Thermomechanical Processing of Medium-Carbon Boron-Bearing Microalloyed-Steel Forgings Targeting Normalized-like Structure and Properties

Abstract

1. Introduction

2. Materials and Methods

2.1. Assumptions and Plan of the Study

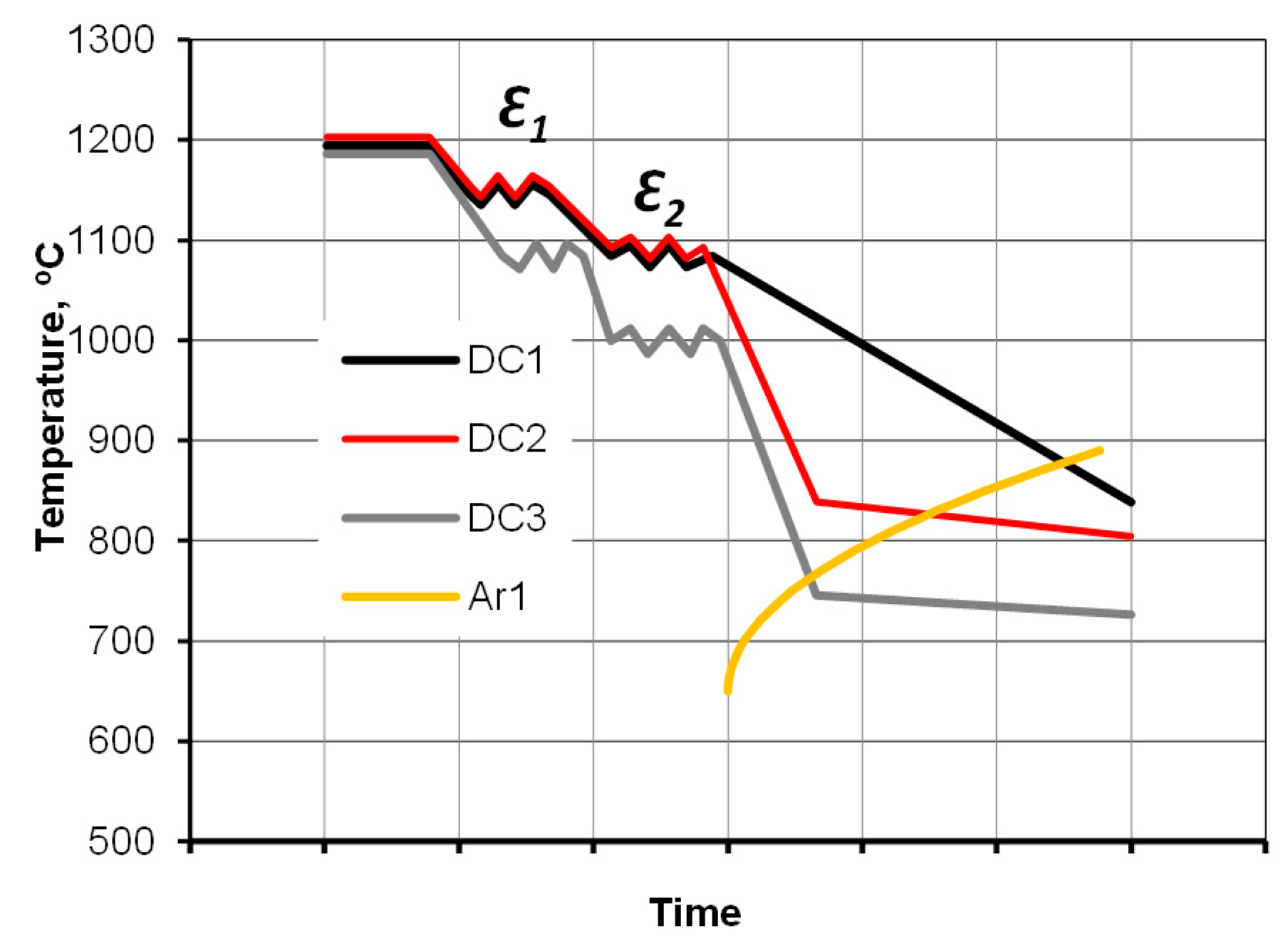

- Direct Cooling: Natural cooling immediately after hot forging without reheating (DC1),

- Direct Cooling (modified strategy): Forging at the same temperature, followed by direct cooling with a revised strategy involving accelerated air cooling interrupted to produce a pseudo-isothermal plateau within the pearlite zone (DC2),

- Direct Cooling using the same strategy for the modified forging regime, that is, a lowered forging temperature (DC3).

2.2. Physical Modeling

2.3. Numerical Modeling

2.4. Material Considerations

- (1)

- Minimum Ti content can amount to %Timin ≈ 3.4%N. Ti forms very stable TiN nitrides with a high solvus temperature. Thus, if all available N will be consumed by TiN formation, B will remain in the solid solution, inhibiting the formation of ferrite and pearlite at the austenite grain boundaries by blocking nucleation sites.

- (2)

- Considering the presence of Al and V, the minimum amount of Al to bind N is 1.93%Al, ≈1.93%N. Formation of AlN (similarly to TiN) promotes B activity on grain boundaries, enhancing hardenability [41]. On the other hand, excessive concentration of coarse aluminum or titanium nitrides may deteriorate impact strength and machinability.

3. Results and Discussion

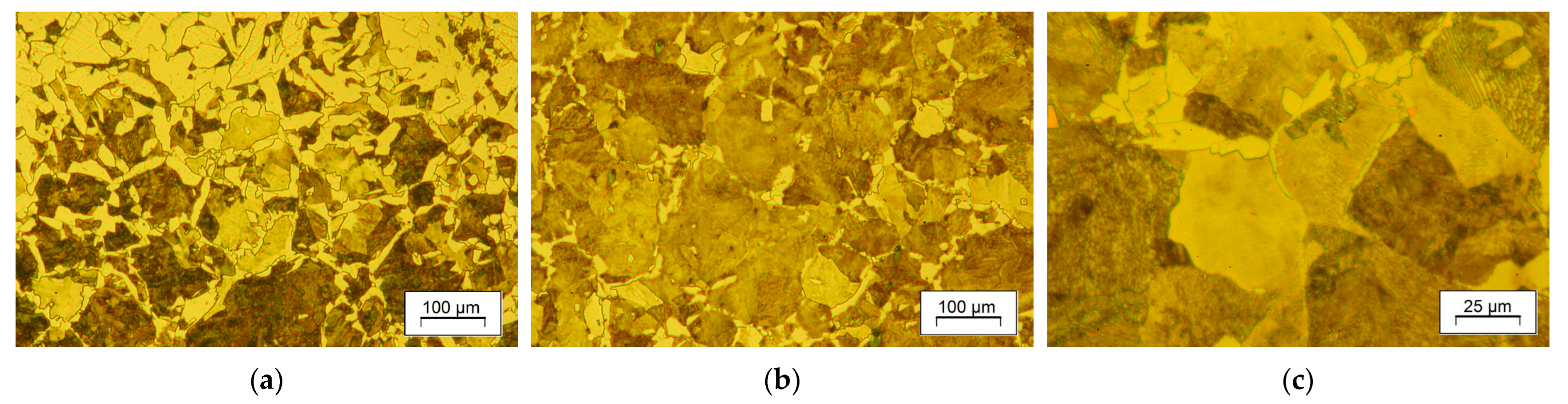

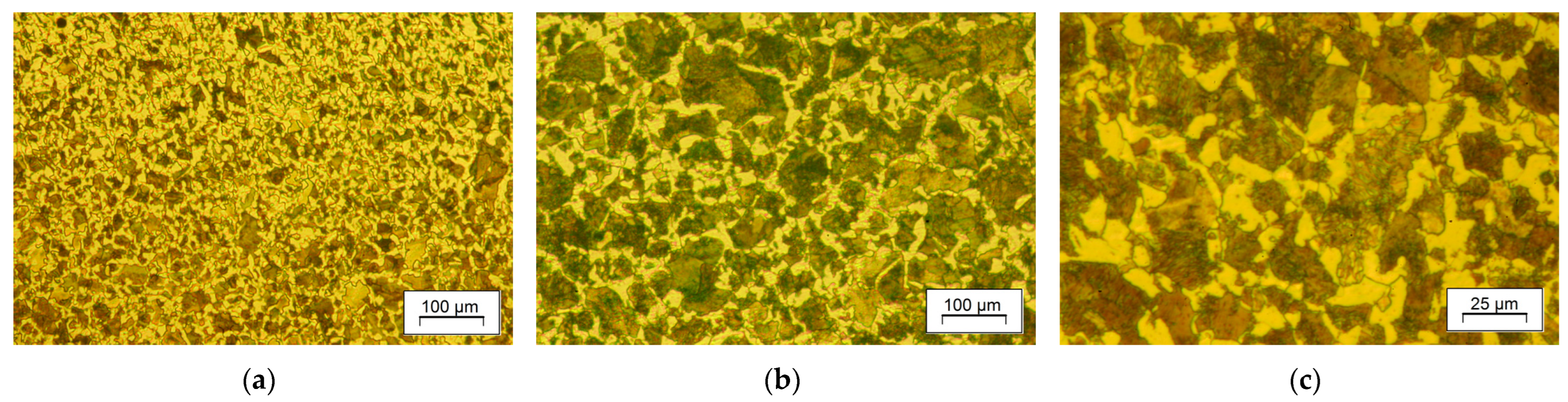

3.1. Characterization the Workpiece Material

3.2. Analysis of Thermo-Mechanical Factors

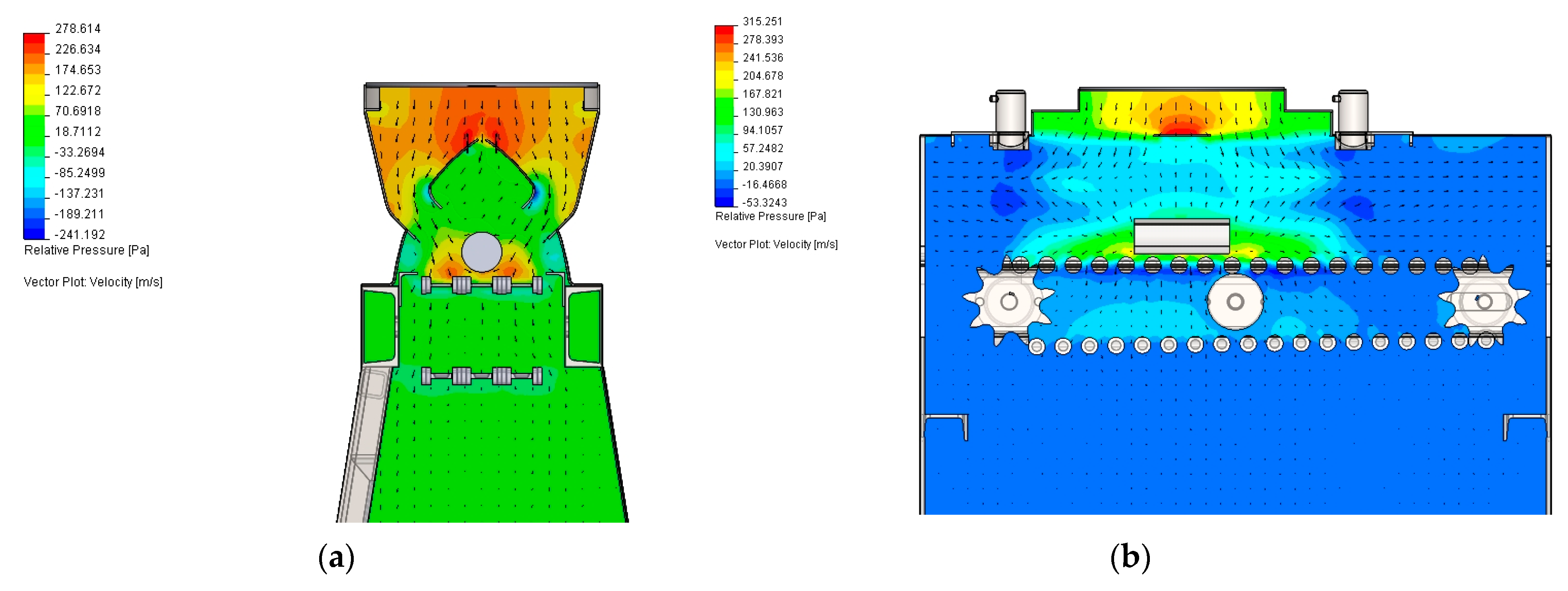

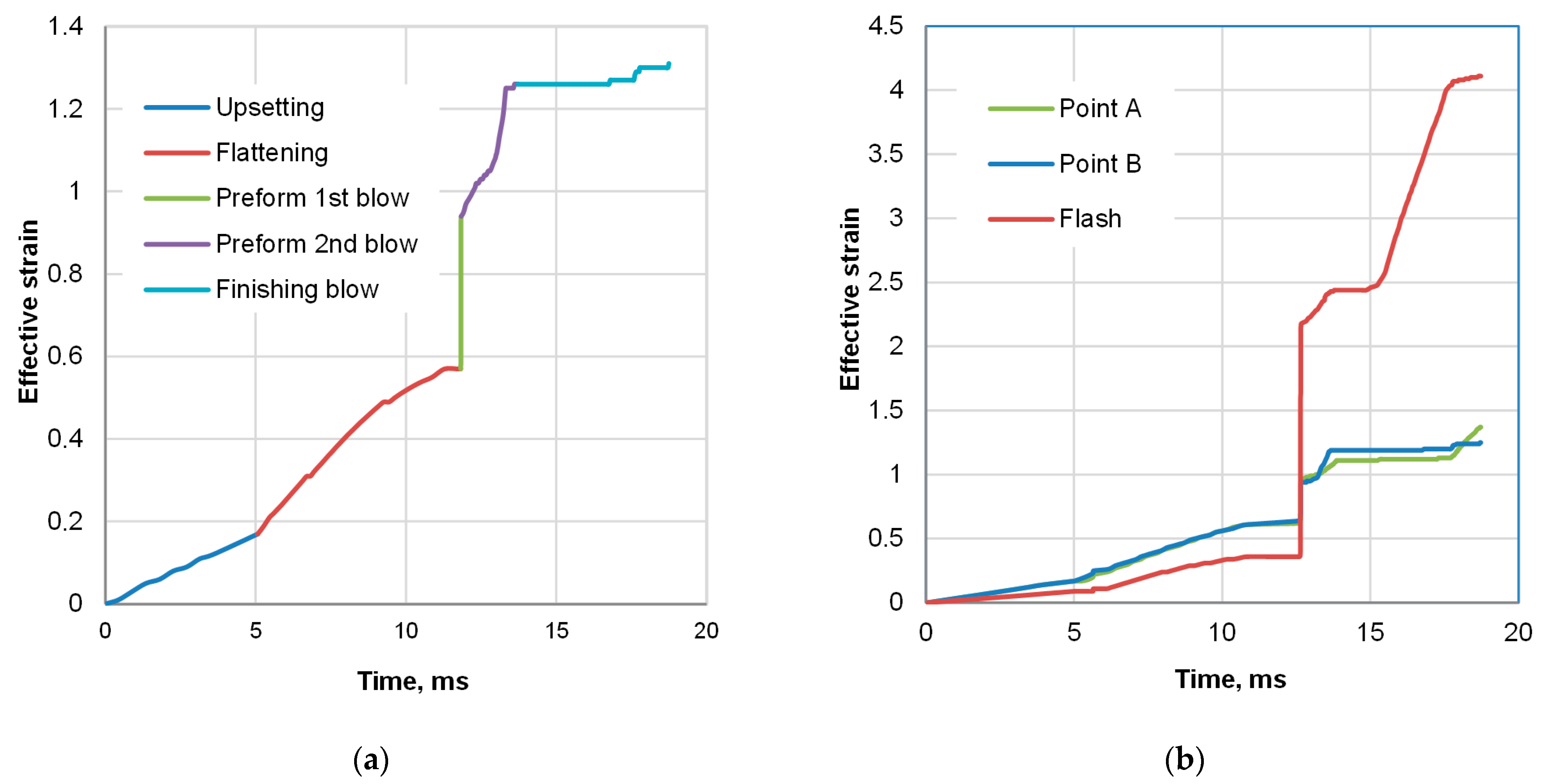

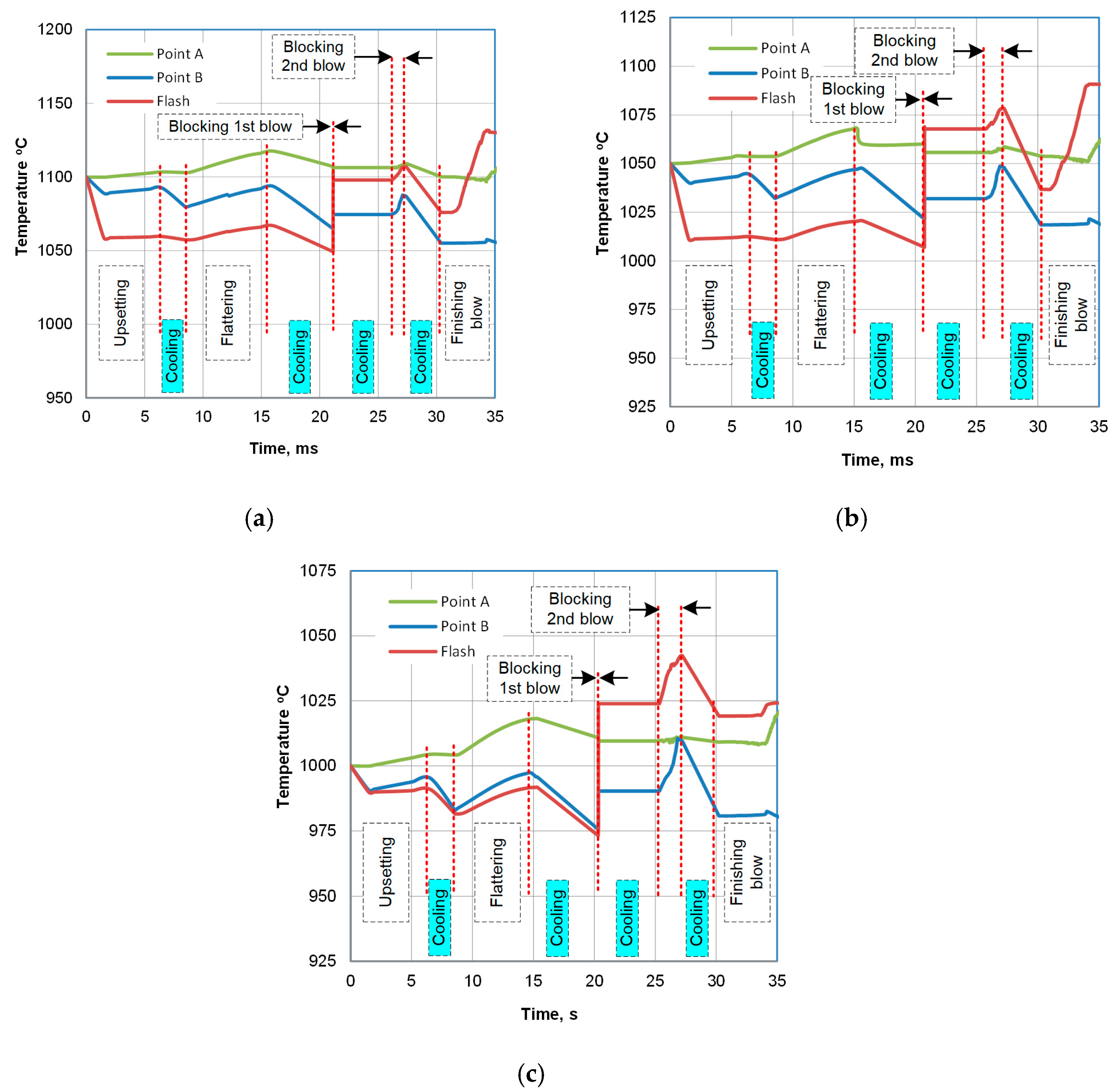

3.2.1. FEM of Hot Forging and Direct Cooling

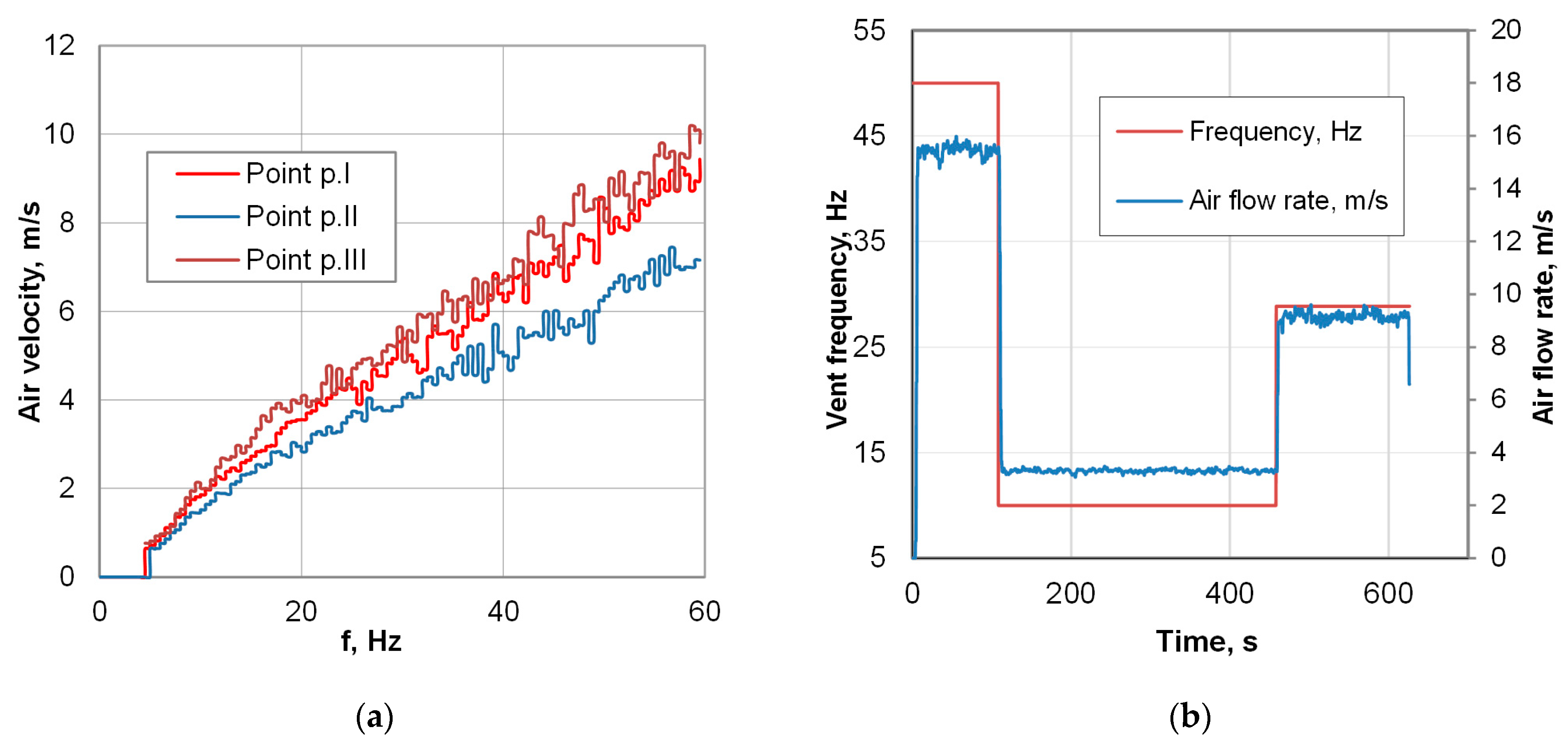

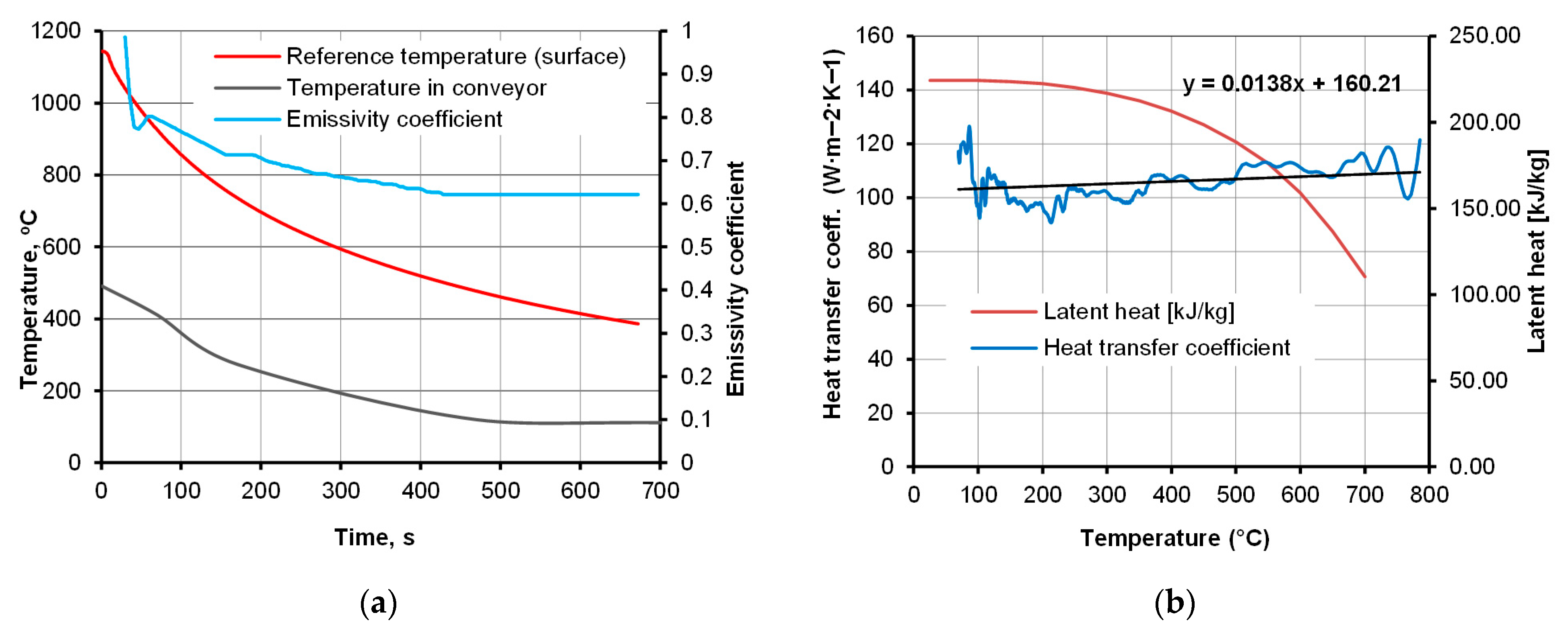

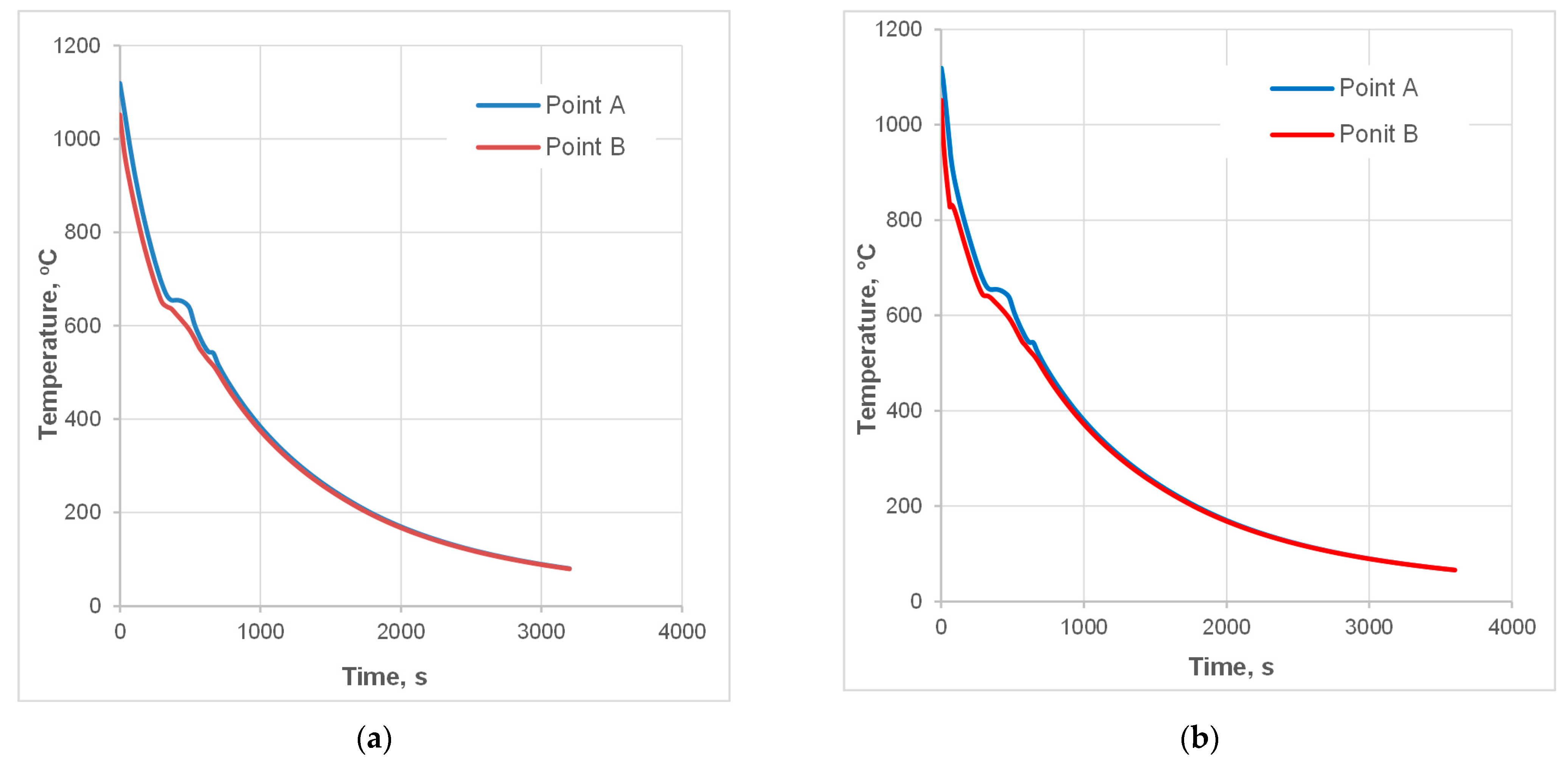

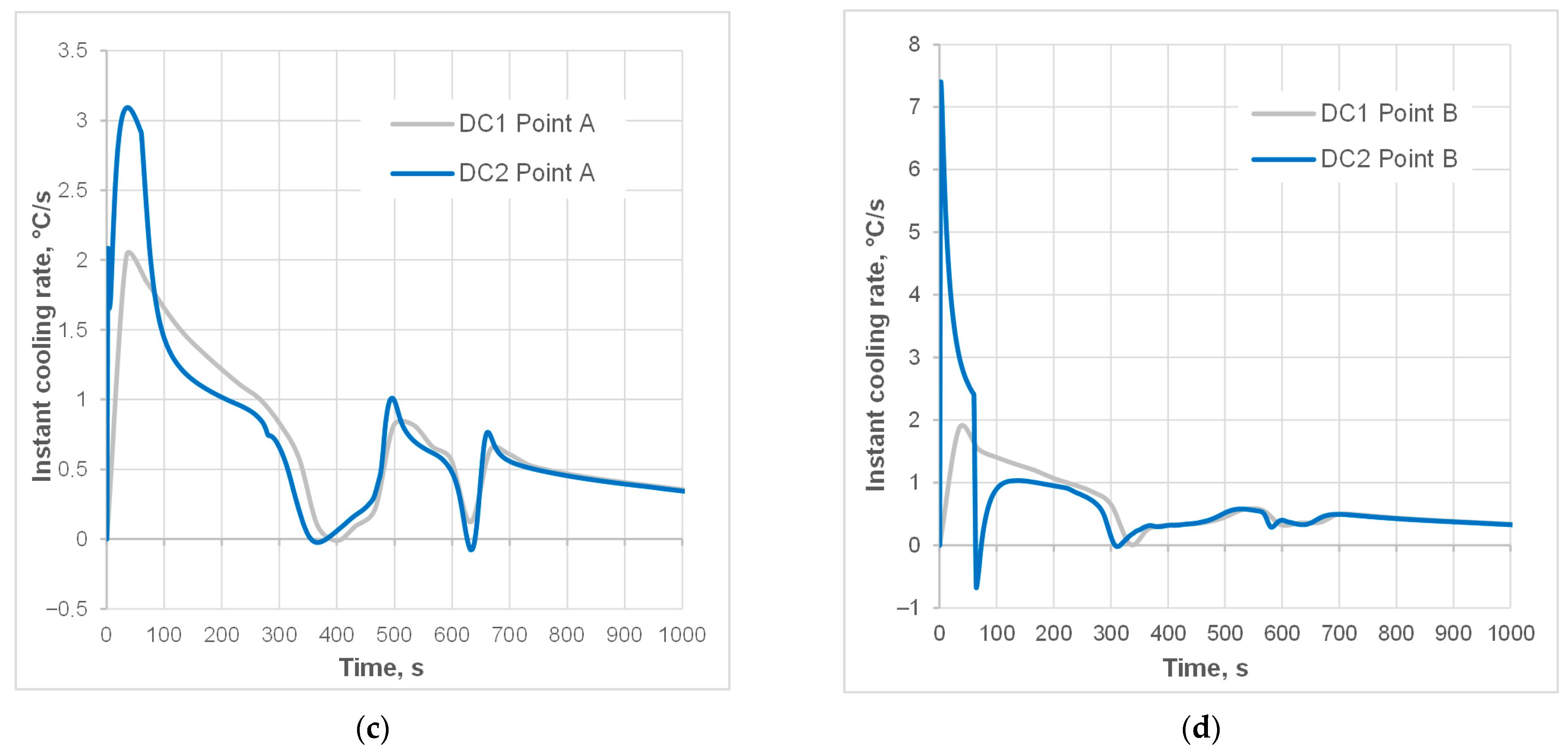

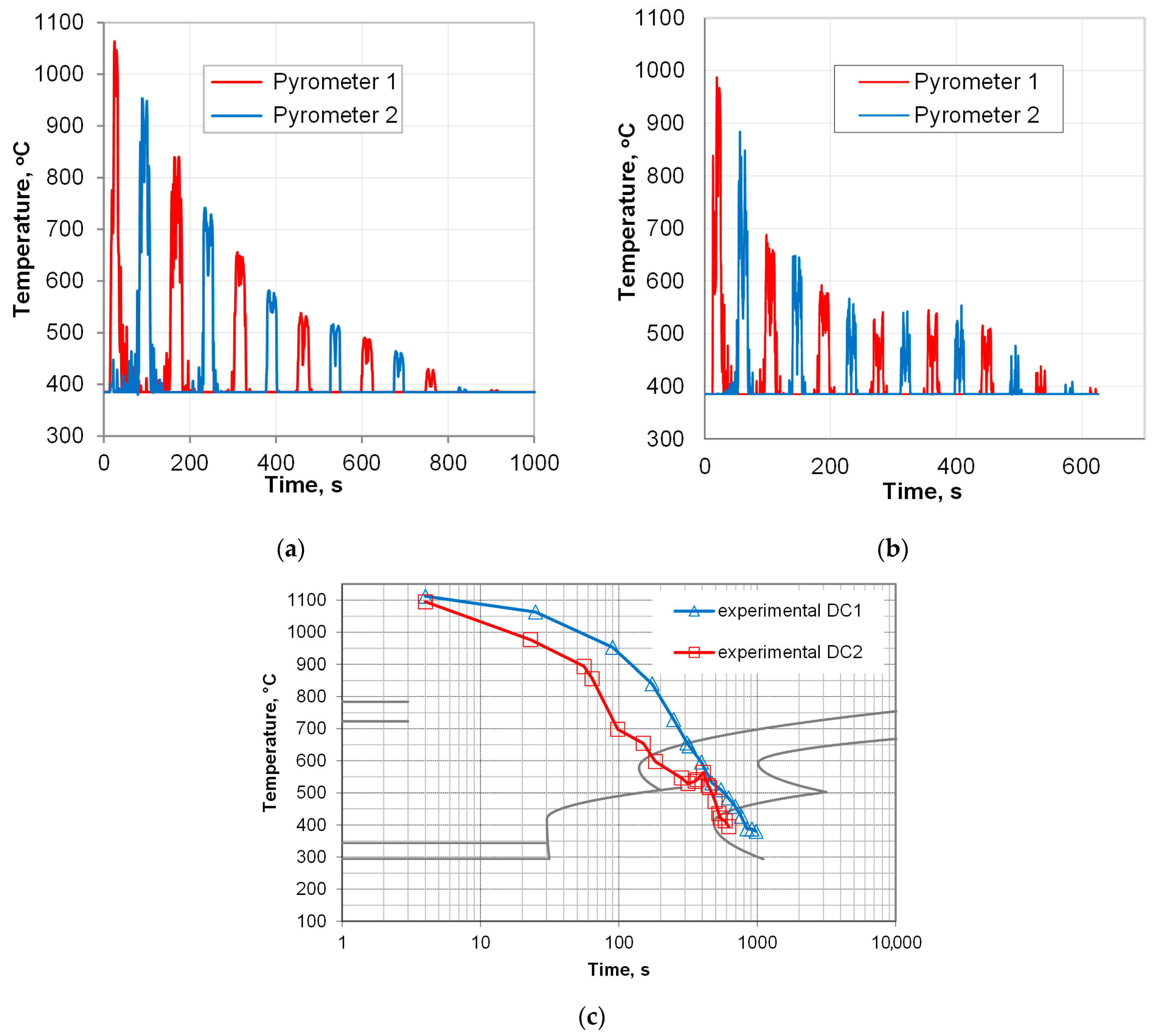

3.2.2. Controlled Cooling Experiments

3.2.3. Evaluation of the Results

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cohen, M.; Owen, W.S. Thermo-mechanical processing of microalloying steels. In Proceedings of Microalloying’75: International Conference on Microalloyed Steels; University of Michigan: Ann Arbor, MI, USA, 1975; pp. 2–8. [Google Scholar]

- Gramlich, A.; Hagedorn, W.; Greiff, K.; Krupp, U. Air cooling martensites—The future of carbon neutral steel forgings? Adv. Eng. Mater. 2023, 25, 2201931. [Google Scholar] [CrossRef]

- Gramlich, A.; Lange, R.; Zitz, U.; Büßenschütt, K. Air-hardening die-forged con-rods—Achievable mechanical properties of bainitic and martensitic concepts. Metals 2022, 12, 97. [Google Scholar] [CrossRef]

- Baker, T.N. Microalloyed steels. Ironmak. Steelmak. 2016, 43, 264–307. [Google Scholar] [CrossRef]

- Arruabarrena, J.; López, B.; Rodriguez-Ibabe, J.M. Influence of DIT parameters on the cementite spheroidization in a low-alloy medium carbon steel. Metall. Mater. Trans. A 2016, 47, 412–423. [Google Scholar] [CrossRef]

- Chen, L.; Chen, K.; Chang, G.; Liu, Y. Effects of applied stress on isothermal phase transformation of austenite to pearlite in heavy rail steels: An experimental and modeling study. Metallogr. Microstruct. Anal. 2016, 5, 402–410. [Google Scholar] [CrossRef]

- Lee, S.Y.; Lee, S.I.; Hwang, B. Sensitivity of microstructural factors influencing the impact toughness of hypoeutectoid steels with ferrite–pearlite structure using multiple regression analysis. J. Korean Inst. Met. Mater. 2016, 54, 637–644. [Google Scholar] [CrossRef]

- Fang, X.; Fan, Z.; Ralph, B.; Evans, P.; Underhill, R. Influence of accelerated cooling on microstructure and mechanical properties of C–Mn steels. Mater. Sci. Technol. 2002, 18, 47–53. [Google Scholar] [CrossRef]

- Semiatin, S.L. ASM Metals Handbook, Vol. 14: Forming and Forging; ASM International: Materials Park, OH, USA, 1993. [Google Scholar]

- Morelli, R.T.; Semiatin, S.L. Heat treatment practices. In Forging Handbook; Forging Industry Association; Byrer, T.G., Semiatin, S.L., Vollmer, D.C., Eds.; ASM International: Cleveland, OH, USA, 1985; Chapter 4. [Google Scholar]

- Werner, W.A. Schmiedeteile: Gestaltung, Anwendung, Beispiele; Verlag Stahleisen: Düsseldorf, Germany, 1984; p. 207. [Google Scholar]

- Kulon, J.; Mynors, D.J.; Broomhead, P. A knowledge-based engineering design tool for metal forging. J. Mater. Process. Technol. 2006, 177, 331–335. [Google Scholar] [CrossRef]

- Show, B.K.; Veerababu, R.; Balamuralikrishnan, R.; Malakondaiah, G. Effect of vanadium and titanium modification on the microstructure and mechanical properties of a microalloyed HSLA steel. Mater. Sci. Eng. A 2010, 527, 1595–1604. [Google Scholar] [CrossRef]

- Mukherjee, M.; Prahl, U.; Bleck, W. Modelling the strain-induced precipitation kinetics of vanadium carbonitride during hot working of precipitation-hardened ferritic–pearlitic steels. Acta Mater. 2014, 71, 234–254. [Google Scholar] [CrossRef]

- Wen, X.L.; Mei, Z.; Jiang, B.; Zhang, L.C.; Liu, Y.Z. Effect of normalizing temperature on microstructure and mechanical properties of a Nb–V microalloyed large forging steel. Mater. Sci. Eng. A 2016, 671, 233–243. [Google Scholar] [CrossRef]

- Wang, J.; Shen, Y.; Liu, Y.; Wang, F.; Jia, N. Tailoring strength and ductility of a Cr-containing high carbon steel by cold-working and annealing. Materials 2019, 12, 4136. [Google Scholar] [CrossRef]

- Timokhina, I.B.; Enomoto, M.; Miller, M.K.; Pereloma, E.V. Microstructure–property relationship in the thermomechanically processed C–Mn–Si–Nb–Al–(Mo) TRIP steels before and after prestraining and bake hardening treatment. Metall. Mater. Trans. A 2012, 43, 2473–2483. [Google Scholar] [CrossRef]

- Bodnar, R.L.; Fletcher, F.B.; Manohar, M. The physical metallurgy of normalized plate steels. Mater. Sci. Technol. 2004, 20, 89–109. [Google Scholar]

- Ghosh, A.; Das, S.; Chatterjee, S.; Mishra, B.; Rao, P.R. Influence of thermo-mechanical processing and different post-cooling techniques on structure and properties of an ultra-low carbon Cu-bearing HSLA forging. Mater. Sci. Eng. A 2003, 348, 299–308. [Google Scholar] [CrossRef]

- Ebrahimi, A.; Moshksar, M.M. Evaluation of machinability in turning of microalloyed and quenched–tempered steels: Tool wear, statistical analysis, chip morphology. J. Mater. Process. Technol. 2009, 209, 910–921. [Google Scholar] [CrossRef]

- Skubisz, P. Results of thermomechanical treatment implementation in hammer drop forging industrial process. Metalurgija 2021, 60, 71–74. [Google Scholar]

- Apostoł, M.; Skubisz, P.; Adrian, H. Determination of heat transfer coefficient for air-atomized water spray cooling and its application in modeling of thermomechanical controlled processing of die forgings. Materials 2022, 15, 2366. [Google Scholar] [CrossRef] [PubMed]

- Skubisz, P.; Żak, A.; Burdek, M.; Lisiecki, Ł.; Micek, P. Design of controlled processing conditions for drop forgings made of microalloy steel grades for mining industry. Arch. Metall. Mater. 2015, 60, 73–79. [Google Scholar] [CrossRef]

- Kokosza, A.; Pacyna, J. Formation of medium-carbon TRIP steel microstructure during annealing in the intercritical temperature range. Arch. Metall. Mater. 2014, 59, 1017–1022. [Google Scholar] [CrossRef]

- Kantanen, P.K.; Javaheri, V.; Somani, M.C.; Porter, D.A.; Kömi, J.I. Effect of deformation and grain size on austenite decomposition during quenching and partitioning of (high) silicon–aluminum steels. Mater. Charact. 2021, 171, 110793. [Google Scholar] [CrossRef]

- Jabłońska, M.B.; Gronostajski, Z.; Tkocz, M.; Jasiak, K.; Kowalczyk, K.; Skwarski, M.; Kostka, M. Specific behavior of high-manganese steels in the context of temperature increase during dynamic deformation. Mater. Res. Proc. 2023, 28, 839–846. [Google Scholar] [CrossRef]

- Guo, L.; Roelofs, H.; Lembke, M.I.; Bhadeshia, H.K.D.H. Modelling of recalescence effect on austenite decomposition. Mater. Sci. Technol. 2017, 33, 1258–1267. [Google Scholar] [CrossRef]

- Shen, Y.F.; Dong, X.X.; Song, X.T.; Jia, N. Carbon content-tuned martensite transformation in low-alloy TRIP steels. Sci. Rep. 2019, 9, 7559. [Google Scholar] [CrossRef]

- Kimura, T.; Kurebayashi, Y. Niobium in microalloyed engineering steels, wire rods and case carburized products. In Niobium: Science and Technology; 2001; pp. 801–819. Available online: https://www.mendeley.com/catalogue/38f3172a-3cde-3c3f-be18-0ba92dfd3b86/ (accessed on 18 September 2025).

- Zhang, Z.; Zhang, K.; Yue, Y.; Ma, N.; Xu, Z. Microstructure and mechanical properties of austempered ultrahigh carbon steel (1.4%C). Mater. Sci. Forum 2011, 682, 97–101. [Google Scholar] [CrossRef]

- Adamczyk, J.; Opiela, M. Influence of the thermo–mechanical treatment parameters on the inhomogeneity of the austenite structure and mechanical properties of the Cr–Mo steel with Nb, Ti, and B microadditions. J. Mater. Process. Technol. 2004, 157–158, 456–461. [Google Scholar] [CrossRef]

- Opiela, M.; Grajcar, A. Elaboration of forging conditions on the basis of the precipitation analysis of MX-type phases in microalloyed steels. Arch. Civ. Mech. Eng. 2012, 12, 427–435. [Google Scholar] [CrossRef]

- Skubisz, P.; Lisiecki, Ł.; Micek, P. Effect of direct cooling conditions on characteristics of drop-forged Ti+V+B microalloy steel. Procedia Manuf. 2015, 2, 159–166. [Google Scholar] [CrossRef][Green Version]

- Bu, F.; Wang, X.M.; Chen, L.; Yang, S.W.; Shang, C.J.; Misra, R.D.K. Influence of cooling rate on the precipitation behavior in Ti–Nb–Mo microalloyed steels during continuous cooling and relationship to strength. Mater. Charact. 2015, 102, 146–155. [Google Scholar] [CrossRef]

- Opiela, M.; Zalecki, W.; Grajcar, A. Influence of plastic deformation on CCT diagrams of newly developed microalloyed steel. J. Achiev. Mater. Manuf. Eng. 2012, 51, 78–89. [Google Scholar]

- Skubisz, P.; Micek, P.; Sińczak, J.; Tumidajewicz, M. Automated determination and on-line correction of emissivity coefficient in controlled cooling of drop forgings. Solid State Phenom. 2011, 177, 76–81. [Google Scholar] [CrossRef]

- Biba, N.; Stebunov, S.; Lishny, A. Model for coupled simulation of thin profile extrusion. Key Eng. Mater. 2012, 504–506, 505–510. [Google Scholar] [CrossRef]

- Biba, N.; Stebunov, S.; Lishny, A. Simulation of material flow coupled with die analysis in complex shape extrusion. Key Eng. Mater. 2014, 585, 85–92. [Google Scholar] [CrossRef]

- Stebunov, S.; Biba, N.; Vlasov, A.; Maximov, A. Thermally and mechanically coupled simulation of metal forming processes. In Proceedings of the 10th International Conference on Technology of Plasticity (ICTP), Aachen, Germany, 25–30 September 2011; Volume 2, pp. 171–175. [Google Scholar]

- Skubisz, P.; Adrian, H. Estimation of heat transfer coefficient of forced-air cooling and its experimental validation in controlled processing of forgings. Numer. Heat Transf. Part A Appl. 2018, 73, 293–305. [Google Scholar] [CrossRef]

- Zhou, X.; Kumar, S.; Zhang, S.; Chen, X.; Gault, B.; Dehm, G.; Hickel, T.; Raabe, D. Boron triggers grain boundary structural transformation in steel. Nat. Commun. 2025, 16, 6927. [Google Scholar] [CrossRef]

- Liu, S.; Zhang, F.; Yang, Z.; Wang, M.; Zheng, C. Effects of Al and Mn on the formation and properties of nanostructured pearlite in high-carbon steels. Mater. Des. 2016, 93, 73–80. [Google Scholar] [CrossRef]

- Hui, W.; Zhang, Y.; Shao, C.; Chen, S.; Zhao, X.; Dong, H. Effect of cooling rate and vanadium content on the microstructure and hardness of medium-carbon forging steel. J. Mater. Sci. Technol. 2016, 32, 545–551. [Google Scholar] [CrossRef]

- El-Bitar, T.; Fouad, N.; Zaky, A.I.; El-Rady, S.A. Effect of cooling rate after controlled forging on properties of low-carbon multi-microalloyed steels. Mater. Sci. Eng. A 2012, 534, 514–520. [Google Scholar] [CrossRef]

- Hannula, J.; Kaijalainen, A.; Porter, D.; Kömi, J. Effect of microalloying elements on prior austenite grain growth of low-carbon slab material. J. Phys. Conf. Ser. 2019, 1270, 012018. [Google Scholar] [CrossRef]

- Ali, M.; Kaijalainen, A.; Hannula, J.; Porter, D.; Kömi, J. Influence of chromium content and prior deformation on the continuous cooling transformation diagram of low-carbon bainitic steels. Key Eng. Mater. 2020, 835, 58–67. [Google Scholar] [CrossRef]

- de Oliveira, M.A.F.; Jorge AMJr Balancin, O. Influence of deformation on the kinetics of phase transformation in a forging steel during warm working. Mater. Res. 2004, 7, 247–253. [Google Scholar] [CrossRef]

- Adamczyk, J.; Opiela, M. Engineering of forged products of microalloyed constructional steels. J. Achiev. Mater. Manuf. Eng. 2006, 15, 153–158. [Google Scholar]

- Ridley, N. Review of the data on the interlamellar spacing of pearlite. Metall. Trans. A Phys. Metall. Mater. Sci. 1983, 15A, 1019–1036. [Google Scholar] [CrossRef]

- Vander Voort, G.F.; Roósz, A. Measurement of the interlamellar spacing of pearlite. Metallography 1984, 17, 1–17. [Google Scholar] [CrossRef]

- Vander Voort, G.F. The interlamellar spacing of pearlite. Pract. Metallogr. 2015, 52, 419–436. [Google Scholar] [CrossRef]

| %C | %Cr | %Si | %Mn | %Mo | %Ni | %Ti | %V | %B | %Nb | %Sn | %N2 | %Al | %P | %S | Fe |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.35 | 0.37 | 0.27 | 1.36 | 0.007 | 0.06 | 0.034 | 0.005 | 0.002 | 0.05 | 0.013 | 0.0105 | 0.02 | 0.013 | 0.011 | bal. |

| Treatment Strategy | Designation | Cooling Strategy | Forging Temperature | Effective Strain | Cooling Start, °C | Max. Cooling Rate, °C/s | |||

|---|---|---|---|---|---|---|---|---|---|

| Tε1 | A | B | A | B | A | B | |||

| conventional normalizing | NA | Reheating + air | 1200 °C | 1.45 | 1.41 | 880 °C | 870 °C | 1.8 | 3.2 |

| Direct cooling 1 | DC1 | Air (tube) | 1150 °C | 1.45 | 1.41 | 1105 °C | 1055 °C | 2.1 | 3.2 |

| Direct cooling 2 | DC2 | Acc air + hold | 1150 °C | 1.45 | 1.41 | 1105 °C | 1055 °C | 4.1 | 7.4 |

| Direct cooling 3 | DC3 | Acc air + hold | 1090 °C | 1.45 | 1.41 | 1060 °C | 1020 °C | 3.5 | 7.0 |

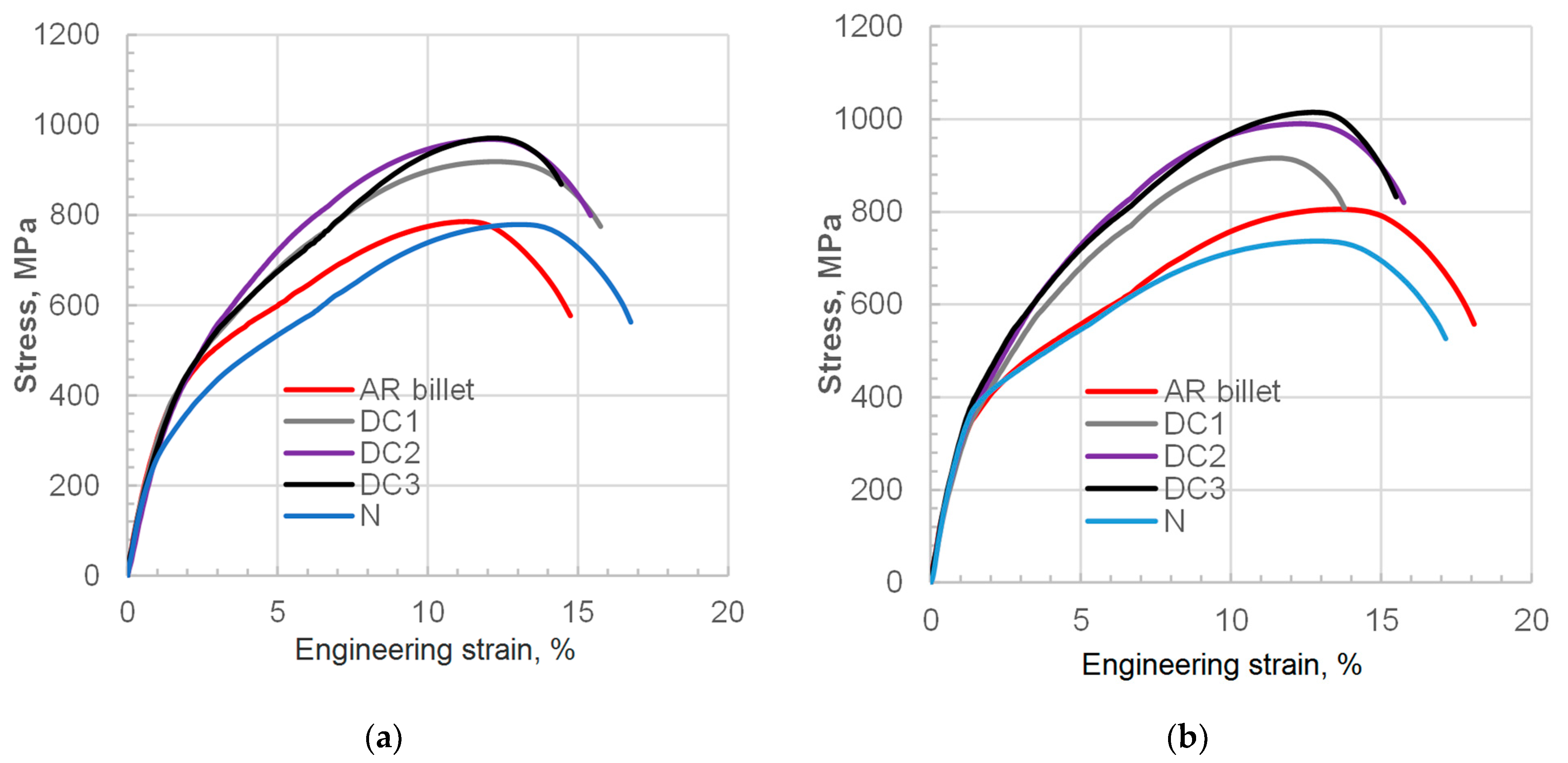

| Sample | Specimen | Rm, MPa | Re, MPa | A10, % | Interlamellar Spacing, μm | Grain Size, (2) μm |

|---|---|---|---|---|---|---|

| As-received (1) | A | 786.5 | 483.1 | 13.4 | 264 ± 63 | 26.82 ± 3.2 |

| B | 806.0 | 475.1 | 16.2 | |||

| conventional normalizing (NA) | A | 779.6 | 424.6 | 14.6 | 208 ± 38 | 18.65 ± 1.7 |

| B | 736.8 | 458.4 | 15.8 | |||

| Direct cooling 1 (DC1) | A | 919.2 | 606.2 | 13.7 | 245 ± 22 | 36.28 ± 3.5 |

| B | 916.3 | 647.2 | 11.9 | |||

| Direct cooling 2 (DC2) | A | 968.1 | 656.2 | 13.4 | 222 ± 39 | 26.32 ± 3.5 |

| B | 989.4 | 648.0 | 13.2 | |||

| Direct cooling 3 (DC3) | A | 971.0 | 605.8 | 12.2 | 190 ± 48 | 19.18 ± 2.8 |

| B | 1015.0 | 652.5 | 12.5 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Skubisz, P.; Micek, P.; Flaga, S. Thermomechanical Processing of Medium-Carbon Boron-Bearing Microalloyed-Steel Forgings Targeting Normalized-like Structure and Properties. Materials 2025, 18, 4871. https://doi.org/10.3390/ma18214871

Skubisz P, Micek P, Flaga S. Thermomechanical Processing of Medium-Carbon Boron-Bearing Microalloyed-Steel Forgings Targeting Normalized-like Structure and Properties. Materials. 2025; 18(21):4871. https://doi.org/10.3390/ma18214871

Chicago/Turabian StyleSkubisz, Piotr, Piotr Micek, and Stanisław Flaga. 2025. "Thermomechanical Processing of Medium-Carbon Boron-Bearing Microalloyed-Steel Forgings Targeting Normalized-like Structure and Properties" Materials 18, no. 21: 4871. https://doi.org/10.3390/ma18214871

APA StyleSkubisz, P., Micek, P., & Flaga, S. (2025). Thermomechanical Processing of Medium-Carbon Boron-Bearing Microalloyed-Steel Forgings Targeting Normalized-like Structure and Properties. Materials, 18(21), 4871. https://doi.org/10.3390/ma18214871