Failure Analysis of Gear on Rail Transit

Abstract

1. Introduction

2. Failure Case Analysis and Discussion

2.1. Effects of Raw Materials

2.1.1. Purity of Raw Materials

2.1.2. Forging Process of Raw Materials

2.2. Effects of Heat Treatment

2.2.1. Surface-Hardened Layer

2.2.2. Overheating

2.2.3. Over-Deformation of the Gear

2.3. Effects of Manufacturing Processes

2.4. Effects of Operational Factors

3. Conclusions and Recommendations

- Material Defects: In the first failure case of the gear shaft, the quenching crack initiated from an alumina inclusion (~800 µm long and ~100 µm wide) located approximately 4.5 mm beneath the surface. Such non-metallic inclusions act as stress concentrators under cyclic loading, initiating fatigue cracks. To mitigate this, we recommend implementing ultrasonic testing for incoming material inspection and enforcing stricter inclusion rating controls, particularly for high-stress component regions.

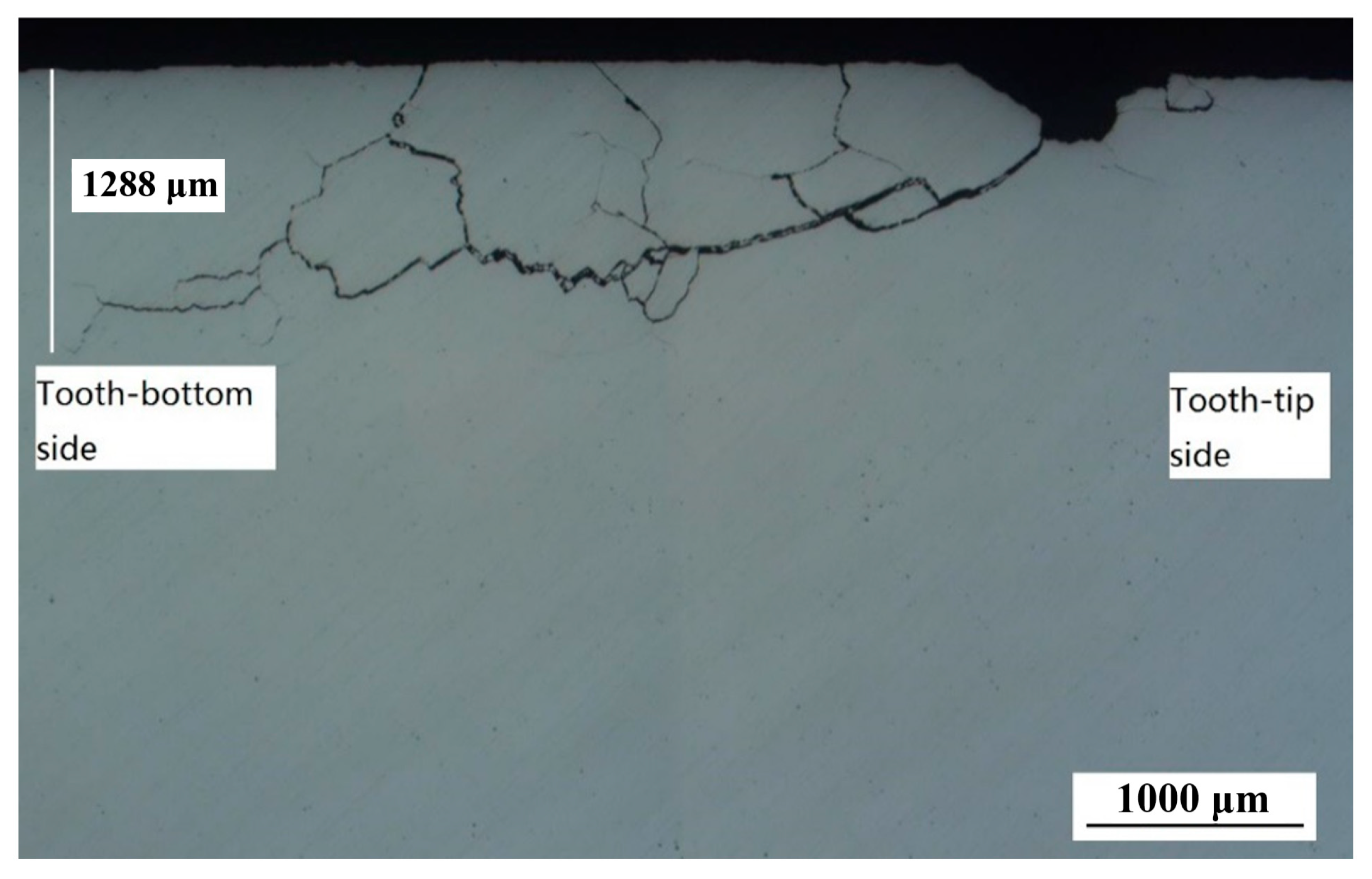

- Improper Heat Treatment: The analysis of a fractured driving gear revealed a non-martensitic microstructure (approximately 60 µm deep, containing coarse upper bainite) at the tooth root. This microstructural anomaly, resulting from an insufficient quenching cooling rate, significantly reduced bending fatigue strength and promoted crack initiation. The corrective measure involves utilizing multi-zone controlled-atmosphere quenching furnaces with real-time monitoring of oil temperature and agitation intensity to ensure optimal cooling rates. Post-process validation via residual stress analysis (e.g., X-ray diffraction) is also recommended.

- Grinding-Induced Defects: The driven gear failure was characterized by crescent-shaped ’black spots’ identified as temper burns. These areas exhibited substantial hardness reduction (by ~100 HV), transforming them into initiation sites for contact fatigue spalling. To prevent this, we propose integrating real-time process monitoring, including infrared thermography and acoustic emission, during gear grinding. Furthermore, optimizing grinding wheel parameters and coolant application strategies is essential to avoid localized overheating.

- Insufficient Lubrication: Several failure cases exhibited thermal scuffing and adhesive wear on tooth flanks, directly attributable to inadequate lubrication or oil film breakdown. This aligns with industry statistics indicating that lubrication issues contribute to nearly 75% of gear failures. Countermeasures include optimizing lubrication system design (nozzle positioning and oil flow), selecting high-performance extreme-pressure lubricants, and implementing online monitoring of oil cleanliness and moisture content to ensure consistent lubrication integrity.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhao, H.; Liang, J.; Liu, C. High-Speed EMUs: Characteristics of Technological Development and Trends. Engineering 2020, 6, 234–244. [Google Scholar] [CrossRef]

- Pan, A.; Gong, Y.; Yang, Z. Failure analysis on abnormal leakage of radiator for high-speed train transformer. Eng. Fail. Anal. 2021, 129, 105673. [Google Scholar] [CrossRef]

- Jiang, J.; Chen, Z.; Zhai, W.; Zhang, T.; Li, Y. Vibration characteristics of railway locomotive induced by gear tooth root crack fault under transient conditions. Eng. Fail. Anal. 2020, 108, 104285. [Google Scholar] [CrossRef]

- Ma, H.; Zeng, J.; Feng, R.; Pang, X.; Wang, Q.; Wen, B. Review on dynamics of cracked gear systems. Eng. Fail. Anal. 2015, 55, 224–245. [Google Scholar] [CrossRef]

- Zhang, Q.; Zhang, J.; Wu, C.; Xu, Z.; Lyu, S. The evaluation of contact fatigue strength for 20MnCr5 carburized gear. Int. J. Precis. Eng. Manuf. 2014, 15, 117–121. [Google Scholar] [CrossRef]

- Chang, H.; Borghesani, P.; Peng, Z. Investigation on the relationship between macropits and wear particles in a gear fatigue process. Wear 2021, 484–485, 203724. [Google Scholar] [CrossRef]

- Zheng, L.; Yang, T.; Xue, S.; Li, G.; Liu, X. Fracture failure analysis of the teeth of conjunction gear made of 20MnCr5S steel. Eng. Fail. Anal. 2022, 134, 106006. [Google Scholar] [CrossRef]

- Zhang, N.; Guo, S.; He, G.; Jiang, B.; Zhou, L.; Chen, Y.; Liu, Y. Failure analysis of the carburized 20MnCr5 gear in fatigue working condition. Int. J. Fatigue 2022, 161, 106938. [Google Scholar] [CrossRef]

- Ghosh, D.; Mondal, A.; Hussain, N.; Kumar De, S.; Ray, S.; Subramanian, C. Failure analysis of helical gear pinion. Mater. Today Proc. 2022, 66, 3714–3717. [Google Scholar] [CrossRef]

- Cai, S.; Sun, J.; He, Q.; Shi, T.; Wang, D.; Si, J.; Yang, J.; Li, F.; Xie, K.; Li, M. 16MnCr5 gear shaft fracture caused by inclusions and heat treatment process. Eng. Fail. Anal. 2021, 126, 105458. [Google Scholar] [CrossRef]

- Qin, X.; Pang, R.; Zhao, X.; Li, F. Fracture failure analysis of internal teeth of ring gear used in reducer of coal mining machine. Eng. Fail. Anal. 2018, 84, 70–76. [Google Scholar] [CrossRef]

- Park, S.; Lee, J.; Moon, U.; Kim, D. Failure analysis of a planetary gear carrier of 1200HP transmission. Eng. Fail. Anal. 2010, 17, 521–529. [Google Scholar] [CrossRef]

- Zhang, D.; Liu, S.; Liu, B.; Jie, H. Investigation on bending fatigue failure of a micro-gear through finite element analysis. Eng. Fail. Anal. 2013, 31, 225–235. [Google Scholar] [CrossRef]

- Rajinikanth, V.; Soni, M.K.; Mahato, B.; Rao, M.A. Microstructural Investigation of rolling contact fatigue (RCF) on a failed planetary gear of a windmill gearbox. Eng. Fail. Anal. 2021, 121, 105167. [Google Scholar] [CrossRef]

- Pan, A.; Yang, Z. Cause analysis and countermeasure on premature failure of a driven gear for the high-speed train. Eng. Fail. Anal. 2022, 139, 106487. [Google Scholar] [CrossRef]

- Ševčík, M.; Hutař, P.; Náhlík, L.; Seitl, S. The effect of constraint level on a crack path. Eng. Fail. Anal. 2013, 29, 83–92. [Google Scholar] [CrossRef]

- Chen, Y.; Jin, Y.; Liang, X.; Kang, R. Propagation path and failure behavior analysis of cracked gears under different initial angles. Mech. Syst. Signal Process. 2018, 110, 90–109. [Google Scholar] [CrossRef]

- Doğan, O.; Yuce, C.; Karpat, F. Effects of rim thickness and drive side pressure angle on gear tooth root stress and fatigue crack propagation life. Eng. Fail. Anal. 2021, 122, 105260. [Google Scholar] [CrossRef]

- Johannes, G.; Anja, W.; Jens, W.; Christos, G.A.; Olena, V.; Horst, B. Characterization of Nonmetallic Inclusions in 18CrNiMo7-6. Met. Mater Trans B 2019, 50, 337–356. [Google Scholar]

- Tekkaya, B.; Dölz, M.; Münstermann, S. Modeling of local hydrogen concentration on microscopic scale to characterize the influence of stress states and non-metallic inclusions in pipeline steels. Int. J. Hydrogen Energy 2024, 50, 1274–1287. [Google Scholar] [CrossRef]

- Guan, J.; Wang, L.; Zhang, C.; Ma, X. Effects of non-metallic inclusions on the crack propagation in bearing steel. Tribol. Int. 2017, 106, 123–131. [Google Scholar] [CrossRef]

- Wu, X.; Song, Z.; He, J.; Feng, H.; Wang, B.; Wu, M. Effect of newly formed Widmanstätten austenite during high temperature cooling on mechanical properties in UNS S32750 duplex stainless steel. Mater. Sci. Eng. A 2022, 851, 143654. [Google Scholar] [CrossRef]

- GB/T 25744—2010; Metallographic examination for carburizing quenching and tempering of steel parts. Standardization Administration of the People’s Republic of China: Beijing, China, 2010.

- Genel, A.K.; Demirkol., B.M. Effect of case depth on fatigue performance of AISI 8620 carburized steel. Int. J. Fatigue 1999, 21, 207–212. [Google Scholar] [CrossRef]

- Gil, F.J.; Ginebra, M.P.; Manero, J.M.; Planell, J.A. Formation of α-Widmanstätten structure: Effects of grain size and cooling rate on the Widmanstätten morphologies and on the mechanical properties in Ti6Al4V alloy. J. Alloys Compd. 2001, 329, 142–152. [Google Scholar] [CrossRef]

- Husson, R.; Dantan, J.; Baudouin, C.; Silvani, S.; Scheer, T.; Bigot, R. Evaluation of process causes and influences of residual stress on gear distortion. CIRP Ann. 2012, 61, 551–554. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pan, A.-X.; Wen, C.; Wang, H.; Tao, P.; Liu, X.; Gong, Y.; Yang, Z.-G. Failure Analysis of Gear on Rail Transit. Materials 2025, 18, 4773. https://doi.org/10.3390/ma18204773

Pan A-X, Wen C, Wang H, Tao P, Liu X, Gong Y, Yang Z-G. Failure Analysis of Gear on Rail Transit. Materials. 2025; 18(20):4773. https://doi.org/10.3390/ma18204773

Chicago/Turabian StylePan, An-Xia, Chao Wen, Haoyu Wang, Ping Tao, Xuedong Liu, Yi Gong, and Zhen-Guo Yang. 2025. "Failure Analysis of Gear on Rail Transit" Materials 18, no. 20: 4773. https://doi.org/10.3390/ma18204773

APA StylePan, A.-X., Wen, C., Wang, H., Tao, P., Liu, X., Gong, Y., & Yang, Z.-G. (2025). Failure Analysis of Gear on Rail Transit. Materials, 18(20), 4773. https://doi.org/10.3390/ma18204773