Microstructural Influences on High Cycle Fatigue Crack Initiation Mechanism in Ti-Al-Mo-Cr-V-Nb-Zr-Sn Metastable β Titanium Alloy

Abstract

1. Introduction

2. Material and Methods

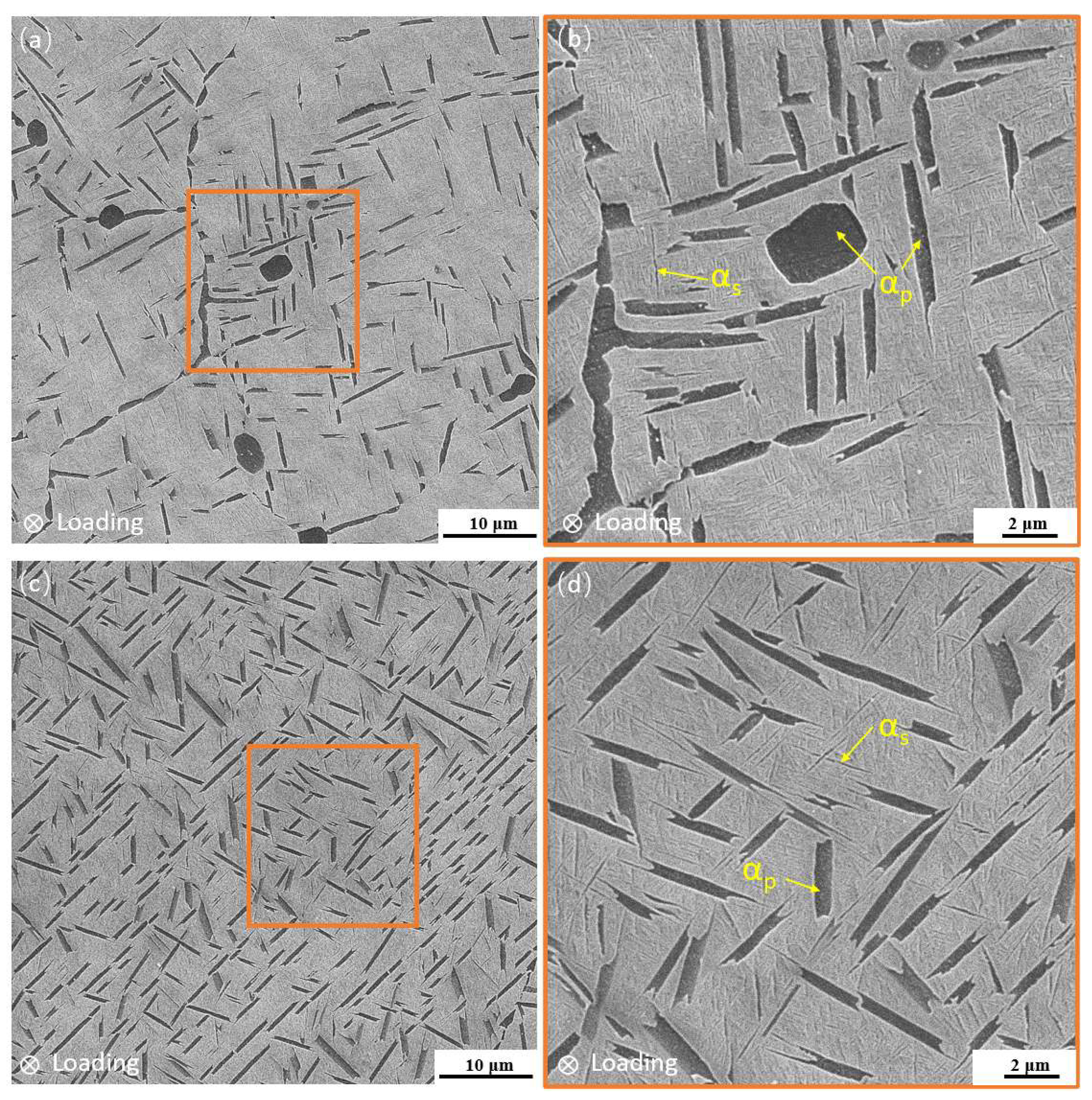

2.1. Microstructure of Materials

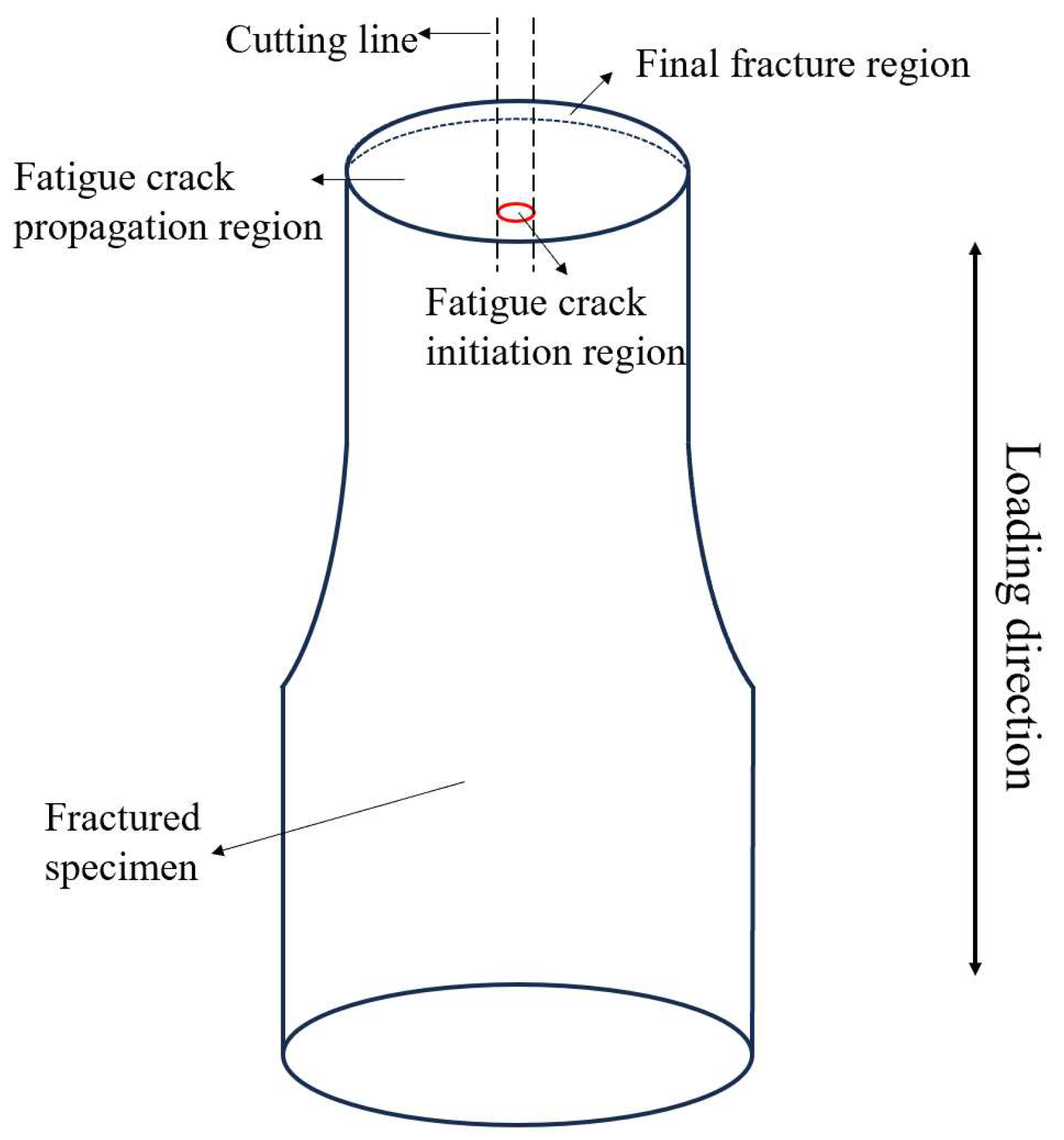

2.2. Tensile and Fatigue Tests

2.3. Characterization Methods

3. Results and Discussion

3.1. Tensile Properties

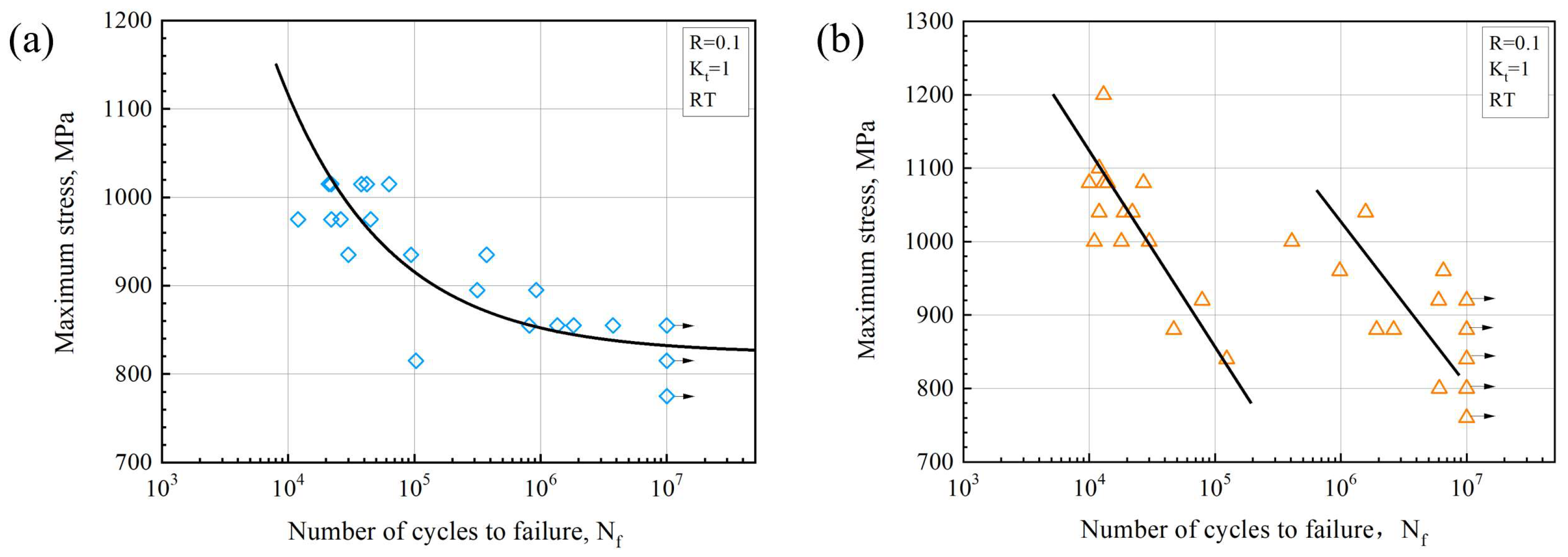

3.2. Characteristics of the S-N Curve

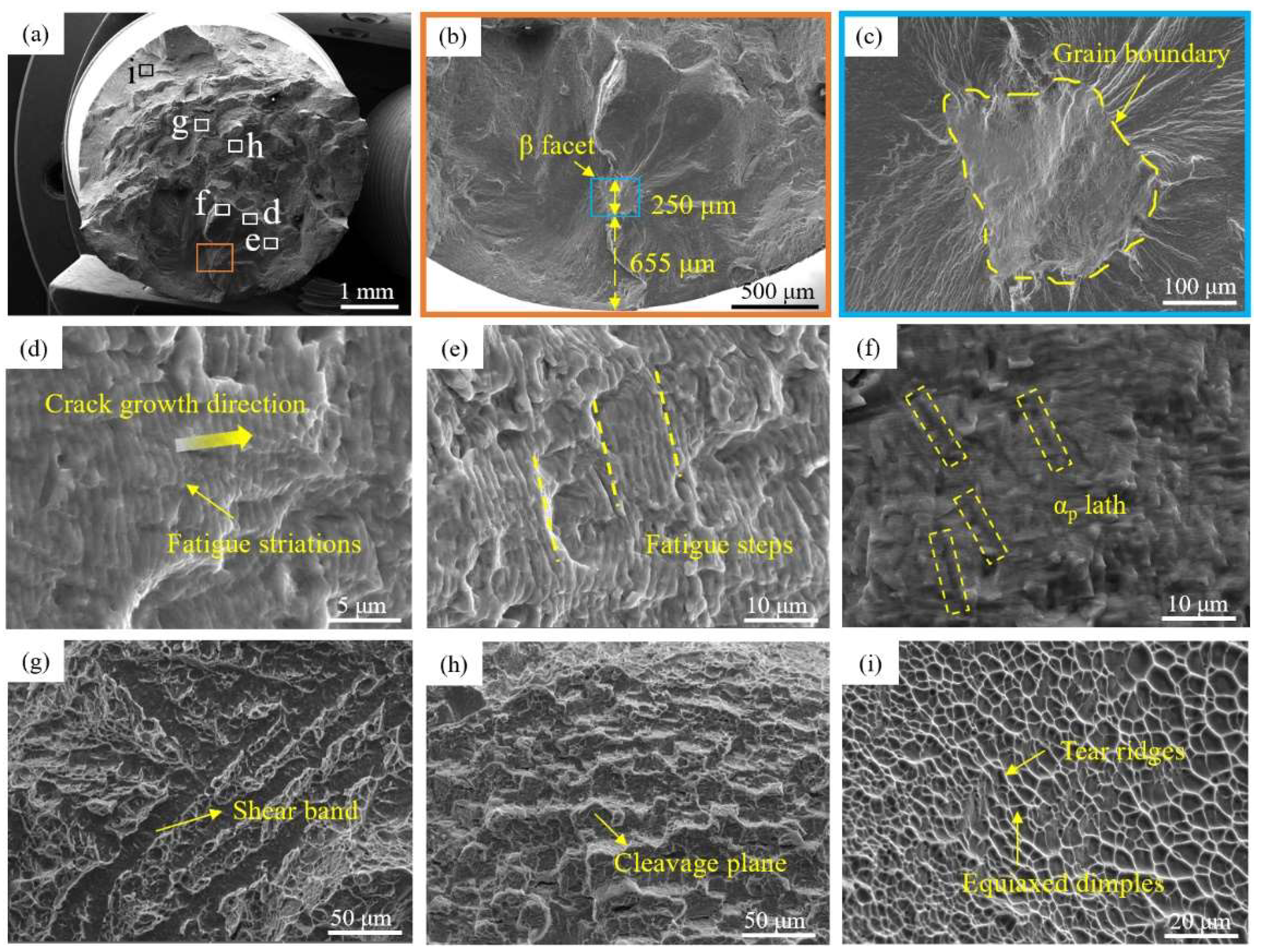

3.3. Fractographic Analysis

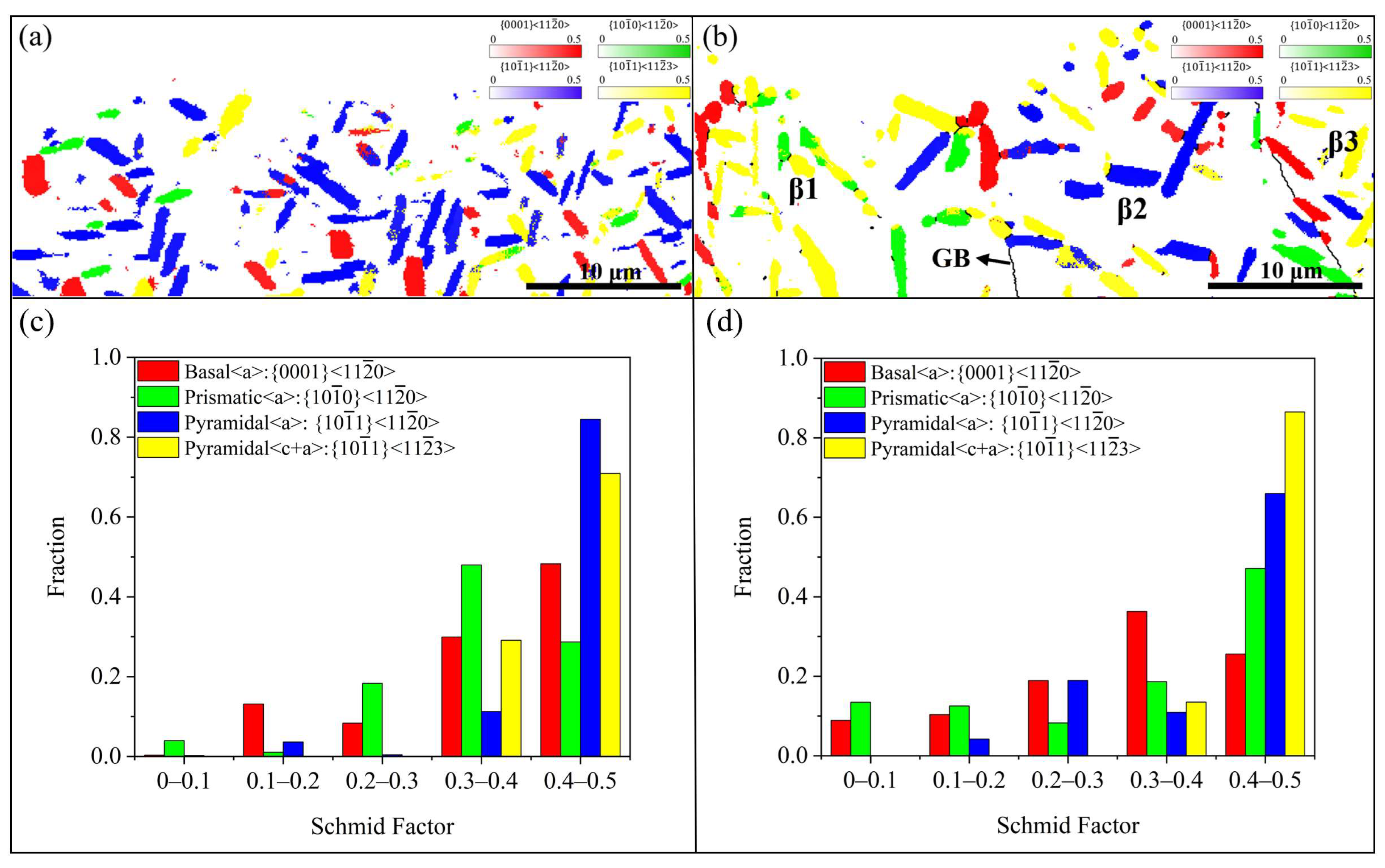

3.4. Crystal Orientation and Schmid Factor Analysis of αp

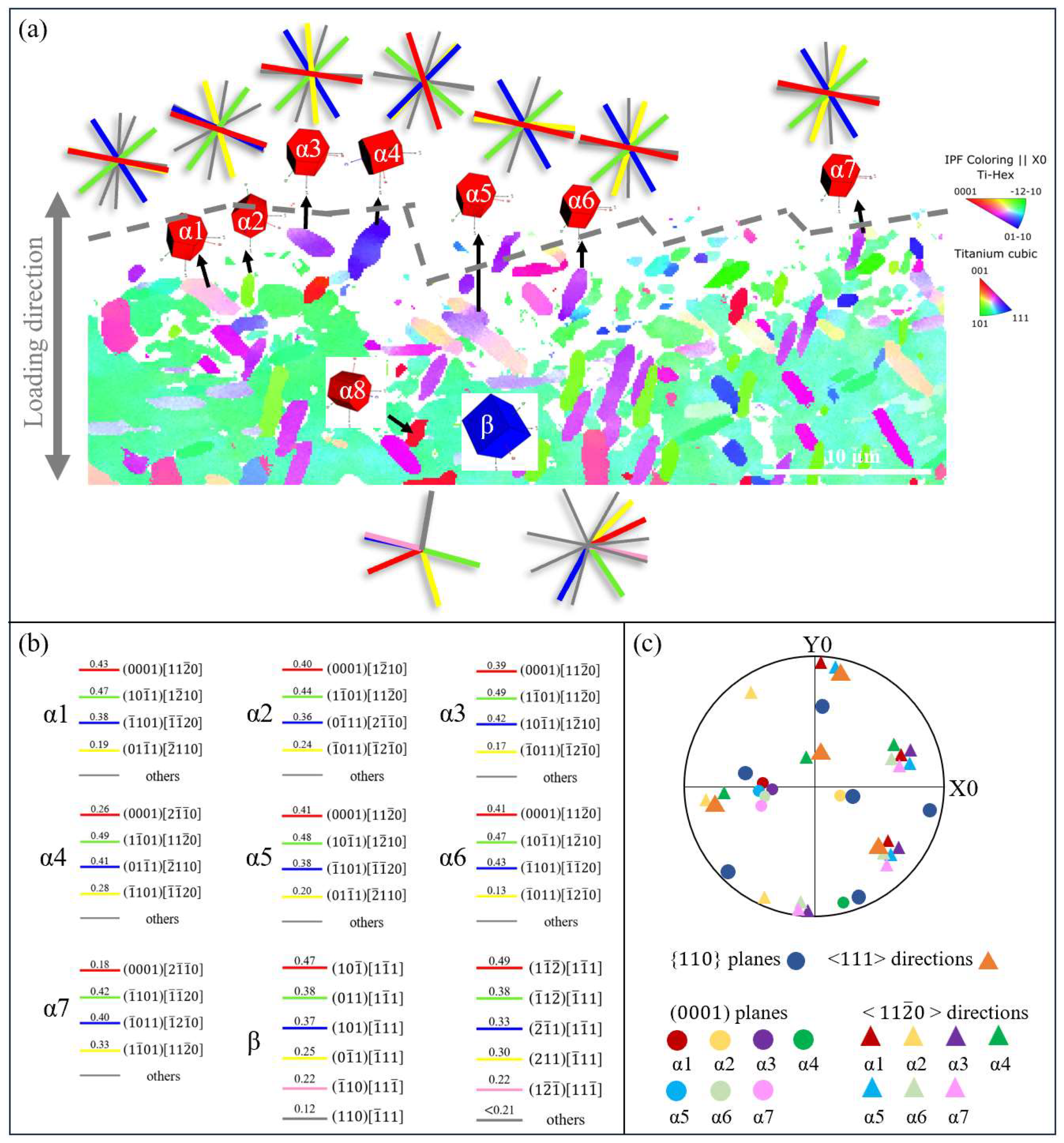

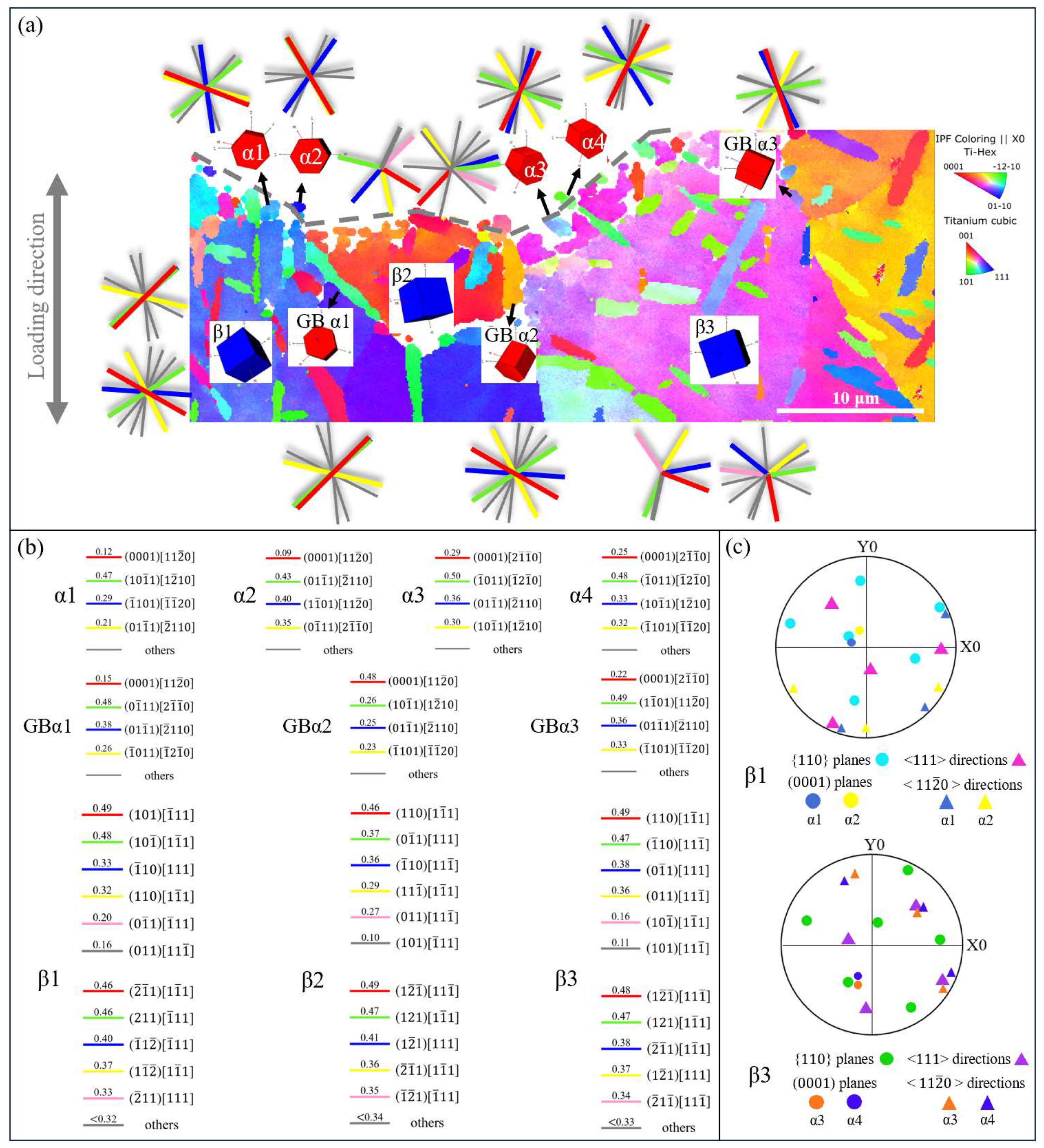

3.5. Fatigue Crack Initiation Mechanisms

4. Conclusions

- The Ti-Al-Mo-Cr-V-Nb-Zr-Sn titanium alloy with a basketweave microstructure has a better high cycle fatigue performance than that with a bimodal microstructure. The bimodal microstructure shows greater fatigue life dispersion. The bimodal microstructure shows a bilinear phenomenon on the S-N curve due to the uncertainty of the microstructure of the crack tip.

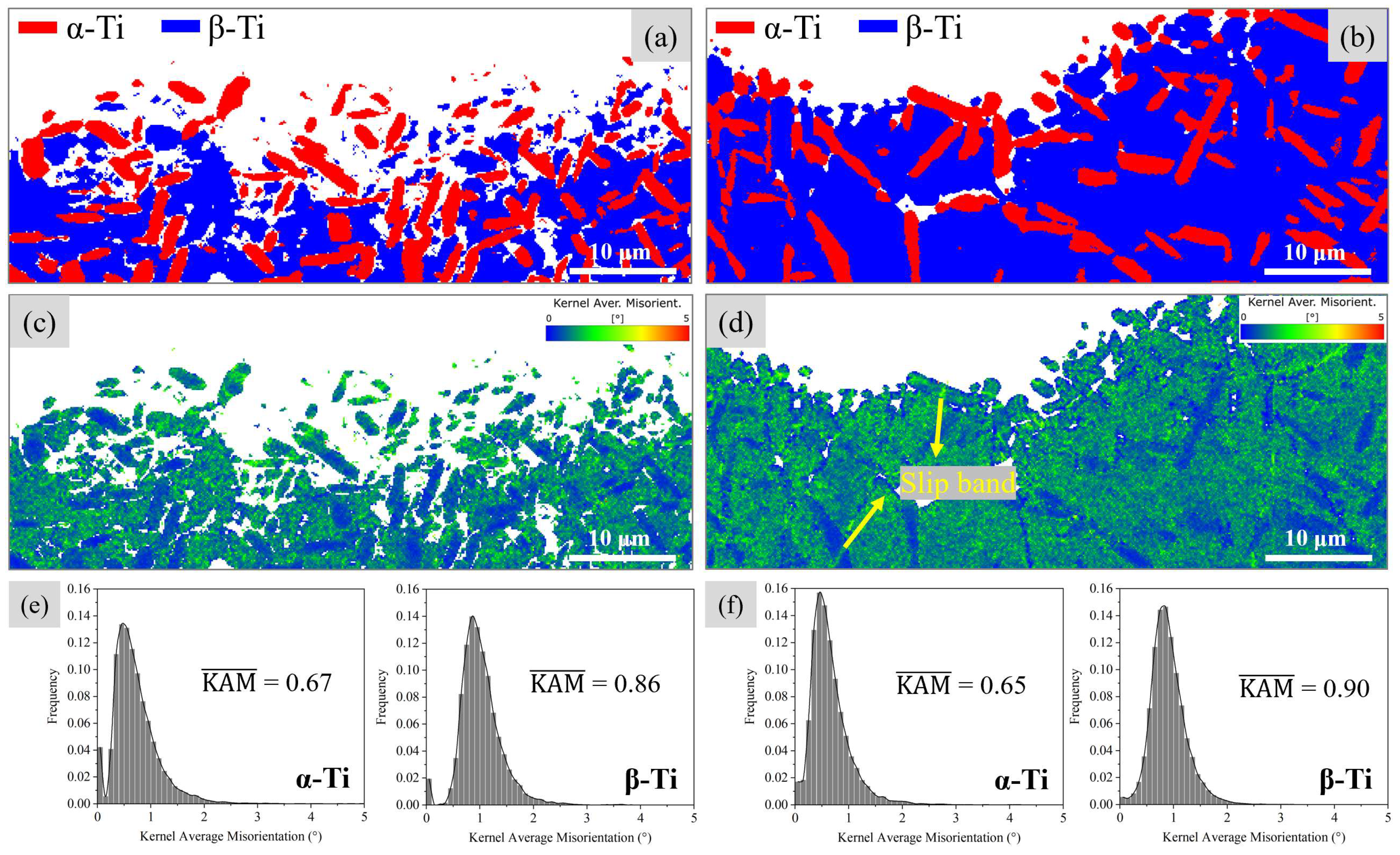

- Both the basketweave microstructure and the bimodal microstructure exhibit high KAM values. The degree of plastic deformation of the β matrix is greater than that of the α phase due to the higher KAM value. This inconsistency of plastic deformation of the phases will lead to the nucleation of fatigue cracks.

- In both microstructures of the Ti-Al-Mo-Cr-V-Nb-Zr-Sn titanium alloy, the primary slip system activated is the pyramidal <a>. The microcrack initiates on the pyramidal plane with the highest SF of αp in most cases. However, the propagation of microcracks can ignore the influence of crystallographic orientation due to the large driving force at the crack tip.

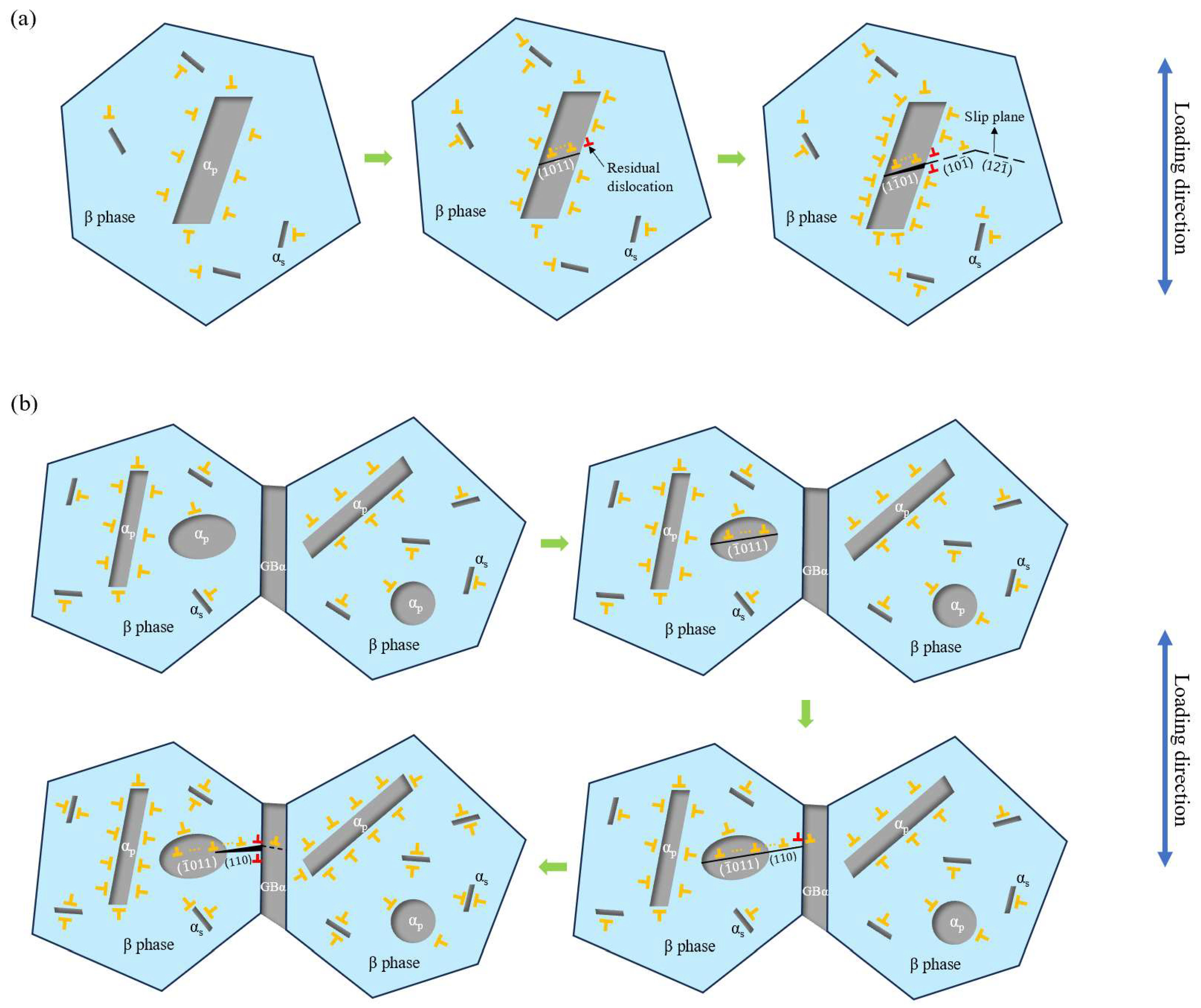

- The phenomenological models of fatigue crack initiation in the basketweave and bimodal microstructures of the Ti-Al-Mo-Cr-V-Nb-Zr-Sn titanium alloy are established to explain the possible mechanisms of fatigue crack initiation.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Pesode, P.; Barve, S. A review—Metastable β titanium alloy for biomedical applications. J. Eng. Appl. Sci. 2023, 70, 25. [Google Scholar] [CrossRef]

- Fan, J.; Li, J.; Kou, H.; Hua, K.; Tang, B.; Zhang, Y. Microstructure and mechanical property correlation and property optimization of a near β titanium alloy Ti-7333. J. Alloys Compd. 2016, 682, 517–524. [Google Scholar] [CrossRef]

- Ding, C.; Liu, C.; Zhang, L.; Deng, Y.; Liu, H.; Wu, D.; Liu, L. Microstructure and tensile properties of a cost-affordable and ultrahigh-strength metastable β titanium alloy with a composition of Ti-6Al-1Mo-1Fe-6.9Cr. J. Alloys Compd. 2022, 901, 163476. [Google Scholar] [CrossRef]

- Du, Z.; Guo, H.; Liu, J.; Cheng, J.; Zhao, X.; Wang, X.; Liu, F.; Cui, X. Microstructure evolution during aging heat treatment and its effects on tensile properties and dynamic Young’s modulus of a biomedical β titanium alloy. Mater. Sci. Eng. A 2020, 791, 139677. [Google Scholar] [CrossRef]

- Yao, T.; Du, K.; Wang, H.; Huang, Z.; Li, C.; Li, L.; Hao, Y.L.; Yang, R.; Ye, H. In situ scanning and transmission electron microscopy investigation on plastic deformation in a metastable β titanium alloy. Acta Mater. 2017, 133, 21–29. [Google Scholar] [CrossRef]

- Tang, W.; Zhang, X.; Yu, C.; Wu, L.; Zhang, H.; Li, C. Microstructural evolution and deformation behavior of a solution-treated Ti-Al-Mo-Fe metastable beta titanium alloy during room-temperature deformation. Crystals 2023, 13, 818. [Google Scholar] [CrossRef]

- Ballor, J.; Poplawsky, J.D.; Devaraj, A.; Misture, S.; Boehlert, C.J. Lattice parameter evolution during the β-to-α and β-to-ω transformations of iron- and aluminum-modified Ti-11Cr(at.%). Crystals 2024, 14, 145. [Google Scholar] [CrossRef]

- Cotton, J.D.; Briggs, R.D.; Boyer, R.R.; Tamirisakandala, S.; Russo, P.; Shchetnikov, N.; Fanning, J.C. State of the art in beta titanium alloys for airframe applications. JOM 2015, 67, 1281–1303. [Google Scholar] [CrossRef]

- Kolli, R.P.; Devaraj, A. A review of metastable beta titanium alloys. Metals 2018, 8, 506. [Google Scholar] [CrossRef]

- Boyer, R.R.; Briggs, R.D. The Use of β titanium alloys in the aerospace industry. J. Mater. Eng. Perform. 2005, 14, 681–685. [Google Scholar] [CrossRef]

- Szolwinski, M.P.; Farris, T.N. Observation, analysis and prediction of fretting fatigue in 2024-T351 aluminum alloy. Wear 1998, 221, 24–36. [Google Scholar] [CrossRef]

- Huang, C.; Zhao, Y.; Xin, S.; Zhou, W.; Li, Q.; Zeng, W.; Tan, C. High cycle fatigue behavior of Ti–5Al–5Mo–5V–3Cr–1Zr titanium alloy with bimodal microstructure. J. Alloys Compd. 2017, 695, 1966–1975. [Google Scholar] [CrossRef]

- Yue, Y.; Dai, L.Y.; Zhong, H.; Zhang, X.Y.; Liang, S.X.; Ma, M.Z.; Liu, R.P. Effect of microstructure on high cycle fatigue behavior of Ti-20Zr-6.5Al-4V alloy. J. Alloys Compd. 2017, 696, 663–669. [Google Scholar] [CrossRef]

- Shi, X.; Zeng, W.; Xue, S.; Jia, Z. The crack initiation behavior and the fatigue limit of Ti–5Al–5Mo–5V–1Cr–1Fe titanium alloy with basket-weave microstructure. J. Alloys Compd. 2015, 631, 340–349. [Google Scholar] [CrossRef]

- Naydenkin, E.V.; Mishin, I.P.; Ratochka, I.V.; Oborin, V.A.; Bannikov, M.V.; Bilalov, D.A.; Naydenkin, K.E. Fatigue and fracture behavior of ultrafine-grained near β titanium alloy produced by radial shear rolling and subsequent aging. Mater. Sci. Eng. A 2021, 810, 140968. [Google Scholar] [CrossRef]

- Wang, S.; Zhang, H.; Zhou, G.; Chen, X.-B.; Chen, L. Effects of microstructure on high-cycle fatigue properties of Ti-4Al-6Mo-2V-5Cr-2Zr alloy. Int. J. Fatigue 2024, 182, 108223. [Google Scholar] [CrossRef]

- Gu, B.; Dang, N.; Zhang, J.J.; Liu, G.Q.; Gu, X.F.; Yang, P. The damage mechanism of the metastable β-titanium alloy Ti5321 with specific microtexture using synchrotron X-ray microtomography. J. Alloys Compd. 2023, 968, 172021. [Google Scholar] [CrossRef]

- Gu, B.; Dang, N.; Zhang, J.J.; Gu, X.F.; Yang, P.; Skrotzki, W. In situ observations of the damage behavior of the metastable β-titanium alloy Ti5321 using synchrotron X-ray microtomography. Mater. Charact. 2024, 207, 113541. [Google Scholar] [CrossRef]

- Sun, J.H.; Gu, H.; Zhang, J.; Jiang, J.; Wu, G.Q.; Sun, Z.G. Ti6Al4V-0.72H on the establishment of flow behavior and the analysis of hot processing maps. Crystals 2024, 14, 345. [Google Scholar] [CrossRef]

- Gao, C.; Zhang, Y.; Jiang, J.; Fu, R.; Du, L.; Pan, X. Research viewpoint on performance enhancement for very-high-cycle fatigue of Ti-6Al-4V alloys via laser-based powder bed fusion. Crystals 2024, 14, 749. [Google Scholar] [CrossRef]

- Wu, Z.; Kou, H.; Chen, N.; Qiang, F.; Fan, J.; Tang, B.; Li, J. Crack initiation mechanism in a high-strength Ti-5Al-7.5V alloy subjected to high cycle fatigue loading. Eng. Fail. Anal. 2023, 148, 107201. [Google Scholar] [CrossRef]

- Luo, H.; Yuan, W.; Xiang, W.; Deng, H.; Yin, H.; Chen, L.; Cao, S. High-cycle fatigue behavior and corresponding microscale deformation mechanisms of metastable Ti55511 alloy with a basket-weave microstructure. Materials 2022, 15, 7144. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Peng, H.; Liu, Y.; Wang, C.; Wang, Q.; Chen, Y. Crack initiation mechanism of titanium alloy in very high cycle fatigue regime at 400 °C considering stress ratio effect. Int. J. Fatigue 2022, 163, 107012. [Google Scholar] [CrossRef]

- GB/T 228.1-2021; Metallic Materials–Tensile Testing–Part 1: Method of Test at Room Temperature. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2021.

- GB/T 3075-2021; Metallic Materials–Fatigue Testing–Axial-Force-Controlled Method. General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China: Beijing, China, 2021.

- Li, M.Y.; Zhang, B.; Song, Z.M.; Luo, X.M.; Zhang, G.P. Detecting the deformation behavior of bimodal Ti-6Al-4V using a digital image correlation technique. Materials 2022, 15, 7504. [Google Scholar] [CrossRef]

- Pang, J.C.; Li, S.X.; Wang, Z.G.; Zhang, Z.F. General relation between tensile strength and fatigue strength of metallic materials. Mater. Sci. Eng. A 2013, 564, 331–334. [Google Scholar] [CrossRef]

- Wu, Z.; Kou, H.; Chen, N.; Zhang, Z.; Qiang, F.; Fan, J.; Tang, B.; Li, J. Microstructural influences on the high cycle fatigue life dispersion and damage mechanism in a metastable β titanium alloy. J. Mater. Sci. Technol. 2021, 70, 12–23. [Google Scholar] [CrossRef]

- Jha, S.K.; Chandran, K.S.R. An unusual fatigue phenomenon: Duality of the S–N fatigue curve in the β-titanium alloy Ti–10V–2Fe–3Al. Scr. Mater. 2003, 48, 1207–1212. [Google Scholar] [CrossRef]

- Chandran, K.S.R.; Jha, S.K. Duality of the S–N fatigue curve caused by competing failure modes in a titanium alloy and the role of Poisson defect statistics. Acta Mater. 2005, 53, 1867–1881. [Google Scholar] [CrossRef]

- Wang, S.; Wen, T.; Han, J.; Srolovitz, D.J. Coherent and semicoherent α/β interfaces in titanium: Structure, thermodynamics, migration. npj Comput. Mater. 2023, 9, 216. [Google Scholar] [CrossRef]

- Murzinova, M.A.; Zherebtsov, S.V.; Klimenko, D.N.; Semiatin, S.L. The effect of β stabilizers on the structure and energy of α/β interfaces in titanium alloys. Metall. Mater. Trans. A 2021, 52, 1689–1698. [Google Scholar] [CrossRef]

- Ankem, S.; Margolin, H. The role of elastic interaction stresses on the onset of plastic flow for oriented two ductile phase structures. Metall. Mater. Trans. A 1980, 11, 963–972. [Google Scholar] [CrossRef]

- Jun, T.S.; Sernicola, G.; Dunne, F.P.E.; Britton, T.B. Local deformation mechanisms of two-phase Ti alloy. Mater. Sci. Eng. A 2016, 649, 39–47. [Google Scholar] [CrossRef]

- Holden, F.C.; Ogden, H.R.; Jaffee, R.I. Heat treatment, structure, and mechanical properties of Ti-Mn alloys. JOM 1954, 6, 169–184. [Google Scholar] [CrossRef]

- Klimova, M.; Zherebtsov, S.; Salishchev, G.; Semiatin, S.L. Influence of deformation on the Burgers orientation relationship between the α and β phases in Ti–5Al–5Mo–5V–1Cr–1Fe. Mater. Sci. Eng. A 2015, 645, 292–297. [Google Scholar] [CrossRef]

- Bhattacharyya, D.; Viswanathan, G.B.; Denkenberger, R.; Furrer, D.; Fraser, H.L. The role of crystallographic and geometrical relationships between α and β phases in an α/β titanium alloy. Acta Mater. 2003, 51, 4679–4691. [Google Scholar] [CrossRef]

- Zhang, R.; Zhao, Q.; Zhao, Y.; Guo, D.; Du, Y. Research progress on slip behavior of α-Ti under quasi-static loading: A review. Metals 2022, 12, 1571. [Google Scholar] [CrossRef]

- Huang, S.; Zhao, Q.; Lin, C.; Wu, C.; Zhao, Y.; Jia, W.; Mao, C. In-situ investigation of tensile behaviors of Ti–6Al alloy with extra low interstitial. Mater. Sci. Eng. A 2021, 809, 140958. [Google Scholar] [CrossRef]

- Wu, Z.; Kou, H.; Chen, N.; Zhang, Z.; Qiang, F.; Fan, J.; Tang, B.; Li, J. The effect of cubic-texture on fatigue cracking in a metastable β titanium alloy subjected to high-cycle fatigue. Int. J. Fatigue 2020, 141, 105872. [Google Scholar] [CrossRef]

- Jia, R.; Zeng, W.; Zhao, Z.; Wang, B.; Chen, H.; Xu, J.; Wang, Q. Crack nucleation and dislocation activities in titanium alloys with the strong transverse texture: Insights for enhancing dwell fatigue resistance. Int. J. Plast. 2024, 175, 103938. [Google Scholar] [CrossRef]

- Meng, L.; Kitashima, T.; Lin, P.; Zheng, L.; Jiang, Z.; Zhao, J. In situ EBSD investigation of microtexture evolution and slip activation of α macrozones during tensile deformation in Ti-6Al-4V alloy. Mater. Sci. Eng. A 2025, 924, 147739. [Google Scholar] [CrossRef]

- Qian, Y.; Fan, Q.; Liu, X.; Wang, D.; Zhou, Y. Crystal plasticity finite element method for slip systems evolution analysis of α/β duplex titanium alloys during quasi-static tensile testing. Appl. Sci. 2020, 10, 1571. [Google Scholar] [CrossRef]

- Du, C.; Maresca, F.; Geers, M.G.D.; Hoefnagels, J.P.M. Ferrite slip system activation investigated by uniaxial micro-tensile tests and simulations. Acta Mater. 2018, 146, 314–327. [Google Scholar] [CrossRef]

- Li, H.; Mason, D.E.; Yang, Y.; Bieler, T.R.; Crimp, M.A.; Boehlert, C.J. Comparison of the deformation behaviour of commercially pure titanium and Ti–5Al–2.5Sn(wt.%) at 296 and 728 K. Philos. Mag. 2013, 93, 2875–2895. [Google Scholar] [CrossRef]

- Pilchak, A.L.; Williams, R.E.A.; Williams, J.C. Crystallography of fatigue crack initiation and growth in fully lamellar Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 106–124. [Google Scholar] [CrossRef]

- Huang, Y.; Jiang, J. A critical review of Von Mises Criterion for compatible deformation of polycrystalline materials. Crystals 2023, 13, 244. [Google Scholar] [CrossRef]

- Yumak, N.; Aslantaş, K. A review on heat treatment efficiency in metastable β titanium alloys: The role of treatment process and parameters. J. Mater. Res. Technol. 2020, 9, 15360–15380. [Google Scholar] [CrossRef]

| Microstructure | Solution-Treated T/Time | Cooling | Aging T/Time | Cooling |

|---|---|---|---|---|

| Basketweave | 816 °C/120 min | Water cooling | 535 °C/480 min | Air cooling |

| Bimodal | 820 °C/120 min | Air cooling | 540 °C/480 min | Air cooling |

| Microstructure | max (MPa) | Nf (Cycle) | Location of Crack Source |

|---|---|---|---|

| Basketweave | 940 | 1.355 × 106 | Sub-surface |

| Bimodal | 800 | 6.056 × 106 | Sub-surface |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, C.; Wang, Y.; Hu, R.; Shang, G.; Wu, Y.; Lu, Y. Microstructural Influences on High Cycle Fatigue Crack Initiation Mechanism in Ti-Al-Mo-Cr-V-Nb-Zr-Sn Metastable β Titanium Alloy. Materials 2025, 18, 336. https://doi.org/10.3390/ma18020336

Zhao C, Wang Y, Hu R, Shang G, Wu Y, Lu Y. Microstructural Influences on High Cycle Fatigue Crack Initiation Mechanism in Ti-Al-Mo-Cr-V-Nb-Zr-Sn Metastable β Titanium Alloy. Materials. 2025; 18(2):336. https://doi.org/10.3390/ma18020336

Chicago/Turabian StyleZhao, Chenxi, Yongxin Wang, Rui Hu, Guoqiang Shang, Yuxue Wu, and Yunmei Lu. 2025. "Microstructural Influences on High Cycle Fatigue Crack Initiation Mechanism in Ti-Al-Mo-Cr-V-Nb-Zr-Sn Metastable β Titanium Alloy" Materials 18, no. 2: 336. https://doi.org/10.3390/ma18020336

APA StyleZhao, C., Wang, Y., Hu, R., Shang, G., Wu, Y., & Lu, Y. (2025). Microstructural Influences on High Cycle Fatigue Crack Initiation Mechanism in Ti-Al-Mo-Cr-V-Nb-Zr-Sn Metastable β Titanium Alloy. Materials, 18(2), 336. https://doi.org/10.3390/ma18020336