Evaluation of Concrete Structural Cracking Behavior Induced by Early Drying Shrinkage

Abstract

1. Introduction

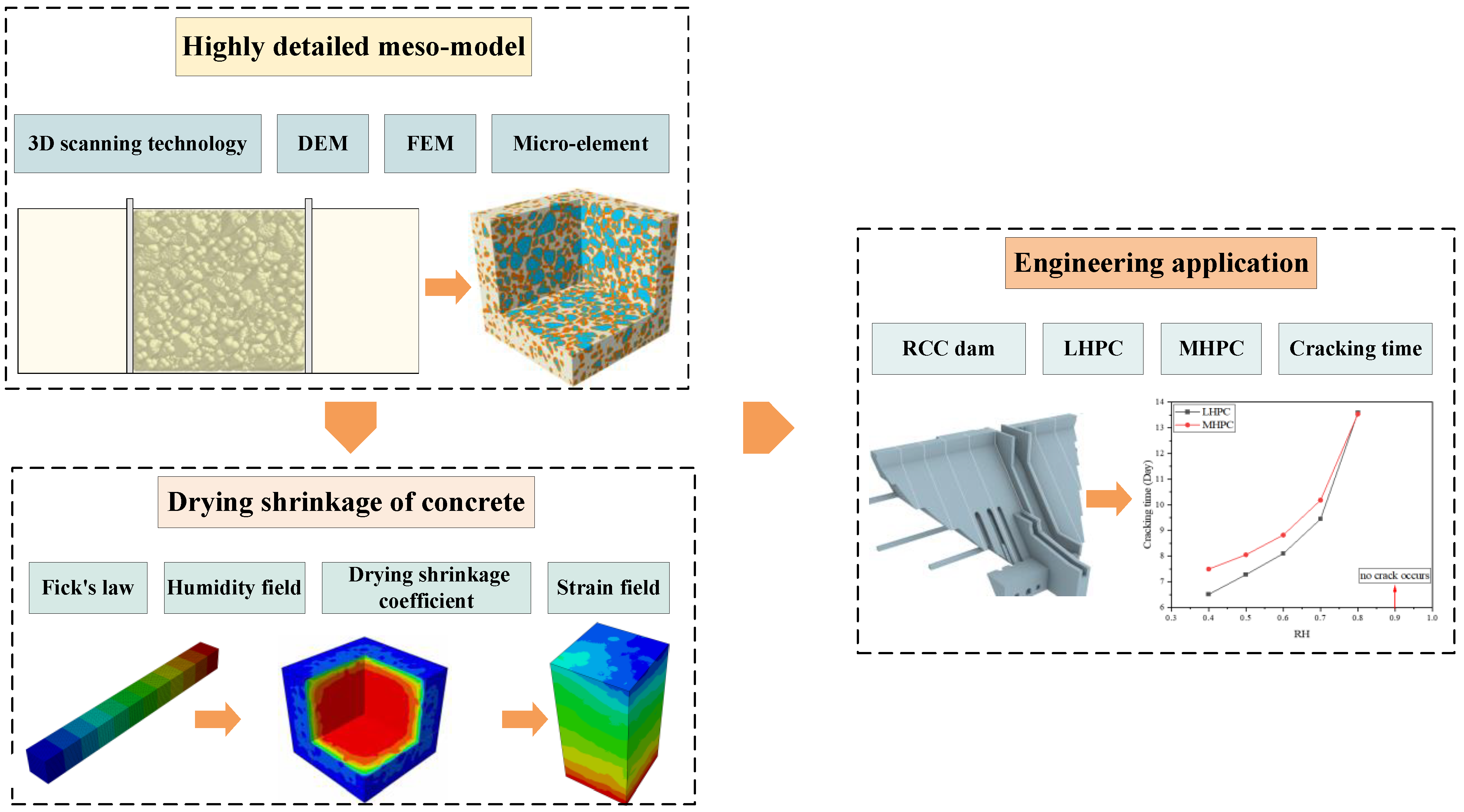

2. Methodology

2.1. Overall Framework

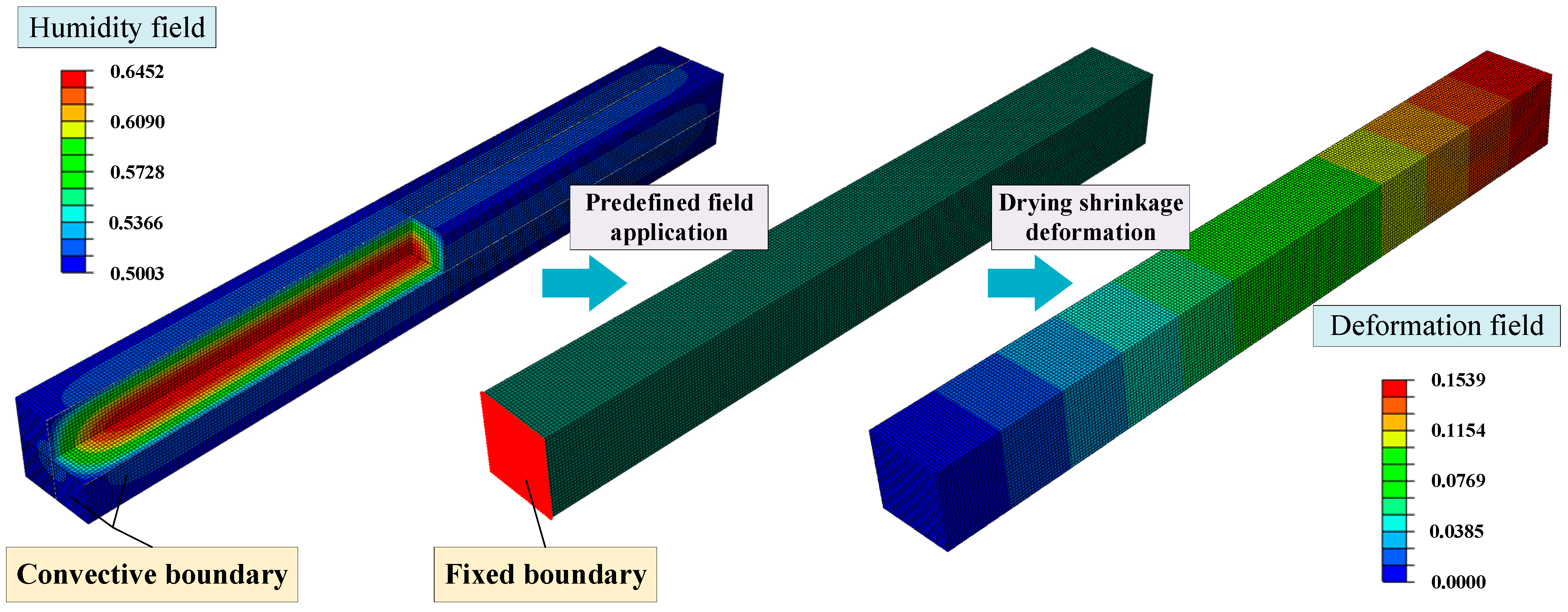

2.2. Humidity Field of the Concrete

2.3. Strain Field of the Concrete

3. Early Drying Shrinkage Performance of Mortar

3.1. Mortar Drying Shrinkage Experiments

3.2. Calibration of Drying Shrinkage Coefficient

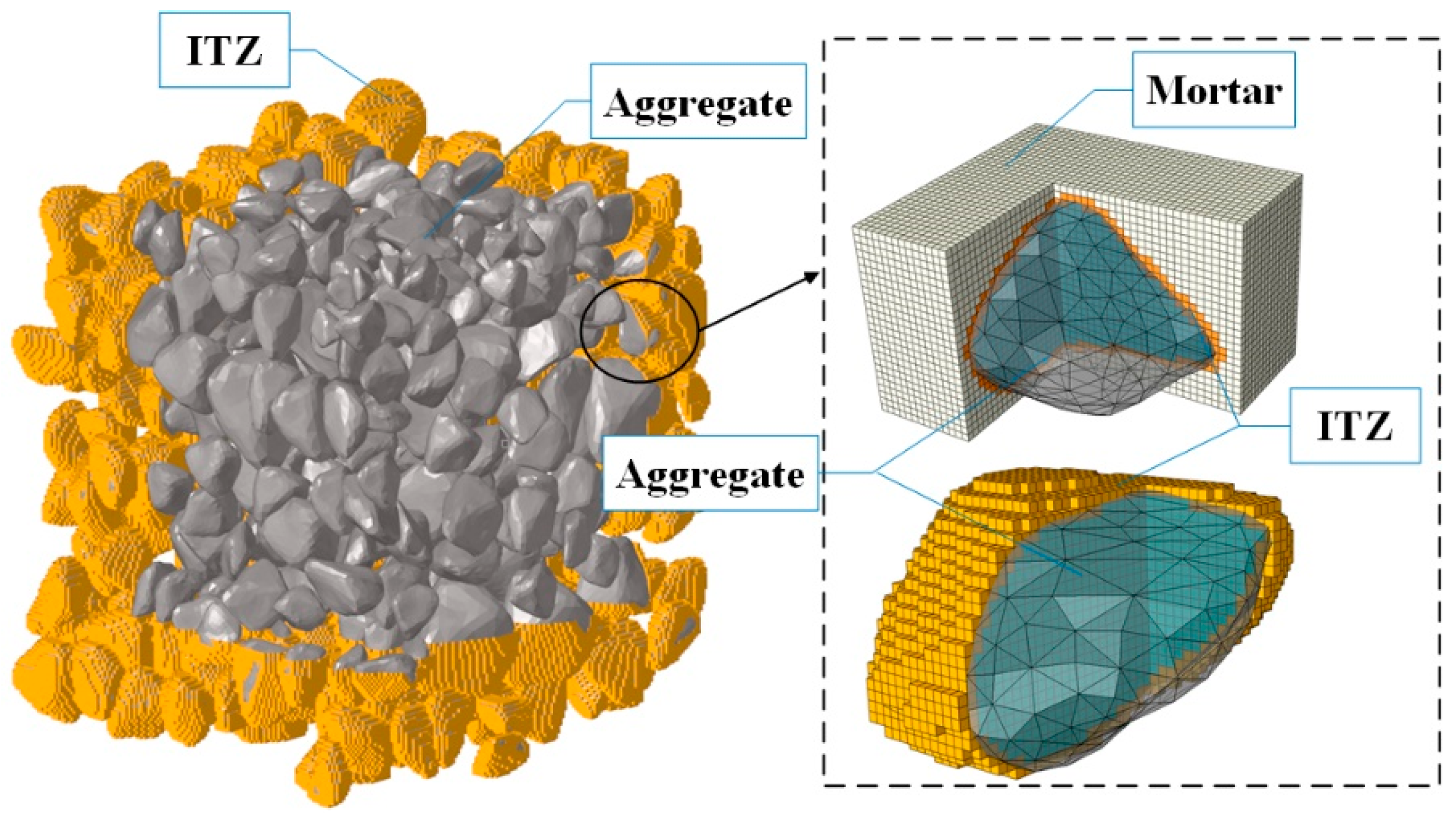

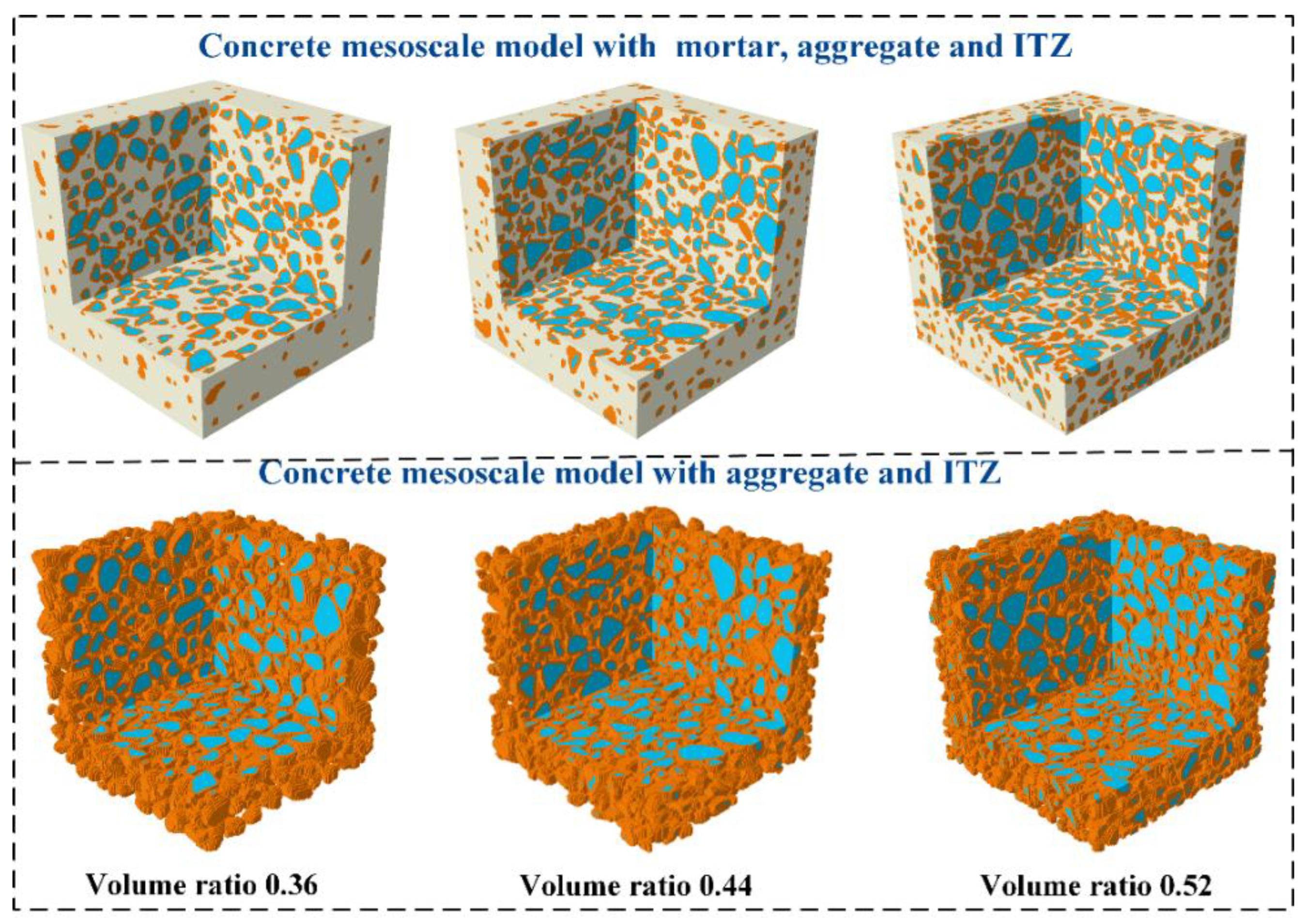

4. Establishment of Highly Detailed Concrete Mesoscale Model

4.1. Generation of Actual Aggregates

4.2. Volume Ratio of the Micro-Element

4.3. Mesoscale Model of Concrete

4.4. Material Properties

5. Concrete Early Drying Shrinkage Characteristics

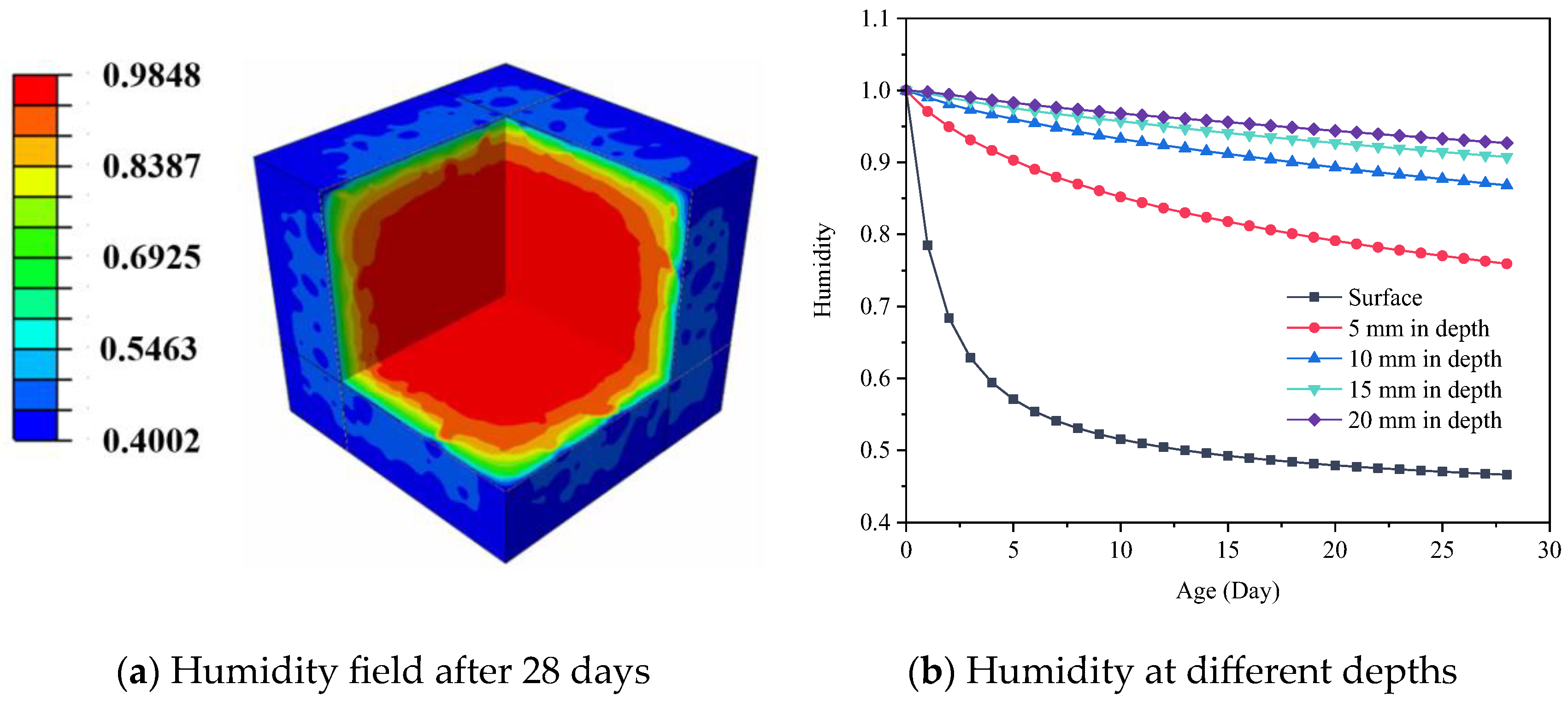

5.1. Concrete Internal Humidity Field

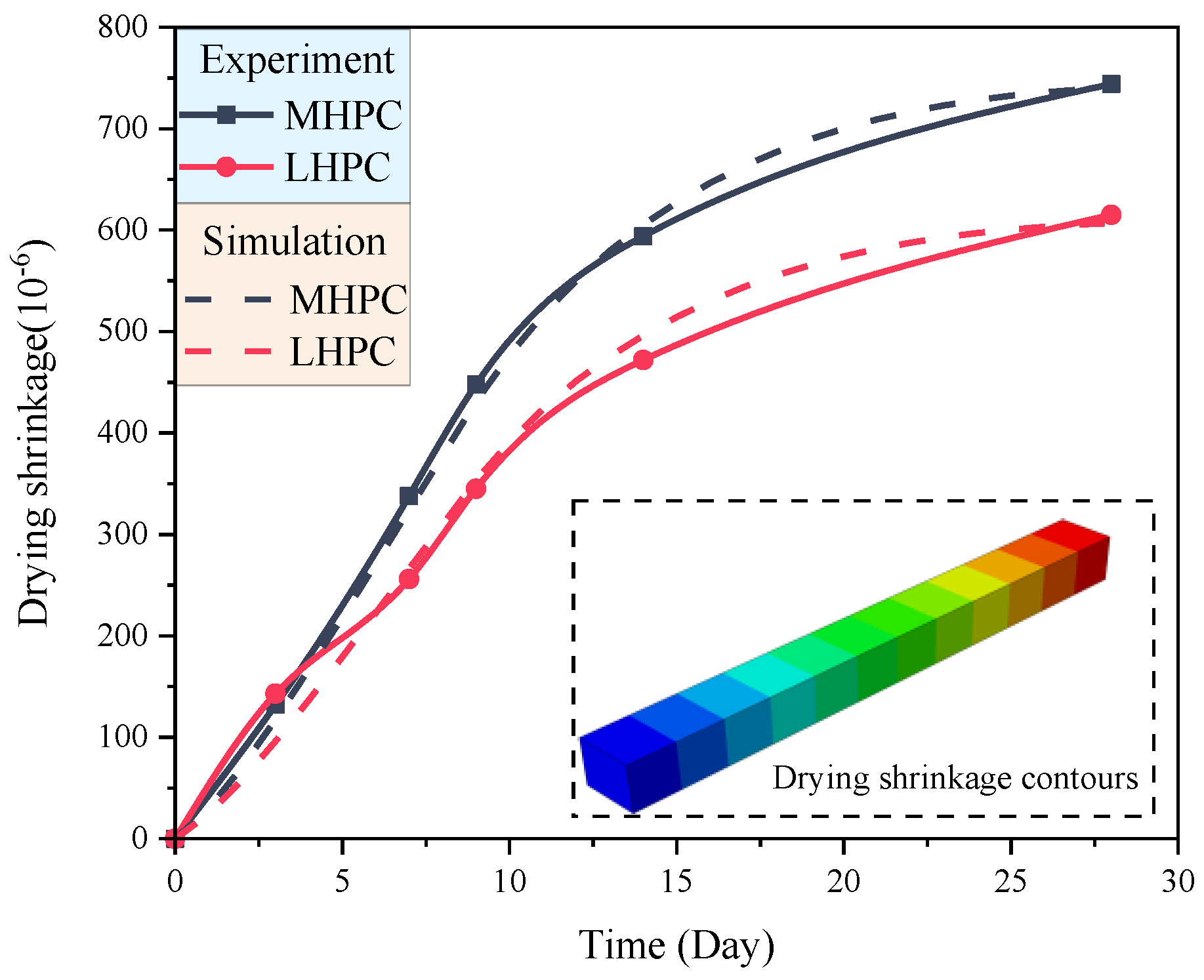

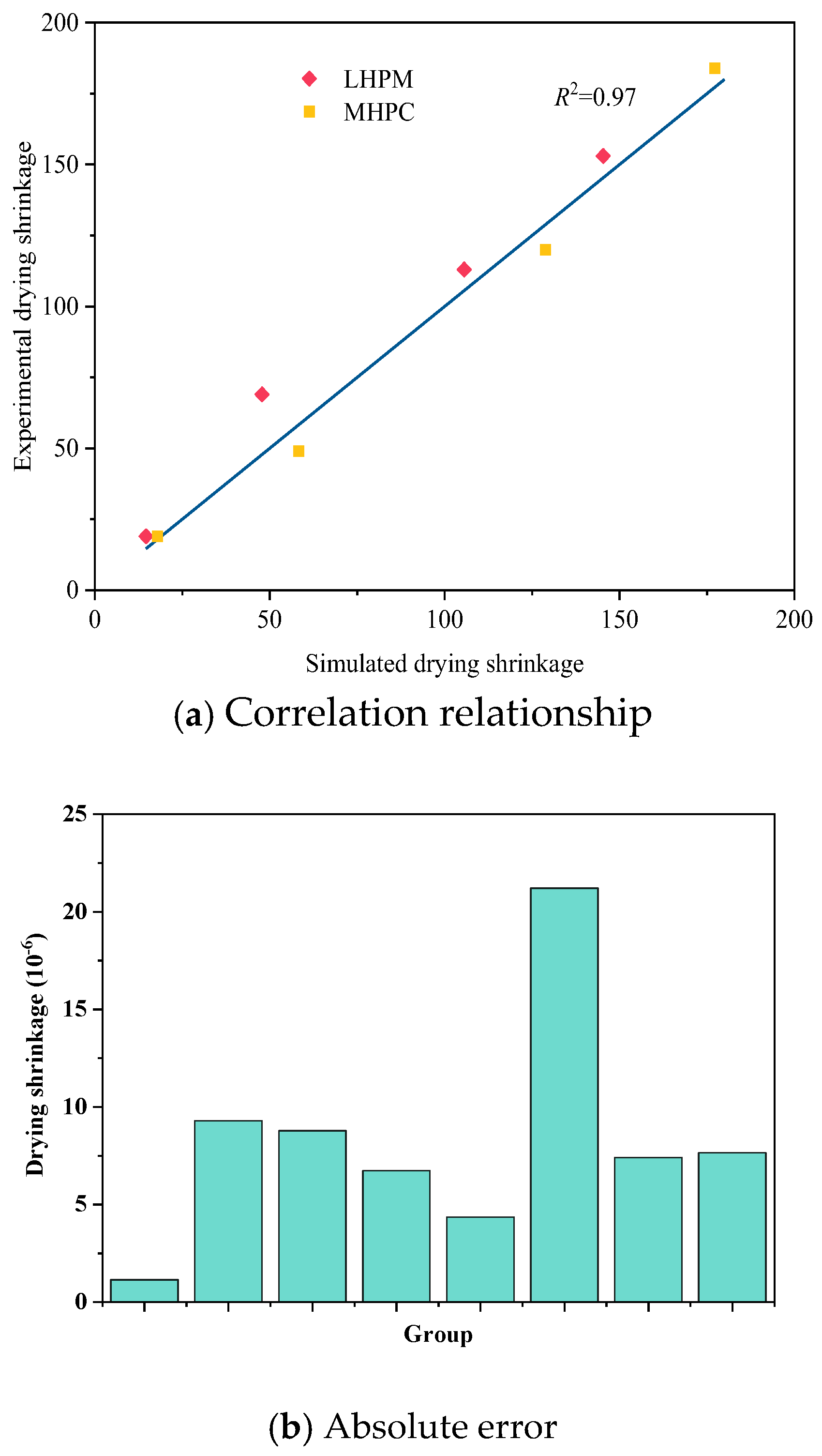

5.2. Verification of Concrete Drying Shrinkage Experiments

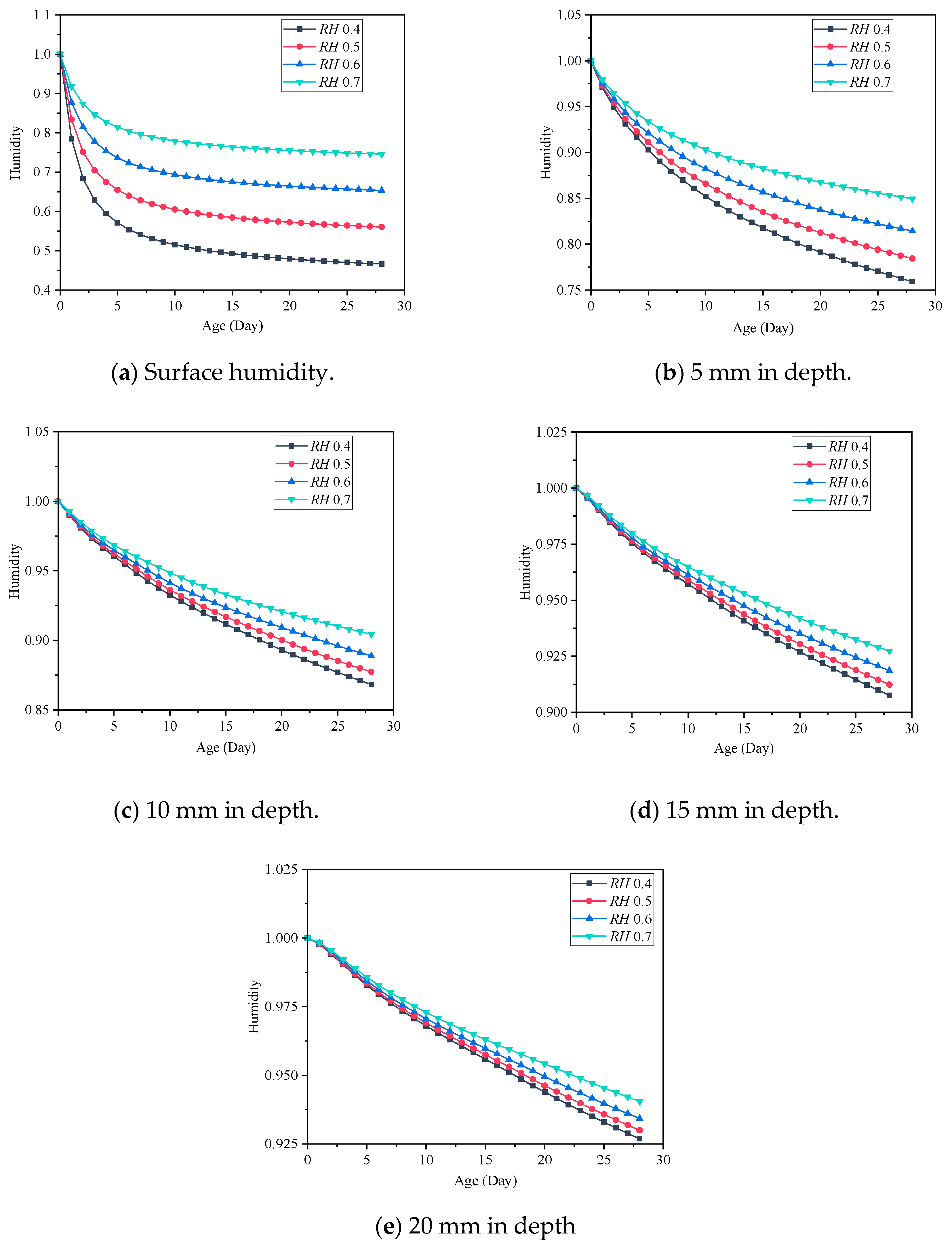

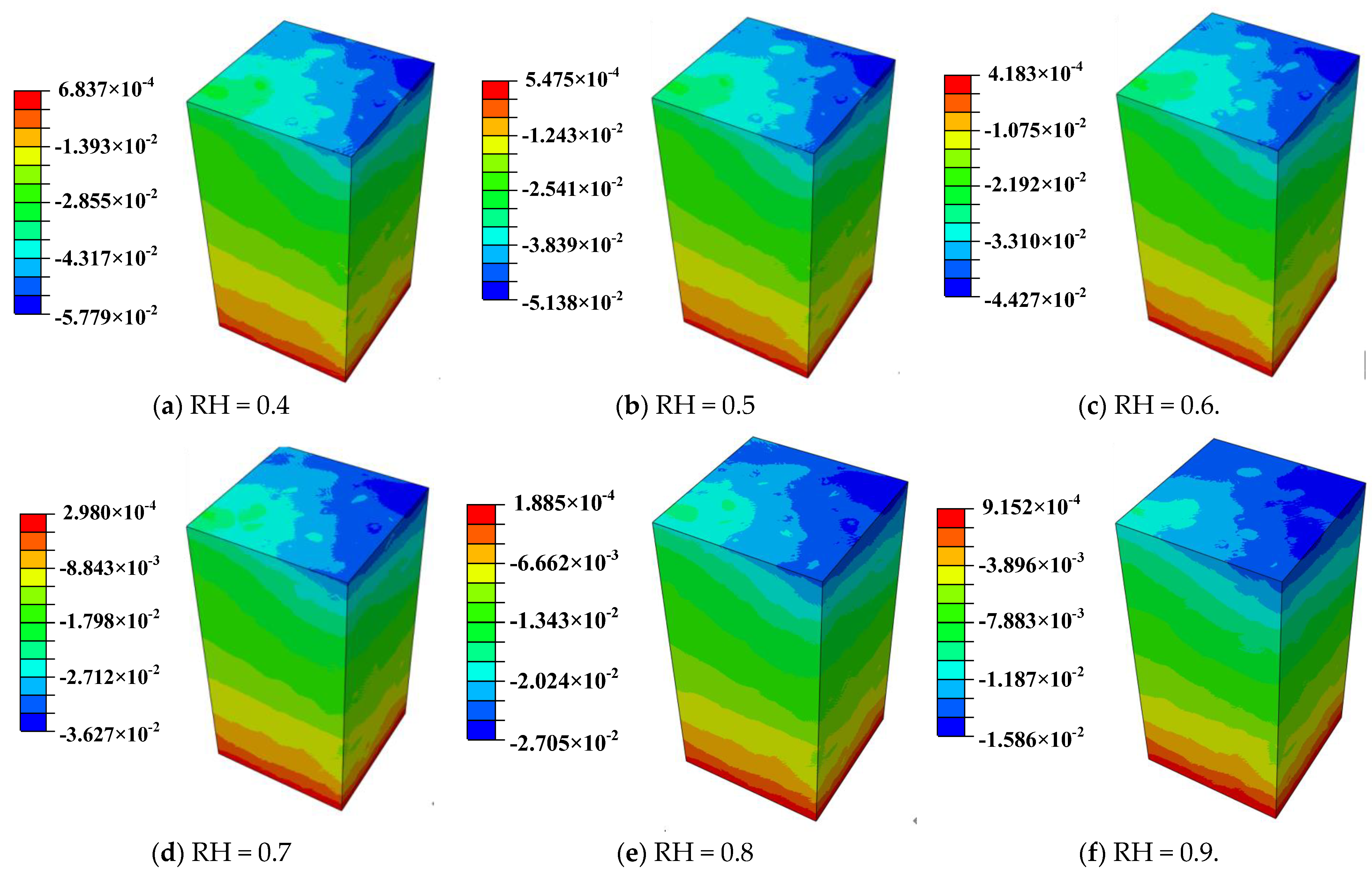

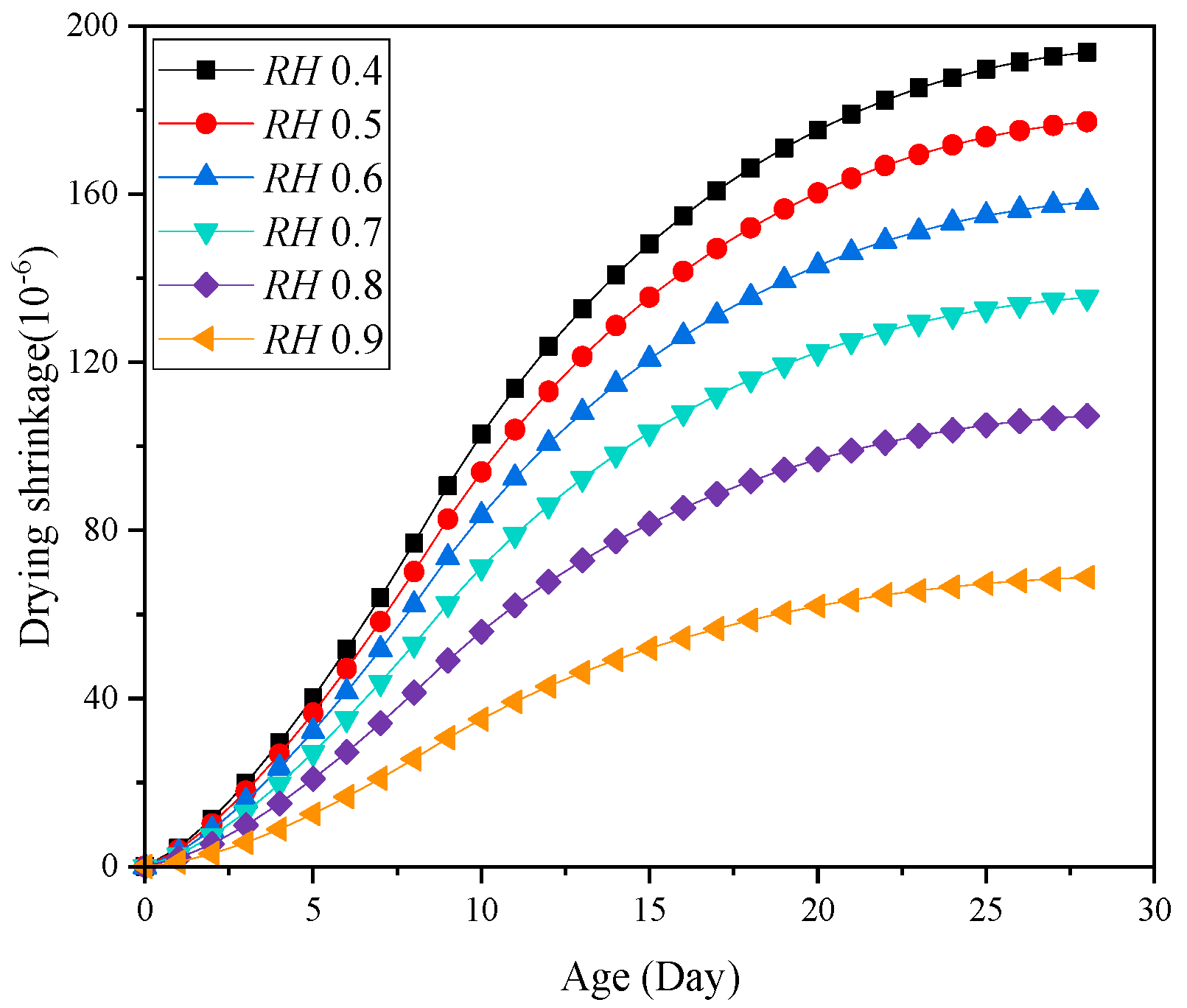

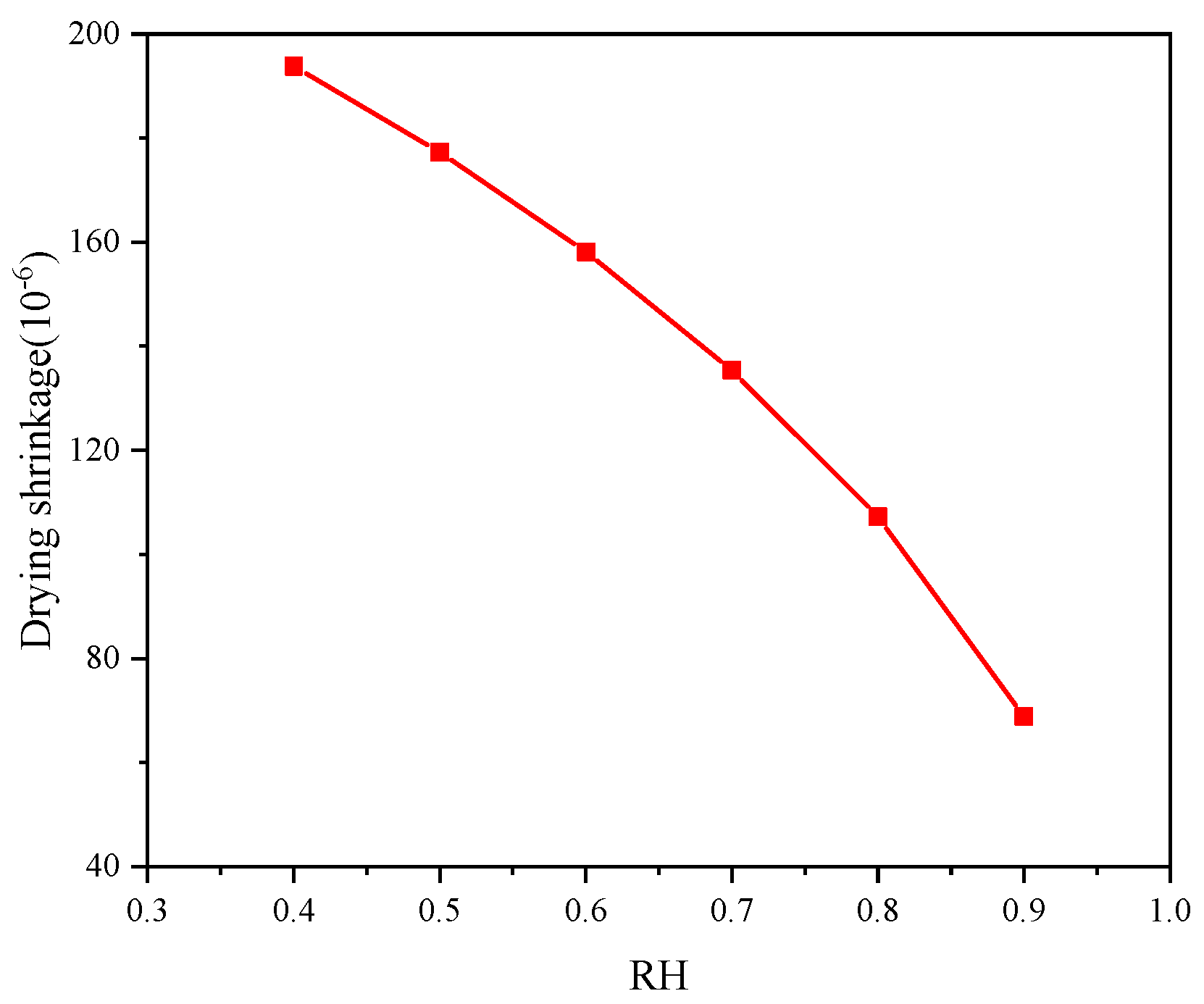

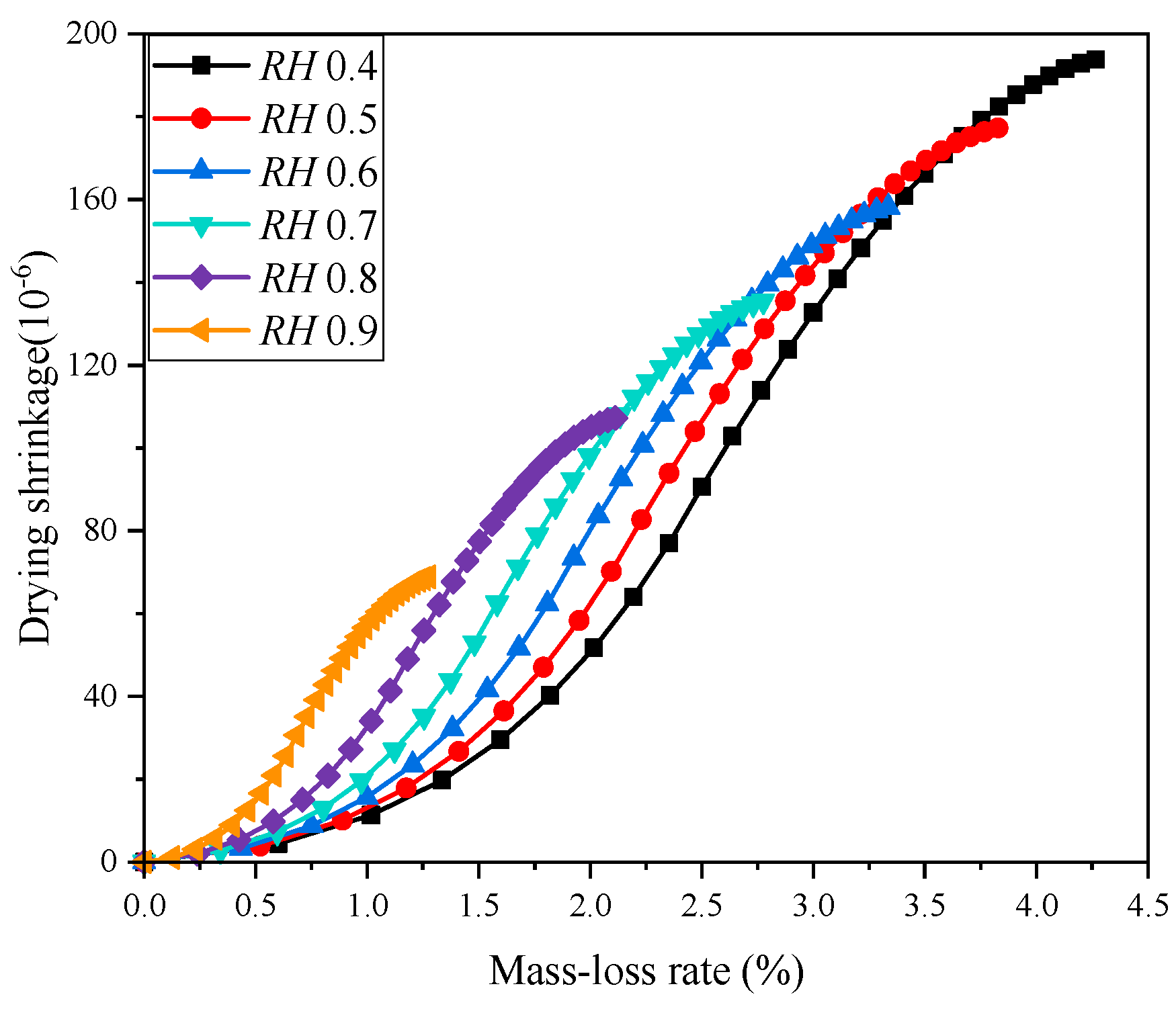

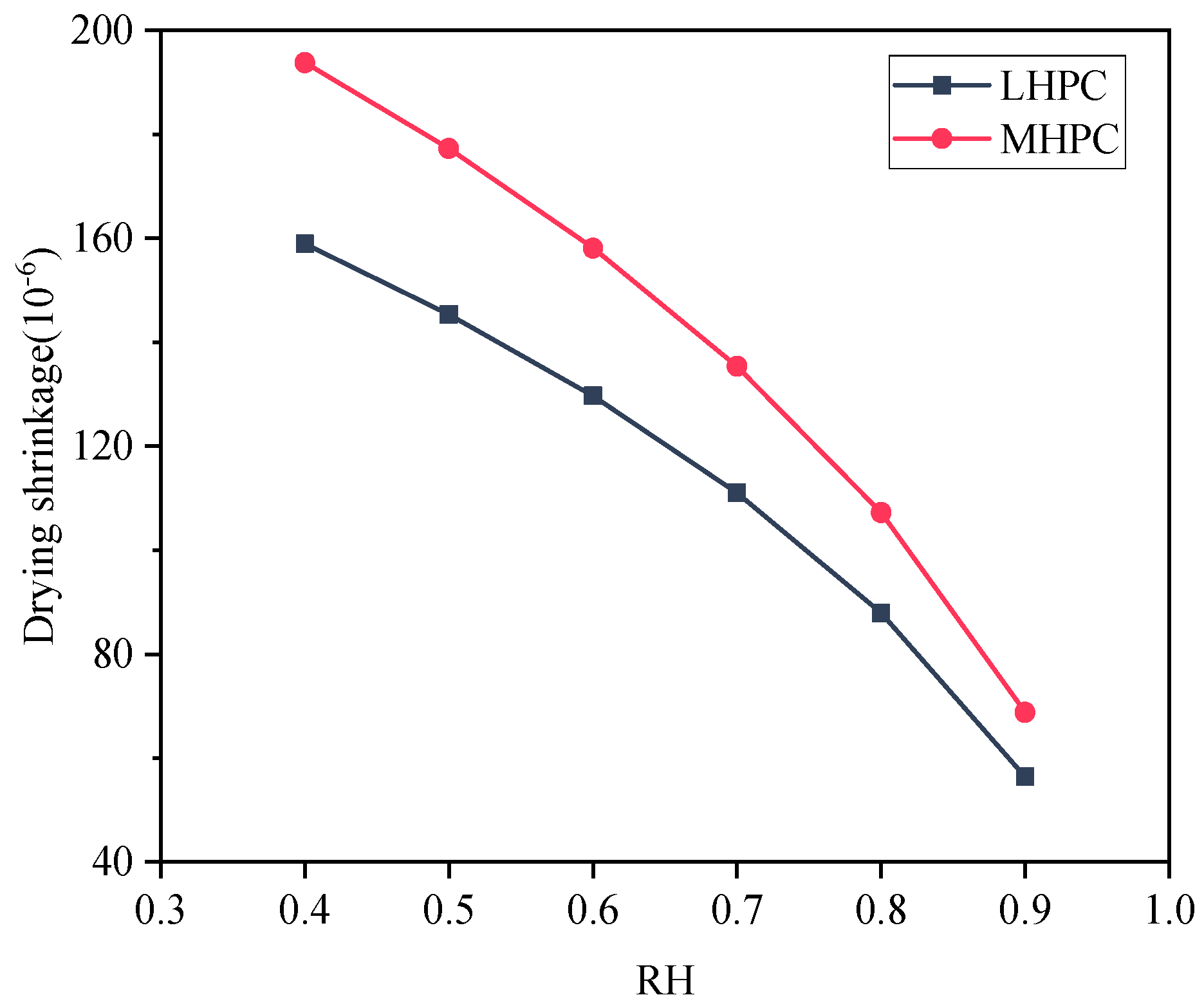

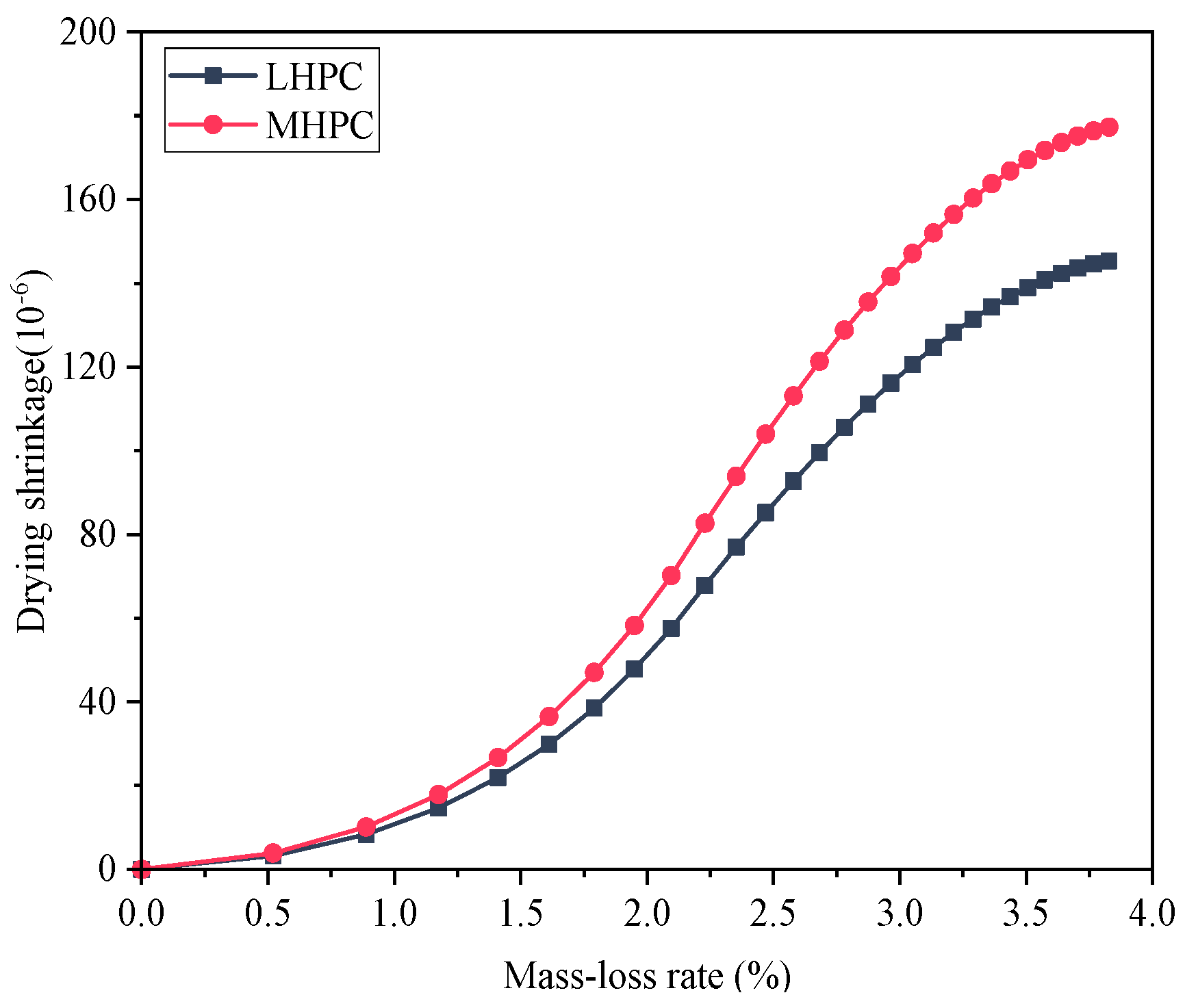

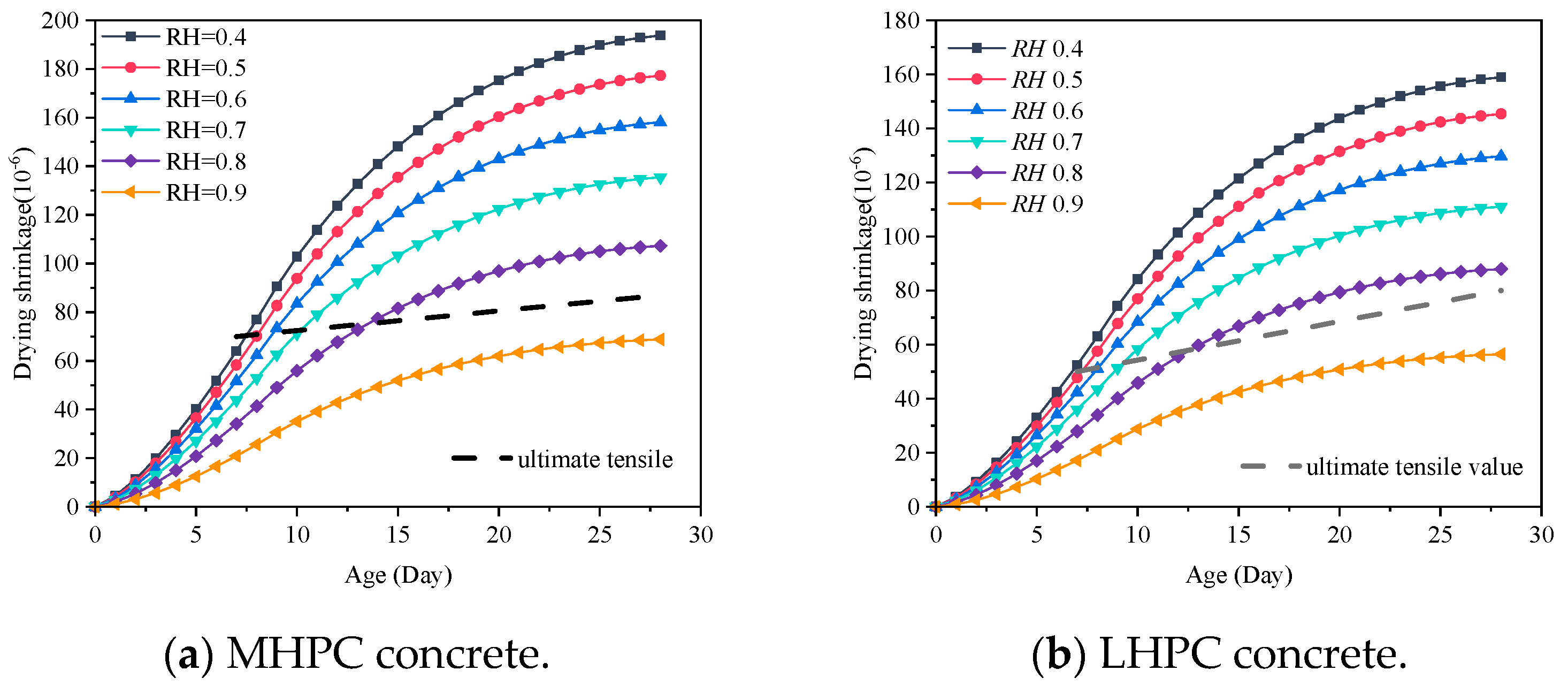

5.3. Influence of the Ambient Humidity on the Concrete Drying Shrinkage

5.4. Influence of the Cement Type on the Concrete Drying Shrinkage

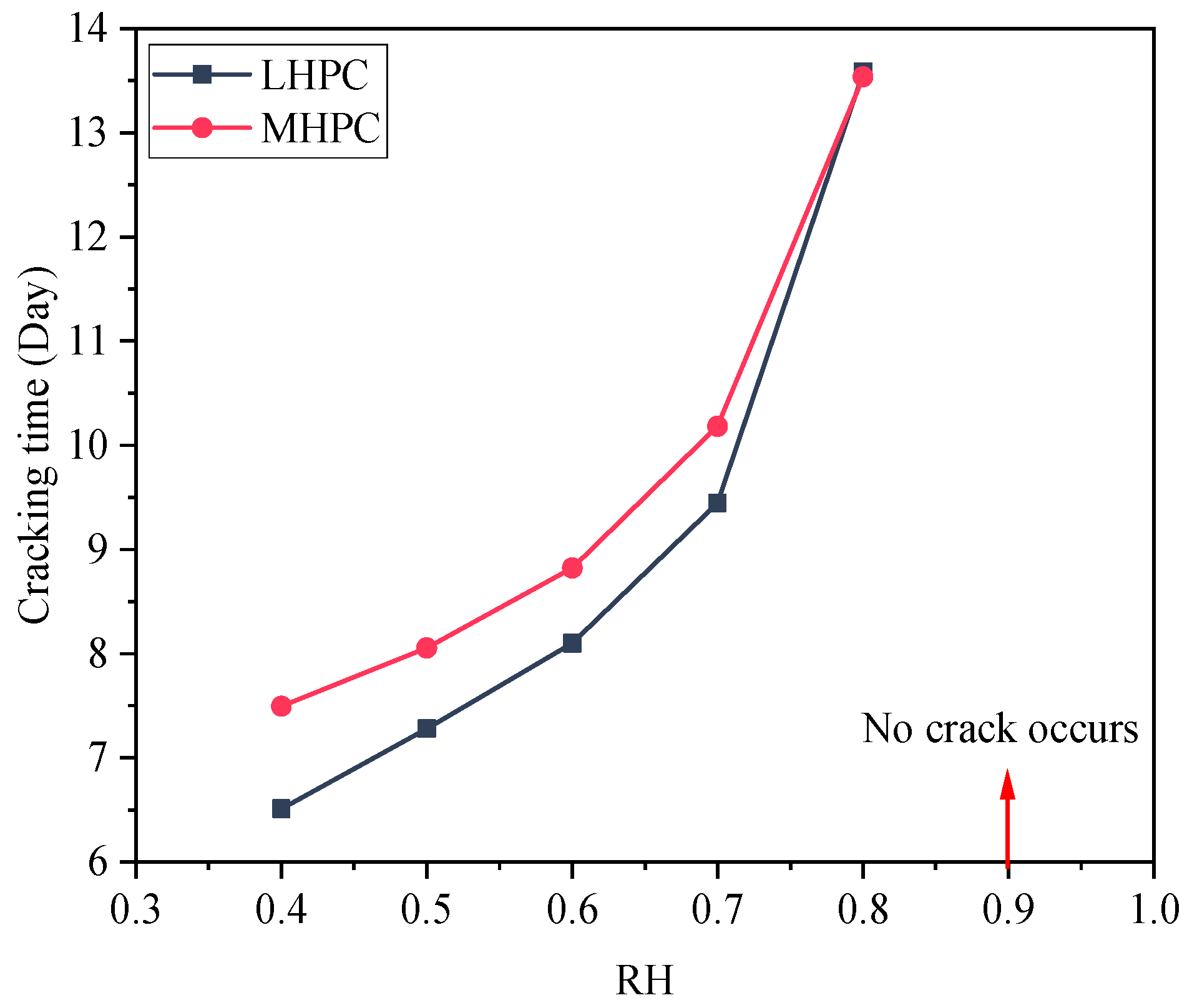

6. Case Study

7. Conclusions

- (1)

- The time-varying models of mortar shrinkage coefficient for the MHPC and LHPC concrete are established, and the relations for mortar shrinkage coefficient are calibrated according to the experiments on the mortar drying shrinkage. It is concluded that the drying shrinkage coefficient of the LHPC mortar is 0.82 times that of the MHPC mortar.

- (2)

- The concrete humidity gradually decreased from the outside surface to the inside, and the surface humidity dropped faster than the internal. The humidity influence range of the concrete specimen is within 15 mm of the surface depth in the early drying shrinkage process.

- (3)

- The early drying shrinkage of the concrete gradually decreases with the increase of ambient humidity or aggregate volume ratio, and the drying shrinkage of the LHPC concrete was apparently lower than that of the MHPC concrete. Therefore, the early drying shrinkage can be controlled by increasing ambient humidity via the LHPC or raising the aggregate volume ratio.

- (4)

- Based on the calculation of the cracking time of the RCC dam gallery in the alpine region, it is found that the LHPC concrete is more sensitive to ambient humidity. When the ambient humidity is 0.9, the MHPC and LHPC concrete exhibit no drying shrinkage crack in the RCC dam gallery.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Nguyen, Q.; Afroz, S.; Zhang, Y.; Kim, T.; Li, W.; Castel, A. Autogenous and total shrinkage of limestone calcined clay cement (LC3) concretes. Constr. Build. Mater. 2022, 314, 125720. [Google Scholar] [CrossRef]

- Shahmirzadi, M.; Gholampour, A.; Kashani, A.; Ngo, T.D. Shrinkage behavior of cementitious 3D printing materials: Effect of temperature and relative humidity. Cem. Concr. Compos. 2021, 124, 104238. [Google Scholar] [CrossRef]

- Azarhomayun, F.; Haji, M.; Kioumarsi, M.; Shekarchia, M. Effect of calcium stearate and aluminum powder on free and restrained drying shrinkage, crack characteristic and mechanical properties of concrete. Cem. Concr. Compos. 2022, 125, 104276. [Google Scholar] [CrossRef]

- Qin, R.; Hao, H.; Rousakis, T.; Lau, D. Effect of shrinkage reducing admixture on new-to-old concrete interface. Compos. Part B Eng. 2019, 167, 346–355. [Google Scholar] [CrossRef]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Silva, R.; De Brito, J.; Dhir, R. Prediction of the shrinkage behavior of recycled aggregate concrete: A review. Constr. Build. Mater. 2015, 77, 327–339. [Google Scholar] [CrossRef]

- Zhang, H.; Wang, Y.; Lehman, D.; Geng, Y.; Kuder, K. Time-dependent drying shrinkage model for concrete with coarse and fine recycled aggregate. Cem. Concr. Compos. 2020, 105, 103426. [Google Scholar] [CrossRef]

- Wang, Q.; Geng, Y.; Wang, Y.; Zhang, H. Drying shrinkage model for recycled aggregate concrete accounting for the influence of parent concrete. Eng. Struct. 2020, 202, 109888. [Google Scholar] [CrossRef]

- Chen, Y.; Wei, J.; Huang, H.; Jin, W.; Yu, Q. Application of 3D-DIC to characterize the effect of aggregate size and volume on non-uniform shrinkage strain distribution in concrete. Cem. Concr. Compos. 2018, 86, 178–189. [Google Scholar] [CrossRef]

- Zhan, P.; He, Z. Application of shrinkage reducing admixture in concrete: A review. Constr. Build. Mater. 2019, 201, 676–690. [Google Scholar] [CrossRef]

- Liu, L.; Fang, Z.; Huang, Z.; Wu, Y. Solving shrinkage problem of ultra-high-performance concrete by a combined use of expansive agent, super absorbent polymer, and shrinkage-reducing agent. Compos. Part B Eng. 2022, 230, 109503. [Google Scholar] [CrossRef]

- Xie, T.; Fang, C.; Ali, M.; Visintin, P. Characterizations of autogenous and drying shrinkage of ultra-high performance concrete (UHPC): An experimental study. Cem. Concr. Compos. 2018, 91, 156–173. [Google Scholar] [CrossRef]

- Wu, Z.; Shi, C.; Khayat, K. Investigation of mechanical properties and shrinkage of ultra-high performance concrete: Influence of steel fiber content and shape. Compos. Part B Eng. 2019, 174, 107021. [Google Scholar] [CrossRef]

- Xia, D.; Song, N.; Li, B.; Zheng, Y.; Guo, W.; Wu, J.; Wang, S. Understanding the synergetic effect of SAP and nano-silica on the mechanical properties, drying shrinkage and microstructures of alkali-activated slag/fly ash-based concrete. Constr. Build. Mater. 2024, 455, 139223. [Google Scholar] [CrossRef]

- Yang, Y.; Yue, X.; Chen, B.; Yang, W.; Guo, W.; Wang, H. Autogenous shrinkage and cracking of ultra-high-performance concrete with soda residue as an internal curing agent. Mater. Struct. 2024, 57, 216. [Google Scholar] [CrossRef]

- Samouh, H.; Rozière, E.; Loukili, A. The differential drying shrinkage effect on the concrete surface damage: Experimental and numerical study. Cem. Concr. Res. 2017, 102, 212–224. [Google Scholar] [CrossRef]

- Samouh, H.; Roziere, E.; Loukili, A. Experimental and numerical study of the relative humidity effect on drying shrinkage and cracking of self-consolidating concrete. Cem. Concr. Res. 2019, 115, 519–529. [Google Scholar] [CrossRef]

- Su, H.; Hu, J.; Li, H. Multi-scale performance simulation and effect analysis for hydraulic concrete submitted to leaching and frost. Eng. Comput. 2018, 34, 821–842. [Google Scholar] [CrossRef]

- Nariman, N.A.; Husek, M.; Ramadan, A.M. Surrogate models for the damage responses of a reinforced concrete beam under explosive charges utilizing coupled finite element–stochastic methods. Eng. Comput. 2022, 39, 285–305. [Google Scholar] [CrossRef]

- Deng, Y.; Shi, X.; Zhang, Y.; Chen, J. Numerical modelling of rutting performance of asphalt concrete pavement containing phase change material. Eng. Comput. 2021, 39, 1167–1182. [Google Scholar] [CrossRef]

- Idiart, A.; Bisschop, J.; Caballero, A.; Lura, P. A numerical and experimental study of aggregate-induced shrinkage cracking in cementitious composites. Cem. Concr. Res. 2012, 42, 272–281. [Google Scholar] [CrossRef]

- Havlásek, P.; Jirásek, M. Multiscale modeling of drying shrinkage and creep of concrete. Cem. Concr. Res. 2016, 85, 55–74. [Google Scholar] [CrossRef]

- Tang, S.; Wang, S.; Ma, T.; Tang, C.; Bao, C.; Huang, X.; Zhang, H. Numerical study of shrinkage cracking in concrete and concrete repair systems. Int. J. Fract. 2016, 199, 229–244. [Google Scholar] [CrossRef]

- Bolander, J.; Berton, S. Simulation of shrinkage induced cracking in cement composite overlays. Cem. Concr. Compos. 2004, 26, 861–871. [Google Scholar] [CrossRef]

- Ožbolt, J.; Balabanić, G.; Periškić, G.; Kušter, M. Modelling the effect of damage on transport processes in concrete. Constr. Build. Mater. 2010, 24, 1638–1648. [Google Scholar] [CrossRef]

- Ožbolt, J.; Balabanić, G.; Kušter, M. 3D Numerical modelling of steel corrosion in concrete structures. Corros. Sci. 2011, 53, 4166–4177. [Google Scholar] [CrossRef]

- Ožbolt, J.; Oršanić, F.; Balabanić, G.; Kušter, M. Modeling damage in concrete caused by corrosion of reinforcement: Coupled 3D FE model. Int. J. Fract. 2012, 178, 233–244. [Google Scholar] [CrossRef]

- Ožbolt, J.; Oršanić, F.; Balabanić, G. Modeling influence of hysteretic moisture behavior on distribution of chlorides in concrete. Cem. Concr. Compos. 2016, 67, 73–84. [Google Scholar] [CrossRef]

- Abdelatif, A.O.; Ožbolt, J.; Gambarelli, S. 3D finite element modelling of corrosion of lap splice joints in concrete. Constr. Build. Mater. 2018, 169, 124–131. [Google Scholar] [CrossRef]

- Ožbolt, J.; Gambarelli, S.; Zadran, S. Coupled hygro-mechanical meso-scale analysis of long-term creep and shrinkage of concrete cylinder. Eng. Struct. 2022, 262, 114332. [Google Scholar] [CrossRef]

- Li, W.; Zhao, Y.; Zhang, Y.; Xie, Z.; Zhang, J.; Huang, F.; Meng, L.; He, Z.; Xia, J.; Zhang, Y.; et al. Optimized mix design method of ultrahigh performance concrete (UHPC) and effect of high steel fiber content: Mechanical performance and shrinkage properties. J. Build. Eng. 2024, 97, 110746. [Google Scholar] [CrossRef]

- Jin, L.; Liu, M.; Zhang, R.; Du, X. 3D meso-scale modelling of the interface behavior between ribbed steel bar and concrete. Eng. Fract. Mech. 2020, 239, 107291. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, M.; Dong, B.; Ma, H. Quantitative evaluation of steel corrosion induced deterioration in rubber concrete by integrating ultrasonic testing, machine learning and mesoscale simulation. Cem. Concr. Compos. 2022, 128, 104426. [Google Scholar] [CrossRef]

- Stamati, O.; Roubin, E.; Andò, E.; Malecot, Y. Phase segmentation of concrete X-ray tomographic images at meso-scale: Validation with neutron tomography. Cem. Concr. Compos. 2018, 88, 8–16. [Google Scholar] [CrossRef]

- Huang, Y.; Yan, D.; Yang, Z.; Liu, G. 2D and 3D homogenization and fracture analysis of concrete based on in-situ X-ray Computed Tomography images and Monte Carlo simulations. Eng. Fract. Mech. 2016, 163, 37–54. [Google Scholar] [CrossRef]

- Huang, Y.; Yang, Z.; Ren, W.; Liu, G.; Zhang, C. 3D meso-scale fracture modelling and validation of concrete based on in-situ X-ray Computed Tomography images using damage plasticity model. Int. J. Solids Struct. 2015, 67–68, 340–352. [Google Scholar] [CrossRef]

- Li, Y.; Ruan, X.; Akiyama, M.; Zhang, M.; Xin, J.; Lim, S. Modelling method of fibre distribution in steel fibre reinforced concrete based on X-ray image recognition. Compos. Part B Eng. 2021, 223, 109124. [Google Scholar] [CrossRef]

- Thilakarathna, P.; Baduge, K.; Melndis, P.; Vimonsatit, V.; Lee, H. Mesoscale modelling of concrete—A review of geometry generation, placing algorithms, constitutive relations and applications. Eng. Fract. Mech. 2020, 231, 06974. [Google Scholar] [CrossRef]

- Peng, R.; Qiu, W.; Teng, F. Three-dimensional meso-numerical simulation of heterogeneous concrete under freeze-thaw. Constr. Build. Mater. 2020, 250, 118573. [Google Scholar] [CrossRef]

- Zhang, H.; Sheng, P.; Zhang, J.; Ji, Z. Realistic 3D modeling of concrete composites with randomly distributed aggregates by using aggregate expansion method. Constr. Build. Mater. 2019, 225, 927–940. [Google Scholar] [CrossRef]

- Guo, J.; Zhang, J.; Yu, H.; Ma, H.; Wu, Z. Experimental and 3D mesoscopic investigation of uniaxial compression performance on basic magnesium sulfate cement-coral aggregate concrete (BMSC-CAC). Compos. Part B Eng. 2022, 236, 109760. [Google Scholar] [CrossRef]

- Xiong, X.; Xiao, Q. Meso-scale simulation of bond behaviour between retarded-bonded tendons and concrete. Eng. Struct. 2021, 228, 111410. [Google Scholar] [CrossRef]

- Yu, Y.; Zheng, Y.; Zhao, X. Mesoscale modeling of recycled aggregate concrete under uniaxial compression and tension using discrete element method. Constr. Build. Mater. 2021, 268, 121116. [Google Scholar] [CrossRef]

- Wang, P.; Gao, N.; Ji, K.; Stewart, L.; Arson, C. DEM analysis on the role of aggregates on concrete strength. Comput. Geotech. 2020, 119, 103290. [Google Scholar] [CrossRef]

- Fu, Q.; Bu, M.; Zhang, Z.; Xu, W.; Yuan, Q.; Niu, D. Hydration characteristics and microstructure of alkali-activated slag concrete: A review. Engineering 2023, 20, 162–179. [Google Scholar] [CrossRef]

- Wang, L.; Yang, H.; Zhou, S.; Chen, E.; Tang, S. Mechanical properties, long-term hydration heat, shinkage behavior and crack resistance of dam concrete designed with low heat Portland (LHP) cement and fly ash. Constr. Build. Mater. 2018, 187, 1073–1091. [Google Scholar] [CrossRef]

- Kim, J.K.; Lee, C.S. Moisture diffusion of concrete considering self-desiccation at early ages. Cem. Concr. Res. 1999, 29, 1921–1927. [Google Scholar] [CrossRef]

- Huang, H.; Garcia, R.; Huang, S.S.; Guadagnini, M.; Pilakoutas, K. A practical creep model for concrete elements under eccentric compression. Mater. Struct. 2019, 52, 119. [Google Scholar] [CrossRef]

- Jiang, Z.; Sun, Z.; Wang, P. Internal relative humidity distribution in high-performance cement paste due to moisture diffusion and self-desiccation. Cem. Concr. Res. 2006, 36, 320–325. [Google Scholar] [CrossRef]

- Wang, Y. Study on long-term behavior of long span concrete arch bridge with stiffed concrete filled steel tube in natural environment. Southwest Jiaotong Univ. 2017. (In Chinese) [Google Scholar]

- Zhao, L.; Wang, P.; Wang, L.; Zhao, T.; Guang, W. Analysis of parameters for temperature and humidity response in concrete: Moisture diffusion coefficient and thermal conductivity. Mater. Rev. 2021, 35, 12075–12080. (In Chinese) [Google Scholar]

- Li, S.; Li, Q. Two dimensional analysis of drying shrinkage micro-cracking in concrete with modified smeared cracking model. Eng. Mech. 2011, 28, 65–71. (In Chinese) [Google Scholar]

- Jin, H.; Zhou, Y. Study of three-dimensional concrete shrinkage crack behavior using a mesoscale concrete model with actual geometry and random aggregate. Sci. Sin. (Technol.) 2022, 52, 1233–1244. (In Chinese) [Google Scholar] [CrossRef]

- JC/T 603-2004; Standard Test Method for Drying Shrinkage of Motar. National Development and Reform Commission: Beijing, China, 2004. (In Chinese)

- ASTM C1698-19; Standard Test Method for Autogenous Strain of Cement Paste and Mortar. American Society of Testing Materials (ASTM): West Conshohocken, PA, USA, 2019.

- Yang, Z.; Ren, W.; Sharma, R.; McDonald, S.; Mostafavi, M.; Vertyagina, Y.; Marrow, T.J. In-situ X-ray computed tomography characterisation of 3D fracture evolution and image-based numerical homogenisation of concrete. Cem. Concr. Compos. 2017, 75, 74–83. [Google Scholar] [CrossRef]

- Jin, L.; Yu, W.; Du, X.; Yang, W. Mesoscopic numerical simulation of dynamic size effect on the splitting-tensile strength of concrete. Eng. Fract. Mech. 2019, 209, 317–332. [Google Scholar] [CrossRef]

- Naderi, S.; Zhang, M. Meso-scale modelling of static and dynamic tensile fracture of concrete accounting for real-shape aggregates. Cem. Concr. Compos. 2021, 116, 103889. [Google Scholar] [CrossRef]

- Li, M.; Zhang, M. Primary investigation of isogeometric analysis for hydraulic structures numerical simulation. J. Hydraul. Eng. 2018, 49, 291–302+312. (In Chinese) [Google Scholar]

- Zhang, M.; Li, M.; Shen, Y.; Zhang, J. Isogeometric shape optimization of high RCC gravity dams with functionally graded partition structure considering hydraulic fracturing. Eng. Struct. 2019, 179, 341–352. [Google Scholar] [CrossRef]

- Maleki, M.; Rasoolan, I.; Khajehdezfuly, A.; Jivkov, A.P. On the effect of ITZ thickness in meso-scale models of concrete. Constr. Build. Mater. 2020, 258, 119639. [Google Scholar] [CrossRef]

- Chen, H.; Xu, B.; Wang, J.; Zhou, T.; Nie, X.; Mo, Y. Parametric analysis on compressive strain rate effect of concrete using mesoscale modeling approach. Constr. Build. Mater. 2020, 246, 118375. [Google Scholar] [CrossRef]

- Jin, L.; Jiang, X.; Xia, H.; Chen, F.; Du, X. Size effect in shear failure of lightweight concrete beams wrapped with CFRP without stirrups: Influence of fiber ratio. Compos. Part B Eng. 2020, 199, 108257. [Google Scholar] [CrossRef]

- Li, M.; Min, Q.; Zhang, M.; Liu, D.; Shen, Y.; Feng, D. Mechanical experiments and precise simulation of a novel functional material: Electrically conductive roller-compacted concrete. Sci. Sin. (Technol.) 2022, 52, 1245–1258. (In Chinese) [Google Scholar] [CrossRef]

- Wang, J.; Li, H.; Ma, C.; Cai, C.; Wang, J. Effect of surface curing condition on the humidity field and moisture transfer in concrete. Constr. Build. Mater. 2024, 411, 134701. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.H.; Han, Y.D. Simulation of moisture field of concrete with pre-soaked lightweight aggregate addition. Constr. Build. Mater. 2015, 96, 599–614. [Google Scholar] [CrossRef]

- Wang, L.; Yang, H.Q.; Dong, Y.; Chen, E.; Tang, S.W. Environmental evaluation, hydration, pore structure, volume deformation and abrasion resistance of low heat Portland (LHP) cement-based materials. J. Clean. Prod. 2018, 203, 540–558. [Google Scholar] [CrossRef]

| Cement Type | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | SO3 | R2O * | Loss on Ignition |

|---|---|---|---|---|---|---|---|---|

| MHPC | 60.3 | 21.7 | 4.3 | 4.8 | 4.9 | 1.9 | 0.4 | 0.9 |

| LHPC | 58.7 | 22.8 | 4.3 | 4.3 | 4.2 | 3.0 | 0.3 | 1.6 |

| Cement Type | 0 Day | 3 Days | 7 Days | 9 Days | 14 Days | 28 Days |

|---|---|---|---|---|---|---|

| MHPC | 0 | 0.0132 | 0.0338 | 0.0448 | 0.0594 | 0.0744 |

| LHPC | 0 | 0.0143 | 0.0256 | 0.0345 | 0.0472 | 0.0615 |

| Parameters | Elastic Modulus (GPa) | Poisson’s Ratio | D | |||

|---|---|---|---|---|---|---|

| E7d | E28d | |||||

| MHPC | Motar | 18.90 | 31.60 | 0.22 | Equation (5) | Equation (8) |

| ITZ | 15.12 | 25.28 | 0.20 | 10 Equation (5) | 2.28 Equation (8) | |

| Aggregate | 50 | 0.20 | 0 | |||

| LHPC | Motar | 20.30 | 27.80 | 0.22 | Equation (5) | Equation (9) |

| ITZ | 16.24 | 22.24 | 0.20 | 10 Equation (5) | 2.28 Equation (9) | |

| Aggregate | 50 | 0.20 | 0 | |||

| Cement Type | Ultimate Tensile Value (10−6) | |

|---|---|---|

| 7 Days | 28 Days | |

| MHPC | 70 | 87 |

| LHPC | 50 | 80 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, M.; Lu, C.; Min, Q.; Wang, X.; He, Y.; Deng, G.; Wang, Y. Evaluation of Concrete Structural Cracking Behavior Induced by Early Drying Shrinkage. Materials 2025, 18, 395. https://doi.org/10.3390/ma18020395

Zhang M, Lu C, Min Q, Wang X, He Y, Deng G, Wang Y. Evaluation of Concrete Structural Cracking Behavior Induced by Early Drying Shrinkage. Materials. 2025; 18(2):395. https://doi.org/10.3390/ma18020395

Chicago/Turabian StyleZhang, Mengxi, Chuntian Lu, Qiaolin Min, Xinyue Wang, Yinpeng He, Genhua Deng, and Yixin Wang. 2025. "Evaluation of Concrete Structural Cracking Behavior Induced by Early Drying Shrinkage" Materials 18, no. 2: 395. https://doi.org/10.3390/ma18020395

APA StyleZhang, M., Lu, C., Min, Q., Wang, X., He, Y., Deng, G., & Wang, Y. (2025). Evaluation of Concrete Structural Cracking Behavior Induced by Early Drying Shrinkage. Materials, 18(2), 395. https://doi.org/10.3390/ma18020395