Microstructure and Mechanical Properties of High-Pressure Die-Casting Mg–Al–RE Alloys with Minor Ca Addition

Abstract

1. Introduction

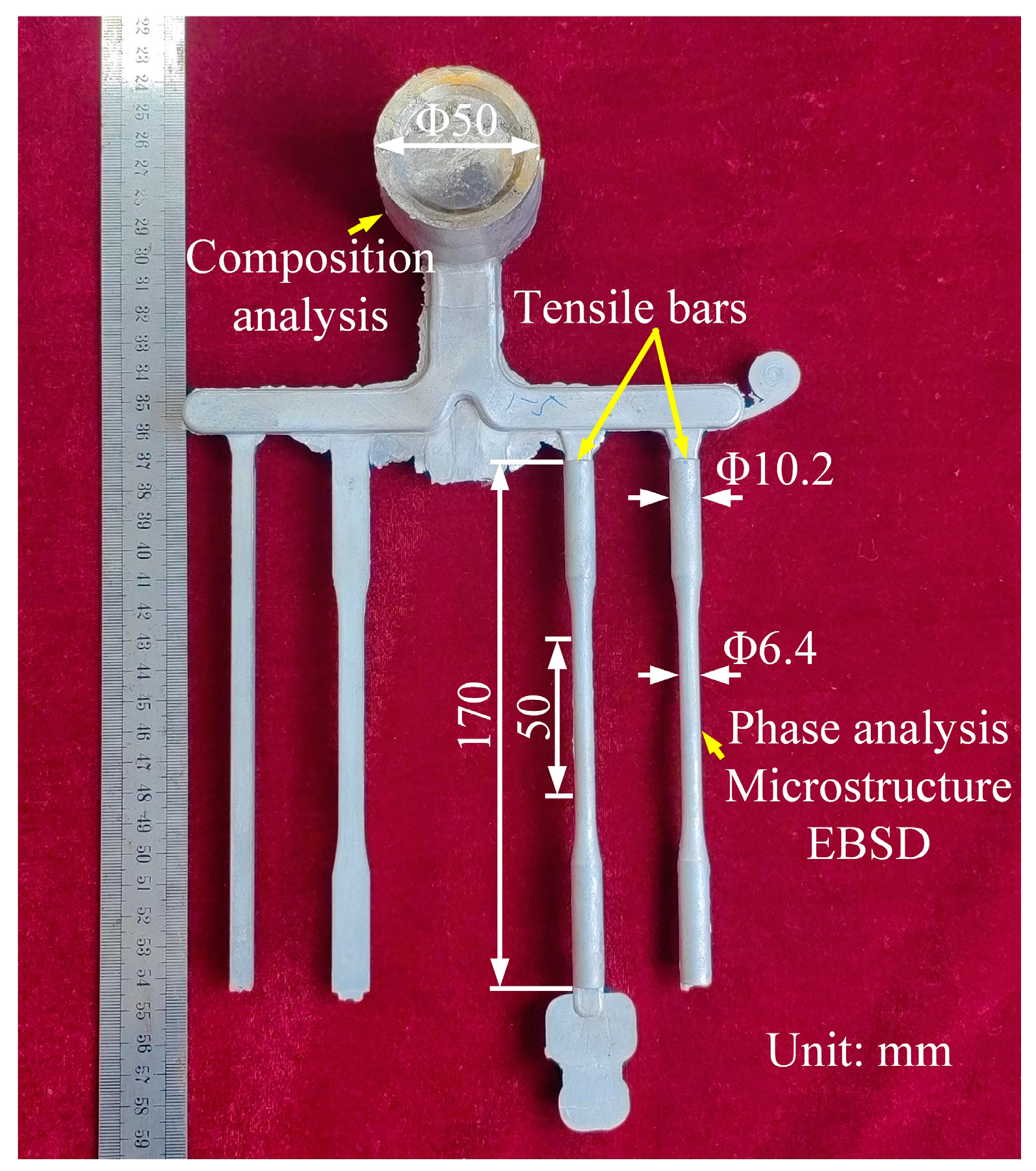

2. Materials and Methods

3. Results and Discussion

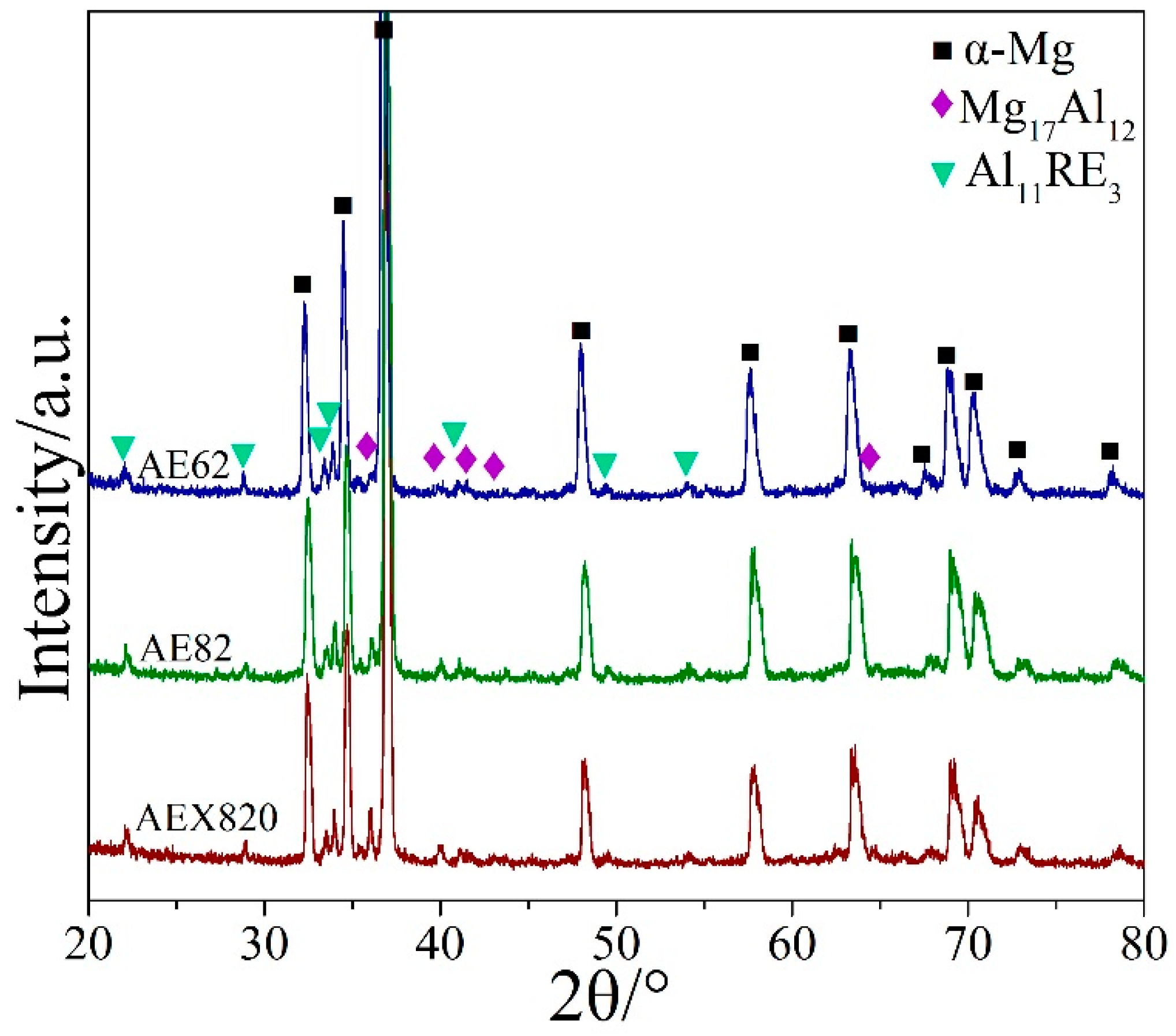

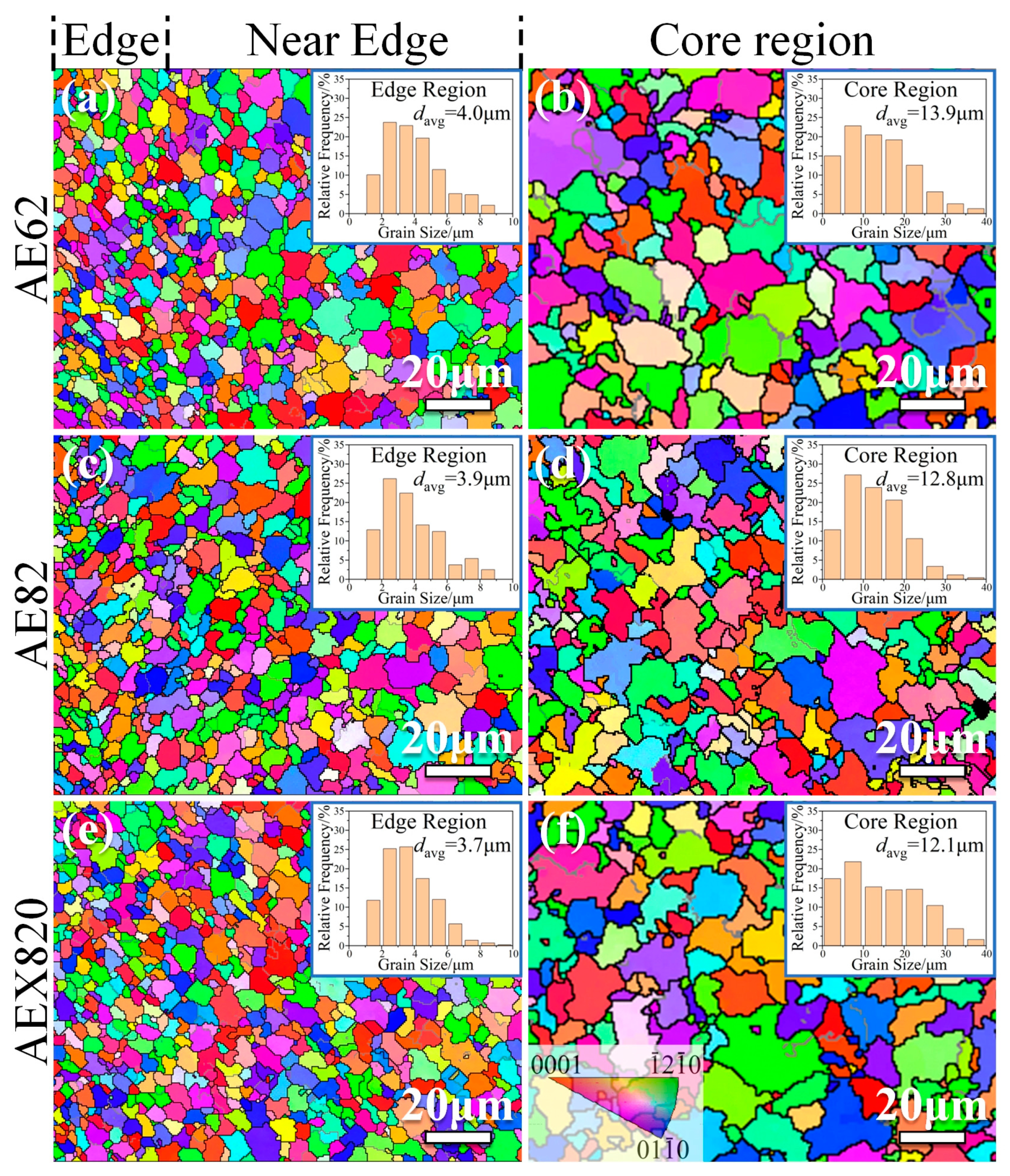

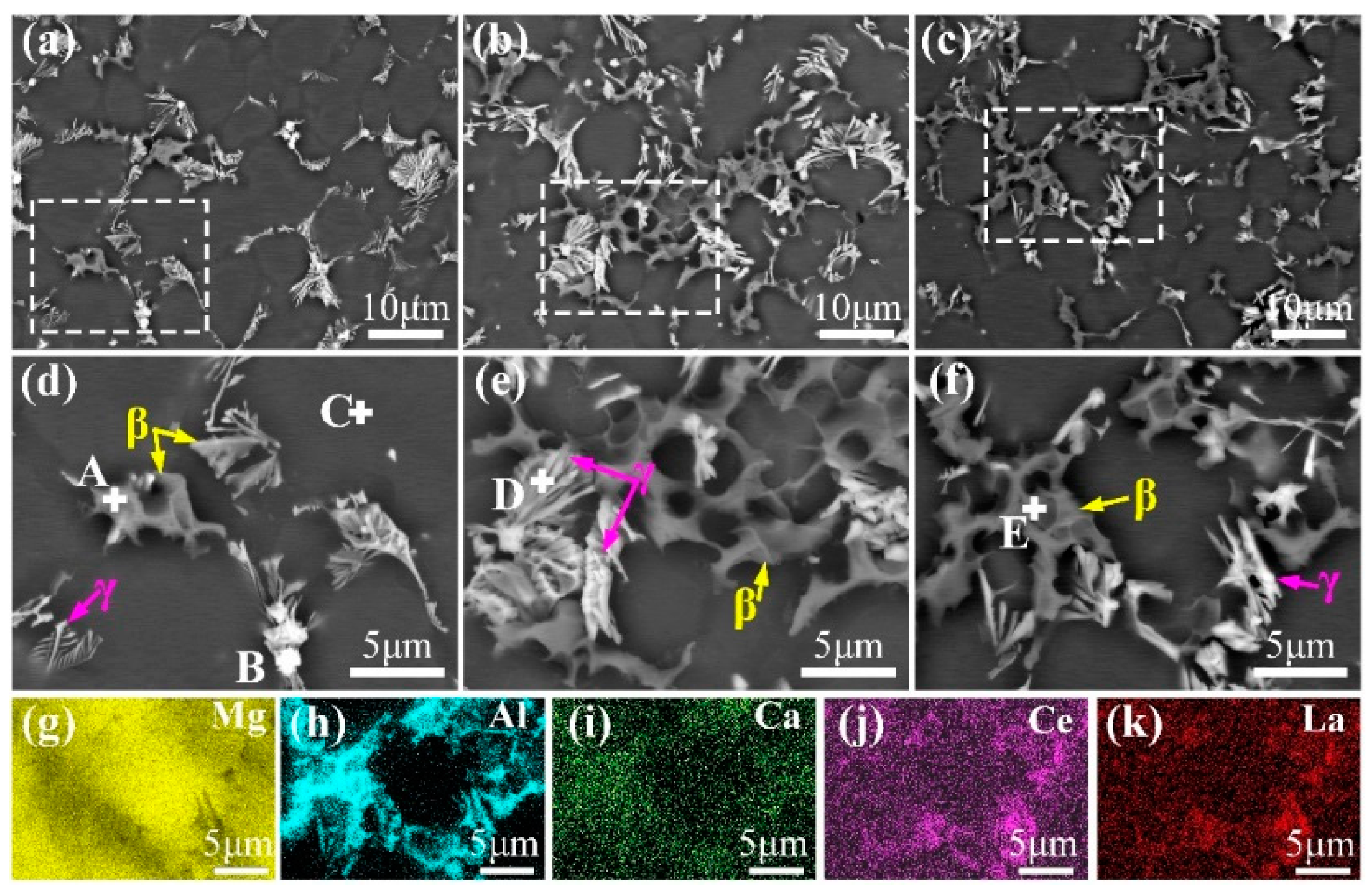

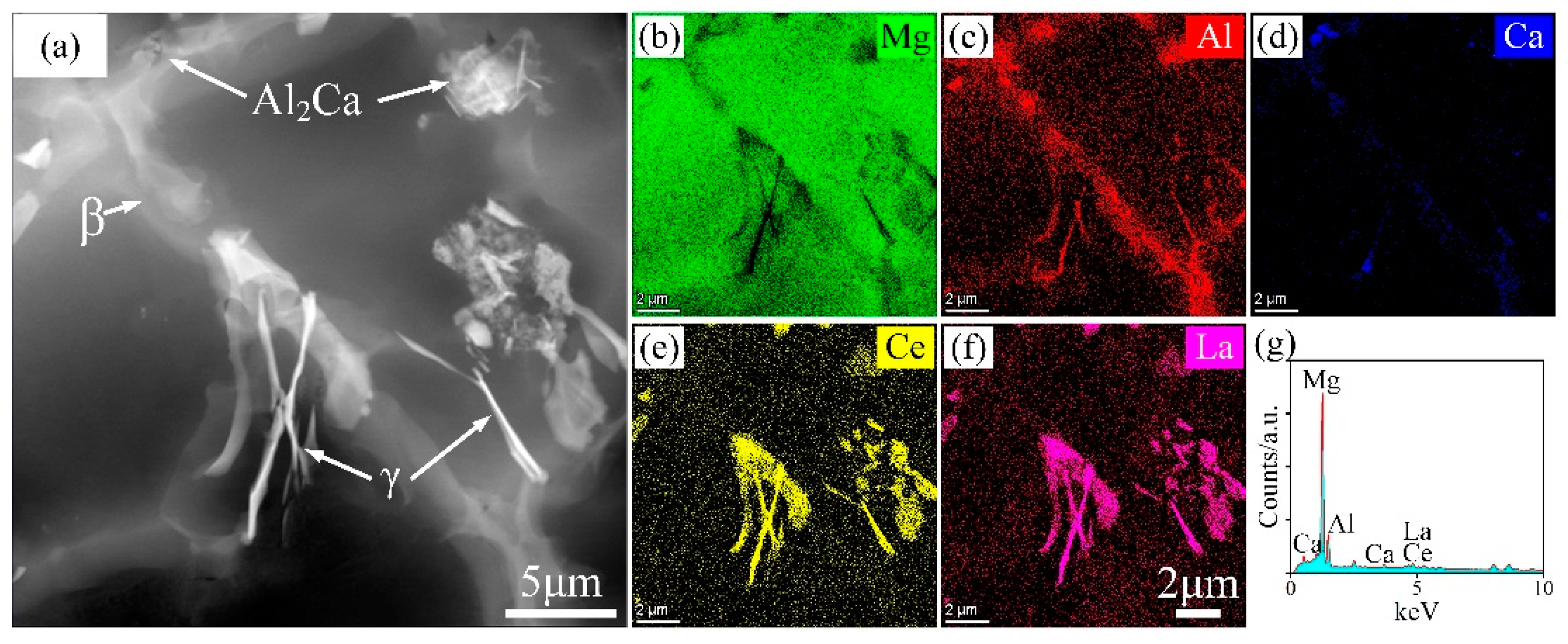

3.1. The Phase Compositions and Microstructures of as-Cast Alloys

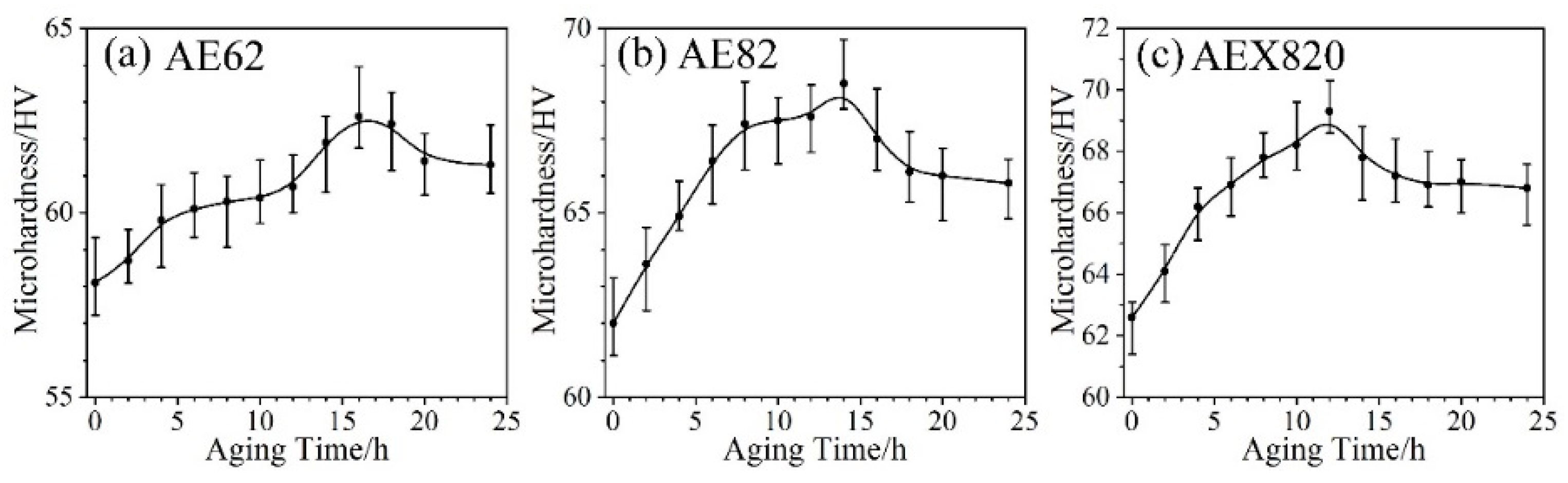

3.2. Age-Hardening Response of HPDC Alloys During T5 Aging Treatment

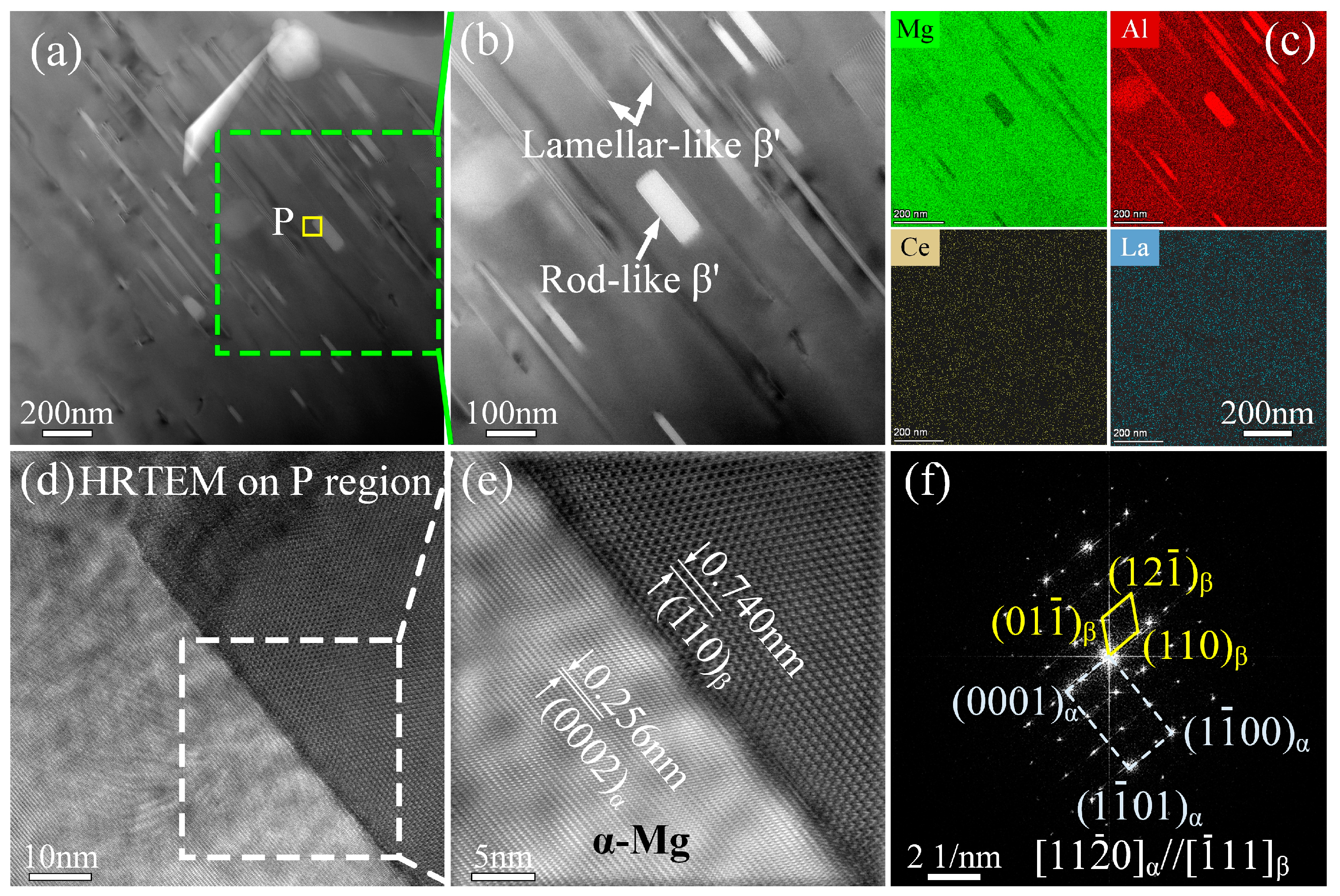

3.3. Microstructures of Peak-Aged Samples

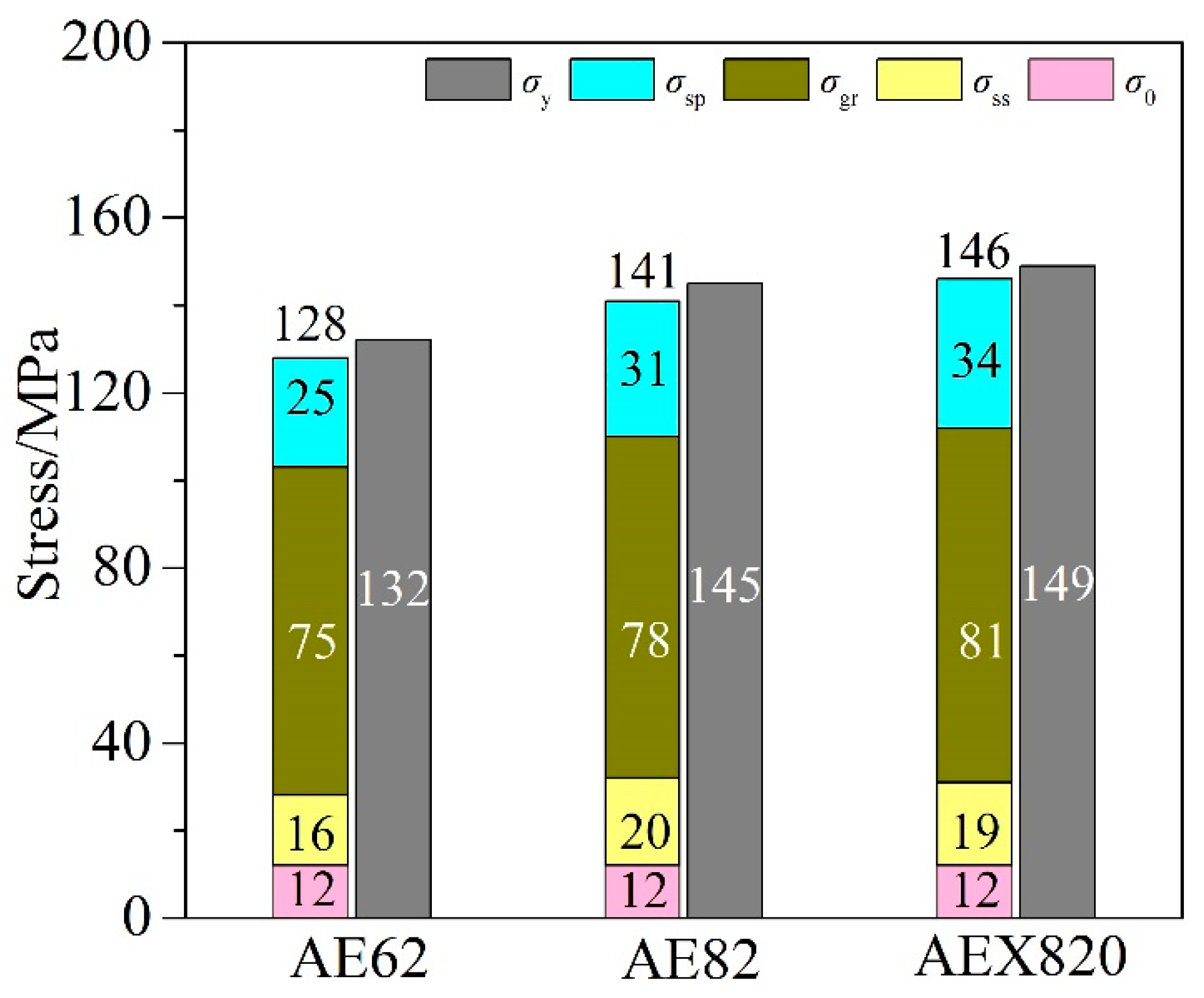

3.4. Tensile Properties and Fracture Behaviors

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Liu, B.Y.; Liu, F.; Yang, N.; Zhai, X.B.; Zhang, L.; Yang, Y.; Li, B.; Li, J.; Ma, E.; Nie, J.F.; et al. Large plasticity in magnesium mediated by pyramidal dislocations. Science 2019, 365, 73–75. [Google Scholar] [CrossRef]

- Li, T.; Song, J.; Zhang, A.; You, G.; Yang, Y.; Jiang, B.; Qin, X.; Xu, C.; Pan, F. Progress and prospects in Mg-alloy super-sized high pressure die casting for automotive structural components. J. Magnes. Alloys 2023, 11, 4166–4180. [Google Scholar] [CrossRef]

- Wang, H.Y.; Zhang, H.; Xu, X.Y.; Zha, M.; Wang, C.; Ma, P.K.; Guan, Z.P. Current research and future prospect on microstructure stability of superplastic light alloys. Acta Metall. Sin. 2018, 54, 1618–1624. [Google Scholar] [CrossRef]

- Xie, H.; Wang, J.; Li, Y.; Song, J.; Hu, H.; Qin, L. Fast shot speed induced microstructure and mechanical property evolution of high pressure die casting Mg-Al-Zn-RE alloys. J. Mater. Technol. 2024, 331, 118523. [Google Scholar] [CrossRef]

- Xu, Y.L.; Zhang, K.; Jian, L.E. Effect of mischmetal on mechanical properties and microstructure of die-cast magnesium alloy AZ91D. J. Rare Earths 2016, 34, 742–746. [Google Scholar] [CrossRef]

- Li, X.; Xiong, S.M.; Guo, Z. On the porosity induced by externally solidified crystals in high-pressure die-cast of AM60B alloy and its effect on crack initiation and propagation. Mater. Sci. Eng. 2015, 633, 35–41. [Google Scholar] [CrossRef]

- Zhu, S.M.; Easton, M.A.; Abbott, T.B.; Nie, J.F.; Dargusch, M.S.; Hort, N.; Gibson, M.A. Evaluation of magnesium die-casting alloys for elevated temperature applications: Microstructure, tensile properties, and creep resistance. Metall. Mater. Trans. 2015, 46, 3543–3554. [Google Scholar] [CrossRef]

- Cao, H.X.; Zhang, Q.; Zhu, W.K.; Cui, S.; Yang, Q.; Wang, Z.B.; Jiang, B. Study on the influence of injection velocity on the evolution of hole defects in die-cast aluminum alloy. Materials 2024, 17, 4990. [Google Scholar] [CrossRef] [PubMed]

- Liu, B.; Yang, J.; Zhang, X.Y.; Yang, Q.; Zhang, J.S.; Li, X.Q. Development and application of magnesium alloy parts for automotive OEMs: A review. J. Magnes. Alloys 2023, 11, 15–47. [Google Scholar] [CrossRef]

- Ueshima, N.; Liu, X.T.; Utsumi, H.; Chiyokubo, T.; Horio, K.; Oikawa, K. Influence of Cu and Mg addition on age-related deterioration in strength and creep behavior of Zn-12Al die casting alloys. Int. J. Mater. Res. 2017, 108, 151–154. [Google Scholar] [CrossRef]

- Zhang, X.R.; Li, A.; Li, X.Z.; Zhang, D.D.; Bi, G.L.; Fang, D.Q.; Ding, X.D.; Sun, J. Fully equiaxed grain structure and isotropic mechanical properties in wire arc additive manufactured Mg-Al-RE alloy. J. Mater. Res. Technol. 2024, 31, 3998–4011. [Google Scholar] [CrossRef]

- Dieringa, H.; Huang, Y.; Wittke, P.; Klein, M.; Walther, F.; Dikovits, M.; Poletti, C. Compression-creep response of magnesium alloy DieMag422 containing barium compared with the commercial creep-resistant alloys AE42 and MRI230D. Mater. Sci. Eng. 2013, 585, 430–438. [Google Scholar] [CrossRef]

- Wang, J.J.; Zhang, K.X.; Ying, G.B.; Cheng, J.B.; Song, D.; Jiang, J.H.; Ma, A.B. Effects of RE (RE 1/4 Sc, Y and Nd) concentration on galvanic corrosion of Mg-Al alloy: A theoretical insight from work function and surface energy. J. Mater. Res. Technol. 2023, 24, 6958–6967. [Google Scholar] [CrossRef]

- Lee, S.G.; Patel, G.R.; Gokhale, A.M.; Sreeranganathan, A.; Horstemeyer, M.F. Quantitative fractographic analysis of variability in the tensile ductility of high-pressure die-cast AE44 Mg-alloy. Mater. Sci. Eng. 2006, 427, 255–262. [Google Scholar] [CrossRef]

- Zhang, J.H.; Liu, K.; Fang, D.Q.; Qiu, X.; Tang, D.X.; Meng, J. Microstructure, tensile properties, and creep behavior of high-pressure die-cast Mg-4Al-4RE-0.4Mn (RE = La, Ce) alloys. J. Mater. Sci. 2009, 44, 2046–2054. [Google Scholar] [CrossRef]

- Su, C.Y.; Li, D.J.; Wang, J.; Shi, R.H.; Luo, A.A.; Zeng, X.Q.; Lin, Z.H.; Chen, J. Enhanced ductility in high-pressure die casting Mg-4Ce-xAl-0.5Mn alloys via modifying second phase. Mater. Sci. Eng. 2020, 773, 138870. [Google Scholar] [CrossRef]

- Sun, W.H.; Shi, X.Y.; Cinkilic, E.; Luo, A.A. Investigation of the non-equilibrium solidification microstructure of a Mg-4Al-2RE (AE42) alloy. J. Mater. Sci. 2016, 51, 6287–6294. [Google Scholar] [CrossRef]

- Bichler, L.; Ravindran, C.; Sediako, D. Onset of hot tearing in AE42 magnesium alloy. Can. Metall. Quart. 2009, 48, 81–89. [Google Scholar] [CrossRef]

- Stemper, L.; Mitas, B.; Kremmer, T.; Otterbach, S.; Uggowitzer, P.J.; Pogatscher, S. Age-hardening of high pressure die casting AlMg alloys with Zn and combined Zn and Cu additions. Mater. Des. 2019, 181, 107927. [Google Scholar] [CrossRef]

- Song, J.; Xiong, S. The correlation between as-cast and aged microstructures of high-vacuum die-cast Mg-9Al-1Zn magnesium alloy. J. Alloys Compd. 2011, 509, 1866–1869. [Google Scholar] [CrossRef]

- Gavras, S.; Easton, M.A.; Gibson, M.A.; Zhu, S.M.; Nie, J.F. Microstructure and property evaluation of high-pressure die-cast Mg-La-rare earth (Nd, Y or Gd) alloys. J. Alloys Compd. 2014, 597, 21–29. [Google Scholar] [CrossRef]

- Zhu, S.M.; Abbott, T.B.; Gibson, M.A.; Nie, J.F.; Easton, M.A. Age hardening in die-cast Mg-Al-RE alloys due to minor Mn additions. Mater. Sci. Eng. 2016, 656, 34–38. [Google Scholar] [CrossRef]

- Pettersen, G.; Westengen, H.; Høier, R.; Lohne, O. Microstructure of a pressure die cast magnesium–4wt.% aluminium alloy modified with rare earth additions. Mater. Sci. Eng. 1996, 207, 115–120. [Google Scholar] [CrossRef]

- Pabel, T.; Geier, G.F.; Rockenschaub, H.; Hopfinger, M. Improved mechanical properties of the high pressure die casting alloy AlSi9Cu3(Fe)(Zn) as a result of the combination of natural and artificial ageing. Int. J. Mater. Res. 2007, 98, 516–520. [Google Scholar] [CrossRef]

- Liu, G.J.; Sun, Y.H.; Xia, N.; Guan, X.F. Effects of Ce-rich misch metal on the microstructures and tensile properties of as-cast Mg-7Al-3Sn-1Zn alloys. Metals 2021, 11, 1648. [Google Scholar] [CrossRef]

- Choi, K.; Shin, J.; Kang, H. The effect of solidification rate on the corrosion resistance of die-cast AZ91 magnesium alloy. Materials 2022, 15, 1259. [Google Scholar] [CrossRef] [PubMed]

- Fu, P.H.; Luo, A.A.; Jiang, H.Y.; Peng, L.M.; Yu, Y.D.; Zhai, C.Q.; Sachdev, A.K. Low-pressure die casting of magnesium alloy AM50: Response to process parameters. J. Mater. Process. Technol. 2008, 205, 224–234. [Google Scholar] [CrossRef]

- Sahu, P.; Shee, S.K.; Hamada, A.S.; Rovatti, L.; Sahu, T.; Mahato, B.; Chowdhury, S.G.; Porter, D.A.; Karjalainen, L.P. Low strain rate deformation behavior of a Cr-Mn austenitic steel at −80 °C. Acta Mater. 2012, 60, 6907–6919. [Google Scholar] [CrossRef]

- Zhang, K.; Jiang, J. Effects of grain size and temperature on slip and twinning activity in a magnesium-rare earth alloy. Mater. Sci. Eng. 2024, 891, 145974. [Google Scholar] [CrossRef]

- Easton, M.A.; Zhu, S.M.; Abbott, T.B.; Dargusch, M.; Murray, M.; Savage, G.; Hort, N.; Gibson, M.A. Evaluation of magnesium die-casting alloys for elevated temperature applications: Castability. Adv. Eng. Mater. 2016, 18, 953–962. [Google Scholar] [CrossRef]

- Liu, M.; Uggowitzer, P.J.; Nagasekhar, A.V.; Schmutz, P.; Easton, M.; Song, G.L.; Atrens, A. Calculated phase diagrams and the corrosion of die-cast Mg-Al alloys. Corros. Sci. 2009, 51, 602–619. [Google Scholar] [CrossRef]

- Shi, X.Y.; Li, D.J.; Luo, A.A.; Hu, B.; Li, L.; Zeng, X.Q.; Ding, W.J. Microstructure and mechanical properties of Mg-7Al-2Sn alloy processed by super vacuum die-casting. Metall. Mater. Trans. 2013, 44, 4788–4799. [Google Scholar] [CrossRef]

- Villars, P.; Calvert, L.D. Pearson’s Handbook of Crystallographic Data for Intermetallic Phases; American Society for Metals: Metals Park, OH, USA, 1991; Volumes 1–3. [Google Scholar]

- Rong, J.; Xiao, W.L.; Fu, Y.; Zhao, X.Q.; Yan, P.; Ma, C.L.; Chen, M.; Huang, C. A high performance Mg-Al-Ca alloy processed by high pressure die casting: Microstructure, mechanical properties and thermal conductivity. Mater. Sci. Eng. A. 2022, 849, 143500. [Google Scholar] [CrossRef]

- Nie, J.F. Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. 2012, 43, 3891–3939. [Google Scholar] [CrossRef]

- Yang, H.; Xie, W.L.; Song, J.F.; Dong, Z.H.; Gao, Y.Y.; Jiang, B.; Pan, F.S. Current progress of research on heat-resistant Mg alloys: A review. Int. J. Miner. Metall. Miner. 2024, 31, 1406–1425. [Google Scholar] [CrossRef]

- Duly, D.; Simon, J.P.; Brechet, Y. On the competition between continuous and discontinuous precipitations in binary Mg-Al alloys. Acta Metall. Mater. 1995, 43, 101–106. [Google Scholar] [CrossRef]

- Celotto, S.; Bastow, T.J. Study of precipitation in aged binary Mg-Al and ternary Mg-Al-Zn alloys using 27 Al NMR spectroscopy. Acta Mater. 2001, 49, 41–51. [Google Scholar] [CrossRef]

- Wang, C.Y.; Cepeda- Jiménez, C.M.; Pérez-Prado, M.T. Dislocation-particle interactions in magnesium alloys. Acta Mater. 2020, 194, 190–206. [Google Scholar] [CrossRef]

- Yang, K.V.; Cáceres, C.H.; Easton, M.A. Strengthening micromechanisms in cold-chamber high pressure die-cast Mg-Al alloys. Metall. Mater. Trans. 2014, 45, 4117–4128. [Google Scholar] [CrossRef]

- Cáceres, C.H.; Poole, W.J.; Bowles, A.L.; Davidson, C.J. Section thickness, macrohardness and yield strength in high-pressure die cast magnesium alloy AZ91. Mater. Sci. Eng. 2005, 402, 269–277. [Google Scholar] [CrossRef]

- Gao, L.; Chen, R.S.; Han, E.H. Effects of rare-earth elements Gd and Y on the solid solution strengthening of Mg alloys. J. Alloys Compd. 2009, 481, 379–384. [Google Scholar] [CrossRef]

- Rong, J.; Zhu, J.N.; Xiao, W.L.; Zhao, X.Q.; Ma, C.L. A high pressure die cast magnesium alloy with superior thermal conductivity and high strength. Intermetallics 2021, 139, 107350. [Google Scholar] [CrossRef]

- Hua, Z.M.; Wang, C.; Wang, T.S.; Du, C.F.; Jin, S.B.; Sha, G.; Gao, Y.P.; Jia, H.L.; Zha, M.; Wang, H.Y. Large hardening response mediated by room-temperature dynamic solute clustering behavior in a dilute Mg-Zn-Ca-Sn-Mn alloy. Acta Mater. 2022, 240, 118308. [Google Scholar] [CrossRef]

- Strobel, K.; Easton, M.A.; Tyagi, V.; Murray, M.; Gibson, M.A.; Savage, G.; Abbott, T.B. Evaluation of castability of high pressure die cast magnesium based alloys. Int. J. Cast Met. Res. 2010, 23, 81–91. [Google Scholar] [CrossRef]

| Alloy | Compositions (wt.%) | ||||

|---|---|---|---|---|---|

| Al | Ce | La | Ca | Mg | |

| AE62 | 5.723 | 1.152 | 0.632 | 0 | Bal. |

| AE82 | 7.675 | 1.196 | 0.643 | 0 | Bal. |

| AEX820 | 7.736 | 1.141 | 0.639 | 0.221 | Bal. |

| Point | Elemental Composition (at. %) | Possible Phases | ||||

|---|---|---|---|---|---|---|

| Al | Ce | La | Ca | Mg | ||

| A | 31.7 | — | — | — | 68.3 | Mg17Al12 |

| B | 21.1 | 6.5 | 3.6 | — | 68.8 | Al2RE |

| C | 2.5 | — | — | — | 98.5 | α-Mg |

| D | 21.3 | 3.6 | 2.0 | — | 73.1 | Al11RE3 |

| E | 29.7 | — | — | 1.1 | 69.2 | Mg17Al12, Al2Ca |

| Alloy | Condition | RT | 175 °C | ||||

|---|---|---|---|---|---|---|---|

| UTS/MPa | YS/MPa | Ef/% | UTS/MPa | YS/MPa | Ef/% | ||

| AE62 | As-cast | ||||||

| Peak-aged | |||||||

| AE82 | As-cast | ||||||

| Peak-aged | |||||||

| AEX820 | As-cast | ||||||

| Peak-aged | |||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guan, S.; Wang, P.; Wang, T.; Wang, C.; Liu, G.; Zhu, Y. Microstructure and Mechanical Properties of High-Pressure Die-Casting Mg–Al–RE Alloys with Minor Ca Addition. Materials 2025, 18, 231. https://doi.org/10.3390/ma18020231

Guan S, Wang P, Wang T, Wang C, Liu G, Zhu Y. Microstructure and Mechanical Properties of High-Pressure Die-Casting Mg–Al–RE Alloys with Minor Ca Addition. Materials. 2025; 18(2):231. https://doi.org/10.3390/ma18020231

Chicago/Turabian StyleGuan, Sheng, Pengyue Wang, Tianhua Wang, Chenggang Wang, Guojun Liu, and Yongfu Zhu. 2025. "Microstructure and Mechanical Properties of High-Pressure Die-Casting Mg–Al–RE Alloys with Minor Ca Addition" Materials 18, no. 2: 231. https://doi.org/10.3390/ma18020231

APA StyleGuan, S., Wang, P., Wang, T., Wang, C., Liu, G., & Zhu, Y. (2025). Microstructure and Mechanical Properties of High-Pressure Die-Casting Mg–Al–RE Alloys with Minor Ca Addition. Materials, 18(2), 231. https://doi.org/10.3390/ma18020231