Microstructure, Mechanical and Tribological Properties of Cold Sprayed Fe-Based Metallic Glass Coatings

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

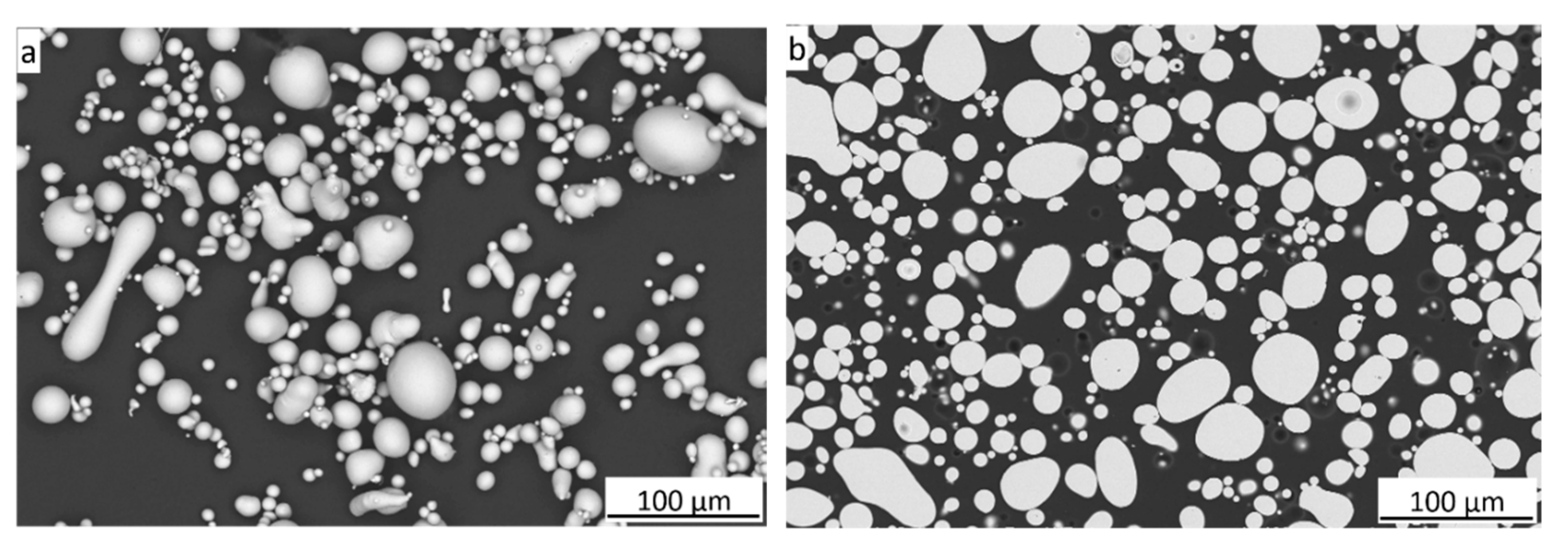

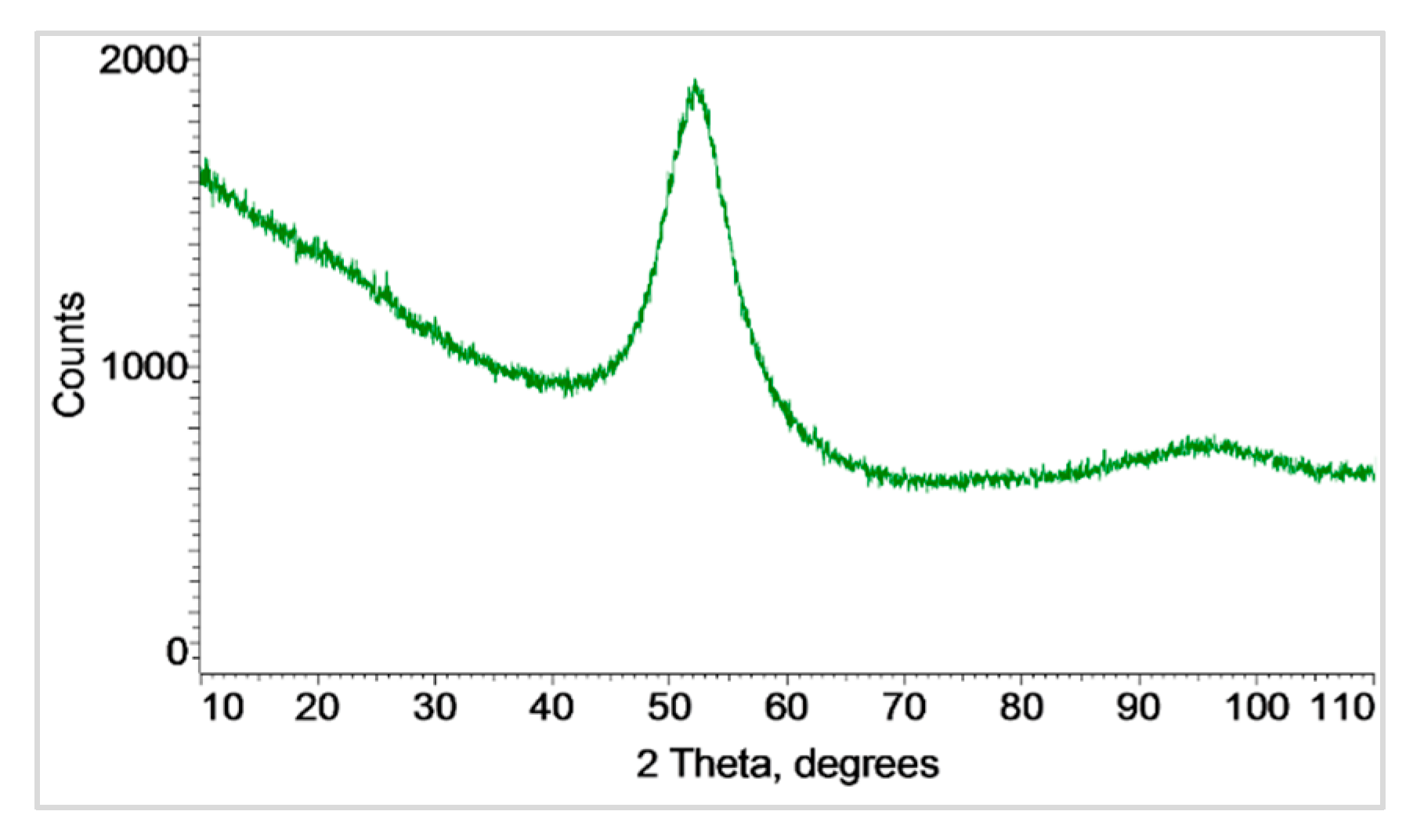

3.1. Characterization of the Powder

3.2. Characterization of the FeSiBCrC Cold Sprayed Coatings

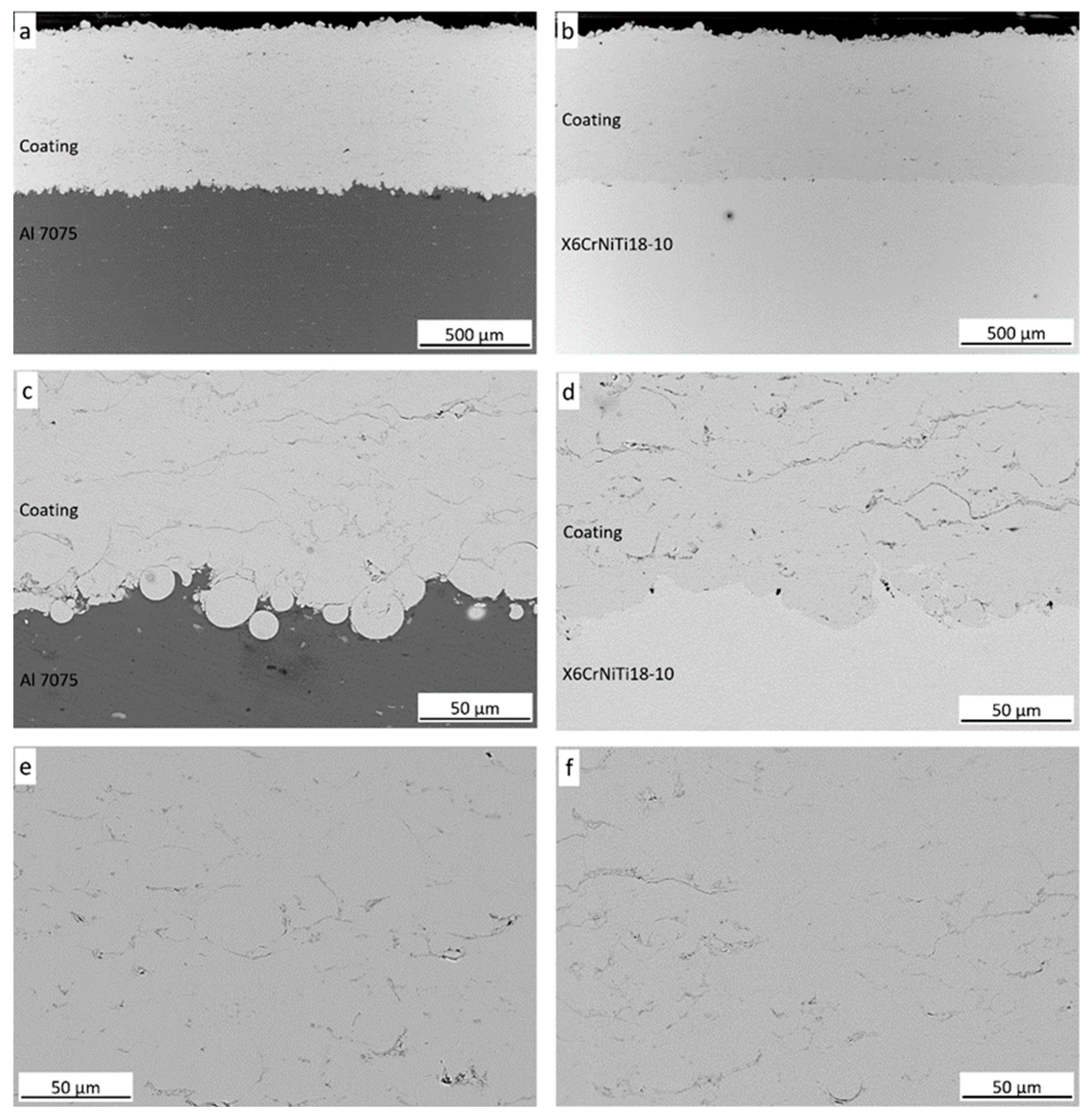

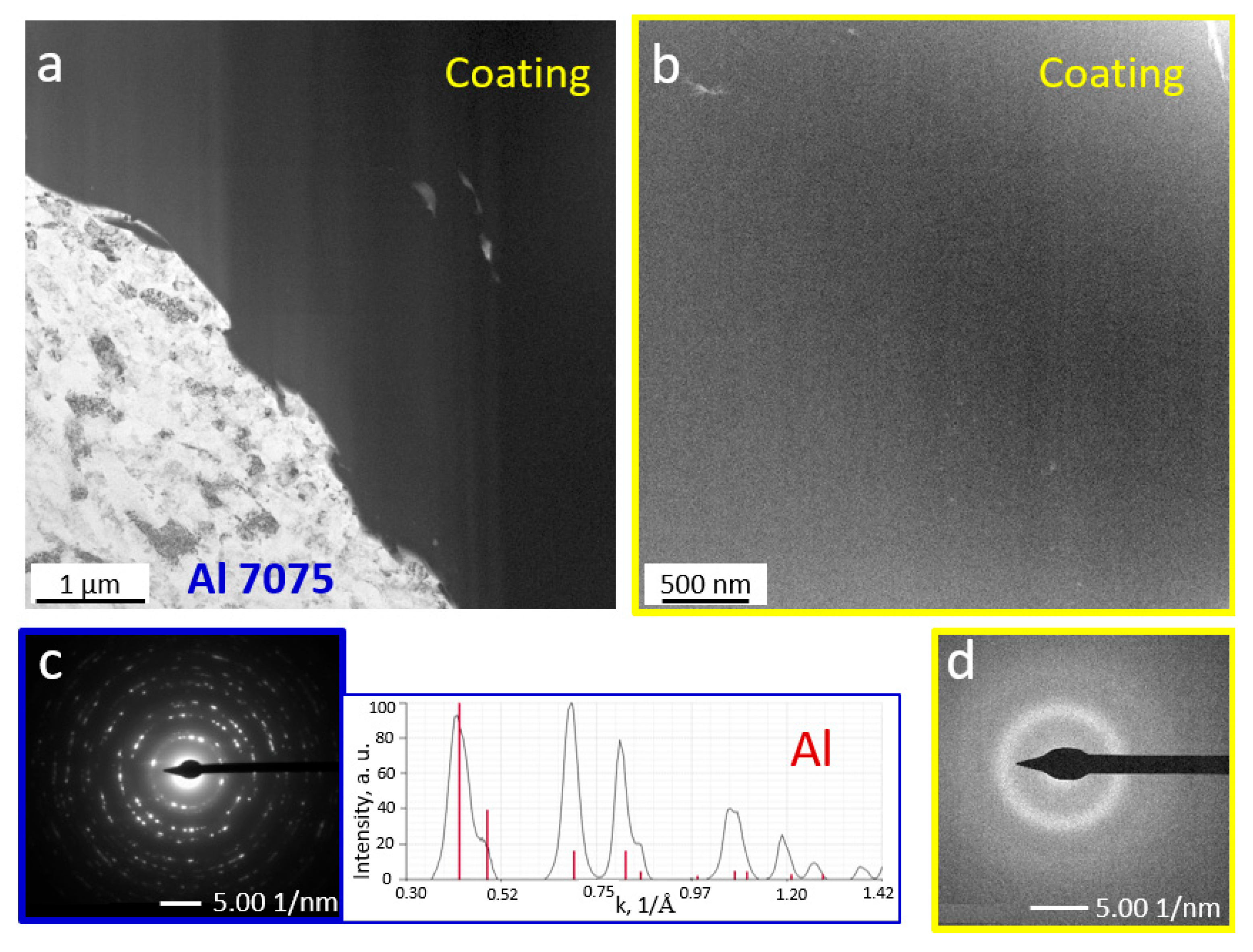

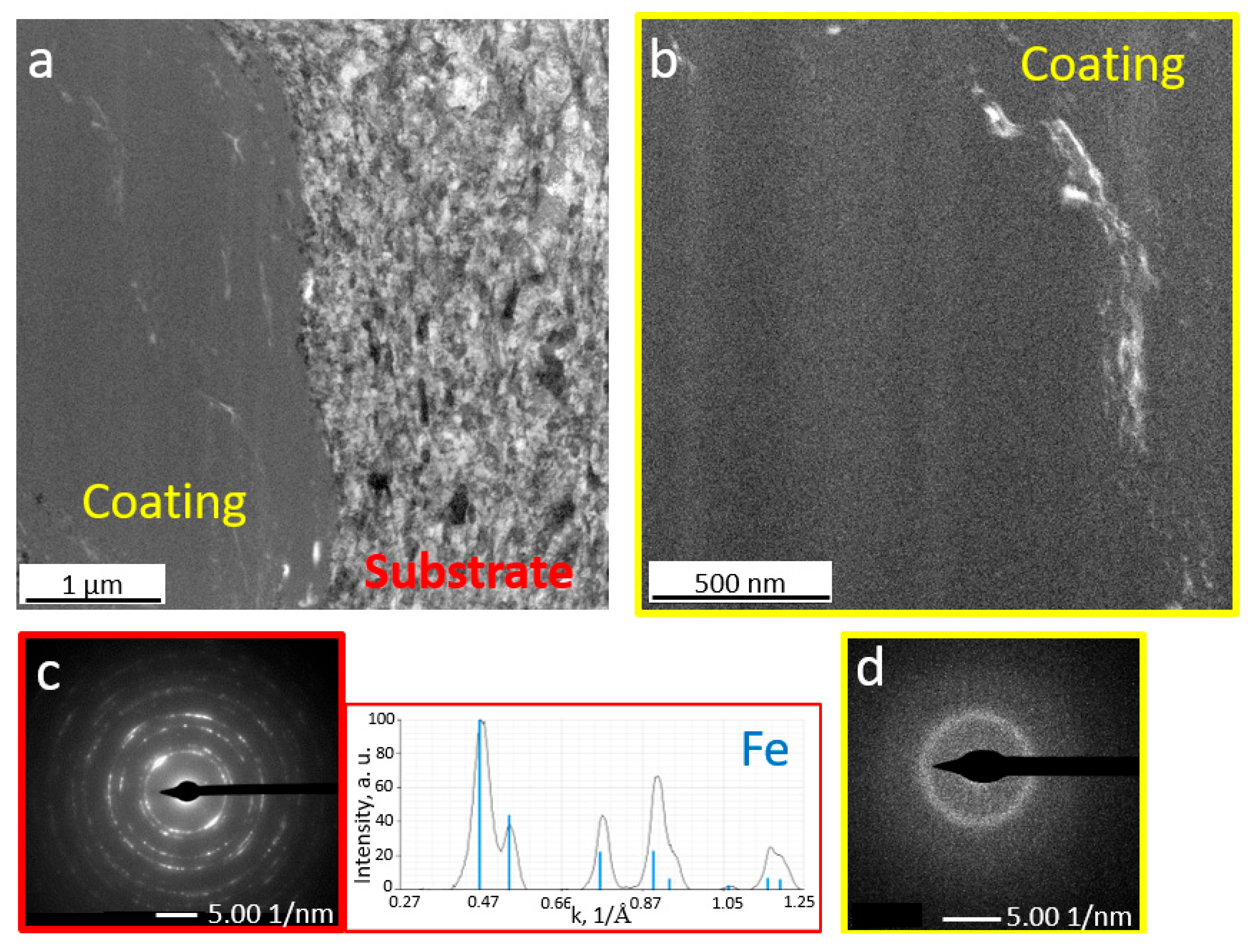

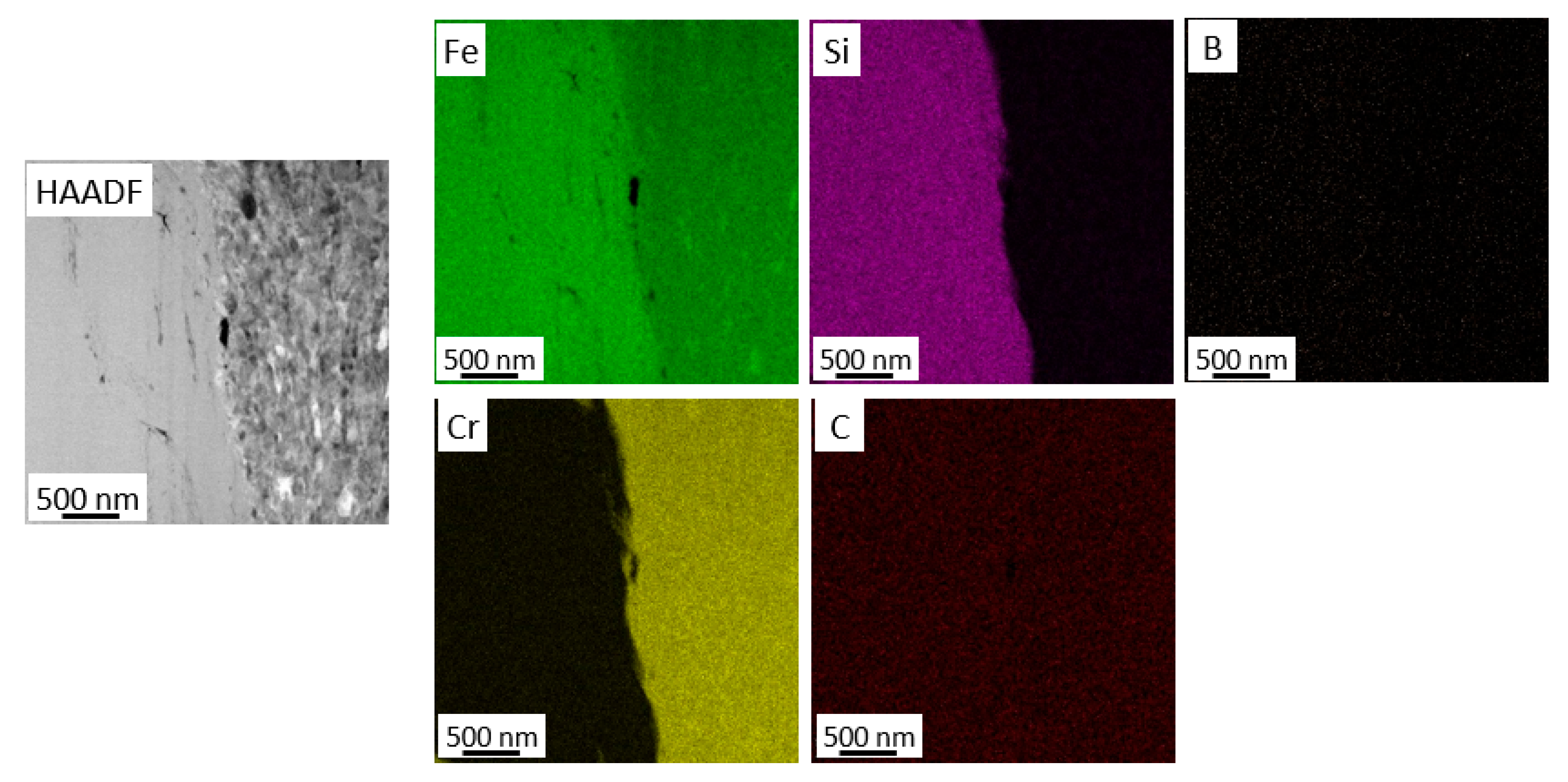

3.2.1. Coating Microstructure

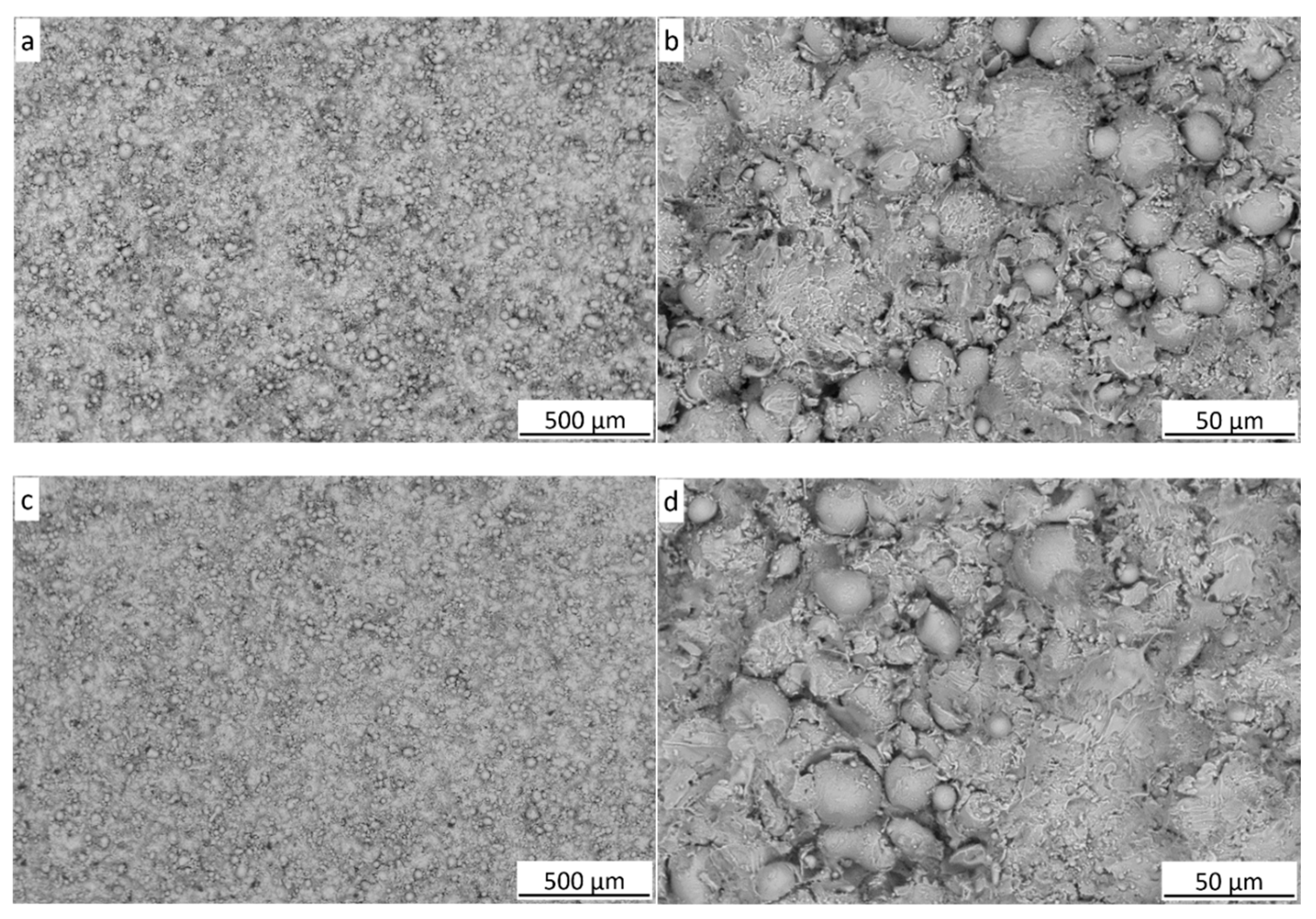

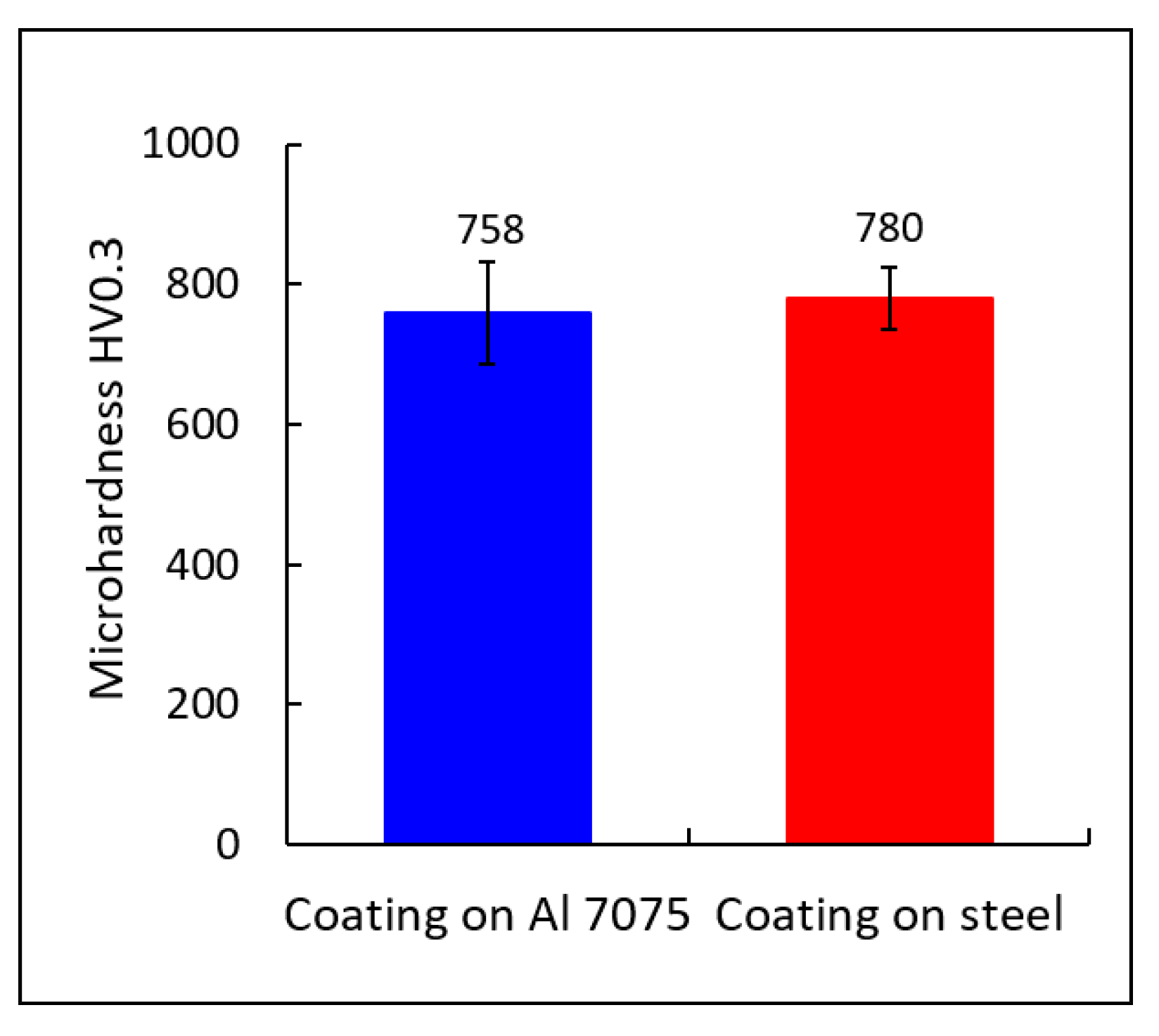

3.2.2. Mechanical and Tribological Properties of the Coatings

4. Conclusions

- Cold spraying of amorphous powders creates possibilities for forming thick (above 700 µm) metallic glass coatings, significantly thicker than those obtained in other thermal spray processes, exhibiting high mechanical properties and wear resistance.

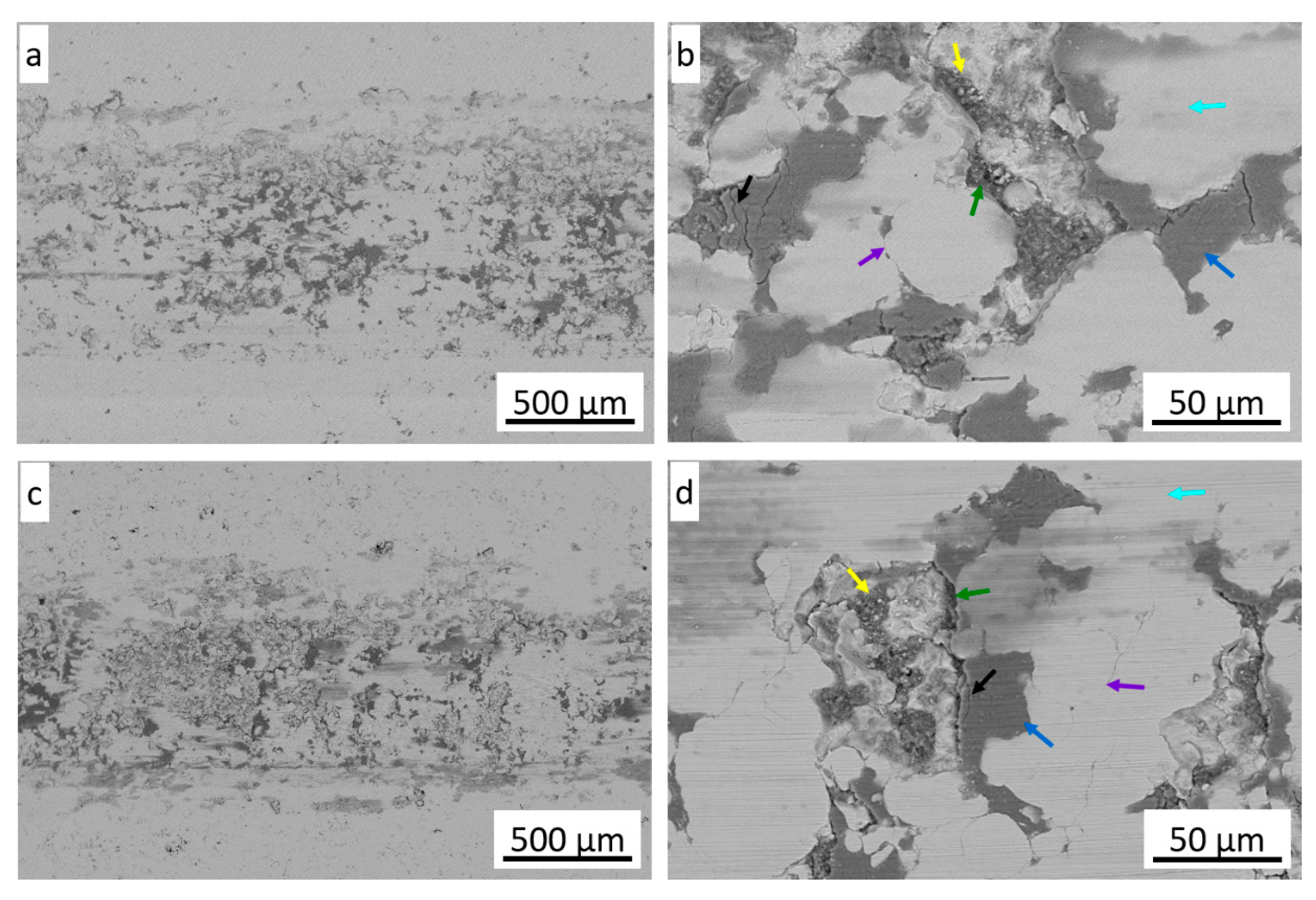

- The coatings cold sprayed on the Al 7075 alloy and steel substrates were characterized by a homogeneous and compact microstructure.

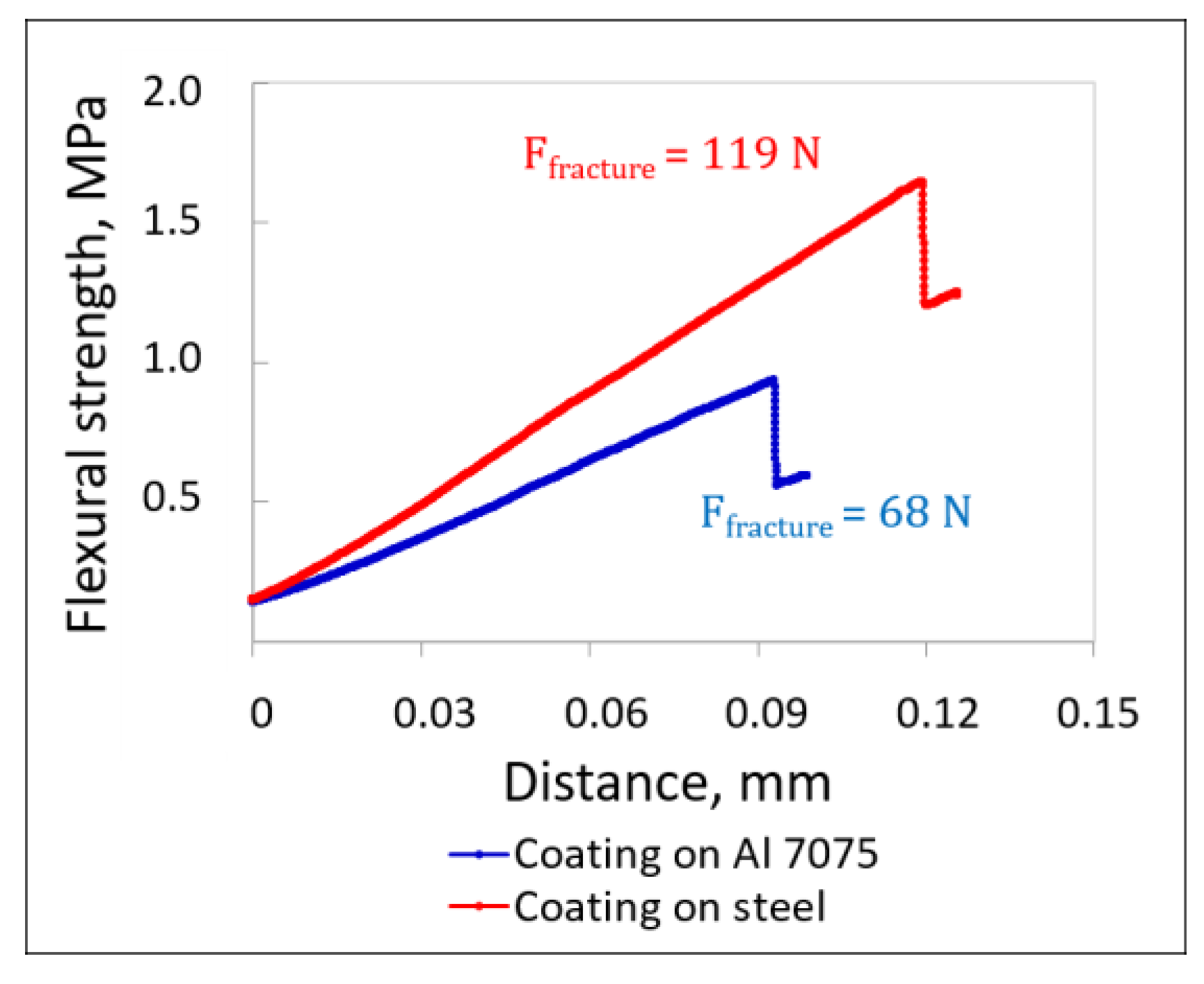

- The coating–substrate systems observed after the three-point bending showed cracks appearing on the coating surfaces, which propagated in the coatings in the direction of the applied force. The flexural strength of the coating–steel substrate system was about 76% higher than in the case of the coating sprayed on the Al alloy.

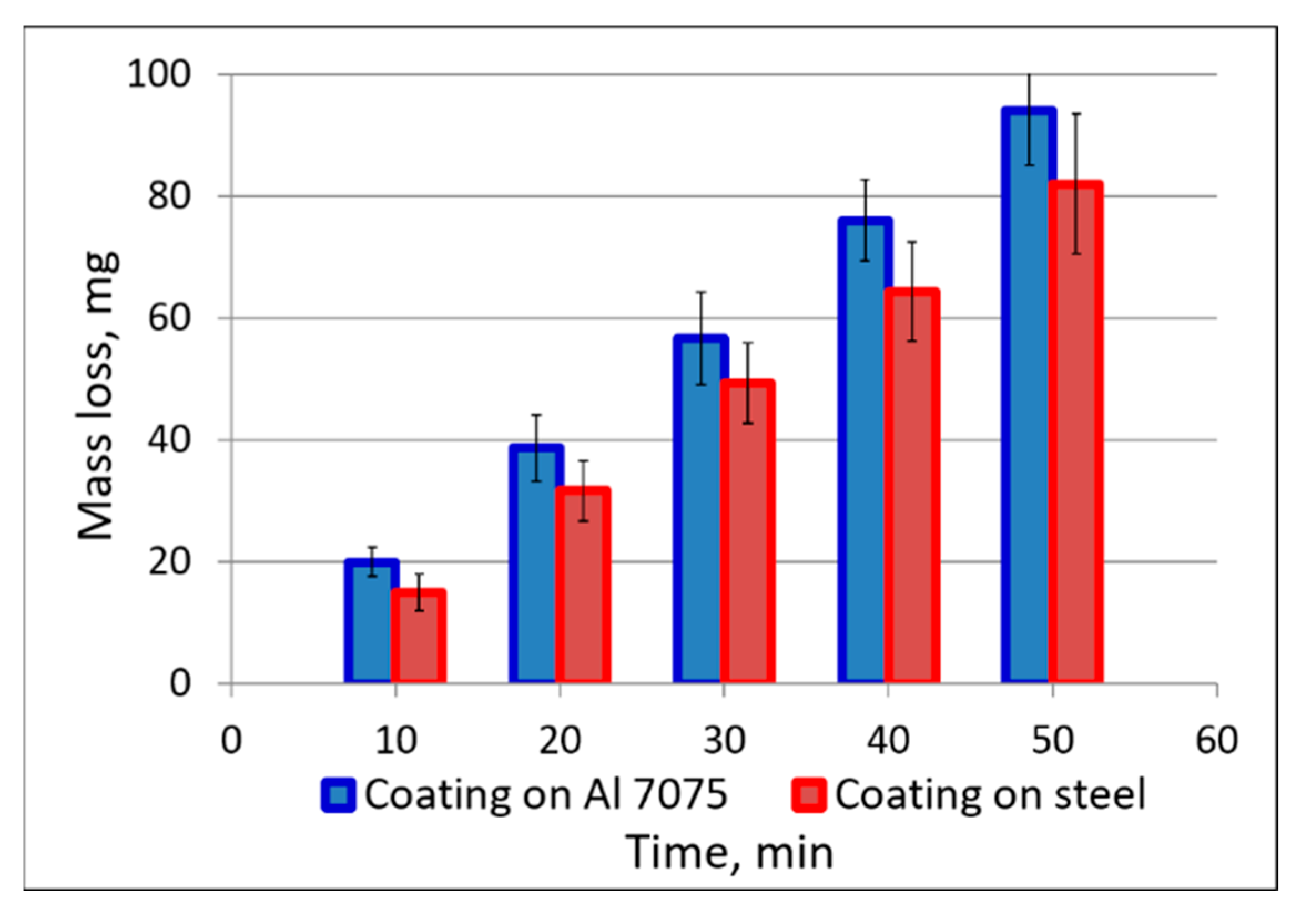

- The coating deposited on the steel substrate showed higher microhardness, better resistance to loose abrasive wear, and a slightly lower wear index when tested in the coating–Si3N4 ball tribological association.

- Both coatings were characterized by a comparable CoF. This indicates that the type of the substrate (steel, Al 7075 alloy) had no effect on CoF.

- Amorphous cold sprayed coatings can be successfully used to protect Al alloy and steel elements operating in dry friction conditions, as indicated by the low values of the wear index. The coatings exhibit similar wear and CoF characteristics; therefore, those cold sprayed on an aluminium alloy should be used where low component weight is a significant factor, while those deposited on steel can operate under bending conditions and at higher temperatures.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Inoue, A. Stabilization of Metallic Supercooled Liquid and Bulk Amorphous Alloys. Acta Mater. 2000, 48, 279–306. [Google Scholar] [CrossRef]

- Wang, H.; Dong, C.; Shek, C.H. Bulk metallic glasses. Mater. Sci. Eng. 2004, 44, 45–89. [Google Scholar] [CrossRef]

- Nowosielski, R.; Babilas, R.; Ochin, P. Thermal and magnetic properties of selected Fe-based metallic glasses. Arch. Mater. Sci. Eng. 2008, 30, 13–16. [Google Scholar]

- Wang, J.Q.; Liu, Y.H.; Chen, M.W.; Xie, G.Q.; Louzguine-Luzgin, D.V.; Inoue, A.; Perepezko, J.H. Rapid Degradation of Azo Dye by Fe-Based Metallic Glass Powder. Adv. Funct. Mater. 2012, 22, 2567–2570. [Google Scholar] [CrossRef]

- Axinte, E. Metallic Glasses from ‘‘Alchemy’’ to Pure Science: Present and Future of Design, Processing and Applications of Glassy Metals. Mater. Des. 2012, 35, 518–556. [Google Scholar] [CrossRef]

- List, A.; Gartner, F.; Mori, T.; Schulze, M.; Assadi, H.; Kuroda, S.; Klassen, T. Cold Spraying of Amorphous Cu50Zr50 Alloys. J. Therm. Spray Technol. 2015, 24, 108–118. [Google Scholar] [CrossRef]

- Inoue, A.; Wang, X.M.; Zhang, W. Developments and applications of bulk metallic glasses. Rev. Adv. Mater. Sci. 2008, 18, 1–9. [Google Scholar]

- Suryanarayana, C.; Inoue, A. Iron-based bulk metallic glasses. Int. Mater. Rev. 2013, 58, 131–166. [Google Scholar] [CrossRef]

- Hess, P.A.; Poon, S.J.; Shiflet, G.J.; Dauskardt, R.H. Indentation fracture toughness of amorphous steel. J. Mater. Res. 2005, 20, 783–786. [Google Scholar] [CrossRef]

- Guo, S.F.; Liu, L.; Li, N.; Li, Y. Fe-based bulk metallic glass matrix composite with large plasticity. Scr. Mater. 2010, 62, 329–332. [Google Scholar] [CrossRef]

- Miracle, D.B.; Concustell, A.; Zhang, Y.; Yavari, A.R.; Greer, A.L. Shear Bands in Metallic Glasses: Size Effects on Thermal Profiles. Acta Mater. 2011, 59, 2831–2840. [Google Scholar] [CrossRef]

- Schmidt, T.; Assadi, H.; Gartner, F.; Richter, H.; Stoltenhoff, T.; Kreye, H.; Klassen, T. From Particle Acceleration to Impact and Bonding in Cold Spraying. J. Therm. Spray Technol. 2009, 18, 794–808. [Google Scholar] [CrossRef]

- Guo, W.; Wu, Y.; Zhang, J.; Hong, S.; Li, G.; Ying, G.; Guo, J.; Qin, Y. Fabrication and Characterization of Thermal-Sprayed Fe-Based Amorphous/Nanocrystalline Composite Coatings: An Overview. J. Therm. Spray Technol. 2014, 23, 1157–1180. [Google Scholar] [CrossRef]

- Bijalwan, P.; Kumar, A.; Nayak, S.K.; Banerjee, A.; Dutta, M.; Laha, T. Microstructure and corrosion behavior of Fe-based amorphous composite coatings developed by atmospheric plasma spraying. J. Alloys Compd. 2019, 796, 47–54. [Google Scholar] [CrossRef]

- Choi, H.; Lee, S.; Kim, B.; Jo, H.; Lee, C. Effect of in-flight particle oxidation on the phase evolution of HVOF NiTiZrSiSn bulk amorphous coating. J. Mat. Sci. 2005, 40, 6121–6126. [Google Scholar] [CrossRef]

- Deshpande, S.; Sampath, S.; Zhang, H. Mechanisms of oxidation and its role in microstructural evolution of metallic thermal spray coatings—Case study for Ni–Al. Surf. Coat. Technol. 2006, 200, 5395–5406. [Google Scholar] [CrossRef]

- Kim, J.; Kang, K.; Yoon, S.; Kumar, S.; Na, H.; Lee, C. Oxidation and crystallization mechanisms in plasma-sprayed Cu-based bulk metallic glass coatings. Acta Mater. 2010, 58, 952–962. [Google Scholar] [CrossRef]

- Su, J.; Kang, J.; Yue, W.; Ma, G.; Fu, Z.; Zhu, L.; She, D.; Wang, H.; Wang, C. Comparison of tribological behavior of Fe-based metallic glass coatings fabricated by cold spraying and high velocity air fuel spraying. J. Non-Cryst. Solids 2019, 522, 119582. [Google Scholar] [CrossRef]

- Dykhuizen, R.C.; Smith, M.F. Gas dynamic principles of cold spray. J. Therm. Spray Technol. 1998, 7, 205–212. [Google Scholar] [CrossRef]

- Papyrin, A. Cold spray technology. Adv. Mater. Process 2001, 159, 49–51. [Google Scholar]

- Assadi, H.; Gartner, F.; Stoltenhoff, T.; Kreye, H. Bonding Mechanism in Cold Gas Spraying. Acta Mater. 2003, 51, 4379–4394. [Google Scholar] [CrossRef]

- Grujicic, M.; Zhao, C.L.; Tong, C.; De Rosset, W.S.; Helfritch, D. Analysis of the Impact Velocity of Powder Particles in the Cold-Gas Dynamic-Spray Process. Mater. Sci. Eng. A 2004, 368, 222–230. [Google Scholar] [CrossRef]

- Assadi, H.; Kreye, H.; Gärtner, F.; Klassen, T. Cold spraying—A materials perspective. Acta Mater. 2016, 116, 382–407. [Google Scholar] [CrossRef]

- Henao, J.; Concustell, A.; Dosta, S.; Cinca, N.; Cano, I.G.; Guilemany, J.M. Influence of the Substrate on the Formation of Metallic Glass Coatings by Cold Gas Spraying. J. Therm. Spray Technol. 2016, 25, 992–1008. [Google Scholar] [CrossRef][Green Version]

- Mridha, S.; Arora, H.S.; Lefebvre, J.; Bhowmick, S.; Mukherjee, S. High temperature in situ compression of thermoplastically formed nano-scale metallic glass. JOM 2017, 69, 39–44. [Google Scholar] [CrossRef]

- Henao, J.; Sharma, M.M. Characterization, Deposition Mechanisms, and Modeling of Metallic Glass Powders for Cold Spray. In Cold-Spray Coatings; Cavaliere, P., Ed.; Springer International Publishing AG: Cham, Switzerland, 2018. [Google Scholar]

- Yoon, S.; Lee, C.; Choi, H.; Kim, H.; Bae, J. Impacting Behavior of Bulk Metallic Glass Powder at an Abnormally High Strain Rate during Kinetic Spraying. Mater. Sci. Eng. A 2007, 449–451, 911–915. [Google Scholar] [CrossRef]

- List, A.; Gartner, F.; Schmidt, T.; Klassen, T. Impact Conditions for Cold Spraying of Hard Metallic Glasses. J. Therm. Spray Technol. 2012, 21, 531–540. [Google Scholar] [CrossRef]

- Trexler, M.; Thadhani, N. Mechanical properties of bulk metallic glasses. Prog. Mater. Sci. 2010, 55, 759–893. [Google Scholar] [CrossRef]

- Fauchais, P.; Montavon, G.; Bertrand, G. From powders to thermally sprayed coatings. J. Therm. Spray Technol. 2010, 19, 57–80. [Google Scholar] [CrossRef]

- Pang, S.J.; Zhang, T.; Asami, K.; Inoue, A. Bulk glassy Fe–Cr–Mo–C–B alloys with high corrosion resistance. Corros. Sci. 2002, 44, 1847–1856. [Google Scholar] [CrossRef]

- Inoue, A.; Shen, B.; Chang, C.T. Super-high strength of over 4000 MPa for Fe-based bulk glassy alloys in [(Fe1−xCox)0.75B0.2Si0.05]96Nb4 system. Acta Mater. 2004, 52, 4093. [Google Scholar] [CrossRef]

- Greer, A.L.; Cheng, Y.Q.; Ma, E. Shear Bands in Metallic Glasses. Mater. Sci. Eng. 2013, 74, 71–132. [Google Scholar] [CrossRef]

- Bobzin, K.; Ote, M.; Konigstein, T. Manufacture of Iron-Based, Amorphous Coatings with High Fracture Toughness. IOP Conf. Ser. Mater. Sci. Eng. 2017, 181, 12012. [Google Scholar] [CrossRef]

- Bobzin, K.; Ote, M.; Konigstein, T. Investigation of Amorphous/Nanocrystalline Iron-Based Thermal Barrier Coatings. J. Therm. Spray Technol. 2017, 26, 388–397. [Google Scholar] [CrossRef]

- Hauer, M.; Gericke, A.; Mohrke, L.; Allebrodt, B.; Henkel, K.-M. Highly Efficient Thermal Barrier Coatings Based on Arc Spraying of Amorphous Fe-based Alloys and NiCrAlY for Use in LH2 Tanks and Other Cryogenic Environments. J. Therm. Spray Technol. 2023, 32, 327–338. [Google Scholar] [CrossRef]

- Cui, S.; Zhai, H.; Lib, W.; Fan, X.; Li, X.; Ning, W.; Xiong, D. Microstructure and corrosion resistance of Fe-based amorphous coating prepared by detonation spray. Surf. Coat. Technol. 2020, 399, 126096. [Google Scholar] [CrossRef]

- Zhang, H.; Xie, Y.; Huang, L.; Huang, S.; Zheng, X.; Chen, G. Effect of feedstock particle sizes on wear resistance of plasma sprayed Fe-based amorphous coatings. Surf. Coat. Technol. 2014, 258, 495–502. [Google Scholar] [CrossRef]

- Bobzin, K.; Zhao, L.; Ote, M.; Konigstein, T. Novel Fe-based wear and corrosion resistant coatings by three-cathode plasma technology. Surf. Coat. Technol. 2017, 318, 288–292. [Google Scholar] [CrossRef]

- Cao, Q.; Huang, G.; Ma, L.; Xing, L. Comparison of a cold-sprayed and plasma-sprayed Fe25Cr20Mo1Si amorphous alloy coatings on 40Cr substrates. Mat. Corros. 2020, 71, 1872–1884. [Google Scholar] [CrossRef]

- Lin, T.-J.; Sheu, H.-H.; Lee, C.-Y.; Lee, H.-B. The study of mechanical properties and corrosion behavior of the Fe-based amorphous alloy coatings using high velocity oxygen fuel spraying. J. Alloys Compd. 2021, 867, 159132. [Google Scholar] [CrossRef]

- Henao, J.; Concustell, A.; Cano, I.G.; Cinca, N.; Dosta, S.; Guilemany, J.M. Influence of Cold Gas Spray Process Conditions on the Microstructure of Fe-Based Amorphous Coatings. J. Alloys Compd. 2015, 622, 995–999. [Google Scholar] [CrossRef]

- Ziemian, C.W.; Wright, W.J.; Cipoletti, D.E. Influence of Impact Conditions on Feedstock Deposition Behavior of Cold-Sprayed Fe-Based Metallic Glass. J. Therm. Spray Technol. 2018, 27, 843–856. [Google Scholar] [CrossRef]

- Souza, C.A.C.; Ribeiro, D.V.; Kiminami, C.S. Corrosion resistance of Fe-Cr-based amorphous alloys: An overview. J. Non-Cryst. Solids 2016, 442, 56–66. [Google Scholar] [CrossRef]

- Trelka, A.; Żórawski, W.; Maj, Ł.; Petrzak, P.; Soboń, D.; Góral, A. The Effect of the Substrate on the Microstructure and Tribological Properties of Cold Sprayed (Cr3C2-25(Ni20Cr))-(Ni-graphite) Cermet Coatings. Materials 2022, 15, 994. [Google Scholar] [CrossRef]

- EN 573-3:2019(E); Aluminium and Aluminium Alloys-Chemical Composition and Form of Wrought Products-Part 3: Chemical Composition and Form of Products. CEN: Bruxelles, Belgium, 2019.

- EN 10088-3:2014(E); Stainless Steels-Part 3: Technical Delivery Conditions for Semifinished Products, Bars, Rods, Wire, Sections and Bright Products of Corrosion Resisting Steels for General Purposes. CEN: Bruxelles, Belgium, 2014.

- Huang, R.; Suo, Z.; Prevost, J.H.; Nix, W.D. Inhomogeneous deformation in metallic glasses. J. Mech. Phys. Solids 2002, 50, 1011–1027. [Google Scholar] [CrossRef]

- Liu, Z.; Chen, W.; Carstensen, J.; Ketkaew, J.; Mota, R.M.O.; Guest, J.K.; Schroers, J. 3D metallic glass cellular structures. Acta Mater. 2016, 105, 35–43. [Google Scholar] [CrossRef]

- Kang, S.H.; Lee, J.H.; Cheon, J.S.; Im, Y.T. The Effect of Strain-Hardening on Frictional Behavior in Tip Test. Int. J. Mech. Sci. 2004, 46, 855–869. [Google Scholar] [CrossRef]

- Żórawski, W.C.; Vicen, M.; Trelka-Druzic, A.; Góral, A.; Makrenek, M.; Adamczak, S.; Bokuvka, O. Microstructure and mechanical properties of cold sprayed amorphous coating. Adv. Sci. Technol. Res. J. 2024, 18, 73–85. [Google Scholar] [CrossRef]

- Gui, M.; Eybel, B.; Asselin, B.; Monerie-Moulin, F. Cracking and spalling behavior of HVOF thermally sprayed WC-Co-Cr coating in bend and axial fatigue tests. J. Mater. Eng. Perform. 2015, 24, 1347–1356. [Google Scholar] [CrossRef]

- Yang, Q.; Li, R.; Liu, Z.Q.; Shi, M.J.; Luo, X.K.; Zhang, T. Compositional dependence of microstructure and tribological properties of plasma sprayed Fe-based metallic glass coatings. Sci. China Technol. Sci. 2012, 55, 1335–1342. [Google Scholar] [CrossRef]

- Milanti, A.; Matikainen, V.; Bolelli, G.; Koivuluoto, H.; Lusvarghi, L.; Vuoristo, P. Microstructure and Sliding Wear Behavior of Fe-Based Coatings Manufactured with HVOF and HVAF Thermal Spray Processes. J. Therm. Spray Technol. 2016, 24, 108–118. [Google Scholar] [CrossRef]

- An, Y.; Hou, G.; Chen, J.; Zhao, X.; Liu, G.; Zhou, H.; Chen, J. Microstructure and tribological properties of iron-based metallic glass coatings prepared by atmospheric plasma spraying. Vacuum 2014, 107, 132–140. [Google Scholar] [CrossRef]

| Chemical Composition wt.% | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Al 7075 (EN 573-3:2019(E)) [46] | |||||||||

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Others (max) | Al |

| 0.4 | 0.5 | 1.2–2.0 | 0.3 | 2.1–2.9 | 0.18–0.28 | 5.1–6.1 | 0.2 | 0.2 | Balance |

| X6CrNiTi18-10 steel (EN 10088-3:2014(E)) [47] | |||||||||

| C | Si | Mn | P | S | Cr | Ni | Others (max) | Fe | |

| 0.18 | 1.0 | 2.0 | 0.045 | 0.03 | 17–19 | 9–12 | Ti:5xC-70 | Balance | |

| Parameters | Values |

|---|---|

| Working gas | 50% N2 + 50% He |

| Gas pressure, MPa | 3.5 |

| Temperature, °C | 700 |

| Powder feeder rate, g/s | 1.03 |

| Standoff distance, mm | 20 |

| Speed of robot arm, mm/s | 200 |

| Number of passes | 5 |

| Coating on Al 7075 | Coating on the Steel | Al 7075 Alloy | X6CrNiTi18-10 Steel | |

|---|---|---|---|---|

| Wear index, Wv·10−6 [mm3/Nm] | 17.6 ± 0.2 | 17.2 ± 1.2 | 2989 ± 135 | 173 ± 10 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Góral, A.; Trelka-Druzic, A.; Żórawski, W.; Maj, Ł.; Vicen, M.; Bokůvka, O.; Petrzak, P.; Garzeł, G. Microstructure, Mechanical and Tribological Properties of Cold Sprayed Fe-Based Metallic Glass Coatings. Materials 2025, 18, 4875. https://doi.org/10.3390/ma18214875

Góral A, Trelka-Druzic A, Żórawski W, Maj Ł, Vicen M, Bokůvka O, Petrzak P, Garzeł G. Microstructure, Mechanical and Tribological Properties of Cold Sprayed Fe-Based Metallic Glass Coatings. Materials. 2025; 18(21):4875. https://doi.org/10.3390/ma18214875

Chicago/Turabian StyleGóral, Anna, Anna Trelka-Druzic, Wojciech Żórawski, Łukasz Maj, Martin Vicen, Otakar Bokůvka, Paweł Petrzak, and Grzegorz Garzeł. 2025. "Microstructure, Mechanical and Tribological Properties of Cold Sprayed Fe-Based Metallic Glass Coatings" Materials 18, no. 21: 4875. https://doi.org/10.3390/ma18214875

APA StyleGóral, A., Trelka-Druzic, A., Żórawski, W., Maj, Ł., Vicen, M., Bokůvka, O., Petrzak, P., & Garzeł, G. (2025). Microstructure, Mechanical and Tribological Properties of Cold Sprayed Fe-Based Metallic Glass Coatings. Materials, 18(21), 4875. https://doi.org/10.3390/ma18214875