Stability and Rheological Properties of Grouts with Waste Glass Powder as Cement Replacement: Influences of Content and Alkali Activator

Abstract

1. Introduction

2. Experimental Materials and Methods

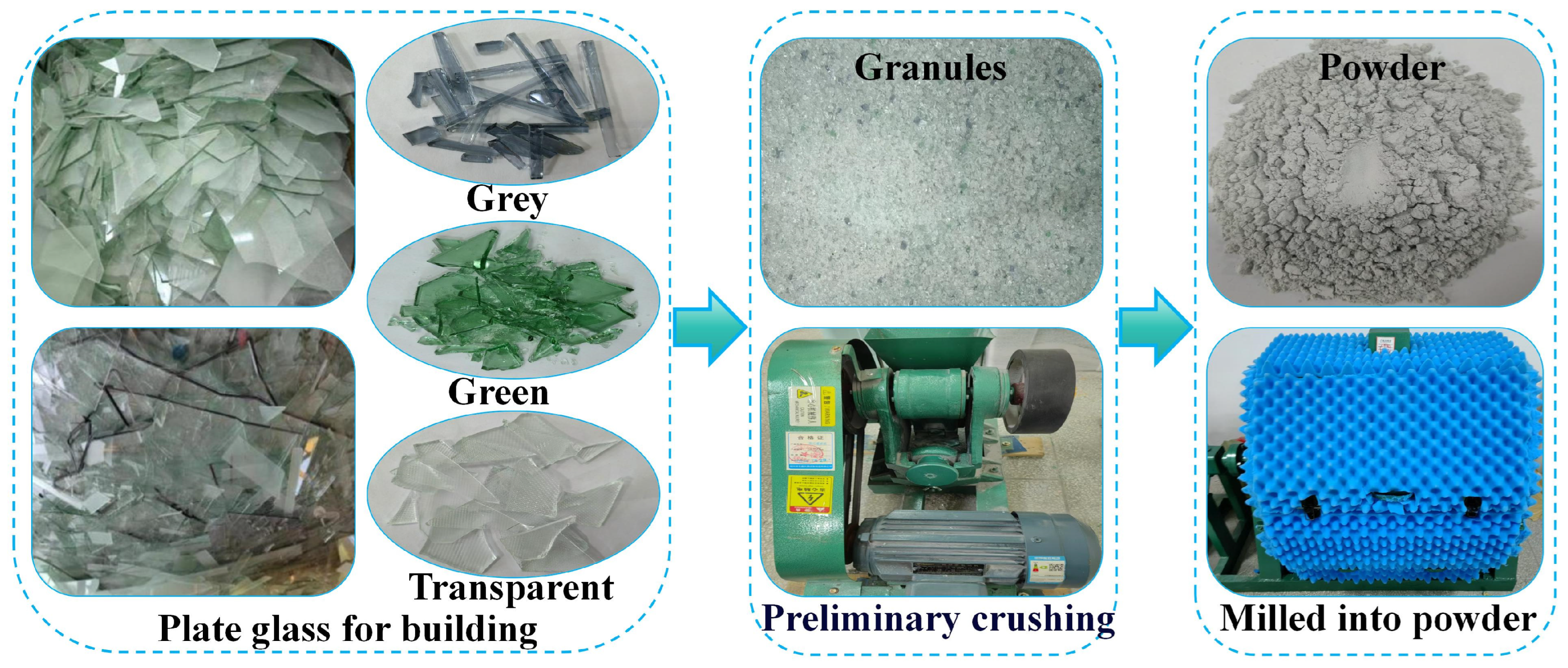

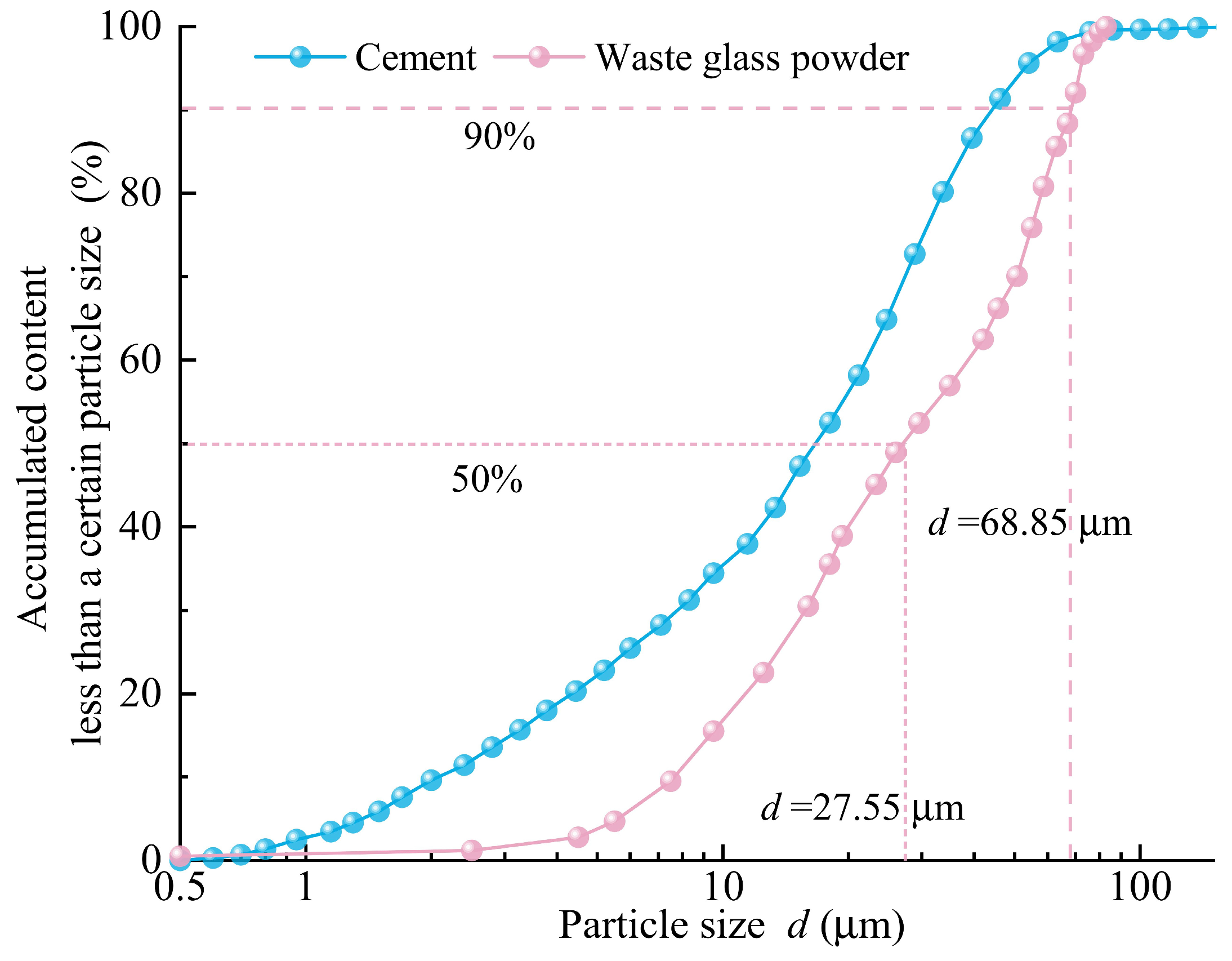

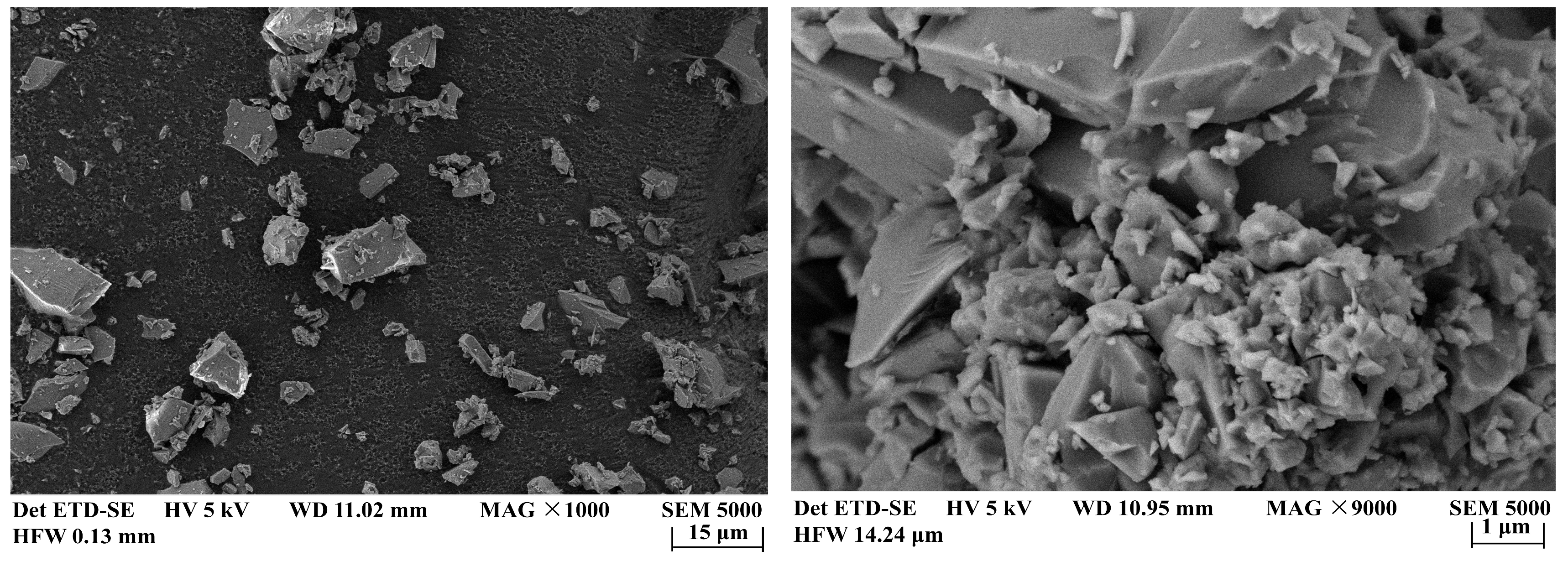

2.1. Raw Materials

2.2. Comprehensive Experimental Design

2.3. Sample Preparation

2.4. Testing Methods

3. Results and Discussion

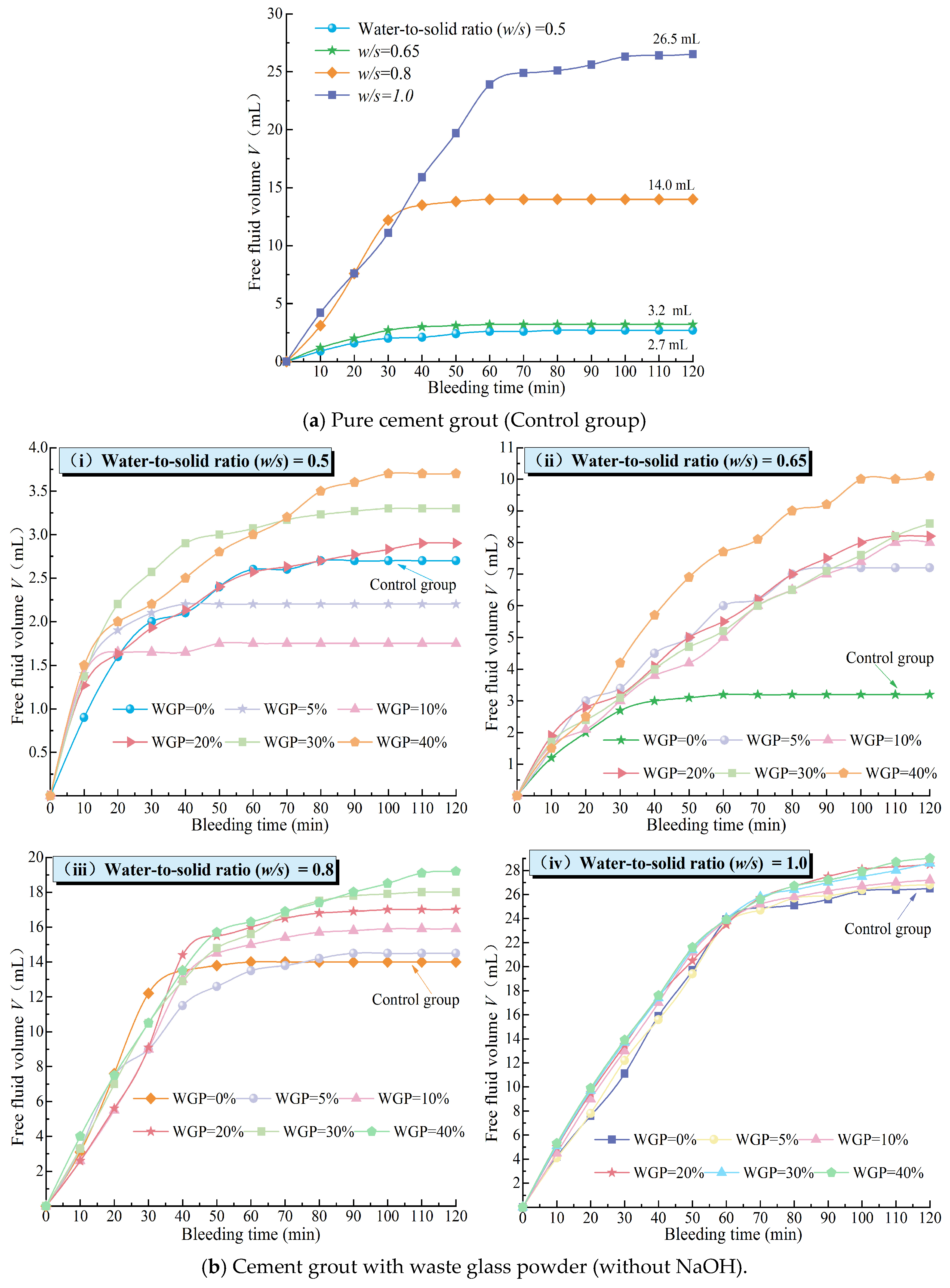

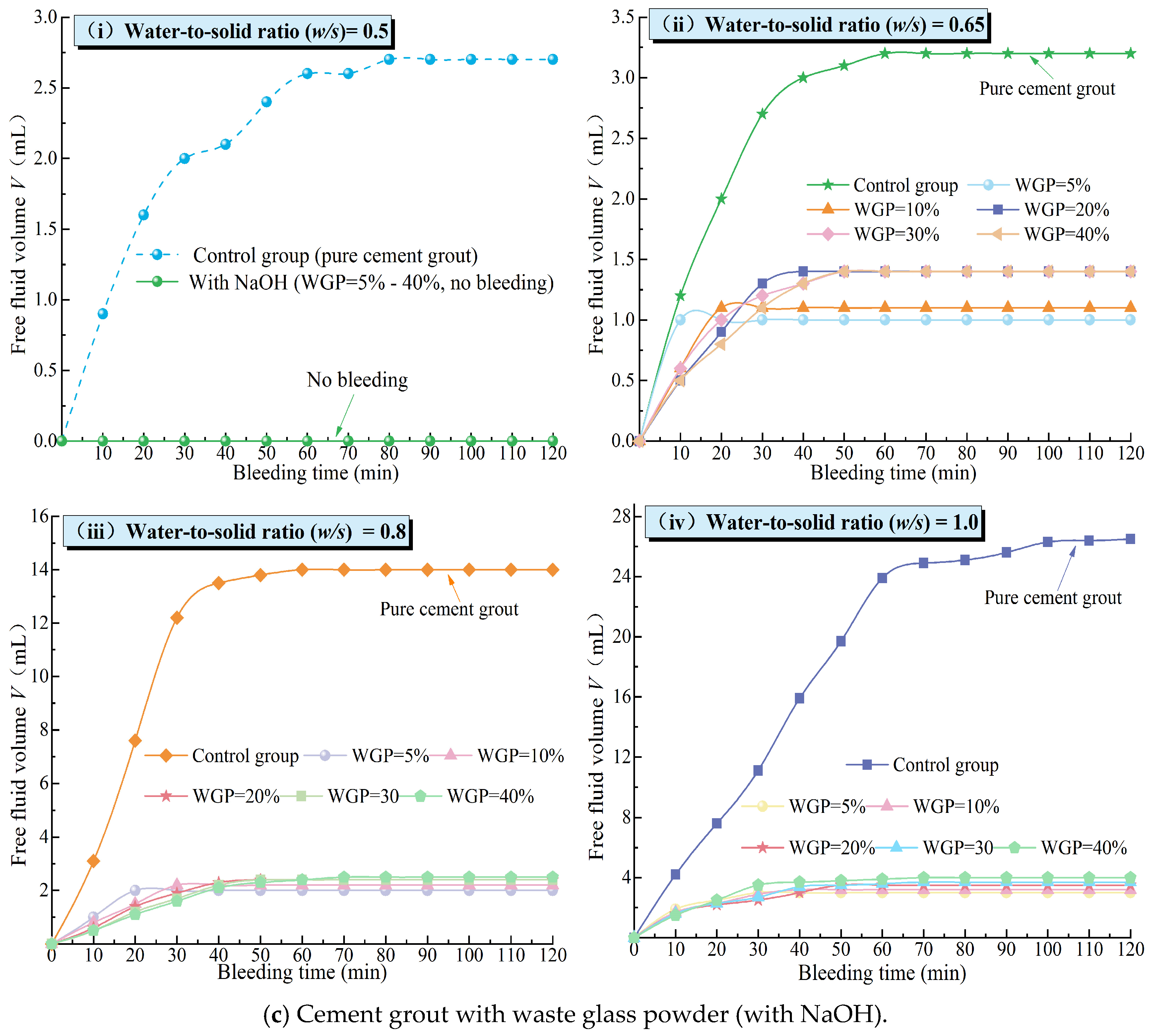

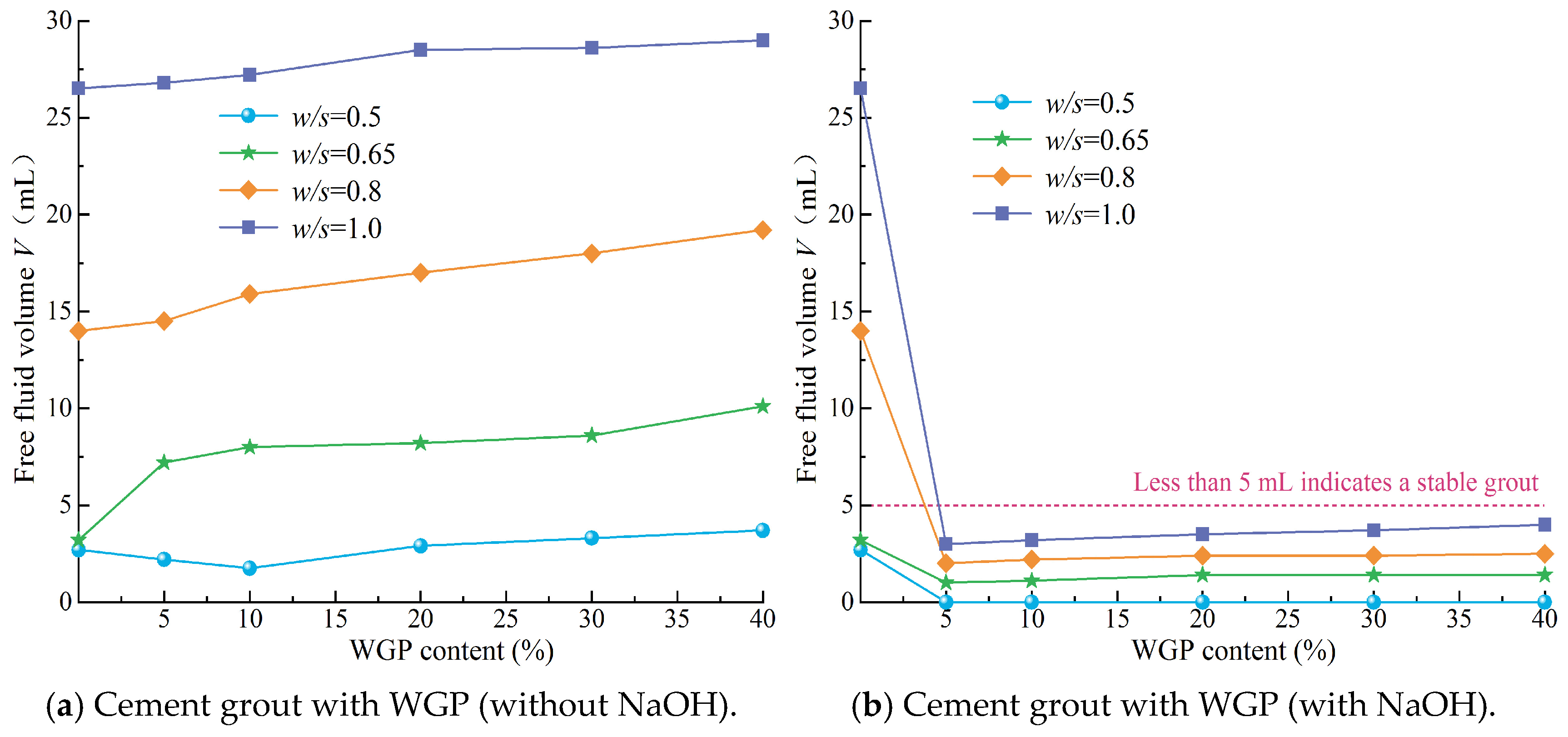

3.1. Stability of WGP–Cement-Based Grout

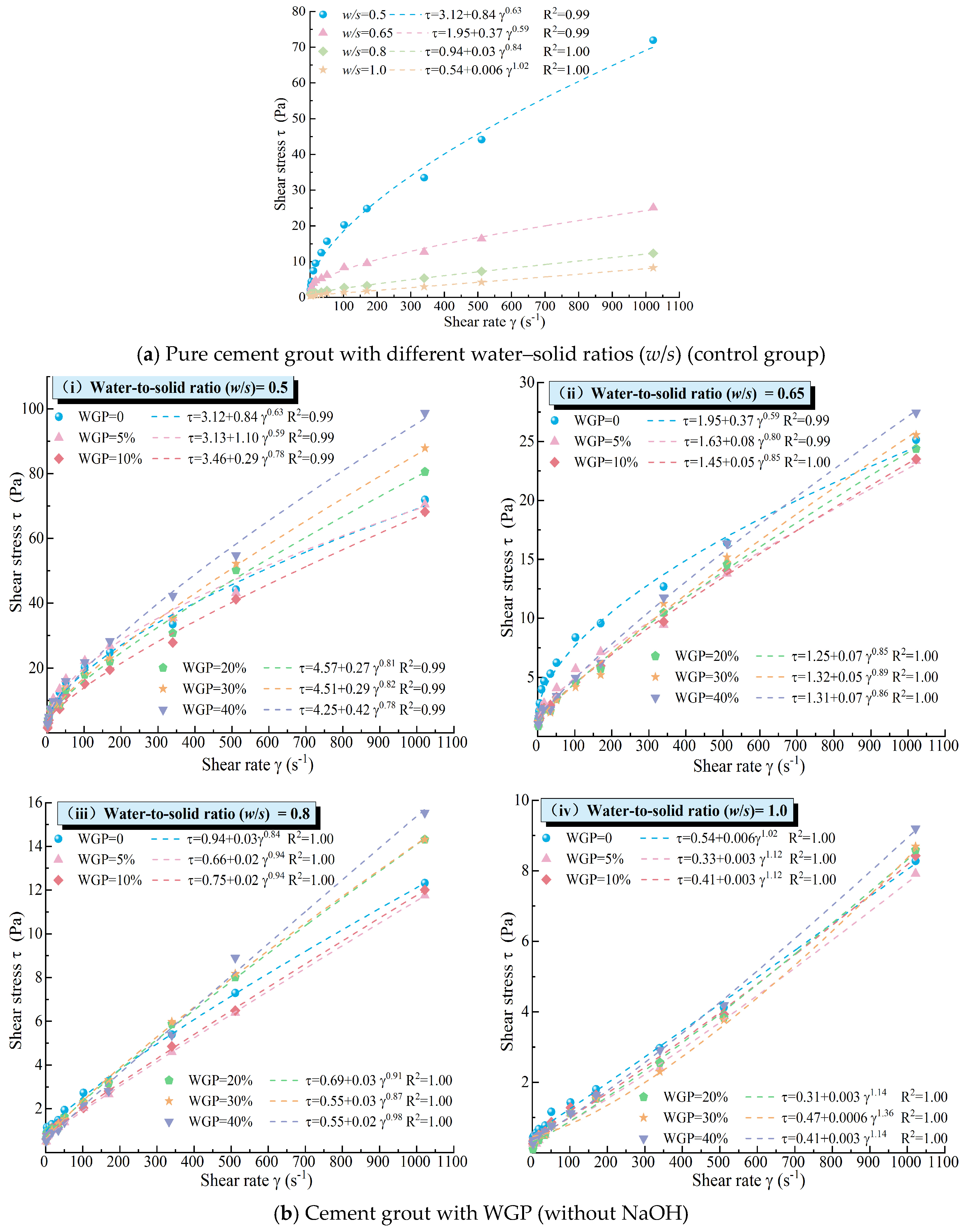

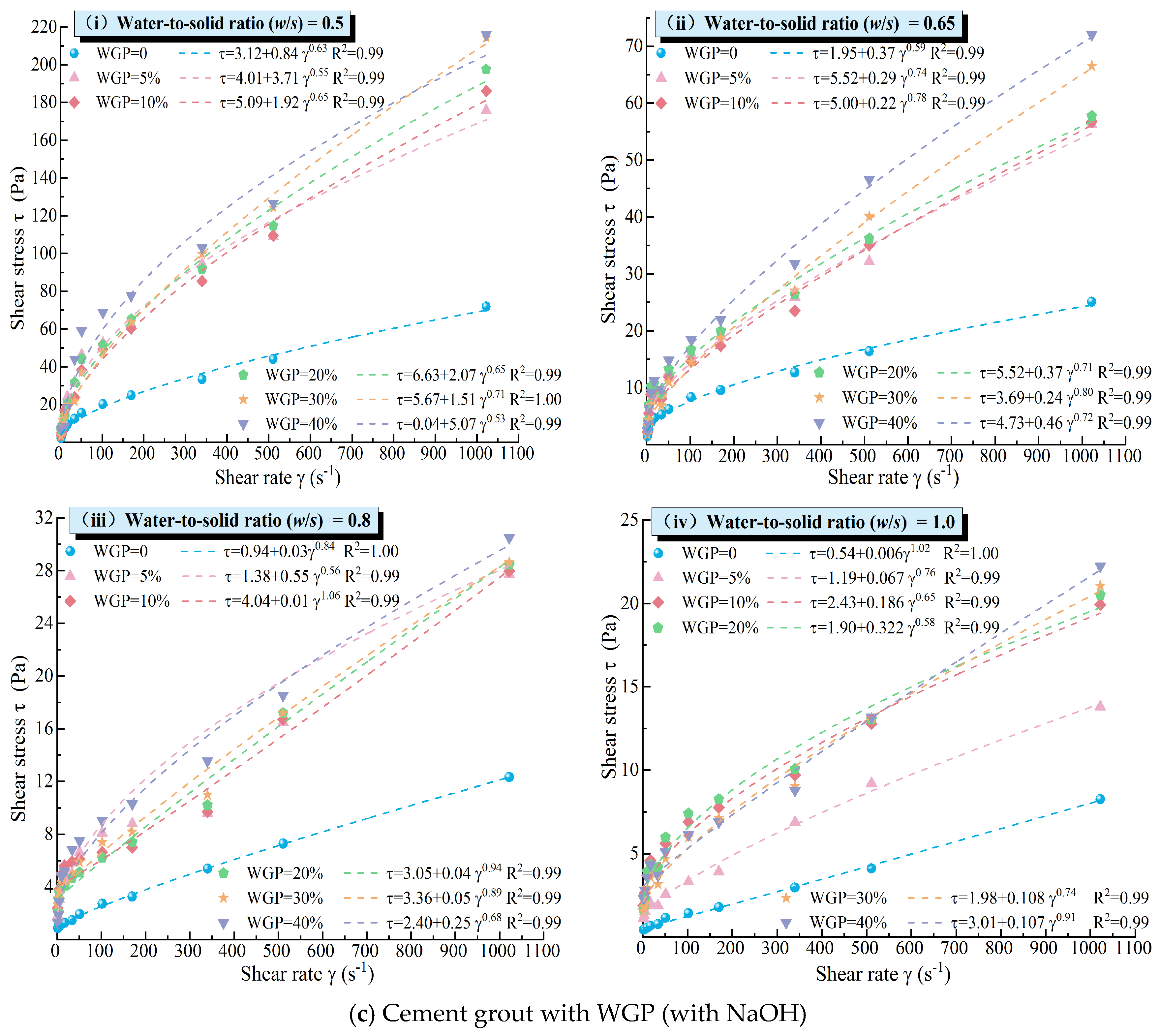

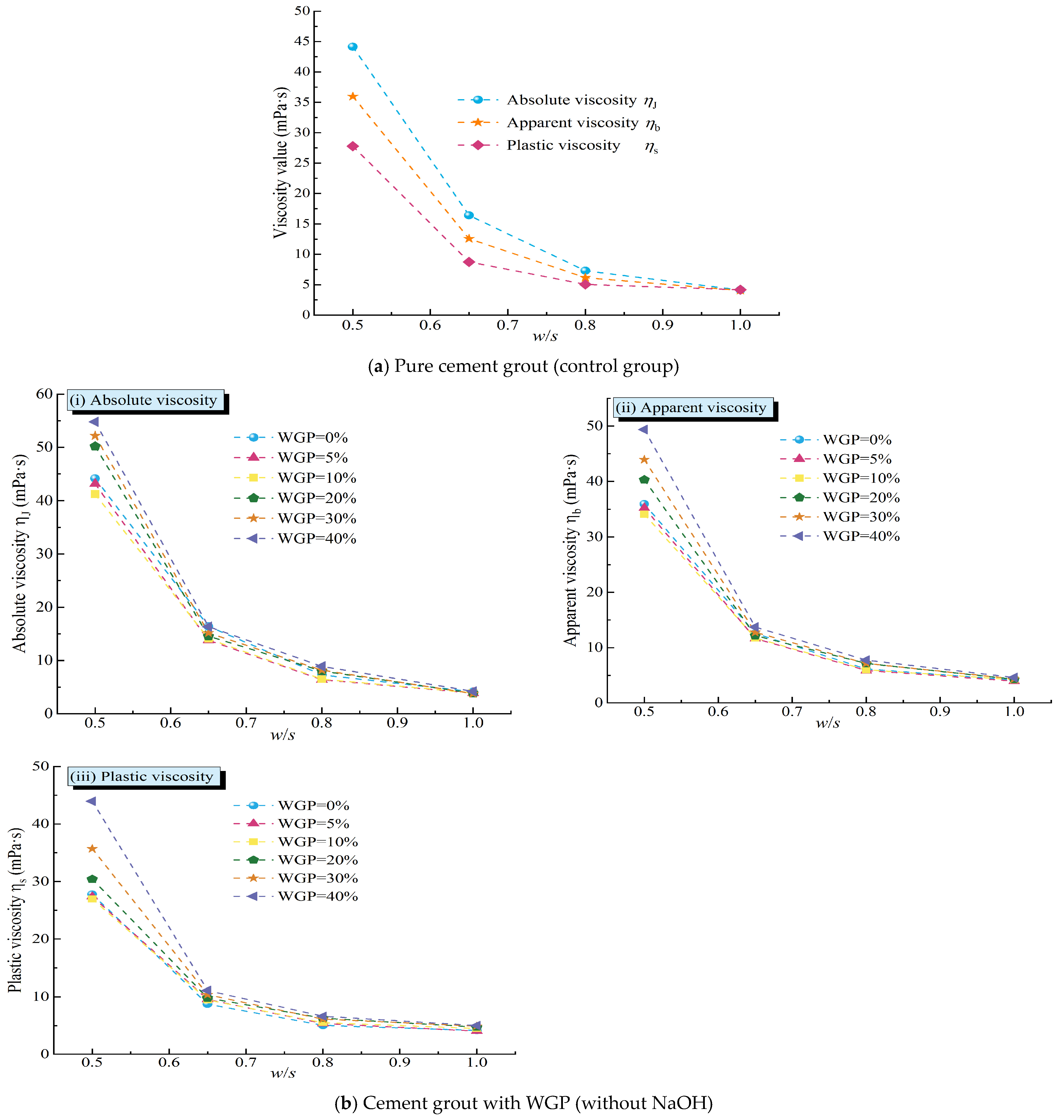

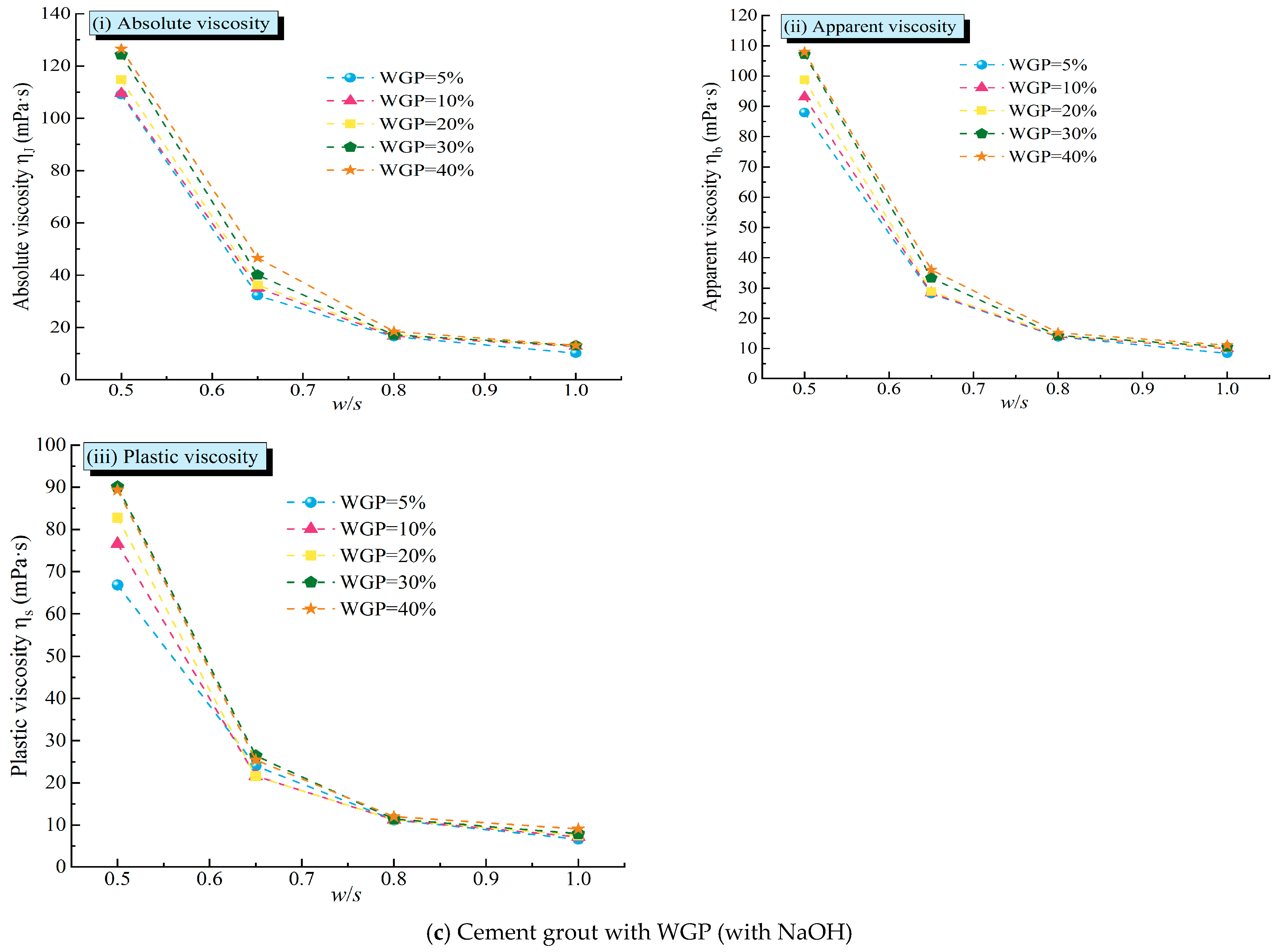

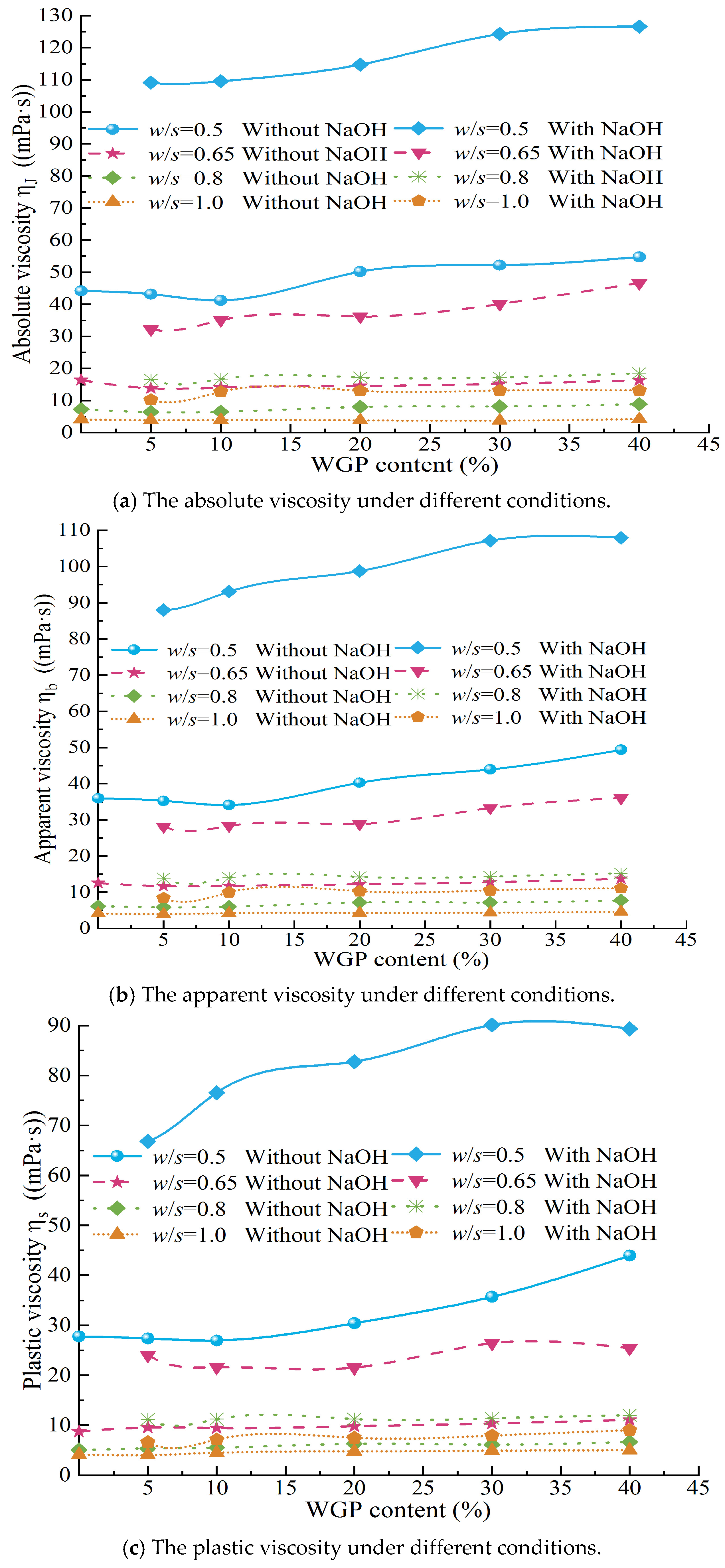

3.2. Rheological Performance of WGP–Cement-Based Grout

4. Conclusion

- (1)

- WGP incorporation generally increases free liquid separation in grout, reducing stability, especially at high w/s ratios without an activator. However, at low w/s ratios (e.g., 0.5) and with 10% WGP, stability is temporarily improved;

- (2)

- At high w/s ratios (0.65) and without an activator, WGP significantly destabilizes grout, whereas at low w/s ratios (0.5) and with ≤40% WGP, grout remains stable;

- (3)

- NaOH alkali activation reduces free liquid separation and shortens the stabilization time in waste glass cement grout, stabilizing originally unstable grouts at w/s ratios < 1.0;

- (4)

- The Herschel–Bulkley model accurately describes waste glass cement grout rheology, with R2 > 0.99, effectively characterizing rheological properties for both pure and WGP-containing grouts;

- (5)

- WGP and NaOH significantly affect grout rheology, altering shear stress and viscosity, particularly at lower w/s ratios. Alkali activation increases shear stress and viscosity, with more pronounced effects at lower w/s ratios;

- (6)

- Grout viscosity is jointly regulated by the w/s ratio, WGP content, and alkali activator, exhibiting a complex interaction mechanism. As the w/s ratio increases, viscosity decreases, while WGP content has a non-linear effect on viscosity, and alkali activation further increases viscosity, especially at lower w/s ratios.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Siddika, A.; Hajimohammadi, A.; Mamun, M.A.A.; Alyousef, R.; Ferdous, W. Waste Glass in Cement and Geopolymer Concretes: A Review on Durability and Challenges. Polymers 2021, 13, 2071. [Google Scholar] [CrossRef] [PubMed]

- Siddika, A.; Hajimohammadi, A.; Ferdous, W.; Sahajwalla, V. Roles of Waste Glass and the Effect of Process Parameters on the Properties of Sustainable Cement and Geopolymer Concrete—A State-of-the-Art Review. Polymers 2021, 13, 3935. [Google Scholar] [CrossRef] [PubMed]

- Sobolev, K.; Tuerker, P.; Soboleva, S.; Iscioglu, G. Utilization of Waste Glass in ECO-cement: Strength Properties and Microstructural Observations. Waste Manag. 2007, 27, 971–976. [Google Scholar] [CrossRef]

- Hu, H.X.; Gan, B.Q.; Deng, C.; Xie, Z.L.; Lu, Y.F.; Cai, Y.H. Experimental Study on the Effect of Water-cement Ratios on the Diffusion Behavior of Sand Soil Grouting. Bull. Eng. Geol. Environ. 2024, 83, 80. [Google Scholar] [CrossRef]

- Hu, H.X.; Deng, C.; Chen, W. The Effect of Magnetization Conditions on the Stability of Cement Grout. Case Stud. Constr. Mater. 2022, 16, e01016. [Google Scholar] [CrossRef]

- Chica, L.; Alzate, A. Cellular Concrete Review: New Trends for Application in Construction. Constr. Build. Mater. 2019, 200, 637–647. [Google Scholar] [CrossRef]

- Monteiro, H.; Moura, B.; Soares, N. Advancements in Nano-enabled Cement and Concrete: Innovative Properties and Environmental Implications. J. Build. Eng. 2022, 56, 104736. [Google Scholar] [CrossRef]

- Hu, H.X.; Deng, C. Effect of Magnetized Water on the Stability and Consolidation Compressive Strength of Cement Grout. Materials 2021, 14, 275. [Google Scholar] [CrossRef] [PubMed]

- Chen, C.H.; Huang, R.; Wu, J.K.; Yang, C.C. Waste E-glass Particles Used in Cementitious Mixtures. Cem. Concr. Res. 2006, 36, 449–456. [Google Scholar] [CrossRef]

- Salahaddin, S.D.; Haido, J.H.; Wardeh, G. The Behavior of UHPC Containing Recycled Glass Waste in Place of Cementitious Materials: A Comprehensive Review. Case Stud. Constr. Mater. 2022, 17, e01494. [Google Scholar] [CrossRef]

- Franco-Luján, V.A.; Ramírez-Arellanes, S.; Gomez-Sanchez, A.; Pérez-Ramos, A.E.; Cruz-García, E.S.; Cruz-Martínez, H. Properties of Fresh and Hardened Cement-based Materials with Waste Glass as Supplementary Cementitious Material: A Review. J. Build. Eng. 2024, 95, 110137. [Google Scholar] [CrossRef]

- Güllü, H.; Canakci, H.; Al Zangana, I.F. Use of Cement Based Grout with Glass Powder for Deep Mixing. Constr. Build. Mater. 2017, 137, 12–20. [Google Scholar] [CrossRef]

- Tho-In, T.; Sata, V.; Boonserm, K.; Chindaprasirt, P. Compressive Strength and Microstructure Analysis of Geopolymer Paste Using Waste Glass Powder and Fly Ash. J. Clean. Prod. 2018, 172, 2892–2898. [Google Scholar] [CrossRef]

- Liu, H.L.; Shi, J.J.; Qu, H.Q.; Ding, D.X. An Investigation on Physical, Mechanical, Leaching and Radiation Shielding Behaviors of Barite Concrete Containing Recycled Cathode Ray Tube Funnel Glass Aggregate. Constr. Build. Mater. 2019, 201, 818–827. [Google Scholar] [CrossRef]

- Arabi, N.; Meftah, H.; Amara, H.; Kebaïli, O.; Berredjem, L. Valorization of Recycled Materials in Development of Self-compacting Concrete: Mixing Recycled Concrete Aggregates-Windshield Waste Glass Aggregates. Constr. Build. Mater. 2019, 209, 364–376. [Google Scholar] [CrossRef]

- Al-Bawi, R.K.; Kadhim, I.T.; Al-Kerttani, O. Strengths and Failure Characteristics of Self-Compacting Concrete Containing Recycled Waste Glass Aggregate. Adv. Mater. Sci. Eng. 2017, 2017, 6829510. [Google Scholar] [CrossRef]

- Yu, X.; Tao, Z.; Song, T.-Y.; Pan, Z. Performance of Concrete Made with Steel Slag and Waste Glass. Constr. Build. Mater. 2016, 114, 737–746. [Google Scholar] [CrossRef]

- Su, Q.; Xu, J.M. Mechanical Properties of Concrete Containing Glass Sand and Rice Husk Ash. Constr. Build. Mater. 2023, 393, 132053. [Google Scholar] [CrossRef]

- Bisht, K.; Ramana, P.V. Sustainable Production of Concrete Containing Discarded Beverage Glass as Fine Aggregate. Constr. Build. Mater. 2018, 177, 116–124. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Sarker, P.K. Alkali Silica Reaction of Waste Glass Aggregate in Alkali Activated Fly Ash and GGBFS Mortars. Mater. Struct. 2019, 52, 93. [Google Scholar] [CrossRef]

- Serpa, D.; de Brito, J.; Pontes, J. Concrete Made with Recycled Glass Aggregates: Mechanical Performance. ACI Mater. J. 2015, 112, 29–38. [Google Scholar] [CrossRef]

- Omoding, N.; Cunningham, L.S.; Lane-Serff, G.F. Effect of Using Recycled Waste Glass Coarse Aggregates on the Hydrodynamic Abrasion Resistance of Concrete. Constr. Build. Mater. 2021, 268, 121177. [Google Scholar] [CrossRef]

- De Castro, S.; de Brito, J. Evaluation of the Durability of Concrete Made with Crushed Glass Aggregates. J. Clean. Prod. 2012, 41, 7–14. [Google Scholar] [CrossRef]

- Kim, I.S.; Choi, S.Y.; Yang, E.I. Evaluation of Durability of Concrete Substituted Heavyweight Waste Glass as Fine Aggregate. Constr. Build. Mater. 2018, 184, 269–277. [Google Scholar] [CrossRef]

- Kuri, J.C.; Hosan, A.; Shaikh, F.U.A.; Biswas, W.K. The Effect of Recycled Waste Glass as a Coarse Aggregate on the Properties of Portland Cement Concrete and Geopolymer Concrete. Buildings 2023, 13, 586. [Google Scholar] [CrossRef]

- Tapas, M.J.; Thomas, P.; Vessalas, K.; Nsiah-Baafi, E.; Martin, L.; Sirivivatnanon, V. Comparative Study of the Efficacy of Fly Ash and Reactive Aggregate Powders in Mitigating Alkali-silica Reaction. J. Build. Eng. 2023, 63, 105571. [Google Scholar] [CrossRef]

- Bazhuni, M.F.; Kamali, M.; Ghahremaninezhad, A. An Investigation into the Properties of Ternary and Binary Cement Pastes Containing Glass Powder. Front. Struct. Civ. Eng. 2019, 13, 741–750. [Google Scholar] [CrossRef]

- Afshinnia, K.; Rangaraju, P.R. Influence of Fineness of Ground Recycled Glass on Mitigation of Alkali–silica Reaction in Mortars. Constr. Build. Mater. 2015, 81, 257–267. [Google Scholar] [CrossRef]

- Ke, G.L.; Li, W.G.; Li, R.Y.; Li, Y.L.; Wang, G. Mitigation Effect of Waste Glass Powders on Alkali–silica Reaction (ASR) Expansion in Cementitious Composite. Int. J. Concr. Struct. Mater. 2018, 12, 67. [Google Scholar] [CrossRef]

- Luhar, S.; Cheng, T.W.; Nicolaides, D.; Luhar, I.; Panias, D.; Sakkas, K. Valorisation of glass Wastes for the Development of Geopolymer Composites–Durability, Thermal and Microstructural Properties: A review. Constr. Build. Mater. 2019, 222, 673–687. [Google Scholar] [CrossRef]

- Liu, J.X.; Duan, Z.H.; Poon, C.S. Combined Use of Waste Glass Powder and Cullet in Architectural Mortar. Cem. Concr. Compos. 2017, 82, 34–44. [Google Scholar] [CrossRef]

- Khan, M.N.N.; Sarker, P.K. Effect of Waste Glass Fine Aggregate on the Strength, Durability and High Temperature Resistance of Alkali-activated Fly Ash and GGBFS Blended Mortar. Constr. Build. Mater. 2020, 263, 120177. [Google Scholar] [CrossRef]

- Bostanci, L. Effect of Waste Glass Powder Addition on Properties of Alkali-activated Silica Fume Mortars. J. Build. Eng. 2020, 29, 101154. [Google Scholar] [CrossRef]

- Zhang, S.; Keulen, A.; Arbi, B.; Ye, G. Waste Glass as Partial Mineral Precursor in Alkali-activated Slag/Fly Ash System. Cem. Concr. Res. 2017, 102, 29–40. [Google Scholar] [CrossRef]

- Miraldo, S.; Lopes, S.; Lopes, A.V.; Pacheco-Torgal, F. Design of Fly Ash-based Alkali-activated Mortars, Containing Waste Glass and Recycled CDW Aggregates, for Compressive Strength Optimization. Materials 2022, 15, 1204. [Google Scholar] [CrossRef] [PubMed]

- Sheng, Z.L.; Zhu, B.R.; Cai, J.M.; Han, J.S.; Zhang, Y.M.; Pan, J.L. Influence of Waste Glass Powder on Printability and Mechanical Properties of 3D Printing Geopolymer Concrete. Dev. Built Environ. 2024, 20, 100541. [Google Scholar] [CrossRef]

- Ozkılıç, Y.; Çelik, A.; Tunç, U.; Karalar, M.; Deifalla, A.; Alomayri, T.; Althoey, F. The Use of Crushed Recycled Glass for Alkali Activated Fly Ash Based Geopolymer Concrete and Prediction of its Capacity. J. Mater. Res. Technol. 2023, 24, 8267–8281. [Google Scholar] [CrossRef]

- Khan, N.N.; Kuri, J.C.; Sarker, P.K. Effect of Waste Glass Powder as a Partial Precursor in Ambient Cured Alkali Activated Fly Ash and Fly Ash-GGBFS Mortars. J. Build. Eng. 2020, 34, 101934. [Google Scholar] [CrossRef]

- Aditto, F.S.; Sobuz, M.H.R.; Saha, A.; Jabin, J.A.; Kabbo, M.K.I.; Hasan, N.M.S.; Islam, S. Fresh, Mechanical and Microstructural Behaviour of High-strength Self-compacting Concrete Using Supplementary Cementitious Materials. Case Stud. Constr. Mater. 2023, 19, e02395. [Google Scholar] [CrossRef]

- Tamanna, N.; Tuladhar, R.; Sivakugan, N. Performance of Recycled Waste Glass Sand as Partial Replacement of Sand in Concrete. Constr. Build. Mater. 2020, 239, 117804. [Google Scholar] [CrossRef]

- Nguyen, V.H.; Sébastien, R.; Gallias, J.L. Influence of Cement Grouts Composition on the Rheological Behaviour. Cem. Concr. Res. 2011, 41, 292–300. [Google Scholar] [CrossRef]

- Eriksson, M.; Friedrich, M.; Vorschulze, C. Variations in the Rheology and Penetrability of Cement-based Grouts-an Experimental Study. Cem. Concr. Res. 2004, 34, 1111–1119. [Google Scholar] [CrossRef]

- Bohloli, B.; Skjolsvold, O.; Justnes, H.; Olsson, R.; Grov, E.; Aarset, A. Cements for Tunnel Grouting-Rheology and Flow Properties Tested at Different Temperatures. Tunn. Undergr. Space Technol. 2019, 91, 103011. [Google Scholar] [CrossRef]

- Gomes, S.D.; Ferrara, L.; Sánchez, L.; Moreno, M.S. A Comprehensive Review of Cementitious Grouts: Composition, Properties. Requir. Adv. Perform. 2023, 375, 130991. [Google Scholar] [CrossRef]

- Assaad, J.J.; Daou, Y. Cementitious Grouts with Adapted Rheological Properties for Injection by Vacuum Techniques. Cem. Concr. Res. 2014, 59, 43–54. [Google Scholar] [CrossRef]

- Çinar, M.; Karpuzcu, M.; Çanakci, H. Measurement of Fresh Properties of Cement-Based Grout Containing Waste Marble Powder. Measurement 2019, 150, 106833. [Google Scholar] [CrossRef]

- Tshamu, T.J.; Håkansson, U. Rheology of Cement Grouts: On the Critical Shear Rate and No-slip Regime in the Couette Geometry. Cem. Concr. Res. 2019, 123, 105769. [Google Scholar] [CrossRef]

- Rahman, M.; Wiklund, J.; Kotzé, R.; Håkansson, U. Yield Stress of Cement Grouts. Tunn. Undergr. Space Technol. 2017, 61, 50–60. [Google Scholar] [CrossRef]

- Rahman, M.; Håkansson, U.; Wiklund, J. In-line Rheological Measurements of Cement Grouts: Effects of Water/cement Ratio and Hydration. Tunn. Undergr. Space Technol. 2015, 45, 34–42. [Google Scholar] [CrossRef]

- Mirzahosseini, M.; Riding, K.A. Influence of Different Particle Sizes on Reactivity of Finely Ground Glass as Supplementary Cementitious Material (SCM). Cem. Concr. Compos. 2015, 56, 95–105. [Google Scholar] [CrossRef]

- Taha, B.; Nounu, G. Utilizing Waste Recycled Glass as Sand/cement Replacement in Concrete. J. Mater. Civ. Eng. 2009, 21, 709–721. [Google Scholar] [CrossRef]

- Su, Q.; Xu, J.M. Mechanical Properties and Damage Constitutive Model of Concrete Containing Waste Glass and Rice Husk Ash in High-temperature Environments. J. Build. Eng. 2024, 97, 110832. [Google Scholar] [CrossRef]

- Celik, A.I.; Tunç, U.; Bahrami, A.; Karalar, M.; Mydin, M.A.O.; Alomayri, T.; Özkiliç, Y.O. Use of Waste Glass Powder toward More Sustainable Geopolymer Concrete. J. Mater. Res. Technol. 2023, 24, 8533–8546. [Google Scholar] [CrossRef]

- Kameche, Z.; Djelil, M.; Dahmani, B. Effects of Incorporating Silica Glass Powder as a Supplementary Cementitious Material on Selected Properties of Portland Cement Mortar. J. Build. Eng. 2023, 78, 107550. [Google Scholar] [CrossRef]

- Al-Nawasir, R.; Al-Humeidawi, B.; Memon, Z.A. Effect of Glass Waste Powder and Date Palm Seed Ash Based Sustainable Cementitious Grouts on the Performance of Semi-flexible Pavement. Case Stud. Constr. Mater. 2024, 21, e03453. [Google Scholar] [CrossRef]

- Canakci, H.; Güllü, H.; Dwle, M.I.K. Effect of Glass Powder Added Grout for Deep Mixing of Marginal Sand with Clay. Arab. J. Sci. Eng. 2018, 43, 1583–1595. [Google Scholar] [CrossRef]

- Liang, G.W.; Li, H.X.; Zhu, H.J.; Liu, T.J.; Chen, Q.; Guo, H.H. Reuse of Waste Glass Powder in Alkali-activated Metakaolin/fly Ash Pastes: Physical Properties, Reaction Kinetics and Microstructure. Resour. Conserv. Recycl. 2021, 173, 105721. [Google Scholar] [CrossRef]

- Dai, T.; Fang, C.L.; Liu, T.L.; Zheng, S.J.; Lei, G.; Jiang, G.S. Waste Glass Powder as a High Temperature Stabilizer in Blended Oil Well Cement Pastes: Hydration, Microstructure and Mechanical Properties. Constr. Build. Mater. 2024, 439, 137359. [Google Scholar] [CrossRef]

- Xu, Y.C.; Xing, G.H.; Zhao, J.H.; Zhang, Y. The Effect of Polypropylene Fiber with Different Length and Dosage on the Performance of Alkali-activated Slag Mortar. Constr. Build. Mater. 2021, 307, 124978. [Google Scholar] [CrossRef]

- Ahmad, J.; Zhou, Z.G.; Usanova, K.I.; Vatin, N.I.; El-Shorbagy, M.A. A Step towards Concrete with Partial Substitution of Waste Glass (WG) in Concrete: A Review. Materials 2022, 15, 2525. [Google Scholar] [CrossRef] [PubMed]

- Aliabdo, A.A.; Abd Elmoaty, A.M.; Aboshama, A.Y. Utilization of Waste Glass Powder in the Production of Cement and Concrete. Constr. Build. Mater. 2016, 124, 866–877. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Shah, K.W.; Dong, Z.Q.; Wu, J. Performance Evaluation and Microstructure Characterization of Seawater and Coral/sea Sand Alkali-activated Mortars. Constr. Build. Mater. 2020, 259, 120403. [Google Scholar] [CrossRef]

- Zhang, B.; Zhu, H.; Shah, K.W.; Feng, P.; Dong, Z.Q. Optimization of Mix Proportion of Alkali-activated Slag Mortars Prepared with Seawater and Coral Sand. Constr. Build. Mater. 2021, 284, 122805. [Google Scholar] [CrossRef]

- Svermova, L.; Sonebi, M.; Bartos, P.J.M. Influence of Mix Proportions on Rheology of Cement Grouts Containing Lime Stone Powder. Cem. Concr. Compos. 2003, 25, 737–749. [Google Scholar] [CrossRef]

- Jiang, X.; Xiao, R.; Bai, Y.; Huang, B.S.; Ma, Y.T. Influence of waste glass powder as a supplementary cementitious material (SCM) on physical and mechanical properties of cement paste under high temperatures. J. Clean. Prod. 2022, 340, 130778. [Google Scholar] [CrossRef]

- Yin, W.S.; Li, X.P.; Sun, T.; Chen, Y.Z.; Xu, F.; Yan, G.; Xu, M.N.; Tian, K. Utilization of Waste Glass Powder as Partial Replacement of Cement for the Cementitious Grouts with Superplasticizer and Viscosity Modifying Agent Binary Mixtures: Rheological and Mechanical performances. Constr. Build. Mater. 2021, 286, 122953. [Google Scholar] [CrossRef]

- Navaneetha, E.; Rao, P.N.; Bahurudeen, A. Compatibility of Waste Glass with Other By-products for the Production of Sustainable Concrete. J. Build. Eng. 2023, 80, 107922. [Google Scholar] [CrossRef]

- Elaqra, H.; Rustom, R. Effect of Using Glass Powder as Cement Replacement on Rheological and Mechanical Properties of Cement Paste. Constr. Build. Mater. 2018, 179, 326–335. [Google Scholar] [CrossRef]

- Niu, Y.F.; Cheng, C.M.; Luo, C.L.; Yang, P.F.; Guo, W.; Liu, Q. Study on Rheological Property, Volumetric Deformation, Mechanical Strength and Microstructure of Mortar Incorporated with Waste Glass Powder (WGP). Constr. Build. Mater. 2023, 408, 133420. [Google Scholar] [CrossRef]

| Topic | Usage | Focus | Novelty/Contribution | References |

|---|---|---|---|---|

| Cement Concrete | Binder; aggregate | Workability; strength; durability | A comprehensive analysis was conducted to determine the characteristics of WG concrete and the challenges faced in the application of WG | [1,2,9,10,11] |

| Fine and coarse aggregate | Workability; durability; strength | Concrete with WG exhibits better performance, with particle size influencing workability, while durability-related properties remain consistent | [21,23] | |

| Fine aggregate | Abrasion and freeze–thaw resistance; sulfate attack; penetration | Concrete with WG exhibits similar properties compared to normal concrete. | [18,19,22,24,40] | |

| Self- compacting concrete | Fine and coarse aggregate | Strengths; absorption; failure characteristics; microstructure | It is possible to produce self-compacting concrete using WG, and concretes containing WG exhibit less brittle behavior than the reference concrete | [15,16] |

| Barite concrete | Fine aggregate | Workability; mechanical properties; alkali–silica reaction | It is efficient, economical and environmentally benign to use WG to produce high-density radiation shielding concrete | [14] |

| Steel slag concrete | Coarse aggregate | Slump; density; modulus of elasticity; strength | The ability to improve the fire resistance of concrete | [17] |

| Geopolymer concrete | Strengths; porosity; sorptivity; chloride permeability | The properties of geopolymer concrete containing 10 to 20% WG were comparable to the corresponding properties of the control | [25] | |

| Binder | Alkali–silica reaction; durability and sustainability | WG geopolymer concrete is classified as a durable structural material with broad application prospects, serving as a promising construction material | [30,36,37] | |

| Mortars | Binder/ fine aggregate | Alkali–silica reaction; pore solution | WGP with a particle size of less than 300 μm exhibits an excellent mitigation effect on ASR expansion. | [20,28,29] |

| Alkali- activated mortars | Fine aggregate | Workability; strength; drying shrinkage; chloride permeability; et al. | In alkali-activated mortar, replacing natural sand with WG cullet in different proportions can result in a performance comparable to that of natural sand | [32] |

| Binder | Workability; strength; permeability; microstructure; et al. | The feasibility of using WGP as a partial precursor in alkali-activated mortars was investigated | [33,35,38] | |

| Cement- based grout | Binder (w/s = 1.3) | The Vicat; compressive strength; ultrasonic pulse velocity | The use of cement-based grout combined with WGP to enhance the clay soil via a deep mixing technique | [12] |

| Binder (w/s = 0.5) | Electrical resistivity and strength; shrinkage | The properties of binary and ternary cement pastes containing WGP were examined | [27] | |

| Geopoly- mer grout | Binder (w/s = 0.6) | Compressive strength; microstructure | The obtained compressive strengths were about 73–104% of those of the control cement-based grout | [13] |

| Binder (w/s = 0.42) | Compressive strength; microstructure | This work significantly advances the understanding of the reactivity and potential of WGP | [34] | |

| Cement- based grout | Binder (w/s = 0.5, 0.65, 0.8, 1.0) | Stability and rheology | This work studies the influence of WGP content and NaOH on the stability and rheological properties of grouts at different w/s ratios | This study |

| Specific Surface Area (m2/kg) | Loss on Ignition (%) | Slag Content (%) | Water-Based Grinding Aid (‰) | Initial Setting Time (min) | Final Setting Time (min) | Alkali Content (%) | Soundness | |

|---|---|---|---|---|---|---|---|---|

| P.O 42.5 | 362 | 3.38 | 11.5 | 1.0 | 158 | 290 | 0.38 | Qualified |

| Standard | ≥300 | ≤5.0 | 5.0~20.0 | ≤5 | ≥45 | ≤600 | 0.6 | Qualified |

| Constituent | SiO2 | CaO | AL2O3 | Fe2O3 | K2O | MgO | SO3 | Na2O | Others |

|---|---|---|---|---|---|---|---|---|---|

| Cement | 21.40 | 62.40 | 6.32 | 4.15 | 0.62 | 2.30 | 2.40 | 0.1 | 0.31 |

| WGP | 70.35 | 10.89 | 1.85 | 0.89 | 0.69 | 1.29 | 0.22 | 12.72 | 1.0 |

| Items | w/s | Cement Content | WGP Content | Activator Content (Na2O) |

|---|---|---|---|---|

| Control group | 0.5 0.65 0.8 1.0 | 100% 95% 90% 80% 70% 60% | 0% 5% 10% 20% 30% 40% | 0% |

| Without activator | ||||

| With activator | 4% |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L.; Deng, C.; Zhou, Y.; Tan, Q.; Yan, W.; Zhou, D.; Zhou, Y. Stability and Rheological Properties of Grouts with Waste Glass Powder as Cement Replacement: Influences of Content and Alkali Activator. Materials 2025, 18, 353. https://doi.org/10.3390/ma18020353

Li L, Deng C, Zhou Y, Tan Q, Yan W, Zhou D, Zhou Y. Stability and Rheological Properties of Grouts with Waste Glass Powder as Cement Replacement: Influences of Content and Alkali Activator. Materials. 2025; 18(2):353. https://doi.org/10.3390/ma18020353

Chicago/Turabian StyleLi, Liuxi, Chao Deng, Yi Zhou, Qundong Tan, Wenqin Yan, Dequan Zhou, and Yi Zhou. 2025. "Stability and Rheological Properties of Grouts with Waste Glass Powder as Cement Replacement: Influences of Content and Alkali Activator" Materials 18, no. 2: 353. https://doi.org/10.3390/ma18020353

APA StyleLi, L., Deng, C., Zhou, Y., Tan, Q., Yan, W., Zhou, D., & Zhou, Y. (2025). Stability and Rheological Properties of Grouts with Waste Glass Powder as Cement Replacement: Influences of Content and Alkali Activator. Materials, 18(2), 353. https://doi.org/10.3390/ma18020353