Residual Stress in Friction Stir Welding of Dissimilar Aluminum Alloys: A Parametric Study

Abstract

1. Introduction

2. Problem Definition and Methodology

2.1. Geometry

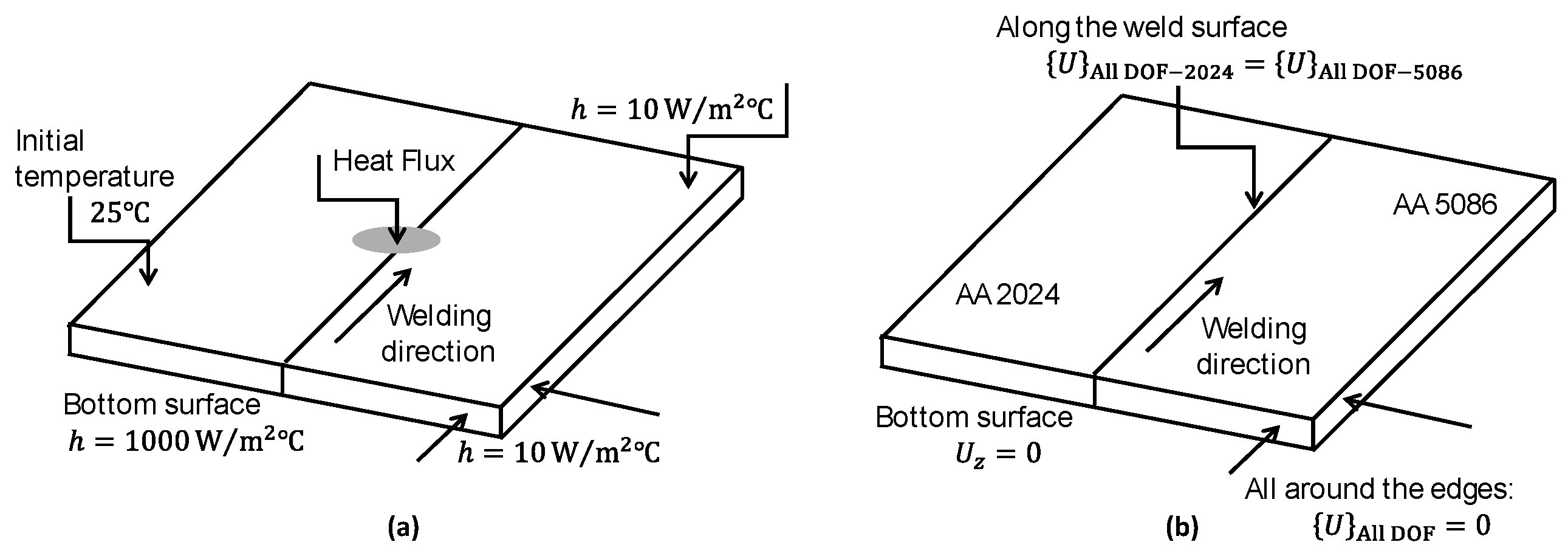

2.2. Thermal Model

Thermal Boundary Conditions

2.3. Mechanical Model

Mechanical Boundary Conditions

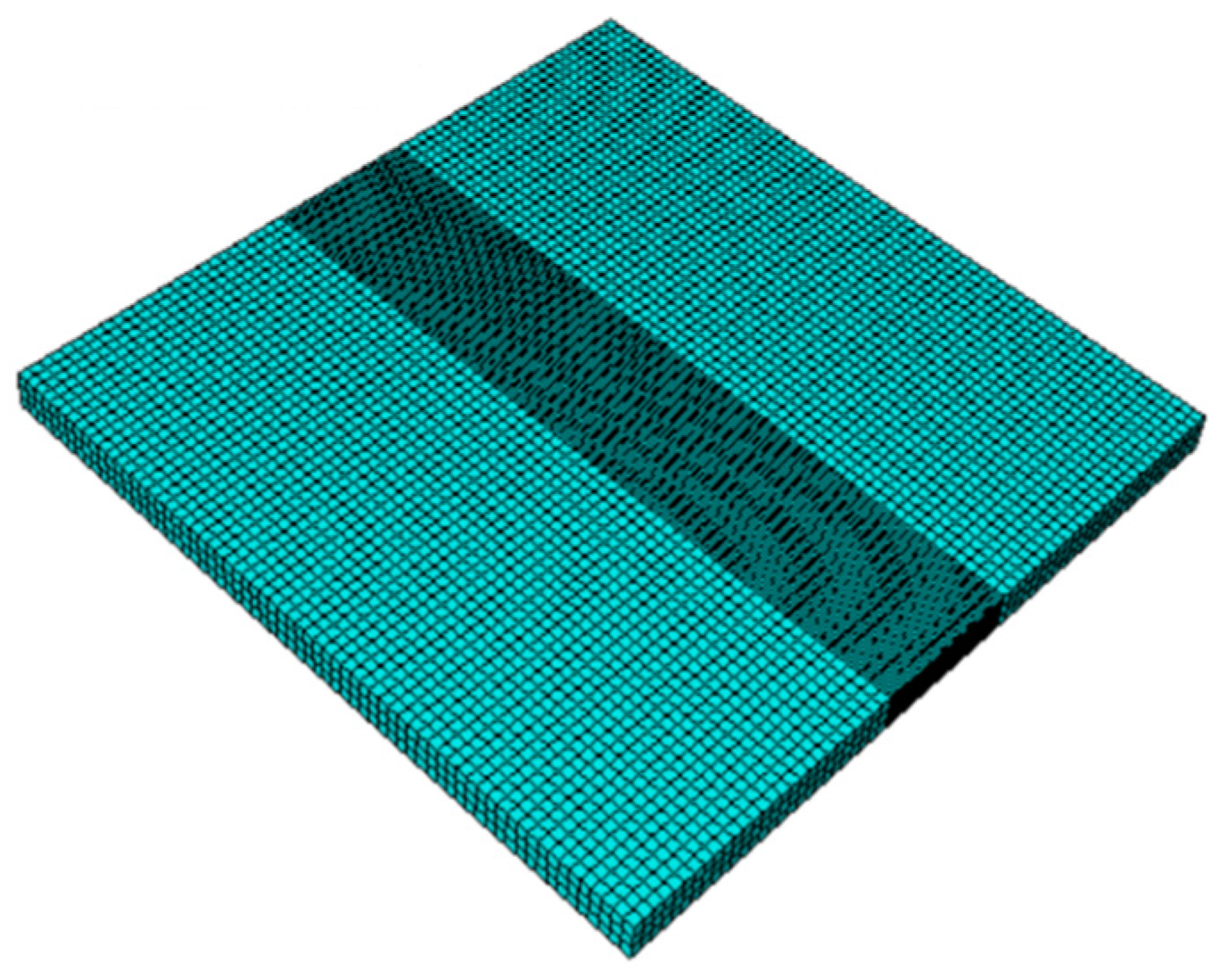

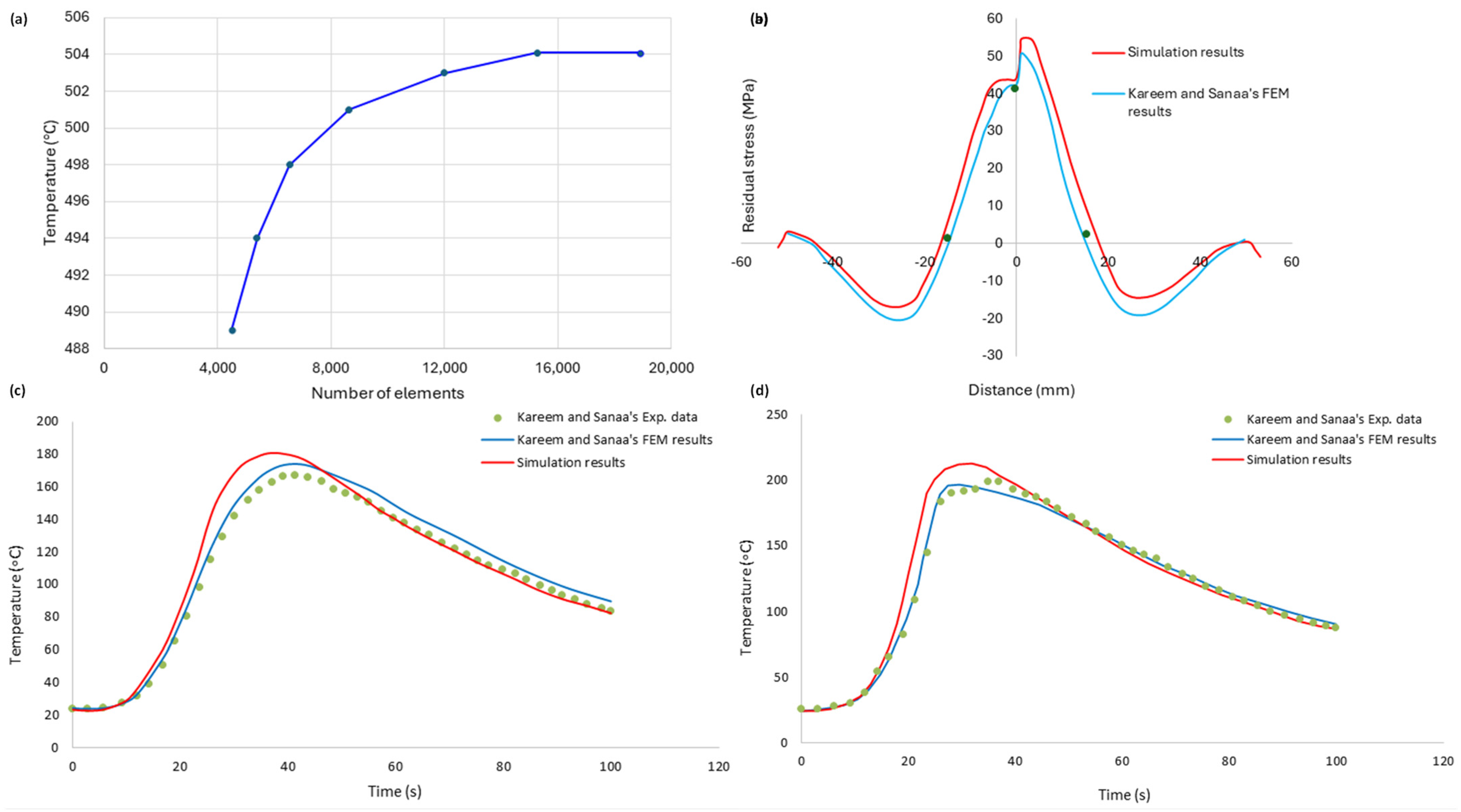

3. Finite Element Model

3.1. Thermal Model

3.2. Mechanical Model

4. Results and Discussion

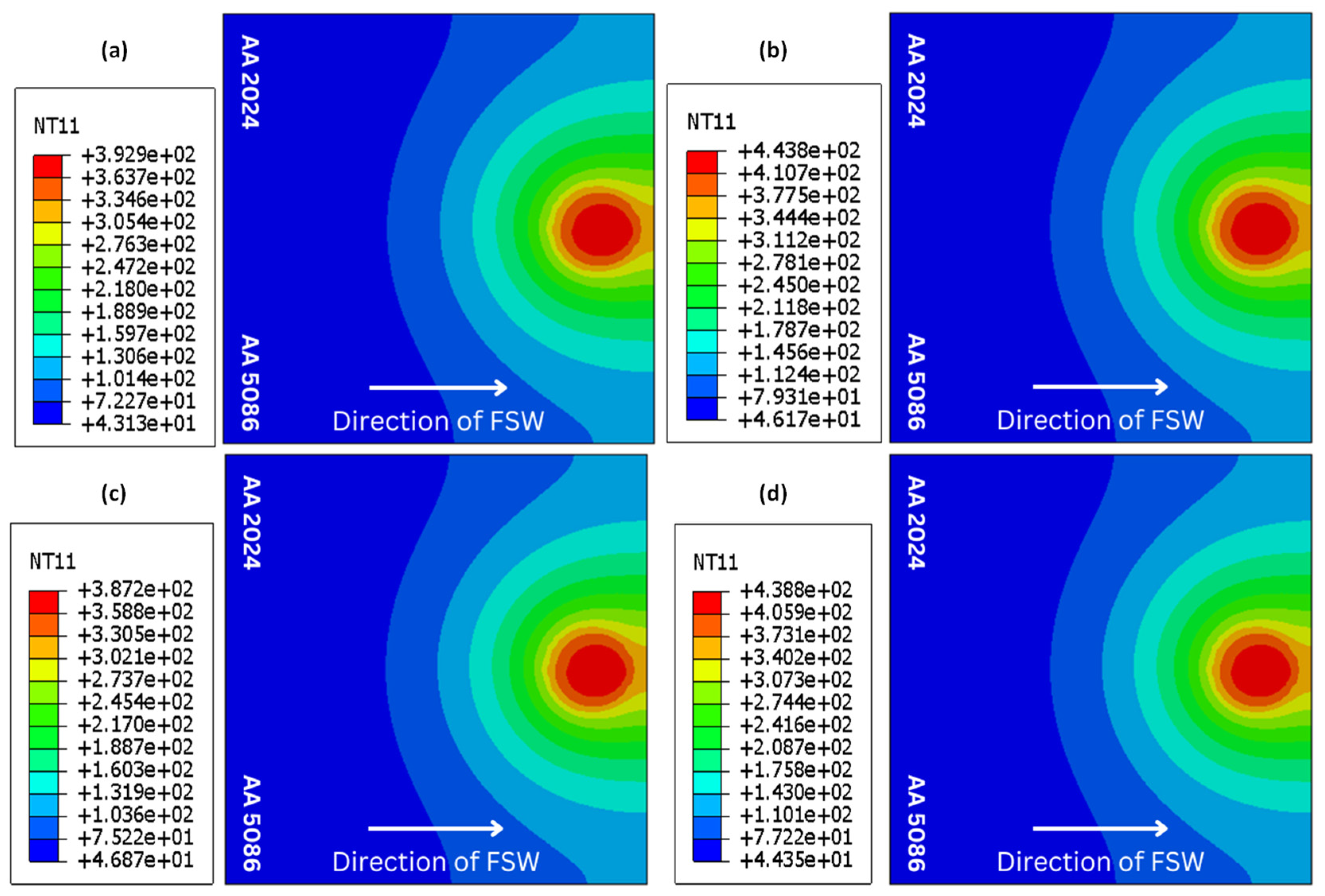

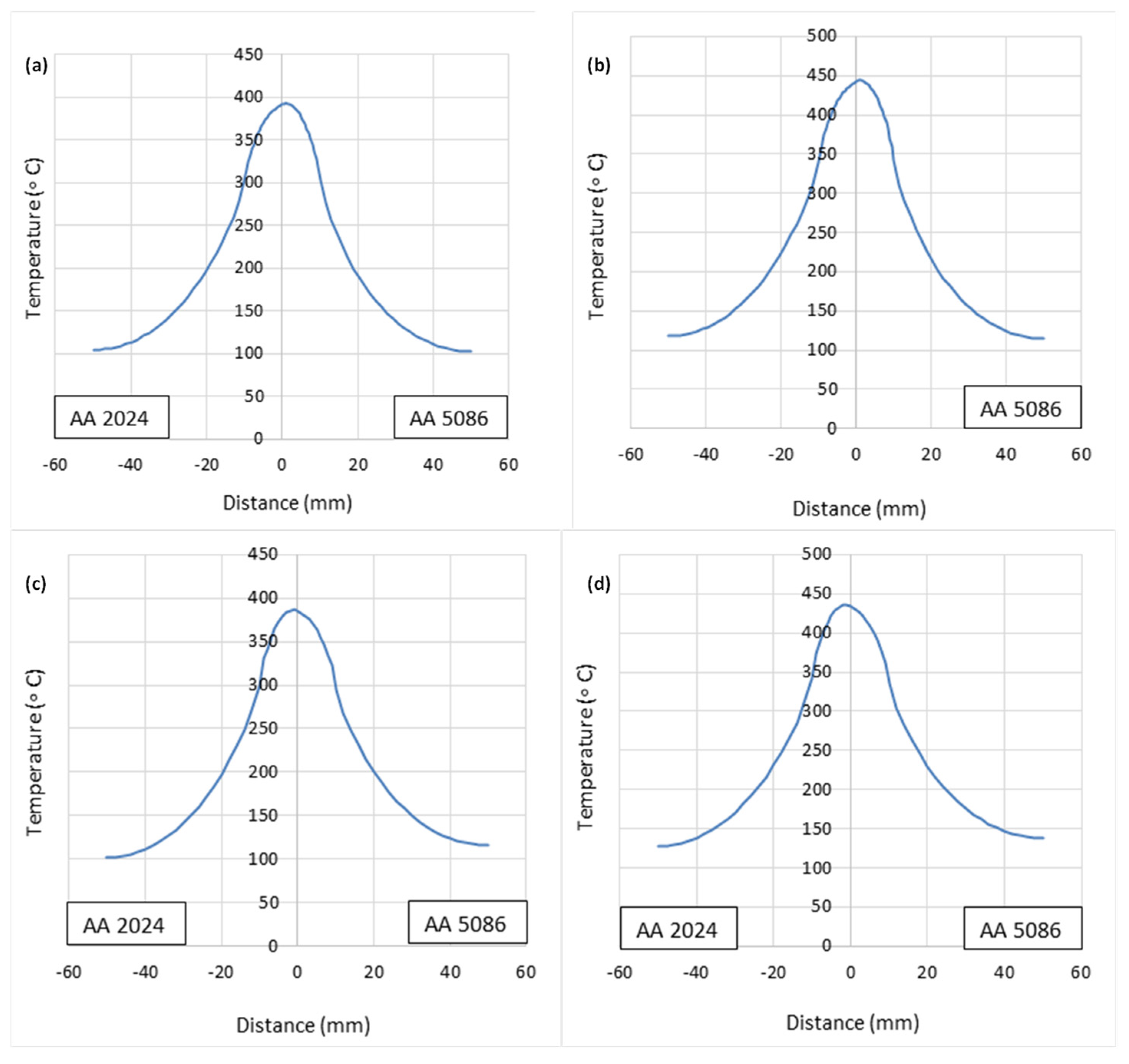

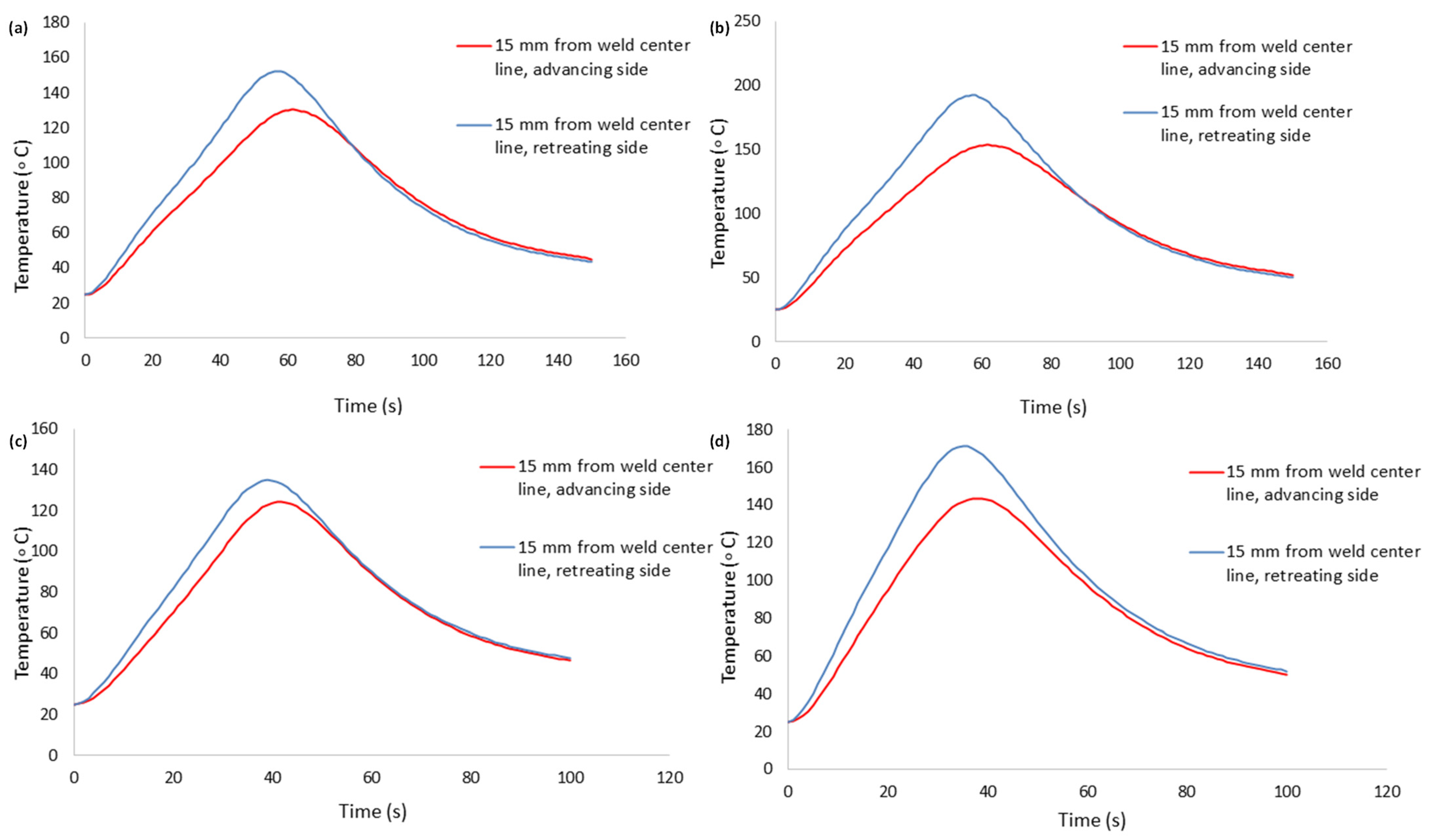

4.1. Temperature Distribution

4.1.1. Effect of Tool Rotational Speed

4.1.2. Effect of Tool Traverse Speed

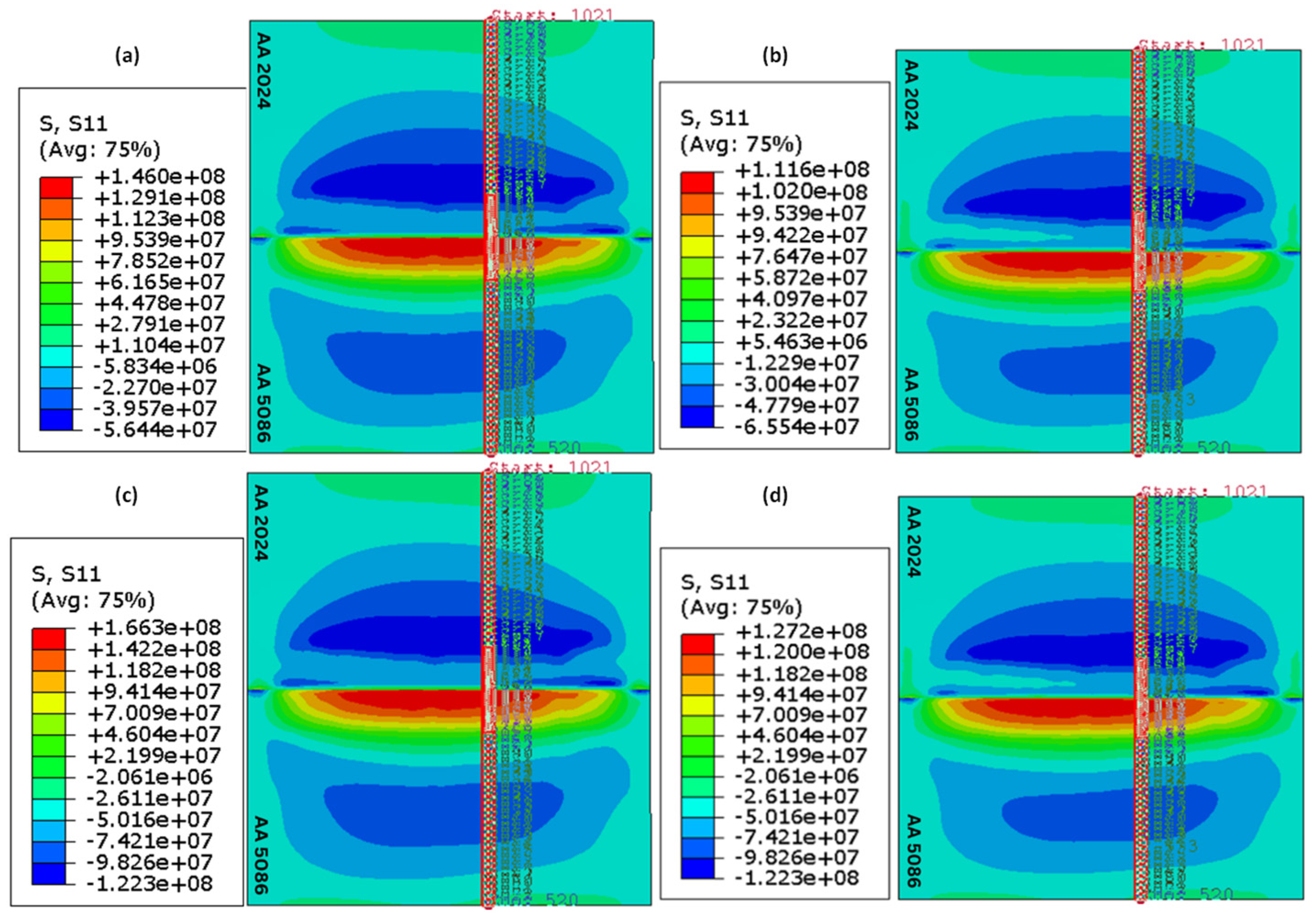

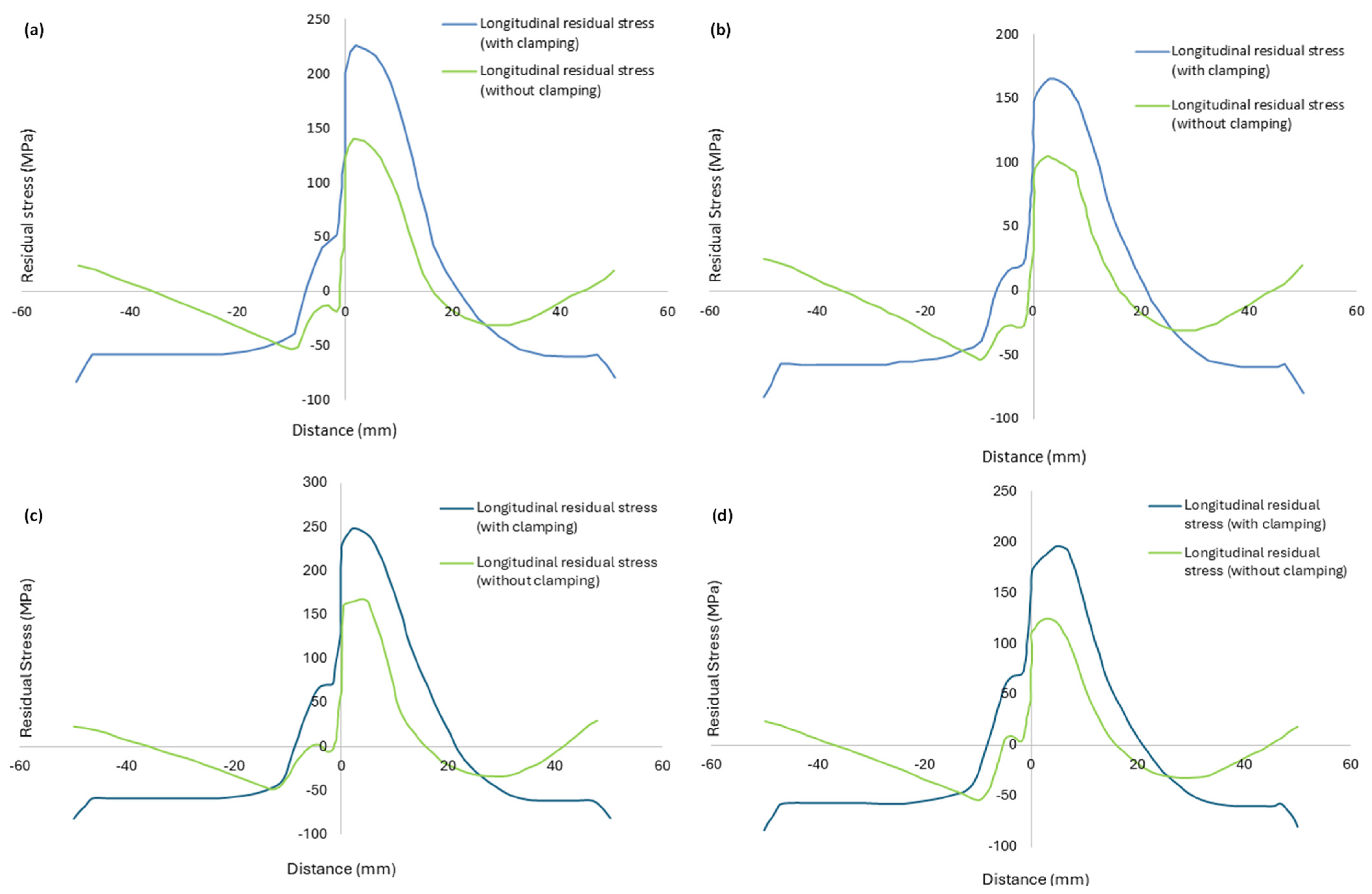

4.2. Residual Stress Distribution

4.2.1. Effect of Tool Rotational Speed

4.2.2. Effect of Tool Traverse Speed

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of Dissimilar Materials. CIRP Ann. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Kulkarni, N.; Mishra, R.S.; Yuan, W. Friction Stir Welding of Dissimilar Alloys and Materials; Butterworth-Heinemann: Oxford, UK, 2015; ISBN 0-12-802621-9. [Google Scholar]

- Wanhill, R.J.H. Chapter 15—Aerospace Applications of Aluminum–Lithium Alloys. In Aluminum-Lithium Alloys; Eswara Prasad, N., Gokhale, A.A., Wanhill, R.J.H., Eds.; Butterworth-Heinemann: Boston, MA, USA, 2014; pp. 503–535. ISBN 978-0-12-401698-9. [Google Scholar]

- Haghshenas, M.; Gerlich, A.P. Joining of Automotive Sheet Materials by Friction-Based Welding Methods: A Review. Eng. Sci. Technol. Int. J. 2018, 21, 130–148. [Google Scholar] [CrossRef]

- Bickford, J.H.; Saunders, H. An Introduction to the Design and Behaviour of Bolted Joints. J. Vib. Acoust. Stress Reliab. 1983, 105, 147–148. [Google Scholar] [CrossRef]

- Small, D.J.; Courtney, P.J. Fundamentals of Industrial Adhesives. Adv. Mater. Process. 2005, 163, 44–47. [Google Scholar]

- Mvola, B.; Kah, P.; Martikainen, J. Welding of Dissimilar Non-Ferrous Metals by GMAW Processes. Int. J. Mech. Mater. Eng. 2014, 9, 21. [Google Scholar] [CrossRef]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Hot Shear Butt Welding. GB Patent 9125978D0, 5 February 1992. [Google Scholar]

- Thomas, W.M.; Nicholas, E.D.; Needham, J.C.; Murch, M.G.; Temple-Smith, P.; Dawes, C.J. Improvements Relating to Friction Welding. EP Patent 0653265A3, 5 July 1995. [Google Scholar]

- Magalhães, V.M.; Leitão, C.; Rodrigues, D.M. Friction Stir Welding Industrialisation and Research Status. Sci. Technol. Weld. Join. 2018, 23, 400–409. [Google Scholar] [CrossRef]

- Sharma, Y.; Mehta, A.; Vasudev, H.; Jeyaprakash, N.; Prashar, G.; Prakash, C. Analysis of Friction Stir Welds Using Numerical Modelling Approach: A Comprehensive Review. Int. J. Interact. Des. Manuf. (IJIDeM) 2023, 18, 5329–5342. [Google Scholar] [CrossRef]

- Soori, M.; Asmael, M.; Solyalı, D. Recent Development in Friction Stir Welding Process. SAE Int. J. Mater. Manuf. 2021, 14, 63–80. [Google Scholar] [CrossRef]

- Kulkarni, N.; Mishra, R.S.; Baumann, J.A. Residual Stresses in Friction Stir Welding; Butterworth-Heinemann: Oxford, UK, 2013; ISBN 0-12-800732-X. [Google Scholar]

- Buglioni, L.; Tufaro, L.N.; Svoboda, H.G. Thermal Cycles and Residual Stresses in FSW of Aluminum Alloys: Experimental Measurements and Numerical Models. Procedia Mater. Sci. 2015, 9, 87–96. [Google Scholar] [CrossRef]

- Shah, P.H.; Badheka, V.J. Friction Stir Welding of Aluminium Alloys: An Overview of Experimental Findings–Process, Variables, Development and Applications. Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl. 2019, 233, 1191–1226. [Google Scholar] [CrossRef]

- Zapata, J.; Toro, M.; López, D. Residual Stresses in Friction Stir Dissimilar Welding of Aluminum Alloys. J. Mater. Process. Technol. 2016, 229, 121–127. [Google Scholar] [CrossRef]

- Farhang, M.; Farahani, M.; Nazari, M.; Sam-Daliri, O. Experimental Correlation Between Microstructure, Residual Stresses and Mechanical Properties of Friction Stir Welded 2024-T6 Aluminum Alloys. Int. J. Adv. Des. Manuf. Technol. 2022, 15, 1–9. [Google Scholar]

- Zhan, Y.; Li, Y.; Zhang, E.; Ge, Y.; Liu, C. Laser Ultrasonic Technology for Residual Stress Measurement of 7075 Aluminum Alloy Friction Stir Welding. Appl. Acoust. 2019, 145, 52–59. [Google Scholar] [CrossRef]

- Jiang, G.U.O.; Haiyang, F.U.; Bo, P.A.N.; Renke, K. Recent Progress of Residual Stress Measurement Methods: A Review. Chin. J. Aeronaut. 2021, 34, 54–78. [Google Scholar]

- Akbari, M.; Asadi, P.; Sadowski, T. A Review on Friction Stir Welding/Processing: Numerical Modeling. Materials 2023, 16, 5890. [Google Scholar] [CrossRef]

- Hattel, J.H.; Sonne, M.R.; Tutum, C.C. Modelling Residual Stresses in Friction Stir Welding of Al Alloys—A Review of Possibilities and Future Trends. Int. J. Adv. Manuf. Technol. 2015, 76, 1793–1805. [Google Scholar] [CrossRef]

- Vilaça, P.; Thomas, W. Friction Stir Welding Technology. In Structural Connections for Lightweight Metallic Structures; Springer: Berlin/Heidelberg, Germany, 2011; pp. 85–124. [Google Scholar]

- Peel, M.; Steuwer, A.; Preuss, M.; Withers, P.J. Microstructure, Mechanical Properties and Residual Stresses as a Function of Welding Speed in Aluminium AA5083 Friction Stir Welds. Acta Mater. 2003, 51, 4791–4801. [Google Scholar] [CrossRef]

- Farhang, M.; Sam-Daliri, O.; Farahani, M.; Vatani, A. Effect of Friction Stir Welding Parameters on the Residual Stress Distribution of Al-2024-T6 Alloy. J. Mech. Eng. Sci. 2021, 15, 7684–7694. [Google Scholar] [CrossRef]

- Arif, A.; Pandey, K.N. Thermo-Mechanical Modeling for Residual Stresses of Friction Stir Welding of Dissimilar Alloys. Int. J. Eng. Sci. Technol. 2013, 5, 1189–1198. [Google Scholar]

- Jamshidi Aval, H.; Serajzadeh, S.; Kokabi, A.H. Experimental and Theoretical Evaluations of Thermal Histories and Residual Stresses in Dissimilar Friction Stir Welding of AA5086-AA6061. Int. J. Adv. Manuf. Technol. 2012, 61, 149–160. [Google Scholar] [CrossRef]

- Salloomi, K.N.; Al-Sumaidae, S. Coupled Eulerian–Lagrangian Prediction of Thermal and Residual Stress Environments in Dissimilar Friction Stir Welding of Aluminum Alloys. J. Adv. Join. Process. 2021, 3, 100052. [Google Scholar] [CrossRef]

- Akbari Mousavi, S.A.A.; Sham Abadi, S.H. Dissimilar Friction Stir Welds in AA 5086-AA 2024: The Effect of Process Parameters on Microstructures and Mechanical Properties. Adv. Mater. Res. 2012, 445, 753–758. [Google Scholar] [CrossRef]

- Irgens, F. Continuum Mechanics; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2008; ISBN 3-540-74298-0. [Google Scholar]

- Riahi, M.; Nazari, H. Analysis of Transient Temperature and Residual Thermal Stresses in Friction Stir Welding of Aluminum Alloy 6061-T6 via Numerical Simulation. Int. J. Adv. Manuf. Technol. 2011, 55, 143–152. [Google Scholar] [CrossRef]

- Johnson, G.R.; Cook, W.H. A Constitutive Model and Data for Metals Subjected to Large Strains, High Strain Rates and High Temperatures. In Proceedings of the 7th International Symposium on Ballistics, The Hague, The Netherlands, 19–21 April 1983. [Google Scholar]

- Ghiasvand, A.; Kazemi, M.; Mahdipour Jalilian, M.; Ahmadi Rashid, H. Effects of Tool Offset, Pin Offset, and Alloys Position on Maximum Temperature in Dissimilar FSW of AA6061 and AA5086. Int. J. Mech. Mater. Eng. 2020, 15, 6. [Google Scholar] [CrossRef]

- Mishra, R.S.; Ma, Z.Y. Friction Stir Welding and Processing. Mater. Sci. Eng. R Rep. 2005, 50, 1–78. [Google Scholar] [CrossRef]

| Designation | Rotational Speed | Traverse Speed (mm/min) |

|---|---|---|

| Material | Density | Temperature | Young’s Modulus | Thermal Expansion | Thermal Conductivity | Specific Heat |

|---|---|---|---|---|---|---|

| Material | Density | Young’s Modulus | Thermal Expansion | Thermal Conductivity | Specific Heat | ||||

|---|---|---|---|---|---|---|---|---|---|

| Material | |||||||

|---|---|---|---|---|---|---|---|

| Designation | ||

|---|---|---|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sarfaraz, Z.; Awan, Y.R.; Saeed, H.A.; Khan, R.; Wieczorowski, M.; Din, N.A. Residual Stress in Friction Stir Welding of Dissimilar Aluminum Alloys: A Parametric Study. Materials 2025, 18, 316. https://doi.org/10.3390/ma18020316

Sarfaraz Z, Awan YR, Saeed HA, Khan R, Wieczorowski M, Din NA. Residual Stress in Friction Stir Welding of Dissimilar Aluminum Alloys: A Parametric Study. Materials. 2025; 18(2):316. https://doi.org/10.3390/ma18020316

Chicago/Turabian StyleSarfaraz, Zulqarnain, Yasser Riaz Awan, Hasan Aftab Saeed, Rehan Khan, Michał Wieczorowski, and Naveed Akmal Din. 2025. "Residual Stress in Friction Stir Welding of Dissimilar Aluminum Alloys: A Parametric Study" Materials 18, no. 2: 316. https://doi.org/10.3390/ma18020316

APA StyleSarfaraz, Z., Awan, Y. R., Saeed, H. A., Khan, R., Wieczorowski, M., & Din, N. A. (2025). Residual Stress in Friction Stir Welding of Dissimilar Aluminum Alloys: A Parametric Study. Materials, 18(2), 316. https://doi.org/10.3390/ma18020316