Comparison of the Modified CTOD Measurement Method with the Double Clip Gauge Method in a Compact Tension Specimen

Abstract

1. Introduction

2. Materials and Methods

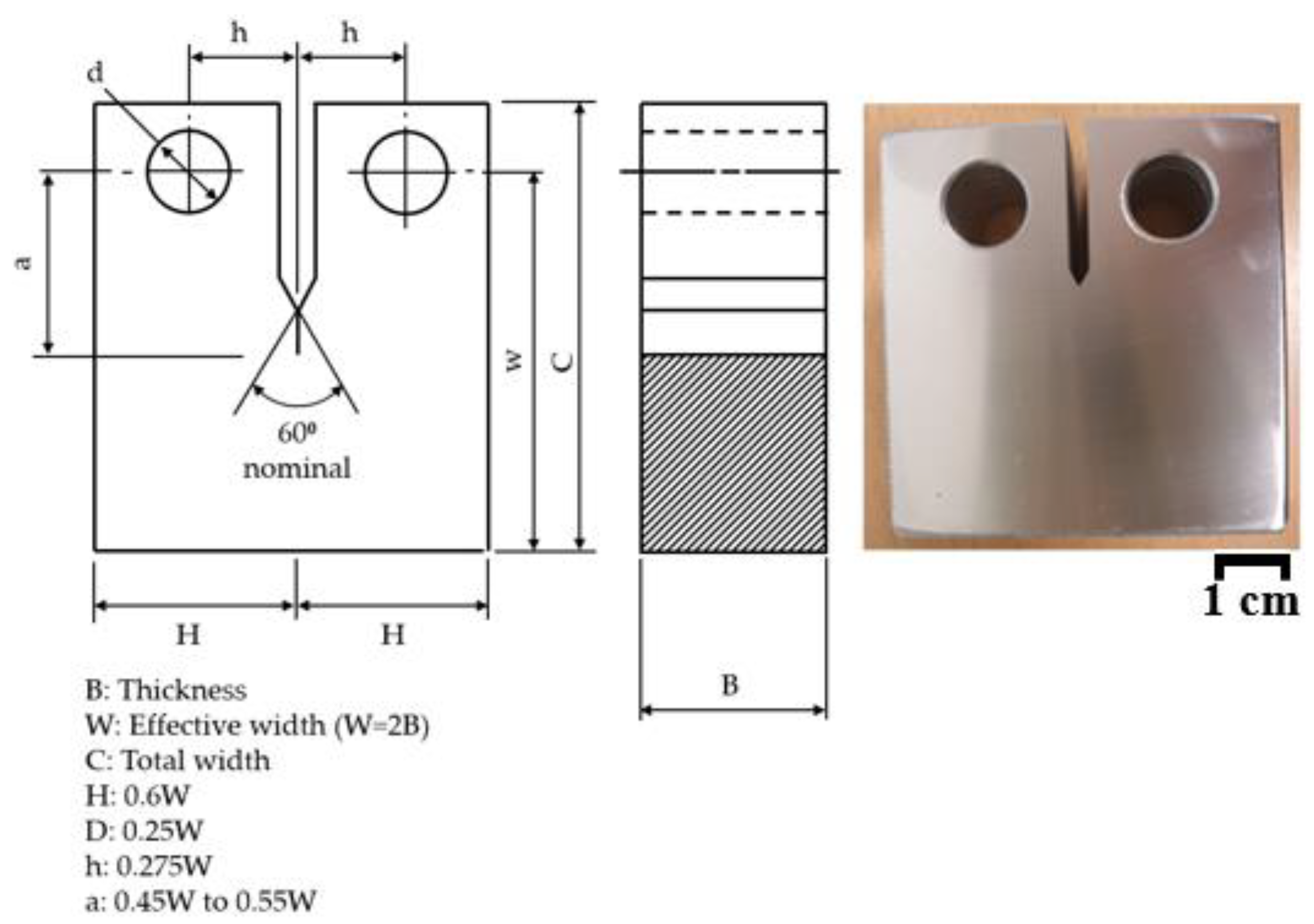

2.1. Experimental Set up

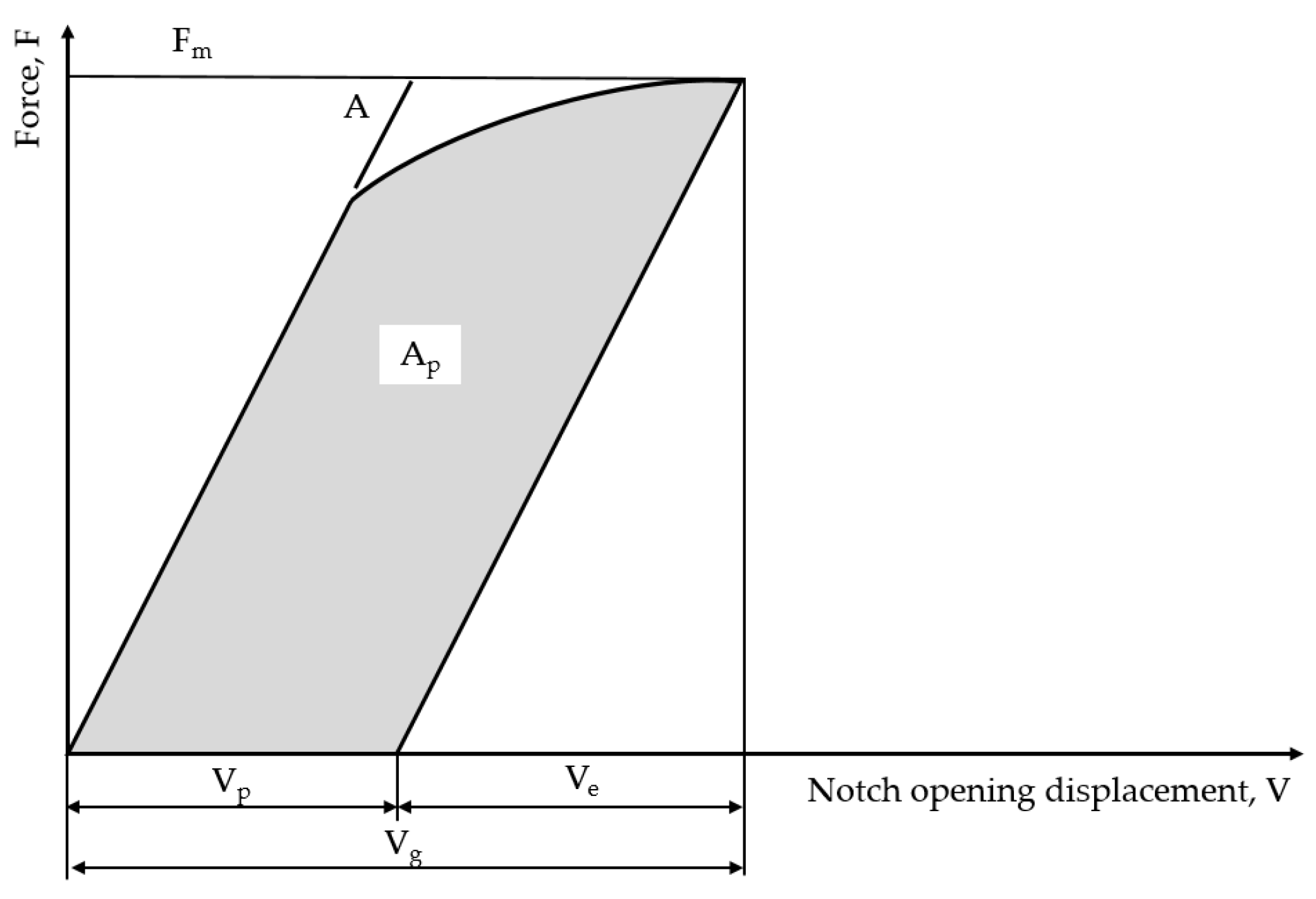

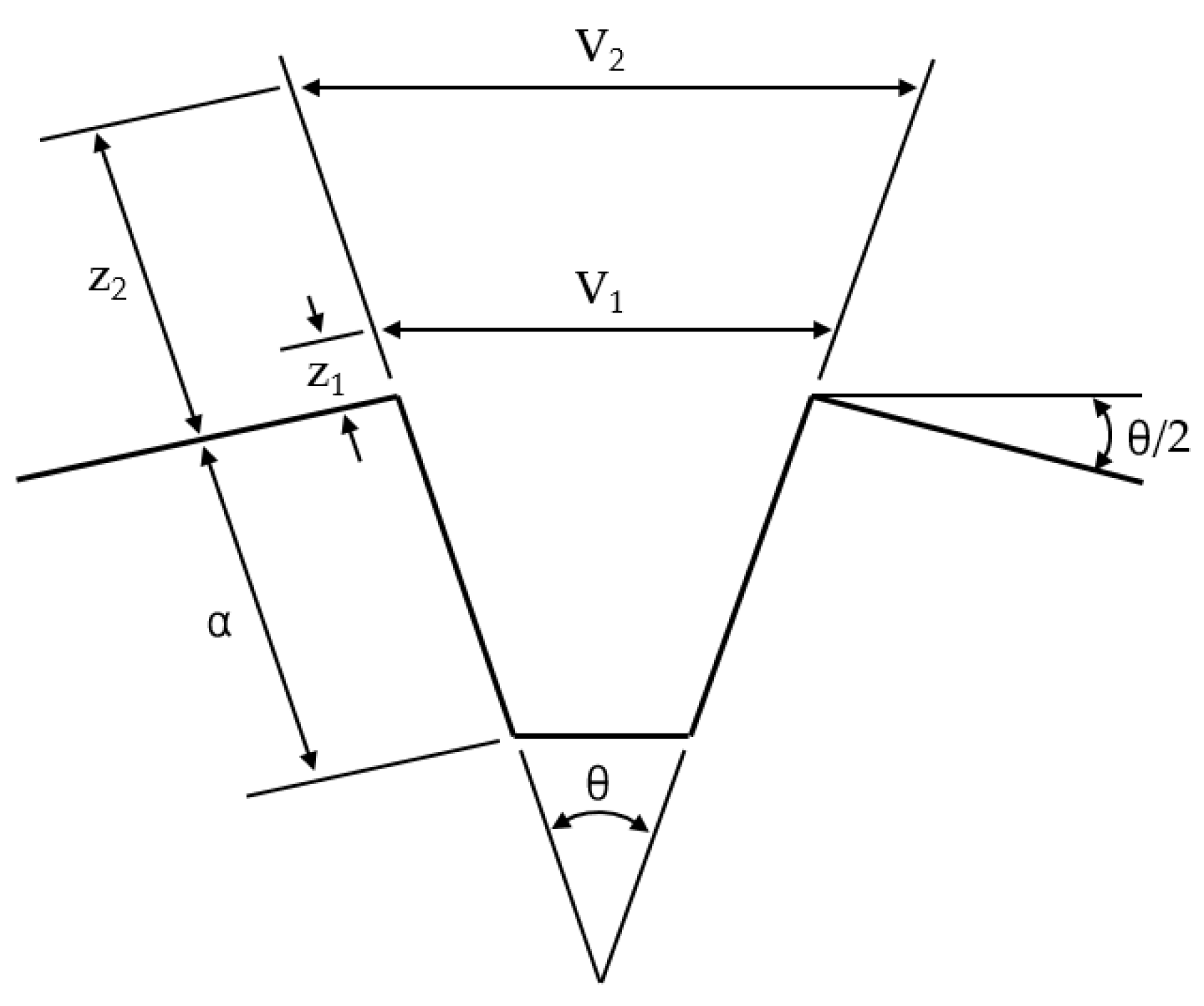

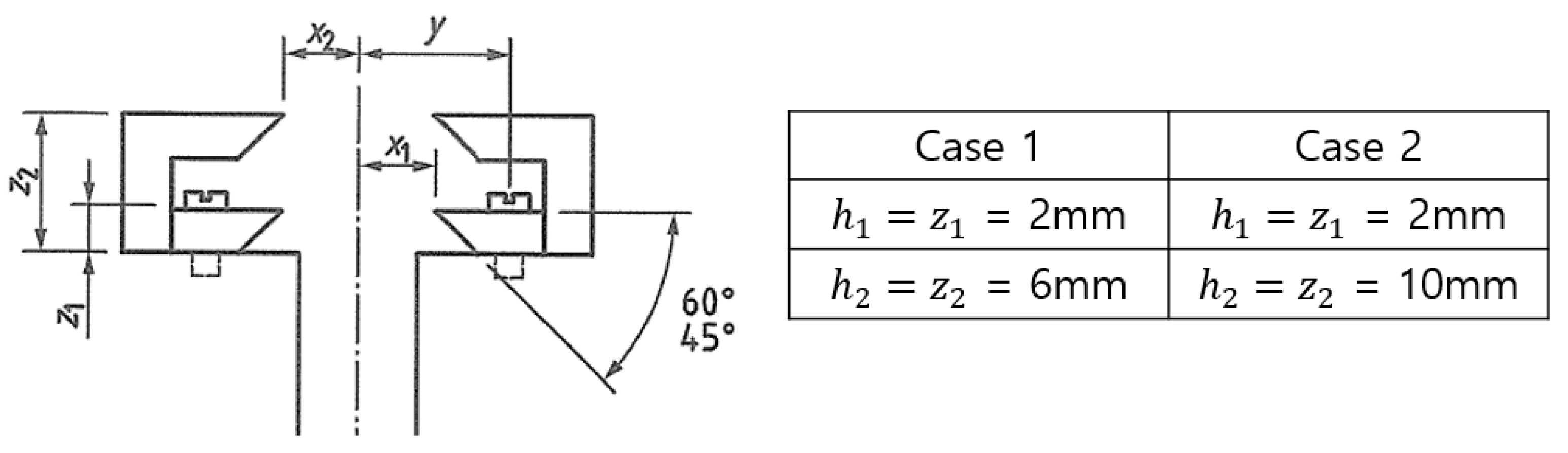

2.2. Double Clip Gauge Method

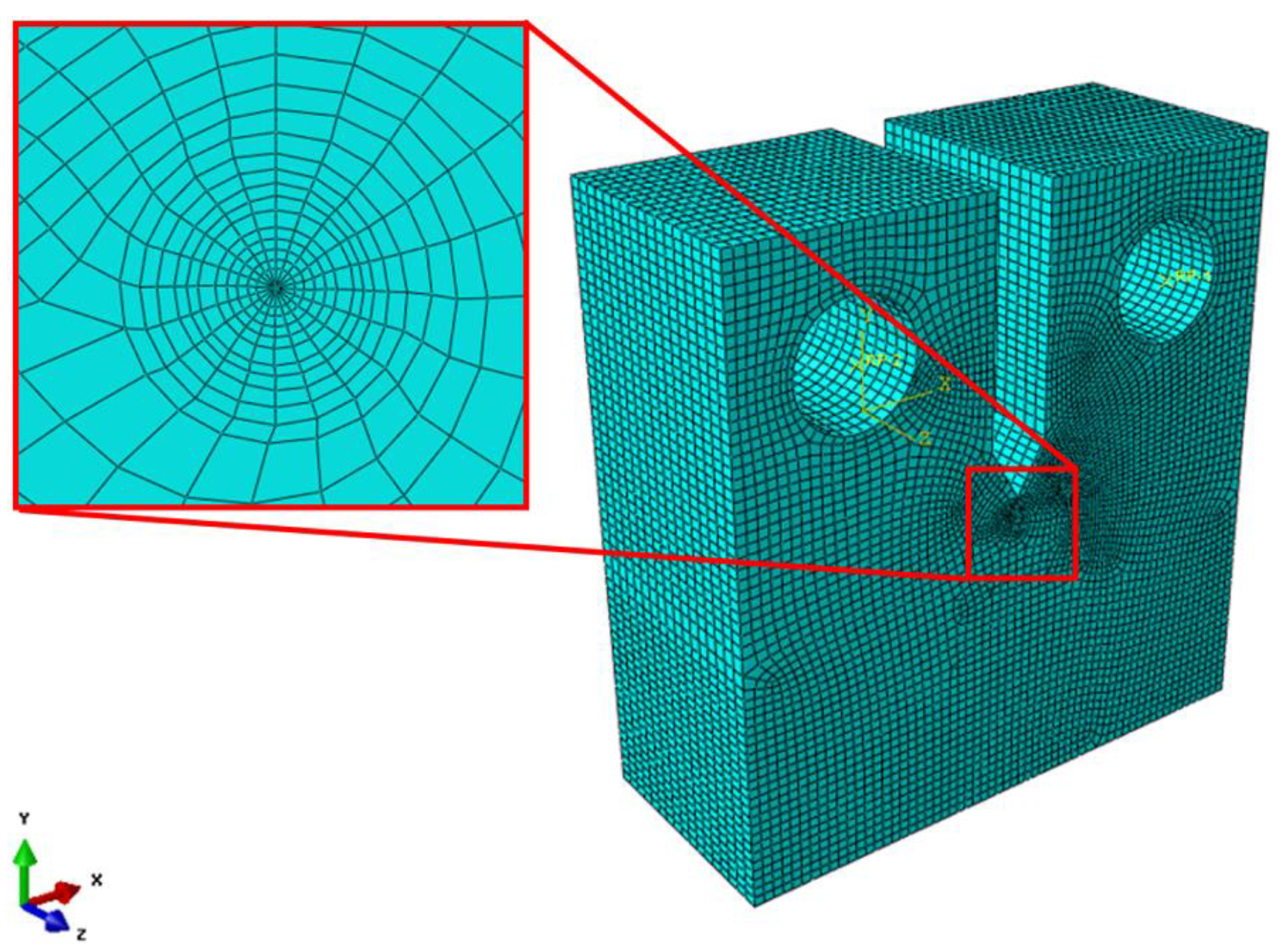

2.3. Finite Element Analysis

3. Results and Discussion

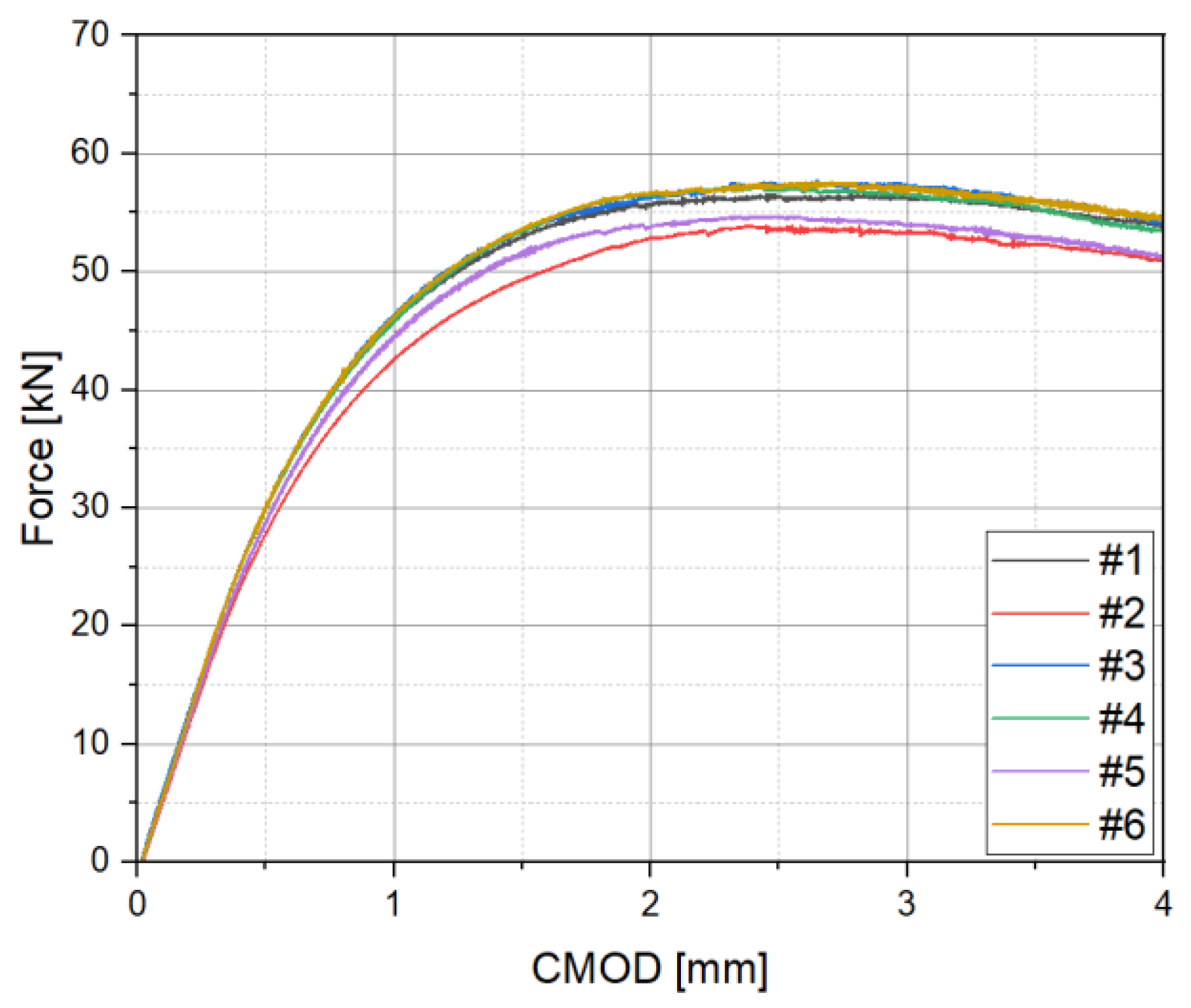

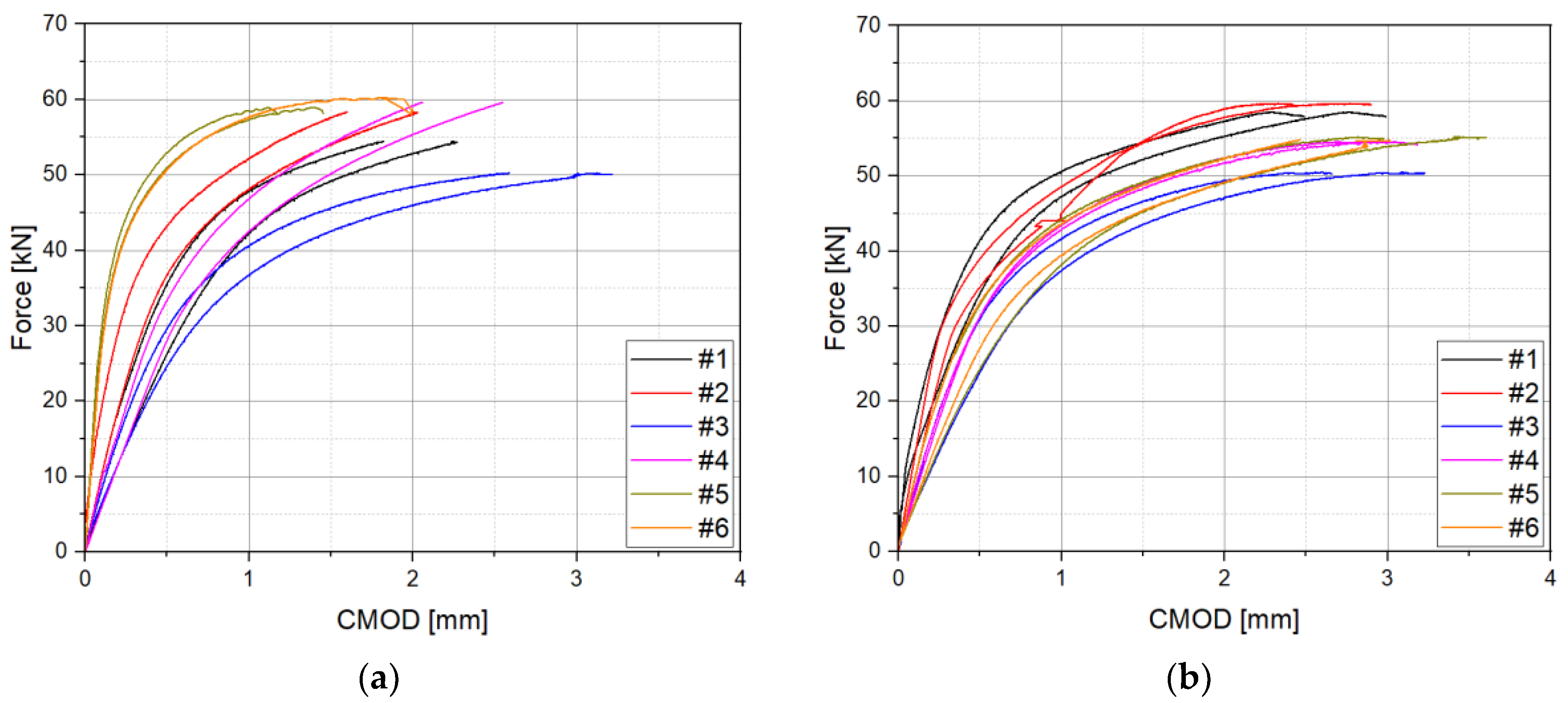

3.1. Double Clip Gauge Method

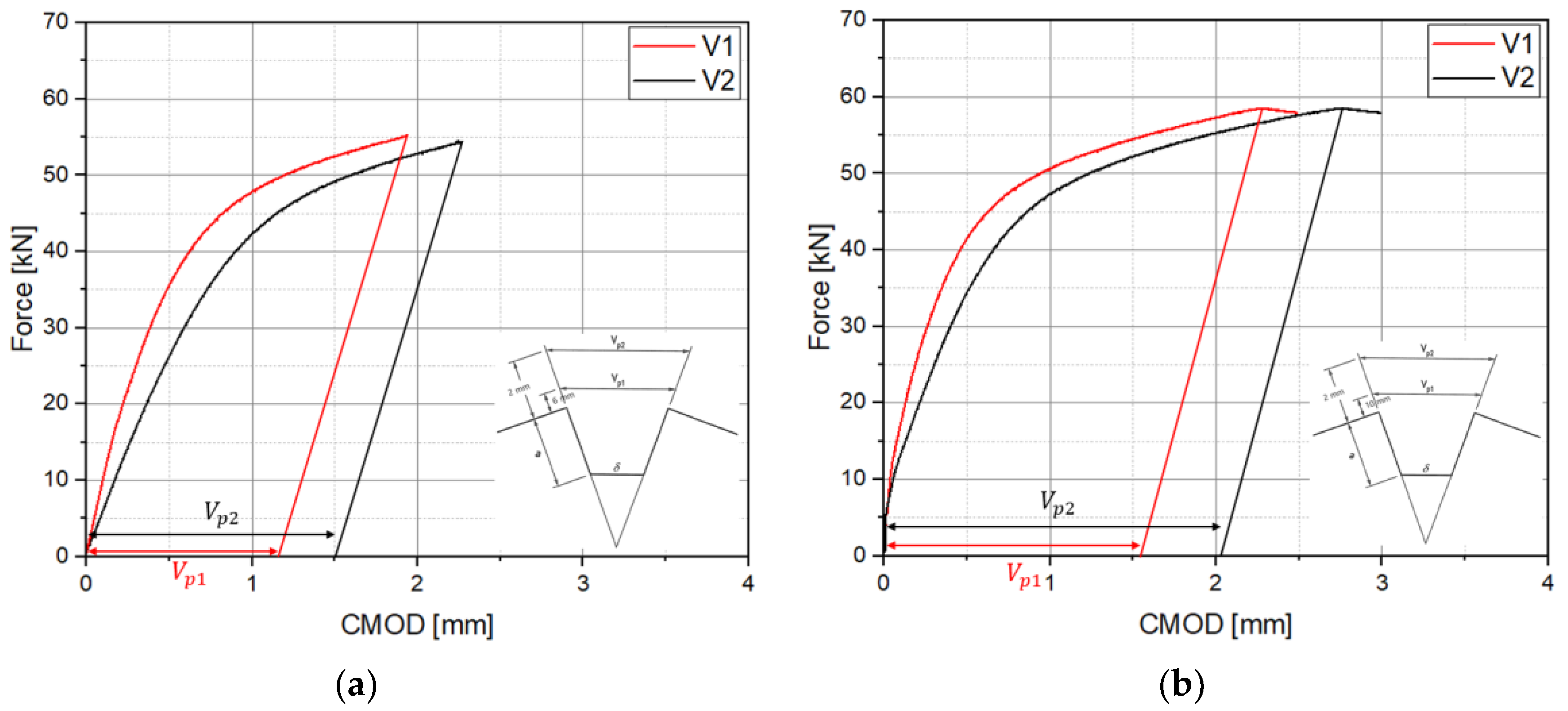

3.1.1. Modified

3.1.2. Results of CTOD Based on Modified

3.2. Validation and Comparison of Using Finite Element Analysis and Other Studies

4. Conclusions

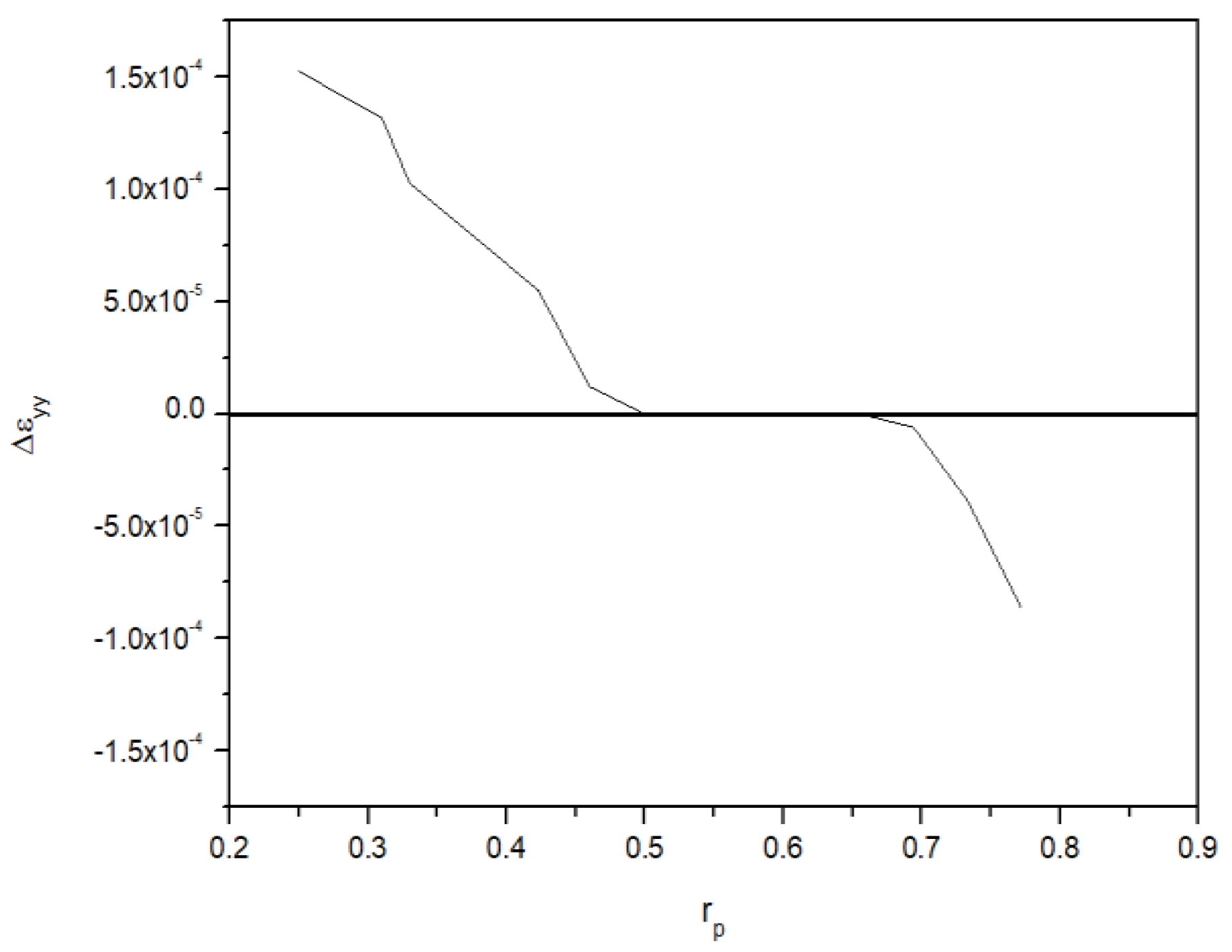

- To reduce the increase in fluctuation due to the increase in the number of tests, which is a shortcoming of the existing CTOD calculation method, a new calculation method for , which affects the CTOD calculation, is proposed, as follows:In addition, in order to derive a reasonable based on the improvement equation, the double clip gauge arrangement at the crack tip was optimized in the experiment as = 2 mm, = 6 mm.

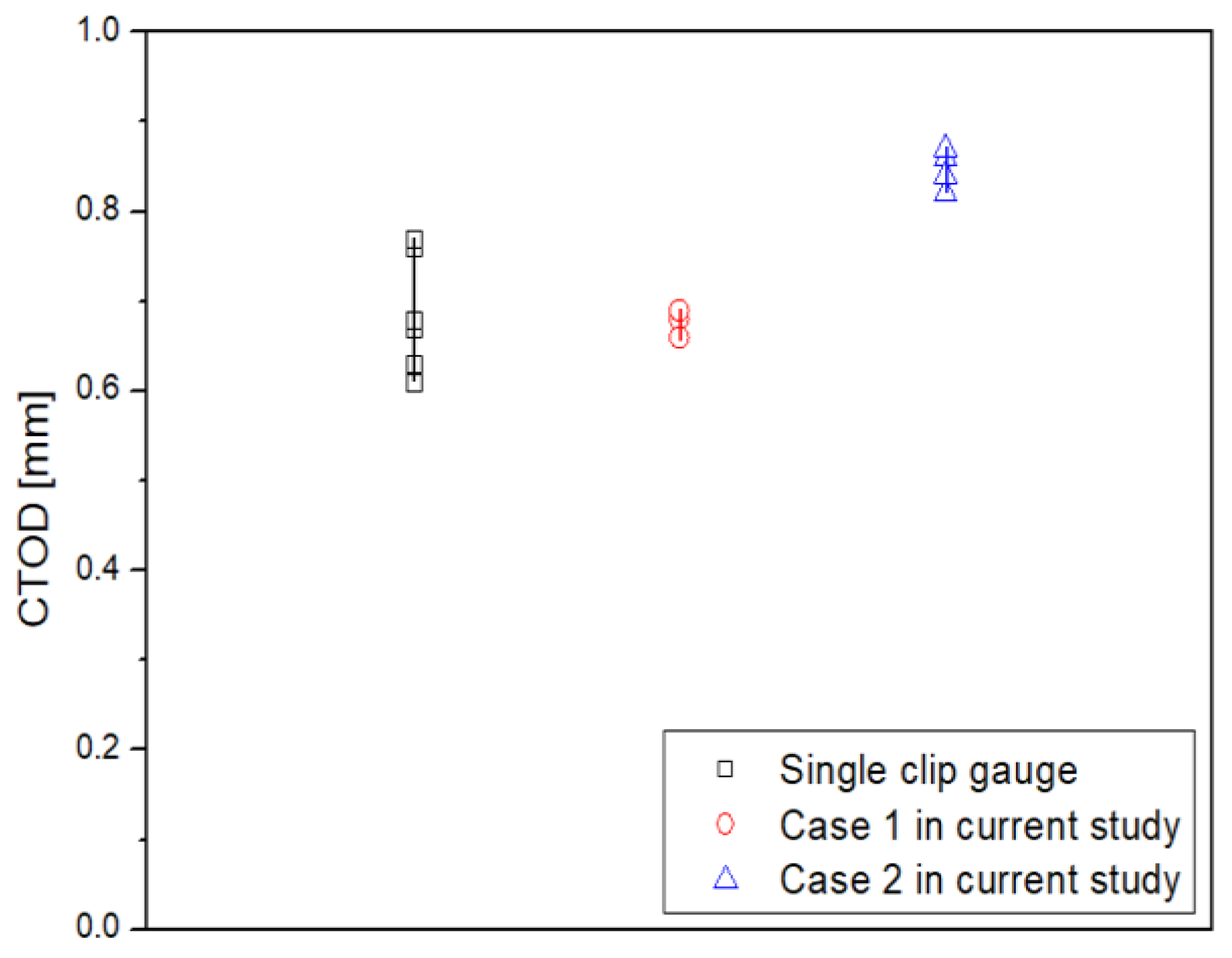

- In the case of the calculation of CTOD using the proposed , the value is 0.77–0.78, and the deviation is 0.01. Compared to the CTOD results (0.61–0.77) and deviation (0.16) derived from the existing single clip gauge, a reduction of approximately 90% is confirmed. Therefore, when the proposed equation is applied, it is verified that the fluctuation, according to the number of tests, is reduced.

- Comparisons are made between FEA results and the previous research to ensure the reliability of the proposed equation. The value, derived from the FEA, is found to be 0.50–0.68, and the value derived from the test results using the optimized double clip gauge arrangement conditions is confirmed to be 0.55–0.68. Therefore, the FEA results and the experimental results showed similar trends. The proposed is at least 23%, and up to 34% higher than the of the existing standards (ISO, BS and WES), but shows a similar trend when compared with the results of previous researchers.

- Finally, the fluctuation of CTOD values by the proposed using the double clip gauge method is lower than other methods. It is estimated that the modified can lead to a reduction in the economic and safety risks of the structural integrity assessment. However, the modified value is required to be used in more cases to reduce the prediction error, and further investigations should be carried out in the future.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhu, X.K.; Joyce, J.A. Review of Fracture toughness (G, K, J, CTOD, CTOA) Testing and Standardization. Eng. Fract. Mech. 2012, 85, 1–46. [Google Scholar] [CrossRef]

- Irwin, G.R. Analysis of Stresses and Strains Near the End of a Crack Traversing a Plate. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar] [CrossRef]

- Rice, J.R. A Path Independent Integral and the Approximate Analysis of Strain Concentration by Notches and Cracks. J. Appl. Mech. 1968, 35, 379–386. [Google Scholar] [CrossRef]

- Wells, A.A. Application of Fracture Mechanics at and Beyond General Yielding. Br. Weld. J. 1963, 10, 563–570. [Google Scholar]

- BS 8571; Method of Test for Determination of Fracture Toughness in Metallic Materials Using Single Edge Notched Tension (SENT) Specimens. British Standard Institution: London, UK, 2014.

- Khor, W.; Moore, P.L.; Pisarski, H.G.; Hasleet, M.; Brown, C.J. Measurement and Prediction of CTOD in Austenitic Stainless Steel. Fatigue Eng. Mater. Struct. 2016, 39, 1433–1442. [Google Scholar] [CrossRef]

- Minnebruggen, K.V.; Verstraete, M.; Hertele, S.; Waele, W.D. Evaluation and Comparison of Double Clip Gauge Method and Delta 5 Method for CTOD Measurement in SE(T) Specimens. J. Test. Eval. 2016, 44, 2414–2423. [Google Scholar] [CrossRef]

- Silvestre, M.N.; Hertele, S.; Sarzosa, D.F.B. On the Experimental Estimation of CTOD Fracture Parameter using SE(T) Specimens based upon Only One Clip Gauge Measurement. Eng. Fract. Mech. 2021, 253, 107856. [Google Scholar] [CrossRef]

- Samadian, K.; Hertele, S.; Waele, W.D. Measurement of CTOD along a Surface Crack by Means of Digital Image Correlation. Eng. Fract. Mech. 2019, 205, 470–485. [Google Scholar] [CrossRef]

- Qiao, Y.; Zhang, Z.X.; Zhou, J. A Modified Model for Calculating Crack Tip Opening Displacement (CTOD) considering Fracture Process Zone (FPZ) in Rock. Geomech. Geophys. Geo-Energy Geo-Resour. 2024, 10, 62. [Google Scholar] [CrossRef]

- ASTM E1820; Standard Test Method for Measurement of Fracture Toughness. American Society for Testing and Materials: West Conshohocken, PA, USA, 2008.

- Tagawa, T.; Kayamori, Y.; Ohata, M.; Handa, T.; Kawabata, T.; Yamashita, Y.; Tsutsumi, K.; Yoshinari, H.; Aihara, S.; Hagihara, Y. Comparison of CTOD Standards: BS 7448-Part 1 and revised ASTM E1290. Eng. Fract. Mech. 2010, 77, 327–336. [Google Scholar] [CrossRef]

- BS 7448; Fracture Mechanics Toughness Tests–Part 1: Method for Determination of KIc, Critical CTOD and Critical J Values of Metallic Materials. British Standard Institution: London, UK, 1991.

- Kang, K.C. Principles of Metallic Science and Engineering Materials, 3rd ed.; Bookshill: Pen Argyl, PA, USA, 1999. [Google Scholar]

- ASTM E8; Standard Test Method for Tension Testing of Metallic Materials. ASTM International: West Conshohocken, PA, USA, 2008.

- Park, D.Y.; Gravel, J.P.; Simha, C.H.M.; Liang, J.; Duan, D.M. Low-Constraint Toughness Testing of Two Single-Edge Notched Tension Methods in a Single Specimen. J. Press. Vessel Technol. 2016, 138, 051401. [Google Scholar] [CrossRef]

- Lee, C.S.; Kim, Y.H.; Kim, T.W.; Lee, J.M. Numerical Fatigue Test Method based on Continuum Damage Mechanics. J. Korea Weld. Join. 2007, 25, 63–69. [Google Scholar]

- Huh, N.S.; Kim, Y.J.; Kim, Y.J.; Choi, Y.H.; Yang, J.S. On Relevant Ramberg-Osgood Fit to Engineering Non-Linear Fracture Mechanics Analysis. J. Mech. Sci. Technol. 2003, 27, 1571–1578. [Google Scholar]

- Moon, D.H.; Park, J.Y.; Kim, M.H. Effects of the Crack Tip Constraint on the Fracture Assessment of an Al 5083-O Weldment for Low Temperature Applications. Materials 2017, 10, 815. [Google Scholar] [CrossRef]

- Park, J.Y.; Kim, M.H. JDP for Assessment of Low Temperature Strength of UACJ Aluminum; Technical Report; JDP: San Luis Obispo, CA, USA, 2015. [Google Scholar]

- Kayamori, Y.; Kawabata, T. Evaluation of Rotational Deformation in Compact Specimens for CTOD Fracture Toughness Testing. In Proceedings of the 2nd International Conference on Structural Integrity, Funchal, Portugal, 4–7 September 2017. [Google Scholar]

- Anderson, T.L. Fracture Mechanics, 4th ed.; CRC Press: Boca Raton, FL, USA, 2017. [Google Scholar]

- Dowling, N.E. Mechanical Behavior of Materials, 4th ed.; Pearson: London, UK, 2013. [Google Scholar]

- Kolednik, O. An Improved Procedure for Calculating COD in Bend and CT Specimens. Eng. Fract. Mech. 1989, 33, 813–826. [Google Scholar] [CrossRef]

- Merkle, J.G.; Corten, H.T. A J Integral Analysis for the Compact Specimen, Considering Axial Force as Well as Bending Effects. J. Press. Vessel Technol. 1974, 96, 286–292. [Google Scholar] [CrossRef]

- Shiratori, M.; Miyoshi, T. Evaluation of J-integral and COD for Compact Tension Specimen. In Fracture Mechanics of Ductile and Tough Materials and Its Applications to Energy Related Structures; Martinus Nijhoff Publishers: The Hague, The Netherlands, 1981; pp. 89–98. [Google Scholar]

- WES 1108; Standard Test Method for Crack-Tip Opening Displacement (CTOD) Fracture Toughness Measurement. The Japan Welding Engineering Society: Tokyo, Japan, 2016.

- ISO 12135; Metallic Materials—Unified Method of Test for the Determination of Quasistatic Fracture Toughness. International Organization for Standardization: Geneva, Switzerland, 2002.

| Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Cr-EQ |

|---|---|---|---|---|---|---|---|---|

| 0.070 | 0.200 | 0.020 | 0.600 | 4.800 | 0.070 | 0.010 | 0.020 | 0.223 |

| E [GPa] | [MPa] | [MPa] |

|---|---|---|

| 52–70 | 157–194 | 324–328 |

| a/W | Control Mode | Crosshead Speed [mm/min] |

|---|---|---|

| 0.5 | Displacement | 1 |

| Test Number | CTOD [mm] |

|---|---|

| #1 | 0.61 |

| #2 | 0.63 |

| #3 | 0.67 |

| #4 | 0.68 |

| #5 | 0.76 |

| #6 | 0.77 |

| Test Number | ||

|---|---|---|

| Case 1 | Case 2 | |

| #1 | 0.63 | 0.80 |

| #2 | 0.64 | 0.76 |

| #3 | 0.55 | 0.75 |

| #4 | 0.68 | 0.72 |

| #5 | 0.67 | 0.80 |

| #6 | 0.61 | 0.79 |

| Classification | |

|---|---|

| Experimental results | 0.55–0.68 |

| Finite element analysis results | 0.50–0.68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, J.Y.; Kim, M.H.; Ji, C.W. Comparison of the Modified CTOD Measurement Method with the Double Clip Gauge Method in a Compact Tension Specimen. Materials 2025, 18, 310. https://doi.org/10.3390/ma18020310

Park JY, Kim MH, Ji CW. Comparison of the Modified CTOD Measurement Method with the Double Clip Gauge Method in a Compact Tension Specimen. Materials. 2025; 18(2):310. https://doi.org/10.3390/ma18020310

Chicago/Turabian StylePark, Jeong Yeol, Myung Hyun Kim, and Chang Wook Ji. 2025. "Comparison of the Modified CTOD Measurement Method with the Double Clip Gauge Method in a Compact Tension Specimen" Materials 18, no. 2: 310. https://doi.org/10.3390/ma18020310

APA StylePark, J. Y., Kim, M. H., & Ji, C. W. (2025). Comparison of the Modified CTOD Measurement Method with the Double Clip Gauge Method in a Compact Tension Specimen. Materials, 18(2), 310. https://doi.org/10.3390/ma18020310