scholar] [CrossRef]

- Bouargane, B.; Laaboubi, K.; Biyoune, M.G.; Bakiz, B.; Atbir, A. Effective and innovative procedures to use phosphogypsum waste in different application domains: Review of the environmental, economic challenges and life cycle assessment. J. Mater. Cycles Waste Manag. 2023, 25, 1288–1308. [Google Scholar] [CrossRef]

- Wang, Q.; Lou, Y.; Peng, Y.; Wang, W.; Luo, X.; Smith, A.S.J. Investigation into Improving the Water Resistance and Mechanical Properties of Calcined Gypsum from Phosphogypsum Composites. Materials 2025, 18, 2703. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, J.; Le, Q.; Wang, D.; Ding, J.; Xu, C. Experimental Study on Acoustic Emission Characteristics of Modified Phosphogypsum at Different Loading Rates. Materials 2025, 18, 2491. [Google Scholar] [CrossRef] [PubMed]

- Ng, C.W.W.; Xie, M.; Leung, A.K. Removal of Hydrogen Sulfide Using Soil Amended with Ground Granulated Blast-Furnace Slag. J. Environ. Eng. 2017, 143, 04017016. [Google Scholar] [CrossRef]

- Kumar, A.G.; Ramasamy, S.; Soundararajan, E.K.; Viswanathan, R. Sustainable utilization of cement kiln dust and GGBS in the development of eco-friendly concrete composite. Matéria 2024, 29, e20240054. [Google Scholar] [CrossRef]

- Erdoğan, Ö.; Mustafa, E.; Durmuş, H.İ. Utilization and efficiency of ground granulated blast furnace slag on concrete properties—A review. Constr. Build. Mater. 2016, 105, 423–434. [Google Scholar]

- Zhao, S.; Wen-Bo, C.; Run-Dong, Z.; Yin-Fu, J.; Yin, J.-H. Solidification/stabilization treatment of Hong Kong marine deposits slurry at high water content by ISSA and GGBS. Constr. Build. Mater. 2023, 372, 130817. [Google Scholar] [CrossRef]

- Chee, B.C.; Kok, Y.C.; Mahyuddin, R.; Lim, G.K. The engineering properties and microstructure development of cement mortar containing high volume of inter-grinded GGBS and PFA cured at ambient temperature. Constr. Build. Mater. 2016, 122, 683–693. [Google Scholar] [CrossRef]

- Raghav, M.; Park, T.; Yang, H.M.; Lee, S.Y.; Karthick, S.; Lee, H.S. Review of the Effects of Supplementary Cementitious Materials and Chemical Additives on the Physical, Mechanical and Durability Properties of Hydraulic Concrete. Materials 2021, 14, 7270. [Google Scholar] [CrossRef]

- Wild, S.; Kinuthia, J.M.; Jones, G.I.; Higgins, D.D. Effects of partial substitution of lime with ground granulated blast furnace slag (GGBS) on the strength properties of lime-stabilised sulphate-bearing clay soils. Eng. Geol. 1998, 51, 37–53. [Google Scholar] [CrossRef]

- Li, X.; Zhang, Q. Dehydration behaviour and impurity change of phosphogypsum during calcination. Constr. Build. Mater. 2021, 311, 125328. [Google Scholar] [CrossRef]

- Bolang, Z.; Kaisheng, C.; Kun, Z.; Luo, D. Mechanical properties and modification mechanism of phosphogypsum stabilized soil. SN Appl. Sci. 2022, 4, 241. [Google Scholar] [CrossRef]

- Tan, Y.; Wu, J.; Zhang, S.; Deng, Y.; Wang, D.; Ming, H. Effect of anionic polyacrylamide amendment on the climatic durability of solidified waste rock fine. Constr. Build. Mater. 2024, 451, 138738. [Google Scholar] [CrossRef]

- Huahui, Q.; Yan, X.; Baoguo, M.; Hongbo, T.; Xingyang, H.; Ying, S.; Zihao, J.; Shiyu, G. Improving the volume stability of the β-hemihydrate phosphogypsum–Cement system by incorporating GGBS. Constr. Build. Mater. 2023, 408, 133807. [Google Scholar]

- Pratap, B. Strength and Microstructural Properties of Phosphogypsum/GGBS-Based Geopolymer Concrete. Iran. J. Sci. Technol. 2025, 49, 2503–2515. [Google Scholar] [CrossRef]

- Gutsalenko, T. Solidification/Stabilization of Harbor Sediments Using GGBS-Based Hydraulic Binders. Ph.D. Thesis, University of Paris-Saclay, Orsay, France, 2020. [Google Scholar]

- Gu, K.; Jin, F.; Al-Tabbaa, A.; Shi, B. Activation of ground granulated blast furnace slag by using calcined dolomite. Constr. Build. Mater. 2014, 68, 252–258. [Google Scholar] [CrossRef]

- Nicula, L.M.; Manea, D.L.; Simedru, D.; Cadar, O.; Dragomir, M.L.; Ardelean, I.; Corbu, O. Potential Role of GGBS and ACBFS Blast Furnace Slag at 90 Days for Application in Rigid Concrete Pavements. Materials 2023, 16, 5902. [Google Scholar] [CrossRef]

- Qi, W.; Duan, G.; Han, Y.; Zhao, Q.; Huang, Y.; Zhu, W.; Pang, H.; Zhang, J. Comparison of mechanical properties and microstructure of GGBS-based cementitious materials activated by different combined alkaline wastes. Constr. Build. Mater. 2024, 422, 135784. [Google Scholar] [CrossRef]

- Yuanchuan, R.; Zuoliang, W.; Guangfei, Q.; Lingrui, K.; Ping, N.; Nanqi, R.; Chaoneng, Z.; Xiuping, C.; Fenghui, W.; Yan, H.; et al. Comprehensive performance study of aluminum ash and calcium carbide slag for brick making under ultra-high pressure. Constr. Build. Mater. 2022, 359, 129526. [Google Scholar] [CrossRef]

- Daosheng, S.; Feixiang, Y.; Yang, D.; Kaiwei, L.; Jinhui, T.; Chengzhe, S.; Yawen, S.; Aiguo, W.; Niuniu, H.; Cheng, H. Utilization of carbide slag in autoclaved aerated concrete (CS-AAC) and optimization: Foaming, hydration process, and physic-mechanical properties. Case Stud. Constr. Mater. 2023, 19, e02354. [Google Scholar]

- Wu, J.; Luo, Z.; Tan, Y.; Sun, D.A.; Deng, Y.; Li, W. Performance evaluation of waste phosphogypsum-based solidified sludge: From laboratory test to field application. Mater. Today Sustain. 2024, 28, 101013. [Google Scholar] [CrossRef]

- Guanzhou, R.; Henghui, F.; Yuan, G.; Hongdong, G.; Tao, W.; Gaowen, Z.; Zhen, Z.; Xianfeng, L.; Chun, P.-J. Recycling and conservation of calcium carbide slag in dispersive soil modification: An evaluation of early age performance. Constr. Build. Mater. 2023, 393, 132079. [Google Scholar] [CrossRef]

- Jiang, X.; Lang, L.; Liu, S.; Mu, F.; Wang, Y.; Zhang, Z.; Han, L.; Duan, S.; Wang, P.; Li, J. Stabilization of iron ore tailing with low-carbon lime/carbide slag-activated ground granulated blast-furnace slag and coal fly ash. Constr. Build. Mater. 2024, 413, 134946. [Google Scholar] [CrossRef]

- Lang, L.; Chen, B.; Li, N. Utilization of lime/carbide slag-activated ground granulated blast-furnace slag for dredged sludge stabilization. Mar. Georesour. Geotechnol. 2020, 39, 659–669. [Google Scholar] [CrossRef]

- Bai, J.; Zhang, H.; Xiao, L. Formation mechanism of carbide slag composite sustained-alkalinity-release particles for the source control of acid mine drainage. Sci. Rep. 2021, 11, 23793. [Google Scholar] [CrossRef] [PubMed]

- Tan, Y.; Ziyang, C.; Ming, H.; Li, H.; Wu, J.; Wu, C.; Hu, B. Preparation and performance evaluation of high-strength phosphogypsum aggregates by compaction and hydration. J. Mater. Cycles Waste Manag. 2024, 26, 149–161. [Google Scholar] [CrossRef]

- GB/T17671; Test Method of Cement Mortar Strength (ISO Method) National Standard. China Building Materials Research Institute Co., Ltd.: Beijing, China, 2021.

- Murali, G.; Azab, M. Recent research in utilization of phosphogypsum as building materials: Review. J. Mater. Res. Technol. 2023, 25, 960–987. [Google Scholar] [CrossRef]

- ASTM D21671M; Standard Test Method for Density and Unit Weight of Soil in Place by the Rubber Balloon Method. ASTM: West Conshohocken, PA, USA, 2015.

- Ying, S.; Cheng, L.; Ming, T.; SenSen, T.; Xiaojing, Y.; Yefan, L. Using modified quartz sand for phosphate pollution control in cemented phosphogypsum (PG) backfill. J. Clean. Prod. 2021, 283, 124652. [Google Scholar] [CrossRef]

- Xingrun, W.; Jin, Y.; Zhiyu, W.; Yongfeng, N.; Qifei, H.; Qi, W. Development of lightweight aggregate from dry sewage sludge and coal ash. J. Waste Manag. 2009, 29, 1330–1335. [Google Scholar]

- Du, M.; Wang, J.; Dong, F.; Wang, Z.; Yang, F.; Tan, H.; Fu, K.; Wang, W. The study on the effect of flotation purification on the performance of α-hemihydrate gypsum prepared from phosphogypsum. Sci. Rep. 2022, 12, 95. [Google Scholar] [CrossRef]

- Men, J.; Li, Y.; Cheng, P.; Zhang, Z. Recycling phosphogypsum in road construction materials and associated environmental considerations: A review. Heliyon 2022, 8, e11518. [Google Scholar] [CrossRef]

- Yang, G.; Li, C.; Xie, W.; Yue, Y.; Kong, C.; Li, X. Effect of carbide slag and steel slag as alkali activators on the key properties of carbide slag-steel slag-slag-phosphogypsum composite cementitious materials. Front. Mater. 2024, 11, 1353004. [Google Scholar] [CrossRef]

- Xiao, Y.; Yongxiang, J.; Chen, Y.; Xiaoke, H.; Yanchang, J.; Xu, L. Research on formulation optimization and hydration mechanism of phosphogypsum-based filling cementitious materials. Front. Environ. Sci. 2022, 10, 1012057. [Google Scholar] [CrossRef]

- Wentao, L.; Yi, Y. Use of carbide slag from acetylene industry for activation of ground granulated blast-furnace slag. Constr. Build. Mater. 2020, 238, 117713. [Google Scholar] [CrossRef]

- Liu, J.; Zhao, J.; Zhao, Y.; Zhang, Y.; Zhang, H.; Zhang, H.; Gu, X.; Tian, G. Resource utilization of solid waste from steel industries in cement-based cementitious materials: Mechanical properties, hydration behaviors, and environmental impact. J. Environ. Chem. Eng. 2023, 11, 109882. [Google Scholar] [CrossRef]

- Hyeoneun, P.; Yeonung, J.; Yubin, J.; Jae-Hong, J.; Oh, J.E. Strength enhancement and pore-size refinement in clinker-free CaO-activated GGBFS systems through substitution with gypsum. Cem. Concr. Compos. 2016, 68, 57–65. [Google Scholar]

- Essama Atenga, J.R.; Tan, Y.; Deng, Y.; Wu, J.; Cai, D.; Li, W. Influences of pretreatment methods on the mechanical and environmental behaviors of PG-GGBS-LM ternary stabilizer. Environ. Sci. Pollut. Res. 2024, 31, 37520–37531. [Google Scholar] [CrossRef]

- Huawei, L.; Wang, R.; Wei, M.; Lei, N.; Wei, T.; Feng, L. Characteristics of carbide-slag-activated GGBS–fly ash materials: Strength, hydration mechanism, microstructure, and sustainability. Constr. Build. Mater. 2024, 422, 135796. [Google Scholar]

- Xiong, Y.; Li, S.; Ren, J.; Zhang, A.; Xu, Q.; Wu, Y.; Zhao, Y.; Ding, Y. Effect of carbon capture on desulfurization gypsum/carbide slag phase-change composites for waste removal and renewable energy storage. J. Environ. Chem. Eng. 2024, 12, 112484. [Google Scholar] [CrossRef]

- James, J.; Arthi, C.; Balaji, G.; Chandraleka, N.; Naveen Kumar, R.H.M. Lime activated flyash-phosphogypsum blend as a low-cost alternative binder. Int. J. Environ. Sci. Technol. IJEST 2022, 19, 8969–8978. [Google Scholar] [CrossRef]

- Dang, V.Q.; Chau, V.N.; Thanh Sang, N.; Huy Thuc, P.; Ho, L.S. Mechanical properties and durability of concrete containing fly ash and GGBS for marine environment: A comprehensive study from laboratory perspective. Proc. Inst. Mech. Eng. 2025. [Google Scholar] [CrossRef]

- Yang, K.-H.; Jung, Y.-B.; Cho, M.-S.; Tae, S.-H. Effect of supplementary cementitious materials on reduction of CO2 emissions from concrete. J. Clean. Prod. 2015, 103, 774–783. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Zhang, G.; Li, G. A novel low-carbon binder: Utilization of municipal solid waste incineration fly ash and flue gas desulfurization gypsum to co-activate granulated blast furnace slag. Constr. Build. Mater. 2025, 472, 140963. [Google Scholar] [CrossRef]

| Chemical Composition | PG | GGBS | CS |

|---|---|---|---|

| SO3 | 49.88% | 3.54% | 0.30% |

| CaO | 36.24% | 37.21% | 95.36% |

| SiO2 | 11.41% | 38.26% | 3.77% |

| K2O | 1.03% | 0.61% | - |

| Fe2O3 | 0.97% | 2.02% | 0.43% |

| Al2O3 | - | 16.42% | - |

| TiO2 | 0.17% | 1.35% | - |

| L.O.I | 0.30% | 0.59% | 0.14% |

| Initial moisture content | 4% | 0.96% | 3.5% |

| Specific density (g/cm3) | 2.6 | 2.8 | 2.4 |

| Surface (m2/kg) | 400 | 450 | 250 |

| pH | 6.4 | 10.94 | 12.42 |

| Diameters (µm) | PG | GGBS | CS |

|---|---|---|---|

| D10 | 5.67 µm | 3.81 µm | 16.94 µm |

| D50 | 52.23 µm | 15.7 µm | 61.32 µm |

| D90 | 141.9 µm | 37.69 µm | 137 µm |

| Serial | PG (%) | GGBS (%) | CS (%) | Water/Binder |

|---|---|---|---|---|

| 0% PG | 0 | 95 | 5 | 0.31 |

| 10% PG | 10 | 85 | 5 | 0.31 |

| 20% PG | 20 | 75 | 5 | 0.31 |

| 30% PG | 30 | 65 | 5 | 0.31 |

| 40% PG | 40 | 55 | 5 | 0.31 |

| Serial | PG (kg/m3) | GGBS (kg/m3) | CS (kg/m3) | Water (kg/m3) | Total (kg/m3) |

|---|---|---|---|---|---|

| 0% PG | 0 | 1417.7 | 74.6 | 462.6 | 1954.9 |

| 10% PG | 148.6 | 1263.3 | 74.3 | 460.7 | 1946.9 |

| 20% PG | 296.0 | 1110.1 | 74.0 | 458.8 | 1939.0 |

| 30% PG | 442.2 | 958.2 | 73.7 | 457.0 | 1931.1 |

| 40% PG | 587.3 | 807.5 | 73.4 | 455.1 | 1923.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tan, Y.; Essama, J.R.A.; Wang, C.; Wu, J.; Ming, H. Strength, Microstructural, and Environmental Performance of Phosphogypsum–GGBS–Carbide Slag Ternary Blended Cement. Materials 2025, 18, 4953. https://doi.org/10.3390/ma18214953

Tan Y, Essama JRA, Wang C, Wu J, Ming H. Strength, Microstructural, and Environmental Performance of Phosphogypsum–GGBS–Carbide Slag Ternary Blended Cement. Materials. 2025; 18(21):4953. https://doi.org/10.3390/ma18214953

Chicago/Turabian StyleTan, Yunzhi, Joseph Roland Atenga Essama, Chong Wang, Jun Wu, and Huajun Ming. 2025. "Strength, Microstructural, and Environmental Performance of Phosphogypsum–GGBS–Carbide Slag Ternary Blended Cement" Materials 18, no. 21: 4953. https://doi.org/10.3390/ma18214953

APA StyleTan, Y., Essama, J. R. A., Wang, C., Wu, J., & Ming, H. (2025). Strength, Microstructural, and Environmental Performance of Phosphogypsum–GGBS–Carbide Slag Ternary Blended Cement. Materials, 18(21), 4953. https://doi.org/10.3390/ma18214953