Microstructure and Thermal Cyclic Behavior of FeNiCoAlTaB High-Entropy Alloy

Abstract

1. Introduction

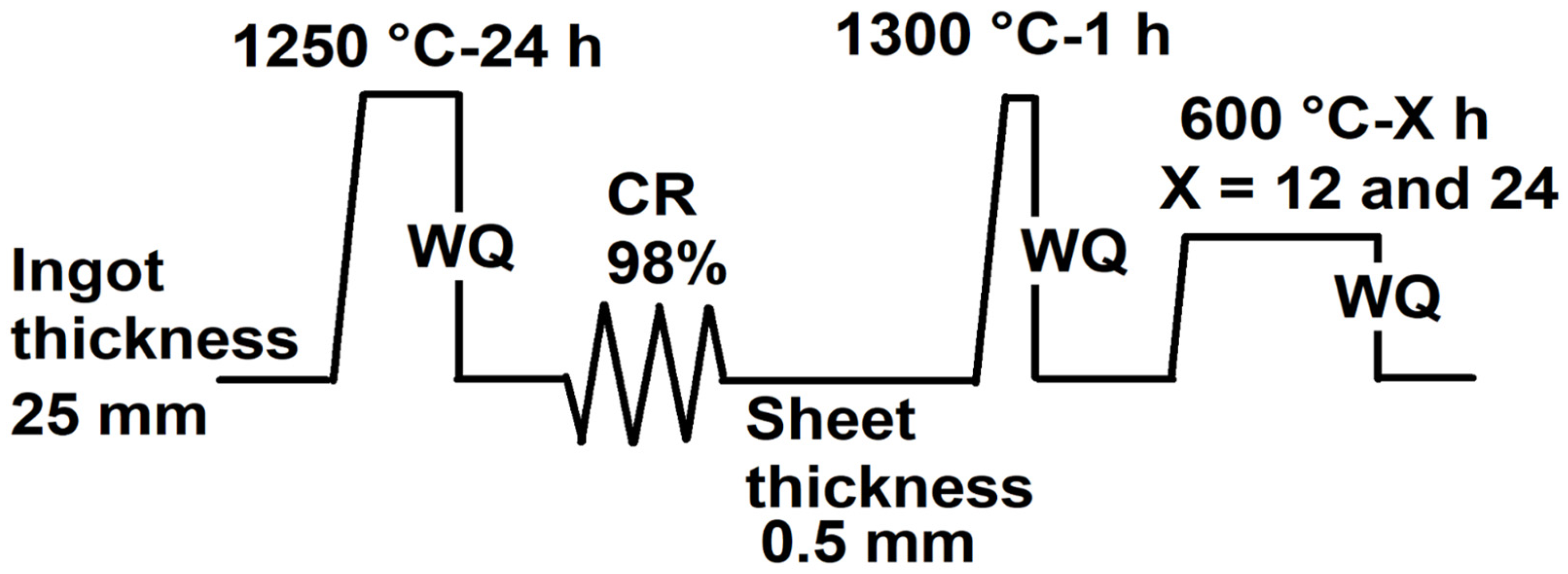

2. Materials and Methods

3. Results and Discussion

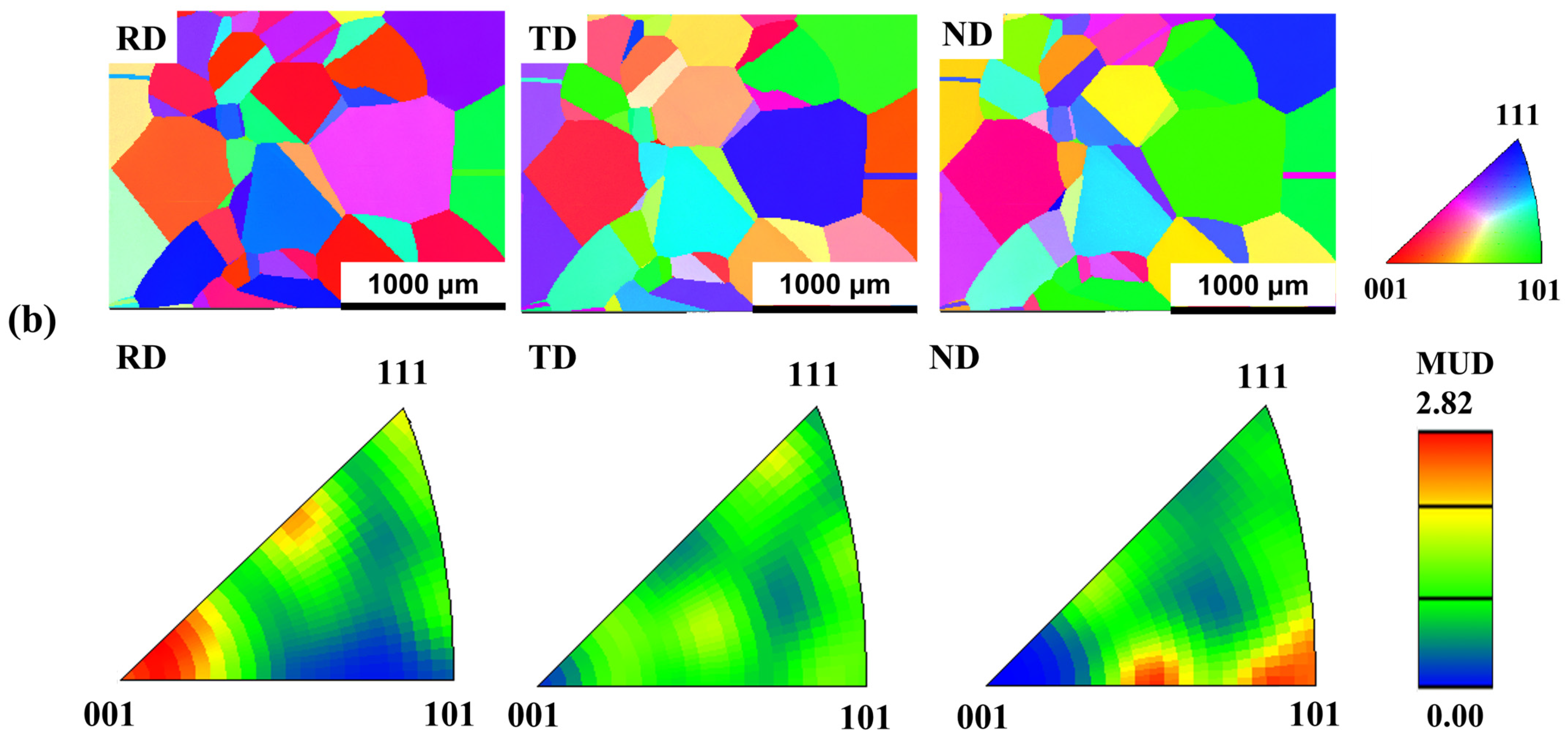

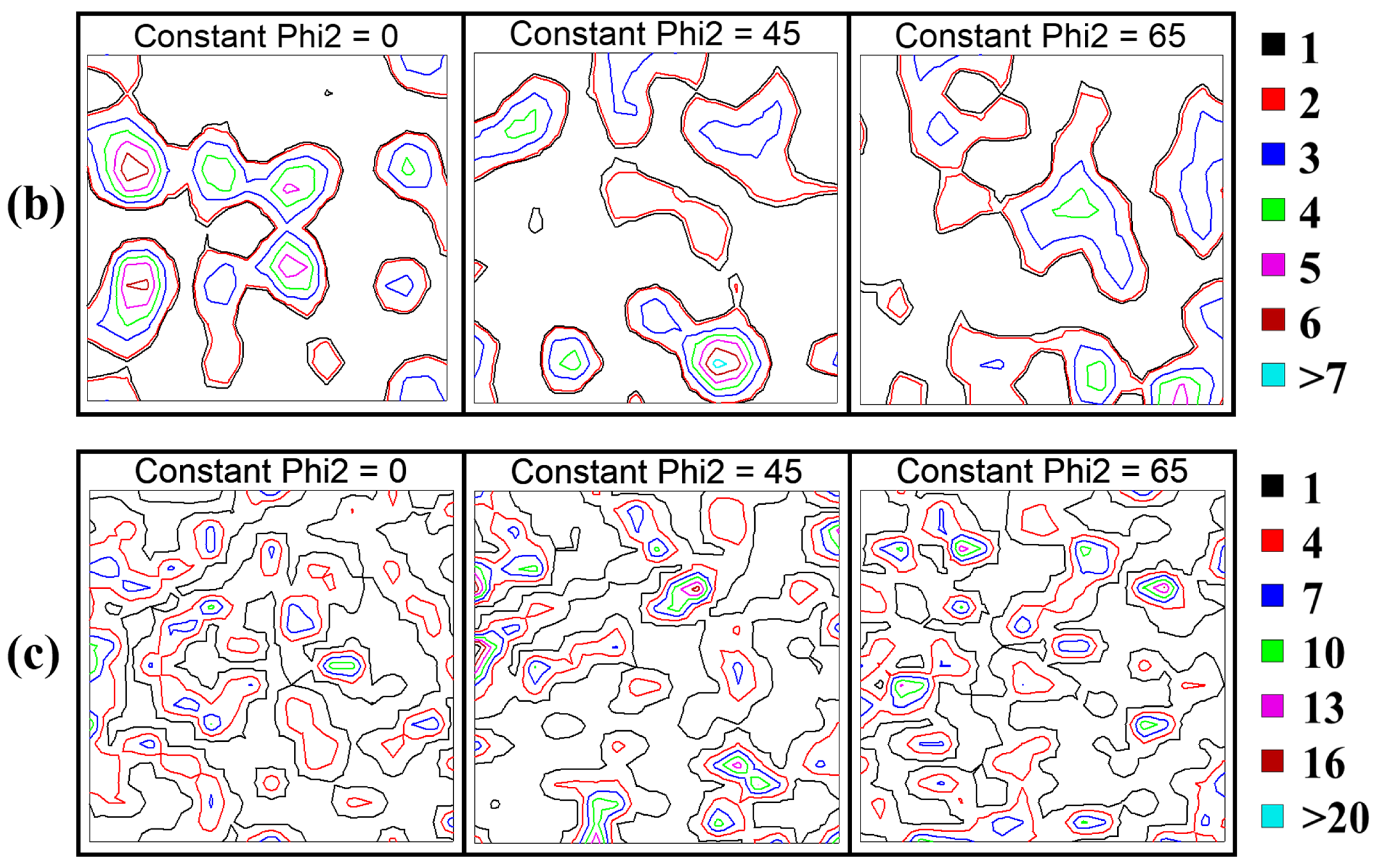

3.1. Evolution of Texture in NCATB-HEA

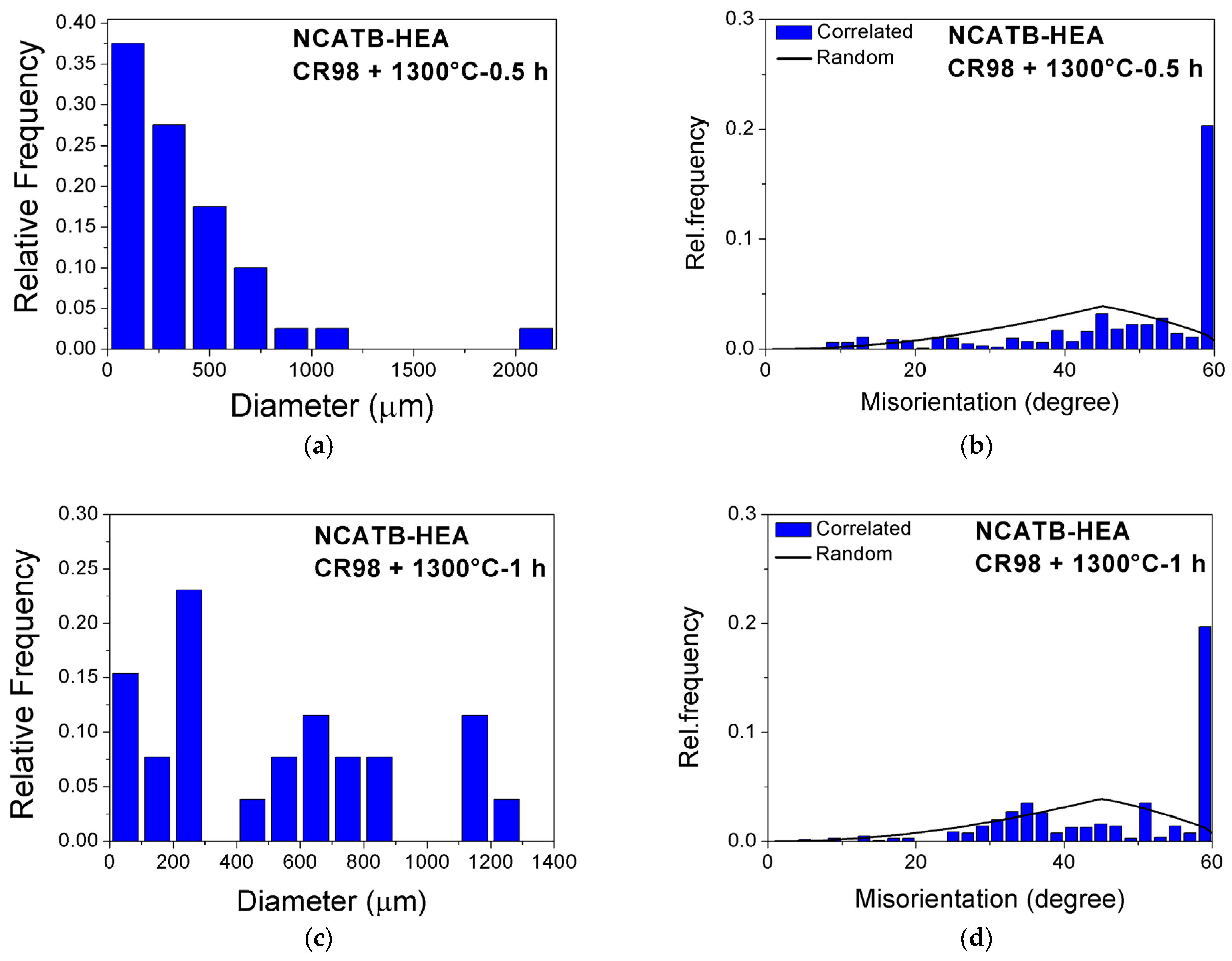

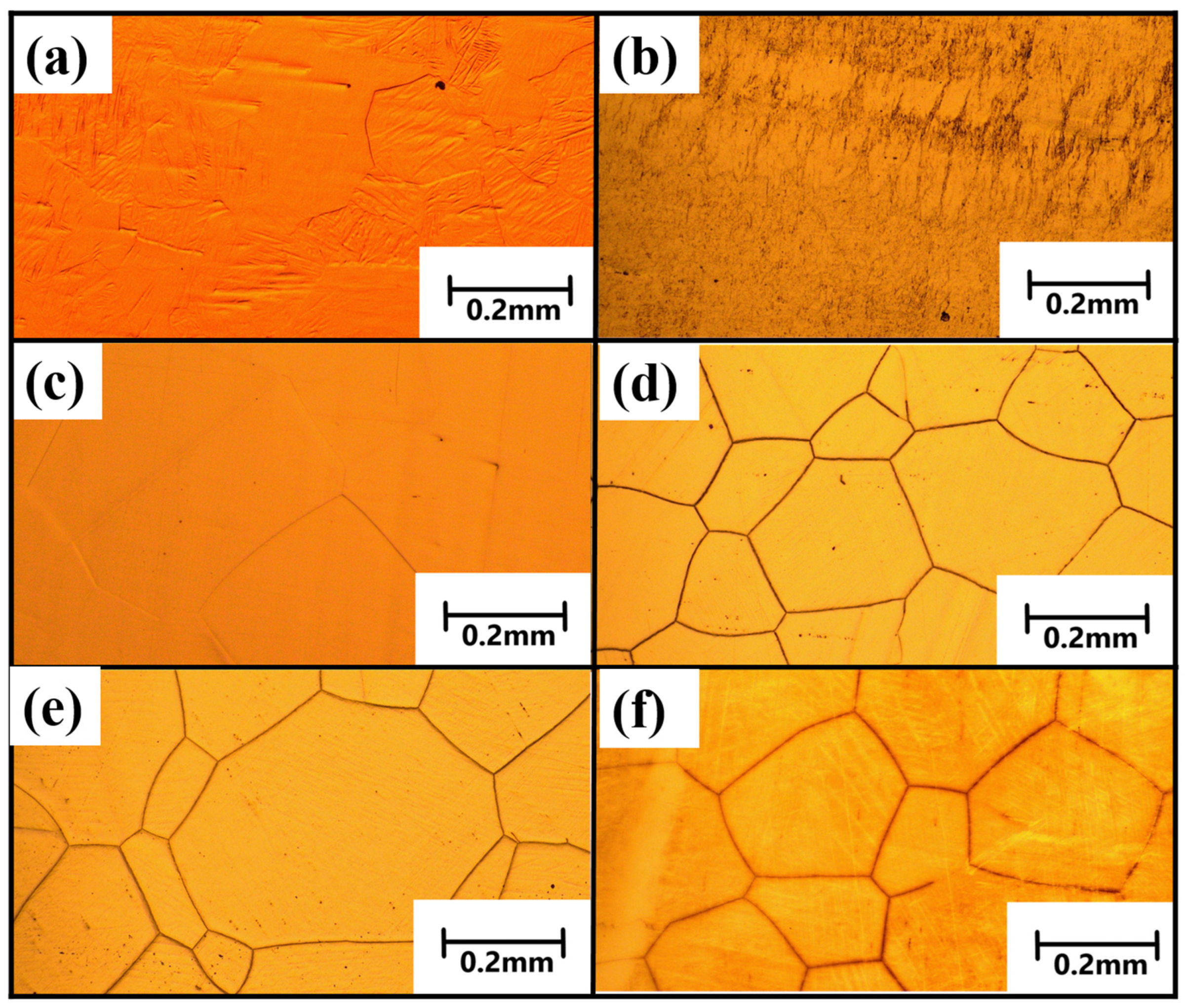

3.2. Grain Morphology in NCATB-HEA

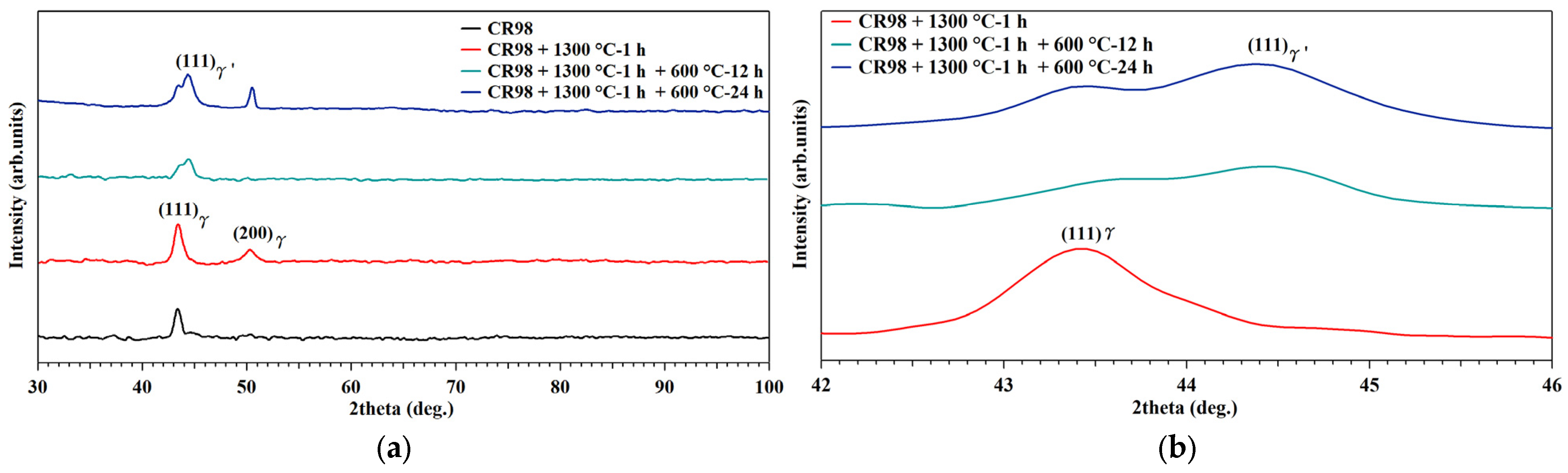

3.3. Crystal Structure in NCATB-HEA

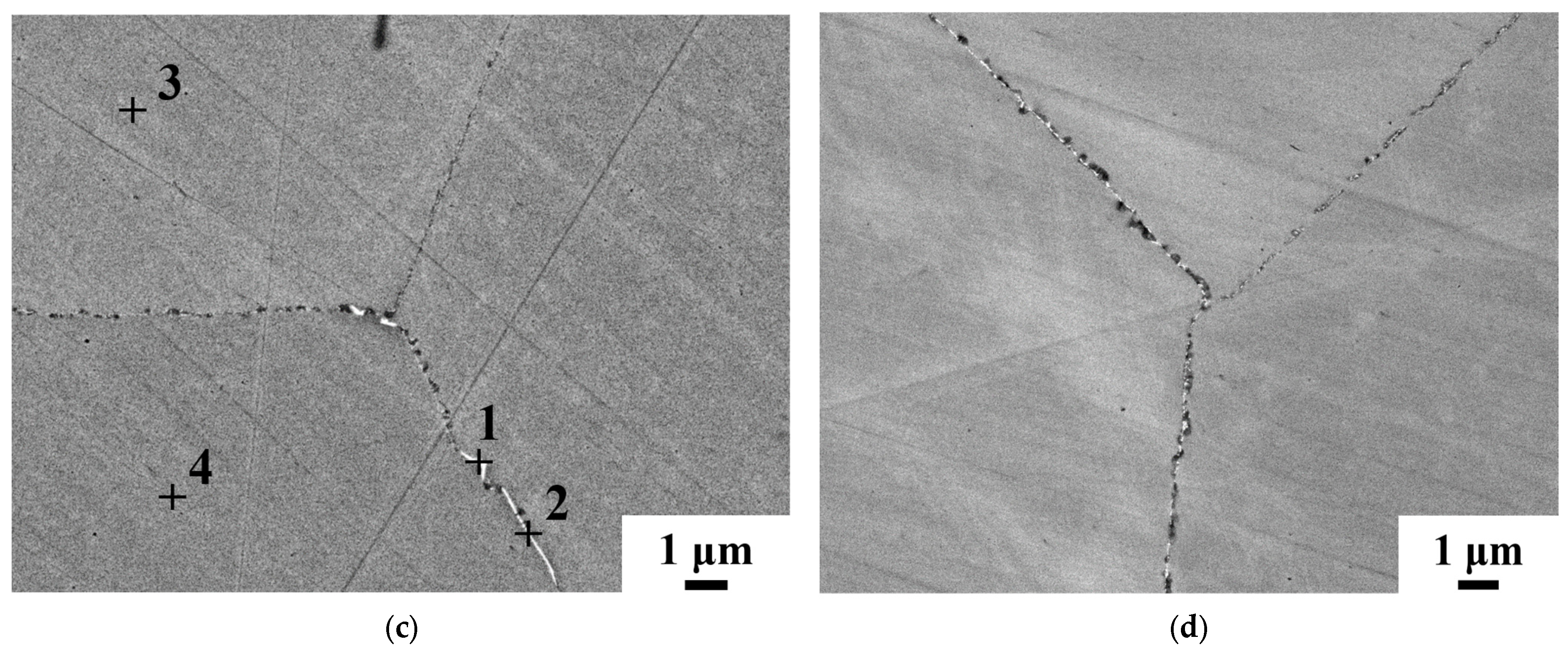

3.4. Microstructure in NCATB-HEA

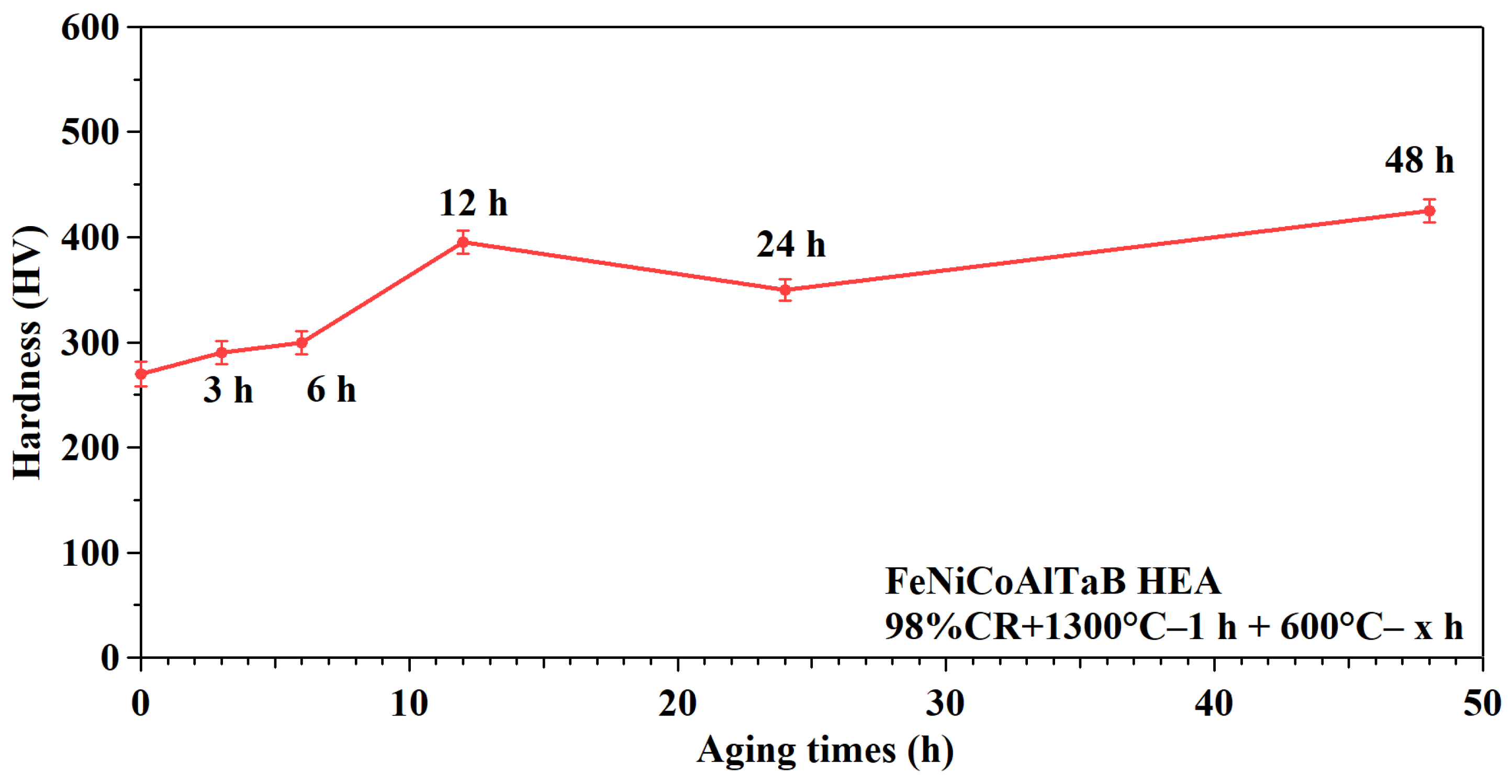

3.5. Hardness in NCATB-HEA

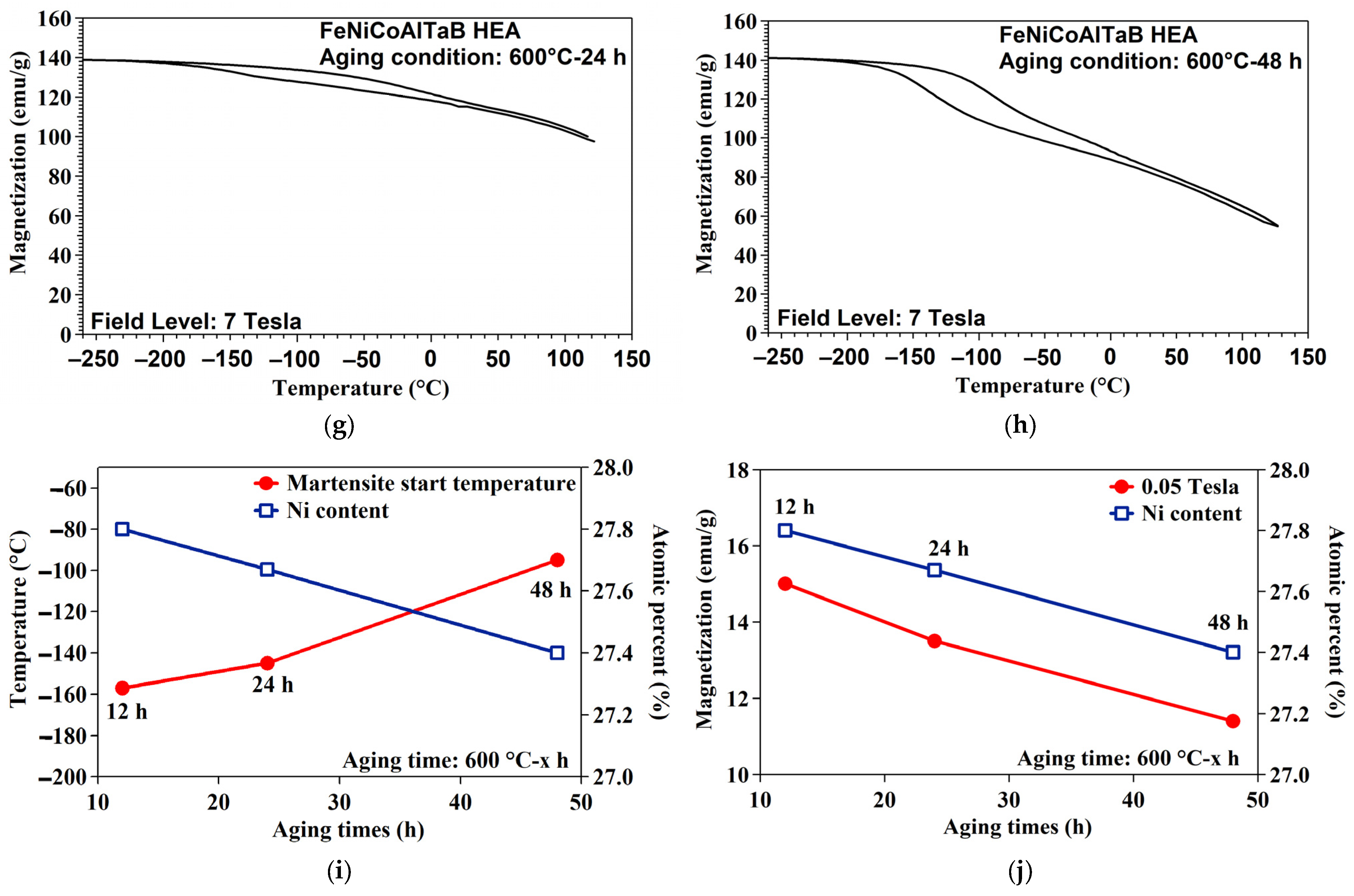

3.6. Transformation Temperatures in NCATB-HEA

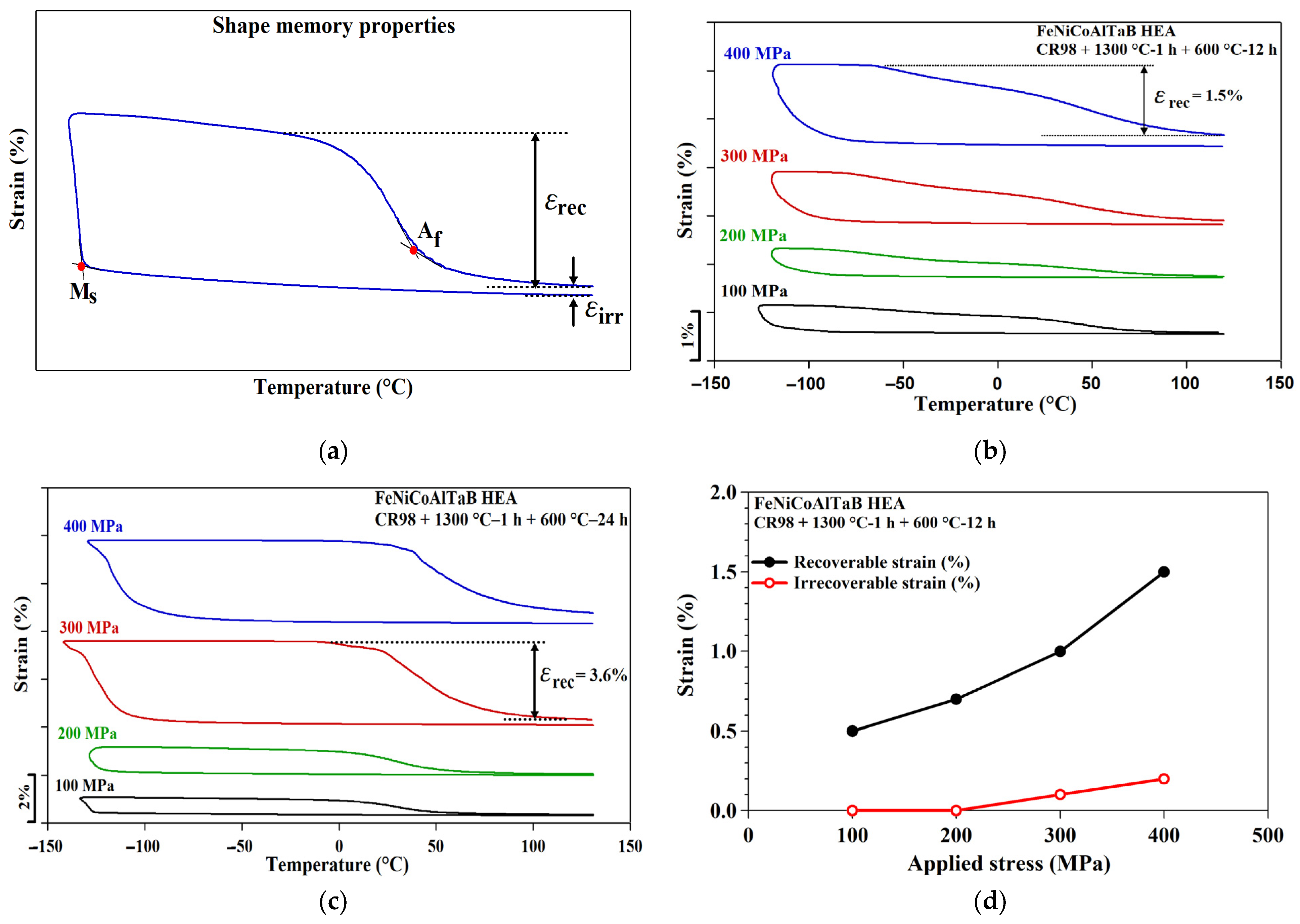

3.7. Shape Memory Properties in NCATB-HEA

4. Conclusions

- EBSD revealed that the average grain size was 356.8 and 504.6 μm for 1300 °C-0.5 h and 1300 °C-1 h, respectively. Both annealing conditions showed that no strong recrystallization texture is formed in NCATB-HEA (CR98).

- The ODF results indicate that the textural components of the cold-rolled sample are Brass, Goss and G/B. The major texture components in the sample annealed at 1300 °C for 1 h were Rt-Cu, Goss, Brass and G/B.

- The hardness value decreases from 12 to 24 h and increases from 24 to 48 h, which is related to the transformation temperatures. The transformation temperatures increase when the aging time increases from 12 to 24 h. However, the transformation temperature tends to decrease as the aging time is prolonged from 24 to 48 h. The SQUID results match with our hardness results.

- XRD analysis revealed that a new peak in the (111) plane of the precipitates emerged, and its intensity increased when the aging time at 600 °C was increased from 12 to 24 h.

- The three-point bending thermal cyclic results show that samples aged at 600 °C for 12 and 24 h showed maximum recoverable strains of 2% and 3.6%, respectively. The stress–temperature slopes for the austenite finish temperatures were 10.3 MPa/°C for 12 h and 6 MPa/°C for 24 h, respectively. The slope value for PXL600 °C-12 h is higher than for PXL600 °C-24 h. The reason for this is that the higher slope value corresponds to a lower recoverable strain.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yeh, J.W. Physical metallurgy of high-entropy alloys. JOM 2015, 67, 2254–2261. [Google Scholar] [CrossRef]

- Yeh, J.W.; Chen, S.K.; Lin, S.J.; Gan, J.Y.; Chin, T.S.; Shun, T.T.; Tsau, C.H.; Chang, S.Y. Nanostructured high entropy alloys with multiple principal elements: Novel alloy design concepts and outcomes. Adv. Eng. Mater. 2004, 6, 299–303. [Google Scholar] [CrossRef]

- Tsai, M.H.; Yeh, J.W. High-entropy alloys: A critical review. Mater. Res. Lett. 2014, 2, 107–123. [Google Scholar] [CrossRef]

- Yeh, J.W. Alloy Design Strategies and Future Trends in High-Entropy Alloys. JOM 2013, 65, 1759–1771. [Google Scholar] [CrossRef]

- Yeh, J.W.; Lin, S.J.; Chin, T.S.; Gan, J.Y.; Chen, S.K.; Shun, T.T.; Tsau, C.H.; Chou, S.Y. Formation of simple crystal structures in Cu-Co-Ni-Cr-Al-Fe-Ti-V alloys with multiprincipal metallic elements. Metall. Mater. Trans. A 2004, 35, 2533–2536. [Google Scholar] [CrossRef]

- Tsai, K.Y.; Tsai, M.H.; Yeh, J.W. Sluggish diffusion in Co–Cr–Fe–Mn–Ni high entropy alloys. Acta Mater. 2013, 61, 4887–4897. [Google Scholar] [CrossRef]

- Yeh, J.W. Recent progress in high entropy alloys. Ann. Chim. Sci. Mater. 2006, 31, 633–648. [Google Scholar] [CrossRef]

- Li, Z.; Pradeep, K.G.; Deng, Y.; Raabe, D.; Tasan, C.C. Metastable high-entropy dual-phase alloys overcome the strength–ductility trade-off. Nature 2016, 534, 227–230. [Google Scholar] [CrossRef]

- Otto, F.; Dlouhý, A.; Pradeep, K.; Kuběnová, M.; Raabe, D.; Eggeler, G.; George, E.P. Decomposition of the single-phase high-entropy alloy CrMnFeCoNi after prolonged anneals at intermediate temperatures. Acta Mater. 2016, 112, 40–52. [Google Scholar] [CrossRef]

- Tasan, C.C.; Deng, Y.; Pradeep, K.G.; Yao, M.J.; Springer, H.; Raabe, D. Composition dependence of phase stability, deformation mechanisms, and mechanical properties of the CoCrFeMnNi high-entropy alloy system. JOM 2014, 66, 1993–2001. [Google Scholar] [CrossRef]

- Li, Z.; Tasan, C.C.; Pradeep, K.G.; Raabe, D. A TRIP-assisted dual-phase high-entropy alloy: Grain size and phase fraction effects on deformation behavior. Acta Mater. 2017, 131, 323–335. [Google Scholar] [CrossRef]

- Tanaka, Y.; Himuro, Y.; Kainuma, R.; Sutou, Y.; Omori, T.; Ishida, K. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 2010, 327, 1488–1490. [Google Scholar] [CrossRef] [PubMed]

- Lee, D.; Omori, T.; Kainuma, R. Ductility enhancement and superelasticity in Fe–Ni–Co–Al–Ti–B polycrystalline alloy. J. Alloys Compd. 2014, 617, 120–123. [Google Scholar] [CrossRef]

- Omori, T.; Abe, S.; Tanaka, Y.; Lee, D.; Ishida, K.; Kainuma, R. Thermoelastic martensitic transformation and superelasticity in Fe–Ni–Co–Al–Nb–B polycrystalline alloy. Scr. Mater. 2013, 69, 812–815. [Google Scholar] [CrossRef]

- Tseng, L.W.; Lee, P.Y.; Lu, N.H.; Hsu, Y.T.; Chen, C.H. Shape memory properties and microstructure of FeNiCoAlTaB shape memory alloys. Crystals 2023, 13, 852. [Google Scholar] [CrossRef]

- Tseng, L.W.; Song, M.; Chen, W.C.; Hsu, Y.T.; Chen, C.H. Superelastic Properties of Aged FeNiCoAlTaB Cold-Rolled Shape Memory Alloys. Metals 2024, 14, 643. [Google Scholar] [CrossRef]

- Ma, J.; Hornbuckle, B.; Karaman, I.; Thompson, G.B.; Luo, Z.; Chumlyakov, Y. The effect of nanoprecipitates on the superelastic properties of FeNiCoAlTa shape memory alloy single crystals. Acta Mater. 2013, 61, 3445–3455. [Google Scholar] [CrossRef]

- Fu, H.; Zhao, H.; Song, S.; Zhang, Z.; Xie, J. Evolution of the cold-rolling and recrystallization textures in FeNiCoAlNbB shape memory alloy. J. Alloys Compd. 2016, 628, 1008–1016. [Google Scholar] [CrossRef]

- Tseng, L.W.; Ma, J.; Karaman, I.; Wang, S.J.; Chumlyakov, Y. Superelastic response of the FeNiCoAlTi single crystals under tension and compression. Scr. Mater. 2015, 101, 1–4. [Google Scholar] [CrossRef]

- Tseng, L.W.; Chen, C.H.; Chen, W.C.; Cheng, Y.; Lu, N.H. Shape memory properties and microstructure of new iron-based FeNiCoAlTiNb shape memory alloys. Crystals 2021, 11, 1253. [Google Scholar] [CrossRef]

- Chumlyakov, Y.I.; Kireeva, I.V.; Pobedennaya, P.; Krooβ, P.; Niendorf, T. Rubber-like behaviour and superelasticity of [001]-oriented FeNiCoAlNb single crystals containing γ- and β-phase particles. J. Alloys Compd. 2021, 856, 158158. [Google Scholar] [CrossRef]

- Chumlyakov, Y.I.; Kireeva, I.V.; Kuksgauzen, I.V.; Kuksgauzen, D.A.; Niendorf, T.; Krooβ, P. Tension-compression asymmetry of the superelastic behavior of high-strength [001]-oriented FeNiCoAlNb crystals. Mater. Lett. 2021, 289, 129395. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, C.; Shin, S.; Casalena, L.; Vecchio, K. Grain boundary precipitation of tantalum and NiAl in superelastic FeNiCoAlTaB alloy. Mater. Sci. Eng. A 2019, 743, 372–381. [Google Scholar] [CrossRef]

- Kim, M.S.; Heo, J.K.; Rodrigue, H.; Lee, H.T.; Pané, S.; Han, M.W.; Ahn, S.H. Shape memory alloy (SMA) actuators: The role of material, form, and scaling effects. Adv. Mater. 2023, 35, 2208517. [Google Scholar] [CrossRef]

- Sohn, J.W.; Ruth, J.S.; Yuk, D.G.; Choi, S.B. Application of shape memory alloy actuators to vibration and motion control of structural systems: A review. Appl. Sci. 2023, 13, 995. [Google Scholar] [CrossRef]

- Zhang, C.; Zhu, C.; Harrington, T.; Casalena, L.; Wang, H.; Shin, S.; Vecchio, K.S. Multifunctional non-equiatomic high entropy alloys with superelastic, high damping, and excellent cryogenic properties. Adv. Eng. Mater. 2019, 21, 1800941. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, Q.; Tang, Y.T.; Xu, M.; Wang, H.; Zhu, C.; Ell, J.; Zhao, S.; MacDonald, B.E.; Cao, P.; et al. Strong and ductile FeNiCoAl-based high-entropy alloys for cryogenic to elevated temperature multifunctional applications. Acta Mater. 2023, 242, 118449. [Google Scholar] [CrossRef]

- Zhang, C.; Wang, X.; Xu, M.; MacDonald, B.E.; Hong, R.; Zhu, C.; Dai, X.; Vecchio, K.S.; Apelian, D.; Hahn, H.; et al. Orientation-dependent superelasticity of a metastable high-entropy alloy. Appl. Phys. Lett. 2021, 119, 161908. [Google Scholar] [CrossRef]

- Huang, A.; Zhang, C.; Li, Z.; Wang, H.; Xu, M.; Zhu, C.; Wang, X.; Meyers, M.A.; Lavernia, E.J. Dynamic mechanical performance of FeNiCoAl-based high-entropy alloy: Enhancement via microbands and martensitic transformation. Mater. Today Adv. 2023, 20, 100439. [Google Scholar] [CrossRef]

- Zhou, Z.; Cui, J.; Ren, X. Phase diagram of FeNiCoAlTaB ferrous shape memory alloy on aging time. AIP Adv. 2017, 7, 045019. [Google Scholar] [CrossRef]

- Tanaka, Y.; Kainuma, R.; Omori, T.; Ishida, K. Alloy design for Fe-Ni-Co-Al-based superelastic alloys. Mater. Today Proc. 2015, 2, S485–S492. [Google Scholar] [CrossRef]

- Babicheva, R.; Jarlöv, A.; Zheng, H.; Dmitriev, S.; Korznikova, E.; Nai, M.L.S.; Ramamurty, U.; Zhou, K. Effect of short-range ordering and grain boundary segregation on shear deformation of CoCrFeNi high-entropy alloys with Al addition. Comput. Mater. Sci. 2022, 215, 111762. [Google Scholar] [CrossRef]

- Li, S.; Cong, D.; Chen, Z.; Li, S.; Song, C.; Cao, Y.; Nie, Z.; Wang, Y. A high-entropy high-temperature shape memory alloy with large and complete superelastic recovery. Mater. Res. Lett. 2021, 9, 263–269. [Google Scholar] [CrossRef]

| Element | β Phases | Matrix | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | Average | 3 | 4 | Average | |

| Fe (at%) | 43.2 | 42.3 | 42.86 * ± 0.5 | 43.9 | 43.1 | 43.57 * ± 0.2 |

| Ni (at%) | 26.3 | 27.4 | 26.73 * ± 0.6 | 27.2 | 28.2 | 27.67 * ± 0.2 |

| Co (at%) | 16.1 | 16.6 | 16.33 * ± 0.3 | 17.2 | 17 | 17.07 * ± 0.4 |

| Al (at%) | 8.5 | 9.2 | 8.8 * ± 0.4 | 9.5 | 9.4 | 9.5 * ± 0.1 |

| Ta (at%) | 5.9 | 4.6 | 5.3 * ± 0.7 | 2.2 | 2.3 | 2.2 * ± 0.1 |

| Element | Matrix (600 °C-12 h) | Matrix (600 °C-48 h) | ||||

|---|---|---|---|---|---|---|

| 1 | 2 | Average | 3 | 4 | Average | |

| Fe (at%) | 44.2 | 42.9 | 43.63 * ± 0.6 | 44.3 | 43.3 | 43.76 * ± 0.5 |

| Ni (at%) | 27.5 | 27.9 | 27.8 * ± 0.3 | 27.2 | 27.7 | 27.4 * ± 0.3 |

| Co (at%) | 16.6 | 17.6 | 16.93 * ± 0.5 | 16.7 | 17.3 | 17.13 * ± 0.4 |

| Al (at%) | 9.3 | 9.4 | 9.33 * ± 0.6 | 9.5 | 9.4 | 9.4 * ± 0.1 |

| Ta (at%) | 2.3 | 2.2 | 2.26 * ± 0.5 | 2.3 | 2.3 | 2.3 * ± 0.1 |

| Thermomechanical Processing | Hardness (HV) |

|---|---|

| CR98 + 1300 °C-1 h | 270 ± 12 |

| CR98 + 1300 °C-1 h + 600 °C-3 h | 290 ± 11 |

| CR98 + 1300 °C-1 h + 600 °C-6 h | 300 ± 11 |

| CR98 + 1300 °C-1 h + 600 °C-12 h | 395 ± 11 |

| CR98 + 1300 °C-1 h + 600 °C-24 h | 350 ± 10 |

| CR98 + 1300 °C-1 h + 600 °C-48 h | 425 ± 11 |

| Aging Condition | Magnetic Field | Transformation Temperature |

|---|---|---|

| 600 °C-12 h | 0.05 T | Af = −48 °C and Ms = −157 °C |

| 600 °C-12 h | 7 T | Af = −45 °C and Ms = −150 °C |

| 600 °C-24 h | 0.05 T | Af = 10 °C and Ms = −145 °C |

| 600 °C-24 h | 7 T | Af = 8 °C and Ms = −125 °C |

| 600 °C-48 h | 0.05 T | Af = −55 °C and Ms = −95 °C |

| 600 °C-48 h | 7 T | Af = −45 °C and Ms = −92 °C |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tseng, L.-W.; Chen, W.-C.; Hsu, Y.-T.; Chen, C.-H. Microstructure and Thermal Cyclic Behavior of FeNiCoAlTaB High-Entropy Alloy. Materials 2025, 18, 387. https://doi.org/10.3390/ma18020387

Tseng L-W, Chen W-C, Hsu Y-T, Chen C-H. Microstructure and Thermal Cyclic Behavior of FeNiCoAlTaB High-Entropy Alloy. Materials. 2025; 18(2):387. https://doi.org/10.3390/ma18020387

Chicago/Turabian StyleTseng, Li-Wei, Wei-Cheng Chen, Yi-Ting Hsu, and Chih-Hsuan Chen. 2025. "Microstructure and Thermal Cyclic Behavior of FeNiCoAlTaB High-Entropy Alloy" Materials 18, no. 2: 387. https://doi.org/10.3390/ma18020387

APA StyleTseng, L.-W., Chen, W.-C., Hsu, Y.-T., & Chen, C.-H. (2025). Microstructure and Thermal Cyclic Behavior of FeNiCoAlTaB High-Entropy Alloy. Materials, 18(2), 387. https://doi.org/10.3390/ma18020387