Fiber-Reinforced Polymer Laminates in Aviation and Structural Engineering: A Synthetic Comparison of Performance Requirements, Design Principles, and Defect Assessment Procedures

Abstract

1. Introduction

2. Design of Components and Laminate Architectures

2.1. Comparative Design Logic and Deterioration Mechanisms in Laminated FRP Composites

2.2. Aviation: Optimized Layups, Thin Plies, and Damage-Tolerant Design

2.3. Structural Engineering: Simplified Layups and Durability-Driven Design

2.4. Standards, Codes, and Certification Frameworks for FRP Laminates

3. In-Service Conditions and Environmental Effects

3.1. Mechanical Loading Spectra

3.2. Environmental Stressors

3.3. Implications for Service Life and Safety

4. Degradation Mechanisms and Damage Detection

4.1. Comparative Overview of Degradation Mechanisms and Detection Practices

4.2. Sector-Specific Damage Evolution and Detection Techniques

4.3. Inspection Regimes and Operational Integration

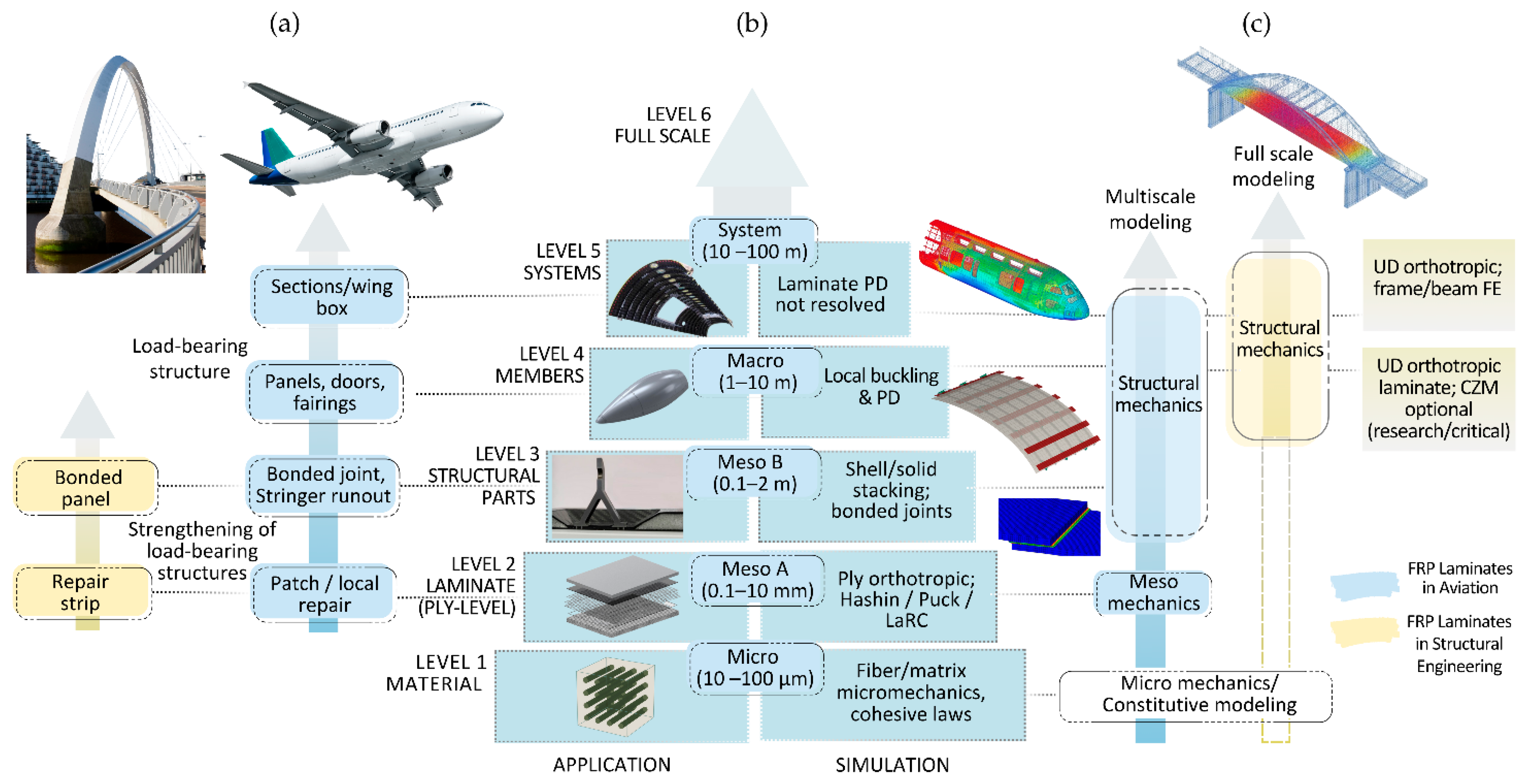

5. Predictive Modeling and Damage Analysis

5.1. Shared Analytical Foundations: CLT and FEM in Sectoral Contexts

5.2. Divergent Modeling Philosophies and Regulatory Drivers

5.3. Calibration Logic and Hybrid Modeling Frameworks

6. Comparative Outlook and Verified Overview

6.1. Modeling Depth and Scalability: Bridging Fidelity and Feasibility

6.2. Surrogate Modeling and Environmental Coupling: Promise and Limitations

6.3. Validation and Standardization: Sectoral Bottlenecks and Integration Potential

7. Conclusions and Future Perspectives

7.1. Novelty of Review

7.2. Future Development Perspectives

- Standardized datasets capturing coupled environmental–mechanical degradation are essential for advancing predictive modeling. The development of open-access repositories and reproducible benchmarks may facilitate cross-sectoral validation and support the integration of hybrid frameworks.

- The incorporation of SHM data into modeling workflows offers a promising avenue for adaptive simulation. Real-time sensor feedback—particularly from embedded systems—could enhance the fidelity of damage progression models and inform maintenance strategies.

- Hybrid modeling frameworks that combine physics-based and data-driven approaches merit further exploration. Techniques such as PINNs and HPRNNs, trained on certified datasets, may offer scalable and interpretable solutions for simulating fatigue, delamination, and environmental aging.

- The development of hybrid reinforcement systems—such as glass–carbon fiber laminates—offers significant potential for maximizing mechanical performance while minimizing material consumption and structural weight. These systems warrant further investigation through hybrid modeling frameworks that can capture their complex degradation and interaction mechanisms.

- While aligning building-block testing procedures and exposure classification standards may enhance methodological compatibility, complete unification of certification strategies across sectors remains unlikely due to fundamentally different serviceability and resistance requirements. Nevertheless, comparative analysis of failure mechanisms and validation practices can support knowledge transfer and inspire improvements in sector-specific methodologies.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Oliveira, T.L.; Hadded, M.; Mimouni, S.; Schaan, R.B. The role of non-destructive testing of composite materials for aerospace applications. NDT 2025, 3, 3. [Google Scholar] [CrossRef]

- Bogenfeld, R.M.; Gorsky, B.; Wille, T. An experimental damage-tolerance investigation of CFRP composites on a sub-structural level. Compos. Part C Open Access 2022, 8, 100267. [Google Scholar] [CrossRef]

- Pongiglione, M.; Calderini, C. Sustainable structural design: Comprehensive literature review. J. Struct. Eng. 2016, 142, 04016139. [Google Scholar] [CrossRef]

- Rincon, L.F.; Moscoso, Y.M.; Hamami, A.E.; Matos, J.C. Degradation models and maintenance strategies for reinforced concrete structures in coastal environments under climate change: A review. Buildings 2024, 14, 562. [Google Scholar] [CrossRef]

- Ogunleye, R.O.; Rusnakova, S.; Zaludek, M.; Emebu, S. The influence of ply stacking sequence on mechanical properties of carbon/epoxy composite laminates. Polymers 2022, 14, 5566. [Google Scholar] [CrossRef]

- Diniță, A.; Rosca, C.M.; Tănase, M.; Stancu, A. A comprehensive review on bridging the research gap in AI-driven material simulation for FRP composites. Comput. Model. Eng. Sci. (CMES) 2025, 144, 147–199. [Google Scholar] [CrossRef]

- Liu, T.; Liu, X.; Feng, P. A comprehensive review on mechanical properties of pultruded FRP composites subjected to long-term environmental effects. Compos. Part B Eng. 2020, 191, 107958. [Google Scholar] [CrossRef]

- Jalal, M.; Ayamsir, A.; Supian, A.B.; Beddu, S.; Nasr, R. Flexural behavior and failure modes of pultruded GFRP tube concrete-filled composite beams: A review of experimental and numerical studies. Buildings 2024, 14, 3966. [Google Scholar] [CrossRef]

- Gonilha, J.; Lazzari, J.A.D.; Correia, R.J.; Silvestre, N. Compressive resistance of thin-walled pultruded GFRP profiles: The role of delamination examined through experiments and FE simulations. Compos. Part B Eng. 2025, 288, 111929. [Google Scholar] [CrossRef]

- Kueh, A.B.H.; Sabah, A.S.H.; Qader, D.N.; Drahman, S.H.; Amran, M. Single and repetitive low-velocity impact responses of sandwich composite structures with different skin and core considerations: A review. Case Stud. Constr. Mater. 2023, 18, e01908. [Google Scholar] [CrossRef]

- Sridhar, M.; Kumar, V.M. Structural and sustainability enhancement of composite sandwich slab panels using novel fibre-reinforced geopolymer concrete. J. Compos. Sci. 2024, 8, 479. [Google Scholar] [CrossRef]

- Singh, S.; Kamble, Z.; Neje, G. Textile-reinforced composite structural-health monitoring systems. Text. Prog. 2024, 56, 415–516. [Google Scholar] [CrossRef]

- Arteiro, A.; Furtado, C.; Catalanotti, G.; Linde, P.; Camanho, P. Thin-ply polymer composite materials: A review. Compos. Part A Appl. Sci. Manuf. 2020, 132, 105777. [Google Scholar] [CrossRef]

- Cameron, C.J.; Larsson, J.; Loukil, M.S.; Murtagh, T.; Wennhage, P. Bearing strength performance of mixed thin/thick-ply, quasi-isotropic composite laminates. Compos. Struct. 2021, 261, 113312. [Google Scholar] [CrossRef]

- Ouyang, T.; Sun, W.; Bao, R.; Tan, R. Effects of matrix cracks on delamination of composite laminates subjected to low-velocity impact. Compos. Struct. 2021, 262, 113354. [Google Scholar] [CrossRef]

- Tabatabaeian, A.; Jerkovic, B.; Harrison, P.; Marchiori, E.; Fotouhi, M. Barely visible impact damage detection in composite structures using deep learning networks with varying complexities. Compos. Part B Eng. 2023, 264, 110907. [Google Scholar] [CrossRef]

- Naser, M.; Hawileh, R.; Abdalla, J. Fiber-reinforced polymer composites in strengthening reinforced concrete structures: A critical review. Eng. Struct. 2019, 198, 109542. [Google Scholar] [CrossRef]

- Hussnain, S.M.; Shah, S.Z.H.; Megat-Yusoff, P.S.M.; Hussain, M.Z. Degradation and mechanical performance of fibre-reinforced polymer composites under marine environments: A review of recent advancements. Polym. Degrad. Stab. 2023, 215, 110452. [Google Scholar] [CrossRef]

- Tefera, G.; Bright, G.; Adali, S. Influence of long-term moisture exposure and temperature on the mechanical properties of hybrid FRP composite specimens. J. Compos. Sci. 2024, 8, 312. [Google Scholar] [CrossRef]

- Tao, R.; Yuan, H.; Liu, Y.; Xian, G.; Li, H. Hygrothermal ageing of aerospace-grade prepreg carbon/epoxy composites: Mechanisms and mechanical property degradation. Polym. Degrad. Stab. 2020, 181, 109395. [Google Scholar] [CrossRef]

- Pascoe, J.A. Slow-growth damage tolerance for fatigue after impact in FRP composites: Why current research won’t get us there. Theor. Appl. Fract. Mech. 2021, 116, 103127. [Google Scholar] [CrossRef]

- Bogenfeld, R.; Gorsky, C. An experimental study of the cyclic compression after impact behavior of CFRP composites. J. Compos. Sci. 2021, 5, 296. [Google Scholar] [CrossRef]

- Hamam, Z.; Godin, N.; Fusco, C.; Doitrand, A.; Monnier, T. Acoustic emission signal due to fiber break and fiber matrix debonding in model composite: A computational study. Appl. Sci. 2021, 11, 8406. [Google Scholar] [CrossRef]

- Guo, R.; Li, C.; Niu, Y.; Xian, G. The fatigue performances of carbon fiber reinforced polymer composites—A review. J. Mater. Res. Technol. 2022, 21, 4773–4789. [Google Scholar] [CrossRef]

- Harman, A.B.; Webb, L.; Chang, P.; Ibrahim, M.; Wright, C.; Grigoriou, K.; Lua, J.; Hoos, K.; Rapking, D.; Mollenhauer, D.; et al. Post-impact fatigue durability assessment of composite laminates for enhanced aircraft sustainment. AIAA J. 2022, 60, 938–950. [Google Scholar] [CrossRef]

- Kassapoglou, C.; Turteltaub, S. Experimental damage tolerance evaluation of thick fabric carbon/epoxy laminates under low-velocity and high-velocity impact and compression-after-impact. J. Compos. Mater. 2022, 56, 761–778. [Google Scholar] [CrossRef]

- Chen, J.; Yao, X.; Cheng, L.; Yang, G.; Li, J.; Wang, S.; Jiang, J. Interfacial toughening and bending performance of the CFRP/aluminum-honeycomb sandwich. Compos. Struct. 2023, 321, 117300. [Google Scholar] [CrossRef]

- Xia, L.; Feng, L.; Xin, W.; Jingyang, Z.; Mengdie, L.; Leizhi, Z.; Huang, H.; Zhishen, W. Fatigue damage propagation of FRP under coupling effect of cyclic load and corrosion. Polym. Compos. 2024, 45, 933–945. [Google Scholar] [CrossRef]

- Li, G.; Chen, Y.; Li, Q. Strength-based collaborative topology optimization for continuous fiber reinforced composites. Comput. Methods Appl. Mech. Eng. 2024, 430, 117206. [Google Scholar] [CrossRef]

- Shabani, P.; Li, L.; Laliberte, J.; Qi, G. Compression after impact (CAI) failure mechanisms and damage evolution in large composite laminates: High-fidelity simulation and experimental study. Compos. Struct. 2024, 339, 118143. [Google Scholar] [CrossRef]

- Wang, X.; Zhao, X.; Wu, Z.; Zhu, Z.; Wang, Z. Interlaminar shear behavior of basalt FRP and hybrid FRP laminates. J. Compos. Mater. 2016, 50, 1073–1084. [Google Scholar] [CrossRef]

- Katunin, A.; Pivdiablyk, I.; Gornet, L.; Rozycki, P. A hybrid method for determination of fatigue limit and non-destructive evaluation of composite structures after low-velocity impact loading. Compos. Part B Eng. 2022, 238, 109898. [Google Scholar] [CrossRef]

- Guo, X.; Cui, H.; Wang, Y.; Chen, Z. Fatigue life prediction of CFRP-strengthened RC beams with flexural crack under hygrothermal environments. Materials 2022, 15, 4681. [Google Scholar] [CrossRef]

- Ortiz, J.D.; Khedmatgozar Dolati, S.S.; Malla, P.; Nanni, A.; Mehrabi, A. FRP-reinforced/strengthened concrete: State-of-the-art review on durability and mechanical effects. Materials 2023, 16, 1990. [Google Scholar] [CrossRef]

- Kowalczyk, J.; Jósko, M.; Wieczorek, D.; Sędłak, K.; Nowak, M. Study of the kinetics of adhesive bond formation using the ultrasonic method. Appl. Sci. 2024, 14, 163. [Google Scholar] [CrossRef]

- Shi, J.-W.; Li, H.-Y.; Cao, W.-H.; Wang, H.-T. Fatigue behavior and bond improvement of the FRP-to-concrete interface after marine corrosion. Eng. Struct. 2025, 332, 120043. [Google Scholar] [CrossRef]

- Alsuhaibani, E. Nondestructive testing of externally bonded FRP concrete structures: A comprehensive review. Polymers 2025, 17, 1284. [Google Scholar] [CrossRef]

- Guermazi, N.; Tarjem, B.A.; Ksouri, I.; Ayedi, H.F. On the durability of FRP composites for aircraft structures in hygrothermal conditioning. Compos. Part B Eng. 2016, 85, 294–304. [Google Scholar] [CrossRef]

- Ueda, M.; Cuong, V.M.; Yamanaka, A.; Sakata, K. Tensile, compressive, and fatigue strength of a quasi-isotropic carbon fiber reinforced plastic laminate with a punched hole. Heliyon 2020, 6, e05690. [Google Scholar] [CrossRef]

- Tsai, S.W. Double–Double: New family of composite laminates. AIAA J. 2021, 59, 4293–4305. [Google Scholar] [CrossRef]

- Riccio, A.; Caprio, F.D.; Tsai, S.; Russo, A.; Sellitto, A. Optimization of composite aeronautical components by re-designing with double-double laminates. Aerosp. Sci. Technol. 2024, 151, 109304. [Google Scholar] [CrossRef]

- González, E.; Maimí, P.; de Aja, S.J.; Cruz, P.; Camanho, P. Effects of interply hybridization on the damage resistance and tolerance of composite laminates. Compos. Struct. 2014, 108, 319–331. [Google Scholar] [CrossRef]

- Li, X.; Yuan, Y.; Zhang, Z. Gradient ply thickness design for enhanced low-velocity impact resistance in ultra-thin ply composite. Extrem. Mech. Lett. 2023, 63, 102054. [Google Scholar] [CrossRef]

- Mallikarachchi, H. Predicting mechanical properties of thin woven carbon fiber reinforced laminates. Thin-Walled Struct. 2019, 135, 297–305. [Google Scholar] [CrossRef]

- Tuo, H.; Lu, Z.; Ma, X.; Xing, J.; Zhang, C. Damage and failure mechanism of thin composite laminates under low-velocity impact and compression-after-impact loading conditions. Compos. Part B Eng. 2019, 163, 642–654. [Google Scholar] [CrossRef]

- Talreja, R.; Waas, A.M. Concepts and definitions related to mechanical behavior of fiber reinforced composite materials. Compos. Sci. Technol. 2022, 217, 109081. [Google Scholar] [CrossRef]

- Jin, H.; An, N.; Jia, Q.; Ma, X.; Zhou, J. A mesoscale computational approach to predict ABD matrix of thin woven composites. Compos. Struct. 2024, 337, 118031. [Google Scholar] [CrossRef]

- Sun, X.; Hallett, S. Failure mechanisms and damage evolution of laminated composites under compression after impact (CAI): Experimental and numerical study. Compos. Part A Appl. Sci. Manuf. 2018, 104, 41–59. [Google Scholar] [CrossRef]

- Saeedifar, M.; Najafabadi, M.A.; Zarouchas, D.; Toudeshky, H.H.; Jalalvand, M. Barely visible impact damage assessment in laminated composites using acoustic emission. Compos. Part B Eng. 2018, 152, 180–192. [Google Scholar] [CrossRef]

- Razali, N.; Mansor, M.R.; Omar, G.; Kamarulzaman, S.A.F.S.; Zin, M.H.; Razali, N. Out-of-autoclave as a sustainable composites manufacturing process for aerospace applications. In Design for Sustainability; Elsevier: Amsterdam, The Netherlands, 2021; pp. 395–413. [Google Scholar] [CrossRef]

- Ding, S.; Zhou, H.; Liu, J.; Zhang, X.; Li, G. Review of the development of the probabilistic damage tolerance assessment of life-limited parts in compliance with the airworthiness regulations. Propuls. Power Res. 2023, 12, 297–321. [Google Scholar] [CrossRef]

- Ghosh, G.; Biswas, D.; Bhattacharyya, R. Advancements in multiscale modeling of damage in composite materials: A comprehensive review. Compos. Part B Eng. 2025, 307, 112819. [Google Scholar] [CrossRef]

- Federal Aviation Administration (FAA). Composite Aircraft Structure, AC 20-107B; U.S. Department of Transportation: Washington, DC, USA, 2009; 37p.

- SAE International. Composite Materials Handbook (CMH-17), Guidelines for Characterization of Structural Materials; Revision H R-540; SAE International: Warrendale, PA, USA, 2022; Volume 1, 778p. [Google Scholar]

- SAE International. Composite Materials Handbook (CMH-17), Materials Properties; Revision H R-484; SAE International: Warrendale, PA, USA, 2018; Volume 2, 1504p. [Google Scholar]

- European Aviation Safety Agency (EASA). Rules for Large Aeroplanes: Subpart D—Design and Construction CS-25.603; 25.605, 25.609, 25.613; EASA: Cologne, Germany, 2023.

- Alderliesten, R. Designing for damage tolerance in aerospace: A hybrid material technology. Mater. Des. 2015, 66, 421–428. [Google Scholar] [CrossRef]

- Gribniak, V.; Misiunaite, I.; Rimkus, A.; Sokolov, A.; Šapalas, A. Deformations of FRP–concrete composite beam: Experiment and numerical analysis. Appl. Sci. 2019, 9, 5164. [Google Scholar] [CrossRef]

- Garnevičius, M.; Gribniak, V. Developing a hybrid FRP-concrete composite beam. Sci. Rep. 2022, 12, 16237. [Google Scholar] [CrossRef] [PubMed]

- Harle, S.M. Durability and long-term performance of fiber reinforced polymer (FRP) composites: A review. Structures 2024, 60, 105881. [Google Scholar] [CrossRef]

- Li, M.; Du, Y.; Li, M. Review on FRP strengthened concrete structures: Current advances, challenges and emerging innovations. Appl. Comput. Eng. 2025, 172, 18–28. [Google Scholar] [CrossRef]

- Alazwari, M.A.; Rao, S.S. Modeling and analysis of composite laminates in the presence of uncertainties. Compos. Part B Eng. 2019, 161, 107–120. [Google Scholar] [CrossRef]

- Ibrahim, M.; Ebead, U.; Al-Ansari, M. Life cycle assessment for fiber-reinforced polymer (FRP) composites used in concrete beams: A state-of-the-art review. In Proceedings of the International Conference on Civil Infrastructure and Construction (CIC), Doha, Qatar, 2–5 February 2020; pp. 777–784. [Google Scholar] [CrossRef]

- Ab Ghani, A.F. Hybrid carbon/glass fiber reinforced polymer; a frontier material for aerospace industry: A review on mechanical properties enhancement. Curr. Sci. Technol. 2021, 1, 41–51. [Google Scholar] [CrossRef]

- Duo, Y.; Liu, X.; Liu, Y.; Tafsirojjaman, T.; Sabbrojjaman, M. Environmental impact on the durability of FRP reinforcing bars. J. Build. Eng. 2021, 43, 102909. [Google Scholar] [CrossRef]

- Qureshi, J. Fibre-reinforced polymer (FRP) in civil engineering. In Next Generation Fiber-Reinforced Composites—New Insights; Li, L., Pereira, A.B., Pereira, A.L., Eds.; IntechOpen Ltd.: London, UK, 2023; 26p. [Google Scholar] [CrossRef]

- Maselli, G.; Ascione, F.; Nesticò, A. Life cycle costing for structural analysis and design. Procedia Struct. Integr. 2023, 64, 1743–1751. [Google Scholar] [CrossRef]

- Ascione, F.; Maselli, G.; Nesticò, A. Sustainable materials selection in industrial construction: A life-cycle based approach to compare the economic and structural performances of glass fibre reinforced polymer (GFRP) and steel. J. Clean. Prod. 2024, 475, 143641. [Google Scholar] [CrossRef]

- Uyttersprot, J.; De Corte, W.; Van Paepegem, W. Mechanical characterization of GFRP tiled laminates for structural engineering applications: Stiffness, strength and failure mechanisms. J. Compos. Sci. 2024, 8, 265. [Google Scholar] [CrossRef]

- Dinulović, M.; Perić, M.; Stamenković, D.; Trninić, M.; Bengin, J. Mathematical modeling and finite element analysis of torsional divergence of carbon plates with an AIREX foam core. Mathematics 2025, 13, 2695. [Google Scholar] [CrossRef]

- Castanie, B.; Azoti, W.; Crouzeix, L.; Bello, A.; Taborda, R.P.; Mahmood, A.; Viste, A. Review of monolithic composite laminate and stiffened structures in aeronautic applications. Compos. Part C Open Access 2025, 17, 100585. [Google Scholar] [CrossRef]

- International Federation for Structural Concrete (fib). Externally Applied FRP Reinforcement for Concrete Structures, fib; Bulletin 90. fib: Lausanne, Switzerland, 2019; 229p. [Google Scholar] [CrossRef]

- ACI PRC-440.2-23; Design and Construction of Externally Bonded Fiber-Reinforced Polymer (FRP) Systems for Strengthening Concrete Structures—Guide. ACI: Farmington Hills, MI, USA, 2023; 109p.

- CNR-DT 200 R1/2013; Guide for the Design and Construction of Externally Bonded FRP Systems for Strengthening Existing Structures. CNR: Roma, Italy, 2014; 154p.

- EN 1992-1-1:2023; Eurocode 2—Design of Concrete Structures—Part 1-1: General Rules and Rules for Building, Bridges and Civil Engineering Structures. CEN: Brussels, Belgium, 2023; 402p.

- International Federation for Structural Concrete (fib). fib Model Code for Concrete Structures 2020; Version 1; fib: Lausanne, Switzerland, 2023; 748p. [Google Scholar]

- Gribniak, V.; Rimkus, A.; Plioplys, L.; Misiunaite, I.; Boris, R.; Pravilonis, T. Evaluating mechanical efficiency of glass fibres in a polymer profile. Polym. Test. 2021, 102, 107338. [Google Scholar] [CrossRef]

- Concrete Society. Design Guidance for Strengthening Concrete Structures Using Fibre Composite Materials, Technical Report 55; The Concrete Society: Crowthorne, UK, 2000; 77p. [Google Scholar]

- Nettles, A.T.; Hodge, A.J. The Impact Response of Carbon/Epoxy Laminates; NASA/TM-97-206317; National Aeronautics and Space Administration (NASA), Marshall Space Flight Center: Huntsville, AL, USA, 1997; 178p.

- Pinho, S.T.; Dávila, C.G.; Camanho, P.P.; Iannucci, L.; Robinson, P. Failure Models and Criteria for FRP Under In-Plane or Three-Dimensional Stress States Including Shear Non-Linearity; NASA/TM-2005-213530; National Aeronautics and Space Administration (NASA): Hanover, MD, USA, 2005; 69p. [Google Scholar]

- Ascione, L.; Caron, J.-F.; Godonou, P.; van IJselmuijden, K.; Knippers, J.; Mottram, T.; Oppe, M.; Sorensen, G.M.; Taby, J.; Tromp, L. Prospect for New Guidance in the Design of FRP; Report EUR 27666 EN; Joint Research Centre (JRC): Ispra, Italy, 2009; 176p. [Google Scholar] [CrossRef]

- Mirmiran, A.; Shahawy, M.; Nanni, A.; Karbhari, V.M.; Yalim, B.; Kalayci, A.S. Recommended Construction Specifications and Process Control Manual for Repair and Retrofit of Concrete Structures Using Bonded FRP Composites; NCHRP Report 69; Transportation Research Board (TRB): Washington, DC, USA, 2008; 80p. [Google Scholar]

- ACI Committee 440. Guide Test Methods for Fiber-Reinforced Polymers (FRPs) for Reinforcing or Strengthening Concrete Structures; ACI PRC-440.3-12; ACI: Farmington Hills, MI, USA, 2012; 23p. [Google Scholar]

- ISO 527-4:2023; Plastics—Determination of Tensile Properties—Part 4: Test Conditions for Isotropic and Orthotropic Fibre-Reinforced Plastic Composites. ISO: Geneva, Switzerland, 2023; 28p. Available online: https://www.iso.org/standard/85809.html (accessed on 22 October 2025).

- ASTM D2344/D2344M-22; Standard Test Method for Short-Beam Strength of Polymer Matrix Composite Materials and Their Laminates. ASTM International: West Conshohocken, PA, USA, 2022; 10p. [CrossRef]

- ASTM D3039/D3039M-17; Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2023; 13p. [CrossRef]

- ASTM D6641/D6641M-23; Standard Test Method for Compressive Properties of Polymer Matrix Composite Materials Using a Combined Loading Compression (CLC) Test Fixture. ASTM International: West Conshohocken, PA, USA, 2023; 13p. [CrossRef]

- ASTM D7205/D7205M-21; Standard Test Method for Tensile Properties of Fiber-Reinforced Polymer Matrix Composite Bars. ASTM International: West Conshohocken, PA, USA, 2021; 13p. [CrossRef]

- ASTM D7913/D7913M-25; Standard Test Method for Bond Strength of Fiber-Reinforced Polymer Composite Bars to Concrete by Pullout Testing. ASTM International: West Conshohocken, PA, USA, 2025; 9p. [CrossRef]

- ASTM D7958/D7958M-17; Standard Test Method for Evaluation of Performance for FRP Composite Bonded to Concrete Substrate Using Beam Test. ASTM International: West Conshohocken, PA, USA, 2017; 8p. [CrossRef]

- Vassilopoulos, A.P. The history of fibre-reinforced polymer composite laminate fatigue. Int. J. Fatigue 2020, 134, 105512. [Google Scholar] [CrossRef]

- Sun, J.; Huang, L.; Dai, Y. Dynamic response and damage accumulation of laminated composites under repeated low-velocity impacts. Materials 2023, 16, 778. [Google Scholar] [CrossRef]

- Wan, Y.; Liu, Y.; Hu, C.; Yao, J.; Wang, F.; Yang, B. The failure mechanism of curved composite laminates subjected to low-velocity impact. Acta Mech. Sin. 2023, 39, 423113. [Google Scholar] [CrossRef]

- Chaupal, P.; Rajendran, P. A review on recent developments in vibration-based damage identification methods for laminated composite structures: 2010–2022. Compos. Struct. 2023, 303, 116809. [Google Scholar] [CrossRef]

- Najmi, J.; Khan, H.A.; Javaid, S.S.; Hameed, A.; Siddiqui, F. Aeroelastic tailoring for aerospace applications. Heliyon 2024, 10, e24151. [Google Scholar] [CrossRef]

- Kawarai, T.; Komuro, M.; Kishi, N. Low-velocity impact-load-carrying behavior of reinforced concrete beams strengthened in flexure by bonding a carbon fiber-reinforced polymer sheet to the tension-side surface. Buildings 2025, 15, 1713. [Google Scholar] [CrossRef]

- Lasen, M.; Di Maio, D.; De Bono, D.; Peluzzo, M. An investigation of fatigue damage growth in composite materials using the vibration response phase decay. arXiv 2024, arXiv:2404.14834. [Google Scholar] [CrossRef]

- Aithal, S.; Padmaraj, N.H.; Kini, V.M.; Pai, D. Fatigue durability test of quasi-isotropic carbon/epoxy laminates in marine environment. Adv. Manuf. Polym. Compos. Sci. 2023, 9, 2275097. [Google Scholar] [CrossRef]

- Sánchez-Carmona, S.; Correa, E.; Barroso, A.; París, F. Fatigue life of unidirectional 90° carbon/epoxy laminates made of conventional and ultra-thin plies varying manufacturing and testing conditions. Fatigue Fract. Eng. Mater. Struct. 2023, 46, 1837–1847. [Google Scholar] [CrossRef]

- Angrizani, C.C.; de Oliveira, B.F.; Lorandi, N.P.; Ornaghi, H.L.; Amico, S.C. Combined hygrothermal aging and mechanical loading effect on unidirectional glass/epoxy composites. Polym. Polym. Compos. 2022, 30, 1–10. [Google Scholar] [CrossRef]

- Aceti, P.; Carminati, L.; Bettini, P.; Sala, G. Hygrothermal ageing of composite structures. Part 1: Technical review. Compos. Struct. 2023, 319, 117076. [Google Scholar] [CrossRef]

- Qi, X.; Tian, J.; Xian, G. Hydrothermal ageing of carbon fiber reinforced polymer composites applied for construction: A review. J. Mater. Res. Technol. 2023, 27, 1017–1045. [Google Scholar] [CrossRef]

- Fernandes, O.; Dutta, J.; Pai, Y. Effect of various factors and hygrothermal ageing environment on the low-velocity impact response of fiber-reinforced polymer composites—A comprehensive review. Cogent Eng. 2023, 10, 2247228. [Google Scholar] [CrossRef]

- Aithal, S.; Hossagadde, P.N.; Kini, M.V.; Pai, D. Durability study of quasi-isotropic carbon/epoxy composites under various environmental conditions. Iran. Polym. J. 2023, 32, 873–885. [Google Scholar] [CrossRef]

- Smoleń, J.; Olesik, P.; Nowacki, B.; Godzierz, M.; Kurtyka, K.; Chaber, P.; Czakiert, J.; Kozioł, M. The influence of UV radiation on the properties of GFRP laminates in underwater conditions. Sci. Rep. 2024, 14, 7446. [Google Scholar] [CrossRef] [PubMed]

- Lukachevskaia, I.G.; Kychkin, A.; Kychkin, A.K.; Vasileva, E.D.; Markov, A.E. Effect of 2000-hour ultraviolet irradiation on surface degradation of glass and basalt fiber-reinforced laminates. Polymers 2025, 17, 1980. [Google Scholar] [CrossRef]

- Sun, Z.; Liu, Q.; Liu, F.; Li, Y.; Guo, F.; Fu, S.-Y. Influences of cryo-thermal cycling on the tensile properties of short carbon fiber/polyetherimide composites. Compos. Struct. 2024, 344, 118336. [Google Scholar] [CrossRef]

- Qiu, Z.; Wu, D.; Zhang, Y.; Liu, C.; Qian, Y.; Cai, D. On the mechanical behavior of carbon fiber/epoxy laminates exposed in thermal cycling environments. Thin-Walled Struct. 2024, 196, 111481. [Google Scholar] [CrossRef]

- Wang, Y.; Li, J.; Chen, Y.; Wang, S.; Wang, X. Multi-physics modelling of thermo–hygro–mechanical ageing in aerospace-grade CFRP laminates. Polym. Compos. 2025, 46, 1653–1668. [Google Scholar] [CrossRef]

- Malighetti, P.; Morlotti, C.; Redondi, R.; Paleari, S. The turnaround tactic and on-time performance: Implications for airlines’ efficiency. Res. Transp. Bus. Manag. 2023, 46, 100874. [Google Scholar] [CrossRef]

- Kim, J.H.; Ha, D.; Kim, M.-S.; Yun, G.J. Experimental investigation of freeze–thaw environmental effects on the fatigue life of CFRP composites. Polym. Test. 2025, 143, 108702. [Google Scholar] [CrossRef]

- Li, X.; Zuo, H.; Yang, B. Repair tolerance assessment for aircraft composite structures using Bayesian updating. Chin. J. Aeronaut. 2024, 37, 360–391. [Google Scholar] [CrossRef]

- Faysal, R.M.; Bhuiyan, M.M.H.; Momin, K.A.; Tafsirojjaman, T.; Liu, Y. A review on the advances of the study on FRP–concrete bond under hygrothermal exposure. Constr. Build. Mater. 2023, 363, 129818. [Google Scholar] [CrossRef]

- Attarchian, N.; Aghamohammadi, R.; Nasrollahzadeh, K. Reliability-based calibration of strength-reduction factors for flexural design of FRP-RC beams under various load combinations. J. Compos. Sci. 2025, 9, 154. [Google Scholar] [CrossRef]

- Shamass, R.; Abarkan, I.; Ferreira, F.P. FRP RC beams by collected test data: Comparison with design standards, parameter sensitivity, and reliability analyses. Eng. Struct. 2023, 297, 116933. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, P.-Y.; Chen, G.-M.; Tan, X.-M. Bond strength evaluation of FRP–concrete interfaces affected by hygrothermal and salt attack using improved meta-learning neural network. Appl. Sci. 2024, 14, 5474. [Google Scholar] [CrossRef]

- Yilmaz, B.; Ba, A.; Jasiuniene, E.; Bui, H.; Berthiau, G. Evaluation of bonding quality with advanced nondestructive testing (NDT) and data fusion. Sensors 2020, 20, 5127. [Google Scholar] [CrossRef]

- Evans, E.E.; Brooks, R.A.; Liu, J.; Hall, Z.E.C.; Liu, H.; Lowe, T.J.E.; Withers, P.J.; Kinloch, A.J.; Dear, J.P. Comparison of X-ray computed tomography and ultrasonic C-scan techniques and numerical modelling of impact damage in a CFRP composite laminate. Appl. Compos. Mater. 2024, 31, 249–264. [Google Scholar] [CrossRef]

- Qureshi, J. A review of fibre reinforced polymer bridges. Fibers 2023, 11, 40. [Google Scholar] [CrossRef]

- Mohammadi, R.; Najafabadi, A.M.; Saghafi, H.; Saeedifar, M.; Zarouchas, D. A quantitative assessment of the damage mechanisms of CFRP laminates interleaved by PA66 electrospun nanofibers using acoustic emission. Compos. Struct. 2021, 258, 113395. [Google Scholar] [CrossRef]

- Jasiūnienė, E.; Yilmaz, B.; Smagulova, D.; Bhat, G.A.; Cicėnas, V.; Žukauskas, E.; Mažeika, L. Non-destructive evaluation of the quality of adhesive joints using ultrasound, X-ray, and feature-based data fusion. Appl. Sci. 2022, 12, 12930. [Google Scholar] [CrossRef]

- Ghadarah, N.; Ayre, D. A review on acoustic emission testing for structural health monitoring of polymer-based composites. Sensors 2023, 23, 6945. [Google Scholar] [CrossRef] [PubMed]

- Smolnicki, M.; Duda, S.; Stabla, P.; Zielonka, P.; Lesiuk, G. Acoustic emission with machine learning in fracture of composites: Preliminary study. Arch. Civ. Mech. Eng. 2023, 23, 254. [Google Scholar] [CrossRef]

- Fei, Q.; Cao, J.; Xu, W.; Jiang, L.; Zhang, J.; Ding, H.; Yan, J. A deep learning-based ultrasonic diffraction data analysis method for accurate automatic crack sizing. Appl. Sci. 2024, 14, 4619. [Google Scholar] [CrossRef]

- Xue, P.; Wei, X.; Li, Z.; Wang, Y.; Selivanov, M.F.; Xiong, J. Mechanics of inner core debonding of composite sandwich beam with CFRP hexagonal honeycomb. Int. J. Solids Struct. 2024, 293, 112760. [Google Scholar] [CrossRef]

- Gribniak, V.; Sultani, H.A.; Rimkus, A.; Boris, R.; Sokolov, A.; Torres, L. Quantifying the flexural stiffness changes in the concrete beams with externally bonded carbon fiber sheets under elevated environment temperature. Alex. Eng. J. 2024, 104, 688–700. [Google Scholar] [CrossRef]

- Li, X.; Yuan, Y. Hybrid and gradient design of ultra-thin-ply composite laminates for synergistic suppression of delamination and fiber fracture damage modes. Eng. Fract. Mech. 2024, 295, 109822. [Google Scholar] [CrossRef]

- Hamzat, A.K.; Murad, M.S.; Adediran, I.A.; Asmatulu, E.; Asmatulu, R. Fiber-reinforced composites for aerospace, energy, and marine applications: An insight into failure mechanisms under chemical, thermal, oxidative, and mechanical load conditions. Adv. Compos. Hybrid Mater. 2025, 8, 152. [Google Scholar] [CrossRef]

- Li, Y.; Lyu, Y.; Wu, B.; Gao, J.; Bian, Z.; He, C. Experimental investigation of bonding quality for CFRP bonded structures with thick adhesive layers based on ultrasonic transmission coefficient spectrums. J. Nondestruct. Eval. 2024, 43, 17. [Google Scholar] [CrossRef]

- Pasadas, D.J.; Barzegar, M.; Ribeiro, A.L.; Ramos, H.G. Locating and imaging fiber breaks in CFRP using guided wave tomography and eddy current testing. Sensors 2022, 22, 7377. [Google Scholar] [CrossRef]

- Fang, Q.; Garrido, I.; Duan, Y.; Maldague, X. Automatic detection and identification of defects by deep learning algorithms from pulsed thermography data. Sensors 2023, 23, 4444. [Google Scholar] [CrossRef]

- Zhang, Y.; Chow, C.L.; Lau, D. Artificial intelligence-enhanced non-destructive defect detection for civil infrastructure. Autom. Constr. 2025, 171, 105996. [Google Scholar] [CrossRef]

- Öchsner, A. Foundations of Classical Laminate Theory; Springer Nature: Cham, Switzerland, 2021; 122p. [Google Scholar] [CrossRef]

- Öchsner, A.; Makvandi, R. A Numerical Approach to the Classical Laminate Theory of Composite Materials: The Composite Laminate Analysis Tool—CLAT v2.0; Springer Nature: Cham, Switzerland, 2023; 170p. [Google Scholar] [CrossRef]

- Massarwa, E.; Aboudi, J.; Ali, H.R. A multiscale modeling for failure predictions of fiber reinforced composite laminates. Compos. Part B Eng. 2019, 175, 107166. [Google Scholar] [CrossRef]

- Piekarczyk, A.; Rasheva, Z.; Kotynia, R. Experimental verification of punching shear with FRP reinforcement: Innovations in the new Eurocode generation. Key Eng. Mater. 2025, 1011, 99–108. [Google Scholar] [CrossRef]

- ASTM D3479/D3479M-19; Standard Test Method for Tension-Tension Fatigue of Polymer Matrix Composite Materials. ASTM International: West Conshohocken, PA, USA, 2019; 6p. [CrossRef]

- ASTM D5528/D5528M-21; Standard Test Method for Mode I Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2021; 14p. [CrossRef]

- ASTM D6671/D6671M-19; Standard Test Method for Mixed Mode I–Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2019; 15p. [CrossRef]

- ASTM D7136/D7136M-20; Standard Test Method for Measuring the Damage Resistance of a Fiber-Reinforced Polymer Matrix Composite to a Drop-Weight Impact Event. ASTM International: West Conshohocken, PA, USA, 2020; 16p. [CrossRef]

- ASTM D7905/D7905M-19; Standard Test Method for Determination of the Mode II Interlaminar Fracture Toughness of Unidirectional Fiber-Reinforced Polymer Matrix Composites. ASTM International: West Conshohocken, PA, USA, 2019; 18p. [CrossRef]

- Kumar, P.K.A.V.; Dean, A.; Reinoso, J.; Paggi, M. A multi phase-field-cohesive zone model for laminated composites: Application to delamination migration. Compos. Struct. 2021, 276, 114471. [Google Scholar] [CrossRef]

- Tan, W.; Martínez-Pañeda, E. Phase field fracture predictions of microscopic bridging behaviour of composite materials. Compos. Struct. 2022, 286, 115242. [Google Scholar] [CrossRef]

- Patel, A.; Sato, E.; Shichijo, N.; Hirata, I.; Takagi, T. A Mixed XFEM and CZM approach for predicting progressive failure in advanced SiC/SiC CMC component. Compos. Part C Open Access 2022, 9, 100325. [Google Scholar] [CrossRef]

- Wu, Z.R.; Yang, Y.; Lei, H. Progressive failure analysis of perforated composite laminates considering nonlinear shear effect. Sci. Rep. 2023, 13, 22375. [Google Scholar] [CrossRef]

- Zhang, Y.; Van Paepegem, W.; De Corte, W. An enhanced progressive damage model for laminated fiber-reinforced composites using the 3D Hashin failure criterion: A multi-level analysis and validation. Materials 2024, 17, 5176. [Google Scholar] [CrossRef]

- Hofman, P.; Van der Meer, F.; Sluys, L. Modeling of progressive high-cycle fatigue in composite laminates accounting for local stress ratios. Compos. Part A Appl. Sci. Manuf. 2024, 183, 108219. [Google Scholar] [CrossRef]

- Hofman, P.; Van der Meer, F.P.; Sluys, L.J. A numerical framework for simulating progressive failure in composite laminates under high-cycle fatigue loading. Eng. Fract. Mech. 2024, 295, 109786. [Google Scholar] [CrossRef]

- Xiong, Z.; Zhu, C.; Yang, Y.; Lin, T.; Li, R. XFEM-based study of fatigue crack propagation in rocket deflector troughs under coupled high-temperature and impact conditions. J. Mar. Sci. Eng. 2024, 12, 207. [Google Scholar] [CrossRef]

- Taherzadeh-Fard, M. Numerical modeling of failure mechanisms in composite laminates: XFEM, CZM and continuum damage models. Mathematics 2025, 13, 1578. [Google Scholar] [CrossRef]

- Liu, Y.; Xie, J.; Chen, X.; Zhang, J.; Wan, M.; Sun, Z.; Yang, C. Characterization of progressive damage behaviour and failure mechanism of carbon fiber reinforced composite laminates. Sci. Rep. 2025, 15, 13791. [Google Scholar] [CrossRef] [PubMed]

- Zheng, J.; Maharaj, C.; Liu, J.; Li, H. A comparative study on the failure criteria for predicting the damage initiation in fiber-reinforced composites. Mech. Compos. Mater. 2022, 58, 125–140. [Google Scholar] [CrossRef]

- Temiz, P. 3D FEM Implementation of LaRC05 Failure Criteria Combined with XFEM and Cohesive Zone Modeling. Master’s Thesis, Middle East Technical University, Ankara, Turkey, 2022; 211p. Available online: https://open.metu.edu.tr/handle/11511/101856 (accessed on 22 October 2025).

- Sharma, P.; Mali, H.S.; Dixit, A. Mode-I interlaminar fracture modeling of DCB composite laminate using finite element techniques. J. Braz. Soc. Mech. Sci. Eng. 2023, 45, 512. [Google Scholar] [CrossRef]

- Ogunleye, R.O.; Rusnáková, S.; Javořík, J.; Žaludek, M.; Kotlánová, B. Advanced sensors and sensing systems for structural health monitoring in aerospace composites. Adv. Eng. Mater. 2024, 26, 2401745. [Google Scholar] [CrossRef]

- Kosova, F.; Altay, Ö.; Ünver, H.Ö. Structural health monitoring in aviation: A comprehensive review and future directions for machine learning. Nondestruct. Test. Eval. 2025, 40, 1–60. [Google Scholar] [CrossRef]

- Mardanshahi, A.; Sreekumar, A.; Yang, X.; Barman, S.K.; Chronopoulos, D. Sensing techniques for structural health monitoring: A state-of-the-art review on performance criteria and new-generation technologies. Sensors 2025, 25, 1424. [Google Scholar] [CrossRef] [PubMed]

- Patel, J.M.; Ramezankhani, M.; Deodhar, A.; Birru, D. Accelerated gradient-based design optimization via differentiable physics-informed neural operator: A composites autoclave processing case study. arXiv 2025, arXiv:2502.11504. [Google Scholar] [CrossRef]

- Wang, W.; Thai, H.-T. A physics-informed neural network framework for laminated composite plates under bending. Thin-Walled Struct. 2025, 210, 113014. [Google Scholar] [CrossRef]

- Ghane, E.; Maia, M.A.; Rocha, I.B.C.M.; Fagerström, M.; Mirakhalaf, M. Multiscale analysis of woven composites using hierarchical physically recurrent neural networks. arXiv 2025, arXiv:2503.04901. [Google Scholar] [CrossRef]

- Arnold, S.M.; Mital, S.K.; Hearley, B.L. Stiffness and fatigue life estimator for polymer composite laminates via surrogate ML models. In Proceedings of the American Society for Composites (ASC) 38th Annual Technical Conference, Boston, MA, USA, 17–20 September 2023; Paper No. 004673. 17p. [Google Scholar]

- Hu, H.; Wei, Q.; Wang, T.; Ma, Q.; Jin, P.; Pan, S.; Li, F.; Wang, S.; Yang, Y.; Li, Y. Experimental and numerical investigation integrated with machine learning (ML) for the prediction strategy of DP590/CFRP composite laminates. Polymers 2024, 16, 1589. [Google Scholar] [CrossRef]

- Khalid, S.; Yazdani, M.H.; Azad, M.M.; Elahi, M.U.; Raouf, I.; Kim, H.S. Advancements in physics-informed neural networks for laminated composites: A comprehensive review. Mathematics 2025, 13, 17. [Google Scholar] [CrossRef]

- Agarwal, M.; Pasupathy, P.; Wu, X.; Recchia, S.S.; Pelegri, A.A. Multiscale computational and artificial intelligence models of linear and nonlinear composites: A review. Small Sci. 2024, 4, 2300185. [Google Scholar] [CrossRef]

- Zhang, G.; Tong, M.; Yan, B.; Wang, F.; Zhang, H. Damage and mechanical repair of composite laminates: Effects of embedded defects and low-velocity impacts. In Proceedings of the 34th Congress of the International Council of the Aeronautical Sciences (ICAS), Florence, Italy, 9–13 September 2024; Paper No. ICAS2024_0748. 16p. [Google Scholar]

- Yan, G.; Wan, B.; Huang, H.; Li, W. Damage and failure monitoring of aerospace insulation layers based on embedded fiber Bragg grating sensors. Polymers 2024, 16, 3543. [Google Scholar] [CrossRef] [PubMed]

- Azanaw, M.G. Blending data-driven surrogates with physics-based topology optimization: A critical review of machine learning-accelerated design in fibre-reinforced polymer and concrete structures. Am. J. Sci. Eng. Technol. 2025, 10, 80–93. [Google Scholar] [CrossRef]

- Lin, K.; Wang, Z. Multiscale mechanics and molecular dynamics simulations of the durability of fiber-reinforced polymer composites. Commun. Mater. 2023, 4, 66. [Google Scholar] [CrossRef]

| Aspect | Aviation Engineering | Structural Engineering |

|---|---|---|

| Primary design philosophy | Damage tolerance: failure is expected, but must remain controlled and predictable | Durability-based: failure is avoided through conservative design and safety margins |

| Typical loading conditions | Cyclic, vibratory, and impact loads; fatigue-critical | Static or sustained loads and environmental aging dominate |

| Laminate configuration | Thin-ply, optimized stacking sequences for weight and fatigue resistance | Standard layups, pultruded profiles briefly used, durability-focused architecture |

| Failure mechanisms | Delamination, matrix cracking, fiber breakage; barely visible impact damage (BVID) | Environmental degradation, interface debonding, visible cracking |

| Inspection strategy | Scheduled NDT and embedded SHM systems; certification-driven | Reactive or periodic inspection; manual or semi-automated methods |

| Modeling approach | Multiscale FEM, progressive damage models, cohesive zone modeling, fatigue simulation | CLT/FEM for global response; empirical degradation factors for aging effects |

| Regulatory framework * | FAA, EASA, SAE International; certification mandates predictive modeling | Eurocode 2, fib Bulletins, and ACI Committee 440 and CNR guidelines; design codes emphasize serviceability and safety |

| Data resolution | Ply-level mechanical and fatigue data, validated through building-block testing | Member-level performance metrics; empirical reduction coefficients |

| Research focus | High-fidelity modeling, residual strength, fatigue life prediction | Long-term durability, bond retention, and environmental exposure effects |

| Failure Type | Aviation Engineering | Structural Engineering |

|---|---|---|

| Matrix cracking | Stress concentration accelerates delamination (early-stage damage) [15,27] | Surface whitening or cracking and visible degradation [17,35,36] |

| AE, UT | Visual inspection, thermography | |

| Fiber–matrix debonding | Load transfer reduction and interlaminar failure initiation [23,27] | Interface deterioration accelerated by moisture/UV [17,18,37] |

| AE, UT | Thermography, AE | |

| Delamination | CAI strength reduction propagated under fatigue (critical failure) [15,26,27,30] | Stiffness reduction [17,31,37] |

| AE, UT, shearography | AE, UT, thermography | |

| Fiber breakage/kinking ‡ | Catastrophic loss of strength (final failure stage) [21,22,23,27] | Failure that precedes matrix/interface degradation [18,37] |

| AE, UT | AE, long-term monitoring | |

| Creep/fatigue effects | Fiber failure accelerated by delamination under fatigue [21,24,25,28,30] | Stiffness reduction and deformation increase under sustained load [17,18,37] |

| AE, UT | AE, long-term monitoring | |

| Environmental degradation | Matrix and interface degradation under thermal cycling, humidity, and de-icing [20,27,29] | Long-term bond degradation under UV, freezing–thawing cycles, and moisture ingress [18,19,37] |

| AE, thermography | AE, thermography, visual inspection | |

| External bond failure | – | Failure of strengthening systems; reduction in flexural/shear capacity [17,31,32,33,36,37] |

| – | UT, thermography, visual inspection | |

| Interlaminar shear failure | – | Loss of laminate integrity; stress concentrations at ply interfaces [7,17,31] |

| – | AE, UT |

| Form | Thickness | Delamination | Fatigue ‡ | CAI | Resistance Mechanism |

|---|---|---|---|---|---|

| UD prepreg | ≤100 µm | ↑ onset | ↑ life | ↑ | Delayed matrix-crack onset; reduced interlaminar driving forces [13,45,48] |

| Spread-tow/ thin woven | Near 60–100 µm | ↑ | ↑ life | ↑ | Reduced tows smooth stress fields; arrested cracks [13,44,47] |

| Hybrid thin/ thick stacks | 60–100 µm (thin ply) | ↑ | ↑ life | ↑ | Thin plies arrest cracks; thick plies carry the load [14,29] |

| Gradient thickness stacks | Graded near 50–150 µm | ↑ impact tolerance | Context- dependent | ↑ | Reduced interlaminar stress peaks [29,43] |

| Ultra-thin laminates | Typically, below 60–80 µm | ↑ | ↑ life | ↑ | Diminished micro-damages; crack confinement [15,43] |

| Regulation | Aviation Engineering | Structural Engineering |

|---|---|---|

| Standards | FAA, EASA | CEN, ISO, ASTM International |

| Composite Aircraft Structure AC 20-107B; Rules for Large Aeroplanes CS-25.603–25.613 [53,56] | Eurocode 2 EN 1992-1-1:2023; ISO 527-4:2023; ASTM Standard Test Methods [75,84,85,86,87,88,89,90] | |

| Guidelines | SAE International | fib, Concrete Society, CNR, ACI Committee 440 |

| Composite Materials Handbook [54,55] | fib Model Code 2020; fib Bulletins; Design Guides TR 55, CNR-DT 200 R1/2013, and ACI PRC-440.2-23; Guide Test Methods ACI PRC-440.3-12 [72,73,74,76,78,83] | |

| Technical reports | NASA | JRC, TRB |

| Reports NASA/TM-97-206317, NASA/TM-2005-213530 [79,80] | JRC Report EUR 27666 EN; NCHRP Report 69 [81,82] |

| Aspect | Aviation Engineering | Structural Engineering |

|---|---|---|

| Exploitation duration | Typically, 20–40 years; governed by fatigue-critical mission profiles [26,27,30] | Often exceeds 50 years; governed by environmental durability and structural redundancy [35,37,119] |

| Service environment | Controlled but mechanically aggressive: cyclic loads, vibration, impact, temperature [27,30,39] | Harsh and variable: moisture, UV radiation, freezing–thawing cycles, chemical exposure [35,37,119] |

| Dominant degradation mechanisms | Matrix cracking, fiber breakage, delamination, BVID [15,23,27,30,39,48,49] | Moisture ingress, UV-induced resin degradation, interfacial debonding, and creep aging [31,35,37,60,119,126] |

| Design philosophy | Damage-tolerant: failure initiation is expected and must be predictable and non-critical [26,27,30,38] | Durability-based: conservative design and empirical factors prevent failure [6,35,37,60] |

| Damage detection strategy | Embedded SHM systems, scheduled NDT (e.g., UT, AE, thermography), certification-driven [21,22,23,24,117,121,125] | Periodic inspection, semi-automated NDT, and reactive maintenance [17,18,31,33,36,37,124] |

| Detection resolution | High-resolution, ply-level monitoring; fatigue and impact damage tracking [23,120,122,123] | Member-level or surface-level detection, focused on visible or environmental damage [31,35,37,119] |

| Inspection frequency | Regular intervals defined by certification protocols (FAA, EASA) [53,56,117,118,125] | Project-specific, often less frequent, and condition-based [31,37,76,124] |

| Parameter | Aviation Engineering | Structural Engineering |

|---|---|---|

| Materials | Carbon fiber reinforcement + epoxy matrix | Glass or carbon fiber reinforcement + epoxy matrix |

| Knock-down factors | Hot/wet environment or fatigue [54]: ↓ stiffness by 10% to 30% ↓ strength by 20% to 50% (system-dependent) | Hot/wet environment or fatigue [60,72,73]: ↓ stiffness by 15% to 40% ↓ strength by 30% to 60% (exposure-dependent) |

| Residual CAI | ↓ by 30% to 60% (depending on the impact energy, layup, and toughening) [2,48,55] | ↓ by 40% to 65% [3,72] |

| Fatigue slope • | From 8.3 to 20 (tension-tension load) [55] | From 6.7 to 12.5 (glass fibers; moisture-sensitive) [91] |

| Moisture diffusion coefficient | Room to elevated temperature: from 10−7 cm2/s to 10−9 cm2/s (matrix-dependent) [55] | Room to elevated temperature: from 10−6 cm2/s to 10−8 cm2/s (glass fibers) [7,60,65] |

| UV exposure | ↓ strength by 10% to 25% [55] | ↓ strength by 15% to 30% [60,65] |

| Scheduled inspections † | Visual inspection after 400 FH to 800 FH; detailed NDI after 18 to 24 months [53,56] | Typical visual inspection after 1 to 5 years; NDI depends on the service conditions. |

| Modeling fidelity ‡ | High (progressive damage, CZM, fatigue, coupled aging; building-block validation) | Medium (CLT/FEM with environmental reduction factors; phenomenological fatigue) |

| Method | Failure Type | Monitoring Depth | Damage Size | Use in Service | Sector Cadence |

|---|---|---|---|---|---|

| Ultrasonic testing | Delamination, debonding, BVID | Through-thickness | Meso → macro (from near 5 mm to over 10 mm) | Scheduled NDI; dock/overhaul | Standard (e.g., [56]) and owner program-based |

| Active thermography | Near-surface delamination, debonding | Near-surface to a few mm | Meso (a few mm) | Rapid screening | Program-based/condition-based |

| Shearography | Debonding, core-skin issues | Near-surface | Meso → macro | Rapid area screening | Program-based |

| Acoustic emission | Matrix/fiber damage progress, delamination onset | Global (source location needed) | Event detection (not for sizing) | Proof/acceptance/monitoring | Event-driven/condition-based |

| Guided waves (Lamb) | Delamination, debonding | Long-range | Macro → meso (tuned) | SHM/monitoring | Continuous/periodic |

| Embedded SHM | Strain anomalies, damage indicators | Local to instrumented path | Not for sizing | Embedded/attached SHM | Continuous |

| Technique | Aviation Engineering | Structural Engineering |

|---|---|---|

| Ultrasonic testing (UT) | Scheduled maintenance and repair procedures (MRO) of structural components to detect delamination and cracks [15,26,27,117,118] | Applied when defects are suspected; used in bridges and tunnels [17,31,37,132] |

| Acoustic emission (AE) | Real-time detection of early-stage damage; embedded sensors used for fatigue and impact monitoring [15,23,27,120,122,123,129] | Used for monitoring bond degradation and creep-related failures in infrastructure [17,18,37,124] |

| Infrared thermography (IRT) | Non-contact, full-field inspection of near-surface defects; used in flight-line triage and maintenance [23,117,130,131] | Drone-assisted surveys and manual scans for surface anomalies [17,35,37] |

| Digital shearography (DS) | Detection of subsurface delamination and adhesive debonding under stress, typical for aerospace maintenance [123] | Applied for capturing bonded joints and surface strain anomalies [31] |

| Aspect | Aviation Engineering | Structural Engineering |

|---|---|---|

| Primary calibration basis | Coupon-, element-, and subcomponent-scale laboratory testing under controlled loading and environmental conditions [53,54,55,56,137,138,139,140,141] | Long-term in-service monitoring, accelerated aging tests, and proof-load trials on structures [18,72,74,88,89,90] |

| Standards and guidelines | Mechanical properties: ASTM D2344, ASTM D3039, ASTM D6641 [85,86,87] Fatigue: ASTM D3479 [137] Impact: ASTM D7136 [140] Delamination: ASTM D5528, ASTM D6671, ASTM D7905 [138,139,141] | FRP–concrete interface and bond: ASTM D7205, ASTM D7958, ASTM D7913 [88,89,90] Tensile & bond durability: ACI Committee 440 [73], CNR guideline [74], fib Bulletin [72] |

| Typical dataset resolution | Ply-level elastic and strength properties, fracture toughness values (Modes I, II, and mixed), impact damage tolerance parameters, fatigue S-N curves [52,145,146] | Member- or system-level stiffness, strength, bond retention factors, and degradation coefficients for various environmental exposure categories [18,72,74,78] |

| Validation objectives | High-fidelity replication of localized damage phenomena (fiber breakage, matrix cracking, delamination) and residual strength reduction [143,144,147,148,149,151] | Assessment of long-term service performance, structural safety margins, and compliance with environmental durability factors [72,73,74] |

| Key limitations | High costs and time requirements for multi-scale test campaigns; variability due to manufacturing defects; limited coupling of environmental effects [135,142,150] | Lack of ply-level data; high variability in field conditions; limited availability of long-term multi-physics datasets [18,144,151] |

| Category | Aviation Engineering | Structural Engineering | Integration Potential |

|---|---|---|---|

| Modeling tools | CLT, FEM, PDM, CZM, XFEM, multiscale simulations [52,145,146,148,150,151] | CLT, FEM, empirical degradation models, global structural assessment tools [72,74,78,147] | High (CLT, FEM), Moderate (XFEM, CZM) |

| Failure criteria | LaRC03 [146], Hashin [154], Puck [155] implemented via UMAT/VUMAT | No explicit ply-level failure modeling; global reduction coefficients reflect degradation [74,78] | Low (LaRC03), Moderate (Hashin), High (empirical coefficients) |

| Fatigue modeling | Certification workflow-integrated S-N curves, Miner’s rule, strain-life models [149,150] | Rarely modeled explicitly; fatigue degradation inferred from environmental exposure categories [73,147] | Moderate |

| Environmental modeling | Limited coupling; often treated sequentially or via modifiers [143,152] | Empirical reduction coefficients applied to material properties; no multi-physics integration [72,74,147] | High |

| Validation strategy | Fatigue, impact, and delamination-validated blocks: coupon → element/component → full-scale [53,54,55,56,138,139,140,141,142] | In-service monitoring, accelerated aging, proof-load testing; long-term durability-focused validation [74,88,89,90] | Moderate |

| Data resolution | Ply-level mechanical, fracture, and fatigue properties [52,148,153] | Member-level stiffness, strength, and bond retention factors [72,74,78,147] | Moderate |

| Hybrid modeling potential | PINNs, HPRNNs, and ML surrogates used for fatigue life prediction and virtual prototyping [160,161,162,163,164] | Emerging use of ML-assisted degradation models and surrogate frameworks for service life estimation [147,164] | High |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Janeikaitė, J.; Misiūnaitė, I.; Gribniak, V. Fiber-Reinforced Polymer Laminates in Aviation and Structural Engineering: A Synthetic Comparison of Performance Requirements, Design Principles, and Defect Assessment Procedures. Materials 2025, 18, 4938. https://doi.org/10.3390/ma18214938

Janeikaitė J, Misiūnaitė I, Gribniak V. Fiber-Reinforced Polymer Laminates in Aviation and Structural Engineering: A Synthetic Comparison of Performance Requirements, Design Principles, and Defect Assessment Procedures. Materials. 2025; 18(21):4938. https://doi.org/10.3390/ma18214938

Chicago/Turabian StyleJaneikaitė, Joana, Ieva Misiūnaitė, and Viktor Gribniak. 2025. "Fiber-Reinforced Polymer Laminates in Aviation and Structural Engineering: A Synthetic Comparison of Performance Requirements, Design Principles, and Defect Assessment Procedures" Materials 18, no. 21: 4938. https://doi.org/10.3390/ma18214938

APA StyleJaneikaitė, J., Misiūnaitė, I., & Gribniak, V. (2025). Fiber-Reinforced Polymer Laminates in Aviation and Structural Engineering: A Synthetic Comparison of Performance Requirements, Design Principles, and Defect Assessment Procedures. Materials, 18(21), 4938. https://doi.org/10.3390/ma18214938