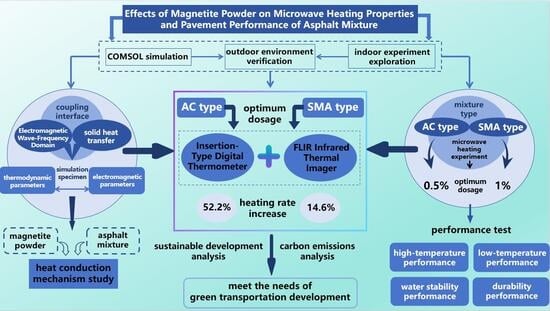

Effects of Magnetite Powder on Microwave Heating Properties and Pavement Performance of Asphalt Mixture

Abstract

1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.1.1. Microwave-Absorbing Materials

2.1.2. Asphalt Materials

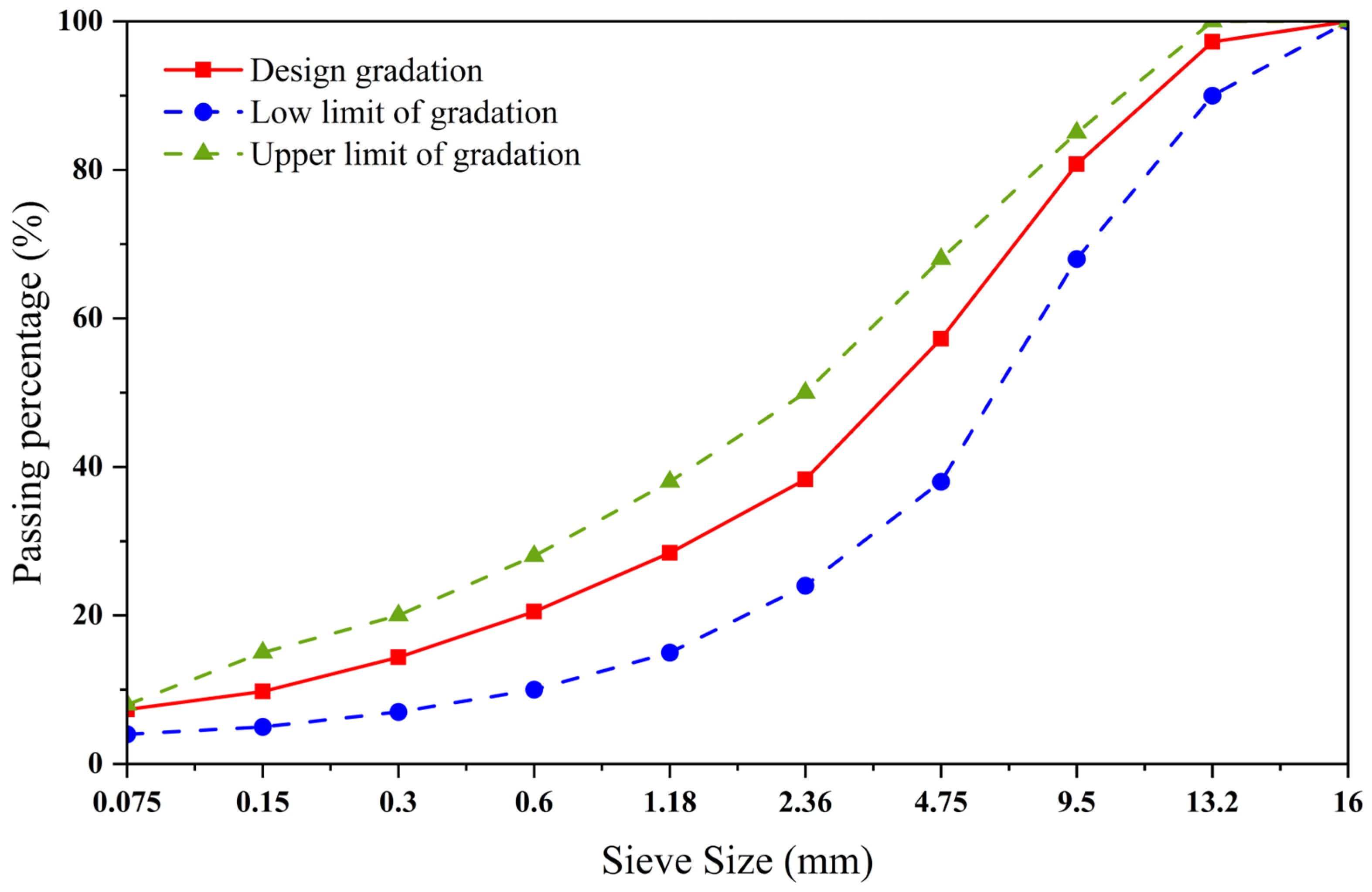

2.1.3. Aggregates and Mineral Powders

2.1.4. Preparation of Asphalt Mixture

- (1)

- Preparation of AC-13 Asphalt Mixture

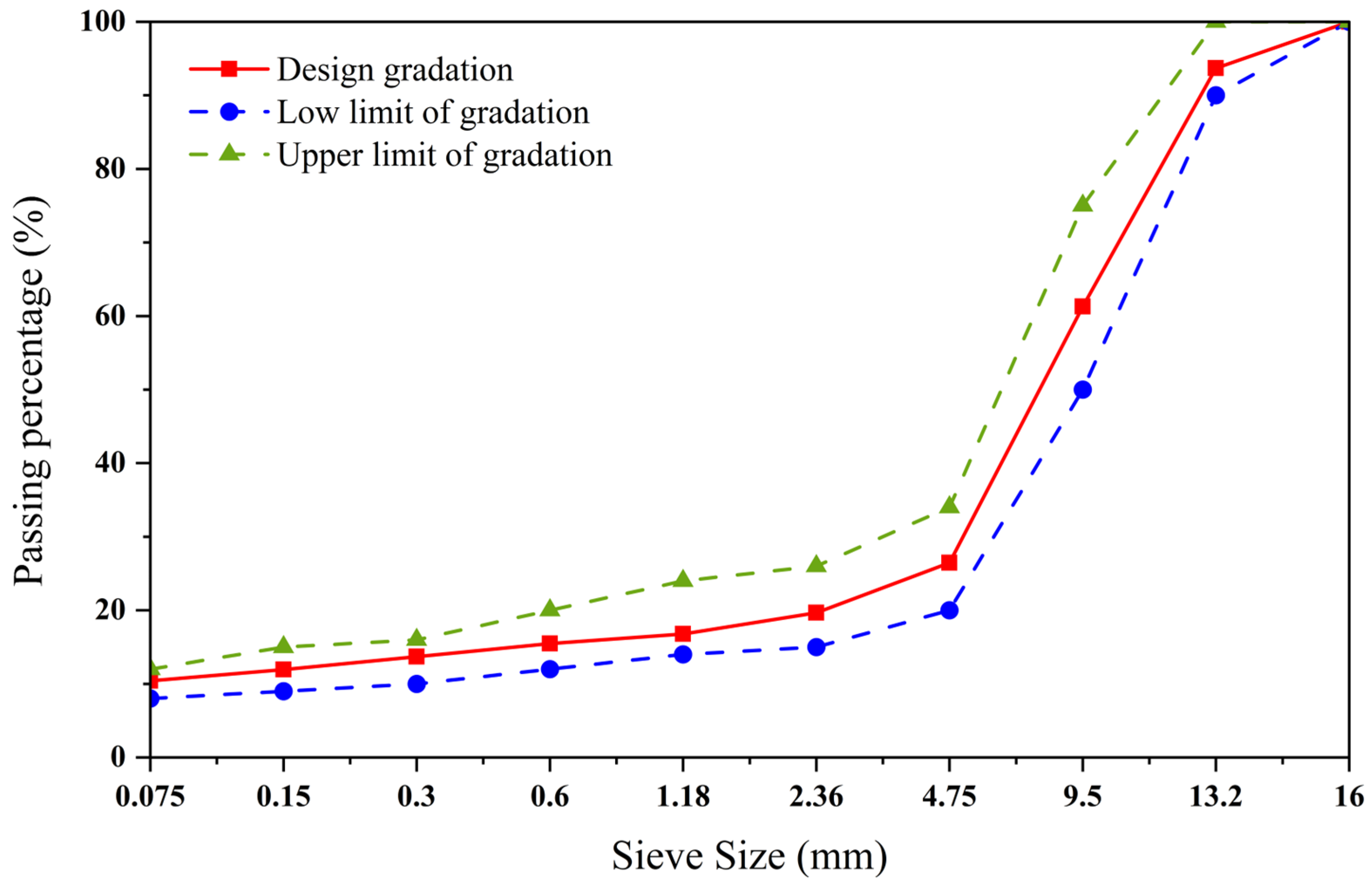

- (2)

- Preparation of SMA-13 Asphalt Mixture

2.1.5. Preparation of Microwave Asphalt Mixture

- (1)

- Preparation of AC-type Microwave Asphalt Mixture

- (2)

- Preparation of SMA-type Microwave Asphalt Mixture

2.2. Performance-Testing Methods for Asphalt Mixtures

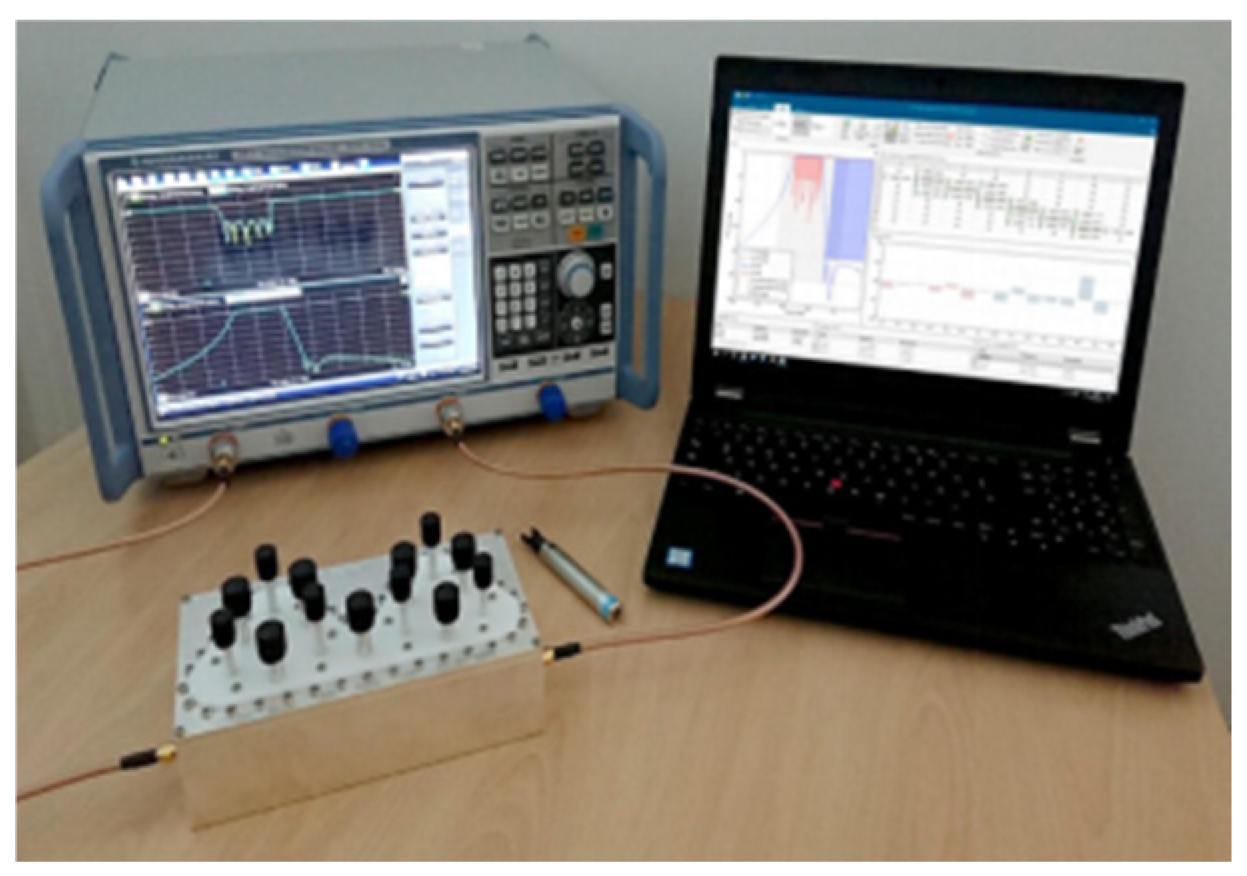

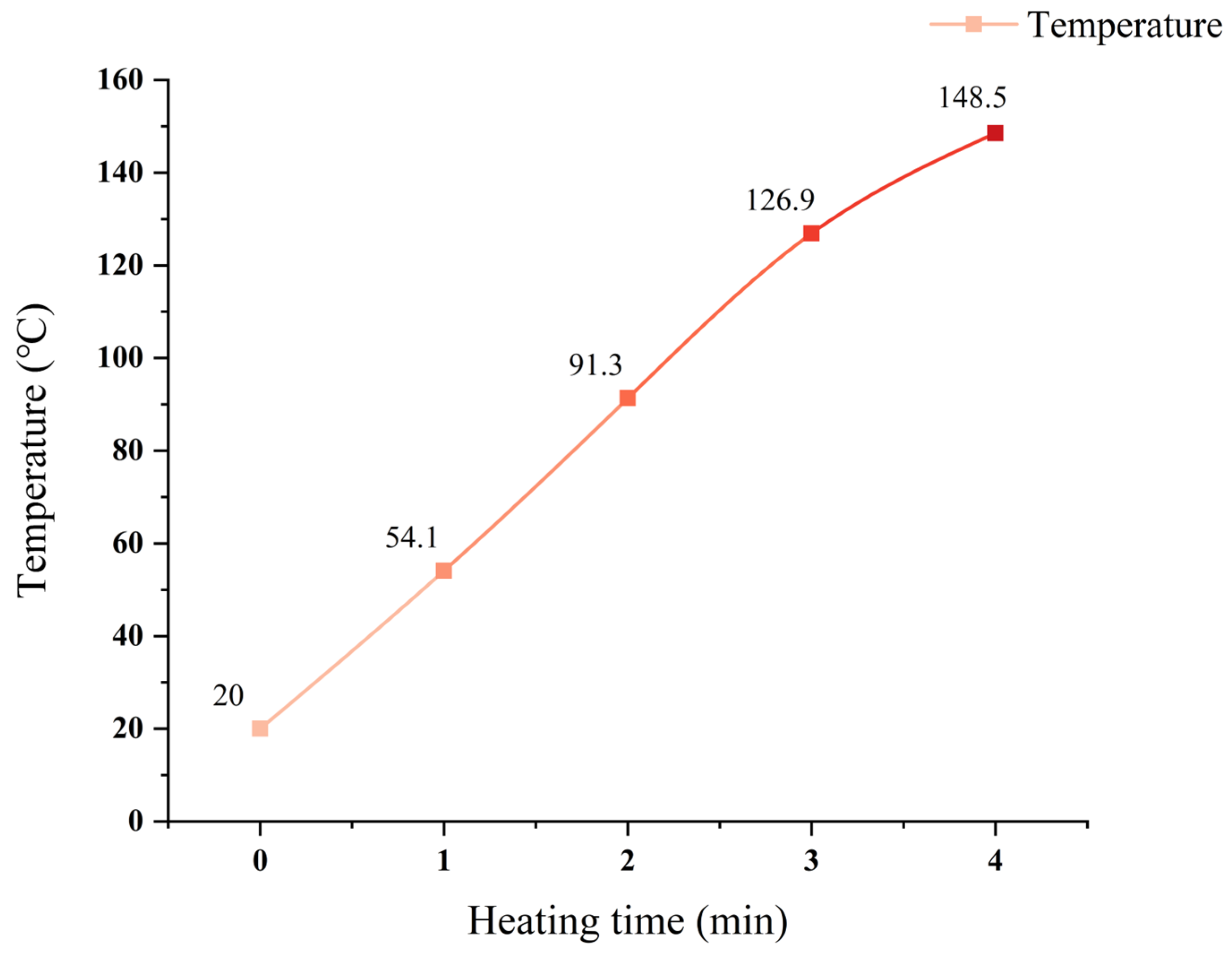

2.2.1. Wave Absorption and Temperature Rise Test

2.2.2. High-Temperature Rutting Test

2.2.3. Low-Temperature Bending Test

2.2.4. Immersed Marshall Test

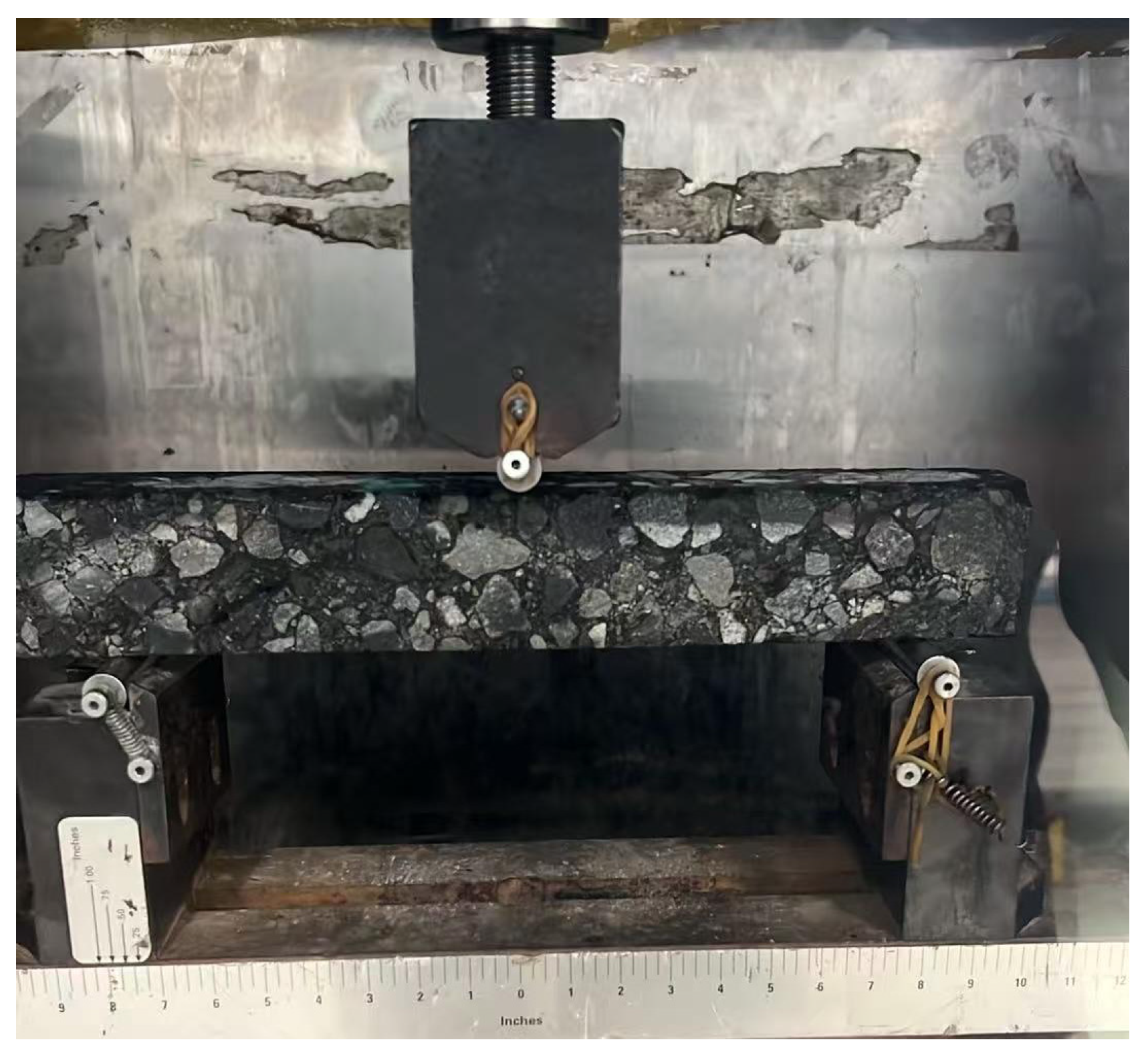

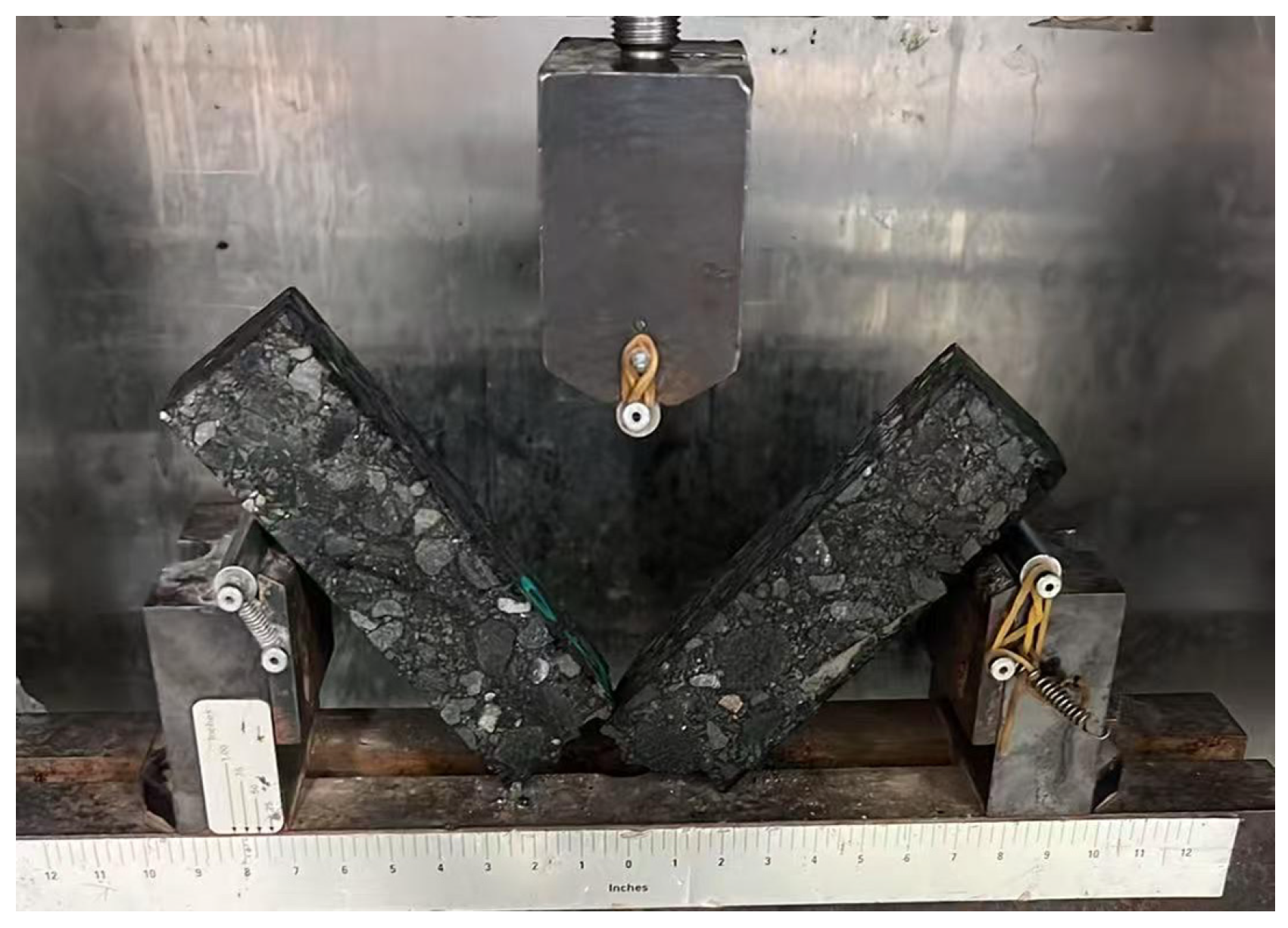

2.2.5. Freeze–Thaw Cycle Splitting Tests and Beam Bending Tests

3. Microwave Heating Simulation Study

3.1. Simulation Method and Model Construction

3.1.1. Theoretical Model

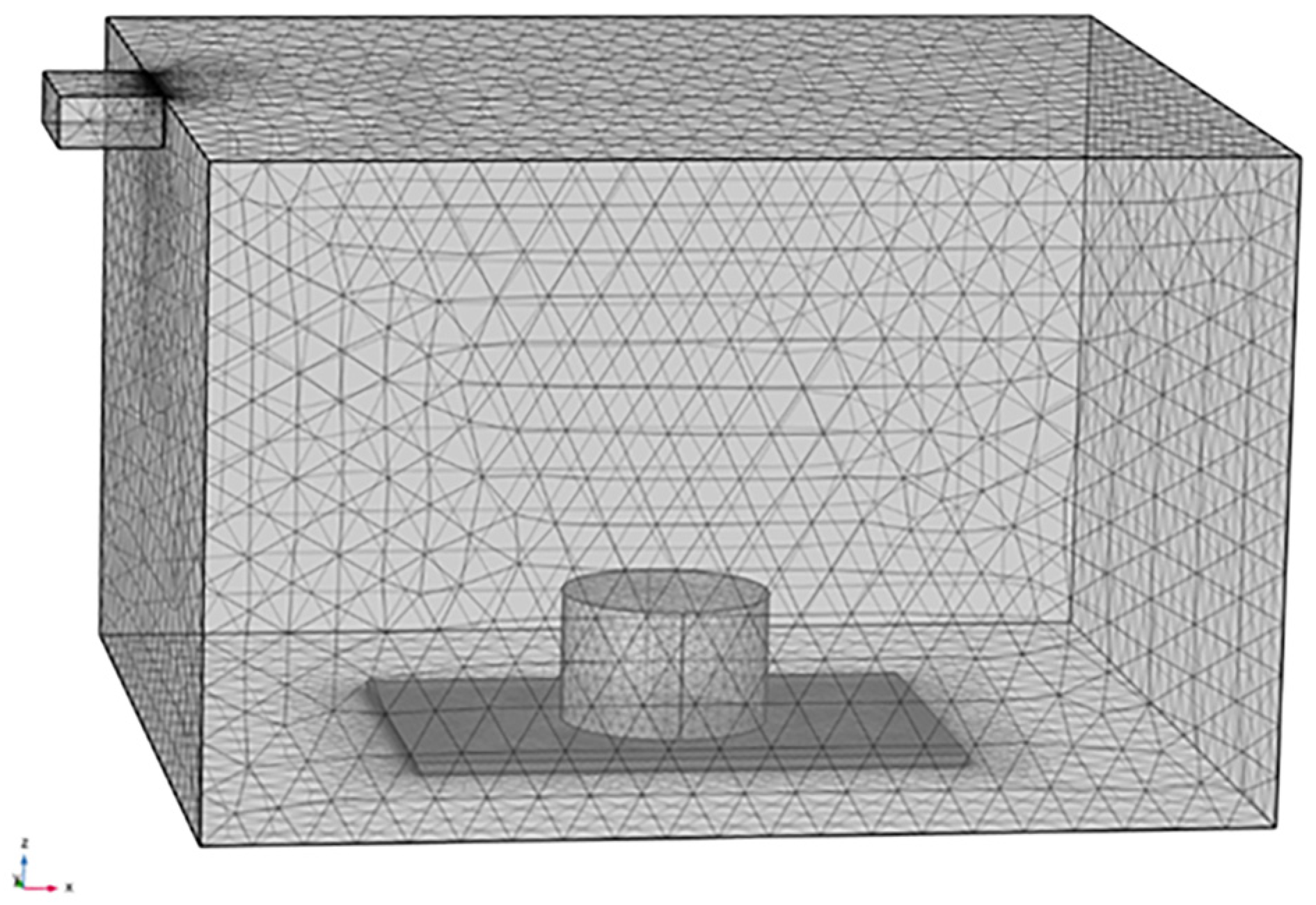

3.1.2. Simulation Model Construction

3.2. Simulation of Microwave Heating of Asphalt Mixtures

3.2.1. Model Parameter Settings

- (1)

- The initial temperature of the geometric model is set to 20 °C (293.15 K); the microwave cavity is filled with air, and the physical parameters of the air are defined by the parameters in the built-in system material library of the COMSOL software; the boundary of the microwave cavity is treated as a perfect electric conductor; and the asphalt mixture specimen is treated as a homogeneous model.

- (2)

- The electromagnetic parameters, such as permittivity and permeability, were derived and measured by means of the four-electrode method [37] based on the basic physical indicators of magnetite powder presented in Table 1. The thermal conductivity was determined in accordance with the (GB/T 5990-2006 [38]) [39]. Additionally, the heat capacity at constant pressure of the asphalt mixture specimen was tested using the method proposed by Grigoriev et al. [40].

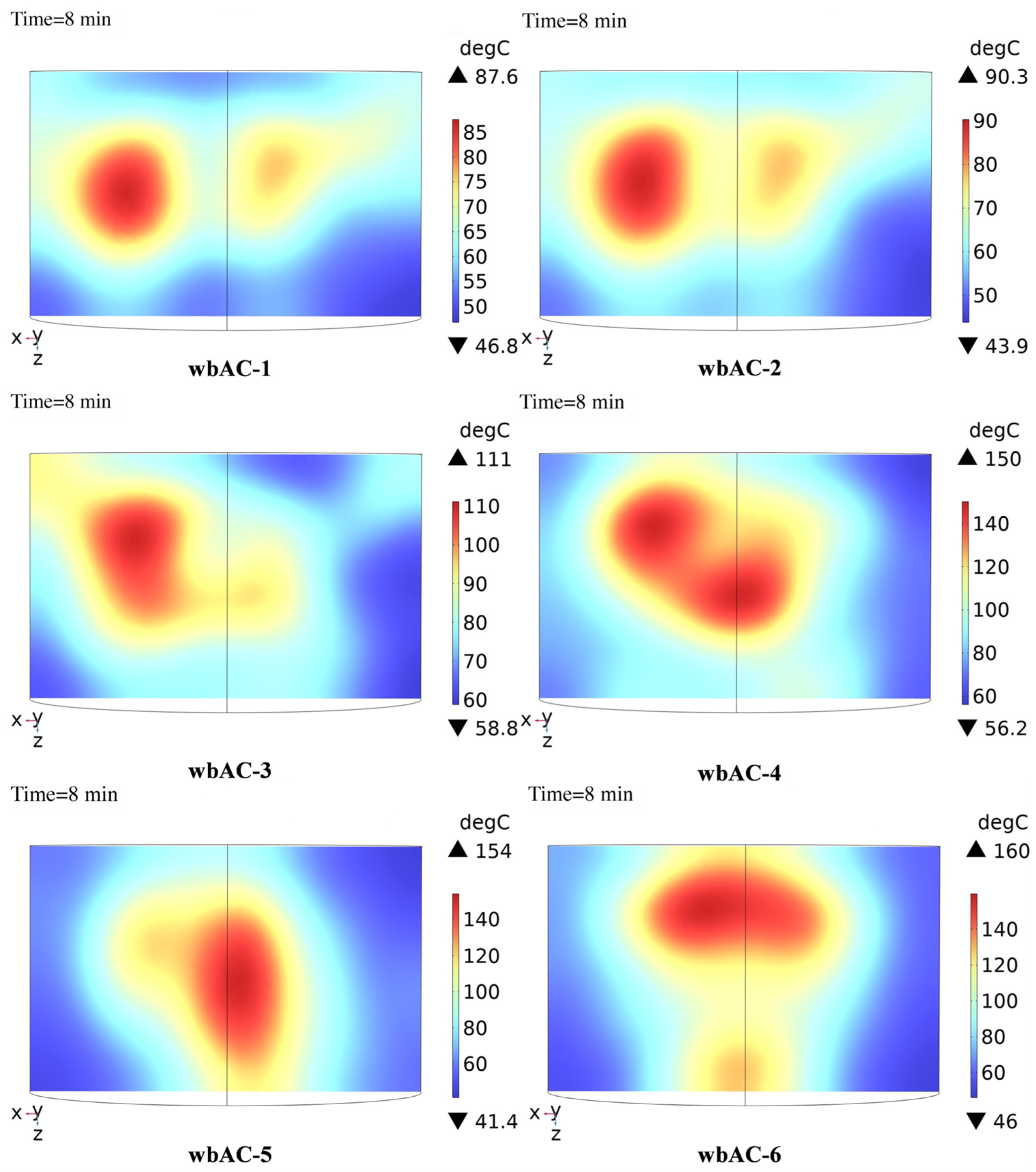

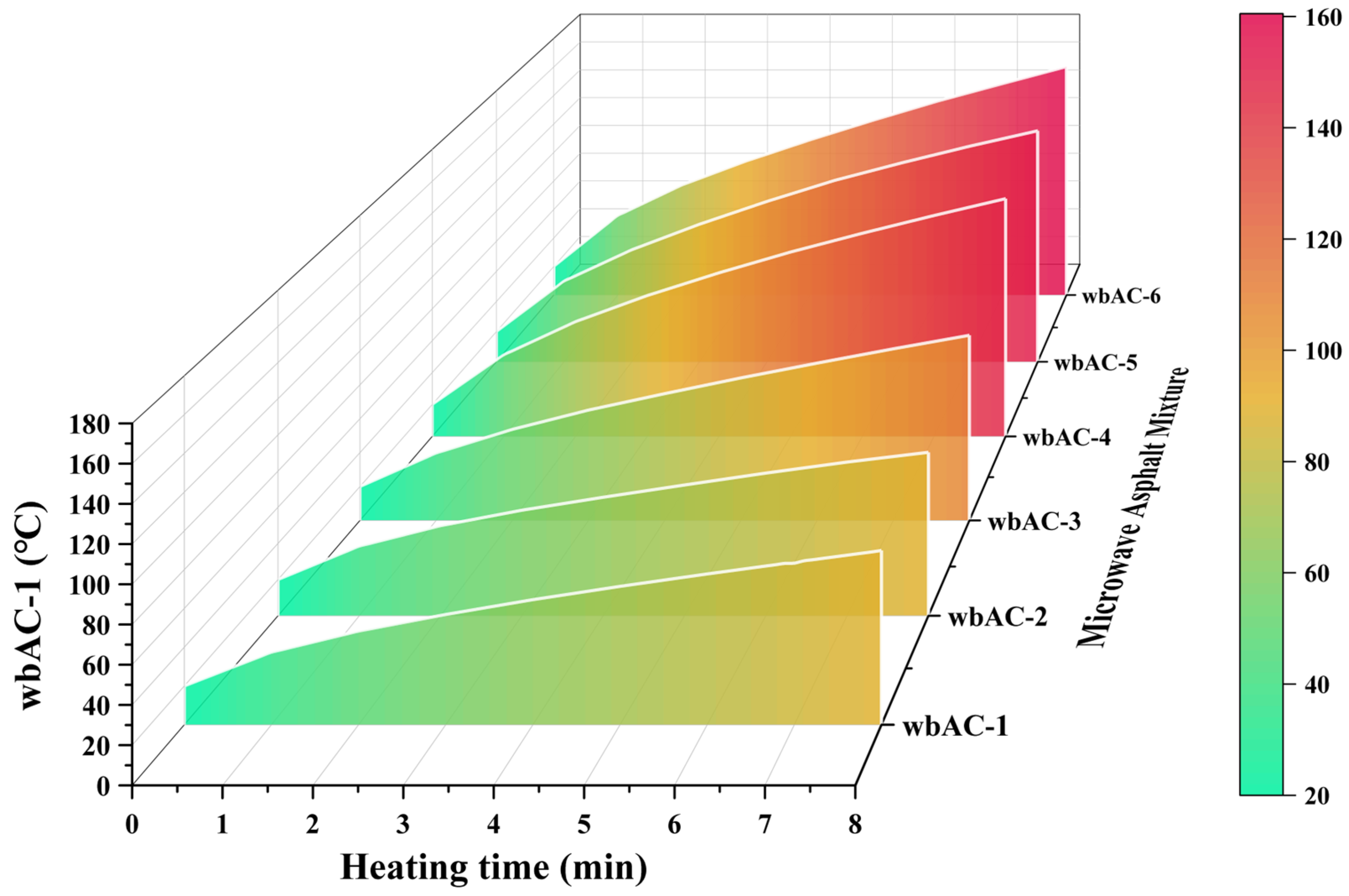

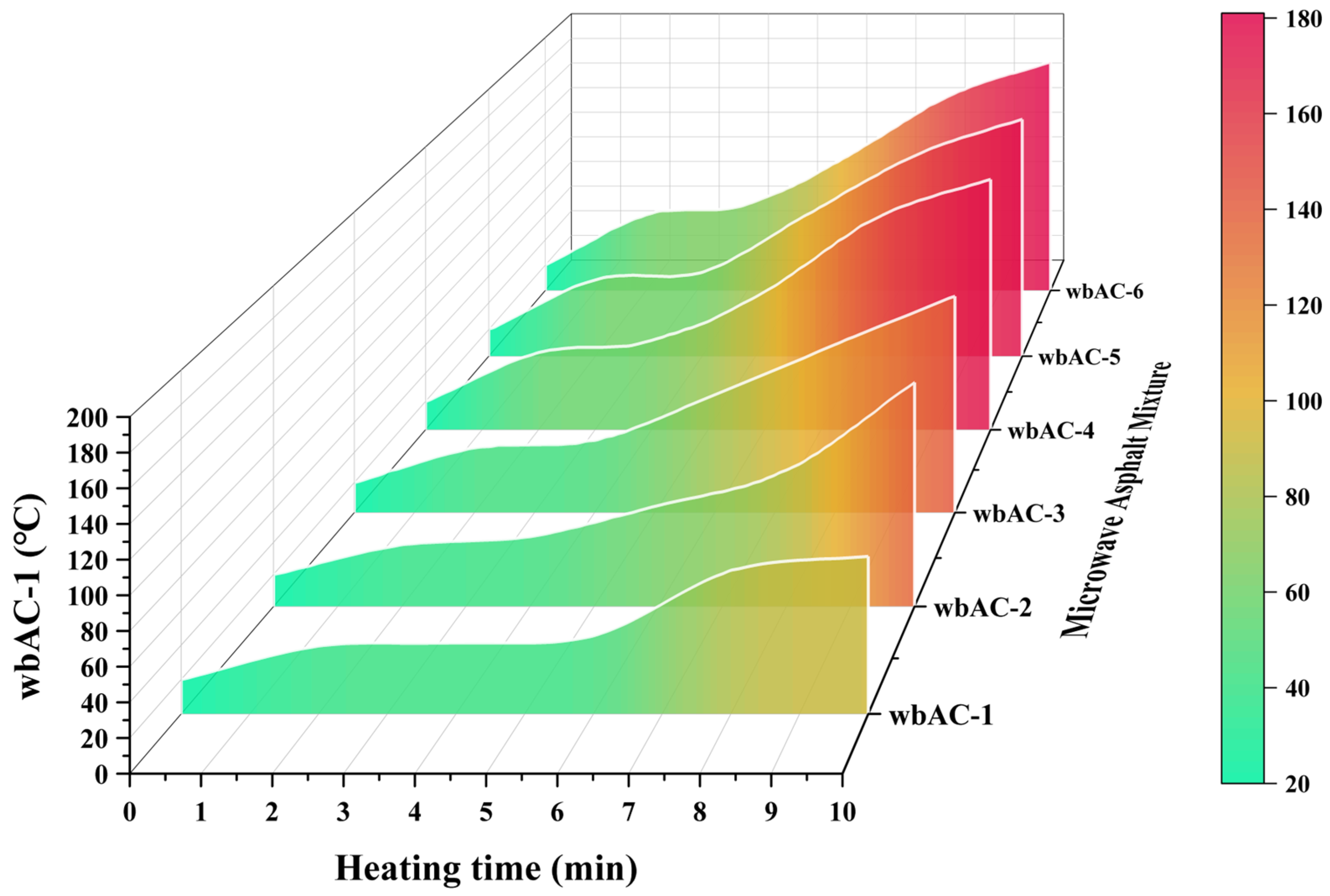

3.2.2. Temperature Distribution of Microwave Asphalt Mixture

4. Results and Discussion of Practical Experiments

4.1. Influence of Magnetite Powder on Microwave-Heating Effect of Asphalt Mixture

4.1.1. Wave Absorption and Temperature Rise Performance of AC-Type Microwave Asphalt Mixture

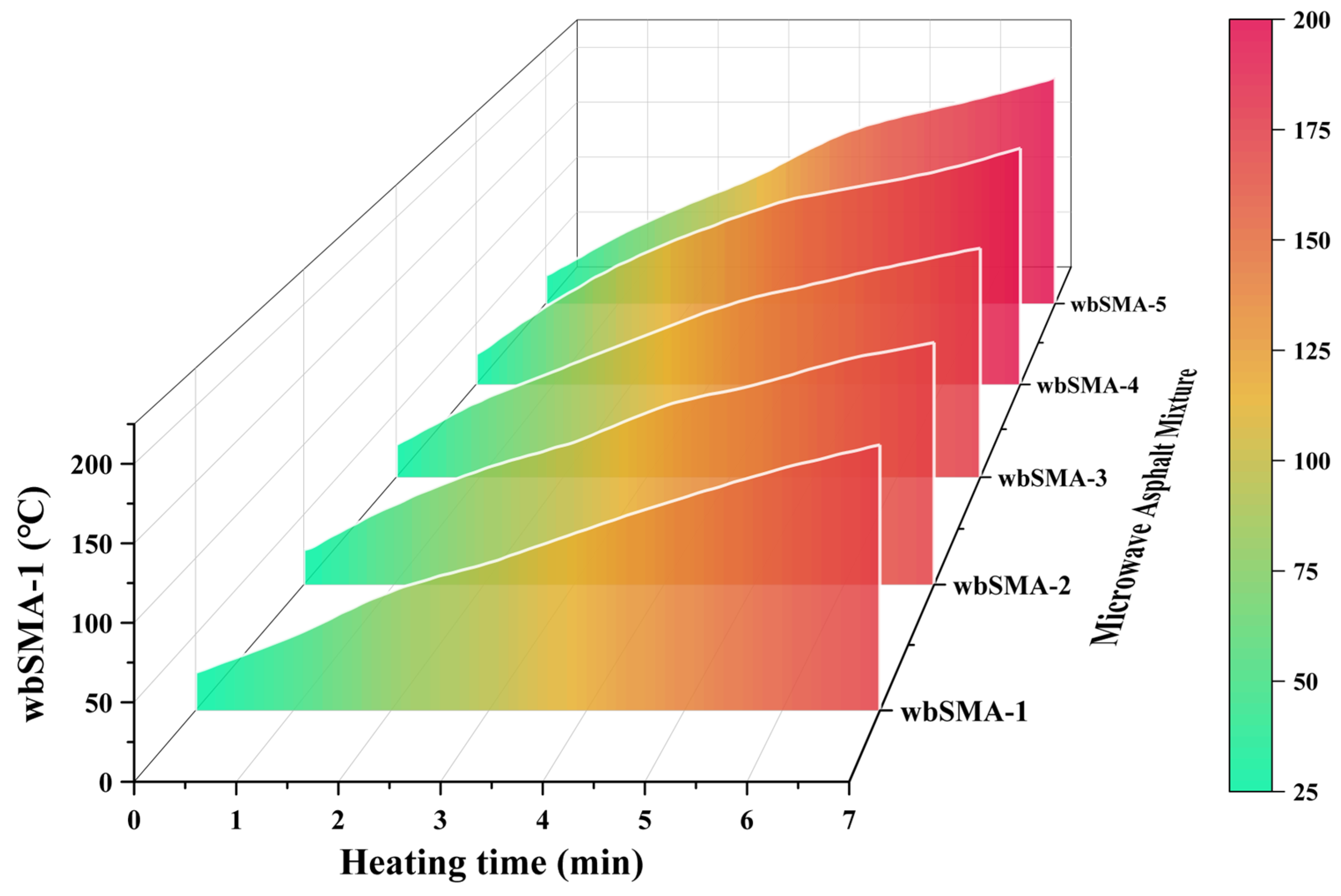

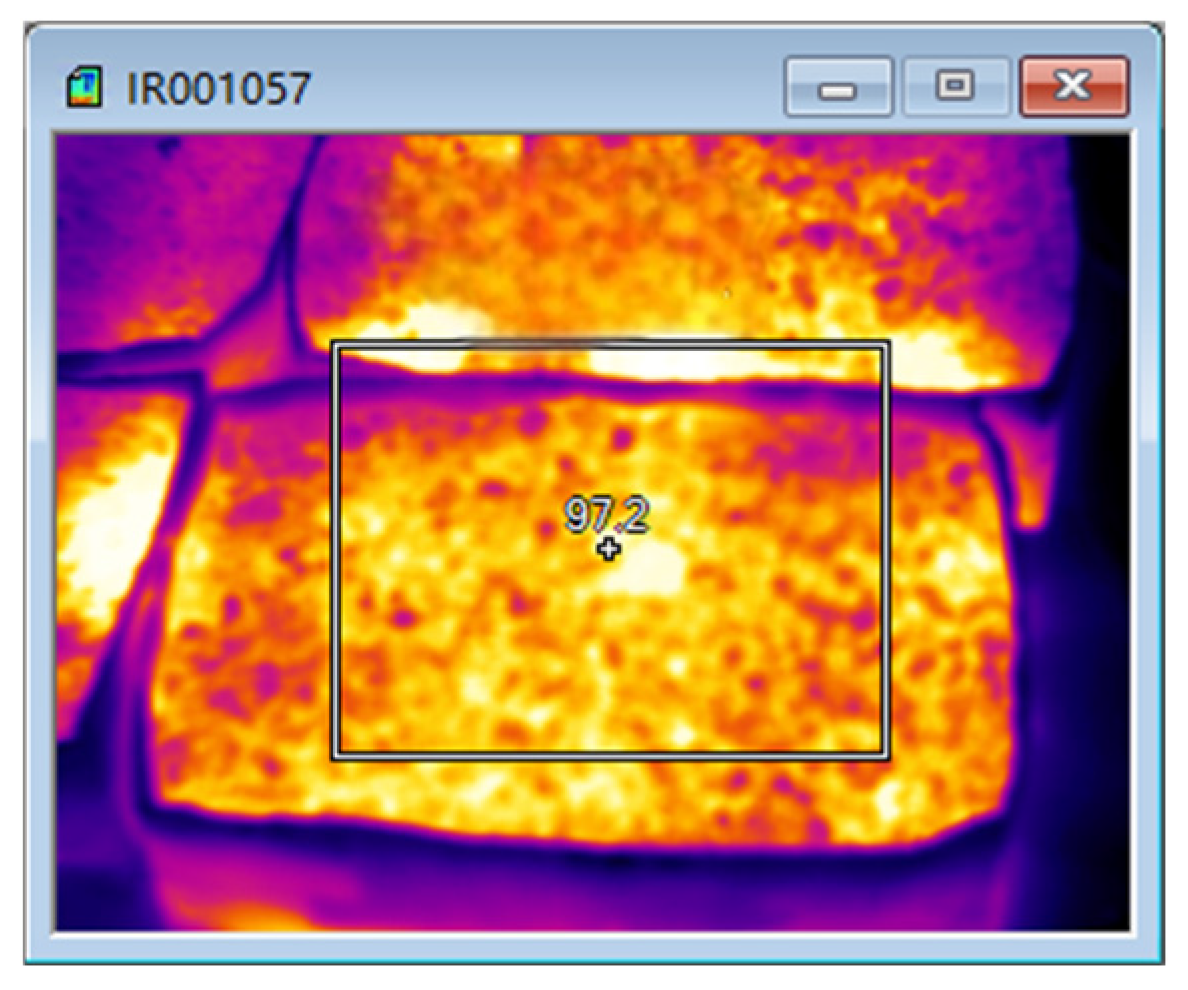

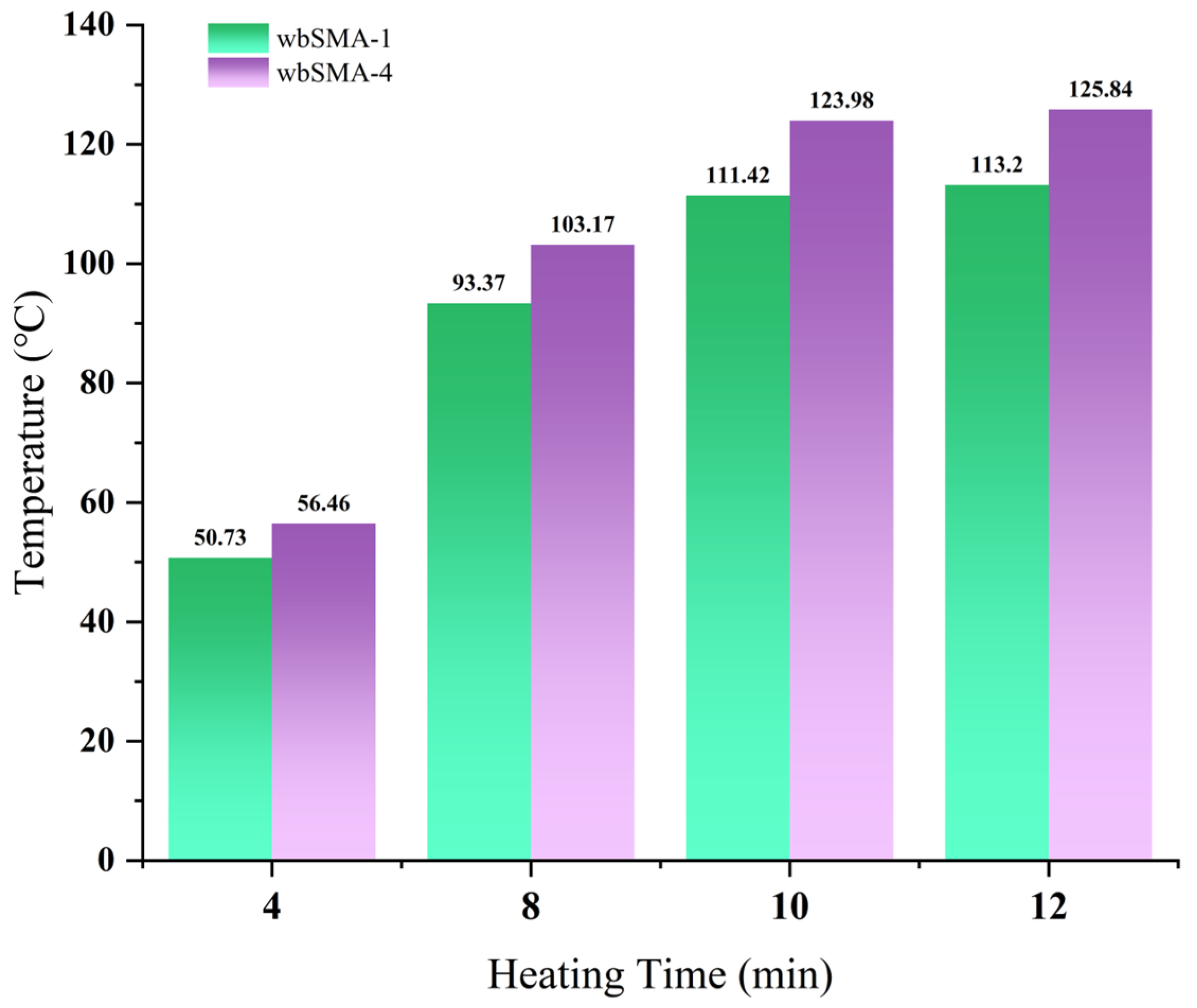

4.1.2. Microwave Absorption and Temperature Rise Performance of SMA-Type Microwave Asphalt Mixture

4.2. Explanation of the Mechanism of Magnetite Powder on the Microwave Heating Effect of Asphalt Mixtures

4.2.1. Percolation Threshold Effect

4.2.2. Magneto-Dielectric Loss Synergetic Saturation

4.2.3. The Impedance Matching Between Electromagnetic Parameters and Microwave Field

4.3. Influence of Wave-Absorbing Materials on Pavement Performance of Asphalt Mixture

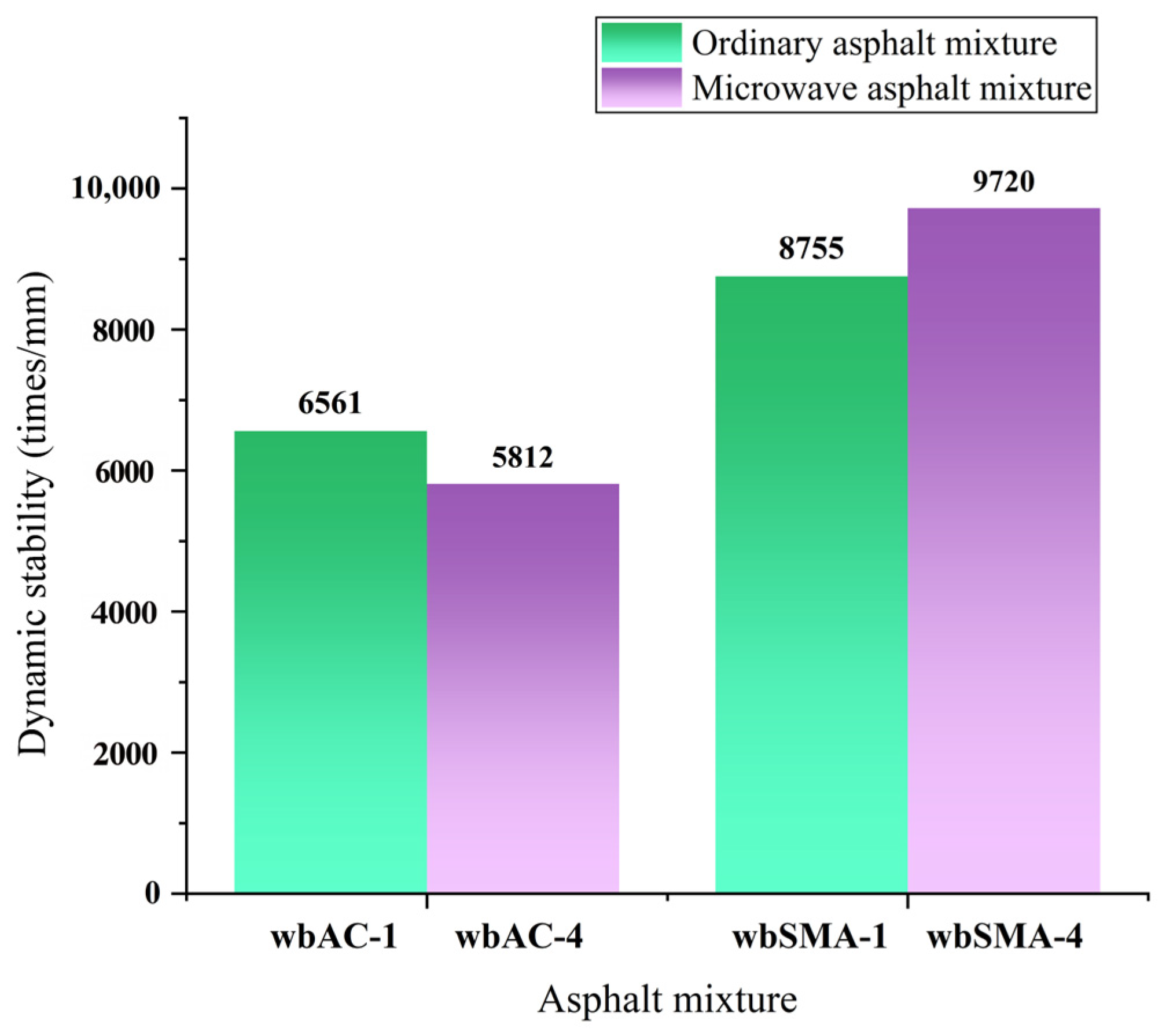

4.3.1. High-Temperature Performance

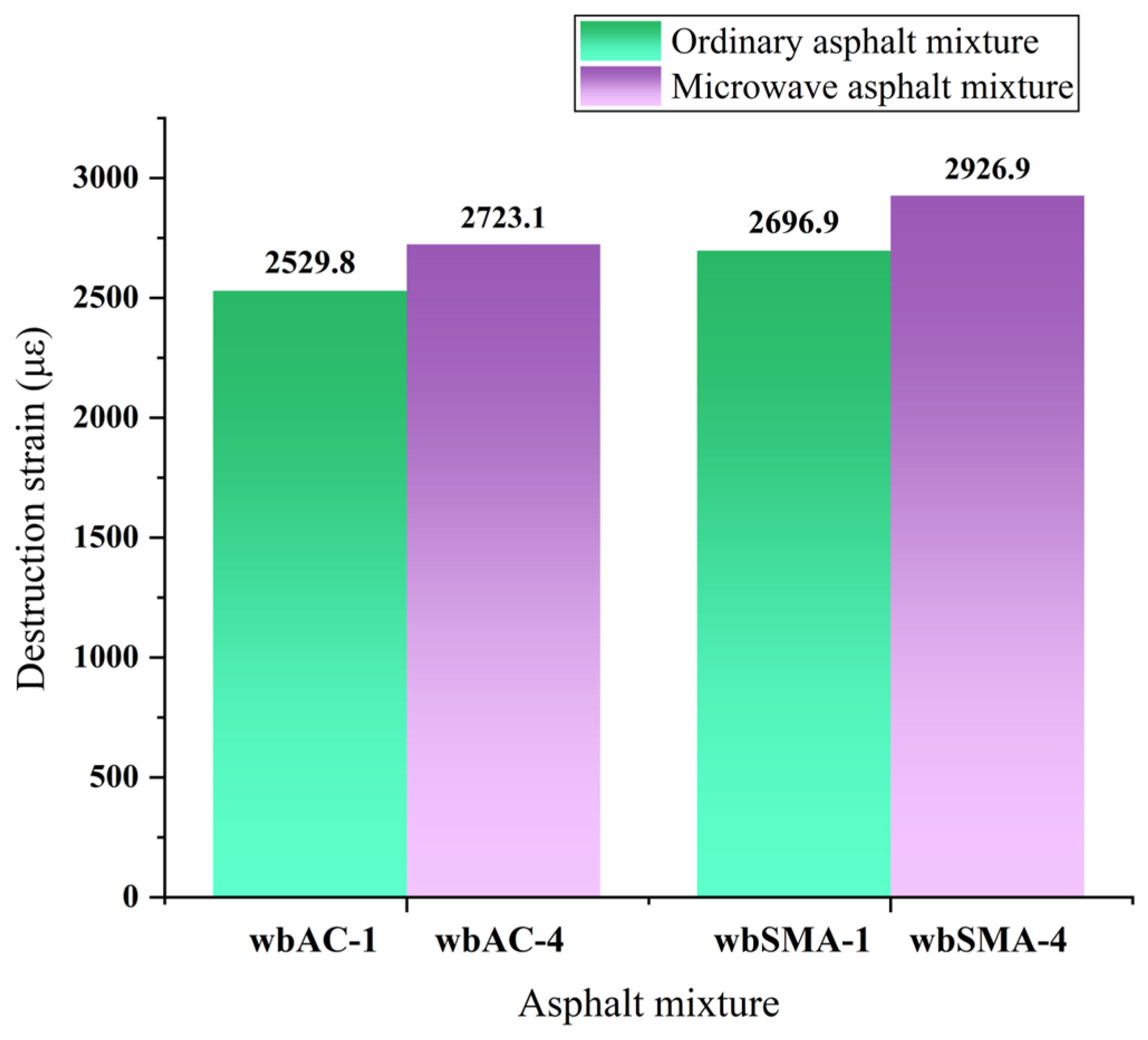

4.3.2. Low-Temperature Performance

4.3.3. Water Stability Performance

4.4. The Influence of Microwave-Absorbing Materials on the Durability Performance of Asphalt Mixtures

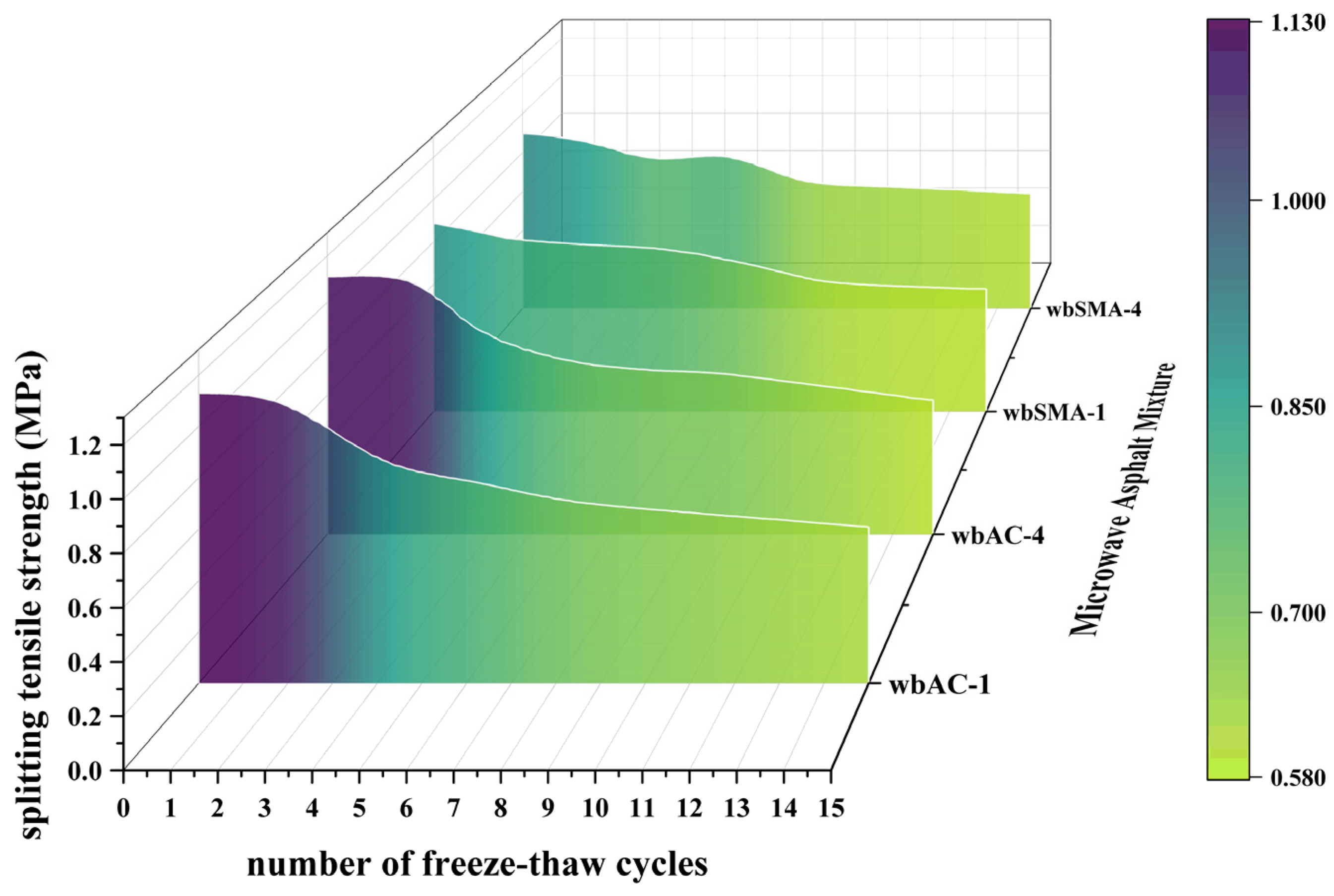

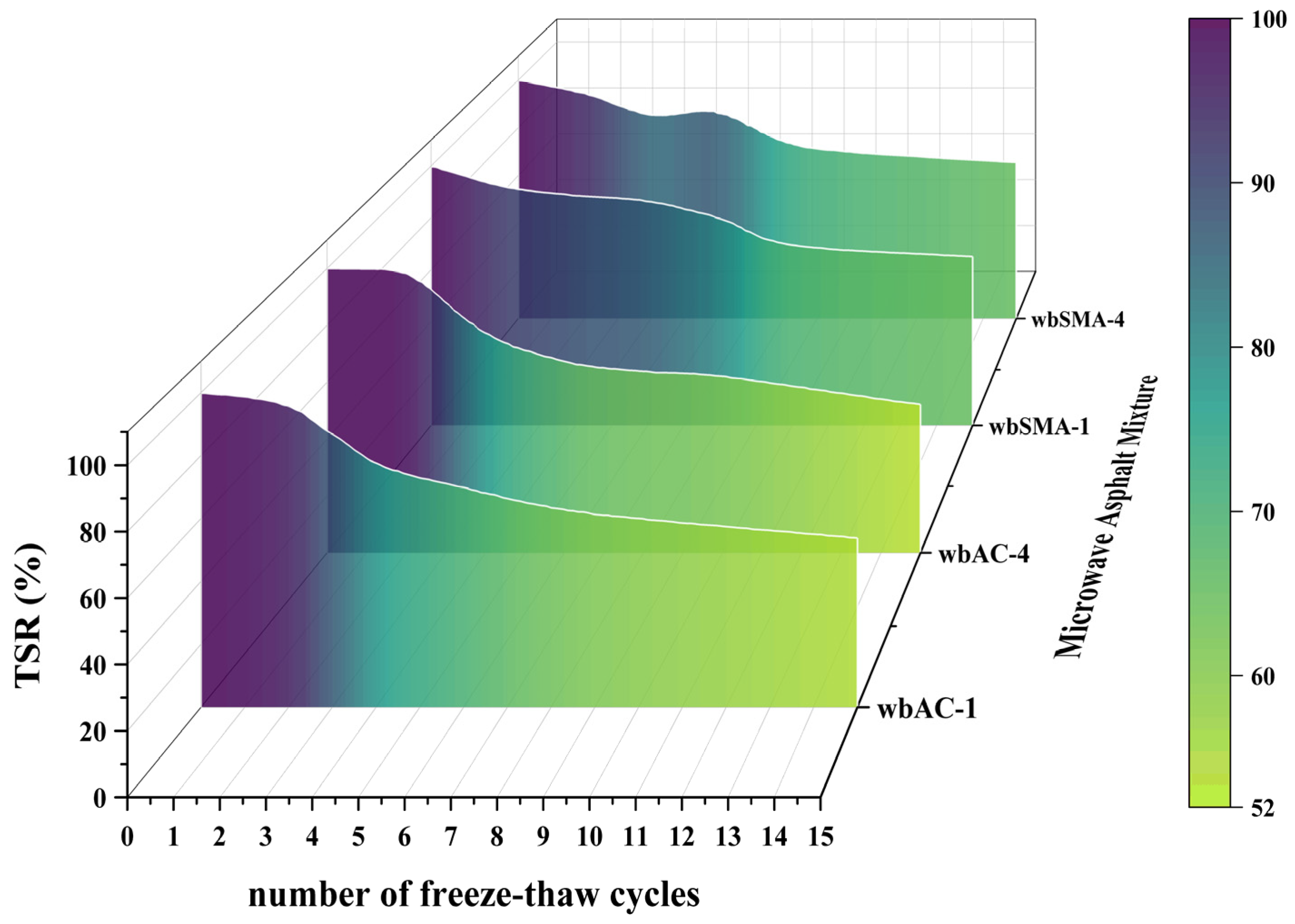

4.4.1. Splitting Test After Freeze–Thaw Cycles

- (1)

- Results and Analysis of Splitting Strength

- (2)

- Analysis of Stiffness Modulus

4.4.2. Low-Temperature Bending Test of Beam Specimens After Freeze–Thaw Cycles

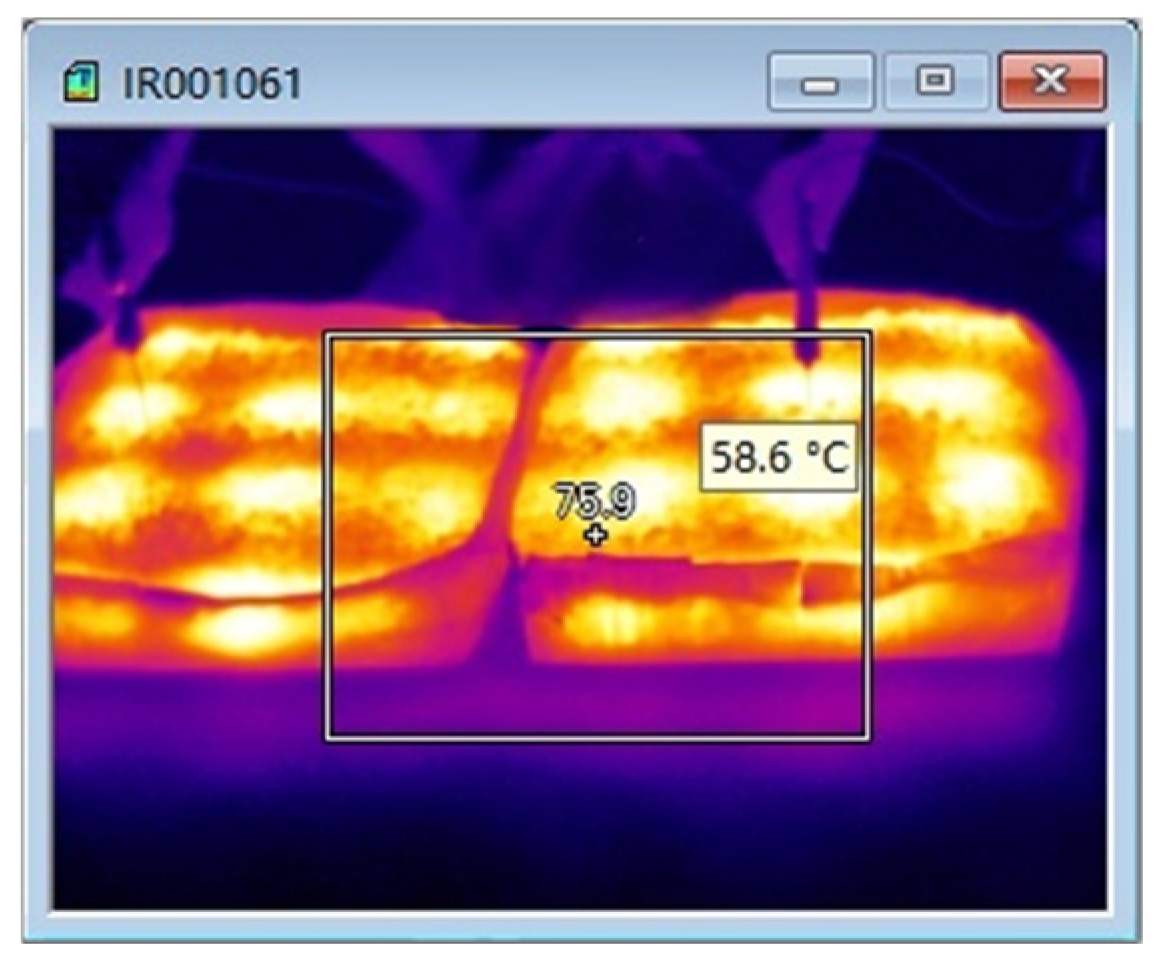

4.5. Comprehensive Verification in Practical Environmen

4.5.1. Test Preparation

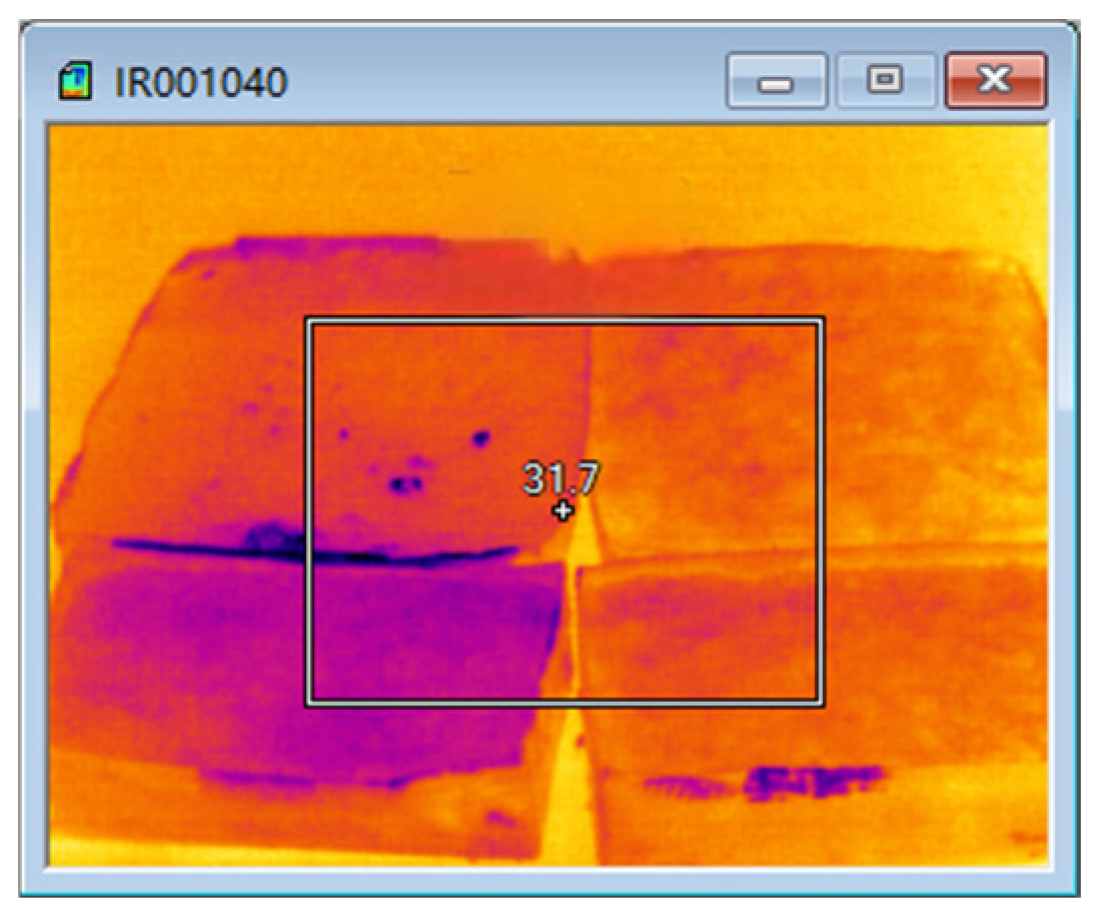

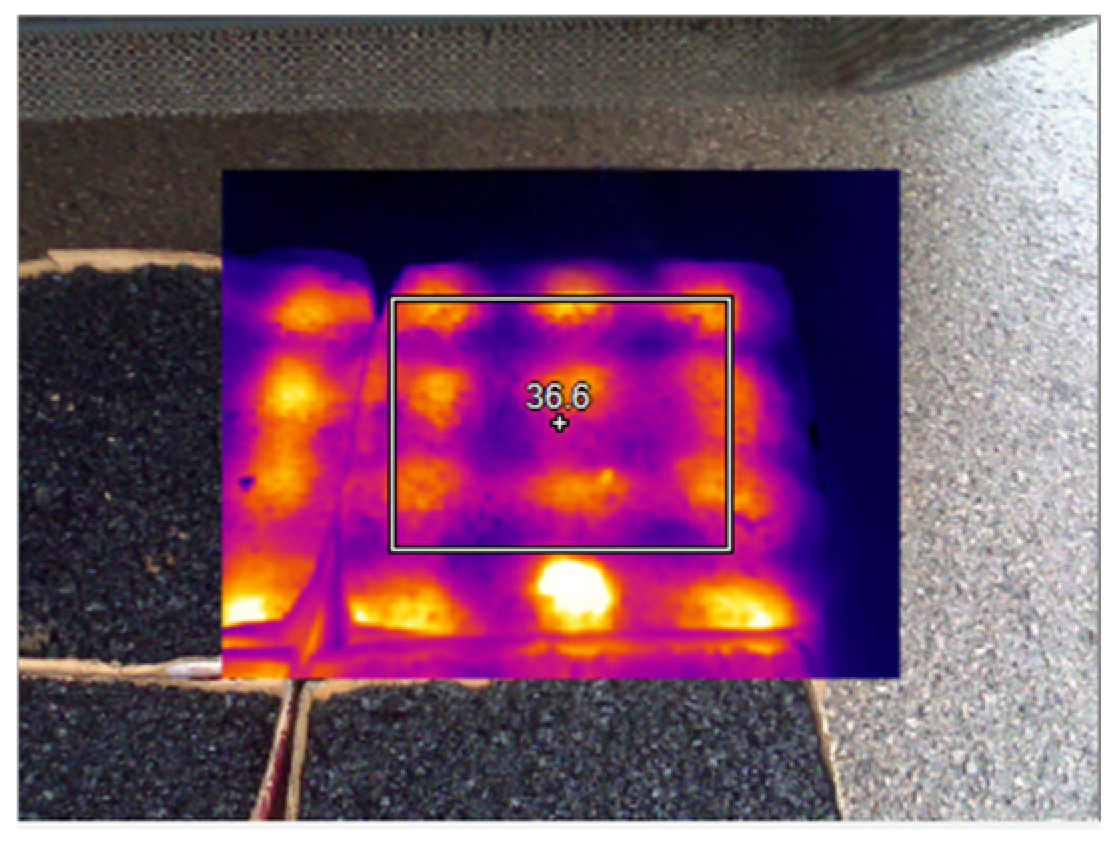

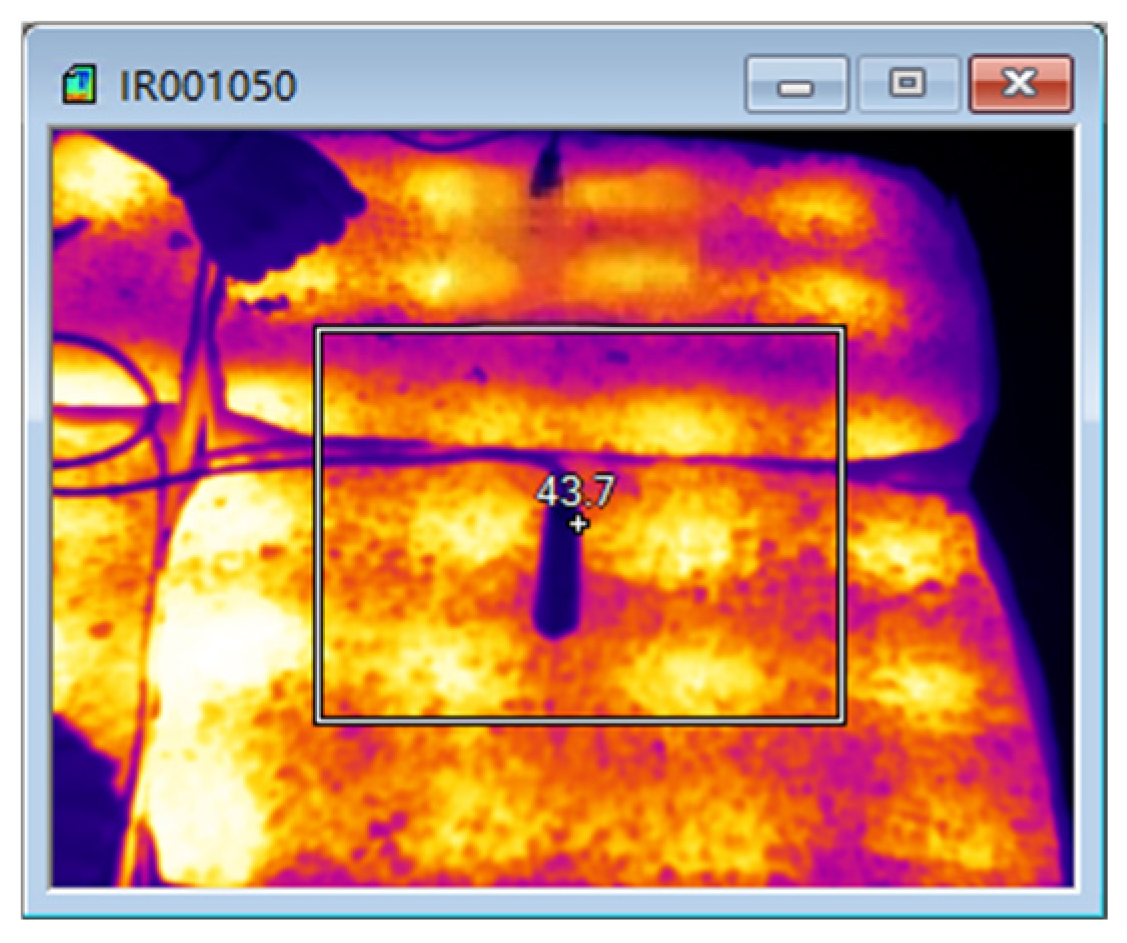

4.5.2. Field Test

- (1)

- Test Methods

- (2)

- Test Results and Analysis

5. Analysis of Sustainability and Carbon Emissions for Magnetite Powder Microwave Asphalt Mixtures

5.1. Sustainability Analysis

5.2. Carbon Emissions Analysis

6. Conclusions

- (1)

- Verified through COMSOL simulation and actual microwave heating tests, the optimal contents of magnetite powder in AC-type and SMA-type asphalt mixtures are 0.5% and 1% relative to the mass of the aggregate, respectively; at these contents, the wave absorption and temperature rise performances of the two types of mixtures increase by 52.2% and 14.6%, respectively, compared with those of ordinary asphalt mixtures.

- (2)

- The key pavement performance indicators of the two types of mixtures under optimal contents are all in line with the requirements of the Specification for Design of Highway Asphalt Pavements (JTG D50-2017 [41]). The high-temperature dynamic stability of the AC-type microwave asphalt mixture decreases by 11.4%, while that of the SMA-type increases by 5.88%; the low-temperature failure strain of both increases by 6.6% and 7.48%, respectively, and their residual stability for water stability decreases by 1.12% and 2.14%, respectively. After 15 freeze–thaw cycles, their splitting tensile strength retention rate and stiffness modulus show extremely small differences from those of ordinary mixtures, and there is no durability degradation problem.

- (3)

- Magnetite-powder-modified asphalt mixtures can achieve multi-dimensional sustainability in terms of resources, economy, and the environment, and their carbon emissions throughout the whole life cycle are significantly reduced. This not only meets the development needs of green transportation but also can provide strong support for the engineering promotion of in-place hot recycling technology.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Diouri, K.; Bousselham, R.; De, A.; Hera, A.; El-Korchi, T.; Mallick, R.B. A Study on the Effect of Milling on Stress Distributions in Asphalt Pavements. In Proceedings of the 9th International Conference on Maintenance and Rehabilitation of Pavements—Mairepav9, Zurich, Switzerland, 1–3 July 2020; Lecture Notes in Civil Engineering. Springer: Berlin/Heidelberg, Germany, 2020; Volume 76, pp. 953–964. [Google Scholar] [CrossRef]

- Souza, J.; Ezaoui, A.; Masdan, M. Environmental Assessment of Two Road Rehabilitation Processes: Full-Depth Reclamation vs. Mill and Fill. In Proceedings of the 10th International Conference on Maintenance and Rehabilitation of Pavements, Guimarães, Portugal, 24–26 July 2024; Lecture Notes in Civil Engineering. Springer: Berlin/Heidelberg, Germany, 2024; Volume 523, pp. 349–359. [Google Scholar] [CrossRef]

- Ozer, H.; Singhvi, P.; Yang, R.; Al-Qadi, I.L.; Abuawad, I. A sustainability evaluation of hot-in-place asphalt recycling technique. In Proceedings of the 8th International Conference on Maintenance and Rehabilitation of Pavements, MAIREPAV 2016, Singapore, 27–29 July 2016; pp. 736–745. [Google Scholar] [CrossRef]

- Kleizienė, R.; Paliukaitė, M.; Vaitkus, A. Analysis of rejuvenation process for effective hot-in-place recycling of asphalt pavement. In Proceedings of the Transport Means—Proceedings of the International Conference, Trakai, Lithuania, 3–5 October 2018; pp. 482–488. [Google Scholar]

- Yao, Y.; Yang, J.; Gao, J.; Zheng, M.; Xu, J.; Zhang, W.; Song, L. Strategy for improving the effect of hot in-place recycling of asphalt pavement. Constr. Build. Mater. 2023, 366, 130054. [Google Scholar] [CrossRef]

- Cao, R.; Leng, Z.; Hsu, S.-C. Comparative eco-efficiency analysis on asphalt pavement rehabilitation alternatives: Hot in-place recycling and milling-and-filling. J. Clean. Prod. 2019, 210, 1385–1395. [Google Scholar] [CrossRef]

- Ma, D.; Chen, C.; Gui, X. Analysis of infrared radiation heating wavelength range of asphalt pavement. Dongnan Daxue Xuebao (Ziran Kexue Ban)/J. Southeast Univ. (Nat. Sci. Ed.) 2022, 52, 730–735. [Google Scholar] [CrossRef]

- Ma, D.; Cao, Y.; Gui, X. Structural design and simulation verification of experimental platform for infrared and hot air collaborative heating. Harbin Gongye Daxue Xuebao/J. Harbin Inst. Technol. 2023, 55, 49–57. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, Z.; Yu, W.; Miao, Y. Review of the Application of Microwave Heating Technology in Asphalt Pavement Self-Healing and De-icing. Polymers 2023, 15, 1696. [Google Scholar] [CrossRef] [PubMed]

- Li, X.; Ma, D.; Liu, X.; Zhu, W. Numerical simulation analysis on heating effects of asphalt pavement by infrared and hot air compounding heating. Dongnan Daxue Xuebao (Ziran Kexue Ban)/J. Southeast Univ. (Nat. Sci. Ed.) 2021, 51, 658–663. [Google Scholar] [CrossRef]

- Nalbandian, K.M.; Carpio, M.; González, Á. Assessment of the sustainability of asphalt pavement maintenance using the microwave heating self-healing technique. J. Clean. Prod. 2022, 365, 132859. [Google Scholar] [CrossRef]

- Noojilla, S.L.A.; Kusam, S.R. Microwave Heating Potential of Aggregates in Bituminous Mixtures: Role of Aggregate Minerology, Dielectric Loss Factor, and Power Level. J. Mater. Civ. Eng. 2024, 36, 04024434. [Google Scholar] [CrossRef]

- Zhao, Y.; Liu, X.; Wei, D. Asphalt mixture with nucleus-shell structural microwave enhanced aggregate: Structure design, preparation and performance. Case Stud. Constr. Mater. 2023, 19, e02248. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, T.; Guo, H.; Wang, Z.; Wang, X. Evaluation of self-healing properties of asphalt mixture containing steel slag under microwave heating: Mechanical, thermal transfer and voids microstructural characteristics. J. Clean. Prod. 2022, 342, 130932. [Google Scholar] [CrossRef]

- Liu, J.; Wang, Z.; Li, M.; Wang, X.; Wang, Z.; Zhang, T. Microwave heating uniformity, road performance and internal void characteristics of steel slag asphalt mixtures. Constr. Build. Mater. 2022, 353, 129155. [Google Scholar] [CrossRef]

- Li, J.; Sha, A.; Wang, Z.; Song, R.; Cao, Y. Investigation of the self-healing, road performance and cost–benefit effects of an iron tailing/asphalt mixture in pavement. Constr. Build. Mater. 2024, 422, 135788. [Google Scholar] [CrossRef]

- Liu, Y.; Qian, Z.; Gong, M.; Zheng, D.; Xu, C. Influence of coarse aggregates’ morphological characteristics on the pore structures of skeleton in porous asphalt mixture. Case Stud. Constr. Mater. 2024, 21, e03718. [Google Scholar] [CrossRef]

- Liu, J.; Jing, H.; Wang, Z.; Wang, X.; Zhang, L. Recycling of steel slag in sustainable bituminous mixtures: Self-healing performance, mechanism, environmental and economic analyses. J. Clean. Prod. 2023, 429, 139496. [Google Scholar] [CrossRef]

- Loureiro, C.D.A.; Silva, H.M.R.D.; Oliveira, J.R.M.; Costa, N.L.S.; Palha, C.A.O. The Effect of Microwave Radiation on the Self-Healing Performance of Asphalt Mixtures with Steel Slag Aggregates and Steel Fibers. Materials 2023, 16, 3712. [Google Scholar] [CrossRef]

- Nian, T.; Wang, M.; Huang, X.; Ge, J.; Song, J.; Li, P. Investigating crack resistance and mechanisms of crack extension in high-content steel fibers reinforced hot recycled asphalt mixtures. Constr. Build. Mater. 2024, 450, 138717. [Google Scholar] [CrossRef]

- Li, W.; Yao, H.; Yang, D.; Peng, C.; Wang, H.; Chen, Z.; Zhao, Y. Study on Pavement Performance of Recycled Asphalt Mixture Modified by Carbon Nanotubes and Waste Engine Oil. Appl. Sci. 2023, 13, 10287. [Google Scholar] [CrossRef]

- GB/T 6730.5-2022; Iron Ores-Determination of Total Iron Content-Titrimetric Method After Reduction with Titanium Trichloride. China Standard Press: Beijing, China, 2022.

- GB/T 6730.8-2016; Iron Ores-Determination of Iron(II) Content-Potassium Dichromate Titrimetric Method. China Standard Press: Beijing, China, 2016.

- GB/T 18711-2002; Magnetite for Use in Coal Preparation—Test Methods. China Standard Press: Beijing, China, 2002.

- GB/T 19077.1-2016; Particle Size Analysis—Laser Diffraction Methods—Part 1: General Principles. China Standard Press: Beijing, China, 2016.

- JTG E42-2023; Specifications for Tests of Aggregates for Highway Engineering. China Communications Press: Beijing, China, 2023.

- T 0353-2023; Test Method for Crushing Value of Coarse Aggregates. China Standard Press: Beijing, China, 2023.

- YS/T 1258.1-2018; Methods for Chemical Analysis of Tin Concentrates—Part 1: Determination of Tin Content—Potassium Iodate Titrimetric Method. China Standard Press: Beijing, China, 2018.

- GB/T 4472-2011; Determination of Density and Relative Density of Chemical Products. China Standard Press: Beijing, China, 2011.

- GB/T 6003.1-2012; Test Sieves—Technical Requirements and Testing—Part 1: Test Sieves of Metal Wire Cloth. China Standard Press: Beijing, China, 2012.

- GB/T 19466.3-2004; Plastics—Differential Scanning Calorimetry (DSC)—Part 3: Determination of Temperatures and Enthalpies of Melting and Crystallization. China Standard Press: Beijing, China, 2004.

- Fan, S.; Zhu, H.; Yuan, H.; Chen, C. Fracture-healing properties of asphalt mixtures and microwave heating thermo-sensitivity analysis of their constituent materials. J. Clean. Prod. 2021, 312, 127763. [Google Scholar] [CrossRef]

- Zhang, M.; Kou, C.; Kang, A.; Xiao, P.; Hu, H. Microscopic characteristics of interface transition zones of hot mix asphalt containing recycled concrete aggregates. J. Clean. Prod. 2023, 389, 136070. [Google Scholar] [CrossRef]

- Huang, X.Y.; Li, B.Y. Mixing temperature design and properties evaluation for SMA-13 mixture. IOP Conf. Ser. Mater. Sci. Eng. 2017, 167, 012057. [Google Scholar] [CrossRef]

- Li, H.; Liu, S.; Yang, F.; He, S.; Jing, H.; Zou, X.; Li, Z.; Sheng, Y. Review of utilization of bamboo fiber in asphalt modification: Insights into preparation, performance, reinforcement, and challenges. J. Clean. Prod. 2024, 468, 143010. [Google Scholar] [CrossRef]

- JTG E20-2023; Test Procedures for Asphalt and Asphalt Mixtures in Highway Engineering. China Communications Press: Beijing, China, 2023.

- Xie, H.; Sun, W.; Li, M.; Feng, X. Mechanical properties and electromagnetic wave absorption characteristics of solid waste low-carbon cementitious materials. J. Clean. Prod. 2024, 467, 142869. [Google Scholar] [CrossRef]

- GB/T 5990-2006; General Test Methods for Pigments and Extenders. China Standard Press: Beijing, China, 2006.

- Jiao, W.; Sha, A.; Liu, Z.; Jiang, W.; Hu, L.; Qin, W. Analytic investigations of snow melting efficiency and temperature field of thermal conductive asphalt concrete combined with electrical-thermal system. J. Clean. Prod. 2023, 399, 136622. [Google Scholar] [CrossRef]

- Grigoriev, B.A.; Gerasimov, A.A.; Alexandrov, I.S.; Nemzer, B.V. (Eds.) Chapter 2—Experimental methods, apparatuses and results of experimental measurements of the thermodynamic properties. In Thermophysical Properties of Individual Hydrocarbons of Petroleum and Natural Gases; Gulf Professional Publishing: Houston, TX, USA, 2022; pp. 13–249. ISBN 9780323952170. [Google Scholar] [CrossRef]

- JTG D50-2017; Specifications for Design of Highway Asphalt Pavements. China Communications Press: Beijing, China, 2017.

| Item | Test Results | Test Method/Tool |

|---|---|---|

| Fe3O4 content | 95% | GB/T 6730.5-2016 [22] GB/T 6730.8-2016 [23] |

| Density (g/cm3) | 4.5 | GB/T 18711-2002 [24] |

| Particle size | 2000 mesh | GB/T 19077.1-2016 [25] |

| Hydrophilic coefficient | 1.43 | JTG E42-2005 [26] T 0353 [27] |

| Melting point (°C) | 1538 | YS/T 1258-2018 [28] |

| Real part of complex permittivity/ε′ | 45.5 | VNA |

| Imaginary part of complex permittivity/ε″ | 9.1 | VNA |

| Loss tangent/tanδ = ε″/ε′ | 0.20 | / |

| Item | Dispersant | Binder | Test Method |

|---|---|---|---|

| Name | Sodium hexametaphosphate (TAMOL-N) | Hydroxypropyl methylcellulose (HPMC) | / |

| Density (g/cm3) | 2.484 | 1.39 | GB/T 4472-2011 [29] |

| Particle size | 500 mesh | 200 mesh | GB/T 6003.1-1997 [30] |

| Melting point (°C) | 616 | / | GB/T 19466.3-2004 [31] |

| Technical Parameters | Test Results | Technical Indicators | |

|---|---|---|---|

| Penetration at 25 °C, 100 g, 5 s (0.1 mm) | 66 | 50–80 | |

| Ductility at 5 cm/min, 5 °C (cm) | 39 | ≥30 | |

| Softening Point (Ring and Ball Method) (°C) | 71.5 | ≥60 | |

| Relative Density (g/cm3) | 1.029 | / | |

| Flash Point (°C) | 335 | ≥230 | |

| Residue after RTFOT (Rolling Thin Film Oven Test) | Mass Loss (%) | 0.01 | ≤0.6 |

| Penetration Ratio (25 °C) (%) | 71 | ≥65 | |

| Ductility (5 cm/min, 5 °C) (cm) | 31 | ≥20 | |

| Technical Parameters | (9.5–13.2) mm | (4.75–9.5) mm | Technical Indicators |

|---|---|---|---|

| Crushing Value (%) | 18.5 | / | ≤20 |

| Los Angeles Abrasion Loss Ratio (%) | 11.3 | 12.4 | ≤28 |

| Apparent Relative Density (g/cm3) | 2.968 | 2.969 | ≥2.6 |

| Needle-like Particle Content (%) | 7.3 | 6.2 | ≤12 |

| Water Absorption Rate (%) | 0.66 | 0.79 | ≤2 |

| Soundness (%) | 4 | 3 | ≤12 |

| Polished Stone Value (PSV) (BPN) | 50 | / | ≥42 |

| Technical Parameters | Fine Aggregates | Technical Indicators |

|---|---|---|

| Apparent Relative Density (g/cm3) | 2.972 | ≥2.5 |

| Clay Content (Content of particles < 0.075 mm) (%) | 2.3 | ≤3 |

| Sand Equivalent (%) | 66 | ≥60 |

| Technical Parameters | Mineral Powder | Technical Indicators |

|---|---|---|

| Apparent Relative Density (g/cm3) | 2.679 | ≥2.5 |

| Specific Surface Area (m2/g) | 1.389 | / |

| Type | Asphalt-Aggregate Ratio (%) | Bulk Relative Density of Specimen | Theoretical Maximum Relative Density | Void Ratio VV (%) | Voids in Mineral Aggregate VMA (%) | Voids Filled with Asphalt VFA (%) | Stability (kN) | Flow Value (0.1 mm) |

|---|---|---|---|---|---|---|---|---|

| AC-13 | 5.0 | 2.508 | 2.610 | 3.9 | 14.1 | 72.3 | 10.34 | 38.5 |

| Requirements | - | - | 3–5 | - | 65–75 | ≥8 | 20–40 | |

| Specimen Number | Real Part of Dielectric Constant | Imaginary Part of Dielectric Constant | Real Part of Permeability | Imaginary Part of Permeability |

|---|---|---|---|---|

| wbAC-1 | 6.41 | 0.082 | 1.0 | 0 |

| wbAC-2 | 6.48 | 0.0945 | 1.0001 | 0 |

| wbAC-3 | 6.67 | 0.1054 | 1.0001 | 0.001 |

| wbAC-4 | 7.13 | 0.134 | 1.0002 | 0.0016 |

| wbAC-5 | 7.61 | 0.0981 | 1.0003 | 0.0024 |

| wbAC-6 | 8.02 | 0.0883 | 1.0005 | 0.0037 |

| Specimen Number | Density (kg/m3) | Heat Capacity at Constant Pressure (J/(kg⋅K)) | Thermal Conductivity (W/(m⋅K)) |

|---|---|---|---|

| wbAC-1 | 2712.3 | 945 | 1.346 |

| wbAC-2 | 2713.4 | 922 | 1.325 |

| wbAC-3 | 2714.5 | 898 | 1.307 |

| wbAC-4 | 2717.6 | 855 | 1.211 |

| wbAC-5 | 2722.9 | 827 | 1.203 |

| wbAC-6 | 2733.7 | 803 | 1.198 |

| Types of Asphalt Mixture | Dynamic Stability (Passes/mm) | Coefficient of Variation (%) | |||||

|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | Average | Requirements | Measured Values | Average | |

| wbAC-1 | 6300 | 7326 | 6058 | 6561 | ≥2800 | 10.3 | ≤20 |

| wbAC-4 | 5159 | 6630 | 5683 | 5812 | 9.5 | ||

| wbSMA-1 | 8750 | 9000 | 8514 | 8755 | ≥3000 | 2.8 | ≤20 |

| wbSMA-4 | 9000 | 9265 | 9545 | 9270 | 2.9 | ||

| Types of Asphalt Mixture | Test Specimen Number | Maximum Load (kN) | Mid-Span Deflection (mm) | Flexural-Tensile Strength (MPa) | Stiffness Modulus (MPa) | Failure Strain (με) | Requirements (με) |

|---|---|---|---|---|---|---|---|

| wbAC-1 | 1 | 1.025 | 0.452 | 8.24 | 3280.0 | 2511.4 | ≥2500 |

| 2 | 1.063 | 0.447 | 8.38 | 3312.7 | 2529.4 | ||

| 3 | 1.078 | 0.432 | 8.39 | 3344.5 | 2509.8 | ||

| 4 | 0.998 | 0.447 | 7.84 | 3048.5 | 2572.0 | ||

| 5 | 1.026 | 0.437 | 8.22 | 3238.4 | 2537.7 | ||

| 6 | 1.011 | 0.430 | 8.11 | 3218.3 | 2518.6 | ||

| Average | 1.034 | 0.441 | 8.20 | 3240.4 | 2529.8 | ||

| wbAC-4 | 1 | 1.060 | 0.515 | 8.52 | 3141.7 | 2711.5 | |

| 2 | 1.067 | 0.510 | 8.46 | 3123.3 | 2708.1 | ||

| 3 | 1.114 | 0.504 | 8.67 | 3223.0 | 2691.4 | ||

| 4 | 1.076 | 0.516 | 8.45 | 3076.6 | 2747.7 | ||

| 5 | 1.082 | 0.500 | 8.55 | 3219.8 | 2655.0 | ||

| 6 | 1.080 | 0.501 | 8.43 | 3159.6 | 2667.8 | ||

| Average | 1.080 | 0.508 | 8.51 | 3157.3 | 2696.9 | ||

| wbSMA-1 | 1 | 1.360 | 0.509 | 10.97 | 4091.9 | 2679.9 | ≥2500 |

| 2 | 1.409 | 0.532 | 11.37 | 4048.4 | 2809.0 | ||

| 3 | 1.378 | 0.519 | 11.30 | 4172.2 | 2709.2 | ||

| 4 | 1.372 | 0.497 | 11.24 | 4306.8 | 2609.3 | ||

| 5 | 1.422 | 0.511 | 11.60 | 4335.4 | 2675.1 | ||

| 6 | 1.396 | 0.544 | 11.40 | 3990.2 | 2856.0 | ||

| Average | 1.390 | 0.519 | 11.31 | 4157.5 | 2723.1 | ||

| wbSMA-4 | 1 | 1.253 | 0.502 | 9.79 | 3651.6 | 2973.7 | |

| 2 | 1.139 | 0.506 | 9.43 | 3541.1 | 2957.1 | ||

| 3 | 1.331 | 0.498 | 10.75 | 4122.9 | 2900 | ||

| 4 | 1.284 | 0.482 | 10.04 | 3890.2 | 2874.1 | ||

| 5 | 1.197 | 0.497 | 9.01 | 3340.2 | 2991.7 | ||

| 6 | 1.280 | 0.483 | 10.40 | 4043.3 | 2865 | ||

| Average | 1.247 | 0.495 | 9.90 | 3764.9 | 2926.9 |

| Types of Asphalt Mixture | Unconditioned (0.5 h) | Conditioned (48 h) | Residual Stability MS0 (%) | Requirements (%) | ||||

|---|---|---|---|---|---|---|---|---|

| Void Content (%) | Stability (kN) | Flow Value (0.1 mm) | Void Content (%) | Stability (kN) | Flow Value (0.1 mm) | |||

| wbAC-1 | 4.3 | 10.62 | 35.4 | 4.2 | 9.17 | 42.7 | 88.7 | ≥85 |

| 4.2 | 10.14 | 36.5 | 4.2 | 9.61 | 41.6 | |||

| 4.1 | 10.53 | 35.2 | 4.0 | 8.99 | 42.8 | |||

| Average | 4.2 | 10.43 | 35.7 | 4.1 | 9.26 | 42.4 | ||

| wbAC-4 | 4.1 | 9.88 | 35.4 | 4.2 | 8.72 | 36.6 | 87.7 | |

| 4.2 | 9.93 | 32.1 | 4.3 | 8.73 | 37.6 | |||

| 4.1 | 9.95 | 34.2 | 4.2 | 8.65 | 39.4 | |||

| Average | 4.1 | 9.92 | 33.9 | 4.2 | 8.7 | 37.9 | ||

| wbSMA-1 | 4.0 | 11.23 | 36.2 | 4.1 | 10.17 | 35.7 | 85.5 | ≥85 |

| 4.2 | 11.47 | 38.7 | 4.1 | 10.05 | 34.6 | |||

| 4.1 | 11.44 | 38.5 | 4.0 | 9.99 | 33.8 | |||

| Average | 4.1 | 11.38 | 37.8 | 4.0 | 10.07 | 34.7 | ||

| wbSMA-4 | 3.8 | 7.10 | 34.3 | 3.7 | 6.34 | 40.2 | 86.6 | |

| 3.7 | 7.45 | 34.2 | 3.8 | 6.02 | 41.3 | |||

| 3.7 | 7.92 | 35.0 | 3.6 | 7.11 | 41.0 | |||

| Average | 3.7 | 7.49 | 34.5 | 3.7 | 6.49 | 40.8 | ||

| Number of Freeze–Thaw Cycles | wbAC-1 (MPa) | wbAC-4 (MPa) | wbSMA-1 (MPa) | wbSMA-4 (MPa) |

|---|---|---|---|---|

| 0 | 1.13 | 1.11 | 0.89 | 0.90 |

| 2 | 1.08 | 1.09 | 0.82 | 0.85 |

| 4 | 0.88 | 0.86 | 0.79 | 0.77 |

| 6 | 0.79 | 0.75 | 0.77 | 0.78 |

| 8 | 0.72 | 0.71 | 0.71 | 0.67 |

| 10 | 0.68 | 0.69 | 0.62 | 0.63 |

| 15 | 0.61 | 0.58 | 0.58 | 0.59 |

| Number of Freeze–Thaw Cycles | wbAC-1 (MPa) | wbAC-4 (MPa) | wbSMA-1 (MPa) | wbSMA-4 (MPa) |

|---|---|---|---|---|

| 0 | 100 | 100 | 100 | 100 |

| 2 | 95.58 | 98.20 | 92.13 | 94.44 |

| 4 | 77.88 | 77.48 | 88.76 | 85.56 |

| 6 | 69.91 | 67.57 | 86.52 | 86.67 |

| 8 | 63.72 | 63.96 | 79.78 | 74.44 |

| 10 | 60.18 | 62.16 | 69.66 | 70.00 |

| 15 | 53.98 | 52.25 | 65.17 | 65.56 |

| Number of Freeze–Thaw Cycles | wbAC-1 (MPa) | wbAC-4 (MPa) | wbSMA-1 (MPa) | wbSMA-4 (MPa) |

|---|---|---|---|---|

| 0 | 390.85 | 387.75 | 6500 | 6450 |

| 2 | 380.56 | 376.85 | 6489 | 6400 |

| 4 | 369.48 | 365.45 | 6450 | 6387 |

| 6 | 356.78 | 351.75 | 6520 | 6350 |

| 8 | 342.23 | 340.78 | 6370 | 6340 |

| 10 | 331.8 | 332.53 | 6350 | 6300 |

| 15 | 315.23 | 310.51 | 6320 | 6278 |

| Number of Freeze–Thaw Cycles | wbAC-1 (MPa) | wbAC-4 (MPa) | wbSMA-1 (MPa) | wbSMA-4 (MPa) |

|---|---|---|---|---|

| 0 | 100 | 100 | 100 | 100 |

| 2 | 97.37 | 97.19 | 99.83 | 99.22 |

| 4 | 94.53 | 94.25 | 99.23 | 99.02 |

| 6 | 91.28 | 90.72 | 100.31 | 98.45 |

| 8 | 87.56 | 87.89 | 98.00 | 98.29 |

| 10 | 84.89 | 85.76 | 97.69 | 97.67 |

| 15 | 80.65 | 80.08 | 97.23 | 97.33 |

| Type of Asphalt Mixtures | Number of Freeze–Thaw Cycles | Maximum Load (kN) | Mid-Span Deflection (mm) | Flexural Tensile Strength (MPa) | Stiffness Modulus (MPa) | Failure Strain (με) |

|---|---|---|---|---|---|---|

| wbAC-1 | 0 | 2.45 | 0.452 | 11.48 | 3177.9 | 3612.4 |

| 5 | 2.31 | 0.447 | 10.82 | 2905.1 | 3724.5 | |

| 10 | 2.23 | 0.432 | 10.45 | 2737.6 | 3824.5 | |

| 15 | 2.29 | 0.447 | 10.73 | 2602.4 | 4123.1 | |

| wbAC-4 | 0 | 2.39 | 0.515 | 10.98 | 2887.6 | 3802.4 |

| 5 | 2.26 | 0.510 | 10.56 | 2689.4 | 3926.5 | |

| 10 | 2.17 | 0.504 | 10.02 | 2529.2 | 3961.7 | |

| 15 | 2.18 | 0.516 | 10.15 | 2390.8 | 4245.5 | |

| wbSMA-1 | 0 | 2.93 | 0.509 | 13.72 | 4013.5 | 3418.5 |

| 5 | 2.25 | 0.532 | 10.56 | 3967.5 | 2661.6 | |

| 10 | 2.09 | 0.519 | 9.82 | 4081.1 | 2406.2 | |

| 15 | 1.87 | 0.497 | 8.76 | 4306.8 | 2360.5 | |

| wbSMA-4 | 0 | 2.74 | 0.502 | 12.86 | 3651.6 | 2973.7 |

| 5 | 2.12 | 0.506 | 9.95 | 3541.1 | 2957.1 | |

| 10 | 1.97 | 0.498 | 9.24 | 4122.9 | 2900 | |

| 15 | 1.85 | 0.482 | 8.69 | 3890.2 | 2874.1 |

| Material Type | 5 min | 10 min | 15 min | 20 min | 25 min | 30 min |

|---|---|---|---|---|---|---|

| wbAC-1 | 39.15 | 50.8 | 67.63 | 75.4 | 85.69 | 100.5 |

| wbAC-4 | 52.23 | 70.41 | 91.9 | 100.65 | 113.54 | 136.1 |

| Material Type | 4 min | 8 min | 10 min | 12 min |

|---|---|---|---|---|

| wbSMA-1 | 50.73 | 93.37 | 111.42 | 113.2 |

| wbSMA-4 | 54.83 | 107.2 | 117.1 | 135.22 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, H.; Zhang, Y.; Hu, F.; Yu, M.; Wang, W. Effects of Magnetite Powder on Microwave Heating Properties and Pavement Performance of Asphalt Mixture. Materials 2025, 18, 4920. https://doi.org/10.3390/ma18214920

Zhu H, Zhang Y, Hu F, Yu M, Wang W. Effects of Magnetite Powder on Microwave Heating Properties and Pavement Performance of Asphalt Mixture. Materials. 2025; 18(21):4920. https://doi.org/10.3390/ma18214920

Chicago/Turabian StyleZhu, Haoran, Yajun Zhang, Feng Hu, Mingming Yu, and Wenfeng Wang. 2025. "Effects of Magnetite Powder on Microwave Heating Properties and Pavement Performance of Asphalt Mixture" Materials 18, no. 21: 4920. https://doi.org/10.3390/ma18214920

APA StyleZhu, H., Zhang, Y., Hu, F., Yu, M., & Wang, W. (2025). Effects of Magnetite Powder on Microwave Heating Properties and Pavement Performance of Asphalt Mixture. Materials, 18(21), 4920. https://doi.org/10.3390/ma18214920